1. Introduction

Research is being actively carried out in various industrial fields in an effort to develop new technologies to enhance productivity. Among these technologies, three-dimensional (3D) printing allows the user to produce desired products without fabricating each individual part or engaging in a repetitious assembly process. Even geometrically complex shapes can be fashioned with precision [

1]. Such 3D printing technology represents a paradigm shift from a conventional labor-intensive industry to one of automated production. This new manufacturing technology was actively adopted in various fields and is widely being used [

2].

In particular, the manufacturing, medical, and foods industries are actively engaged in research on ways of utilizing 3D printers [

3,

4,

5]. In 1997, Pegna [

6] became the first to apply 3D printing technology to a construction project. After Khoshnevis [

7], a professor at the University of Southern California, introduced contour crafting (the current form of 3D additive construction, commonly referred to as 3DAC), 3D printing technology garnered increasing interest in the construction industry.

The 3DAC technique consists of a concrete printer, 3D modeling software, and the material used in printing. These three components can be independently considered. The fields of specialization related to these components include mechanical elements, 3D modeling using computers, and the cementitious materials employed in printing [

8]. Among these three research areas, cementitious printing materials are key to 3DAC, and their importance was highlighted accordingly. A new committee (i.e., Committee 564: 3D Printing with Cementitious Materials) focusing on cementitious materials for 3D printing was organized by the American Concrete Institute (ACI) in 2018, commencing activities in March 2019 [

9]. Thus, research regarding cement-based 3DAC materials is expected to become increasingly common. However, additional work is required to establish appropriate standards for the 3DAC process. Currently, there are no specifications of printing, such as the acceptable range of cross-section sizes for the extrusion nozzle, layer height, printing speed, layer cycle-time, etc. [

10].

Recent work on concrete materials used in 3DAC mainly employed silica fume, fly ash, superplasticizers, and viscosity-modifying agents as admixture in the cement [

11,

12]. Numerous studies were also conducted on the mix proportions and properties of mortars modified with ethylene-vinyl acetate (EVA). However, the results of these existing EVA-modified mortars cannot be applied to the 3DAC process because low workability is required; 3DAC materials must be added layer upon layer after extrusion. If EVA powder is employed as an admixture in cement mortar or concrete, the workability is improved. This is due to the ball-bearing action of the dispersible EVA powder [

13]. Also, adhesion at the interface between the EVA-modified mortar and attached materials is improved due to the polymer film produced by the EVA powder [

14,

15]. EVA also offers improved water resistance and high resistance to the diffusion of chloride ions, oxygen, and carbon dioxide [

16]. Yet another important feature is that EVA-modified mortars can be employed as a pre-mixed 3DAC material; dry mix is available with EVA powder, cement, aggregates, etc. [

13]. Thus, the use of EVA-modified mortars can offer a notable advantage in 3DAC because they provide a reduction in both the manpower and cost associated with handling and transporting materials. It is this fact that motivates the present study.

The requirements for proper use of 3DAC material can be broken down into two categories: the material’s fresh and hardened properties. The fresh properties required include flowability, extrudability, buildability, and open time. The necessary hardened properties consist of compressive and flexural strengths [

17,

18,

19]. The fresh properties of EVA-modified mortars were studied by Yeon et al. [

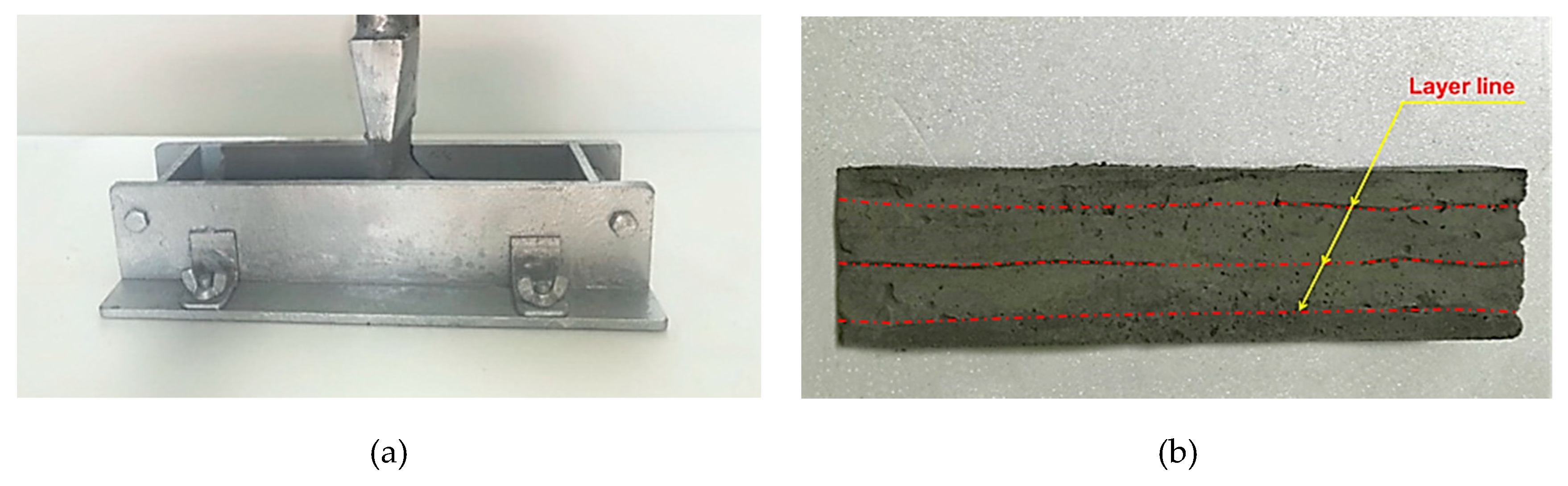

20], and the optimal flow of EVA-modified mortars was determined. As a next step, this study experimentally investigated the strength development of EVA-modified mortars, in order to determine whether such materials would be feasible for 3DAC use. This work is significant because the compressive and flexural strengths of EVA-modified mortars, which are crucial to determining the stability of a structure, were investigated via two types of specimens that were produced for comparison purposes (i.e., cast and printed).

4. Conclusions

This study experimentally investigated the compressive and flexural strengths of EVA-modified mortars for use in 3DAC applications. The compressive and flexural strengths of the cast and printed specimens were also determined and compared in order to assess the optimal properties of EVA-modified mortars for use in 3DAC applications. The following conclusions were drawn:

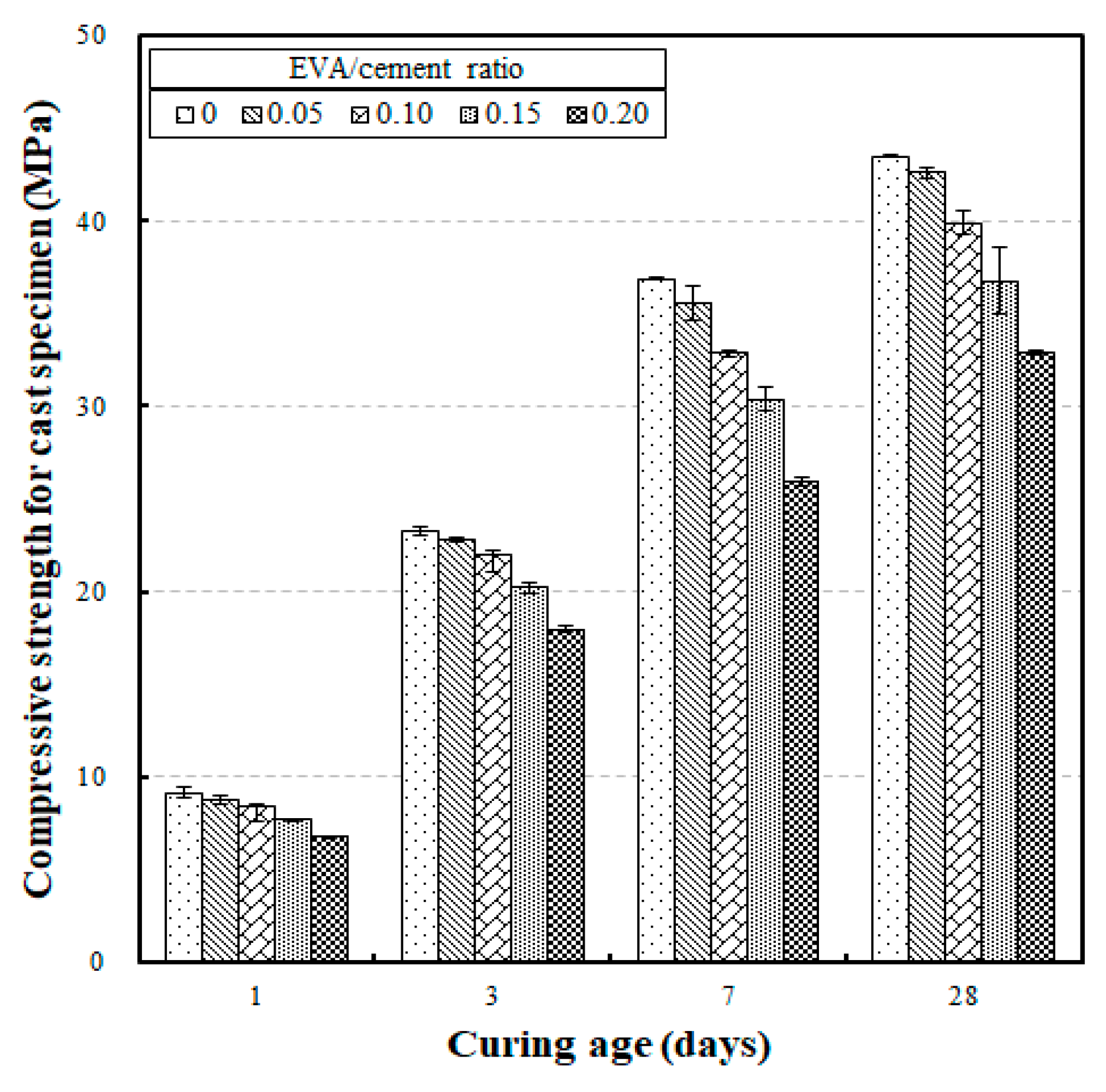

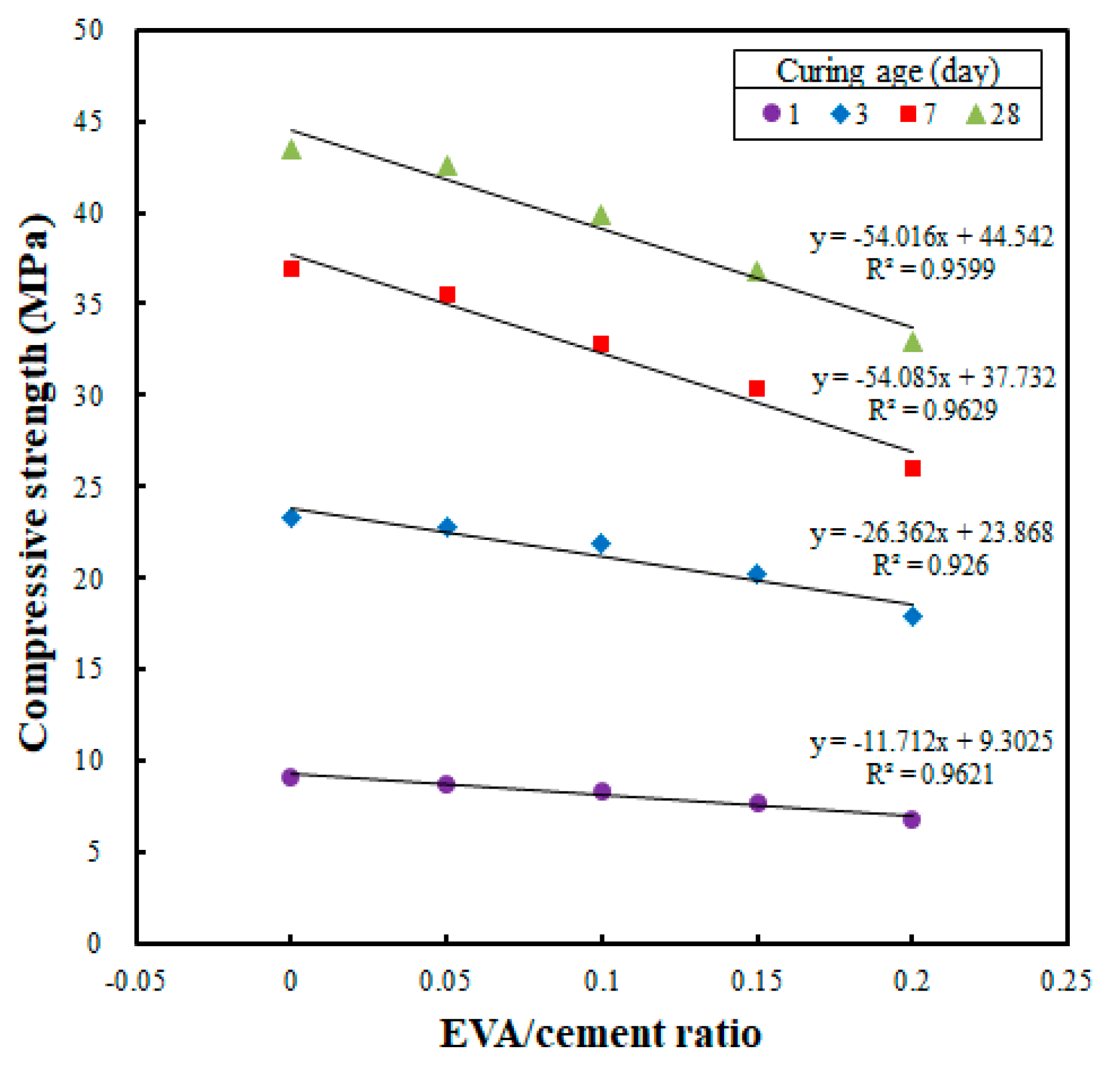

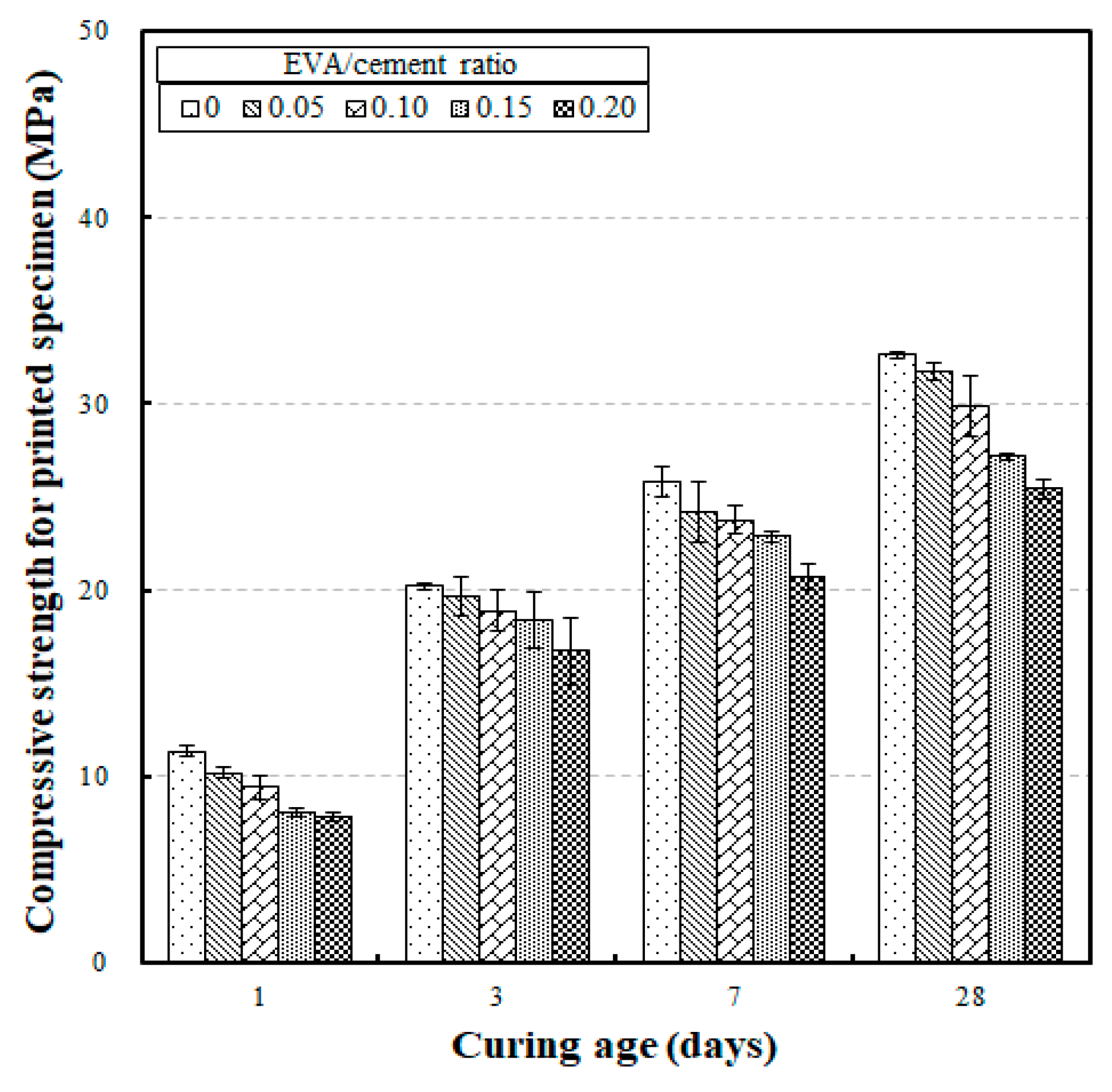

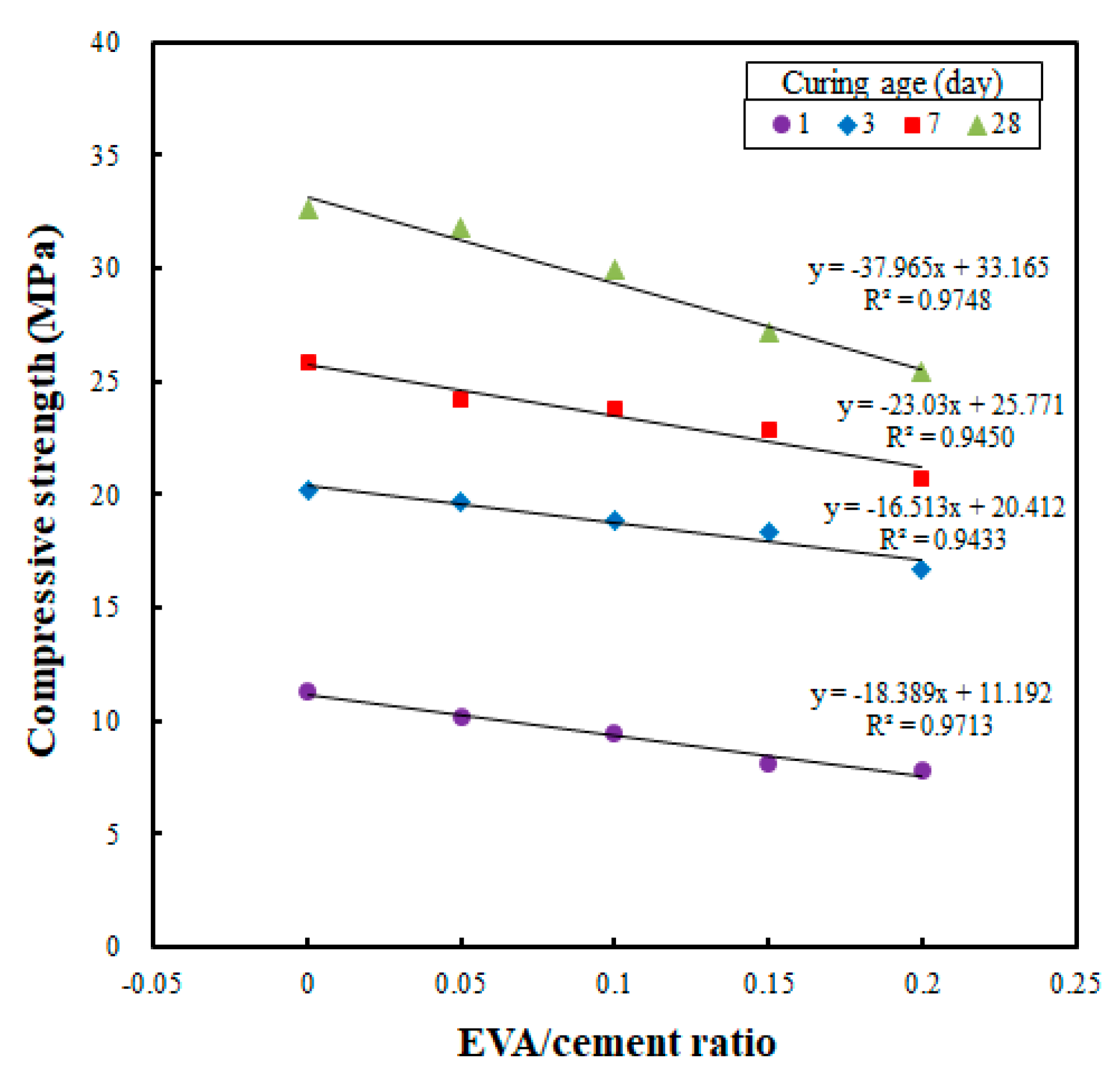

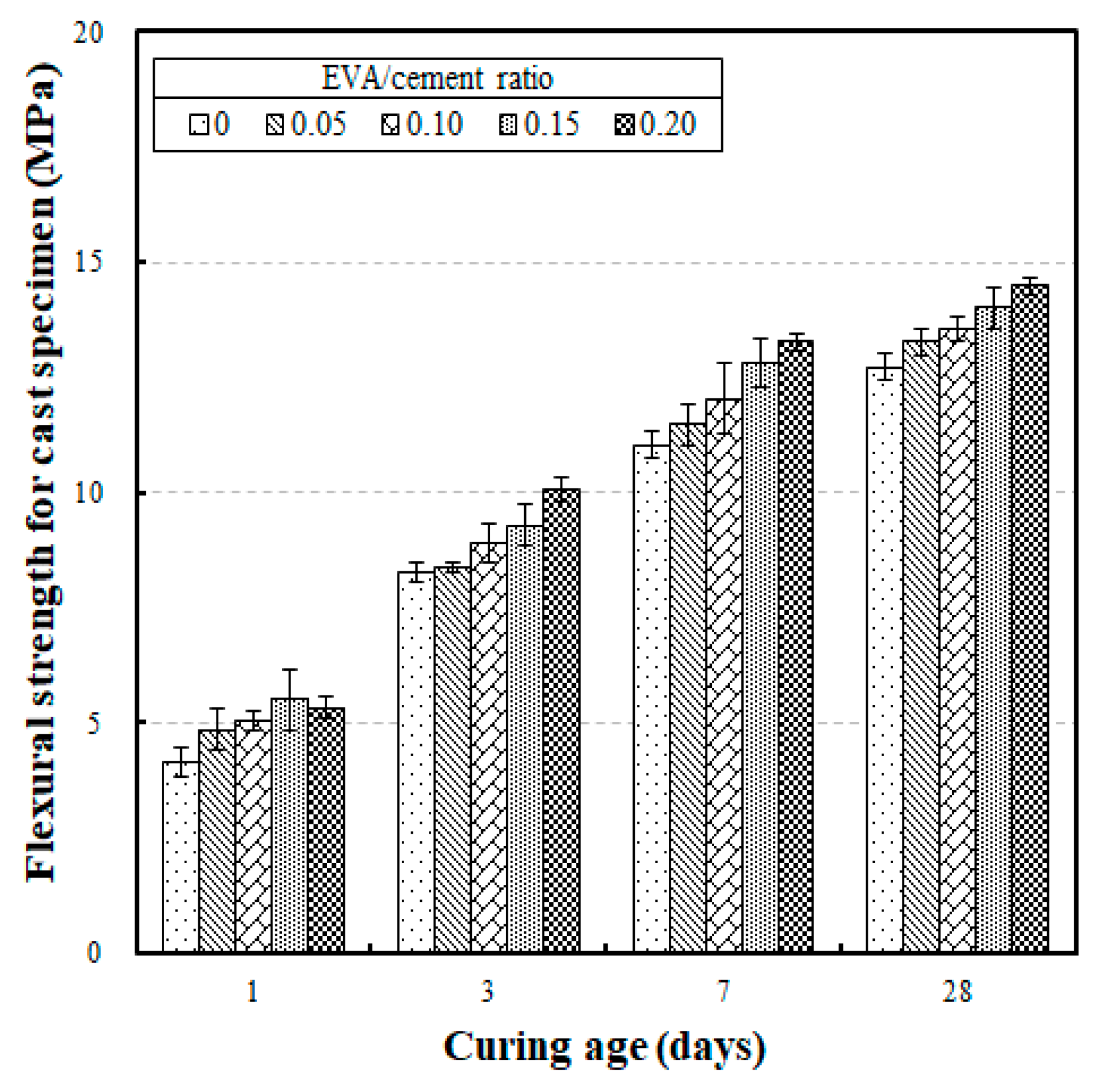

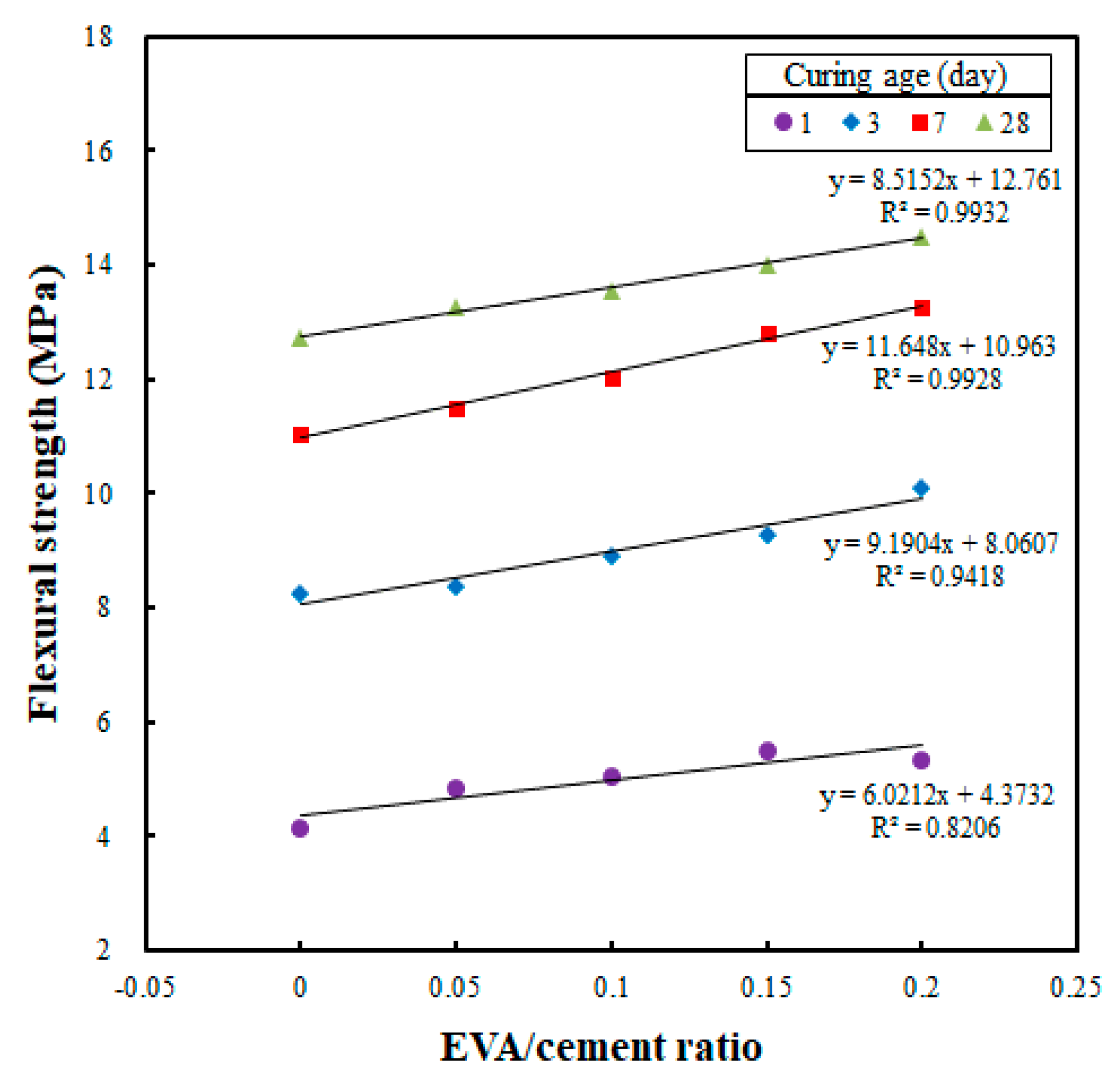

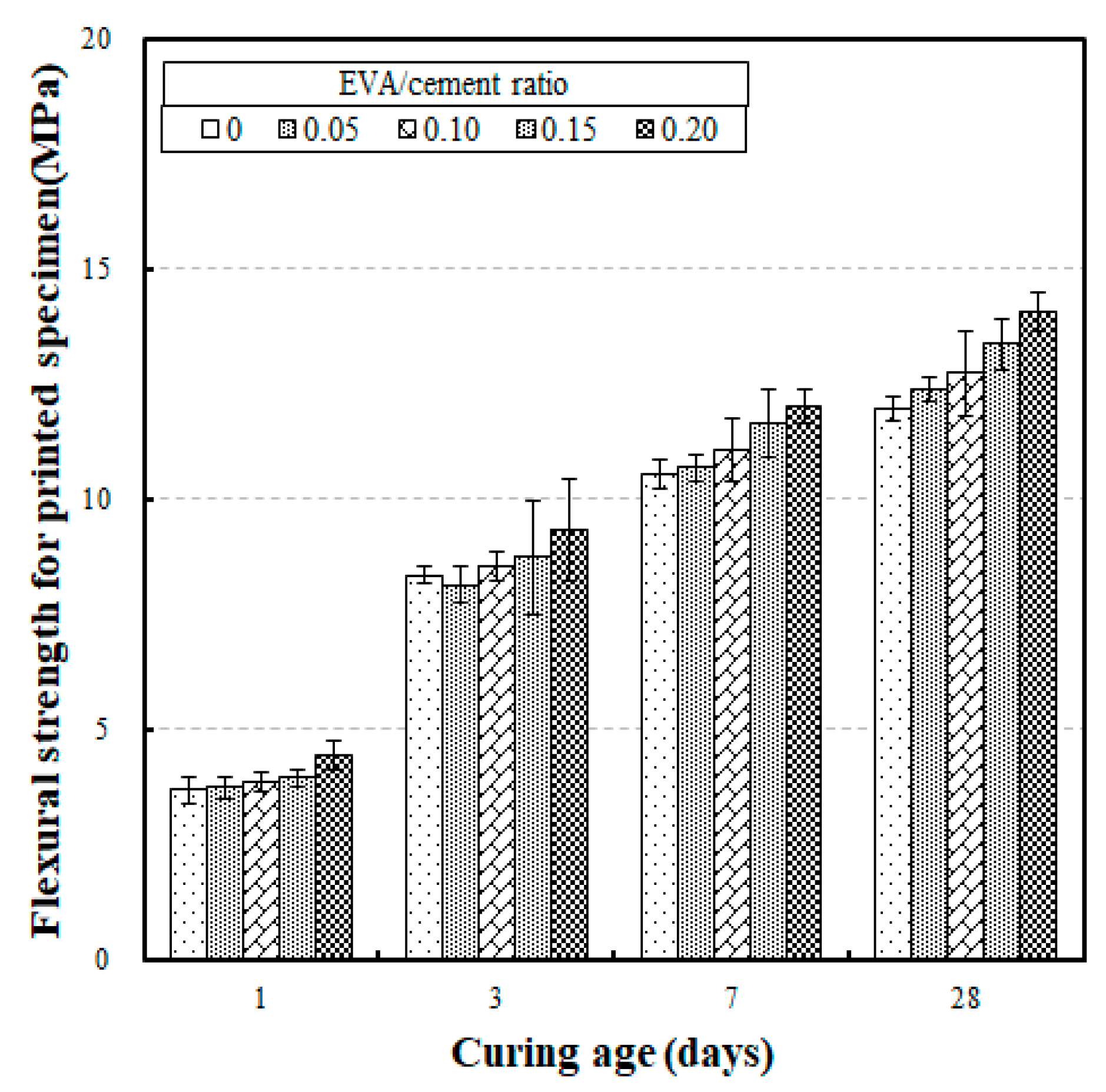

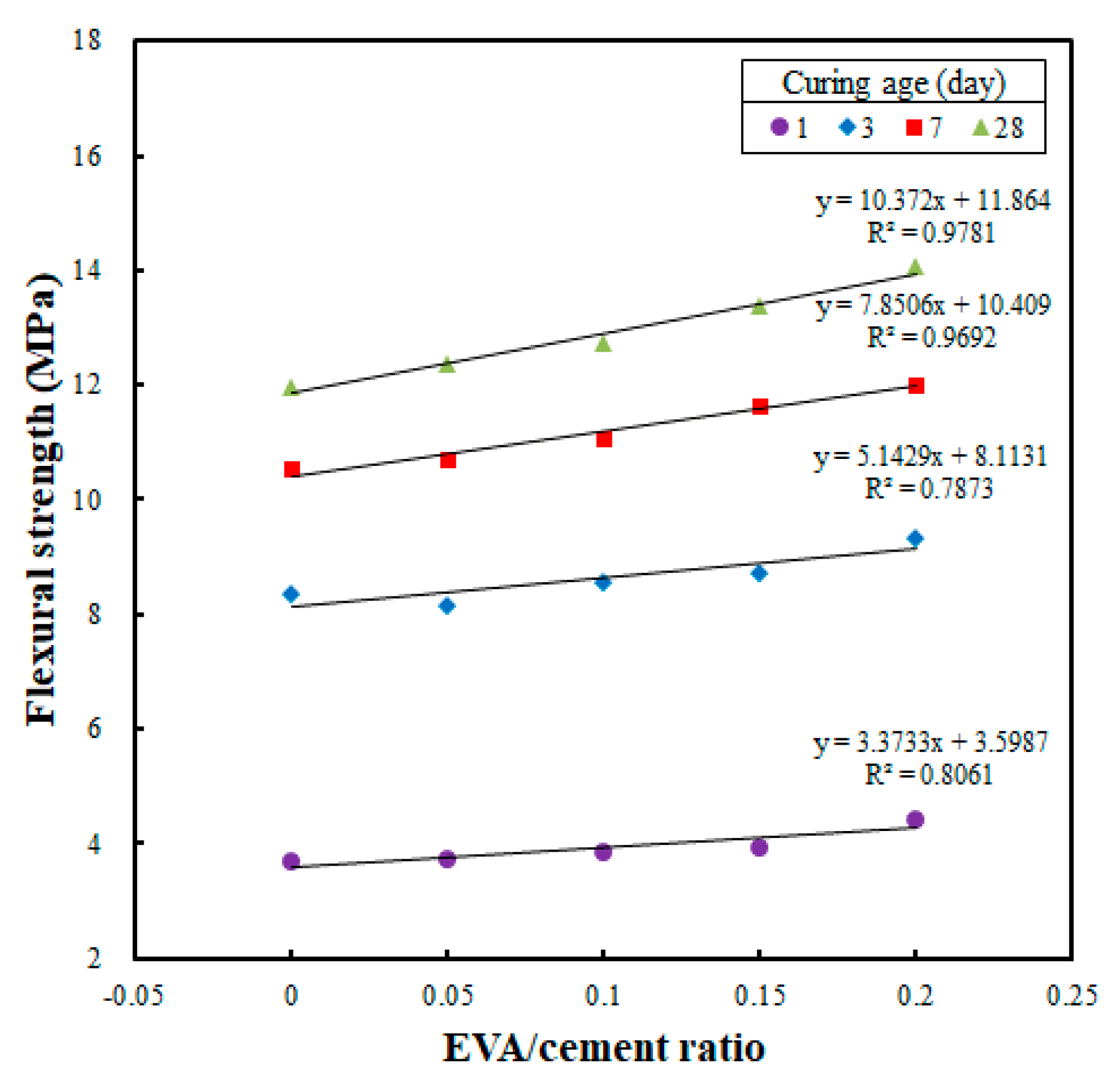

The compressive strengths at a curing age of 28 days for the cast specimens were 32.92 MPa to 43.50 MPa, and 25.43 MPa to 32.62 MPa for the printed specimens. The flexural strengths of the cast and printed specimens at a curing age of 28 days were 12.73 MPa to 14.49 MPa and 12.73 MPa to 14.49 MPa, respectively.

The compressive strengths of the cast and printed specimens were similar when organized according to curing age. The compressive strengths at a curing age of seven days developed from 76% to 85%, as compared to the compressive strengths after 28 days. The flexural strengths of the cast and printed specimens were also similar. The flexural strengths for seven days ranged between 85% and 92%, relative to when the curing age was 28 days.

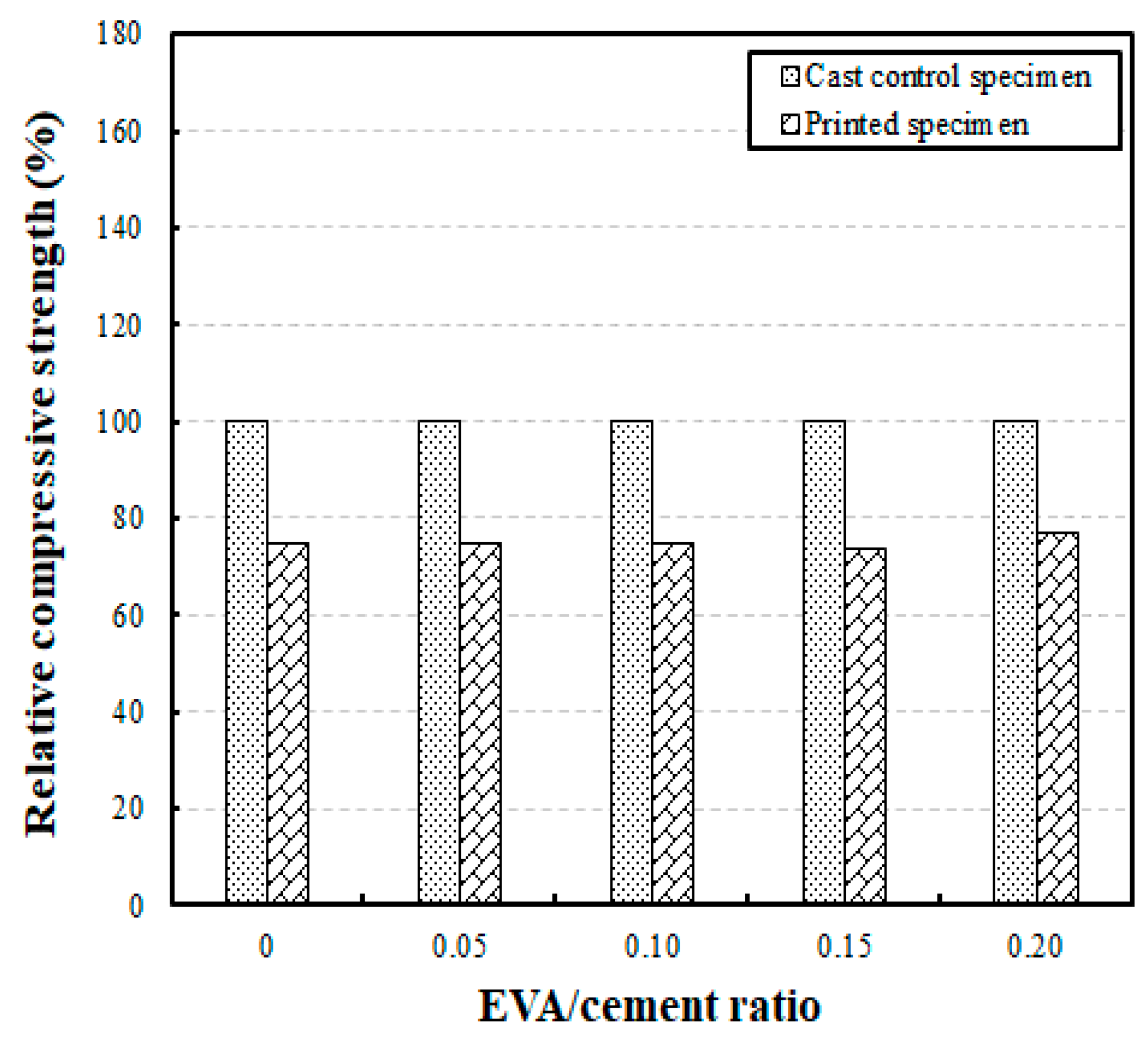

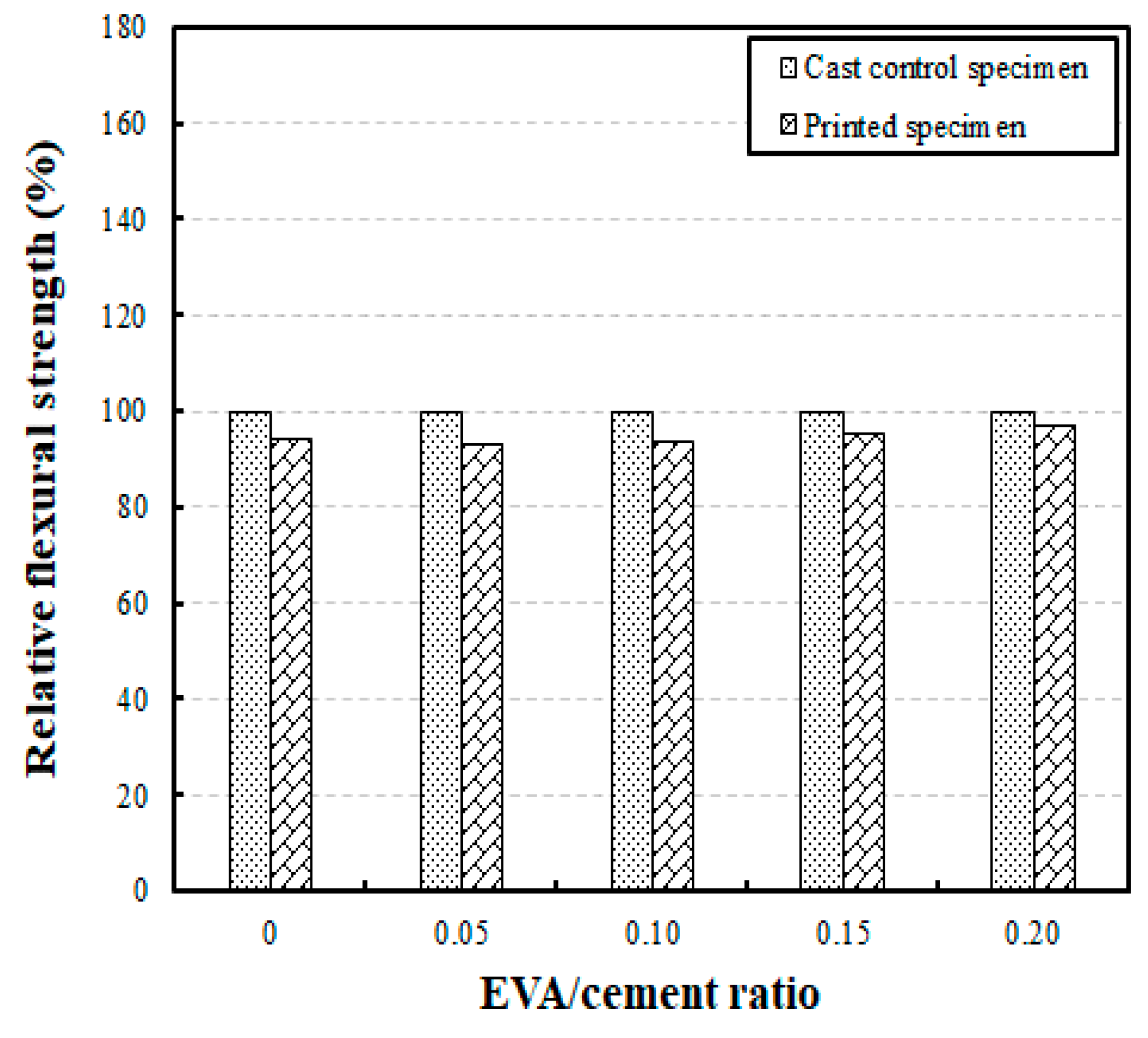

If an EVA/cement ratio of zero was set as the reference (i.e., 100%), the rate of compressive strength development for the cast specimens was 75.6% when the EVA/cement ratio was 0.20; for the printed specimens, this value was 77.9%. The rate of flexural strength development for the cast specimens was 113.8% when the EVA/cement ratio was 0.20; it was 117.5% for the printed specimens.

Overall, the strengths of the printed specimens were lower than those of the cast specimens, by 23% to 26% and 3% to 7% for compressive and flexural strengths, respectively.

Considering these test results, the EVA-modified mortars showed high rates of strength development at early curing ages. Thus, these mortars are advantageous for 3DAC. It was also determined that the optimal EVA/cement ratios should range from 5% to 15% for 3DAC. However, the compressive and flexural strengths of the printed specimens were lower than those of the cast specimens. Moreover, the compressive strengths of the EVA-modified mortars decreased when the EVA content was increased. Therefore, these shortcomings should be examined in future research.