Regulating Precipitates by Simple Cold Deformations to Strengthen Mg Alloys: A Review

Abstract

1. Introduction

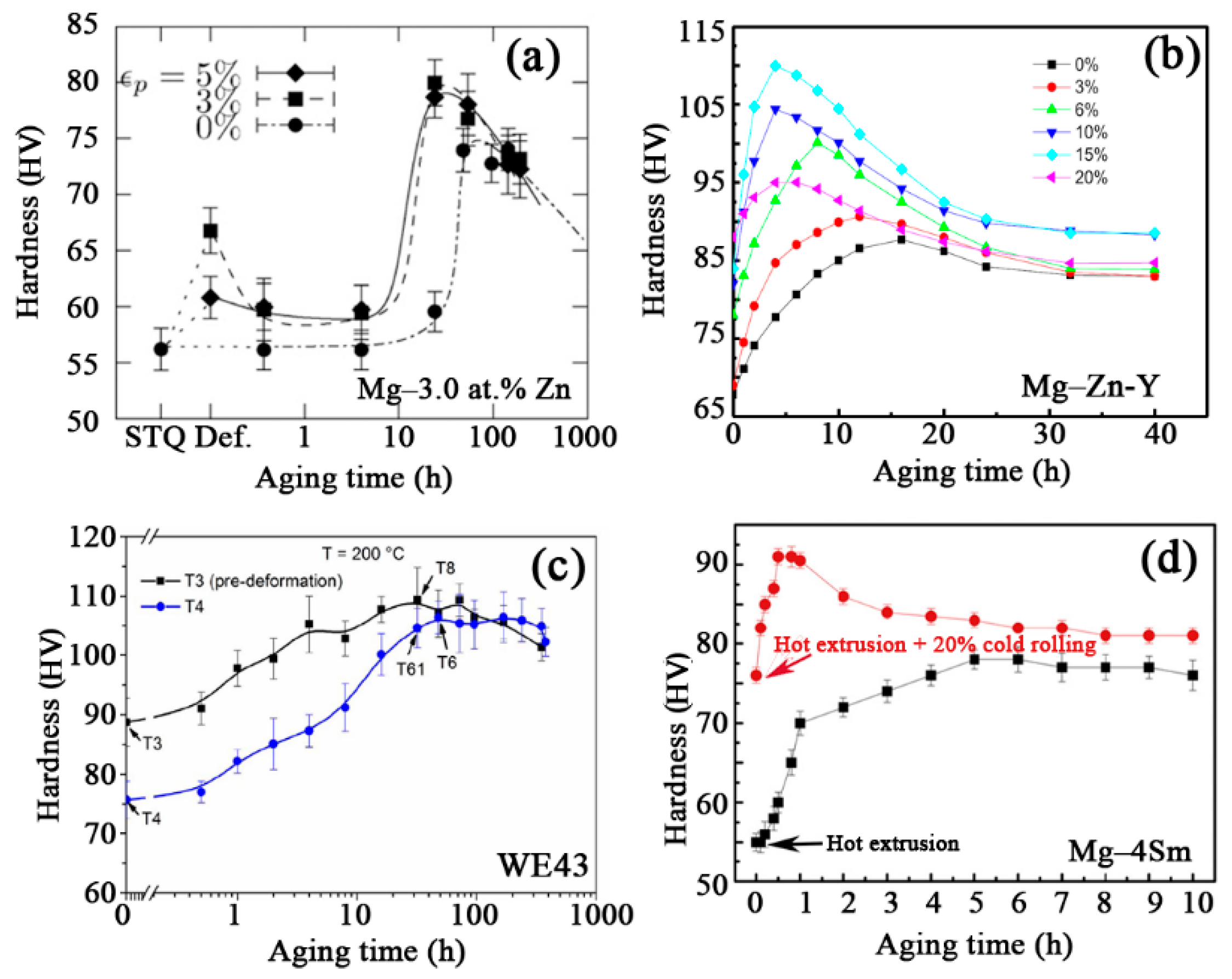

2. Influences of Pre-Cold Deformation on Aging Precipitation

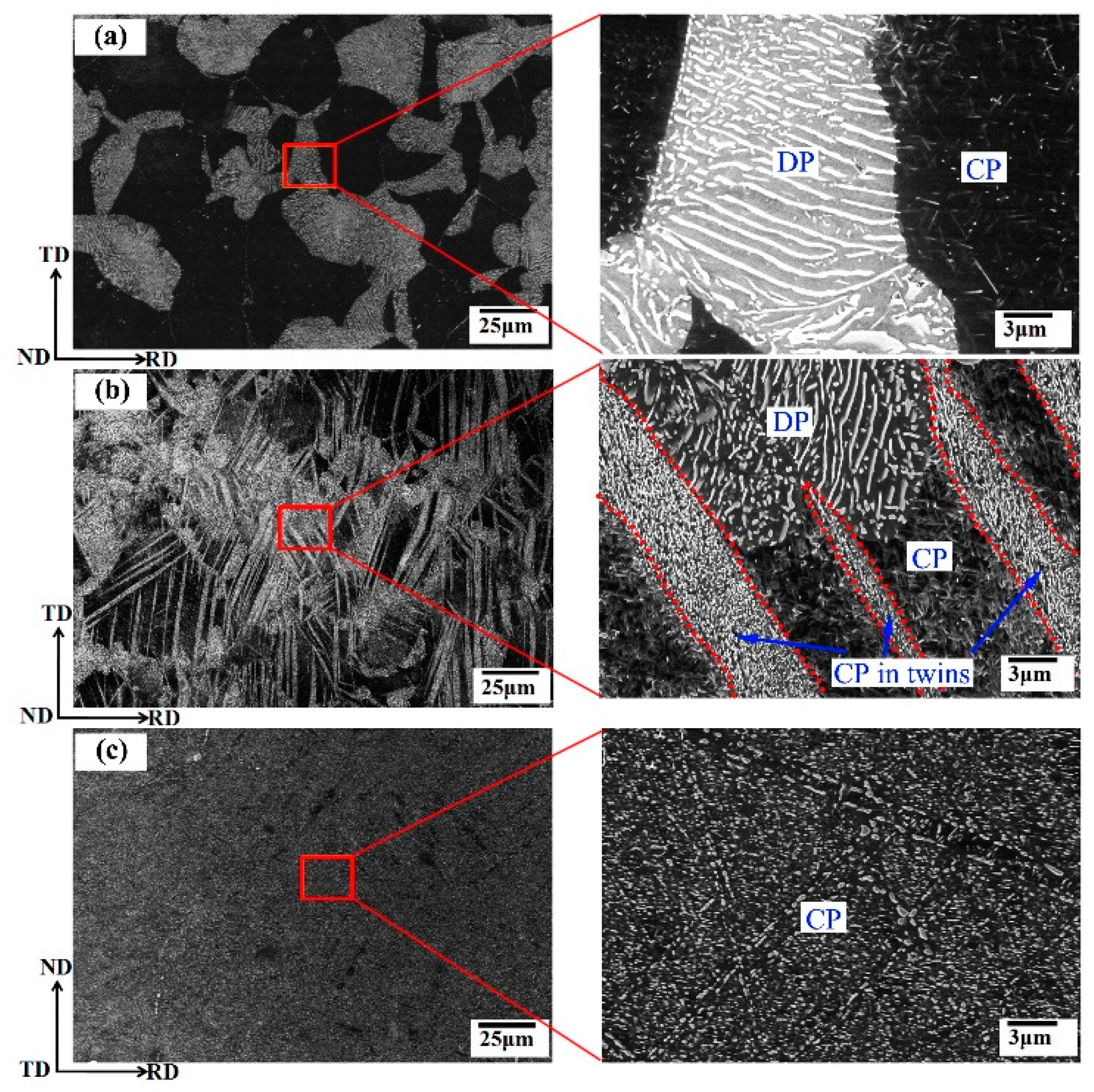

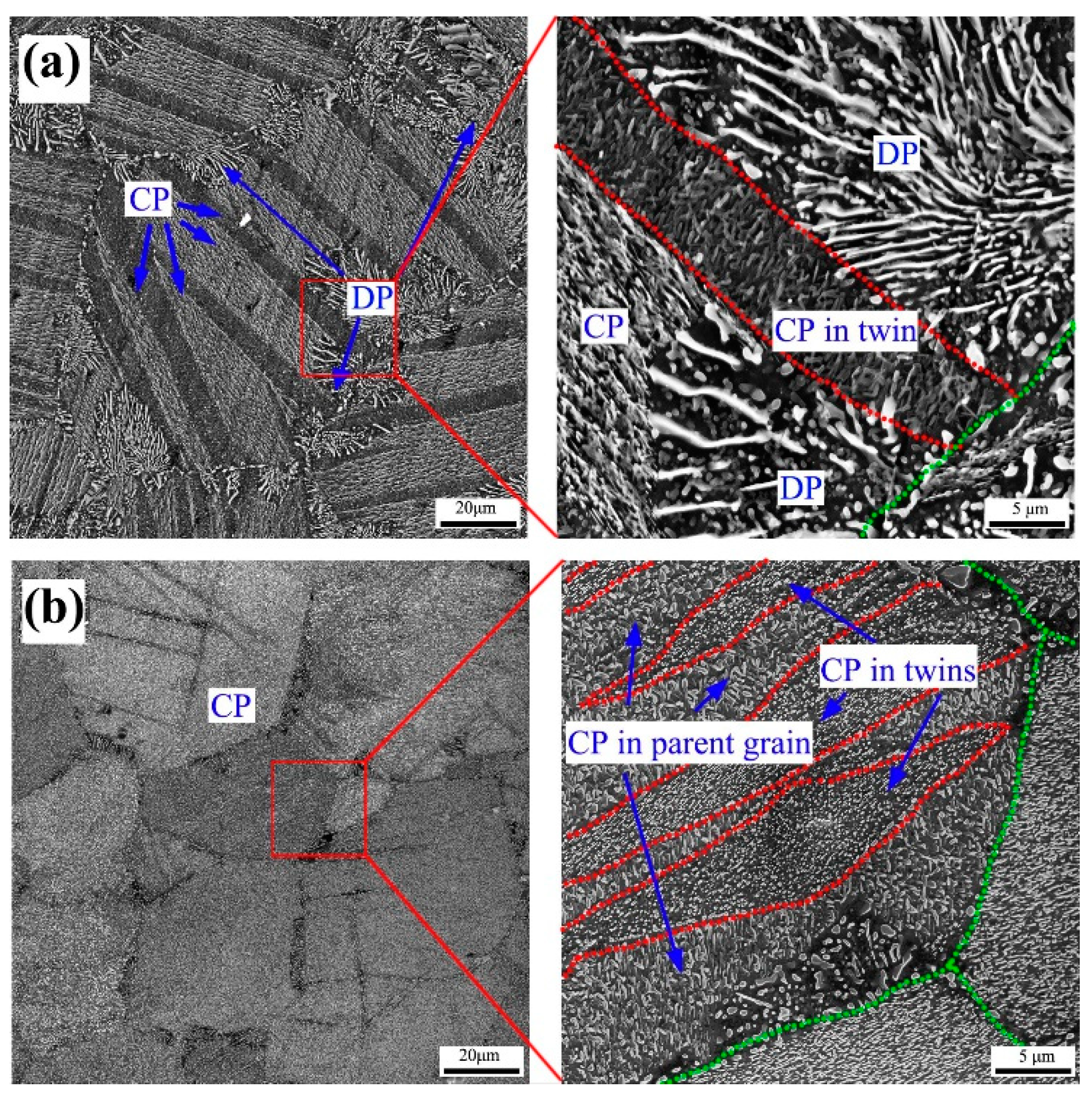

2.1. Mg-Al Alloy Systems

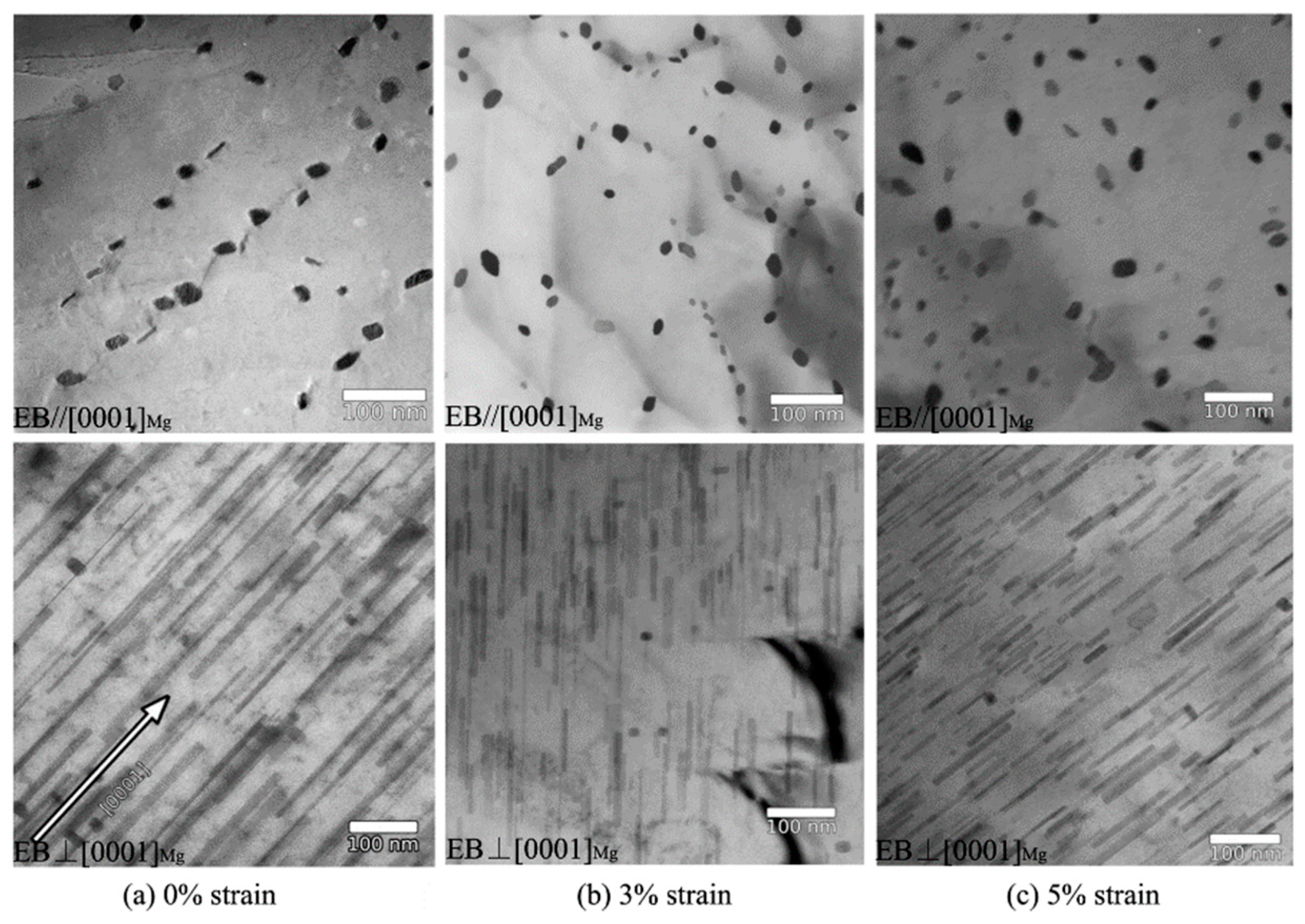

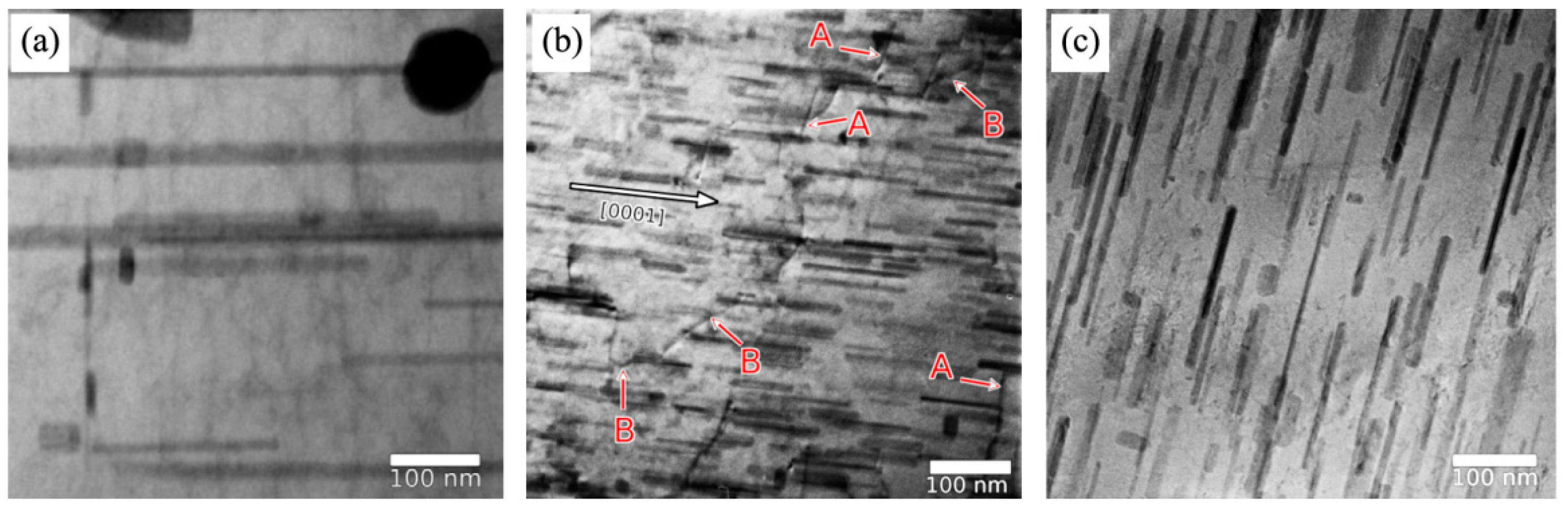

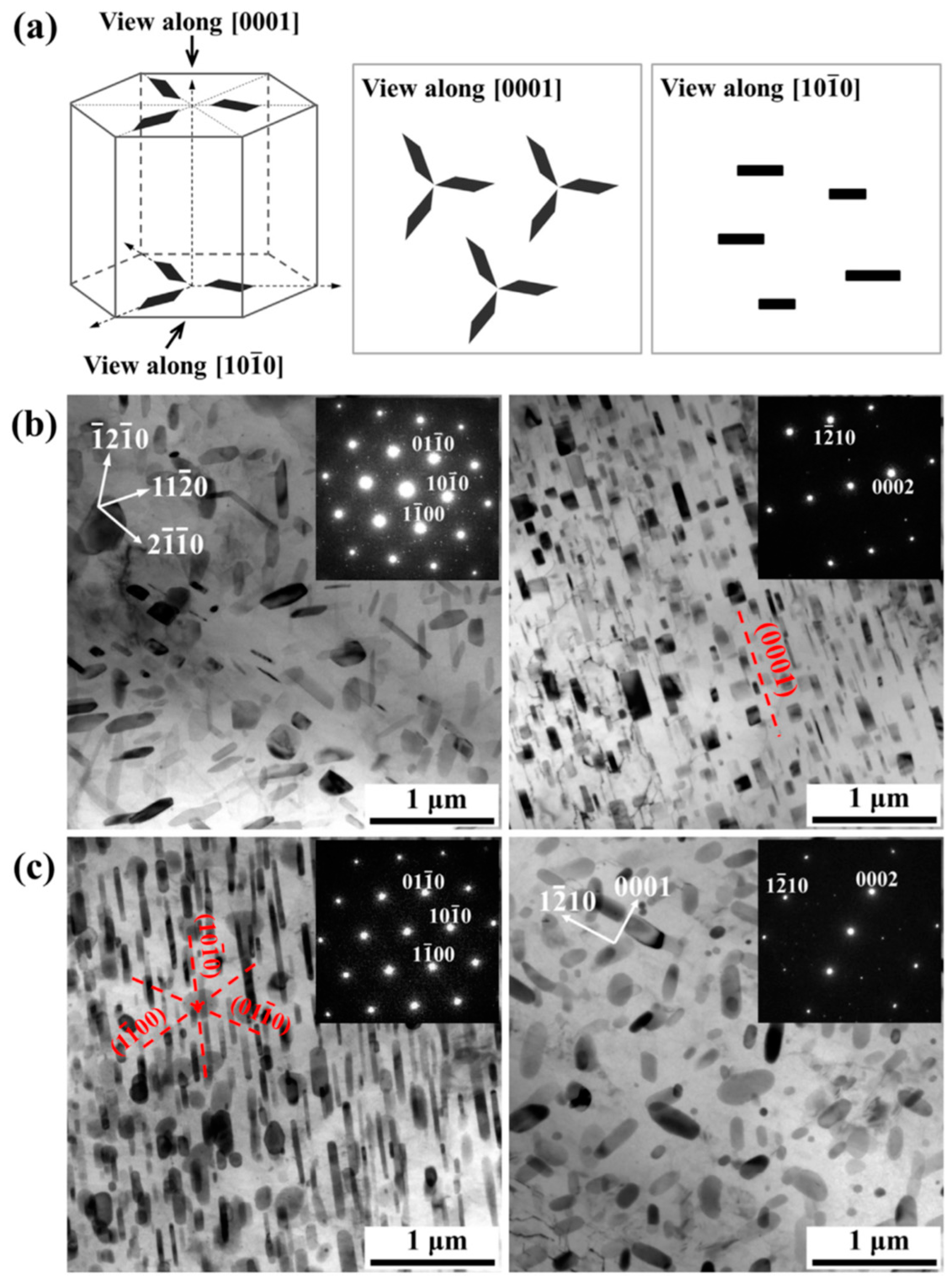

2.2. Mg-Zn Alloy Systems

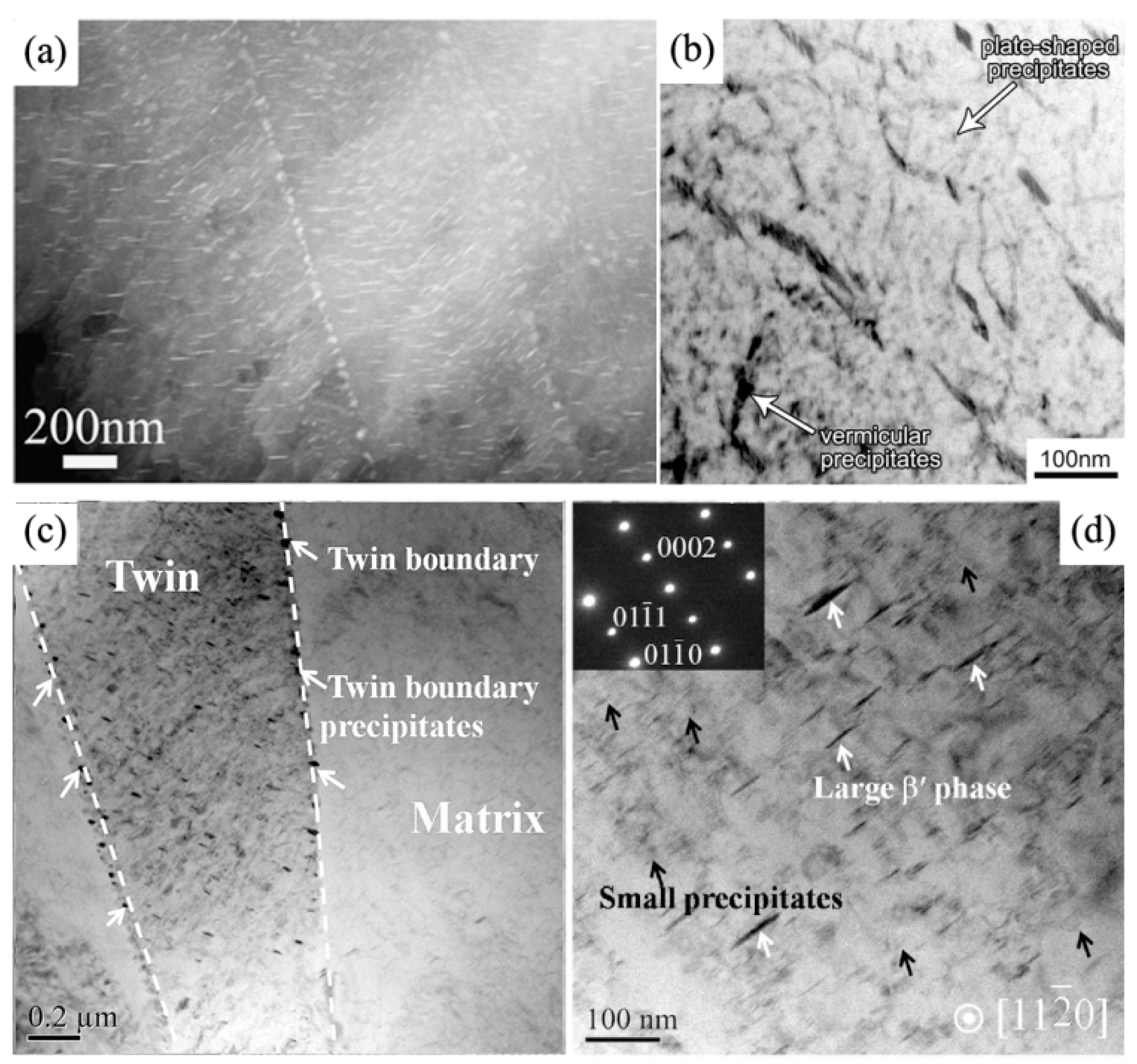

2.3. Mg-RE Alloy Systems

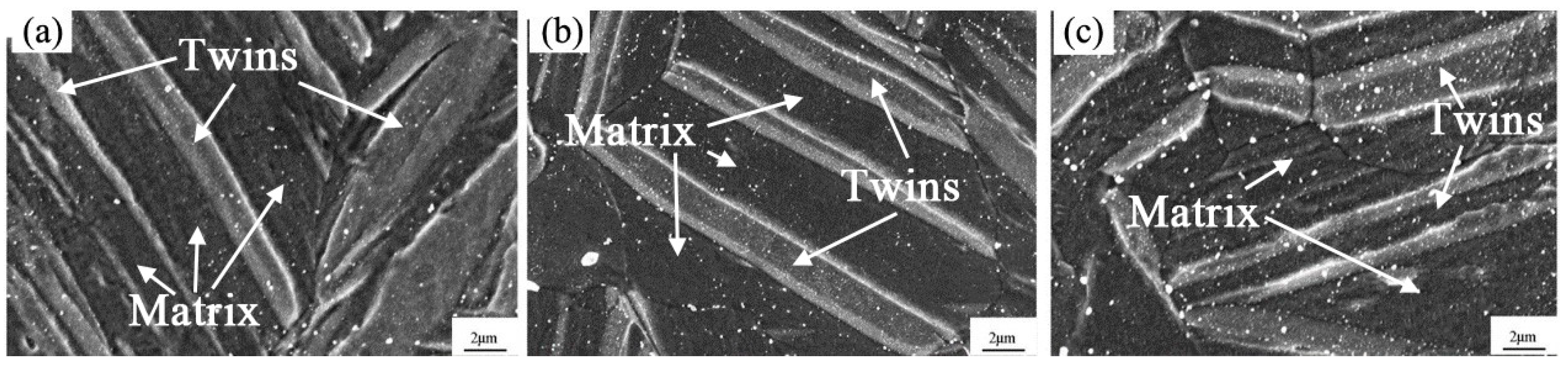

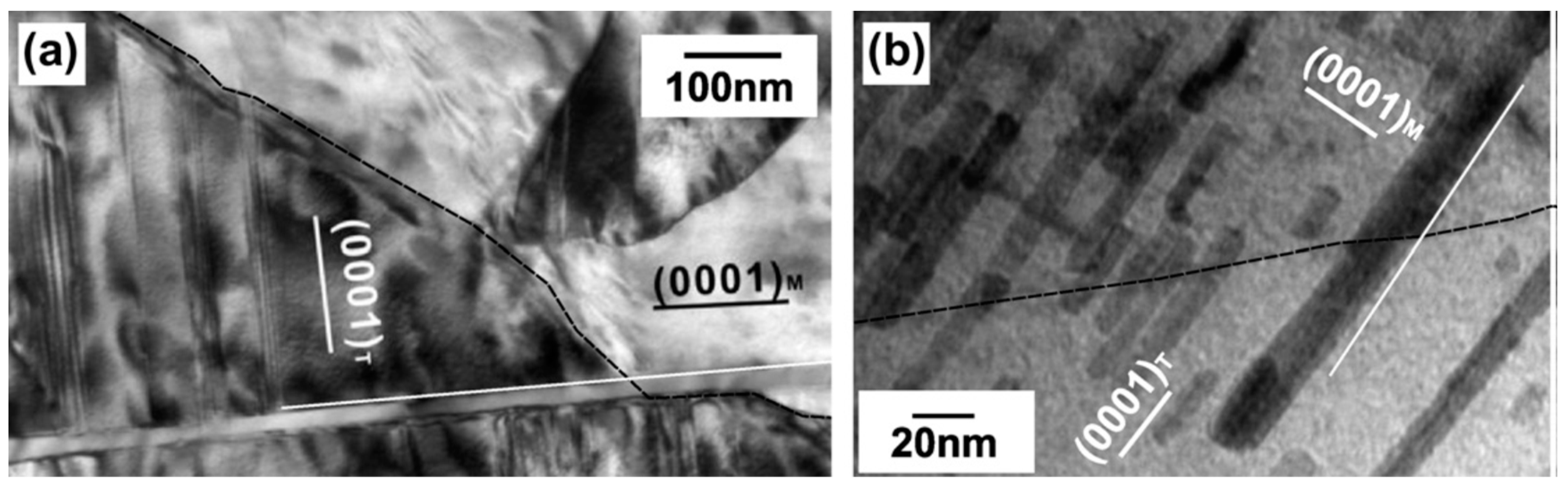

3. Deformation Induced Transition in Precipitate Orientation/Shape

4. Strengthening Mechanism via Combined Use of Cold Deformation and Aging

5. Conclusions and Outlooks

- Pre-cold deformation before aging can accelerate precipitation and enhance the age-hardening effect. It has been widely used to enhance the strength of peak-aged Mg alloys. It is generally believed that this is due to crystal defects via cold deformation providing heterogeneous nucleation sites. Although some researchers have found that the precipitates favorably nucleated on twin boundaries and dislocations, the micro-mechanism has been lacking in-depth systematic investigation. The relationship between the type of crystal defects and the features of precipitates needs to be built.

- As reviewed above, dislocations and deformation twins usually exhibit different influences on the precipitation behavior in Mg alloys, especially in Mg-Al and Mg-Zn alloy systems. It could be related to the different crystal defects evolution in parent grain and twins, as discussed in Section 2.1. Moreover, microalloying could change the influence of dislocations or twins on precipitation behavior, as discussed in Mg-Zn and Mg-RE alloy systems. For these phenomena, micro-mechanism is unclear and it needs to be further revealed.

- Post-cold deformation after aging can be an optional method for regulating precipitate orientation. It has been confirmed that twinning-detwinning can remarkably change the orientation relationship between precipitates and Mg matrix. As a simple and low-cost method, it is considered that it has large potential as a regulation technology of precipitate orientation. Currently, this method is less useful in improving the strength/toughness and anisotropy of magnesium alloys. The study on the transition of precipitation orientation and its influence on mechanical properties will be key in revealing the effect of this method.

- Cold deformation can promote uniform precipitation and eliminate the precipitate-free zone in Mg-RE alloy systems. Moreover, cold deformation can also induce non-uniform distribution of precipitates. It is closely related with features and distributions of crystal defects, which are controlled by the strain state. It is expected that the optimized heterogeneous precipitation could exhibit better comprehensive properties. Thus, it is necessary to develop Mg alloys with heterogeneous precipitation via cold deformation, and revealed the relationship between heterogeneous precipitation and mechanical properties.

- Cold deformation can influence precipitate features, which resulted in a change in the precipitation hardening effect. It should be also pointed out that cold deformation could also generate deformed microstructure (e.g., dislocations, twins, stacking faults, deformation texture, etc.), which could arouse an additional hardening/softening effect. Multiple structure control, including precipitates and deformed microstructure, should be taken into account to evaluate the change and optimization in mechanical properties.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pan, H.; Ren, Y.; Fu, H.; Zhao, H.; Wang, L.; Meng, X.; Qin, G. Recent developments in rare-earth free wrought magnesium alloys having high strength: A review. J. Alloy. Compd. 2016, 663, 321–331. [Google Scholar] [CrossRef]

- Nie, J.F. Precipitation and Hardening in Magnesium Alloys. Metall. Mater. Trans. A 2012, 43, 3891–3939. [Google Scholar] [CrossRef]

- Nie, J. Effects of precipitate shape and orientation on dispersion strengthening in magnesium alloys. Scr. Mater. 2003, 48, 1009–1015. [Google Scholar] [CrossRef]

- Robson, J.; Stanford, N.; Barnett, M.; Robson, J. Effect of precipitate shape on slip and twinning in magnesium alloys. Acta Mater. 2011, 59, 1945–1956. [Google Scholar] [CrossRef]

- Liu, B.Y.; Yang, N.; Wang, J.; Barnett, M.; Xin, Y.C.; Wu, D.; Xin, R.L.; Li, B.; Narayan, R.L.; Nie, J.F.; et al. Insight from in situ microscopy into which precipitate morphology can enable high strength in magnesium alloys. J. Mater. Sci. Technol. 2018, 34, 1061–1066. [Google Scholar] [CrossRef]

- Zhang, M.X.; Kelly, P. Crystallography of Mg17Al12 precipitates in AZ91D alloy. Scr. Mater. 2003, 48, 647–652. [Google Scholar] [CrossRef]

- Buha, J. Reduced temperature (22–100°C) ageing of an MgZn alloy. Mater. Sci. Eng. A 2008, 492, 11–19. [Google Scholar] [CrossRef]

- Li, T.; Du, Z.; Zhang, K.; Li, X.; Yuan, J.; Li, Y.; Ma, M.; Shi, G. Morphology and crystallography of β precipitate phase in Mg-Gd-Y-Nd-Zr alloy. Trans. Nonferr. Met. Soc. China 2012, 22, 2877–2882. [Google Scholar] [CrossRef]

- Xie, H.; Pan, H.; Ren, Y.; Sun, S.; Wang, L.; He, Y.; Qin, G. Co-existences of the two types of β′ precipitations in peak-aged Mg-Gd binary alloy. J. Alloy. Compd. 2018, 738, 32–36. [Google Scholar] [CrossRef]

- Kim, S.H.; Lee, J.U.; Kim, Y.J.; Bae, J.H.; You, B.S.; Park, S.H. Accelerated precipitation behavior of cast Mg-Al-Zn alloy by grain refinement. J. Mater. Sci. Technol. 2018, 34, 265–276. [Google Scholar] [CrossRef]

- Liu, F.; Xin, R.; Wang, C.; Song, B.; Liu, Q. Regulating precipitate orientation in Mg-Al alloys by coupling twinning, aging and detwinning processes. Scr. Mater. 2019, 158, 131–135. [Google Scholar] [CrossRef]

- Gao, X.; Nie, J. Characterization of strengthening precipitate phases in a Mg–Zn alloy. Scr. Mater. 2007, 56, 645–648. [Google Scholar] [CrossRef]

- Huang, X.; Han, G.; Huang, W. T6 Treatment and Its Effects on Corrosion Properties of an Mg–4Sn–4Zn–2Al Alloy. Materials 2018, 11, 628. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Wang, J.; Huang, S.; Liu, S.; Pan, F. Substitution of Ni for Zn on microstructure and mechanical properties of Mg–Gd–Y–Zn–Mn alloy. J. Magnes. Alloy. 2017, 5, 355–361. [Google Scholar] [CrossRef]

- Tahreen, N.; Zhang, D.; Pan, F.; Jiang, X.; Li, D.; Chen, D. Strengthening mechanisms in magnesium alloys containing ternary I, W and LPSO phases. J. Mater. Sci. Technol. 2018, 34, 1110–1118. [Google Scholar] [CrossRef]

- Geng, J.; Gao, X.; Fang, X.; Nie, J. Enhanced age-hardening response of Mg–Zn alloys via Co additions. Scr. Mater. 2011, 64, 506–509. [Google Scholar] [CrossRef]

- Mendis, C.; Ohishi, K.; Kawamura, Y.; Honma, T.; Kamado, S.; Hono, K. Precipitation-hardenable Mg–2.4Zn–0.1Ag–0.1Ca–0.16Zr (at.%) wrought magnesium alloy. Acta Mater. 2009, 57, 749–760. [Google Scholar] [CrossRef]

- Muga, C.; Guo, H.; Xu, S.; Zhang, Z.; Zhang, Z. Effects of aging and fast-cooling on the mechanical properties of Mg-14Li-3Al-3Ce alloy. Mater. Sci. Eng. A 2017, 689, 195–202. [Google Scholar] [CrossRef]

- Chen, Y.; Pan, S.; Tang, S.; Liu, W.; Tang, C.; Xu, F. Formation mechanisms and evolution of precipitate-free zones at grain boundaries in an Al-Cu-Mg-Mn alloy during homogenization. J. Mater. Sci. 2016, 51, 7780–7792. [Google Scholar] [CrossRef]

- Jiang, J.; Wu, J.; Ni, S.; Yan, H.; Song, M. Improving the mechanical properties of a ZM61 magnesium alloy by pre-rolling and high strain rate rolling. Mater. Sci. Eng. A 2018, 712, 478–484. [Google Scholar] [CrossRef]

- Jia, W.; Ning, F.; Ding, Y.; Le, Q.; Tang, Y.; Cui, J. Role of pre-width reduction in deformation behavior of AZ31B alloy during break-down rolling and finish rolling. Mater. Sci. Eng. A 2018, 720, 11–23. [Google Scholar] [CrossRef]

- Hu, T.; Xiao, W.; Wang, F.; Li, Y.; Lyu, S.; Zheng, R.; Ma, C. Improving tensile properties of Mg-Sn-Zn magnesium alloy sheets using pre-tension and ageing treatment. J. Alloy. Compd. 2018, 735, 1494–1504. [Google Scholar] [CrossRef]

- Song, B.; Yang, Q.; Zhou, T.; Chai, L.; Guo, N.; Liu, T.; Guo, S.; Xin, R. Texture control by {10–12} twinning to improve the formability of Mg alloys: A review. J. Mater. Sci. Technol. 2019, 35, 2269–2282. [Google Scholar] [CrossRef]

- Kang, Y.; Wang, X.; Zhang, N.; Yan, H.; Chen, R. Effect of pre-deformation on microstructure and mechanical properties of WE43 magnesium alloy. Mater. Sci. Eng. A 2017, 689, 435–445. [Google Scholar] [CrossRef]

- Guo, F.; Zhang, D.; Fan, X.; Li, J.; Jiang, L.; Pan, F. Microstructure, texture and mechanical properties evolution of pre-twinning Mg alloys sheets during large strain hot rolling. Mater. Sci. Eng. A 2016, 655, 92–99. [Google Scholar] [CrossRef]

- Li, G.; Zhang, J.; Wu, R.; Liu, S.; Song, B.; Jiao, Y.; Yang, Q.; Hou, L. Improving age hardening response and mechanical properties of a new Mg-RE alloy via simple pre-cold rolling. J. Alloy. Compd. 2019, 777, 1375–1385. [Google Scholar] [CrossRef]

- Song, B.; Wang, C.; Guo, N.; Pan, H.; Xin, R. Improving Tensile and Compressive Properties of an Extruded AZ91 Rod by the Combined Use of Torsion Deformation and Aging Treatment. Materials 2017, 10, 280. [Google Scholar] [CrossRef]

- Wang, C.; Xin, R.; Li, D.; Song, B.; Wu, M.; Liu, Q. Enhancing the age-hardening response of rolled AZ80 alloy by pre-twinning deformation. Mater. Sci. Eng. A 2017, 680, 152–156. [Google Scholar] [CrossRef]

- Wang, C.; Xin, R.; Li, D.; Song, B.; Liu, Z.; Liu, Q. Tailoring the Microstructure and Mechanical Property of AZ80 Alloys by Multiple Twinning and Aging Precipitation. Adv. Eng. Mater. 2017, 19, 1700332. [Google Scholar] [CrossRef]

- Yang, P.; Wang, L.N.; Xie, Q.G.; Li, J.Z.; Ding, H.; Lu, L.L. Influence of deformation on precipitation in AZ80 magnesium alloy. Int. J. Miner. Metall. Mater. 2011, 18, 338–343. [Google Scholar] [CrossRef]

- Pan, H.; Pan, F.; Peng, J.; Gou, J.; Tang, A.; Wu, L.; Dong, H. High-conductivity binary Mg–Zn sheet processed by cold rolling and subsequent aging. J. Alloy. Compd. 2013, 578, 493–500. [Google Scholar] [CrossRef]

- Chen, X.; Liu, L.; Pan, F. Strength improvement in ZK60 magnesium alloy induced by pre-deformation and heat treatment. J. Wuhan Univ. Technol. Sci. Ed. 2016, 31, 393–398. [Google Scholar] [CrossRef]

- Chen, H.; Liu, T.; Zhang, Y.; Song, B.; Hou, D.; Pan, F. The yield asymmetry and precipitation behavior of pre-twinned ZK60 alloy. Mater. Sci. Eng. A 2016, 652, 167–174. [Google Scholar] [CrossRef]

- Song, B.; Xin, R.; Sun, L.; Chen, G.; Liu, Q. Enhancing the strength of rolled ZK60 alloys via the combined use of twinning deformation and aging treatment. Mater. Sci. Eng. A 2013, 582, 68–75. [Google Scholar] [CrossRef]

- Zhao, S.; Guo, E.; Wang, L.; Wu, T.; Feng, Y. Effect of pre-compressive strain on microstructure and mechanical properties of Mg–2.7Nd–0.4Zn–0.5Zr alloy. Mater. Sci. Eng. A 2015, 647, 28–33. [Google Scholar] [CrossRef]

- Zheng, K.; Dong, J.; Zeng, X.; Ding, W.; Ding, W. Effect of pre-deformation on aging characteristics and mechanical properties of a Mg–Gd–Nd–Zr alloy. Mater. Sci. Eng. A 2008, 491, 103–109. [Google Scholar] [CrossRef]

- Li, R.; Xin, R.; Chapuis, A.; Liu, Q.; Fu, G.; Zong, L.; Yu, Y.; Guo, B.; Guo, S. Effect of cold rolling on microstructure and mechanical property of extruded Mg–4Sm alloy during aging. Mater. Charact. 2016, 112, 81–86. [Google Scholar] [CrossRef]

- Li, R.; Nie, J.; Huang, G.; Xin, Y.; Liu, Q. Development of high-strength magnesium alloys via combined processes of extrusion, rolling and ageing. Scr. Mater. 2011, 64, 950–953. [Google Scholar] [CrossRef]

- Kim, Y.J.; Kim, S.H.; Lee, J.U.; Choi, J.O.; Kim, H.S.; Kim, Y.M.; Kim, Y.; Park, S.H. Effects of cold pre-forging on microstructure and tensile properties of extruded AZ80 alloy. Mater. Sci. Eng. A 2017, 708, 405–410. [Google Scholar] [CrossRef]

- Li, S.; Tang, W.; Chen, R.; Ke, W. Effect of pre-induced twinning on microstructure and tensile ductility in GW92K magnesium alloy during multi-direction forging at decreasing temperature. J. Magnes. Alloy. 2014, 2, 287–292. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K. Discontinuous and continuous precipitation in magnesium—Aluminium type alloys. J. Alloy. Compd. 2009, 477, 870–876. [Google Scholar] [CrossRef]

- Hong, S.G.; Park, S.H.; Lee, C.S. Role of {10–12} twinning characteristics in the deformation behavior of a polycrystalline magnesium alloy. Acta Mater. 2010, 58, 5873–5885. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, T.; Ding, X.; Xu, S.; He, J.; Chen, H.; Pan, F.; Lu, L. The precipitation behavior of a pretwinned Mg–6Al–1Zn alloy and the effect on subsequent deformation. J. Mater. Res. 2014, 29, 2141–2146. [Google Scholar] [CrossRef]

- Wang, F.; Hazeli, K.; Molodov, K.D.; Barrett, C.D.; Al-Samman, T.; Molodov, D.A.; Kontsos, A.; Ramesh, K.T.; el Kadiri, H.; Agnew, S.R. Characteristic dislocation substructure in {10–12} twins in hexagonal metals. Scr. Mater. 2018, 143, 81–85. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, X.; Shu, Y.; Tan, L.; Liu, Q. Two types of basal stacking faults within {10–12} twin in deformed magnesium alloy. Mater. Lett. 2016, 185, 355–358. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, Q.; Li, B.; Zhang, X.; Tan, L.; Liu, Q. Non-dislocation-mediated basal stacking faults inside {10–11} twins. Scr. Mater. 2017, 141, 85–88. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, Q.; Liu, Y.; Liu, H.; Lin, T. Effect of twins on the crystallographic characteristics of the Mg 17 Al 12 phase in the pre-compressed AZ91 alloy. Mater. Lett. 2018, 230, 166–169. [Google Scholar] [CrossRef]

- Gu, X.F.; Wang, M.; Shi, Z.Z.; Chen, L.; Yang, P. Asymmetrical Precipitation on the {10–12} Twin Boundary in the Magnesium Alloy. Metall. Mater. Trans. A 2018, 49, 4446–4451. [Google Scholar] [CrossRef]

- Yan, K.; Bai, J.; Liu, H.; Jin, Z.Y. The precipitation behavior of MgZn 2 and Mg 4 Zn 7 phase in Mg-6Zn (wt.%) alloy during equal-channel angular pressing. J. Magnes. Alloy. 2017, 5, 336–339. [Google Scholar] [CrossRef]

- Shi, G.L.; Zhang, D.F.; Zhang, H.J.; Zhao, X.B.; Qi, F.G.; Zhang, K. Influence of pre-deformation on age-hardening response and mechanical properties of extruded Mg–6%Zn–1%Mn alloy. Trans. Nonferr. Met. Soc. China 2013, 23, 586–592. [Google Scholar] [CrossRef]

- Li, Q.; Huang, G.; Huang, X.; Pan, S.; Tan, C.; Liu, Q. On the texture evolution of Mg–Zn–Ca alloy with different hot rolling paths. J. Magnes. Alloy. 2017, 5, 166–172. [Google Scholar] [CrossRef]

- Rosalie, J.M.; Somekawa, H.; Singh, A.; Mukai, T. Effect of precipitation on strength and ductility in a Mg–Zn–Y alloy. J. Alloy. Compd. 2013, 550, 114–123. [Google Scholar] [CrossRef]

- Singh, A.; Tsai, A.P. Structural characteristics of β1 precipitates in Mg-Zn-based alloys. Scr. Mater. 2007, 57, 941–944. [Google Scholar] [CrossRef]

- Clark, J. Transmission electron microscopy study of age hardening in a Mg-5 wt.% Zn alloy. Acta Met. 1965, 13, 1281–1289. [Google Scholar] [CrossRef]

- Rosalie, J.M.; Somekawa, H.; Singh, A.; Mukai, T. The effect of size and distribution of rod-shaped β1’ precipitates on the strength and ductility of a Mg-Zn alloy. Mater. Sci. Eng. A 2012, 539, 230–237. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Wells, M.A. Analysis of the hot deformation of ZK60 magnesium alloy. J. Magnes. Alloy. 2017, 5, 369–387. [Google Scholar] [CrossRef]

- Chen, H.; Kang, S.B.; Yu, H.; Cho, J.; Kim, H.W.; Min, G. Effect of heat treatment on microstructure and mechanical properties of twin roll cast and sequential warm rolled ZK60 alloy sheets. J. Alloy. Compd. 2009, 476, 324–328. [Google Scholar] [CrossRef]

- Song, B.; Xin, R.; Guo, N.; Xu, J.; Sun, L.; Liu, Q. Dependence of tensile and compressive deformation behavior on aging precipitation in rolled ZK60 alloys. Mater. Sci. Eng. A 2015, 639, 724–731. [Google Scholar] [CrossRef]

- Liu, Z.; Xin, R.; Wu, X.; Liu, D.; Liu, Q. Improvement in the strength of friction-stir-welded ZK60 alloys via post-weld compression and aging treatment. Mater. Sci. Eng. A 2018, 712, 493–501. [Google Scholar] [CrossRef]

- Jiang, M.; Xu, C.; Nakata, T.; Yan, H.; Chen, R.; Kamado, S. Enhancing strength and ductility of Mg-Zn-Gd alloy via slow-speed extrusion combined with pre-forging. J. Alloy. Compd. 2017, 694, 1214–1223. [Google Scholar] [CrossRef]

- Shao, X.; Peng, Z.; Jin, Q.; Ma, X. Atomic scale characterizing interaction between {10–13} twin and stacking faults with solute atoms in an Mg-Zn-Y alloy. Mater. Sci. Eng. A 2017, 700, 468–472. [Google Scholar] [CrossRef]

- Li, Z.; Wan, D.; Huang, Y.; Ye, S.; Hu, Y. Characterization of a Mg95.5Zn1.5Y3 alloy both containing W phase and LPSO phase with or without heat treatment. J. Magnes. Alloy. 2017, 5, 217–224. [Google Scholar]

- Singh, A.; Osawa, Y.; Somekawa, H.; Mukai, T. Effect of Solidification Cooling Rate on Microstructure and Mechanical Properties of an Extruded Mg-Zn-Y Alloy. Metals 2018, 8, 337. [Google Scholar] [CrossRef]

- Zhu, W.; Liu, W.; Zhang, Y.G.; Ma, Q.Q.; Zhang, J.; Xu, C. Influence of Ni Alloying on the Precipitation of Quasicrystal Phase in As-Cast Mg 96.5 Zn 1 Y 1.5 Mn 1 Alloy. Adv. Eng. Mater. 2019, 21, 1801238. [Google Scholar] [CrossRef]

- Ye, J.; Lin, X.P.; Zhao, T.B.; Liu, N.N.; Xie, H.B.; Niu, Y.; Teng, F. Influence of pre-strain on the aging hardening effect of the Mg-9.02Zn-1.68Y alloy. Mater. Sci. Eng. A 2016, 663, 49–55. [Google Scholar] [CrossRef]

- Ren, W.; Xin, R.; Xu, J.; Song, B.; Zhang, L.; Liu, Q. Effects of precipitate type on twin/slip activity in ZK60 alloys and yield asymmetry. J. Alloy. Compd. 2019, 792, 610–616. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, J.; Feng, Y.; Xie, J.; Liu, Y.; Liu, S.; Meng, J.; Yang, Q.; Liu, Z.; Wu, R. Development of Hot-Extruded Mg–RE–Zn Alloy Bar with High Mechanical Properties. Materials 2019, 12, 1722. [Google Scholar] [CrossRef]

- Jung, I.H.; Sanjari, M.; Kim, J.; Yue, S. Role of RE in the deformation and recrystallization of Mg alloy and a new alloy design concept for Mg–RE alloys. Scr. Mater. 2015, 102, 1–6. [Google Scholar] [CrossRef]

- Majd, A.M.; Farzinfar, M.; Pashakhanlou, M.; Nayyeri, M.J. Effect of RE elements on the microstructural and mechanical properties of as-cast and age hardening processed Mg–4Al–2Sn alloy. J. Magnes. Alloy. 2018, 6, 309–317. [Google Scholar] [CrossRef]

- Gao, Z.; Hu, L.; Li, J.; An, Z.; Li, J.; Huang, Q. Achieving High Strength and Good Ductility in As-Extruded Mg–Gd–Y–Zn Alloys by Ce Micro-Alloying. Materials 2018, 11, 102. [Google Scholar] [CrossRef]

- You, S.; Huang, Y.; Kainer, K.U.; Hort, N. Recent research and developments on wrought magnesium alloys. J. Magnes. Alloy. 2017, 5, 239–253. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, S.; Wu, R.; Hou, L.; Zhang, M. Recent developments in high-strength Mg-RE-based alloys: Focusing on Mg-Gd and Mg-Y systems. J. Magnes. Alloy. 2018, 6, 277–291. [Google Scholar] [CrossRef]

- Liu, H.; Gao, Y.; Liu, J.; Zhu, Y.; Wang, Y.; Nie, J. A simulation study of the shape of β’ precipitates in Mg–Y and Mg–Gd alloys. Acta Mater. 2013, 61, 453–466. [Google Scholar] [CrossRef]

- Xin, R.; Li, L.; Zeng, K.; Song, B.; Liu, Q. Structural examination of aging precipitation in a Mg–Y–Nd alloy at different temperatures. Mater. Charact. 2011, 62, 535–539. [Google Scholar] [CrossRef]

- Hilditch, T.; Nie, J.; Muddle, B.C. Werkstoff Informationsgesellschaft. In Magnesium Alloys and Their Applications; Mordike, B.L., Kainer, K.U., Eds.; Wiley-VCH: Frankfurt, Germany, 1998; pp. 339–344. [Google Scholar]

- Čížek, J.; Procházka, I.; Smola, B.; Stulíková, I.; Očenášek, V. Influence of deformation on precipitation process in Mg–15wt.%Gd alloy. J. Alloy. Compd. 2007, 430, 92–96. [Google Scholar] [CrossRef]

- Fang, D.; Ma, N.; Cai, K.; Cai, X.; Chai, Y.; Peng, Q. Age hardening behaviors, mechanical and corrosion properties of deformed Mg–Mn–Sn sheets by pre-rolled treatment. Mater. Des. 2014, 54, 72–78. [Google Scholar] [CrossRef]

- Peng, Q.; Ma, N.; Li, X.; Zhang, J. Age hardening response of a Mg–5wt.%Sc alloy under an applied stress field. Mater. Lett. 2012, 78, 58–61. [Google Scholar] [CrossRef]

- Zhao, H.; Pan, J.; Li, H.; Tian, Y.; Peng, Q. Spherical strengthening precipitate in a Mg-10wt%Y alloy with superhigh pressure aging. Mater. Lett. 2013, 96, 16–19. [Google Scholar] [CrossRef]

- Agnew, S.R.; Duygulu, O. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B. Int. J. Plast. 2005, 21, 1161–1193. [Google Scholar] [CrossRef]

- Geng, J.; Chun, Y.; Stanford, N.; Davies, C.; Nie, J.; Barnett, M. Processing and properties of Mg–6Gd–1Zn–0.6Zr. Mater. Sci. Eng. A 2011, 528, 3659–3665. [Google Scholar] [CrossRef]

- Jain, J.; Cizek, P.; Poole, W.J.; Barnett, M.R. The role of back stress caused by precipitates on {10–12} twinning in a Mg–6Zn alloy. Mater. Sci. Eng. A 2015, 647, 66–73. [Google Scholar] [CrossRef]

- Song, B.; Pan, H.; Chai, L.; Guo, N.; Zhao, H.; Xin, R. Evolution of gradient microstructure in an extruded AZ31 rod during torsion and annealing and its effects on mechanical properties. Mater. Sci. Eng. A 2017, 689, 78–88. [Google Scholar] [CrossRef]

- Zhang, W.; Huo, W.; Lu, J.; Hu, J.; Wei, Q.; Zhang, Y. Gradient shear banding in a magnesium alloy induced by sliding friction treatment. Vacuum 2017, 143, 95–97. [Google Scholar] [CrossRef]

- Lu, K. Making strong nanomaterials ductile with gradients. Science 2014, 345, 1455–1456. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, Y. Heterogeneous materials: A new class of materials with unprecedented mechanical properties. Mater. Res. Lett. 2017, 5, 527–532. [Google Scholar] [CrossRef]

- Luo, X.; Huang, T.; Wang, Y.; Xin, Y.; Wu, G. Strong and ductile AZ31 Mg alloy with a layered bimodal structure. Sci. Rep. 2019, 9, 5428. [Google Scholar] [CrossRef]

- He, J.; Jin, L.; Wang, F.; Dong, S.; Dong, J. Mechanical properties of Mg-8Gd-3Y-0.5Zr alloy with bimodal grain size distributions. J. Magnes. Alloy. 2017, 5, 423–429. [Google Scholar] [CrossRef]

- Pan, H.; Fu, H.; Song, B.; Ren, Y.; Zhao, C.; Qin, G. Formation of profuse dislocations in deformed calcium-containing magnesium alloys. Philos. Mag. Lett. 2016, 96, 249–255. [Google Scholar] [CrossRef]

- Pan, H.; Huang, Q.; Qin, G.; Fu, H.; Xu, M.; Ren, Y.; She, J.; Song, B.; Li, B. Activations of stacking faults in the calcium-containing magnesium alloys under compression. J. Alloy. Compd. 2017, 692, 898–902. [Google Scholar] [CrossRef]

- Wang, F.; Agnew, S.R. Dislocation transmutation by tension twinning in magnesium alloy AZ31. Int. J. Plast. 2016, 81, 63–86. [Google Scholar] [CrossRef]

- Wang, L.; Song, B.; Zhang, Z.; Zhang, H.; Han, T.; Cao, X.; Wang, H.; Cheng, W. Enhanced Stretch Formability of AZ31 Magnesium Alloy Thin Sheet by Induced Precompression and Sequent Annealing. Materials 2018, 11, 1401. [Google Scholar] [CrossRef]

- Bailey, J.E.; Hirsch, P.B. The dislocation distribution, flow stress, and stored energy in cold-worked polycrystalline silver. Philos. Mag. 1960, 5, 485–497. [Google Scholar] [CrossRef]

- Song, B.; Guo, N.; Liu, T.; Yang, Q. Improvement of formability and mechanical properties of magnesium alloys via pre-twinning: A review. Mater. Des. 2014, 62, 352–360. [Google Scholar] [CrossRef]

- Wen, H.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J. Strengthening mechanisms in a high-strength bulk nanostructured Cu–Zn–Al alloy processed via cryomilling and spark plasma sintering. Acta Mater. 2013, 61, 2769–2782. [Google Scholar] [CrossRef]

- Zhu, S.; Ringer, S.P. On the role of twinning and stacking faults on the crystal plasticity and grain refinement in magnesium alloys. Acta Mater. 2018, 144, 365–375. [Google Scholar] [CrossRef]

- Wang, F.; Bhattacharyya, J.J.; Agnew, S.R. Effect of precipitate shape and orientation on Orowan strengthening of non-basal slip modes in hexagonal crystals, application to magnesium alloys. Mater. Sci. Eng. A 2016, 666, 114–122. [Google Scholar] [CrossRef]

- Xu, C.; Nakata, T.; Qiao, X.G.; Zheng, M.Y.; Wu, K.; Kamado, S. Ageing behavior of extruded Mg–8.2Gd–3.8Y–1.0Zn–0.4Zr (wt.%) alloy containing LPSO phase and γ’ precipitates. Sci. Rep. 2017, 7, 43391. [Google Scholar] [CrossRef]

- Zhang, X.; Li, B.; Liu, Q. Non-equilibrium basal stacking faults in hexagonal close-packed metals. Acta Mater. 2015, 90, 140–150. [Google Scholar] [CrossRef]

- Li, B.; Yan, P.; Sui, M.; Ma, E.; Yan, P. Transmission electron microscopy study of stacking faults and their interaction with pyramidal dislocations in deformed Mg. Acta Mater. 2010, 58, 173–179. [Google Scholar] [CrossRef]

- Sandlöbes, S.; Friák, M.; Zaefferer, S.; Dick, A.; Yi, S.; Letzig, D.; Pei, Z.; Zhu, L.F.; Neugebauer, J.; Raabe, D. The relation between ductility and stacking fault energies in Mg and Mg–Y alloys. Acta Mater. 2012, 60, 3011–3021. [Google Scholar] [CrossRef]

- Song, B.; Shu, X.; Pan, H.; Li, G.; Guo, N.; Liu, T.; Chai, L.; Xin, R. Influence of Torsion Route on the Microstructure and Mechanical Properties of Extruded AZ31 Rods. Adv. Eng. Mater. 2017, 19, 1700267. [Google Scholar] [CrossRef]

- Song, B.; Liu, T.; Xin, R.; Yang, H.; Guo, N.; Chai, L.; Huang, Y.; Hort, N. Influence of Torsion on Precipitation and Hardening Effects during Aging of an Extruded AZ91 Alloy. J. Mater. Eng. Perform. 2019, 28, 4403–4414. [Google Scholar] [CrossRef]

| Materials | Deformation before Aging | Pre-Strain Amount | Loading Direction | Rp0.2 (Mpa) | Rp0.2 (Mpa) | Elong (%) | Elong (%) |

|---|---|---|---|---|---|---|---|

| Before Aging | After Aging | Before Aging | After Aging | ||||

| As-cast | Tension | 0% | Tension | 134 | 222 | 21 | 2.5 |

| Mg–11Gd–2Nd–0.5Zr [36] | 5% | 276 | 2 | ||||

| 10% | 298 | 1.4 | |||||

| As-cast | Forging (Multi-axial) | 0% | Tension | 155 | 204 | 6.9 | 1.1 |

| WE43 [24] | 15% | 272 | 0.7 | ||||

| Extruded | Rolling (ED) | 0% | Tension (ED) | 90 | 155 | 10 | 6 |

| Mg–4Sm [37] | 20% | 2 | |||||

| Extruded | Rolling (ED) | 0% | Tension (ED) | 190 | 305275 | 19.5 | 7.0 |

| Mg-14Gd-0.5Zr [38] | 10% | 255 | 375 | 12 | 3.0 | ||

| 19% | 295 | 420 | 4.5 | 2.3 | |||

| 27% | 305 | 445 | 3.5 | 2.0 | |||

| As-cast | Rolling | 0% | Tension (RD) | 132 | 147 | 14.8 | 8.9 |

| Mg-2.1Gd-1.7Ho-1.4Y-1.3Nd-0.9Er-0.5Zn-0.5Zr [26] | 12% | 224 | 259 | 6.5 | 5.4 | ||

| Rolled | Compression (TD) | 0% | Tension (RD) | 171 | 202 | 12.6 | 7.2 |

| AZ80 [28] | 10% | 283 | 9.1 | ||||

| Extruded | Tension (ED) | 0% | Tension (ED) | 143 | 273 | 0.25 | 16 |

| Mg–3Zn [55] | 3% | 305 | 15 | ||||

| 5% | 309 | 15 | |||||

| Rolled | Compression (ED) | 0% | Tension (RD) | 185 | 223 | 18.4 | 14.2 |

| ZK60 [34] | 3% | 217 | 258 | 16.6 | 16.6 | ||

| Extruded | Tension (ED) | 0% | Tension (ED) | 204 | 320 | 14 | 6 |

| ZM61 [50] | 5% | 347 | 6 | ||||

| 10% | 356 | 4 | |||||

| Extruded | Tension (ED) | 0% | Tension (ED) | 150 | 217 | - | - |

| Mg-3Zn-0.5Y [52] | 3% | 281 | |||||

| 5% | 287 | ||||||

| Rolled | Tension (RD) | 0% | Tension (RD) | 185 | 196 | 24.2 | 17.7 |

| Mg-5Sn-2Zn [22] | 3% | 233 | 14.1 | ||||

| 10% | 260 | 10.6 |

| Materials | Pre-Deform | Pre-Strain | Peak Aging | Precipitates | Precipitate Size (nm) |

|---|---|---|---|---|---|

| As-cast | Forging (Multi-axial) | 0% | 200 °C/48 h | β″; β′ | 25 × 25 × 3; 25 × 25 × 3 |

| WE43 [24] | 15% | 200 °C/32 h | 15 × 15 × 2; 15 × 15 × 3 (Length × width × thickness) | ||

| Extruded | Rolling (ED) | 0% | 200 °C/36 h | β′ | 13.8 × 7.2 |

| Mg-14Gd-0.5Zr alloy [38] | 27% | 200 °C/16 h | 8.9 × 6.8 (Length × width) | ||

| Extruded | Tension (ED) | 0% | 150 °C/48 h | rod-like β′1 | 440 × 60 |

| Mg–3Zn [55] | 5% | 150 °C/32 h | 14 × 9 (Length × diameter) | ||

| Extruded | Tension (ED) | 0% | 150 °C/256 h | rod-like β′1 | 475 × 20 |

| Mg-3Zn-0.5Y [52] | 3% | 150 °C/48 h | 102 × 12 | ||

| 5% | 150 °C/32 h | 67 × 10 (Length × diameter) | |||

| Rolled | Tension (RD) | 0% | 150 °C/48 h | Mg2Sn | 204 |

| Mg-5Sn-2Zn sheet [22] | 3% | 150 °C/48 h | 149 | ||

| 10% | 150 °C/48 h | 119 (Mean size) | |||

| As-cast | Rolling | 0% | 200 °C/36 h | β″ | 4.4 × 14.8 |

| Mg-2.1Gd-1.7Ho-1.4Y-1.3Nd-0.9Er-0.5Zn-0.5Zr [26] | 12% | 200 °C/9 h | 3.1 × 10.1 (Diameter × thickness) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, B.; She, J.; Guo, N.; Qiu, R.; Pan, H.; Chai, L.; Yang, C.; Guo, S.; Xin, R. Regulating Precipitates by Simple Cold Deformations to Strengthen Mg Alloys: A Review. Materials 2019, 12, 2507. https://doi.org/10.3390/ma12162507

Song B, She J, Guo N, Qiu R, Pan H, Chai L, Yang C, Guo S, Xin R. Regulating Precipitates by Simple Cold Deformations to Strengthen Mg Alloys: A Review. Materials. 2019; 12(16):2507. https://doi.org/10.3390/ma12162507

Chicago/Turabian StyleSong, Bo, Jia She, Ning Guo, Risheng Qiu, Hucheng Pan, Linjiang Chai, Changlin Yang, Shengfeng Guo, and Renlong Xin. 2019. "Regulating Precipitates by Simple Cold Deformations to Strengthen Mg Alloys: A Review" Materials 12, no. 16: 2507. https://doi.org/10.3390/ma12162507

APA StyleSong, B., She, J., Guo, N., Qiu, R., Pan, H., Chai, L., Yang, C., Guo, S., & Xin, R. (2019). Regulating Precipitates by Simple Cold Deformations to Strengthen Mg Alloys: A Review. Materials, 12(16), 2507. https://doi.org/10.3390/ma12162507