Experimental Investigation on the Quasi-Static Tensile Capacity of Engineered Cementitious Composites Reinforced with Steel Grid and Fibers

Abstract

1. Introduction

2. Experimental Program

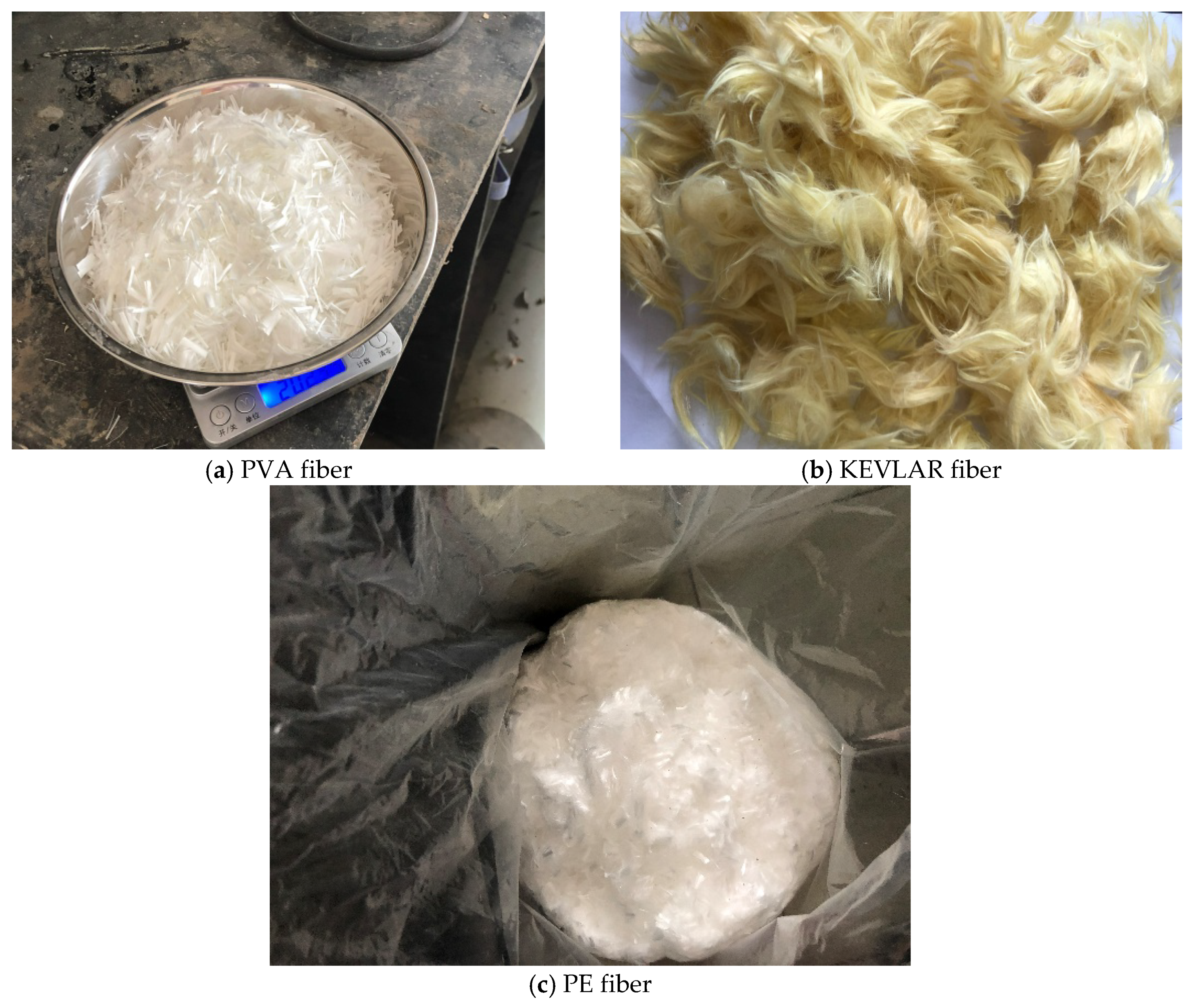

2.1. Materials and Mixture Proportions

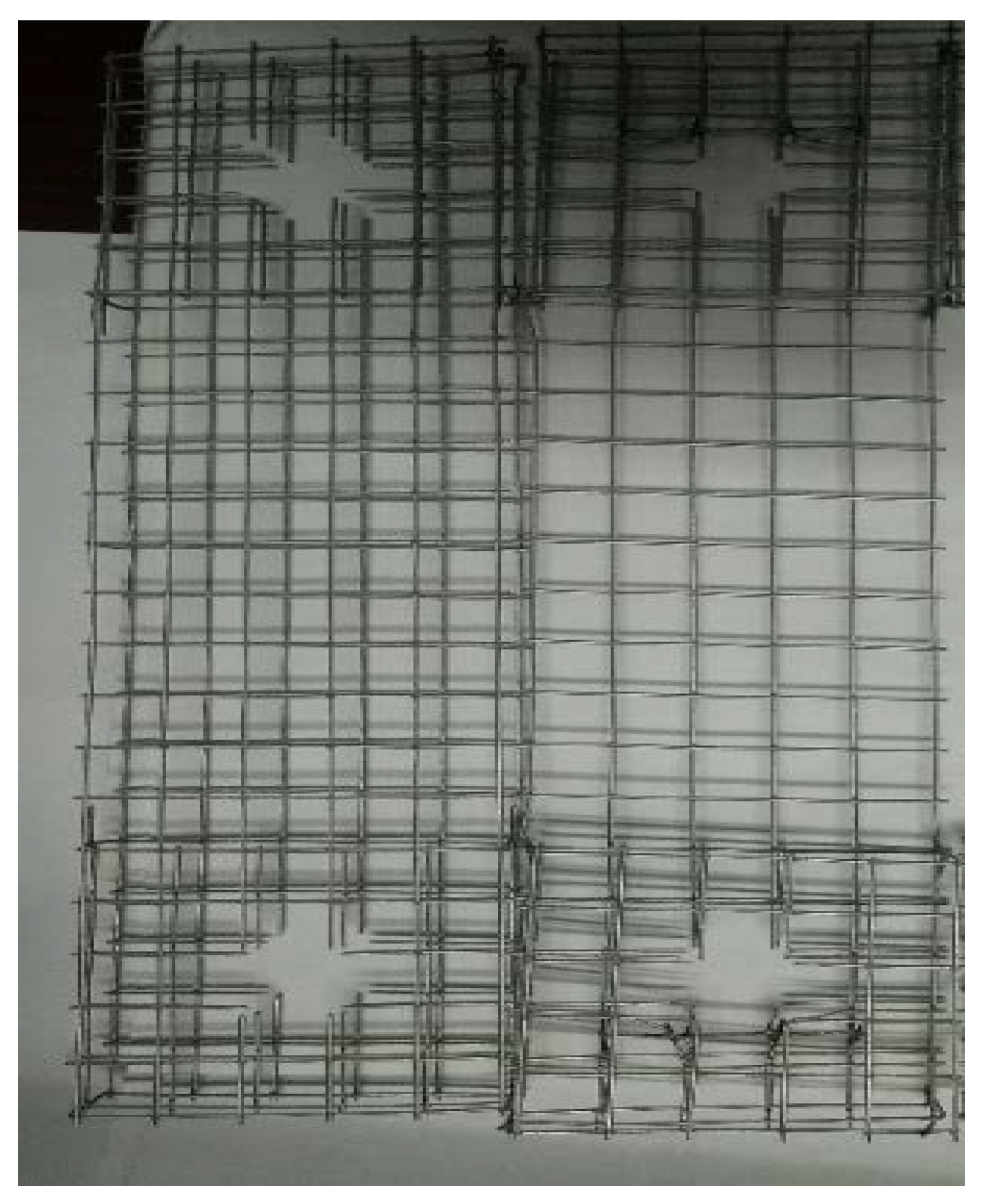

2.2. Specimen Fabrication and Test Setup

- (1).

- Spread lubricant on the inner surface of the mold for the convenience of the demolding process. Install the steel grid in the middle part of the mold.

- (2).

- Weigh-up the material ingredients of the tested ECCs, including cement, siliceous fly ash, water, superplasticizer, and fibers according to the mixture proportion. When the KEVLAR fiber is used, a cleaning process should be carried out with alcohol to remove grease from the fiber surfaces.

- (3).

- The cement and siliceous fly ash are first dry-mixed in the mixer for 3 min. The superplasticizer is mixed with the water, and they are then added into the dry mixture and mixed for a further 2 min to produce a consistent and uniform matrix. The fibers are then added into the matrix and mixed for an additional 3 min to make the fibers spread in the mixture until they reach a uniform state.

- (4).

- The fresh ECC mixtures are cast into the steel molds. The molds are then placed on a shake-table to eject entrapped air and produce a denser matrix by the vibration of the table-board. The specimens are demolded after 24 h and then set in a curing room for 28 days, where the temperature is 20 ± 0.5 °C, and the relative humidity is 95 ± 5%.

- (5).

- When the curing process is finished, thin steel pieces are adhered to the ends of the specimens with epoxy resin adhesive in order to provide extra reinforcement at the location where the specimens are connected to the tensile-loading machine. The specimens with the end reinforcement are shown in Figure 3.

3. Test Results and Discussion

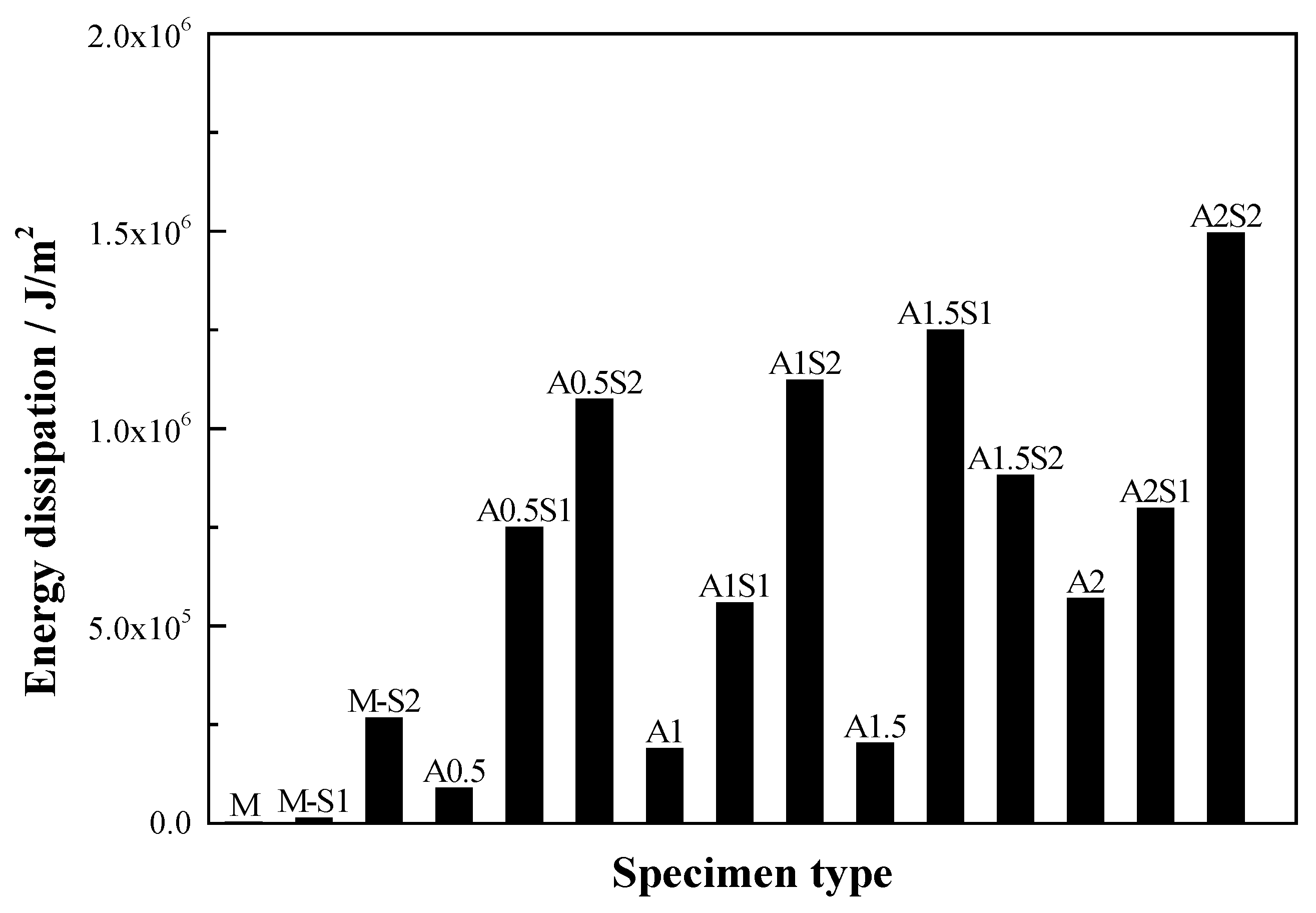

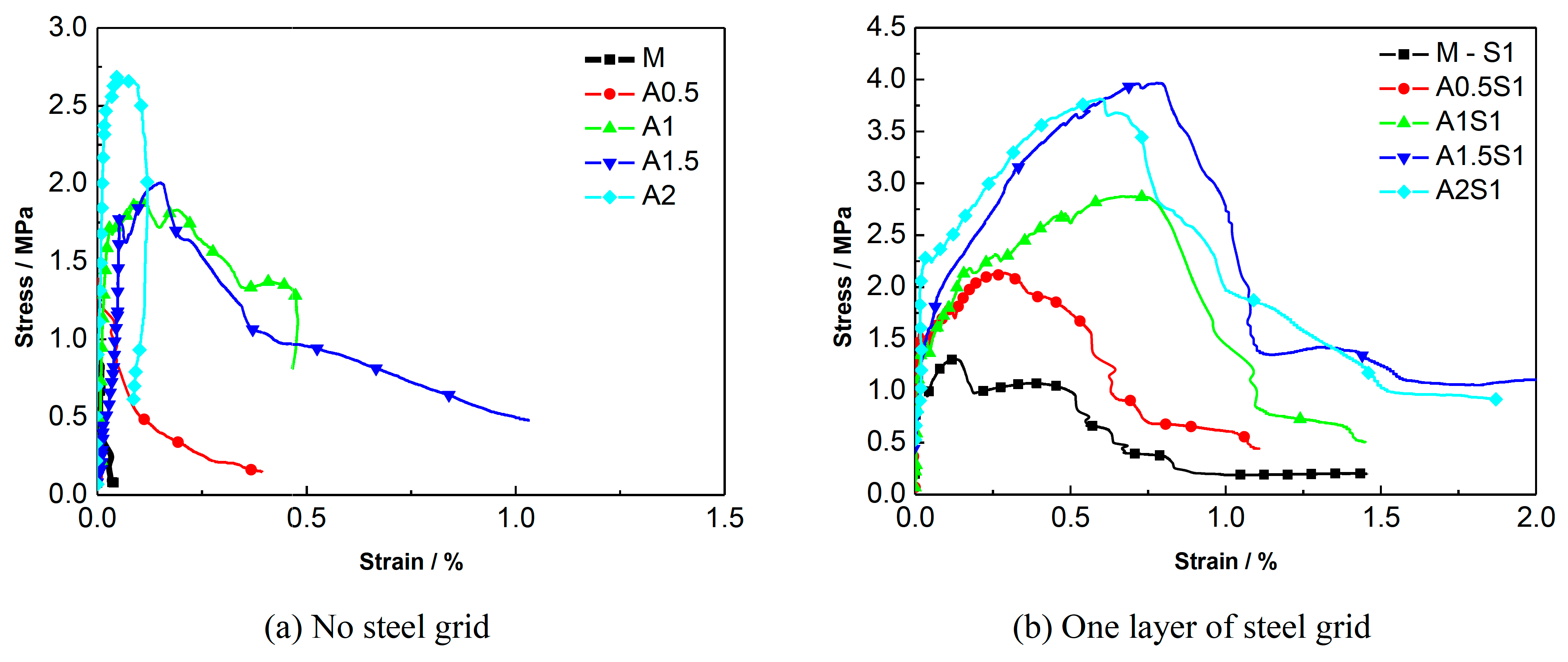

3.1. Quasi-Static Tensile Test Results of the Steel Grid-PVAFiber Reinforced ECC

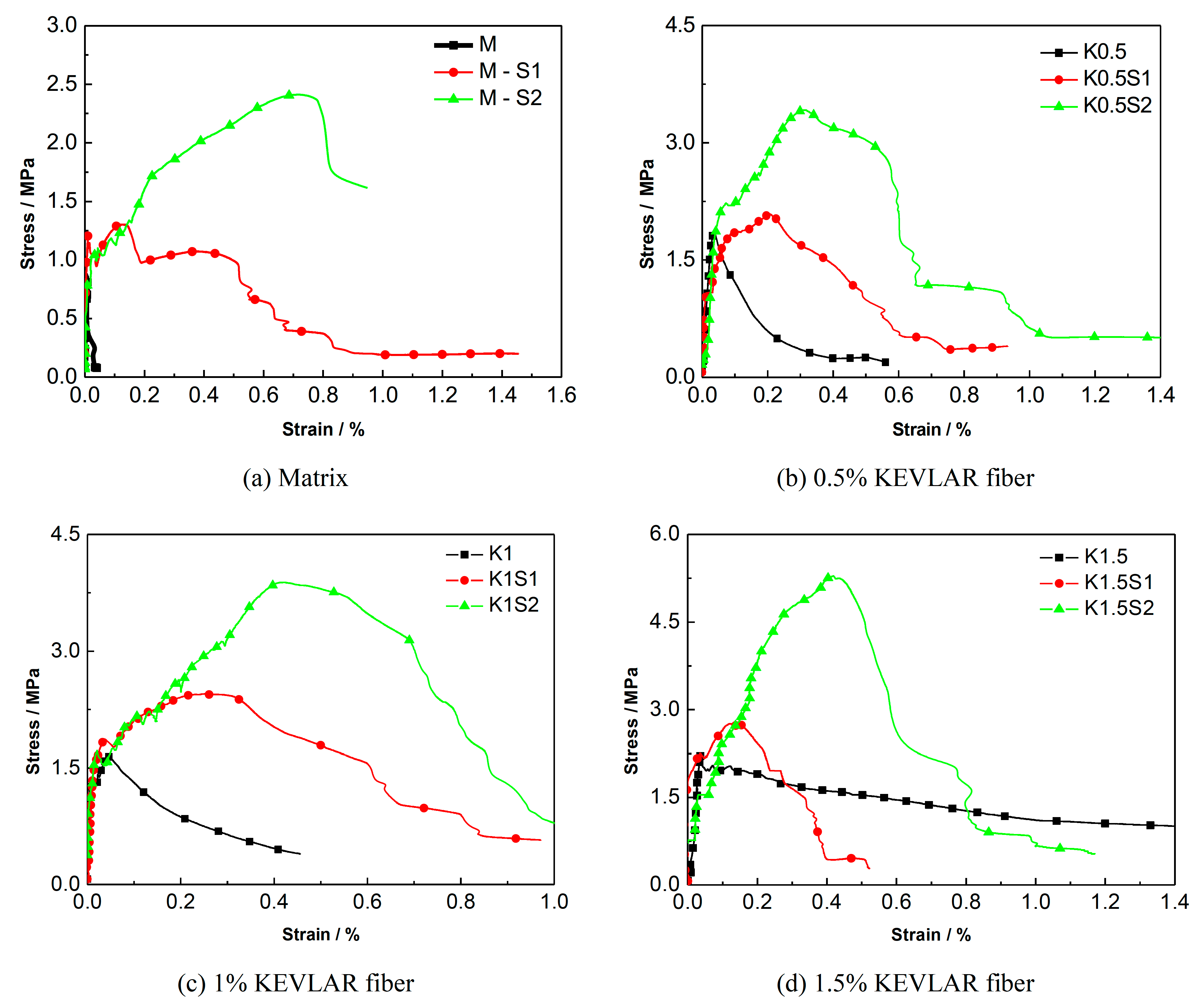

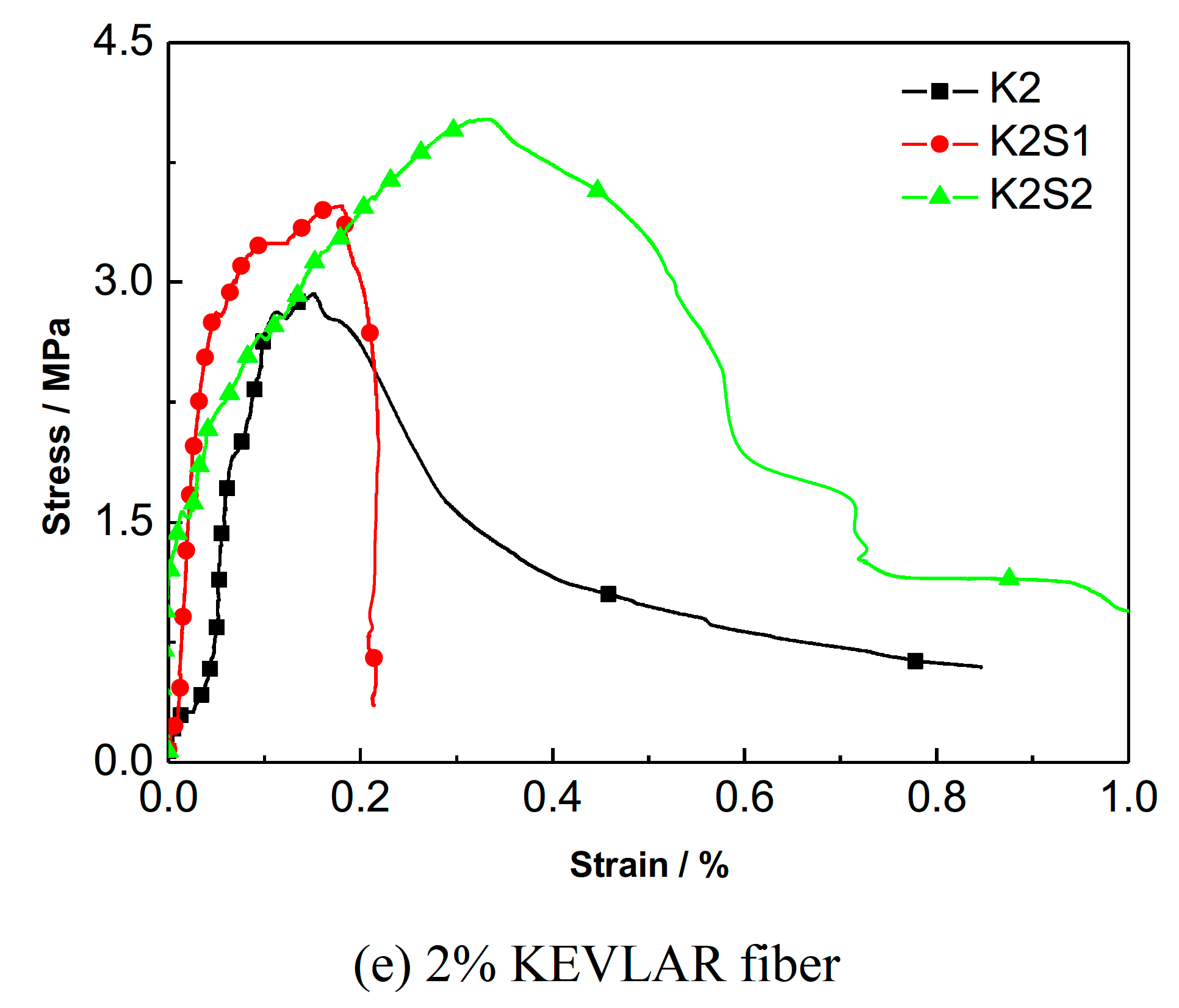

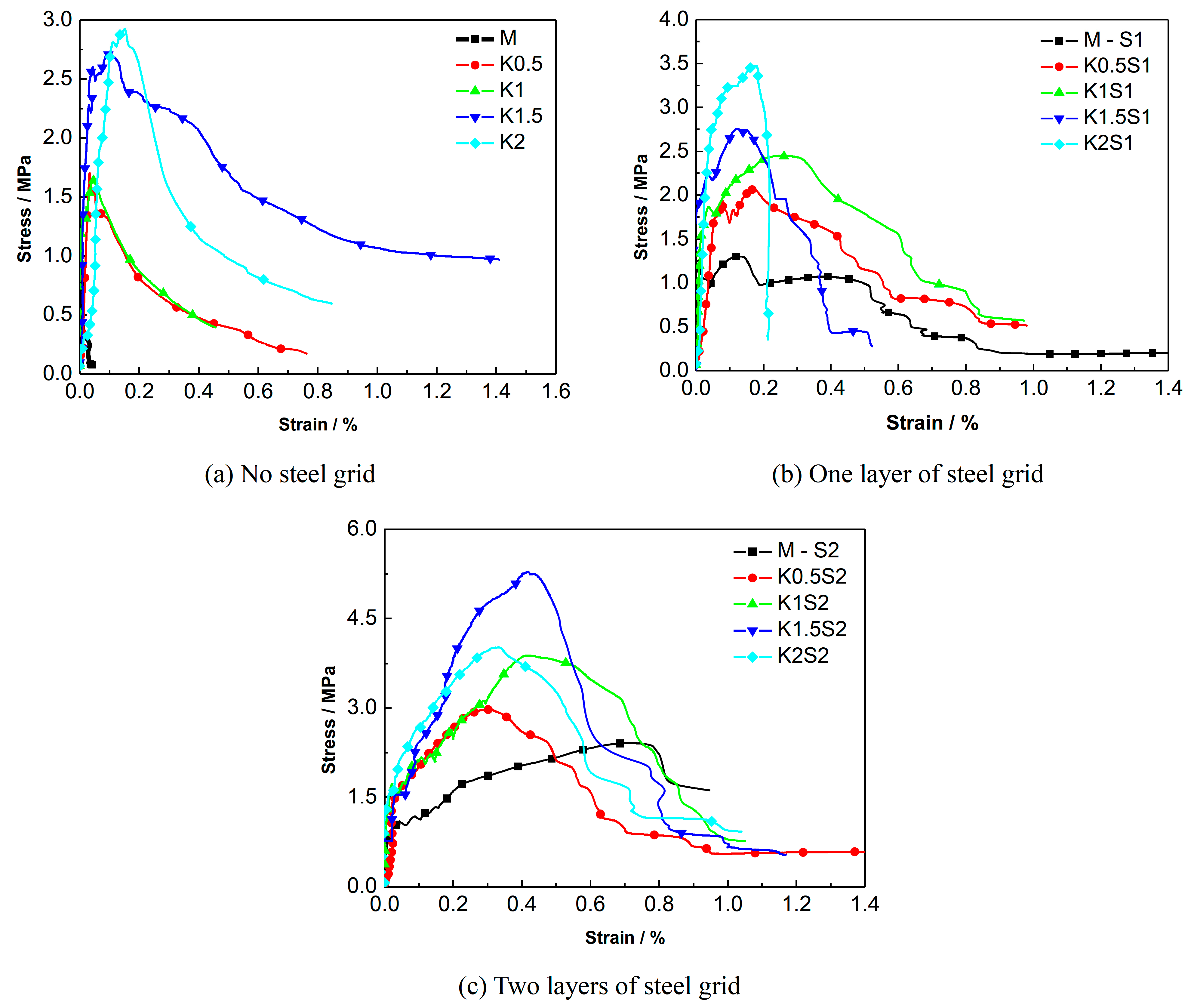

3.2. Quasi-Static Tensile Test Results of the Steel Grid-KEVLARFiber Reinforced ECC

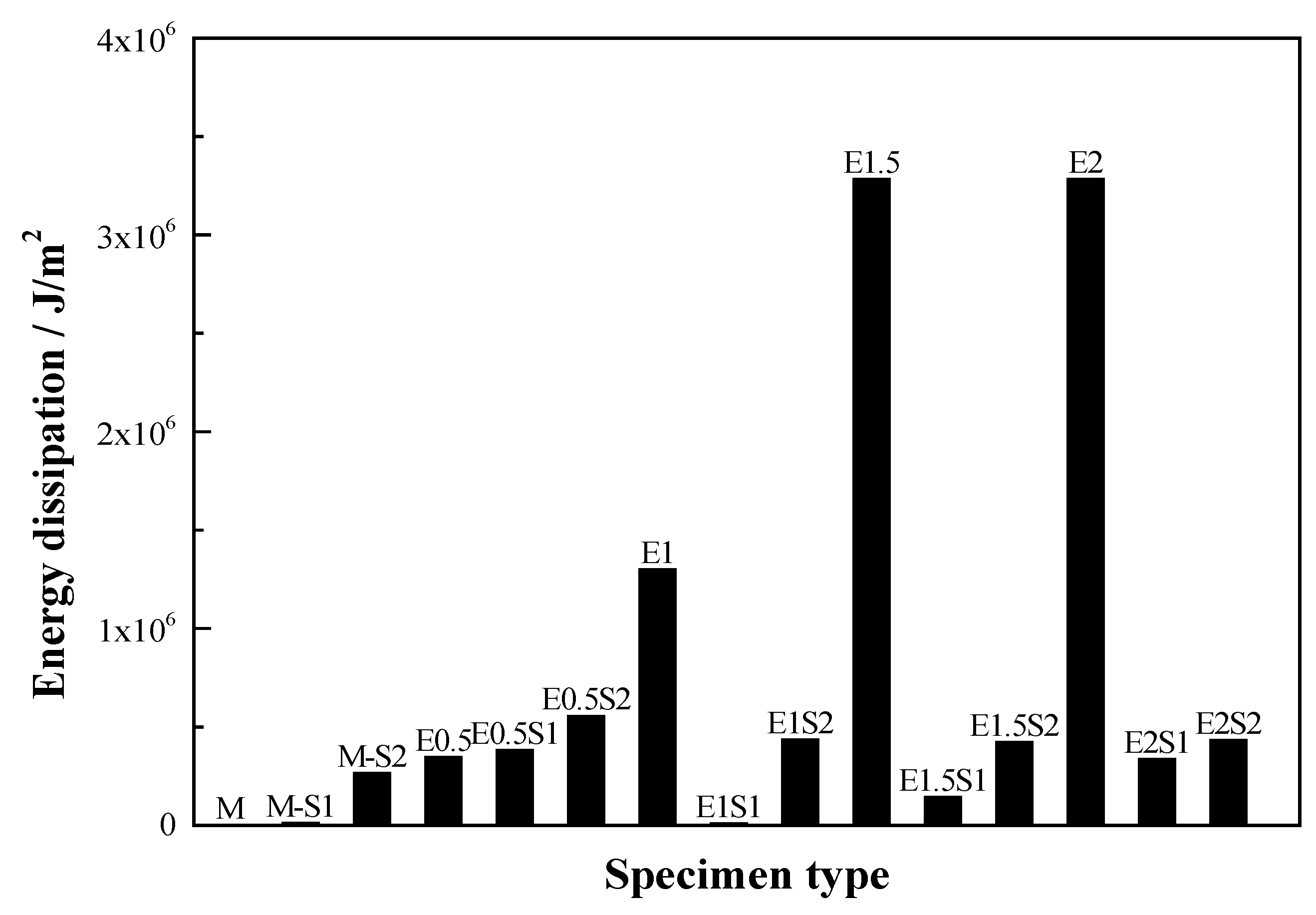

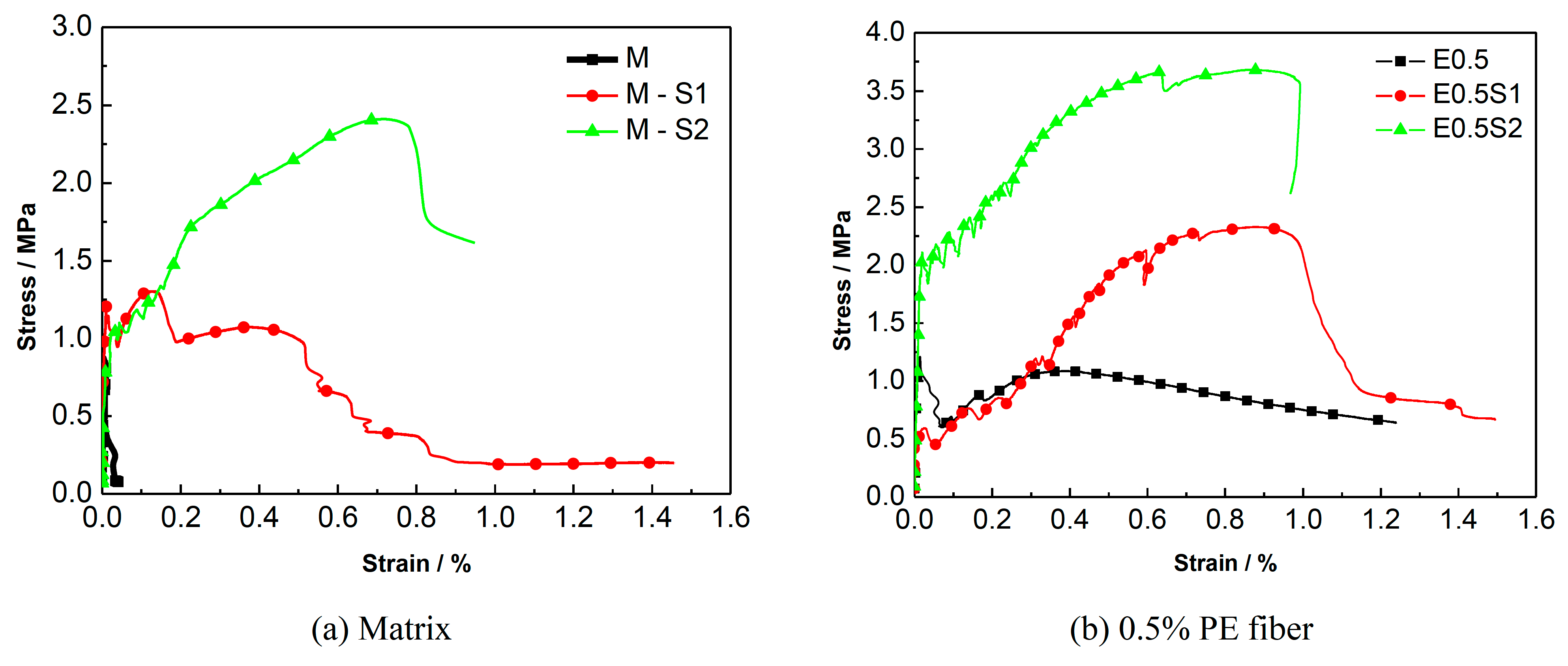

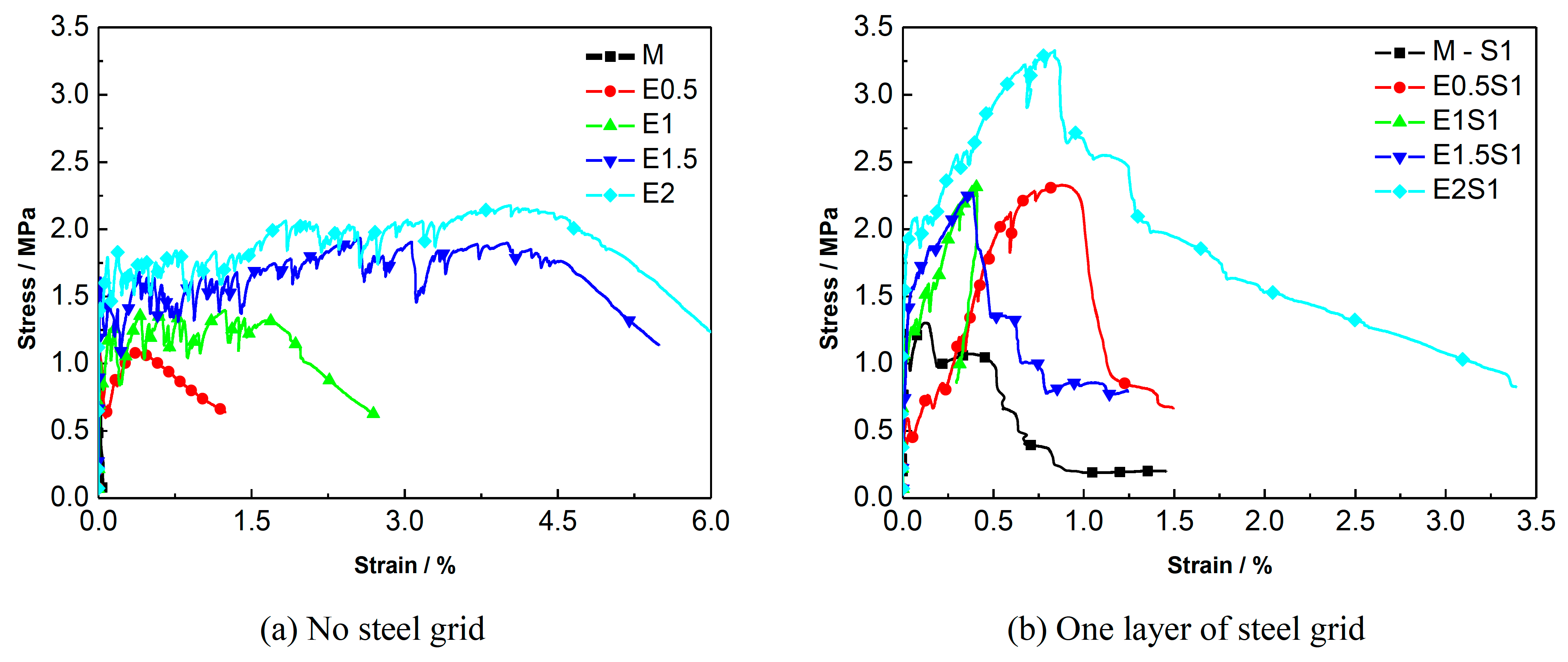

3.3. Quasi-Static Tensile Test Results of the Steel Grid-PEFiber Reinforced ECC

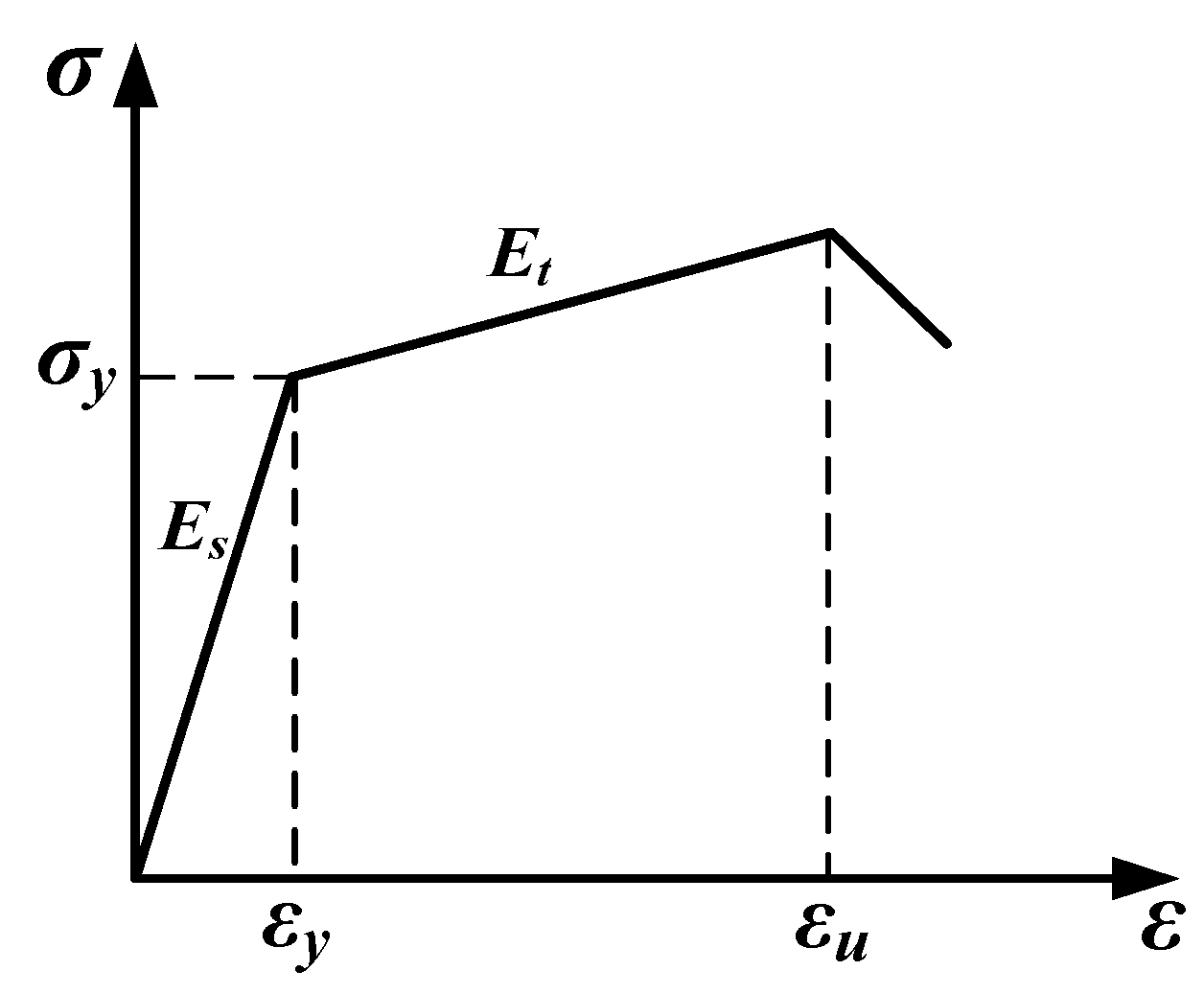

4. Mechanical Model for Quasi-Static Tensile Strength of Steel Grid-Fiber Reinforced ECC

4.1. Model Development

4.2. Model Validation

5. Conclusions

- (1).

- On the whole, the steel grid-PVA fiber, steel grid-KEVLAR fiber, and steel grid-PE fiber reinforced ECCs all have higher tensile strength and ductility than the ECC matrix. They can also exhibit excellent energy dissipation performance.

- (2).

- The ultimate tensile strength of the reinforced ECC can be improved by the addition of steel grids. For the steel grid-PVA fiber reinforced ECC, when the fiber volume fraction is 1.5%, a maximal peak tensile stress increase of about 95% or 160% compared to the matrix specimen by adding one layer or two layers of steel grid can be obtained, respectively. For the steel grid-KEVLAR fiber reinforced ECC, when the fiber volume fraction is 1.0%, the maximal peak tensile stress increase of about 50% or 140% compared to the matrix specimen by adding one layer or two layers of steel grid can be obtained, respectively. For the steel grid-PE fiber reinforced ECC, when the fiber volume fraction is 0.5%, the maximal peak tensile stress increase of about 80% or 190% compared to the matrix specimen by adding one layer or two layers of steel grid can be obtained, respectively. A more remarkable increase of ultimate tensile strength can be obtained by adding two layers of steel grid, but it is more difficult to have a firm bonding with the ECC matrix for two layers of steel grid than one layer of steel grid.

- (3).

- The ultimate tensile strength of the reinforced ECC can be enhanced with the increase of fiber volume fraction. For all of the fiber types investigated, a volume fraction between 1.5% and 2% can make the reinforced ECC gain the best tensile strength. With these higher fiber volume fractions, the reinforced ECC exhibits strain hardening behavior, and its peak tensile stress increases considerably. The energy dissipation performance of the reinforced ECC can also be enhanced remarkably.

- (4).

- The ductility of PVA fiber reinforced ECC can be improved by the addition of steel grids and the increase of fiber volume fraction. The phenomenon of multiple-cracking can be observed for steel grid-PVA fiber reinforced ECC. The steel grid-PE fiber reinforced ECC also exhibits significant ductility and energy dissipation performance. Under those circumstances when excellent ductility and energy dissipation performance are required, it is better to use PVA fibers or PE fibers. The ductility of the steel grid-KEVLAR fiber reinforced ECC can be improved by the addition of steel grids. The ductility and energy dissipation performance of the steel grid-PE fiber reinforced ECC can be improved with the increase of fiber volume fraction.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, V.C. On Engineered Cementitious Composites (ECC). J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Tran, T.K.; Kim, D.J. Investigating Direct Tensile Behavior of High Performance Fiber Reinforced Cementitious Composites at High Strain Rates. Cem. Concr. Res. 2013, 50, 62–73. [Google Scholar] [CrossRef]

- Arboleda, D.; Carozzi, F.G.; Nanni, A.; Poggi, C. Testing Procedures for the Uniaxial Tensile Characterization of Fabric-Reinforced Cementitious Matrix Composites. J. Compos. Constr. 2016, 20, 44–54. [Google Scholar] [CrossRef]

- Kim, J.S.; Cho, C.G.; Moon, H.J.; Kim, H.; Lee, S.J.; Kim, W.J. Experiments on Tensile and Shear Characteristics of Amorphous Micro Steel (AMS) Fibre-Reinforced Cementitious Composites. Int. J. Concr. Struct. Mater. 2017, 11, 647–655. [Google Scholar] [CrossRef]

- Ali, M.A.E.M.; Soliman, A.M.; Nehdi, M.L. Hybrid-Fiber Reinforced Engineered Cementitious Composite under Tensile and Impact Loading. Mater. Des. 2017, 117, 139–149. [Google Scholar] [CrossRef]

- Nehdi, M.L.; Ali, M.A.E.M. Experimental and Numerical Study of Engineered Cementitious Composite with Strain Recovery under Impact Loading. Appl. Sci. 2019, 9, 994. [Google Scholar] [CrossRef]

- Yu, K.Q.; Wang, Y.C.; Yu, J.T.; Xu, S.L. A Strain-Hardening Cementitious Composites with the Tensile Capacity up to 8%. Constr. Build. Mater. 2017, 137, 410–419. [Google Scholar] [CrossRef]

- Yu, K.Q.; Dai, J.G.; Lu, Z.D.; Poon, C.S. Rate-Dependent Tensile Properties of Ultra-High Performance Engineered Cementitious Composites (UHP-ECC). Cem. Concr. Compos. 2018, 93, 218–234. [Google Scholar] [CrossRef]

- Curosu, I.; Liebscher, M.; Mechtcherine, V.; Bellmannb, C.; Michelb, S. Tensile Behavior of High-Strength Strain-Hardening Cement-Based Composites (HS-SHCC) Made with High-Performance Polyethylene, Aramid and PBO Fibers. Cem. Concr. Res. 2017, 98, 71–81. [Google Scholar] [CrossRef]

- Zhou, Y.W.; Xi, B.; Yu, K.Q.; Sui, L.L.; Xing, F. Mechanical Properties of Hybrid Ultra-High Performance Engineered Cementitious Composites Incorporating Steel and Polyethylene Fibers. Materials 2018, 11, 1448. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Yin, C.L.; Ma, F.Q.; Huang, Z.Y. Mechanical Properties and Carbonation Durability of Engineered Cementitious Composites Reinforced by Polypropylene and Hydrophilic Polyvinyl Alcohol Fibers. Materials 2018, 11, 1147. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.J.; Kim, S.; Yoo, D.Y. Hybrid Effect of Twisted Steel and Polyethylene Fibers on the Tensile Performance of Ultra-High-Performance Cementitious Composites. Polymers 2018, 10, 879. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.F.; Wang, W.W.; Harries, K.A.; Zheng, Y.Z. Uniaxial Tensile Stress-Strain Behavior of Carbon-Fiber Grid-Reinforced Engineered Cementitious Composites. J. Compos. Constr. 2018, 22, 163–176. [Google Scholar] [CrossRef]

- Al-Gemeel, A.N.; Zhuge, Y.; Youssf, O. Experimental Investigation of Basalt Textile Reinforced Engineered Cementitious Composite under Apparent Hoop Tensile Loading. J. Build. Eng. 2019, 23, 270–279. [Google Scholar] [CrossRef]

- Li, B.B.; Xiong, H.B.; Jiang, J.F.; Dou, X.X. Tensile Behavior of Basalt Textile Grid Reinforced Engineering Cementitious Composite. Compos. Pt. B Eng. 2019, 156, 185–200. [Google Scholar] [CrossRef]

- Sun, M.; Chen, Y.Z.; Zhu, J.Q.; Sun, T.; Shui, Z.H.; Ling, G.; Zhong, H.X.; Zheng, Y.R. Effect of Modified Polyvinyl Alcohol Fibers on the Mechanical Behavior of Engineered Cementitious Composites. Materials 2019, 12, 37. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.B.; Zhang, J.; Wang, J.H.; Shi, J.H. Tensile Performance of Polyvinyl Alcohol-Steel Hybrid Fiber Reinforced Cementitious Composite with Impact of Water to Binder Ratio. J. Compos. Mater. 2015, 49, 2169–2186. [Google Scholar]

- Abrishambaf, A.; Pimentel, M.; Nunes, S. Influence of Fibre Orientation on the Tensile Behaviour of Ultra-High Performance Fibre Reinforced Cementitious Composites. Cem. Concr. Res. 2017, 97, 28–40. [Google Scholar] [CrossRef]

- Wu, H.L.; Yu, J.; Zhang, D.; Zheng, J.X.; Li, V.C. Effect of Morphological Parameters of Natural Sand on Mechanical Properties of Engineered Cementitious Composites. Cem. Concr. Compos. 2019, 100, 108–119. [Google Scholar] [CrossRef]

- Pourfalah, S. Behaviour of Engineered Cementitious Composites and Hybrid Engineered Cementitious Composites at High Temperatures. Constr. Build. Mater. 2018, 158, 921–937. [Google Scholar] [CrossRef]

- Du, Q.; Wei, J.; Lv, J. Effects of High Temperature on Mechanical Properties of Polyvinyl Alcohol Engineered Cementitious Composites (PVA-ECC). Int. J. Civ. Eng. 2018, 16, 965–972. [Google Scholar] [CrossRef]

- Lawn, B. Fracture of Brittle Solids, 2nd ed.; Cambridge University Press: New York, NY, USA, 1993; ISBN 0521409721. [Google Scholar]

- Marshall, D.B.; Cox, B.N.; Evans, A.G. Mechanics of Matrix Cracking in Brittle-Matrix Fiber Composites. Acta Metall. 1985, 33, 2013–2021. [Google Scholar] [CrossRef]

- Li, V.C.; Leung, C.K.Y. Steady-State and Multiple Cracking of Short Random Fiber Composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, Y.; Backer, S. A Micromechanical Model of Tension Softening and Bridging Toughening of Short Random Fiber Reinforced Brittle Matrix Composites. J. Mech. Phys. Solids 1991, 39, 607–625. [Google Scholar] [CrossRef]

- Kanda, T.; Li, V.C. A New Micromechanics Design Theory for Pseudo Strain Hardening Cementitious Composite. J. Eng. Mech. ASCE 1999, 125, 373–381. [Google Scholar] [CrossRef]

| Specific Surface Area | Initial Setting Time | Final Setting Time | Compression Strength (3 Days) | Bending Strength (3 Days) |

|---|---|---|---|---|

| (m2/kg) | (min) | (min) | (MPa) | (MPa) |

| 381 | 181 | 243 | 23.5 | 5.3 |

| Diameter | Standard Length | Tensile Strength | Elongation Ratio | Elastic Modulus | Density |

|---|---|---|---|---|---|

| (μm) | (mm) | (MPa) | (GPa) | (g/cm3) | |

| 40 | 12 | 1560 | 6.5% | 41 | 1.3 |

| Tensile Strength | Elastic Modulus | Elongation Ratio | Standard Length | Density |

|---|---|---|---|---|

| (MPa) | (GPa) | (mm) | (g/cm3) | |

| 2920 | 70.5 | 3.6% | 12 | 1.44 |

| Tensile Strength | Elastic Modulus | Elongation Ratio | Standard Length | Density |

|---|---|---|---|---|

| (GPa) | (GPa) | (mm) | (g/cm3) | |

| 2.18 | 66 | 3.5% | 12 | 0.97 |

| Cement | Siliceous Fly Ash | Water | Superplasticizer |

|---|---|---|---|

| 1.0 | 0.11 | 0.3 | 0.013 |

| Specimen Type | Initial Cracking Stress (MPa) | Peak Stress (MPa) | Ultimate Strain (%) | Energy Dissipation (J/m2) |

|---|---|---|---|---|

| M | 0.98 | 0.98 | 0.01 | 1578 |

| M-S1 | 0.86 | 1.29 | 0.72 | 11,896 |

| M-S2 | 1.77 | 2.33 | 0.32 | 265,793 |

| A0.5 | 1.39 | 1.39 | 0.05 | 88,070 |

| A0.5S1 | 1.56 | 2.13 | 0.58 | 749,070 |

| A0.5S2 | 3.34 | 3.34 | 0.60 | 1,072,785 |

| A1 | 1.77 | 1.92 | 0.35 | 188,565 |

| A1S1 | 2.05 | 2.58 | 0.28 | 557,326 |

| A1S2 | 1.58 | 2.99 | 0.50 | 1,121,904 |

| A1.5 | 1.78 | 2.00 | 0.23 | 201,600 |

| A1.5S1 | 3.89 | 3.90 | 1.3 | 1,248,030 |

| A1.5S2 | 5.14 | 5.14 | 0.64 | 880,790 |

| A2 | 2.63 | 2.80 | 0.39 | 568,008 |

| A2S1 | 3.93 | 3.93 | 0.67 | 796,900 |

| A2S2 | 5.73 | 5.73 | 1.08 | 1,494,499 |

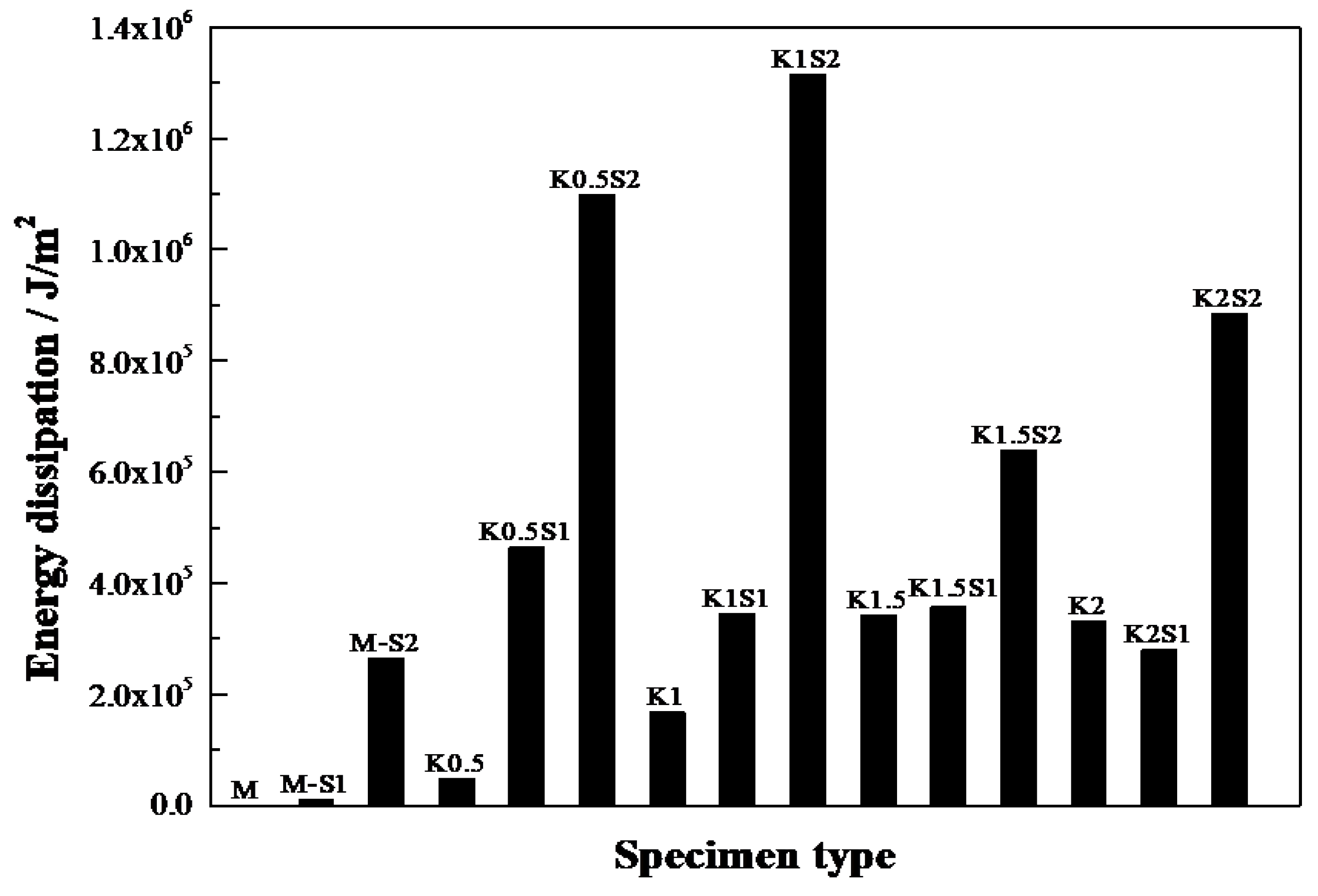

| Specimen Type | Initial Cracking Stress (MPa) | Peak Stress (MPa) | Ultimate Strain (%) | Energy Dissipation (J/m2) |

|---|---|---|---|---|

| M | 0.98 | 0.98 | 0.01 | 1578 |

| M-S1 | 0.86 | 1.29 | 0.72 | 11,896 |

| M-S2 | 1.77 | 2.33 | 0.32 | 265,793 |

| K0.5 | 1.79 | 1.79 | 0.06 | 49,591 |

| K0.5S1 | 1.93 | 2.07 | 0.16 | 464,231 |

| K0.5S2 | 3.28 | 3.28 | 0.55 | 1,099,560 |

| K1 | 1.6 | 1.6 | 0.12 | 168,336 |

| K1S1 | 1.88 | 2.45 | 0.42 | 345,744 |

| K1S2 | 3.81 | 3.81 | 0.59 | 1,314,334 |

| K1.5 | 2.21 | 2.21 | 0.26 | 343,120 |

| K1.5S1 | 2.25 | 2.76 | 0.22 | 357,616 |

| K1.5S2 | 4.48 | 4.88 | 0.45 | 639,744 |

| K2 | 2.93 | 2.93 | 0.24 | 332,010 |

| K2S1 | 3.05 | 3.39 | 0.35 | 280,896 |

| K2S2 | 4.15 | 4.15 | 0.29 | 884,450 |

| Specimen Type | Initial Cracking Stress (MPa) | Peak Stress (MPa) | Ultimate Strain (%) | Energy Dissipation (J/m2) |

|---|---|---|---|---|

| M | 0.98 | 0.98 | 0.01 | 1578 |

| M-S1 | 0.86 | 1.29 | 0.72 | 11,896 |

| M-S2 | 1.77 | 2.33 | 0.32 | 265,793 |

| E0.5 | 1.21 | 1.21 | 0.24 | 347,384 |

| E0.5S1 | 1.35 | 2.19 | 1.15 | 381,290 |

| E0.5S2 | 1.52 | 3.59 | 0.50 | 556,080 |

| E1 | 1.01 | 1.40 | 1.98 | 1,300,963 |

| E1S1 | 1.17 | 2.32 | 0.4 | 8278.26 |

| E1S2 | 3.60 | 3.60 | 0.51 | 436,100 |

| E1.5 | 1.64 | 1.94 | 4.87 | 3,284,074 |

| E1.5S1 | 2.67 | 2.97 | 0.58 | 142,450 |

| E1.5S2 | 3.96 | 3.96 | 0.58 | 422,240 |

| E2 | 1.8 | 2.18 | 5.18 | 3,284,074 |

| E2S1 | 3.24 | 3.33 | 1.02 | 335,440 |

| E2S2 | 4.34 | 4.34 | 0.79 | 432,075 |

| Specimen Type | Analytical Initial Tensile Strength (MPa) | Experimental Initial Tensile Strength(MPa) | Error (%) |

|---|---|---|---|

| E0.5S1 | 1.18 | 1.35 | −12.6 |

| E0.5S2 | 1.60 | 1.52 | 5.3 |

| E1S1 | 2.09 | 1.17 | 78.6 |

| E1S2 | 2.77 | 3.60 | −23.1 |

| E1.5S1 | 2.77 | 2.67 | 3.7 |

| E1.5S2 | 3.44 | 3.96 | −13.1 |

| E2S1 | 3.43 | 3.24 | 5.9 |

| E2S2 | 4.11 | 4.34 | −5.3 |

| Specimen Type | Analytical Ultimate Tensile Strength (MPa) | Experimental Ultimate Tensile Strength (MPa) | Error (%) |

|---|---|---|---|

| E0.5S1 | 2.86 | 2.19 | 30.6 |

| E0.5S2 | 4.73 | 3.59 | 31.8 |

| E1S1 | 3.84 | 2.32 | 65.5 |

| E1S2 | 5.71 | 3.60 | 58.6 |

| E1.5S1 | 4.83 | 2.97 | 62.6 |

| E1.5S2 | 6.70 | 3.96 | 69.2 |

| E2S1 | 5.81 | 3.33 | 74.5 |

| E2S2 | 7.68 | 4.34 | 77.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Liu, W.; Wu, J.; Wu, W.; Wu, M. Experimental Investigation on the Quasi-Static Tensile Capacity of Engineered Cementitious Composites Reinforced with Steel Grid and Fibers. Materials 2019, 12, 2666. https://doi.org/10.3390/ma12172666

Li L, Liu W, Wu J, Wu W, Wu M. Experimental Investigation on the Quasi-Static Tensile Capacity of Engineered Cementitious Composites Reinforced with Steel Grid and Fibers. Materials. 2019; 12(17):2666. https://doi.org/10.3390/ma12172666

Chicago/Turabian StyleLi, Liang, Wenli Liu, Jun Wu, Wenjie Wu, and Meng Wu. 2019. "Experimental Investigation on the Quasi-Static Tensile Capacity of Engineered Cementitious Composites Reinforced with Steel Grid and Fibers" Materials 12, no. 17: 2666. https://doi.org/10.3390/ma12172666

APA StyleLi, L., Liu, W., Wu, J., Wu, W., & Wu, M. (2019). Experimental Investigation on the Quasi-Static Tensile Capacity of Engineered Cementitious Composites Reinforced with Steel Grid and Fibers. Materials, 12(17), 2666. https://doi.org/10.3390/ma12172666