The δ Phase Precipitation of an Inconel 718 Superalloy Fabricated by Electromagnetic Stirring Assisted Laser Solid Forming

Abstract

1. Introduction

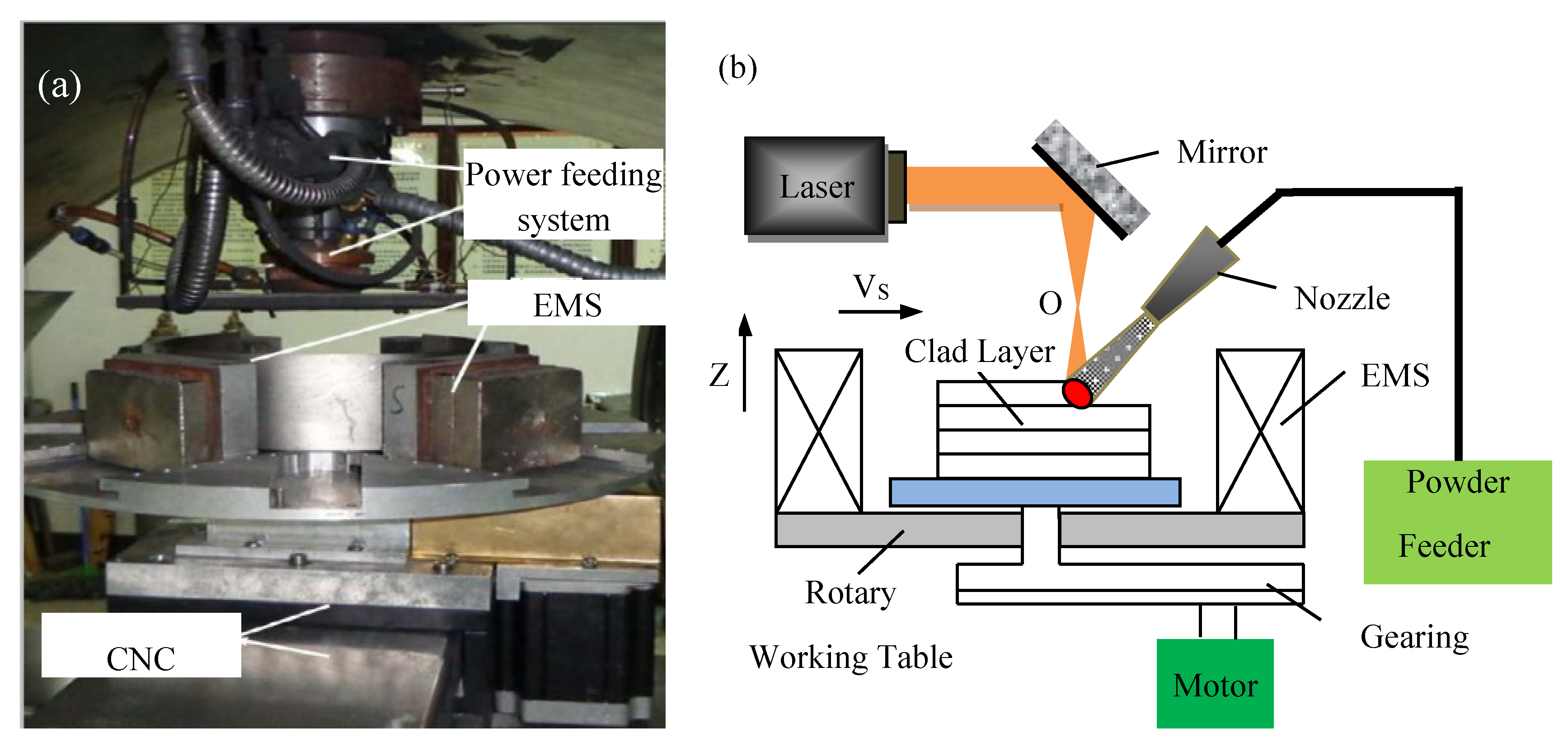

2. Experimental Methods

3. Results and Discussion

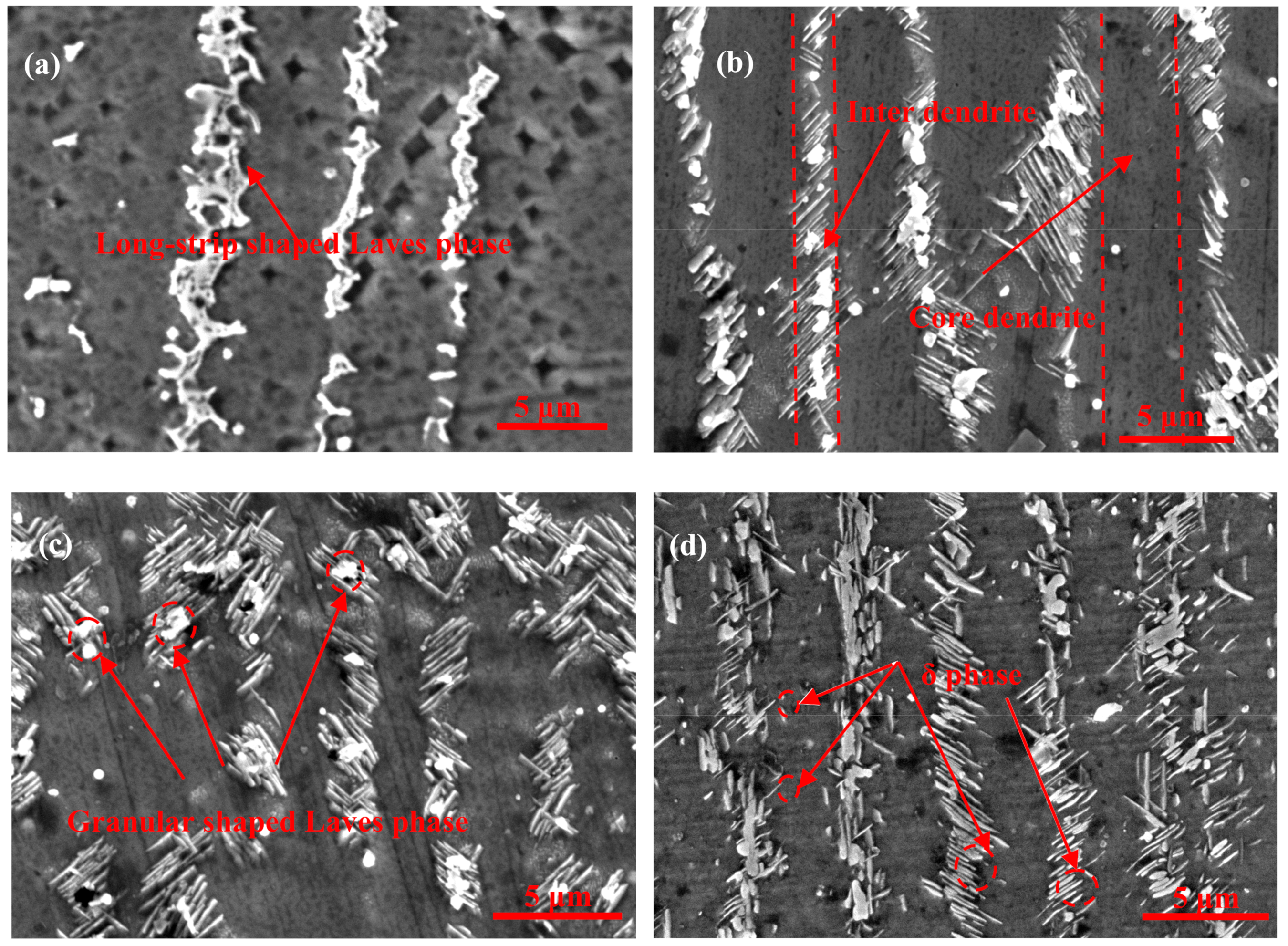

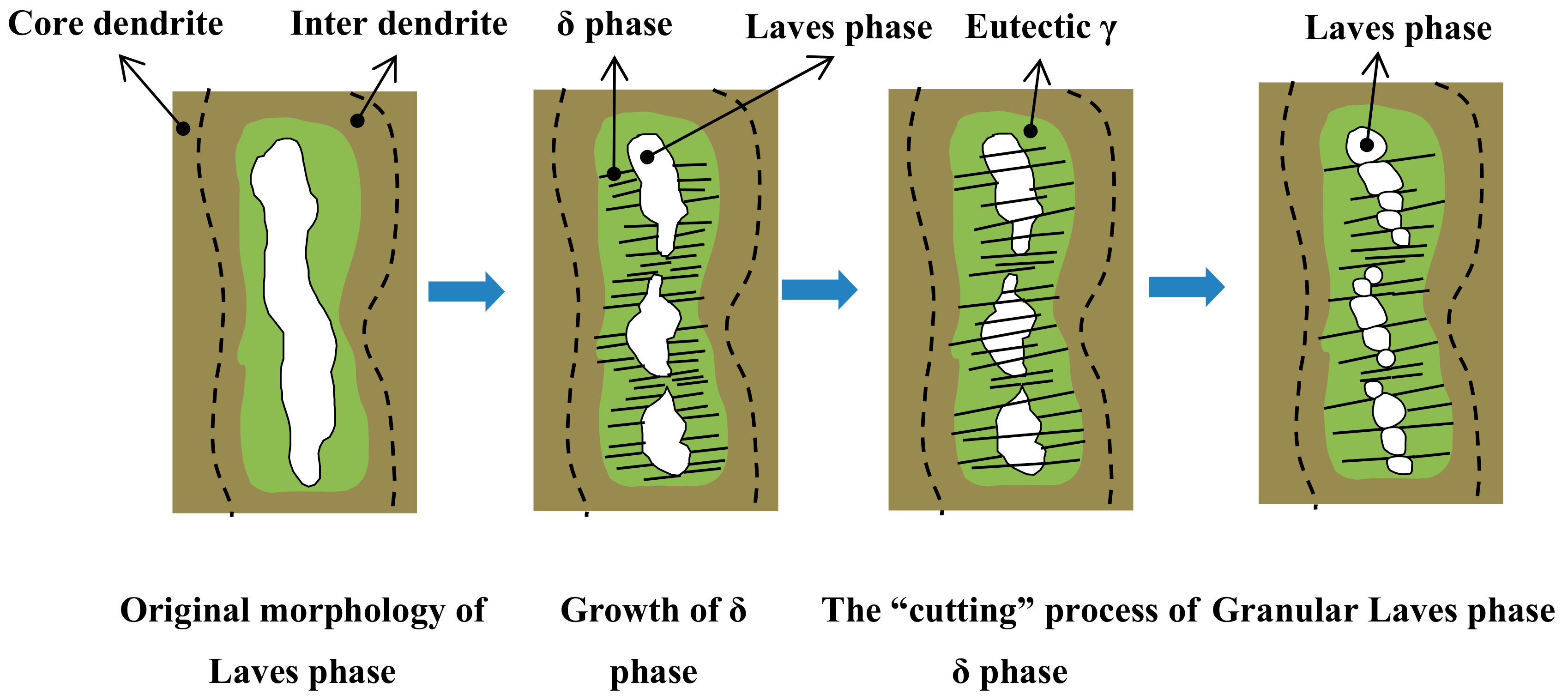

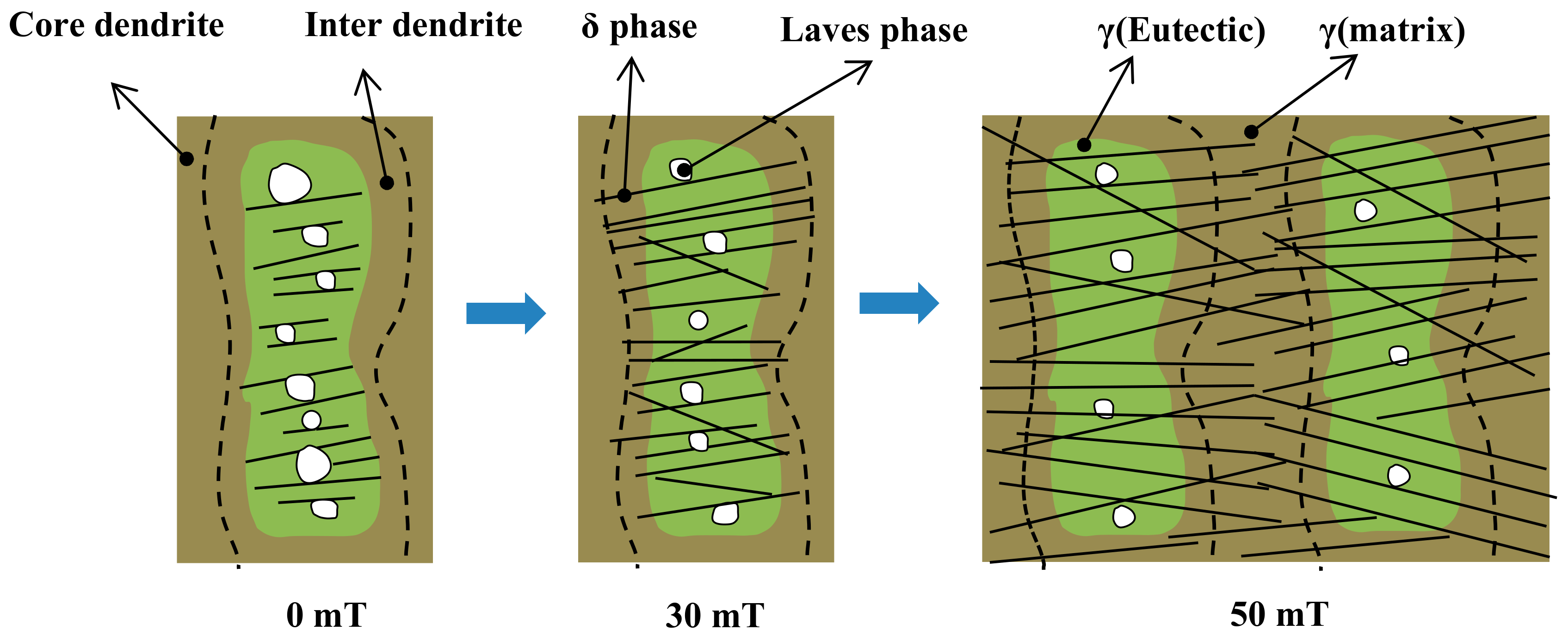

3.1. The “Cutting” and “Dissolution” of the Laves Phase Through the Precipitation of the δ Phase

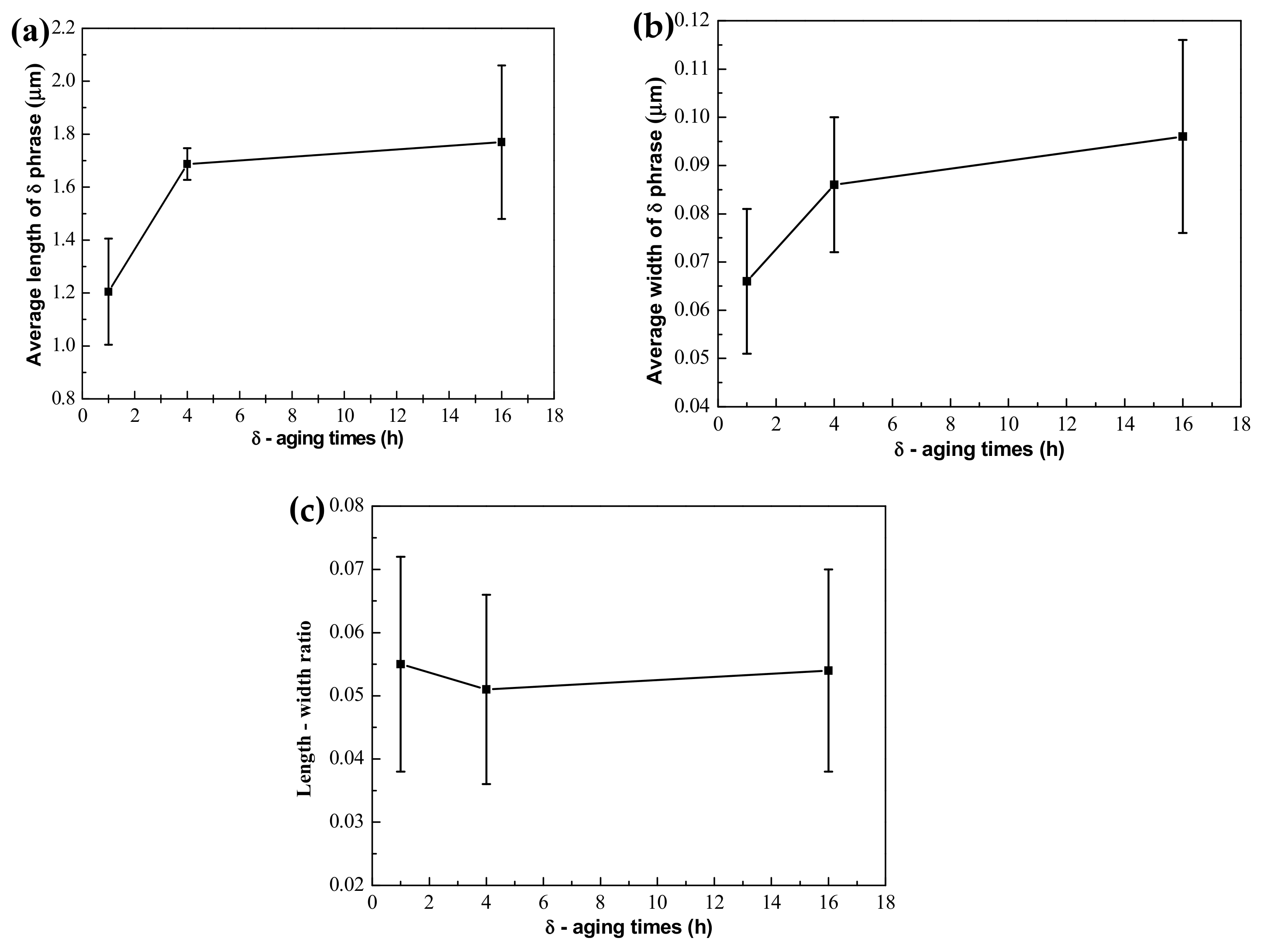

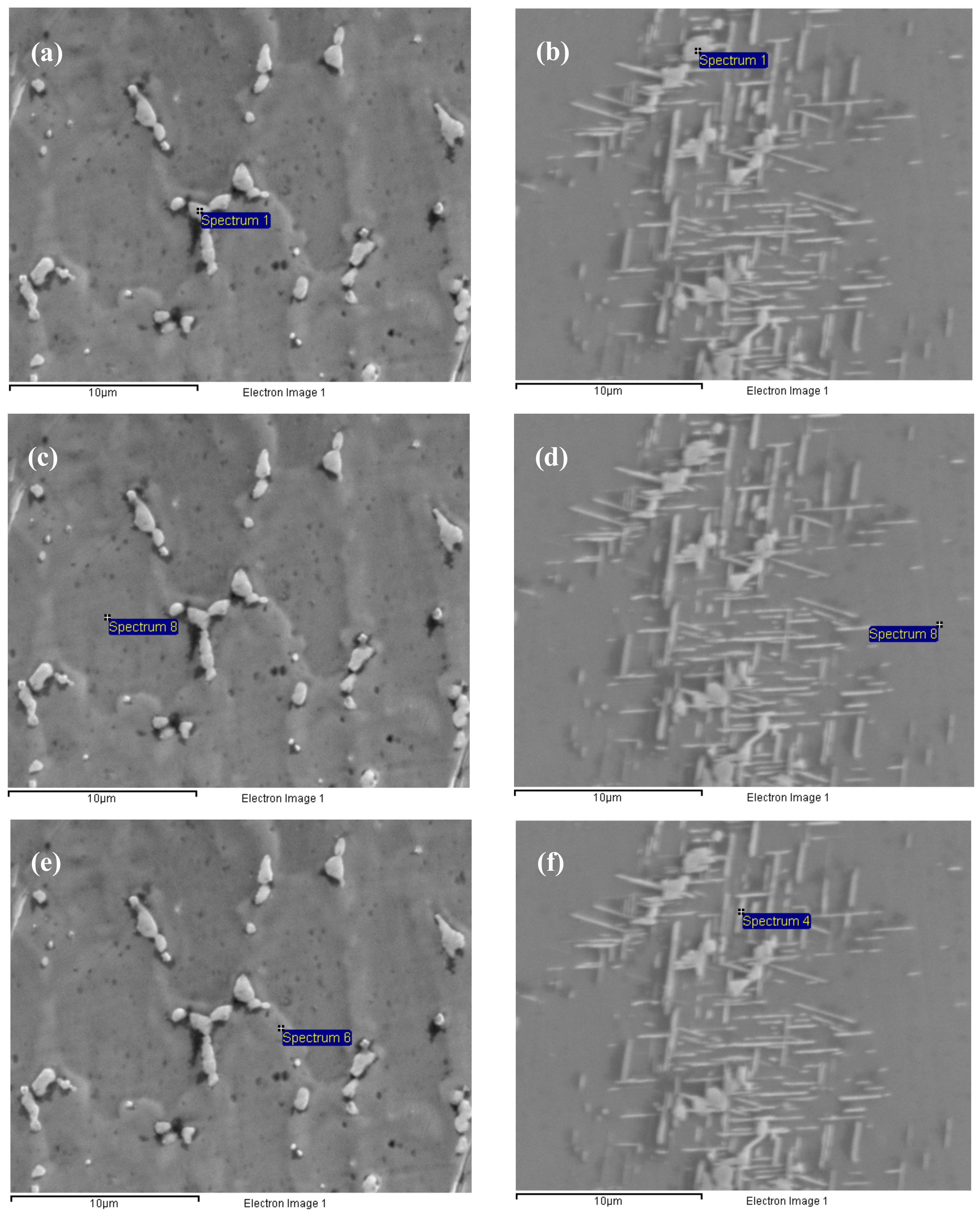

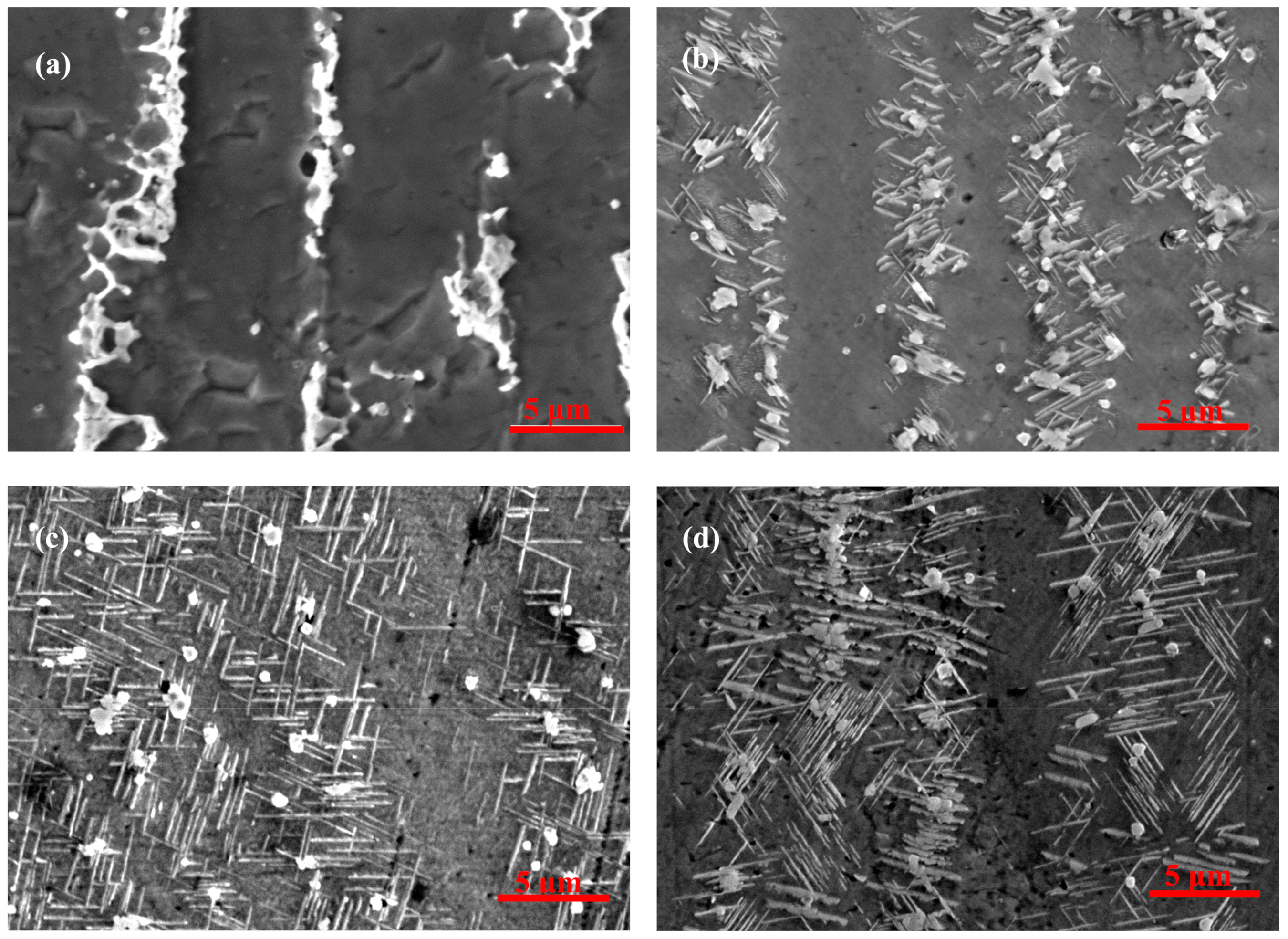

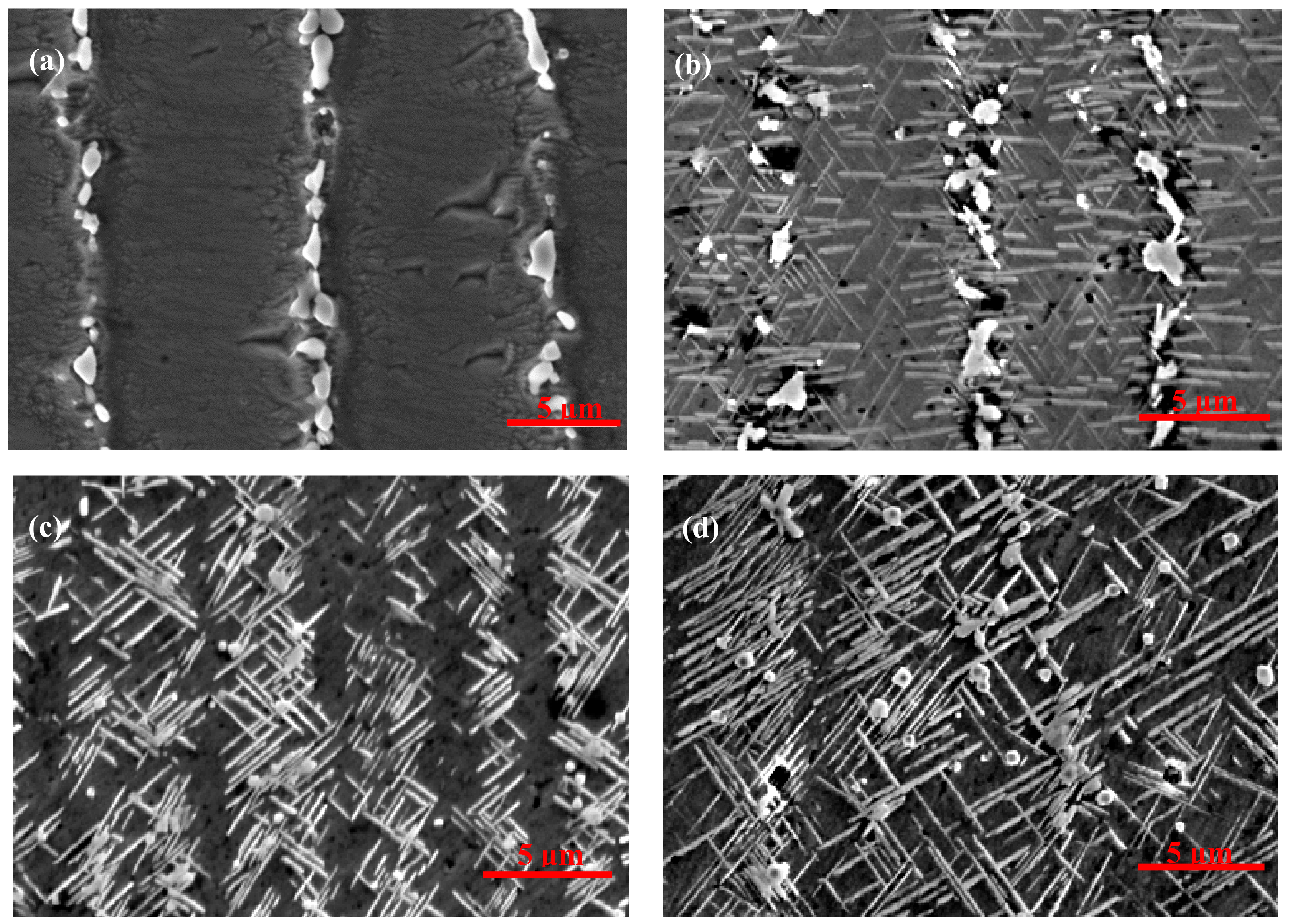

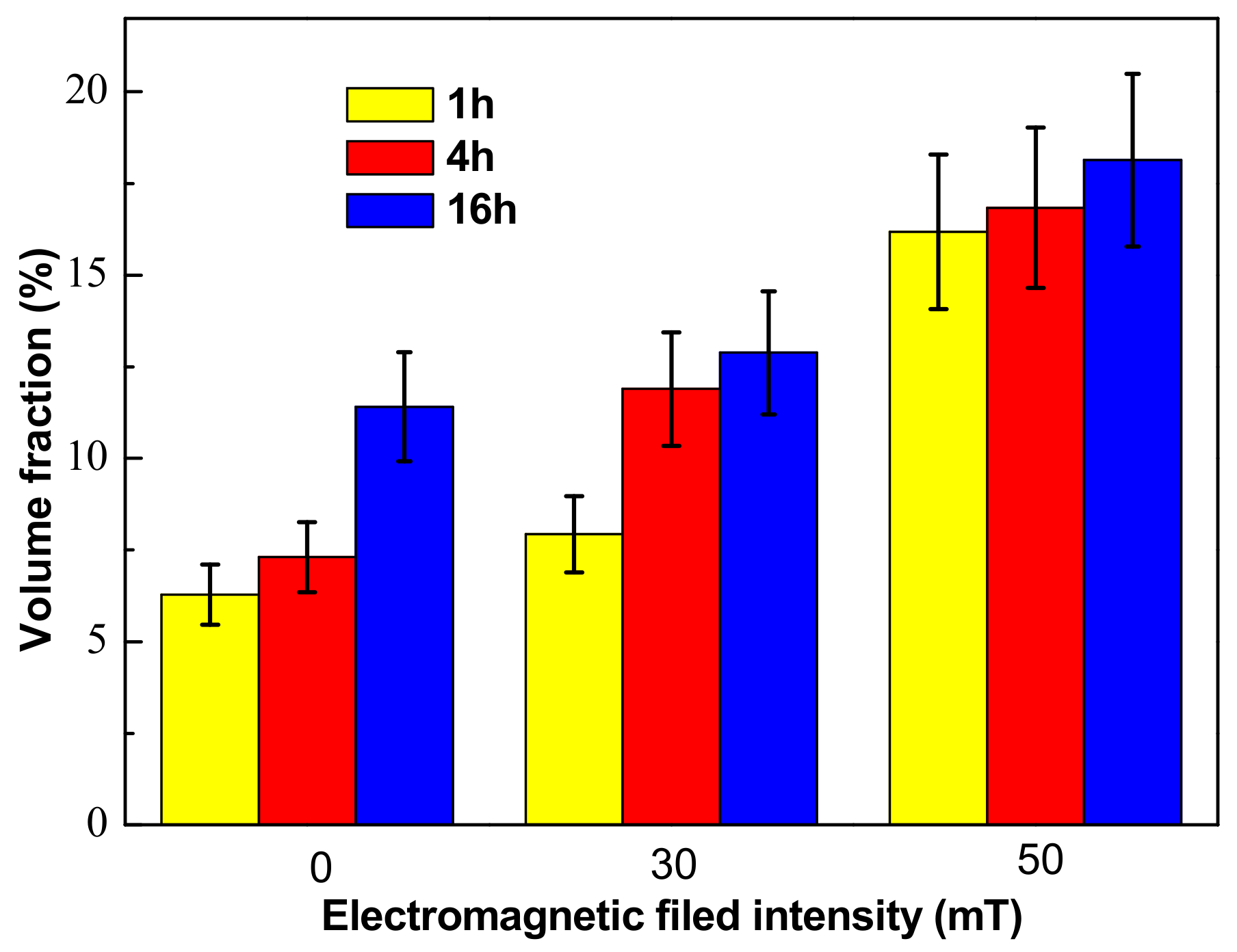

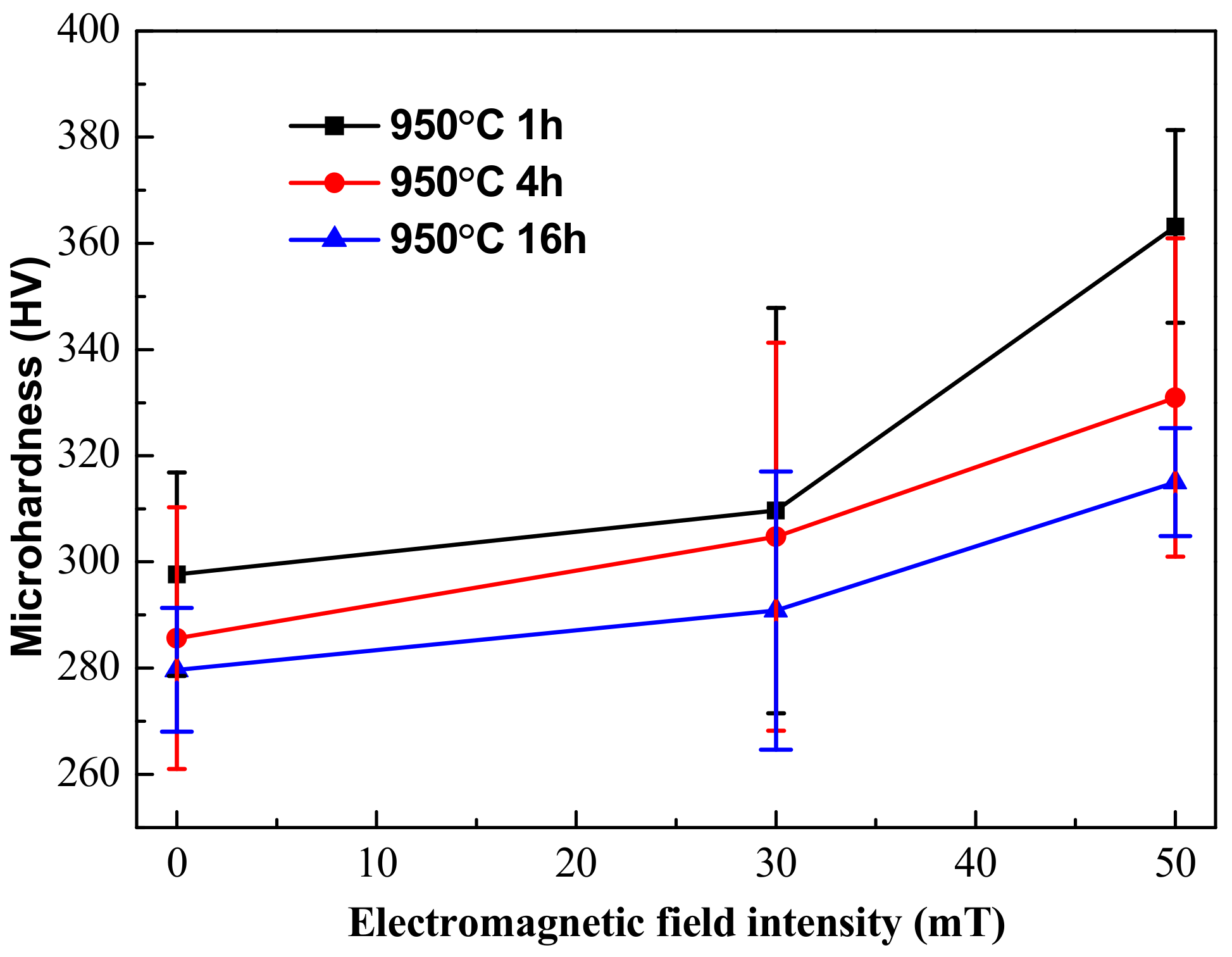

3.2. Effect of Electromagnetic Filed Intensity on Precipitation of the δ Phase

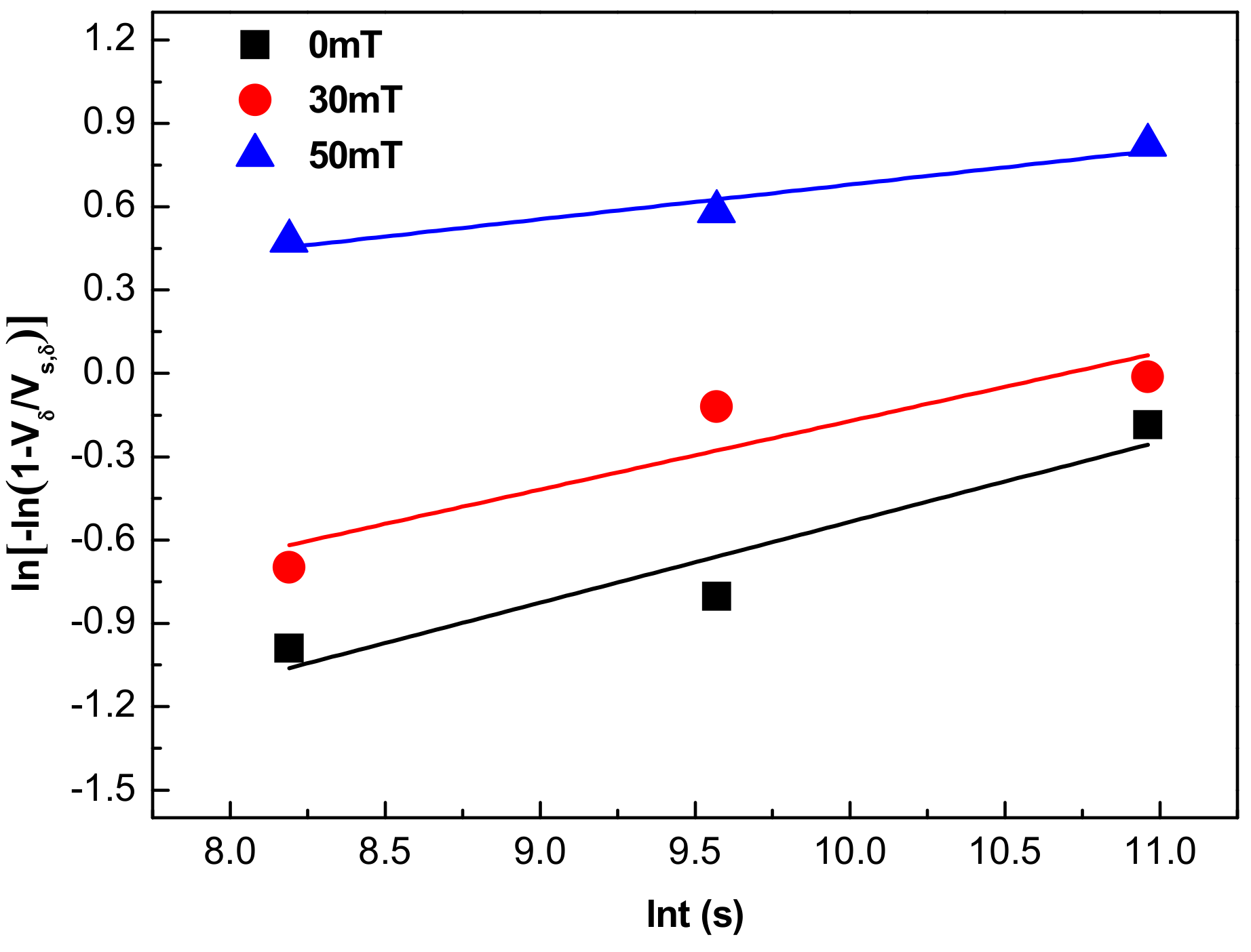

3.3. Precipitation Kinetics Analysis of Phase Precipitation

3.4. Electrochemical Corrosion of the Weld

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhuang, J.Y.; Du, J.H.; Deng, Q. Deformed Superalloy GH4169; Metallurgical Industry Press: Beijing, China, 2006. [Google Scholar]

- Liu, F.C.; Lin, X.; Leng, H. Microstructural changes in a laser solid forming Inconel 718 superalloy thin wall in the deposition direction. Opt. Laser Technol. 2013, 45, 330–335. [Google Scholar] [CrossRef]

- Zhu, L.; Xu, Z.F.; Gu, Y.F. Effect of laser power on the microstructure and mechanical properties of heat treated Inconel 718 superalloy by laser solid forming. J. Alloys Compd. 2018, 746, 159–167. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, F.G.; Zhang, K. Dendritic microstructure and hot cracking of laser additive manufactured Inconel 718 under improved base cooling. J. Alloys Compd. 2016, 670, 312–321. [Google Scholar] [CrossRef]

- Qi, H.; Azer, M.; Ritter, A. Studies of Standard Heat Treatment Effects on Microstructure and Mechanical Properties of Laser Net Shape Manufactured INCONEL 718. Metall. Mater. Trans. A 2009, 10, 2410–2422. [Google Scholar] [CrossRef]

- Xi, M.Z.; Gao, S.Y. Study on Tensile Mechanical Properties of Inconel 718 Superalloy by Laser Rapid Prototyping. Chin. J. Lasers 2012, 39, 68–73. [Google Scholar]

- Zhao, W.W.; Lin, X.; Liu, F.C. Effect of heat treatment on microstructure and mechanical properties of Inconel 718 superalloy. Chin. J. Lasers 2009, 36, 3220–3225. [Google Scholar] [CrossRef]

- Ming, X.L.; Chen, J.; Tan, H. High-temperature coarsening behavior of γ″ phase of laser solid forming GH4169 superalloy. J. Mater. Eng. 2014, 8, 8–14. [Google Scholar]

- Chang, S.H. In situ TEM observation of γ′, γ″ and δ precipitations on Inconel 718 superalloy through HIP treatment. J. Alloys Compd. 2009, 486, 716–721. [Google Scholar] [CrossRef]

- Liu, F.C.; Lin, X.; Yang, G.L. Microstructure and residual stress of laser rapid formed Inconel 718 nickel-base superalloy. Opt. Laser Technol. 2011, 43, 208–213. [Google Scholar] [CrossRef]

- Du, J.H.; Lu, X.D.; Qu, J.L. High-temperature Structure Stability and Mechanical Properties of Novel 718 Superalloy. Mater. Sci. Eng. A 2007, 452, 584–591. [Google Scholar] [CrossRef]

- Xu, D.F.; Tian, C.S. Study on Laves phase resolving behavior of GH4169 alloy steel based on mathematical model during heat treatment. Foundry Technol. 2014, 35, 2570–2572. [Google Scholar]

- Liu, F.C.; Lin, X.; Yu, X.B. Interface and crystal orientation evolution during laser solid forming GH4169 alloy during recrystallization. Acta Metall. Sin. 2014, 50, 463–470. [Google Scholar]

- Chen, W.; Li, C.C.; Li, H. Effects of Heat Treatment on Microstructure and Mechanical Properties of Modified Inconel 718C Alloy. Trans. Metal Heat Treat. 2007, 32, 81–87. [Google Scholar]

- Song, K.; Yu, K.; Lin, X. Microstructure and mechanical properties of heat treated laser solid forming Inconel 718 superalloy. Acta Metall. Sin. 2015, 51, 935–942. [Google Scholar]

- Yang, Y.R.; Liang, X.F. Effect of δ phase on the long-term performance of GH4169 alloy at high temperature. J. Aeronaut. Mater. 1996, 16, 39–43. [Google Scholar]

- Slama, C.; Abdellaoui, M. Structural characterization of the aged Inconel 718. J. Alloys Compd. 2000, 306, 277–284. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, L. Effect of solid-solution treatment on microstructure and properties of GH4169 alloy. Trans. Metal Heat Treat. 2007, 28, 176–179. [Google Scholar] [CrossRef]

- Radavich, J.F. The physical metallurgy of cast and wrought alloy 718. In Proceedings of the Conference Proceedings on Superalloy, Pittsburgh, PA, USA, 12–14 June 1989; pp. 229–240. [Google Scholar]

- Cai, D.Y.; Zhang, W.H.; Liu, W.C. Dissolution Behavior of Phase δ in Inconel 718. J. Alloys Iron Steel Res. 2002, 14, 61–64. [Google Scholar]

- Schneider, A.; Avilov, V.; Gumenyuk, A. Laser Beam Welding of Aluminum Alloys Under the Influence of an Electromagnetic Field. Phys. Procedia 2013, 41, 4–11. [Google Scholar] [CrossRef]

- Zhai, L.L.; Ban, C.Y.; Zhang, J.W. Investigation on Laser Cladding Ni-base Coating Assisted by Electromagnetic Field. Opt. Laser Technol. 2019, 114, 81–88. [Google Scholar] [CrossRef]

- Zhou, J.Z.; Xu, J.L.; Huang, S. Effect of laser surface melting with alternating magnetic field on wear and corrosion resistance of magnesium alloy. Surf. Coay. Technol. 2017, 309, 212–219. [Google Scholar] [CrossRef]

- Qin, L.Y.; Yang, G.; Bian, H.Y. Experimental study on electromagnetic stirring assisted laser deposition of titanium alloy. Chin. J. Lasers 2014, 41, 0303004. [Google Scholar]

- Yu, X.B.; Liu, F.C.; Lin, X. Microstructure and hardness analysis of laser solid forming GH4169 alloy by electromagnetic stirring. Appl. Laser 2014, 34, 513–516. [Google Scholar]

- Li, Y.J.; Ma, X.P.; Yang, Y.S. Grain refinement of as-cast superalloy IN718 under action of low voltage pulsed magnetic field. Trans. Nonferrous Metals Soc. China 2011, 6, 1277–1282. [Google Scholar] [CrossRef]

- Jia, P.; Wang, N.G.; Lu, H. Effect of Electromagnetic Field on Solidification Structure and Mechanical Properties of Inconel 625 Alloy. Acta Metall. Sin. 2013, 49, 1573–1580. [Google Scholar] [CrossRef]

- Zhan, G.F.; Wang, N.G.; Jiang, N. Effect of Electromagnetic Stirring on As-Cast Microstructure of GH3030 Superalloy. Spec. Cast. Nonferrous Alloys 2012, 32, 6–8. [Google Scholar]

- Idell, Y.; Levine, L.E.; Allen, A.J. Unexpected δ-Phase Formation in Additive-Manufactured Ni-Based Superalloy. J. Minerals Metals Mater. Soc. 2016, 68, 950–959. [Google Scholar] [CrossRef]

- Ding, R.G.; Huang, Z.W.; Li, H.Y. Electron microscopy study of direct laser deposited IN718. Mater. Charact. 2015, 106, 324–337. [Google Scholar] [CrossRef]

- Liu, F.C.; Cheng, H.M.; Yu, X.B. Control of microstructure and mechanical properties of laser solid formed Inconel 718 superalloy by electromagnetic stirring. Opt. Laser Technol. 2018, 99, 342–350. [Google Scholar] [CrossRef]

- Azadian, S.; Wei, L.Y.; Warren, R. Delta phase precipitation in Inconel 718. Mater. Charact. 2004, 53, 7–16. [Google Scholar] [CrossRef]

- Lu, T.; Wang, Y.; Yao, Q. Microstructure and Bending Properties of High Volume Fraction SiC Particle Reinforced Aluminum Matrix Composites. Hot Work. Technol. 2017, 24, 158–161. [Google Scholar]

- Avrami, M. Kinetics of phase change. I General theory. J. Chem. Phys. 1939, 7, 1103–1112. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of Phase Change. II Transformation Time Relations for Random Distribution of Nuclei. J. Chem. Phys. 1940, 8, 212–224. [Google Scholar] [CrossRef]

- Avrami, M. Granulation, phase change, and microstructure kinetics of phase change. J. Chem. Phys. 2004, 9, 177–184. [Google Scholar] [CrossRef]

| Material | C | Nb | Cr | Fe | Al | Ti | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| Powder | 0.03 | 5.2 | 19.7 | 18.4 | 0.6 | 1.0 | 3.0 | Bal. |

| LSF sample | 0.05 | 5.6 | 19.6 | 18.2 | 0.5 | 1.1 | 3.3 | Bal. |

| AMS: 5663 | 0.08 max | 4.75–5.5 | 17–21 | 16–20 | 0.2–0.8 | 0.65–1.15 | 2.8–3.3 | Bal. |

| Laser Power (W) | Scanning Speed (mm/s) | Powder Supply Rate (g/min) | Shielding Gas Flux (L/min) | Spot Diameter (mm) | Overlap of Adjacent Passes (%) | Δ Z (mm) |

|---|---|---|---|---|---|---|

| 2000–2200 | 6–8 | 8–12 | 6 | 3 | 25–40 | 0.3 |

| Aging Time | 1 h | 4 h | 16 h |

|---|---|---|---|

| Length | 1.205 | 1.687 | 1.770 |

| Width | 0.066 | 0.086 | 0.096 |

| Length-width ratio | 0.055 | 0.051 | 0.054 |

| Laves Phase | γ (Eutectic) | Core Dendrite | |

|---|---|---|---|

| Aging 0 h | 25.3 | 9.1 | 2.5 |

| Aging 12 h | 24.8 | 6.3 | 3.5 |

| Aging Time | 0 mT | 30 mT | 50 mT |

|---|---|---|---|

| 1 h | 1.205 μm | 1.273 μm | 1.852 μm |

| 4 h | 1.687 μm | 1.810 μm | 2.120 μm |

| 16 h | 1.770 μm | 1.820 μm | 2.861 μm |

| Aging Time | 0 mT | 30 mT | 50 mT |

|---|---|---|---|

| 1 h | 0.066 μm | 0.073 μm | 0.087 μm |

| 4 h | 0.086 μm | 0.089 μm | 0.095 μm |

| 16 h | 0.091 μm | 0.093 μm | 0.098 μm |

| Length–Width Ratio | 0 mT | 30 mT | 50 mT |

|---|---|---|---|

| 1 h | 0.055 | 0.057 | 0.047 |

| 4 h | 0.051 | 0.049 | 0.045 |

| 16 h | 0.053 | 0.050 | 0.034 |

| 0 mT | 30 mT | 50 mT | |

|---|---|---|---|

| Core dendrite | 2.4 | 5.8 | 6.5 |

| 0 mT | 30 mT | 50 mT | |

|---|---|---|---|

| 1 h | 6.284 | 7.937 | 16.183 |

| 4 h | 7.316 | 11.895 | 16.841 |

| 16 h | 11.413 | 12.880 | 18.142 |

| Electromagnetic Field Intensities/mT | Precipitation Rate α | Time Index n |

|---|---|---|

| 0 | 0.032 | 0.290 |

| 30 | 0.071 | 0.247 |

| 50 | 0.567 | 0.125 |

| Microhardness | 0 mT | 30 mT | 50 mT |

|---|---|---|---|

| 1 h | 297.70 | 309.69 | 363.16 |

| 4 h | 285.66 | 304.80 | 330.95 |

| 16 h | 279.69 | 290.86 | 315.02 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, F.; Liu, F.; Hu, X.; Yang, X.; Huang, C.; Shi, D. The δ Phase Precipitation of an Inconel 718 Superalloy Fabricated by Electromagnetic Stirring Assisted Laser Solid Forming. Materials 2019, 12, 2604. https://doi.org/10.3390/ma12162604

Lyu F, Liu F, Hu X, Yang X, Huang C, Shi D. The δ Phase Precipitation of an Inconel 718 Superalloy Fabricated by Electromagnetic Stirring Assisted Laser Solid Forming. Materials. 2019; 12(16):2604. https://doi.org/10.3390/ma12162604

Chicago/Turabian StyleLyu, Feiyue, Fencheng Liu, Xiaoan Hu, Xiaoguang Yang, Chunping Huang, and Duoqi Shi. 2019. "The δ Phase Precipitation of an Inconel 718 Superalloy Fabricated by Electromagnetic Stirring Assisted Laser Solid Forming" Materials 12, no. 16: 2604. https://doi.org/10.3390/ma12162604

APA StyleLyu, F., Liu, F., Hu, X., Yang, X., Huang, C., & Shi, D. (2019). The δ Phase Precipitation of an Inconel 718 Superalloy Fabricated by Electromagnetic Stirring Assisted Laser Solid Forming. Materials, 12(16), 2604. https://doi.org/10.3390/ma12162604