Influence of Zn and Sn on the Precipitation Behavior of New Al–Mg–Si Alloys

Abstract

1. Introduction

2. Materials and Methods

3. Results

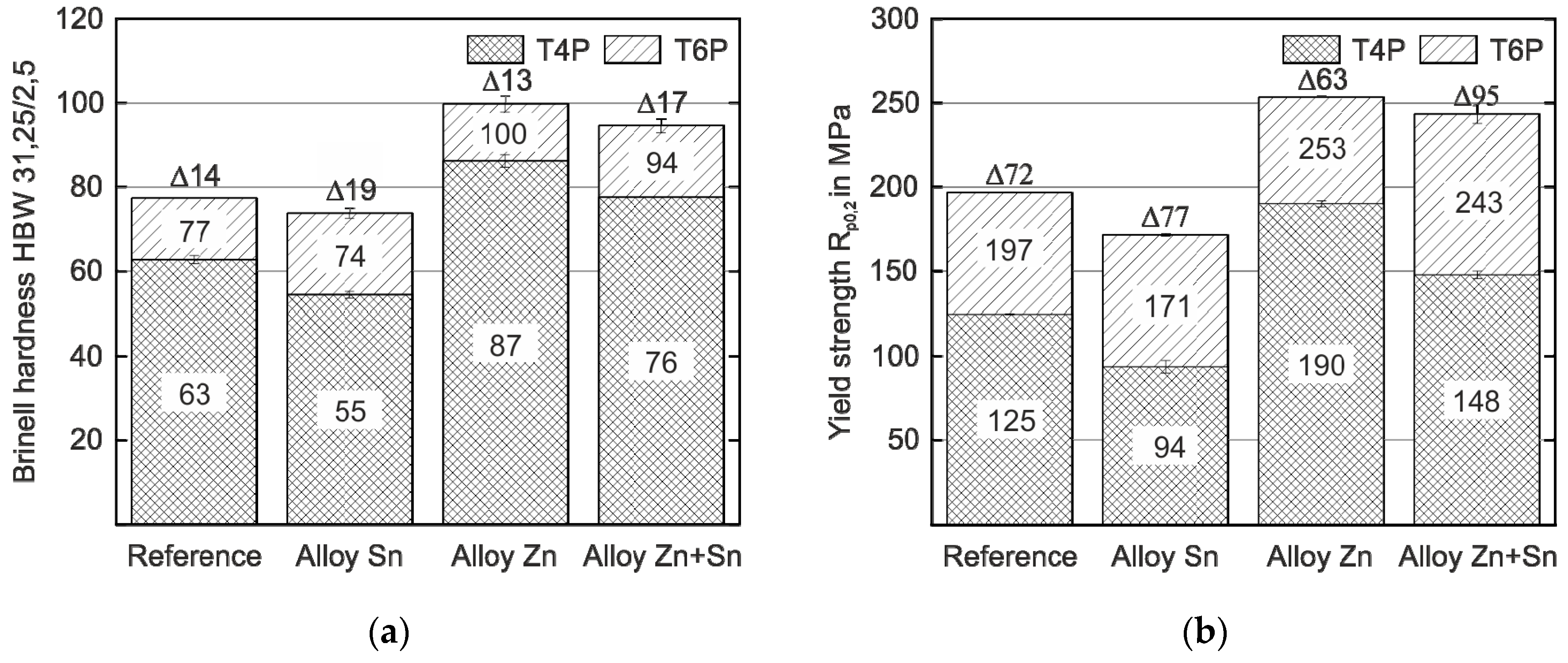

3.1. Hardness and Tensile Tests

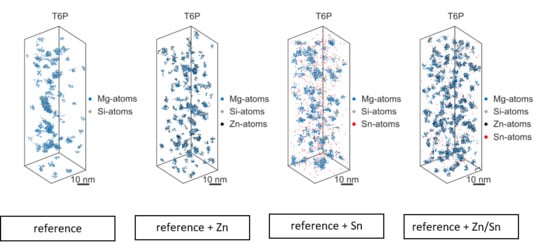

3.2. Atom Probe Tomography

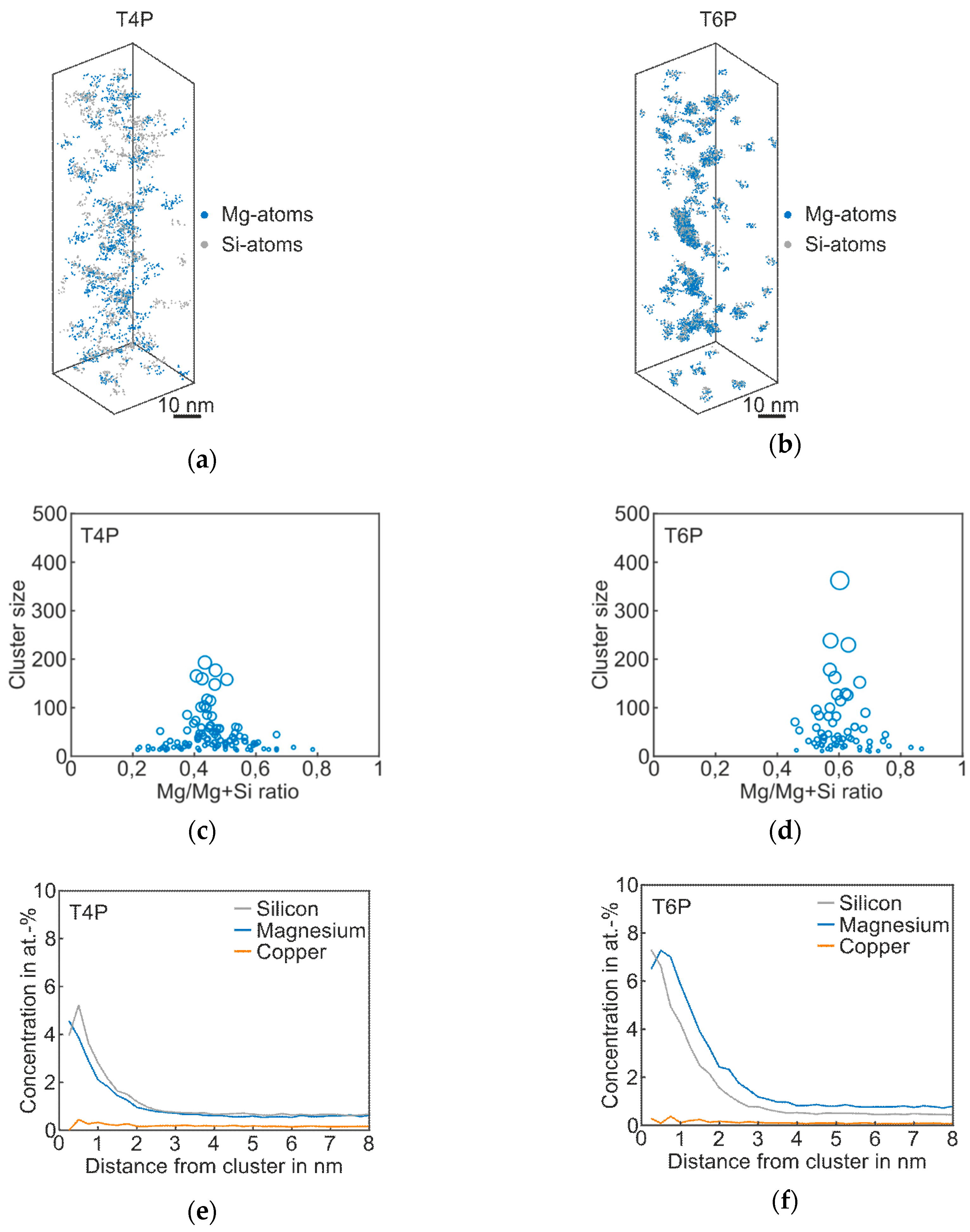

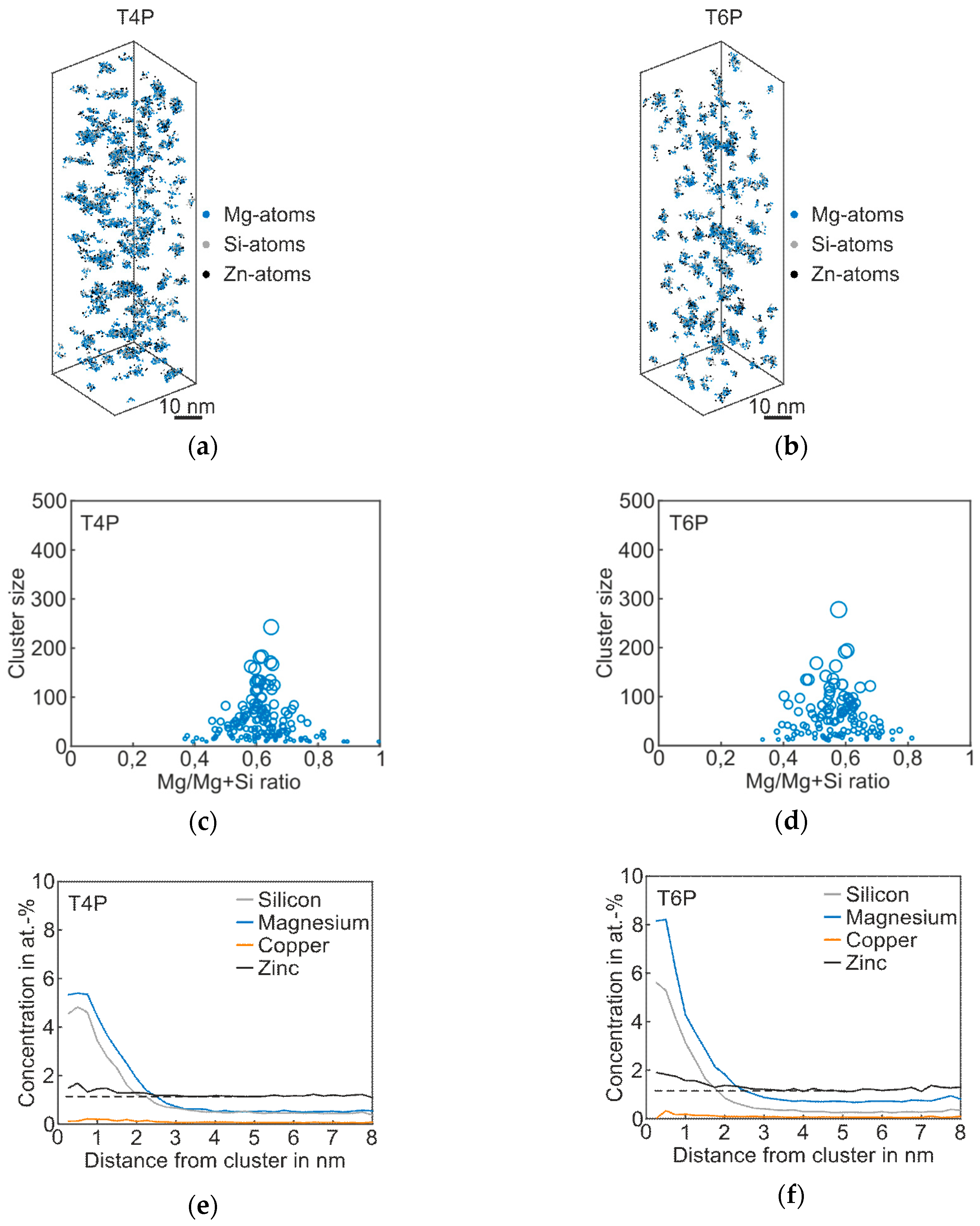

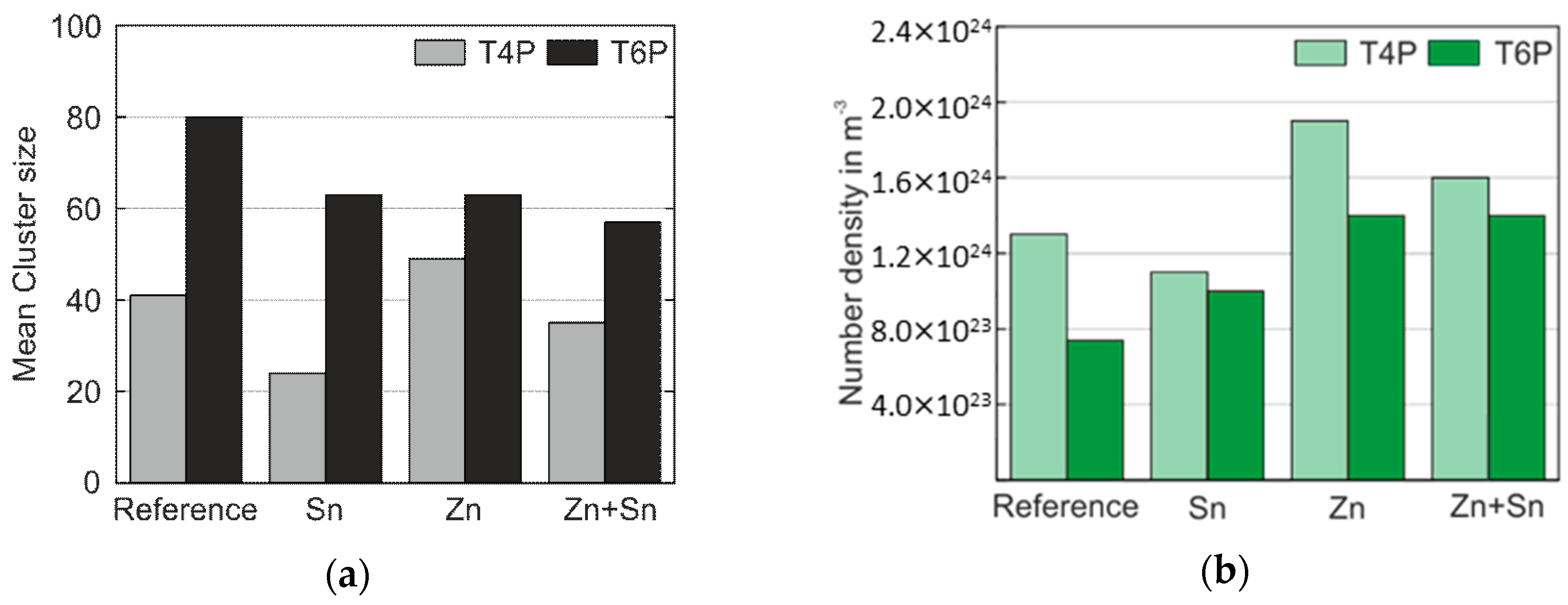

3.2.1. Comparison of T4P and T6P Conditions

Reference Alloy

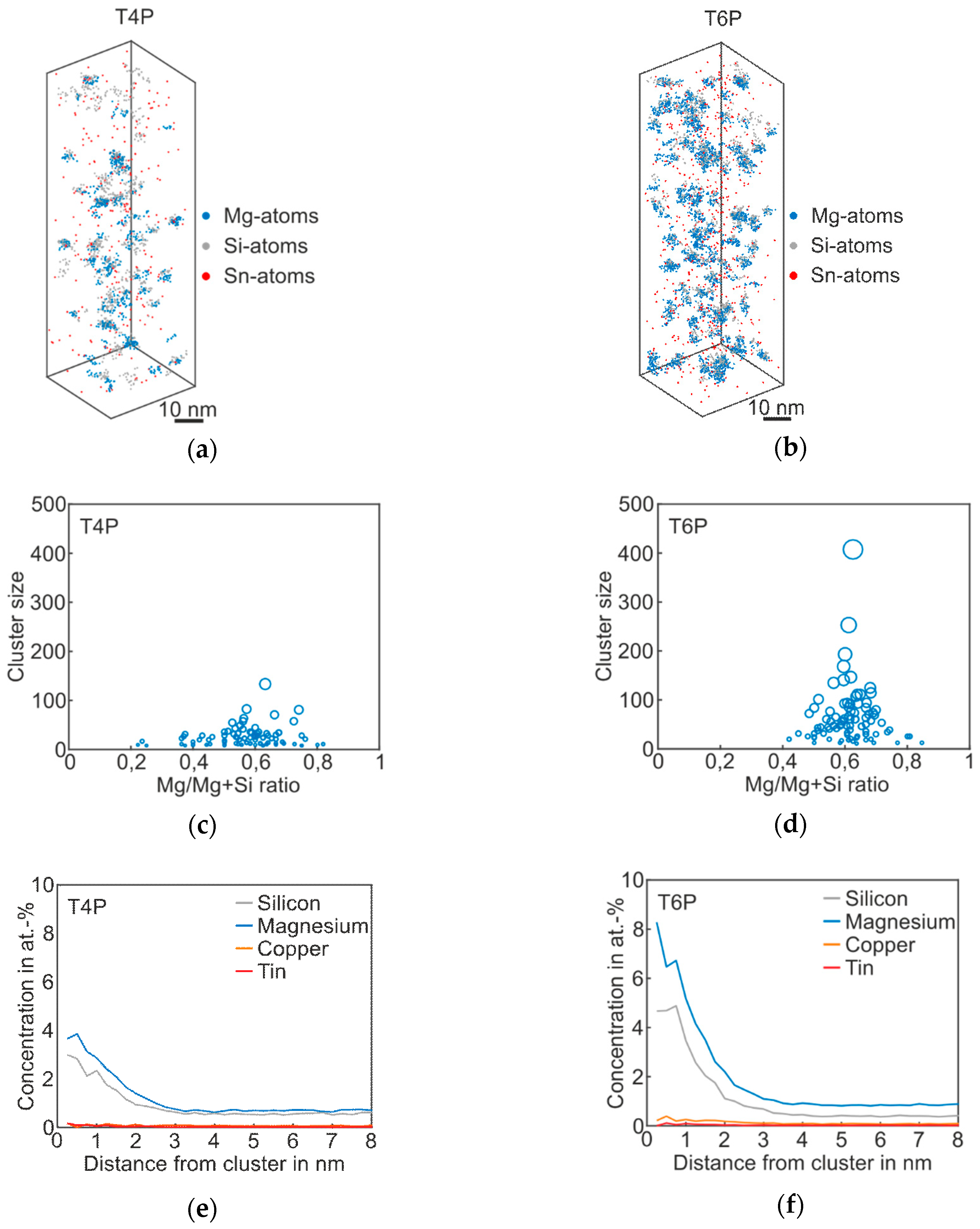

Alloy Sn

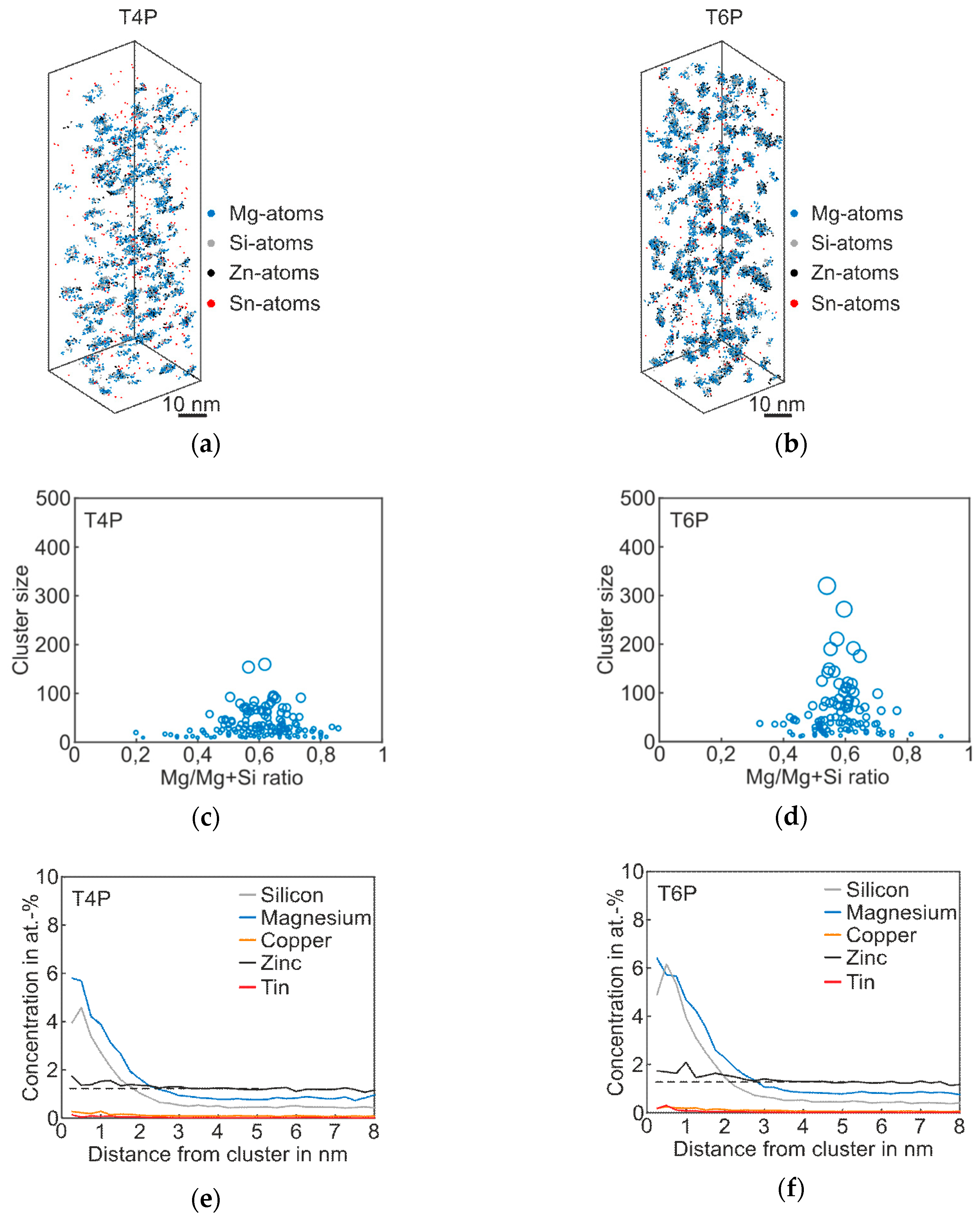

Alloy Zn

Alloy Zn + Sn

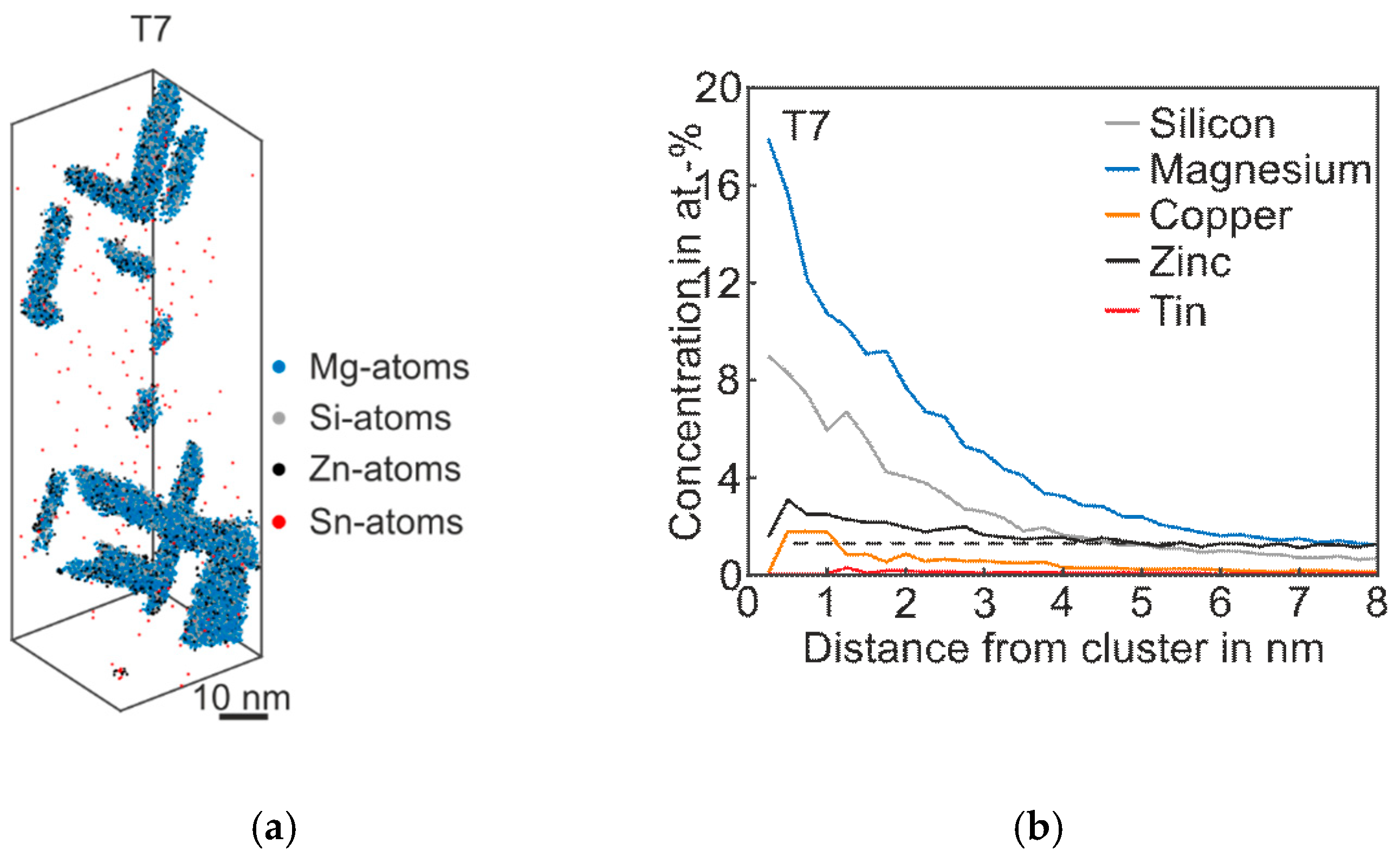

3.2.2. T7 Condition

Alloy Zn + Sn

4. Discussion

5. Conclusions

- Adding Sn produces a decrease in hardness in the pre-aged condition because Sn-trapping of vacancies suppresses cluster formation. The vacancies are released from the Sn atoms during the paint bake process, leading to rapid growth of already existing clusters. Consequently, the hardness increase from the pre-aged to the paint baked condition is more pronounced than in the Sn-free reference alloy.

- Adding Zn promotes Mg–Si co-cluster formation. The number density and average size of the Mg–Si co-clusters are significantly increased, generating the highest hardness even in the pre-aged condition. During the paint bake cycle, further cluster growth takes place and, thus, the Zn-modified alloy shows the highest hardness value.

- Simultaneous addition of both Sn and Zn produces a synergetic effect. The size of the clusters is slightly decreased by the presence of Sn, but their number density stays high because of Zn. This causes a hardness which is lower than that of the solely Zn-modified alloy in the pre-aged condition, but more pronounced hardening is achieved during the paint bake cycle. This is preferred, since it enables the forming of sheets in the soft pre-aged condition and application in the hard paint baked state.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Polmear, I.; St John, D.; Nie, J.-F.; Qian, M. Light Alloys: Metallurgy of the Light Metals; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Mrówka-Nowotnik, G. Influence of chemical composition variation and heat treatment on microstructure and mechanical properties of 6xxx alloys. Arch. Mater. Sci. Eng. 2010, 46, 98–107. [Google Scholar]

- Hirsch, J. Recent development in aluminium for automotive applications. Trans. Nonferrous Met. Soc. China 2014, 24, 1995–2002. [Google Scholar] [CrossRef]

- Holmestad, R.; Bjørge, R.; Ehlers, F.J.H.; Torsæter, M.; Marioara, C.D.; Andersen, S.J. Characterization and structure of precipitates in 6xxx Aluminium Alloys. J. Phys. Conf. Ser. 2012, 371, 012082. [Google Scholar] [CrossRef]

- Zheng, G.W.; Li, H.; Lei, C.; Fu, J.; Bian, T.J.; Yang, J.C. Natural aging behaviors and mechanisms of 7050 and 5A90 Al alloys: A comparative study. Mater. Sci. Eng. A 2018, 718, 157–164. [Google Scholar] [CrossRef]

- Cuniberti, A.; Tolley, A.; Riglos, M.V.C.; Giovachini, R. Influence of natural aging on the precipitation hardening of an AlMgSi alloy. Mater. Sci. Eng. A 2010, 527, 5307–5311. [Google Scholar] [CrossRef]

- Cao, L.; Rometsch, P.A.; Couper, M.J. Clustering behaviour in an Al–Mg–Si–Cu alloy during natural ageing and subsequent under-ageing. Mater. Sci. Eng. A 2013, 559, 257–261. [Google Scholar] [CrossRef]

- Ostermann, F. Anwendungstechnologie Aluminium; Springer-Verlag: Berlin, Germany, 2015. [Google Scholar]

- Zhen, L.; Kang, S.B. The effect of pre-aging on microstructure and tensile properties of Al-Mg-Si alloys. Scr. Mater. 1997, 36, 1089–1094. [Google Scholar] [CrossRef]

- Pogatscher, S.; Antrekowitsch, H.; Werinos, M.; Moszner, F.; Gerstl, S.S.A.; Francis, M.F.; Curtin, W.A.; Löffler, J.F.; Uggowitzer, P.J. Diffusion on Demand to Control Precipitation Aging: Application to Al-Mg-Si Alloys. Phys. Rev. Lett. 2014, 112, 225701. [Google Scholar] [CrossRef]

- Werinos, M.; Antrekowitsch, H.; Ebner, T.; Prillhofer, R.; Uggowitzer, P.J.; Pogatscher, S. Hardening of Al–Mg–Si alloys: Effect of trace elements and prolonged natural aging. Mater. Des. 2016, 107, 257–268. [Google Scholar] [CrossRef]

- Pogatscher, S.; Antrekowitsch, H.; Werinos, M.; Rank, G.; Kais, A.; Prillhofer, R.; Loffler, J.F.; Uggowitzer, P.J. Statistical and Thermodynamic Optimization of Trace-Element Modified Al-Mg-Si-Cu Alloys. In Light Metals 2015; Hyland, M., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015; pp. 263–270. [Google Scholar]

- Sadhukhan, S.; Kundu, M.; Ghosh, M. Effect of Trace Added Sn on Mechanical Properties of Al-Zn-Mg Alloy. Adv. Mater. Res. 2014, 828, 73–80. [Google Scholar] [CrossRef]

- Werinos, M.; Antrekowitsch, H.; Fragner, W.; Ebner, T.; Uggowitzer, P.; Pogatscher, S. Influence of Sn-solubility on Suppression of Natural Aging in an AA6061 Aluminum Alloy. In Proceedings of the Materials Science & Technology 2014 Conference and Exhibition, Pittsburgh, PA, USA, 12–16 October 2014; Volume 2. [Google Scholar]

- Saga, M.; Kikuchi, M. Effect of Sn Addition on the Two-Step Aging Behavior in Al-Mg-Si Alloys for Automotive Application. In Proceedings of the 9th International Conference on Aluminium Alloys, Brisbane, Australia, 2–5 August 2004. [Google Scholar]

- Pogatscher, S.; Werinos, M.; Antrekowitsch, H.; Uggowitzer, P.J. The Role of Vacancies in the Aging of Al-Mg-Si Alloys. Mater. Sci. Forum 2014, 794, 1008–1013. [Google Scholar] [CrossRef]

- Ding, X.P.; Cui, H.; Zhang, J.X.; Li, H.X. The effect of Zn on the age hardening response in an Al–Mg–Si alloy. Mater. Des. 2015, 59, 1229–1235. [Google Scholar] [CrossRef]

- Guo, M.X.; Zhang, Y.; Zhang, X.K.; Zhang, J.S.; Zhuang, L.Z. Non-isothermal precipitation behaviors of Al-Mg-Si-Cu alloys with different Zn contents. Mater. Sci. Eng. A 2016, 669, 20–32. [Google Scholar] [CrossRef]

- Yan, L.; Zhang, Y.; Li, X.; Li, Z.; Wang, F.; Liu, H.; Xiong, B. Effect of Zn addition on microstructure and mechanical properties of an Al–Mg–Si alloy. Prog. Nat. Sci. Mater. Int. 2014, 24, 97–100. [Google Scholar] [CrossRef]

- Cao, C.; Zhang, D.; He, Z.; Zhuang, L.; Zhang, J. Enhanced and accelerated age hardening response of Al-5.2Mg-0.45Cu (wt%) alloy with Zn addition. Mater. Sci. Eng. A 2016, 666, 34–42. [Google Scholar] [CrossRef]

- Saito, T.; Wenner, S.; Osmundsen, E.; Marioara, C.D.; Andersen, S.J.; Røyset, J.; Lefebvre, W.; Holmestad, R. The effect of Zn on precipitation in Al–Mg–Si alloys. Philos. Mag. 2014, 94, 2410–2425. [Google Scholar] [CrossRef]

- Felfer, P.; Ceguerra, A.V.; Ringer, S.P.; Cairney, J.M. Detecting and extracting clusters in atom probe data: A simple, automated method using Voronoi cells. Ultramicroscopy 2015, 150, 30–36. [Google Scholar] [CrossRef]

- Aurenhammer, F. Voronoi Diagrams—A Survey of a Fundamental Geometric Data Structure. ACM Comput. Surv. 1991, 23, 345–405. [Google Scholar] [CrossRef]

- Du, Q.; Faber, V.; Gunzburger, M. Centroidal Voronoi Tessellations: Applications and Algorithms. SIAM Rev. 1999, 41, 637–676. [Google Scholar] [CrossRef]

- Park, J.K.; Ardell, A.J. Microstructures of the commercial 7075 Al alloy in the T651 and T7 tempers. MTA 1983, 14, 1957–1965. [Google Scholar] [CrossRef]

- Marioara, C.D.; Lefebvre, W.; Andersen, S.J.; Friis, J. Atomic structure of hardening precipitates in an Al–Mg–Zn–Cu alloy determined by HAADF-STEM and first-principles calculations: Relation to η-MgZn2. J. Mater. Sci. 2013, 48, 3638–3651. [Google Scholar] [CrossRef]

- Hull, D.; Bacon, D.J. Introduction to Dislocations; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Zinkle, S.J.; Matsukawa, Y. Observation and analysis of defect cluster production and interactions with dislocations. J. Nucl. Mater. 2004, 329, 88–96. [Google Scholar] [CrossRef]

- Pogatscher, S.; Antrekowitsch, H.; Leitner, H.; Ebner, T.; Uggowitzer, P.J. Mechanisms controlling the artificial aging of Al–Mg–Si Alloys. Acta Mater. 2011, 59, 3352–3363. [Google Scholar] [CrossRef]

- Yuan, B.; Guo, M.; Wu, Y.; Zhang, J.; Zhuang, L.; Lavernia, E.J. Influence of treatment pathways on the precipitation behaviors of Al-Mg-Si-Cu-(Zn)-Mn alloys. J. Alloy. Compd. 2019, 797, 26–38. [Google Scholar] [CrossRef]

- Guo, M.X.; Zhang, Y.D.; Li, G.J.; Jin, S.B.; Sha, G.; Zhang, J.S.; Zhuang, L.Z.; Lavernia, E.J. Solute clustering in Al-Mg-Si-Cu-(Zn) alloys during aging. J. Alloy. Compd. 2019, 774, 347–363. [Google Scholar] [CrossRef]

- Li, Y.; Gao, G.; Wang, Z.; Di, H.; Li, J.; Xu, G. Effects of the Mg/Si Ratio on Microstructure, Mechanical Properties, and Precipitation Behavior of Al–Mg–Si–1.0 wt%-Zn Alloys. Materials 2018, 11, 2591. [Google Scholar] [CrossRef] [PubMed]

- Perry, A.J. Solute-Vacancy Interaction Energies and the Effect of 0.009 at.% Mg on the Ageing Kinetics of an A1-4.01 at.% Zn Alloy. Acta Metall. 1966, 14, 1143–1156. [Google Scholar] [CrossRef]

- Wolverton, C. Solute–vacancy binding in aluminum. Acta Mater. 2007, 55, 5867–5872. [Google Scholar] [CrossRef]

- Wolverton, C. Crystal structure and stability of complex precipitate phases in Al–Cu–Mg–(Si) and Al–Zn–Mg alloys. Acta Mater. 2001, 49, 3129–3142. [Google Scholar] [CrossRef]

| Alloy | Al | Mg | Si | Zn | Sn | Cu |

|---|---|---|---|---|---|---|

| Reference | Bal. | 1.0 | 0.5 | - | - | 0.17 |

| Alloy Sn | Bal. | 1.0 | 0.5 | - | 0.04 | 0.17 |

| Alloy Zn | Bal. | 1.0 | 0.5 | 3.0 | - | 0.17 |

| Alloy Zn + Sn | Bal. | 1.0 | 0.5 | 3.0 | 0.04 | 0.17 |

| Condition | Mean Cluster Size | Average Mg/Si Ratio | Number Density |

|---|---|---|---|

| T4P | 41 | 0.8 | 1.3 × 1024 m−3 |

| T6P | 80 | 1.5 | 7.4 × 1023 m−3 |

| Condition | Mean Cluster Size | Average Mg/Si Ratio | Number Density |

|---|---|---|---|

| T4P | 24 | 1.4 | 1.1 × 1024 m−3 |

| T6P | 63 | 1.6 | 1.0 × 1024 m−3 |

| Condition | Mean Cluster Size | Average Mg/Si Ratio | Number Density |

|---|---|---|---|

| T4P | 49 | 1.7 | 1.9 × 1024 m−3 |

| T6P | 63 | 1.7 | 1.4 × 1024 m−3 |

| Condition | Mean Cluster Size | Average Mg/Si Ratio | Number Density |

|---|---|---|---|

| T4P | 35 | 1.5 | 1.6 × 1024 m−3 |

| T6P | 57 | 1.5 | 1.4 × 1024 m−3 |

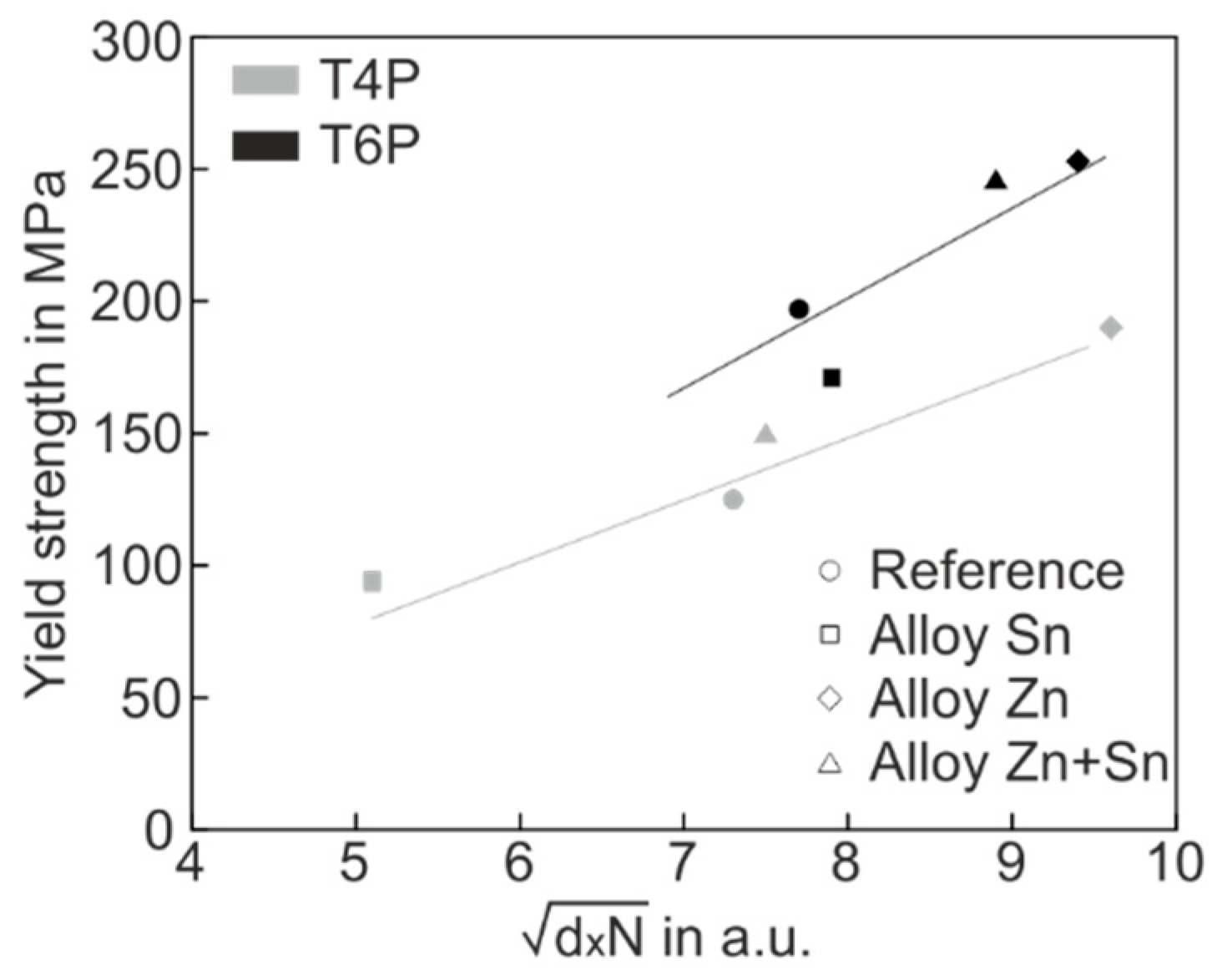

| Alloys | ||

|---|---|---|

| T4P | T6P | |

| Reference | 7.3 | 7.7 |

| Alloy Sn | 5.1 | 7.9 |

| Alloy Zn | 9.6 | 9.4 |

| Alloy Zn + Sn | 7.5 | 8.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glöckel, F.; Uggowitzer, P.J.; Felfer, P.; Pogatscher, S.; Höppel, H.W. Influence of Zn and Sn on the Precipitation Behavior of New Al–Mg–Si Alloys. Materials 2019, 12, 2547. https://doi.org/10.3390/ma12162547

Glöckel F, Uggowitzer PJ, Felfer P, Pogatscher S, Höppel HW. Influence of Zn and Sn on the Precipitation Behavior of New Al–Mg–Si Alloys. Materials. 2019; 12(16):2547. https://doi.org/10.3390/ma12162547

Chicago/Turabian StyleGlöckel, Felix, Peter J. Uggowitzer, Peter Felfer, Stefan Pogatscher, and Heinz Werner Höppel. 2019. "Influence of Zn and Sn on the Precipitation Behavior of New Al–Mg–Si Alloys" Materials 12, no. 16: 2547. https://doi.org/10.3390/ma12162547

APA StyleGlöckel, F., Uggowitzer, P. J., Felfer, P., Pogatscher, S., & Höppel, H. W. (2019). Influence of Zn and Sn on the Precipitation Behavior of New Al–Mg–Si Alloys. Materials, 12(16), 2547. https://doi.org/10.3390/ma12162547