Effect of Fineness of Basaltic Volcanic Ash on Pozzolanic Reactivity, ASR Expansion and Drying Shrinkage of Blended Cement Mortars

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Fly Ash (FA)

2.1.2. Basaltic Volcanic Ash (VA)

2.2. Mix Proportions and Test Methods

2.2.1. Mix Proportions

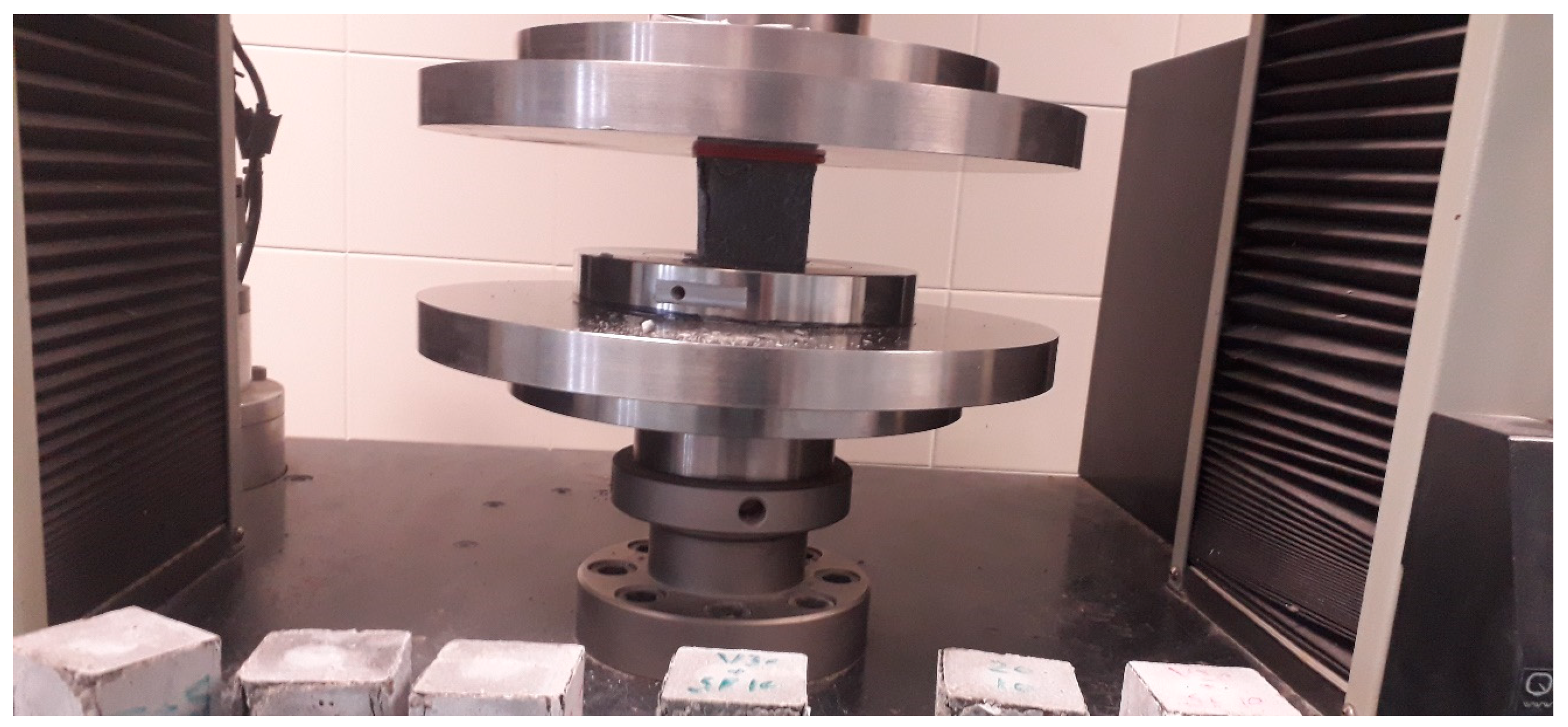

2.2.2. Mixing and Testing for Compressive Strength of Mortar Cubes

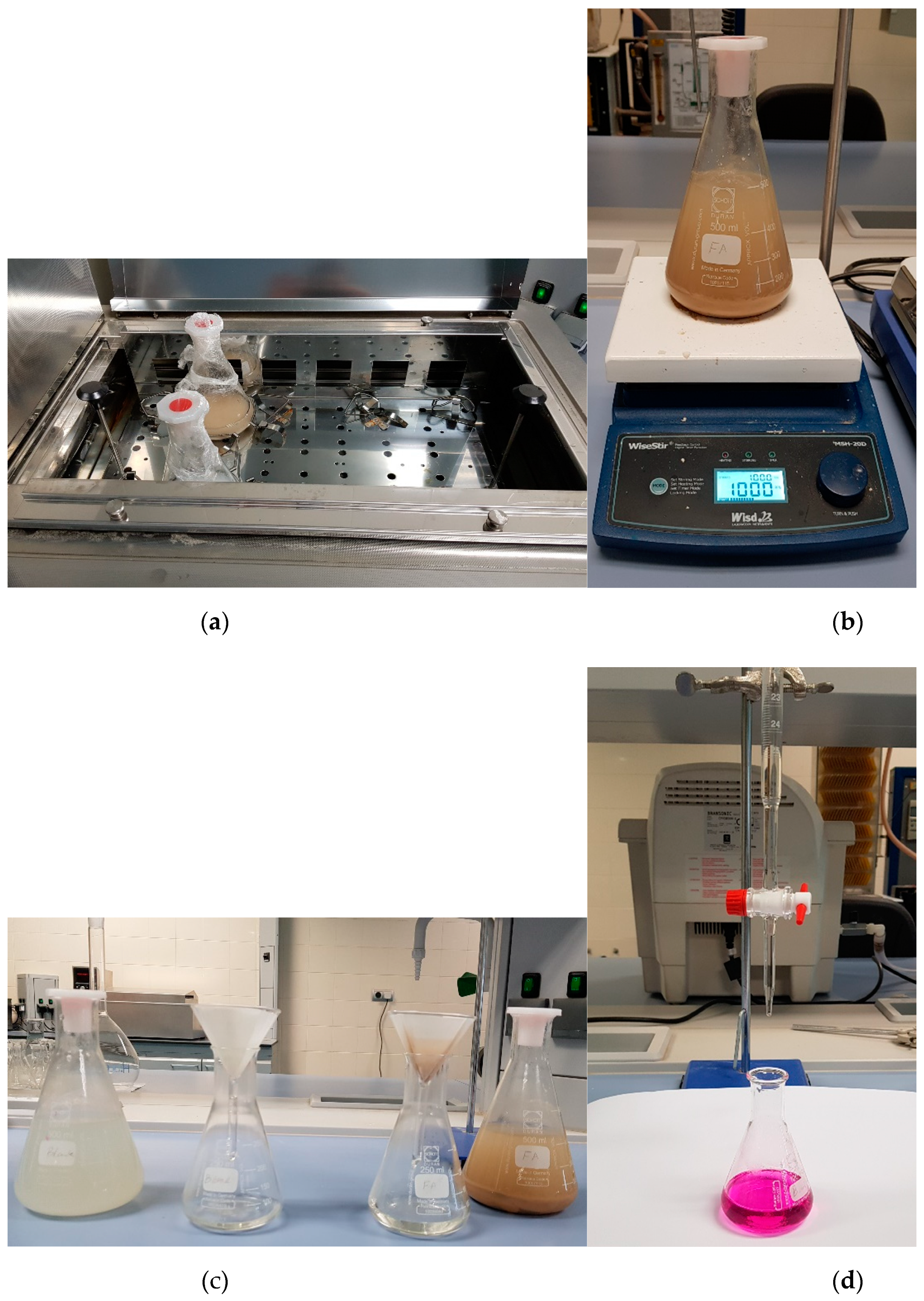

2.3. Modified Chappelle Test to Evalute Reactivity of Pozzolanic Materials

- m2: weight of pozzolanic material in grams;

- m3: weight of CaO mixed with pozzolanic material in grams;

- m4: Weight of CaO in the blank sample in grams;

- v2: volume of 0.1 M HCl consumed by the sample solution in milliliters and

- v3: volume of 0.1 M HCl consumed by the blank solution in milliliters.

- V1: volume of 0.1 M HCl consumed by the blank solution in milliliters and

- V2: volume of 0.1 M HCl consumed by the sample solution in milliliters.

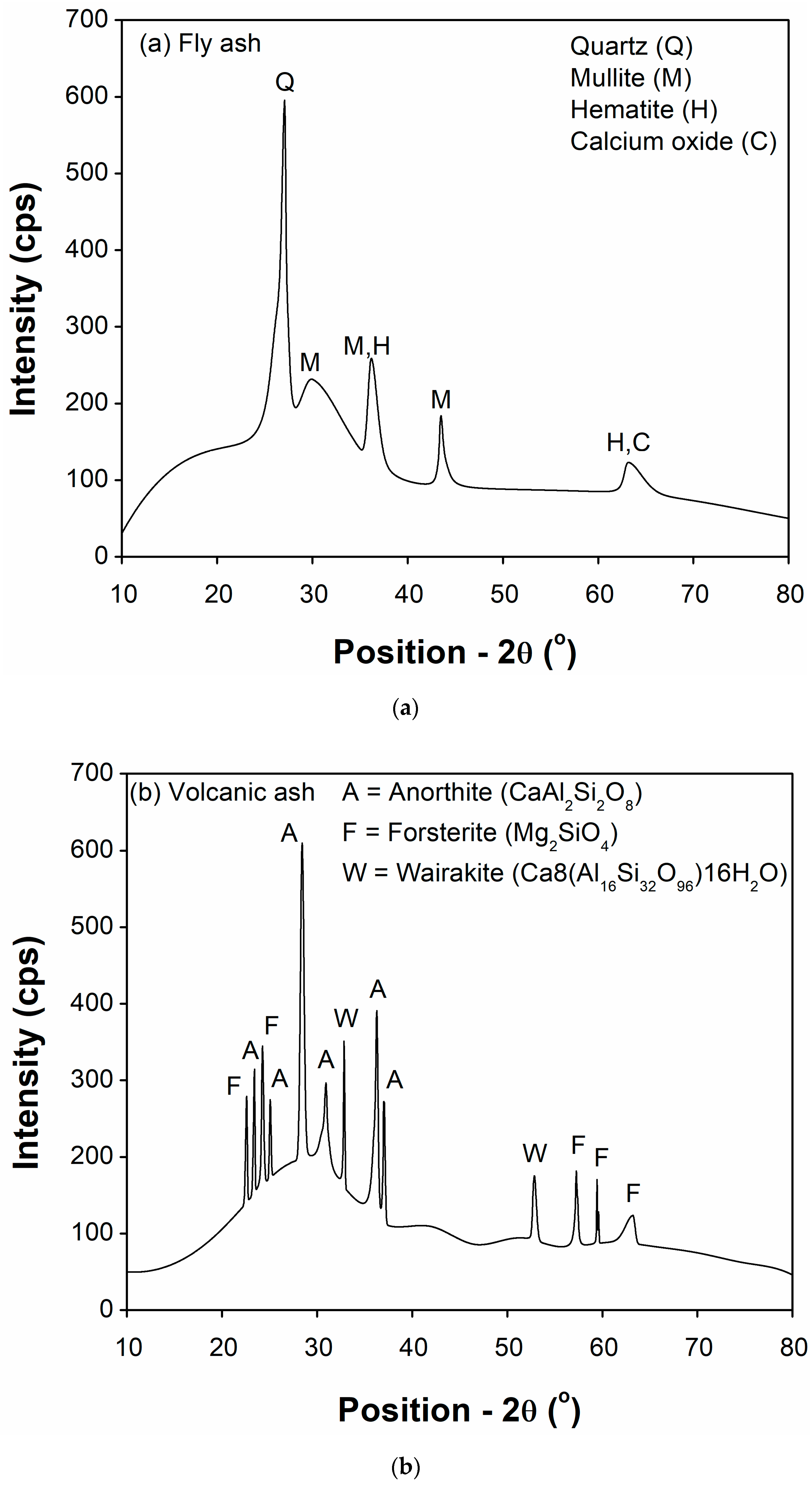

2.4. X-Ray Diffraction (XRD) of Pastes Containing Pozzolanic Materials

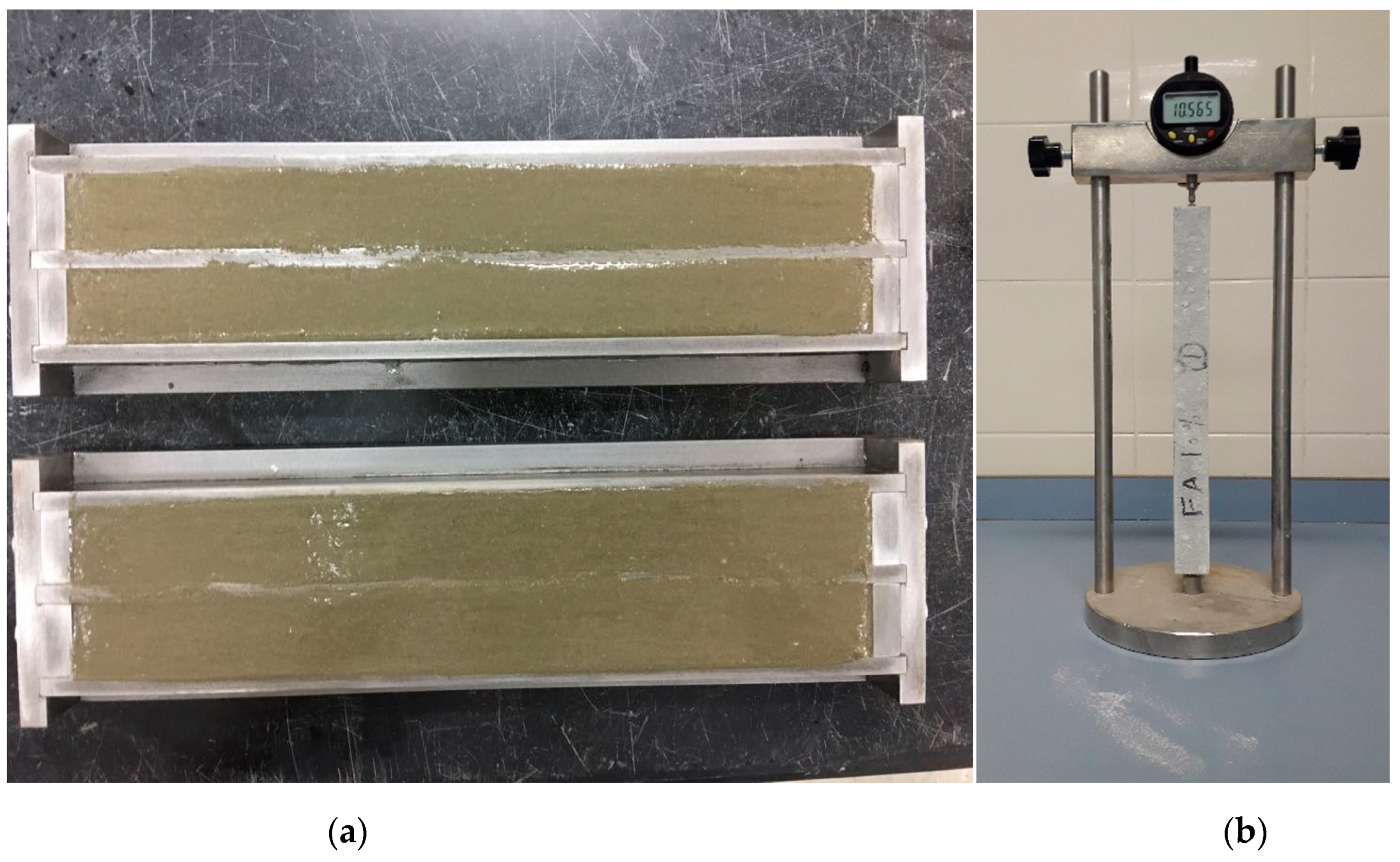

2.5. Specimen Preparation and Test Method to Measure Expansion due to Alkali Silica Reaction

2.6. Specimen Preparation and Test Method to Measure Drying Shrinkage

3. Results and Discussions

3.1. Chemical and Physical Characteristic of Basaltic Volcanic Ash

3.2. Chappelle Reactivity Test

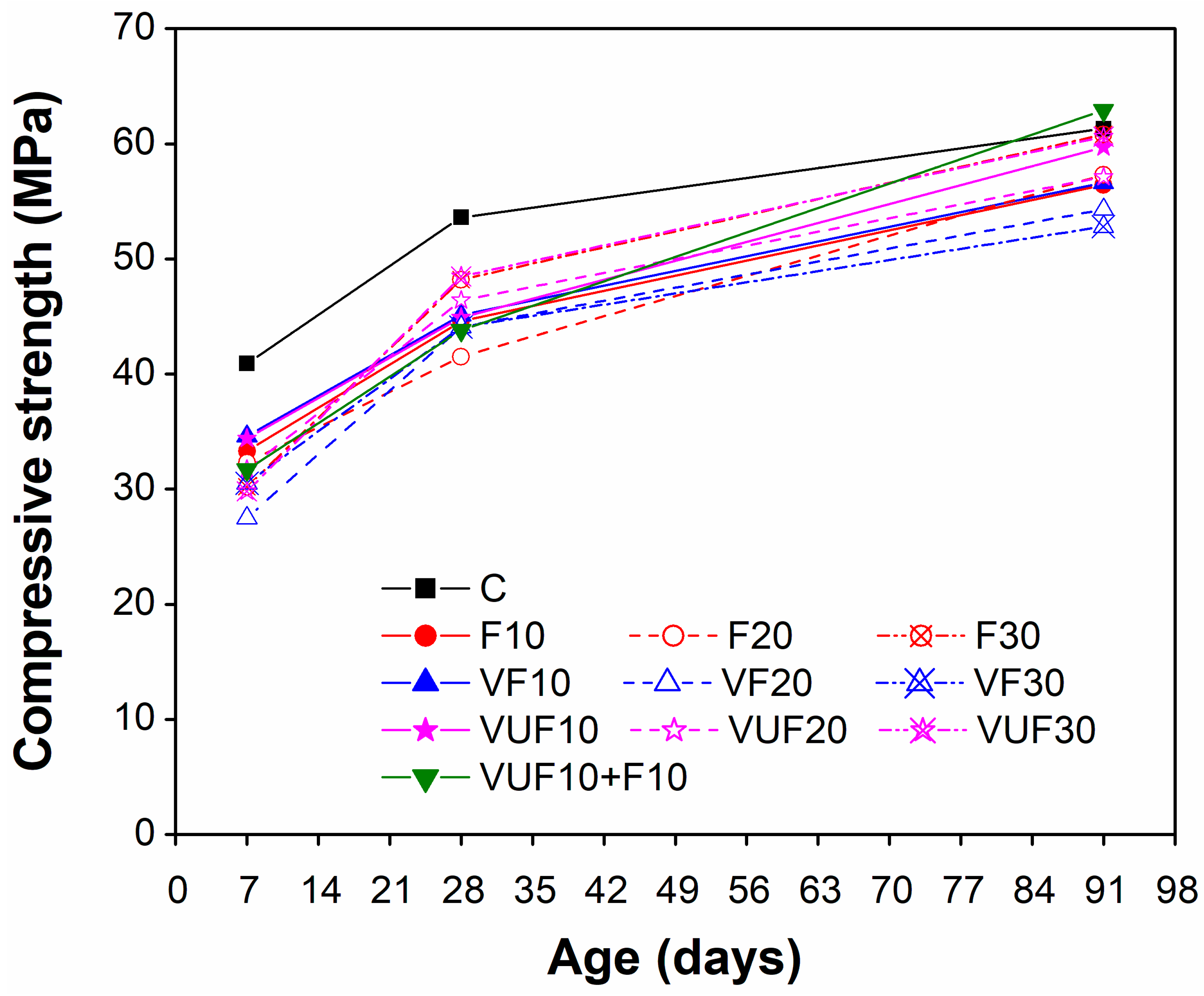

3.3. Compressive Strength of Control Mortar and Mortars Containing Pozzolanic Materials

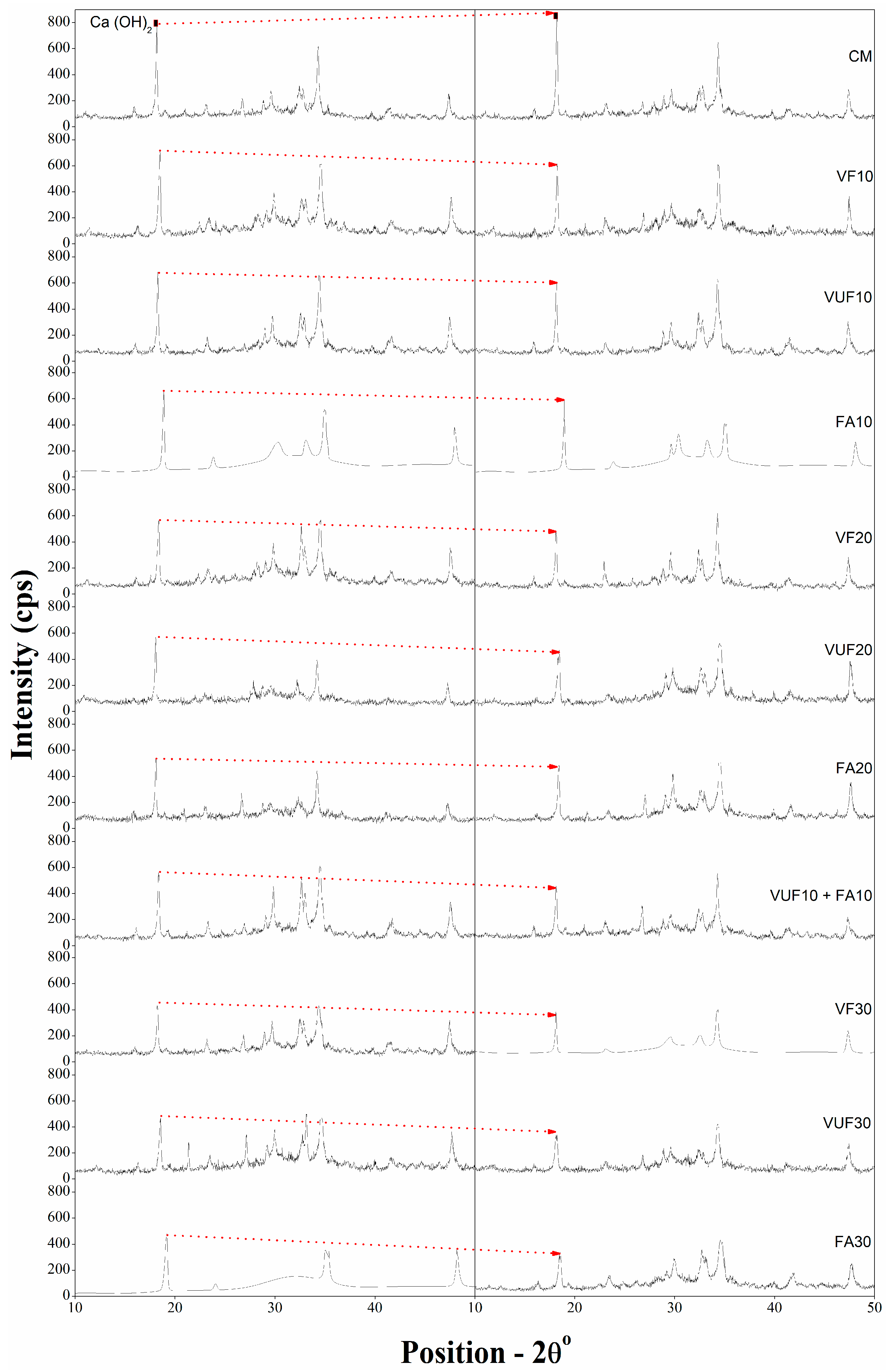

3.4. X-Ray Diffraction of Cement Pastes Containing Pozzolanic Materials

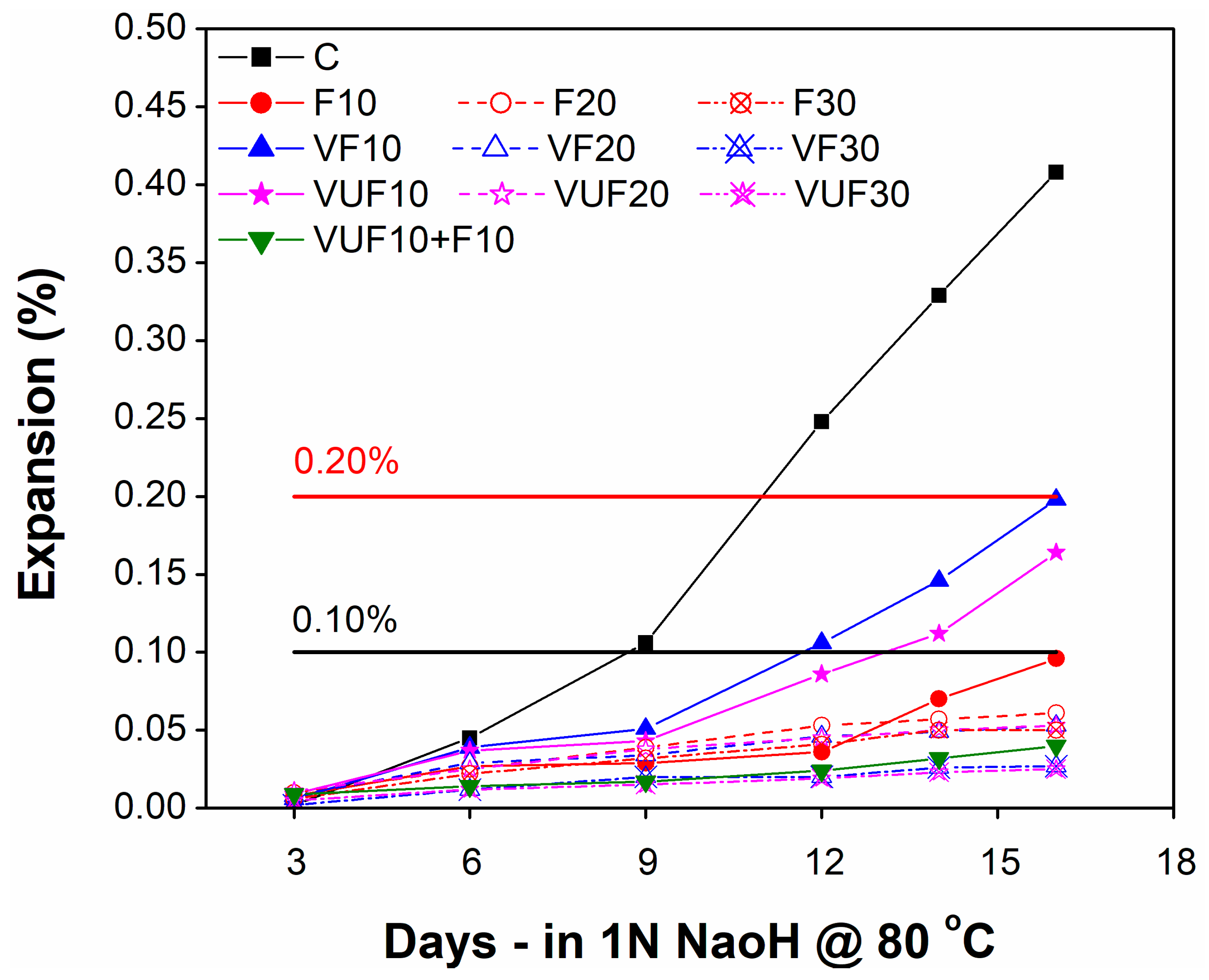

3.5. Influence of Pozzolanic Materials on Expansion Caused by Alkali Silica Reaction (ASR)

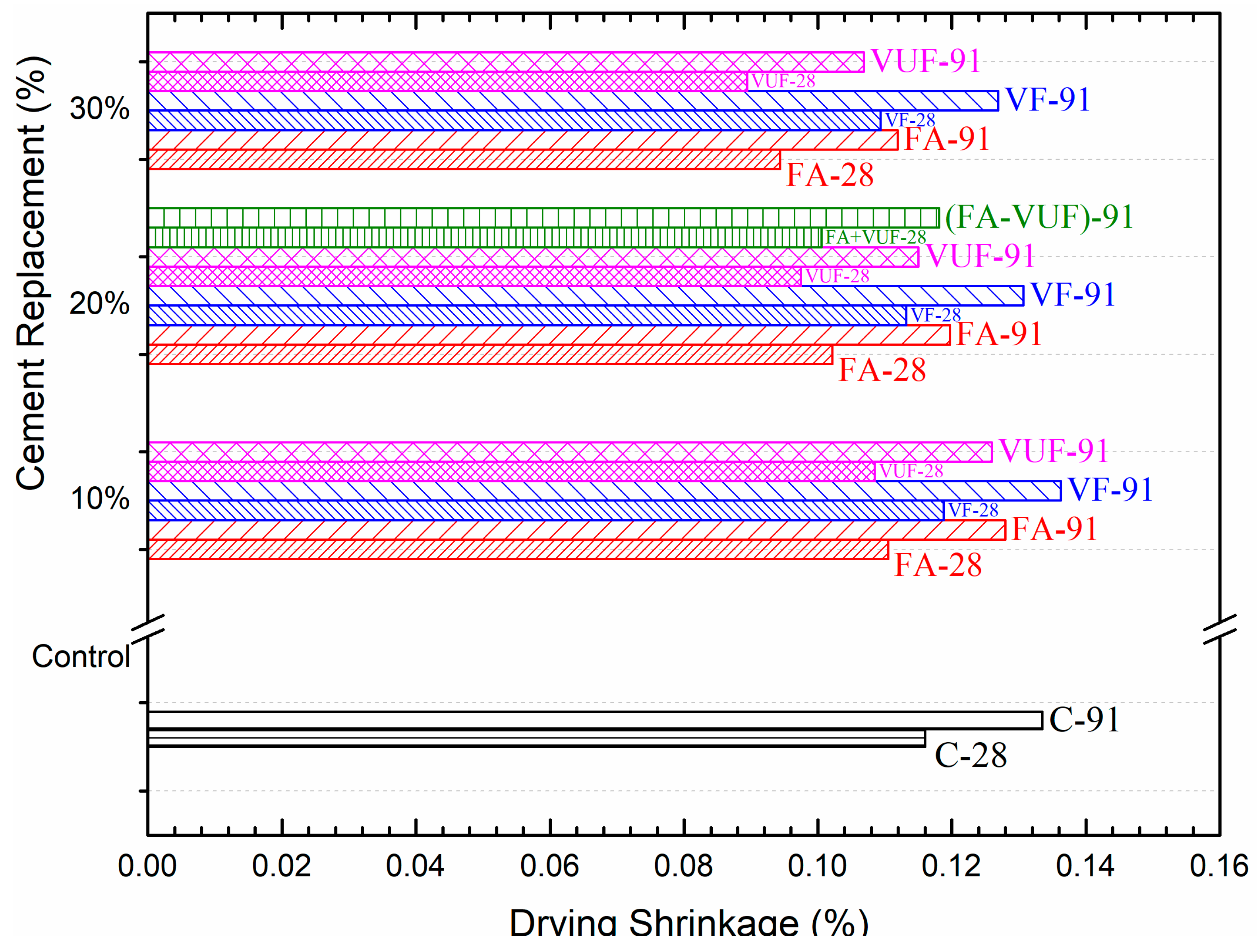

3.6. Influence of Pozzolanic Materials on Drying Shrinkage with Respect to Aging

4. Conclusions

- -

- An increase in the fineness of VA, significantly increased the Chappelle reactivity. On the other hand, FA, prepared under controlled conditions, showed better Chappelle reactivity compared to both VF and VUF.

- -

- The incorporation of VF, VUF, and FA at different percentages (10%, 20% and 30%) resulted in a decrease in the compressive strength of mortar cubes at early ages (7 and 28 days) as compared to control samples; this is attributed to the slow pozzolanic reaction of these materials. On the other hand, compressive strength was significantly improved for all pozzolan-incorporated mixes at a later age when samples were further cured up to 91 days. It was found that at lower percentage replacement (10%), FA showed better compressive strength than both VF and VUF at all ages (7, 28 and 91 days). However, at higher percentage replacement (20 and 30%), mortar containing VUF exhibited almost the same compressive strength as that of FA at later ages (91 days). Moreover, the hybrid mixture (10% VUF + 10% FA) exhibited better compressive strength than all other mixes including control, particularly at later ages (91 days). This can be attributed to the high fineness and increased pozzolanic reactivity of both VUF and FA.

- -

- The intensity of Ca(OH)2 as shown by the peak, was reduced in all mixes regardless of type (VA or FA), fineness (VF or VUF) or percentage (10%, 20%, and 30%) of pozzolanic materials. The reduction in the amount of Ca(OH)2 is due to the lesser amount of cement used in all mixes, except the control, as well as due to the pozzolanic reactivity of FA and VA. More importantly, the rate of depletion of Ca(OH)2 in mixes having VUF or FA was faster compared to mixes with VF at all corresponding percentage replacements. The increased pozzolanic reactivity of both VUF and FA is because of their greater fineness as compared to VF. Similar pozzolanic behavior of VUF suggests that it is a viable substitute for commercially available FA for economical and sustainable concretes.

- -

- The results indicated reduced alkali silica expansion in all mixes containing VA or FA regardless of their percentage substitution with cement, except at the lower percentage (10%) for both VF and VUF, where they did not satisfy ASTM standard limits. Unlike VA, FA was equally effective in mitigating ASR expansion even at lower percentages (10%). As a matter of fact, both VF and VUF showed better resistance against ASR expansion as compared to FA at higher percentages of 20% and 30%. Eventually, the results suggested the utilization of more than 10% VA, irrespective of its fineness, to control ASR related expansion of concrete.

- -

- Just like the findings for ASR expansion, the drying shrinkage of all mortar bars also decreased with an increase in the amount of VF, VUF or FA. The drying strain of all the mixes at 28 days was less than the control sample except for VF. However, all the mixes, including VF demonstrated less shrinkage as compared to the control at 91 days. Moreover, the mortar containing VUF showed the best results against drying shrinkage among all mixes, irrespective of their percentage replacements with cement and aging. This must be attributed to the very fine particle size of VUF, which enhances the filling ability and reduces the pore volume of paste.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Klee, H. The Cement Sustainability Initiative: Recycling Concrete-Summary; World Business Council for Sustainable Development (WBCSD): Geneva, Switzerland, 2009; pp. 1–8. [Google Scholar]

- Suzette, M.K. Department of the Interior USGS. In Mineral Commodity Summaries 2009; Government Printing Office: Washington, WA, USA, 2009. [Google Scholar]

- IEA-WBCSD, Cement Technology Roadmap 2009-Carbon emissions reductions up to 2050. 2009. Available online: https://www.iea.org/publications/freepublications/publication/Cement.pdf (accessed on 6 June 2019).

- Devi, K.S.; Lakshmi, V.V.; Alakanandana, A. Impacts of cement industry on environment-an overview. Asia Pac. J. Res. 2017, 1, 156–161. [Google Scholar]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: In the US cement industry. Energy 2009, 25, 1189–1214. [Google Scholar]

- Uzal, B.; Turanli, L.; Mehta, P.K. High-volume natural pozzolan concrete for structural applications. ACI Mater. J. 2007, 104, 535–538. [Google Scholar]

- Papadakis, V.; Tsimas, S. Supplementary cementing materials in concrete: part I: Efficiency and design. Cem. Concr. Res. 2002, 32, 1525–1532. [Google Scholar] [CrossRef]

- Rodríguez-Camacho, R.; Uribe-Afif, R. Importance of using the natural pozzolans on concrete durability. Cem. Concr. Res. 2002, 32, 1851–1858. [Google Scholar] [CrossRef]

- Tomkins, C.D. Redefining What’s Possible for Clean Energy by 2020; Gigaton Throwdown: San Francisco, CA, USA, 2009. [Google Scholar]

- Jasinski, S.M. Department of the Interior USGS. In Mineral Commodity Summaries 2016; U.S. Geological Survey: Reston, VA, USA, 2016. [Google Scholar]

- Khan, M.I.; Alhozaimy, A.M. Properties of natural pozzolan and its potential utilization in environmental, friendly concrete. Can. J. Civ. Eng. 2011, 38, 71–78. [Google Scholar] [CrossRef]

- Moufti, M.R.; Sabtan, A.A.; El-Mahdy, O.R.; Shehata, W.M. Assessment of the industrial utilization of scoria materials in central Harrat Rahat Saudi Arab. Eng. Geol. 2000, 57, 155–162. [Google Scholar] [CrossRef]

- Sabtan, A.A.; Shehata, W.M. Evaluation of engineering, properties of scoria in central Harrat Rahat Saudi Arab. B. Eng. Geol. Environ. 2000, 59, 219–225. [Google Scholar] [CrossRef]

- Abdul Hafiz, K.; Tayeb, O.; Ghandurah, R.; Roobol, J. Economic evaluation of basaltic and its derivatives in the north of Harrat Rahat. In Proceedings of the 5th Meeting of Saudi Society Earth Sciences, Dhahran, Saudi Arabia, 26–29 October 1998; p. 24. [Google Scholar]

- Moufti, M.R.; Sabtan, A.A.; El-Mahdy, O.; Shehata, W.M. Preliminary geologic and engineering assessment of the pyroclastic deposits in the central part of Harrat Rahat. In Proceedings of the 5th Meeting of Saudi Society Earth Sciences, Dhahran, Saudi Arabia, 26–29 October 1998; p. 25. [Google Scholar]

- MPMR Report. Atlas of industrial minerals-natural pozzolan and basalt. Directorate General of Mineral Resources, Ministry of Petroleum and Mineral Resources (MPMR); Kingdom of Saudi Arabia. 2000. Available online: https://sgs.org.sa/Arabic/Products/إصدارات/Reports/النسخة%20الانجليزية.pdf (accessed on 22 January 2019).

- Malhotra, V.M. Condensed Silica Fume in Concrete; FIP Commission of Thomas Telford House: London, UK, 1988. [Google Scholar]

- Malhotra, V.M.; Mehta, P.K. Natural Pozzolanic and Cementitious Materials-Advances in Concrete Technology; Gordon and Breach Publishers: Amsterdam, The Netherlands, 1996. [Google Scholar]

- Khan, M.I.; Lynsdale, C.J. Strength, permeability and carbonation of high-performance concrete. Cem. Concr. Res. 2002, 32, 123–131. [Google Scholar] [CrossRef]

- Khan, M.I. Permeation of high performance concrete. J. Mater. Civil. Eng. 2003, 15, 84–92. [Google Scholar] [CrossRef]

- Alhoziamy, A.; Soroushian, P.; Mirza, F. Effects of curing condition and age on chloride permeabilty of fly ash mortar. ACI Mater. J. 1996, 93, 87–95. [Google Scholar]

- Al-Chaar, G.K.; Alkadi, M.; Asteris, P.G. Natural Pozzolan as a Partial Substitute for Cement in Concrete. Open Constr. Build. Technol. J. 2013, 7, 33–42. [Google Scholar] [CrossRef]

- Celik, K.; Jackson, M.D.; Mancio, M.; Meral, C.; Emwas, A.H.; Mehta, P.K.; Monteiro, P.J.M. High-volume natural volcanic pozzolan and limestone powder as partial replacements for portland cement in self-compacting and sustainable concrete. Cem. Concr. Compos. 2014, 45, 136–147. [Google Scholar] [CrossRef]

- Kunal, K.P.; Anfal, F.A.; Mohammad, F.A.; Cheahuychou, M.; Ali, B.; Steven, D.; Palkovic, O.B. Microstructure of cement paste with natural pozzolanic volcanic ash and Portland cement at different stages of curing. Constr. Build. Mater. 2016, 113, 423–441. [Google Scholar]

- Charkhi, A.; Kazemian, H.; Kazemeini, M. Optimized experimental design for natural clinoptilolite zeolite ball milling to produce nano powders. Powder Technol. 2010, 203, 389–396. [Google Scholar] [CrossRef]

- Kosanovic, C.; Subotic, B.; Smit, I.; Cizmek, A.; Stubicar, M.; Tonejc, A. Study of structural transformations in potassium-exchanged zeolite A induced by thermal and mechanochemical treatments. J. Mater. Sci. 1997, 32, 73–78. [Google Scholar] [CrossRef]

- Saamiya, S.; Raissa, D.F.; Maria, C.G.J. Calcining natural zeolites to improve their effect on cementitious mixture workability. Cem. Concr. Res. 2016, 85, 102–110. [Google Scholar]

- Moussa, H.; Larbi, K.; Martin, C.; Pierre, C. Evaluation and improvement of pozzolanic activity of andesite for its use in eco-efficient cement. Constr. Build. Mater. 2013, 47, 1268–1277. [Google Scholar]

- Kucukyıldırım, E.; Uzal, B. Characteristics of calcined natural zeolites for use in high-performance pozzolan blended cements. Constr. Build. Mater. 2014, 73, 229–234. [Google Scholar] [CrossRef]

- Alaettin, K.; Zeynep, S. Effect of heat treatment on pozzolanic activity of volcanic pumice used as cementitious material. Cem. Concr. Compos. 2015, 57, 128–132. [Google Scholar]

- Burris, L.E.; Juenger, M.C.G. Milling as a pretreatment method for increasing the reactivity of natural zeolites for use as supplementary cementitious materials. Cem. Concr. Compos. 2016, 65, 163–170. [Google Scholar] [CrossRef]

- Khan, K.; Amin, M.N. Influence of fineness of volcanic ash and its blends with quarry dust and slag on compressive strength of mortar under different curing temperatures. Constr. Build. Mater. 2017, 154, 514–528. [Google Scholar] [CrossRef]

- Rehab, M.; Patil, K.K.; Ali, B.; Oral, B. In situ Raman studies on cement paste prepared with natural pozzolanic volcanic ash and Ordinary Portland Cement. Constr. Build. Mater. 2017, 148, 444–454. [Google Scholar]

- ASTM C150/C150M-16e1. Standard Specification for Portland Cement. Available online: http://www.astm.org (accessed on 20 January 2019).

- ASTM C33/C33M-18. Standard Specification for Concrete Aggregates. Available online: http://www.astm.org (accessed on 20 January 2019).

- ISO 13320:2009. Particle Size Analysis—Laser Diffraction Methods; International Organization for Standardization: Geneva, Switzerland, 2009; Available online: https://www.iso.org/standard/44929.html (accessed on 9 June 2017).

- Malhotra, V.M.; Mehta, P.K. High-Performance, High-Volume Fly Ash Concrete: Supplementary Cementing Materials for Sustainable Development; Inc.: Ottawa, ON, Canada, 2002. [Google Scholar]

- ASTM-C618–15. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. Available online: http://www.astm.org (accessed on 22 January 2019).

- Camp, V.E.; Roobol, M.J. The Arabian continental alkali basalt province: Part 1. Evolution of Harrat Rahat. Kingdom of Saudi Arabia. Bull. Geol. Soc. Am. 1989, 101, 71–95. [Google Scholar] [CrossRef]

- Roobol, M.J.; Pint, J.J.; Al-Shanti, M.A.; Al-Juaid, A.J.; Al-Amoudi, S.A.; Pint, S.; Al-Eisa, A.M.; Allam, F.; Al-Sulaimani, G.S.; Banakhar, A.S. Preliminary Survey for Lavatube Caves on Harrat Kishb, Kingdom of Saudi Arabia; Saudi Geological Survey: Jeddah, Saudi Arabia, 2002. [Google Scholar]

- Camp, V.E.; Roobol, M.J.; Hooper, P.R. The Arabian continental alkali basalt province: Part III, Evolution of Harrat Kishb, Kingdom of Saudi Arabia. GAS Bull. 1992, 104, 379–396. [Google Scholar] [CrossRef]

- Camp, V.E.; Roobol, M.J.; Hooper, P.R. The Arabian continental alkali basalt province: Part II. Evolution of Harrats Khaybar, Ithnayn and Kura, Kingdom of Saudi Arabia. GSA Bull. 1991, 103, 363–391. [Google Scholar] [CrossRef]

- Al-Nakhebi, Z.; Laurent, D. Prospecting for Pozzolan in Midwest Harrat Rahat. Open-File Report BRGM-OF-05-15: Abstracts of Saudi geological survey reports 2014, Kingdom of Saudi Arabia. 1985. Available online: https://sgs.org.sa/Arabic/Products/إصدارات/Reports/النسخة%20الانجليزية.pdf (accessed on 22 January 2019).

- Sabbahi, A.A. Geology and resources of basalt quarry site Kishb-12, southern Harrat Kishb; Open file report SGS-OF-2002-1, Saudi Geological Survey: Abstracts of Saudi geological survey reports 2014, Kingdom of Saudi Arabia. 2002. Available online: https://sgs.org.sa/Arabic/Products/إصدارات/Reports/النسخة%20الانجليزية.pdf (accessed on 22 January 2019).

- Kurdi, H.H. Geology and resources of basalt quarry site Kishb-13, Southern Harrat Kishb; Open file report SGS-OF-2002-4: Abstracts of Saudi geological survey reports 2014, Kingdom of Saudi Arabia. 2002. Available online: https://sgs.org.sa/Arabic/Products/إصدارات/Reports/النسخة%20الانجليزية.pdf (accessed on 22 January 2019).

- Abdul-Hafez, K. Geology and resources of basalt quarry site Kishb-6 (Jabal al Labah), Southern Harrat Kishb; Open file report SGS-OF-2002-5: Abstracts of Saudi geological survey reports 2014, Kingdom of Saudi Arabia. 2004. Available online: https://sgs.org.sa/Arabic/Products/إصدارات/Reports/النسخة%20الانجليزية.pdf (accessed on 22 January 2019).

- Al-Sehly, T.; Doban, A.; Al-Wagdani, K.; Abdul-Hafez, K.; Al-Harthy, I. Evaluation of engineering properties and industrial utilization of scoria, Harrat Hutaymah; Open file report SGS-OF-2005-19: Abstracts of Saudi geological survey reports 2014, Kingdom of Saudi Arabia. 2006. Available online: https://sgs.org.sa/Arabic/Products/إصدارات/Reports/النسخة%20الانجليزية.pdf (accessed on 22 January 2019).

- ASTM C109/C109M-16a. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). Available online: www.astm.org (accessed on 22 January 2019).

- ASTM C305–14. Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency. Available online: http://www.astm.org (accessed on 22 January 2019).

- ASTM C230/C230M-14. Standard Specification for Flow Table for Use in Tests of Hydraulic Cement. Available online: http://www.astm.org (accessed on 17 January 2017).

- ASTM C1437-15. Standard Test Method for Flow of Hydraulic Cement Mortar. Available online: http://www.astm.org (accessed on 17 January 2017).

- AFNOR-Association Française de Normalisation-Standard NF P 18-513/2012-Pozzolanic Addition for Concrete-Metakaolin-Definitions, Specifications and Conformity Criteria; La Plaine Saint-Denis: AFNOR: Paris, France, 2012; Available online: https://www.boutique.afnor.org/standard/nf-p18-513/addition-for-concrete-metakaolin-specifications-and-conformity-criteria/article/760894/fa175740 (accessed on 12 June 2019).

- ASTM C1567-13. Standard Test Method for Determining the Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and Aggregate (Accelerated Mortar-Bar Method). Available online: http://www.astm.org (accessed on 22 January 2019).

- ASTM C1260-14. Standard Test Method for Potential Alkali Reactivity of Aggregates (Mortar-Bar Method). Available online: http://www.astm.org (accessed on 22 January 2019).

- Idir, R.; Cyr, M.; Tagnit-Hamou, A. Use of fine glass as ASR inhibitor in glass aggregate mortars. Constr. Build. Mater. 2010, 24, 9–12. [Google Scholar] [CrossRef]

- Jin, W.; Meyer, C.; Baxter, S. Glascrete-concrete with glass aggregate. ACI Mater. J. 2000, 97, 8–13. [Google Scholar]

- ASTM C490/C490M-17. Standard Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete. Available online: http://www.astm.org (accessed on 22 January 2019).

- ASTM C596-18. Standard Test Method for Drying Shrinkage of Mortar Containing Hydraulic Cement. Available online: http://www.astm.org (accessed on 22 January 2019).

- ASTM C311/C311M-18. Standard Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland-Cement Concrete. Available online: http://www.astm.org (accessed on 22 January 2019).

- Chindaprasirt, P.; Jaturapitakkubuildl, C.; Sinsiri, T. Effect of fly ash fineness on microstructure of blended cement paste. Constr. Build. Mater. 2007, 21, 1534–1541. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete, 2nd ed.; Prentice-Hall: New Jersey, NJ, USA, 2003. [Google Scholar]

- Zhuang, F.; Zhang, F.Y.; Du, J.Y.; Chen, H.W.; Li, H.L.; Dan, J.M. Study of influence of fly ash on the properties of mortar. J. Shihezi Uinv. 2012, 30, 87–91. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-SHZN201201020.htm (accessed on 12 June 2019).

- Morsy, M.S.; Alsalloum, Y.A.; Abbas, H.; Alsayed, S.H. Behavior of blended mortars containing nano-metakaolin at elevated temperatures. Constr. Build. Mater. 2012, 35, 900–905. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Gong, J.X.; Zhao, S.M. Experimental study on shrinkage of HPC containing fly ash and ground granulated blast-furnace slag. Constr. Build. Mater. 2017, 155, 145–153. [Google Scholar] [CrossRef]

| C | FA | VF | VUF | |

|---|---|---|---|---|

| Physical properties | ||||

| Specific gravity (g/cm3) | 3.15 | 2.83 | 2.64 | |

| Fineness (m2/kg) (Blain) | 344 | − | − | − |

| Fineness (m2/cc) (Microtrac S3500) | 0.5670 | 1.027 | 0.816 (˂38 μ) | 1.194 (˂20 μ) |

| Chemical properties (oxides, % by weight) | ||||

| SiO2 | 20.9 | 51.5 | 46.4 | |

| Al2O3 | 5.18 | 24.3 | 14.4 | |

| Fe2O3 | 3.04 | 8.87 | 12.8 | |

| (SiO2 + Al2O3 + Fe2O3) * | − | 84.7 | 73.6 | |

| CaO | 63.9 | 5.15 | 8.80 | |

| MgO | 1.65 | 3.50 | 8.30 | |

| Na2O | 0.10 | 2.38 | 3.80 | |

| K2O | 0.52 | 1.47 | 1.90 | |

| SO3 | 2.61 | 0.23 | 0.80 | |

| LOI ** | 2.51 | 0.25 | 2.80 | |

| Compounds (%) | ||||

| C2S | 52.1 | − | − | |

| C3S | 19.6 | − | − | |

| C3A | 8.17 | − | − | |

| C4AF | 8.81 | − | − | |

| Mix ID | Flow (mm) ASTM C1437 | Superplasticizer (% of Binder) |

|---|---|---|

| CM | 110 | 1.25 |

| FA10 | 110 | 0.95 |

| FA20 | 111 | 0.70 |

| FA30 | 112 | 0.50 |

| VF10 | 110 | 1.60 |

| VF20 | 109 | 1.85 |

| VF30 | 109 | 2.00 |

| VUF10 | 109 | 1.60 |

| VUF20 | 110 | 1.88 |

| VUF30 | 109 | 2.05 |

| VUF10FA10 | 111 | 1.30 |

| Chappelle Activity | ||

|---|---|---|

| Materials | mg Ca(OH)2/g sample | mg CaO/g sample |

| FA | 666.27 | 911.37 |

| VA ˂ 38 μ (VF) | 257.61 | 853.63 |

| VA ˂ 20 μ (VUF) | 336.73 | 871.51 |

| Mix ID | Compressive Strength (MPa) | ||

|---|---|---|---|

| 7 days | 28 days | 91 days | |

| CM | 40.9 | 53.6 | 61.3 |

| FA10 | 33.3 | 44.6 | 56.4 |

| FA20 | 32.3 | 41.5 | 57.3 |

| FA30 | 30.2 | 48.2 | 60.8 |

| VF10 | 34.6 | 45.1 | 56.6 |

| VF20 | 30.5 | 44.1 | 52.8 |

| VF30 | 27.5 | 44.1 | 54.3 |

| VUF10 | 34.4 | 44.9 | 59.7 |

| VUF20 | 31.7 | 46.4 | 57.1 |

| VUF30 | 29.8 | 48.5 | 60.6 |

| VUF10FA10 | 31.7 | 43.8 | 62.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, K.; Amin, M.N.; Saleem, M.U.; Qureshi, H.J.; Al-Faiad, M.A.; Qadir, M.G. Effect of Fineness of Basaltic Volcanic Ash on Pozzolanic Reactivity, ASR Expansion and Drying Shrinkage of Blended Cement Mortars. Materials 2019, 12, 2603. https://doi.org/10.3390/ma12162603

Khan K, Amin MN, Saleem MU, Qureshi HJ, Al-Faiad MA, Qadir MG. Effect of Fineness of Basaltic Volcanic Ash on Pozzolanic Reactivity, ASR Expansion and Drying Shrinkage of Blended Cement Mortars. Materials. 2019; 12(16):2603. https://doi.org/10.3390/ma12162603

Chicago/Turabian StyleKhan, Kaffayatullah, Muhammad Nasir Amin, Muhammad Umair Saleem, Hisham Jahangir Qureshi, Majdi Adel Al-Faiad, and Muhammad Ghulam Qadir. 2019. "Effect of Fineness of Basaltic Volcanic Ash on Pozzolanic Reactivity, ASR Expansion and Drying Shrinkage of Blended Cement Mortars" Materials 12, no. 16: 2603. https://doi.org/10.3390/ma12162603

APA StyleKhan, K., Amin, M. N., Saleem, M. U., Qureshi, H. J., Al-Faiad, M. A., & Qadir, M. G. (2019). Effect of Fineness of Basaltic Volcanic Ash on Pozzolanic Reactivity, ASR Expansion and Drying Shrinkage of Blended Cement Mortars. Materials, 12(16), 2603. https://doi.org/10.3390/ma12162603