Author Contributions

Conceptualization, X.F. and S.L.; methodology, S.L. and W.L.; software, X.F. and S.L.; validation, X.F., S.L. and W.L.; formal analysis, F.H. and W.L.; investigation, X.F. and W.L.; resources, S.L.; data curation, X.F., S.L. and F.H.; writing—original draft preparation, X.F., S.L. and W.L.; writing—review and editing, X.F., S.L. and W.L.; visualization, X.F., S.L. and W.L.; supervision, S.L.; project administration, S.L.; funding acquisition, S.L.

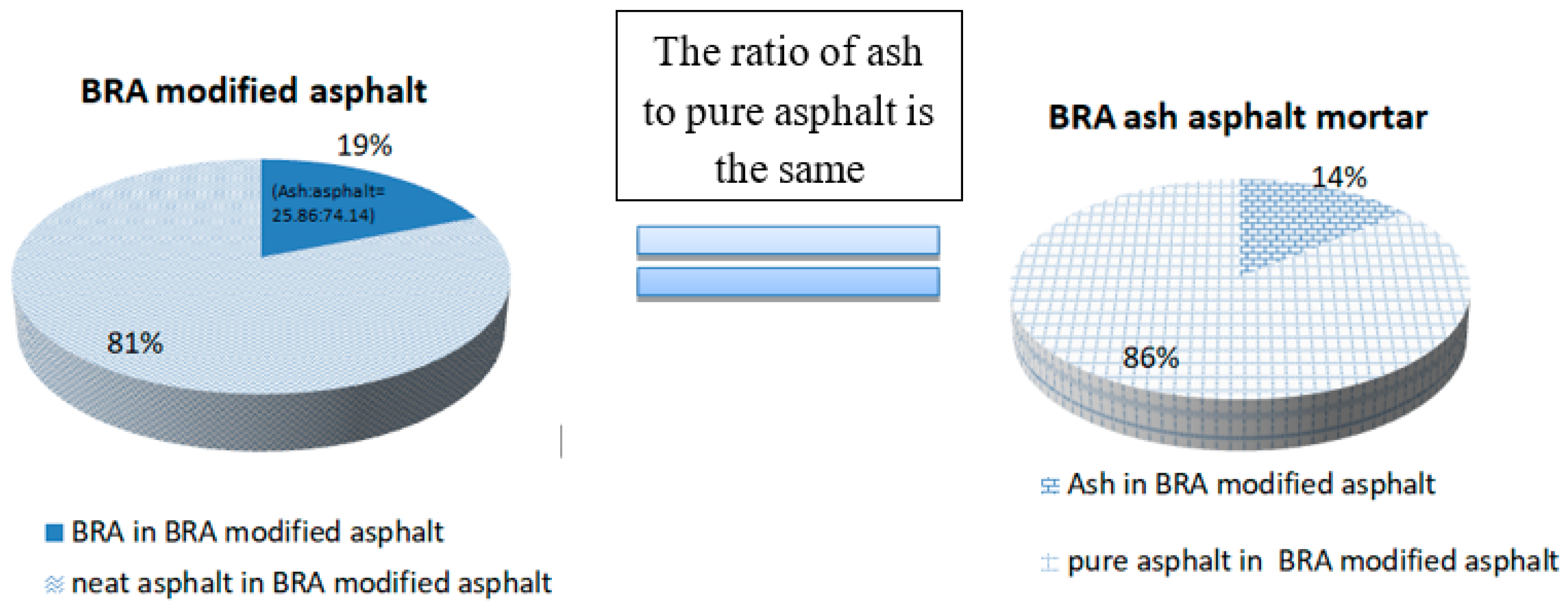

Figure 1.

The ratio of ash to pure asphalt is the same.

Figure 1.

The ratio of ash to pure asphalt is the same.

Figure 2.

Flow chart for preparing modified asphalt.

Figure 2.

Flow chart for preparing modified asphalt.

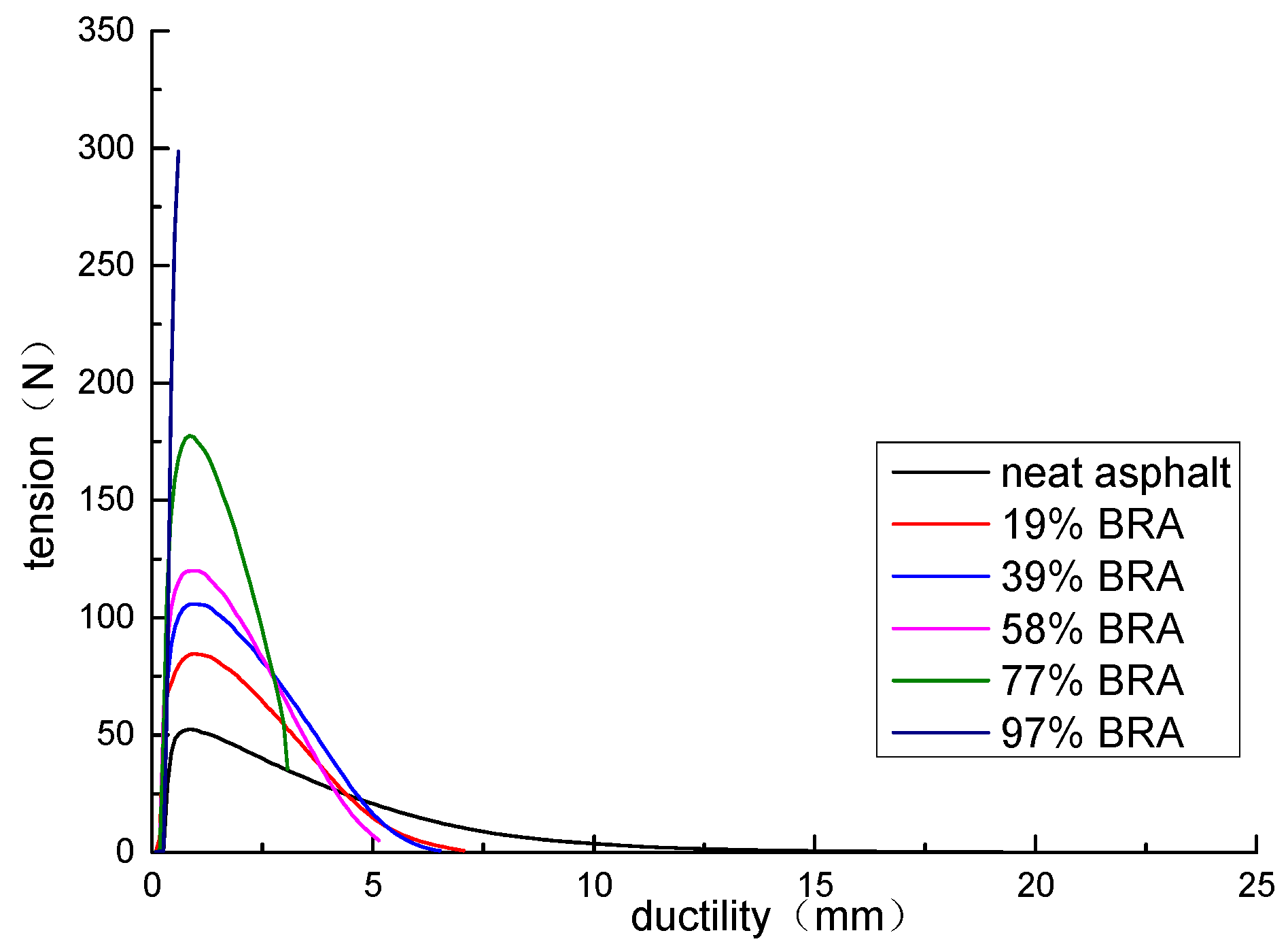

Figure 3.

Relationship between tensile force and ductility of BRA-modified asphalt.

Figure 3.

Relationship between tensile force and ductility of BRA-modified asphalt.

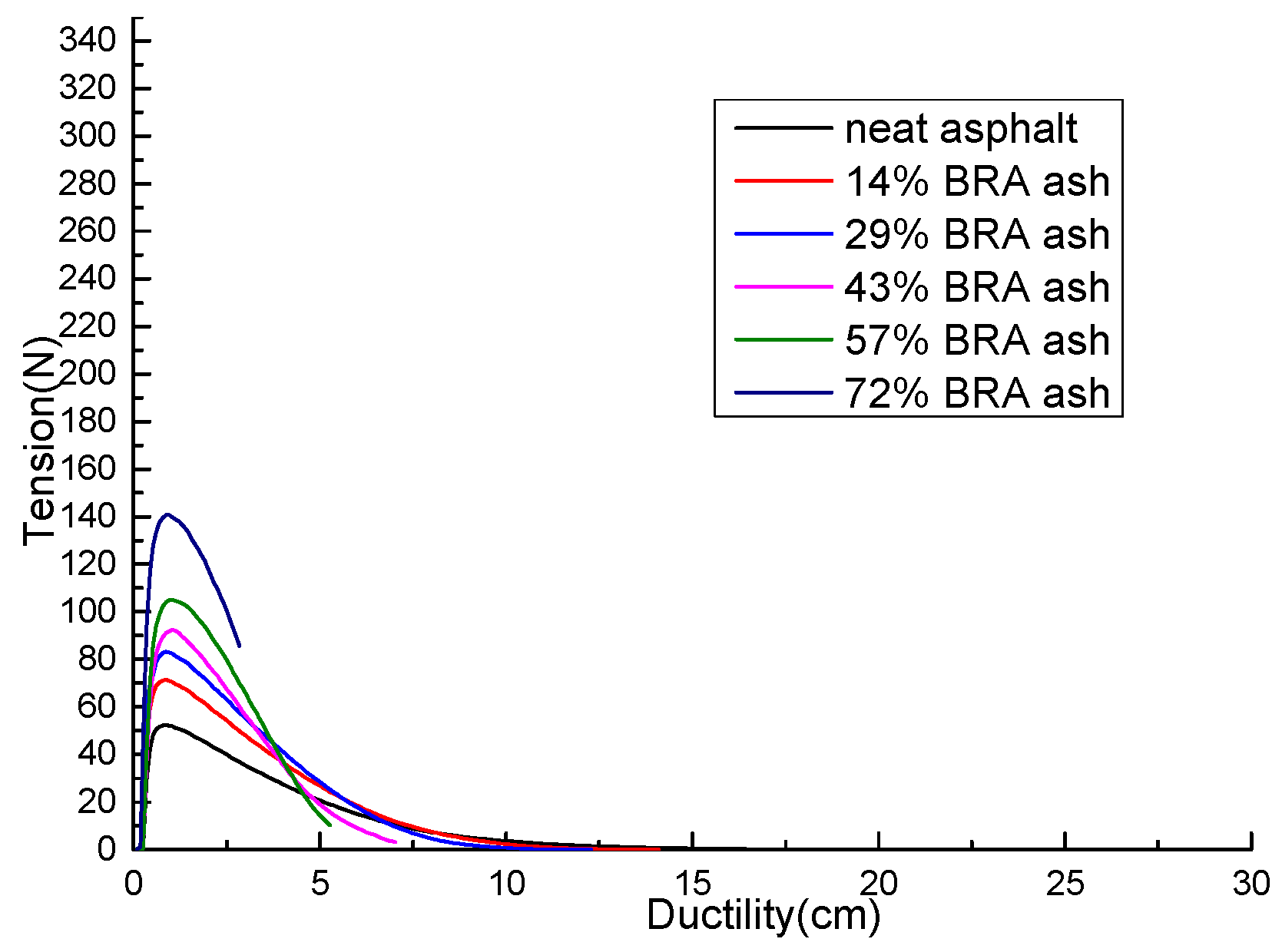

Figure 4.

Comparison between tensile force and ductility of asphalt mortar with different BRA ash content.

Figure 4.

Comparison between tensile force and ductility of asphalt mortar with different BRA ash content.

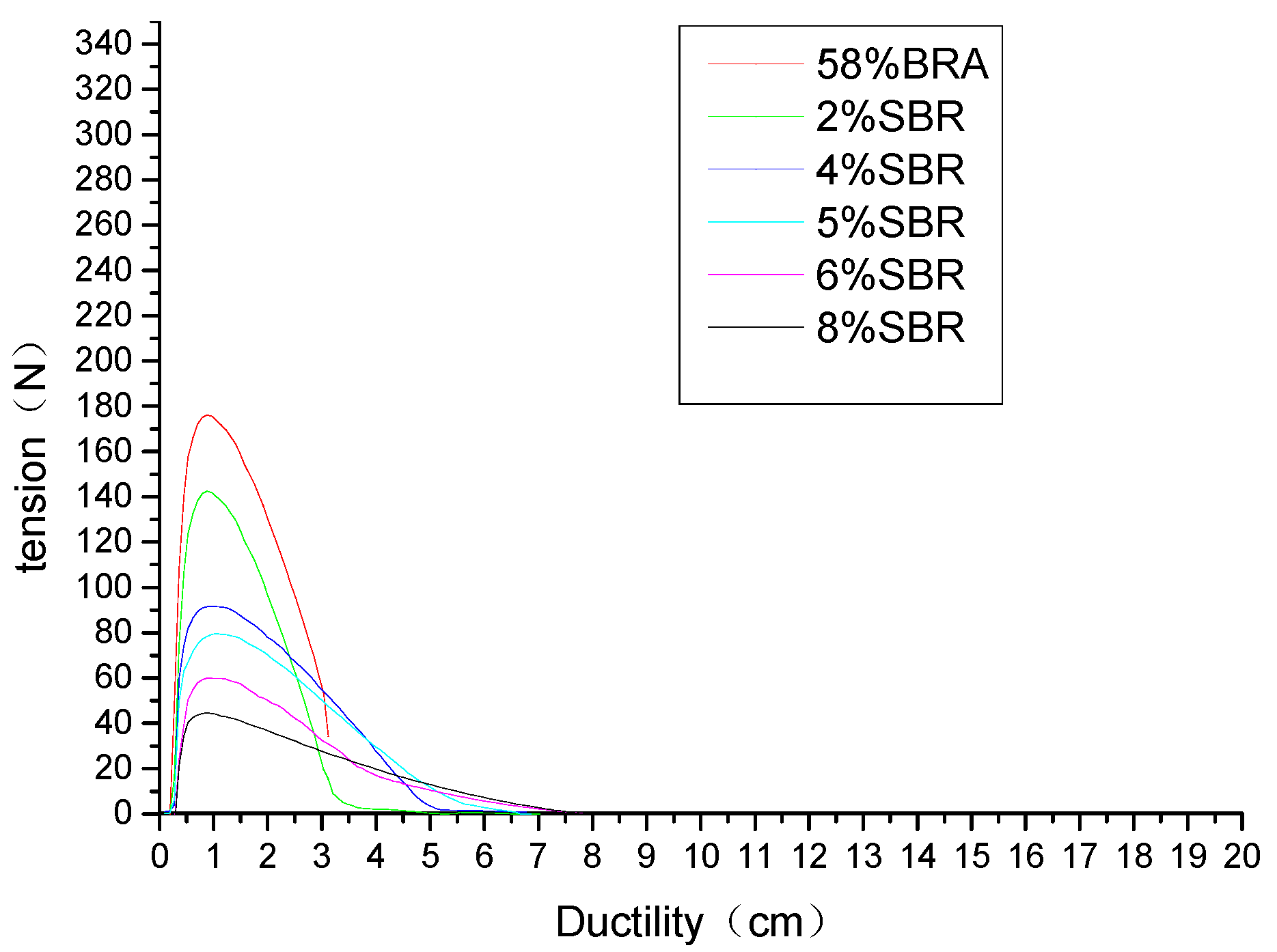

Figure 5.

Ductility test of BRA–SBR composite modified asphalt.

Figure 5.

Ductility test of BRA–SBR composite modified asphalt.

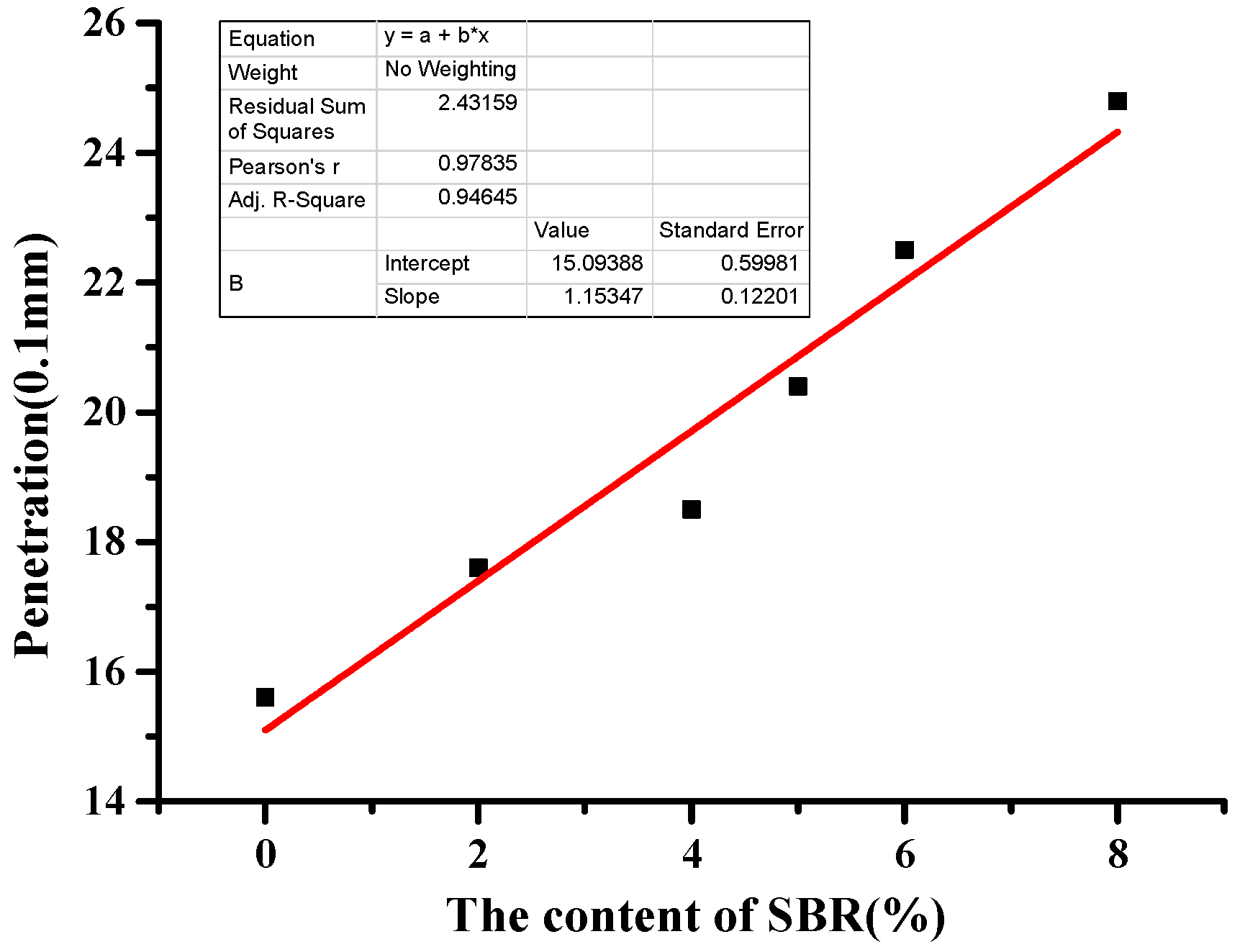

Figure 6.

Fitting curves of SBR content and penetration.

Figure 6.

Fitting curves of SBR content and penetration.

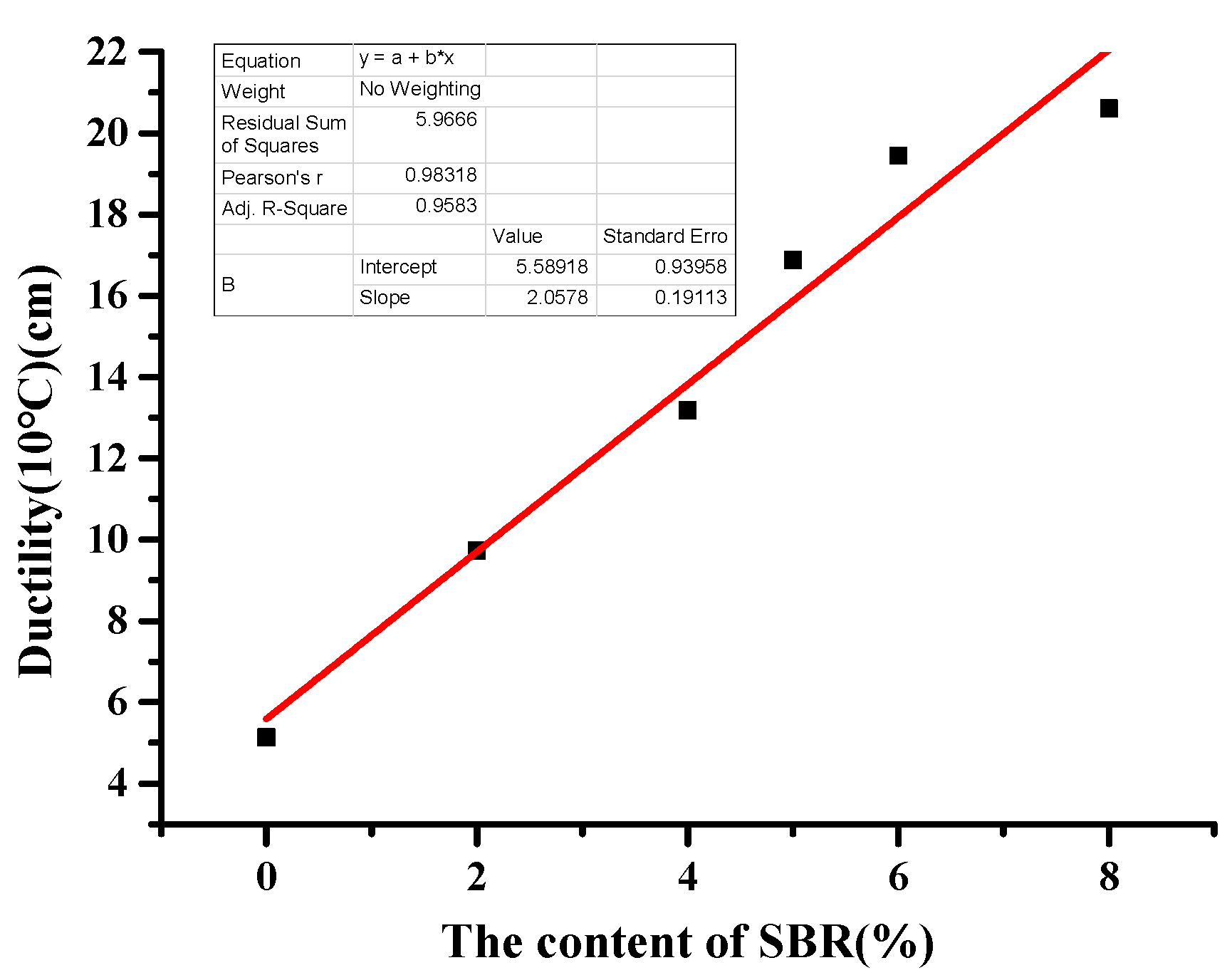

Figure 7.

Fitting curves of SBR content and ductility.

Figure 7.

Fitting curves of SBR content and ductility.

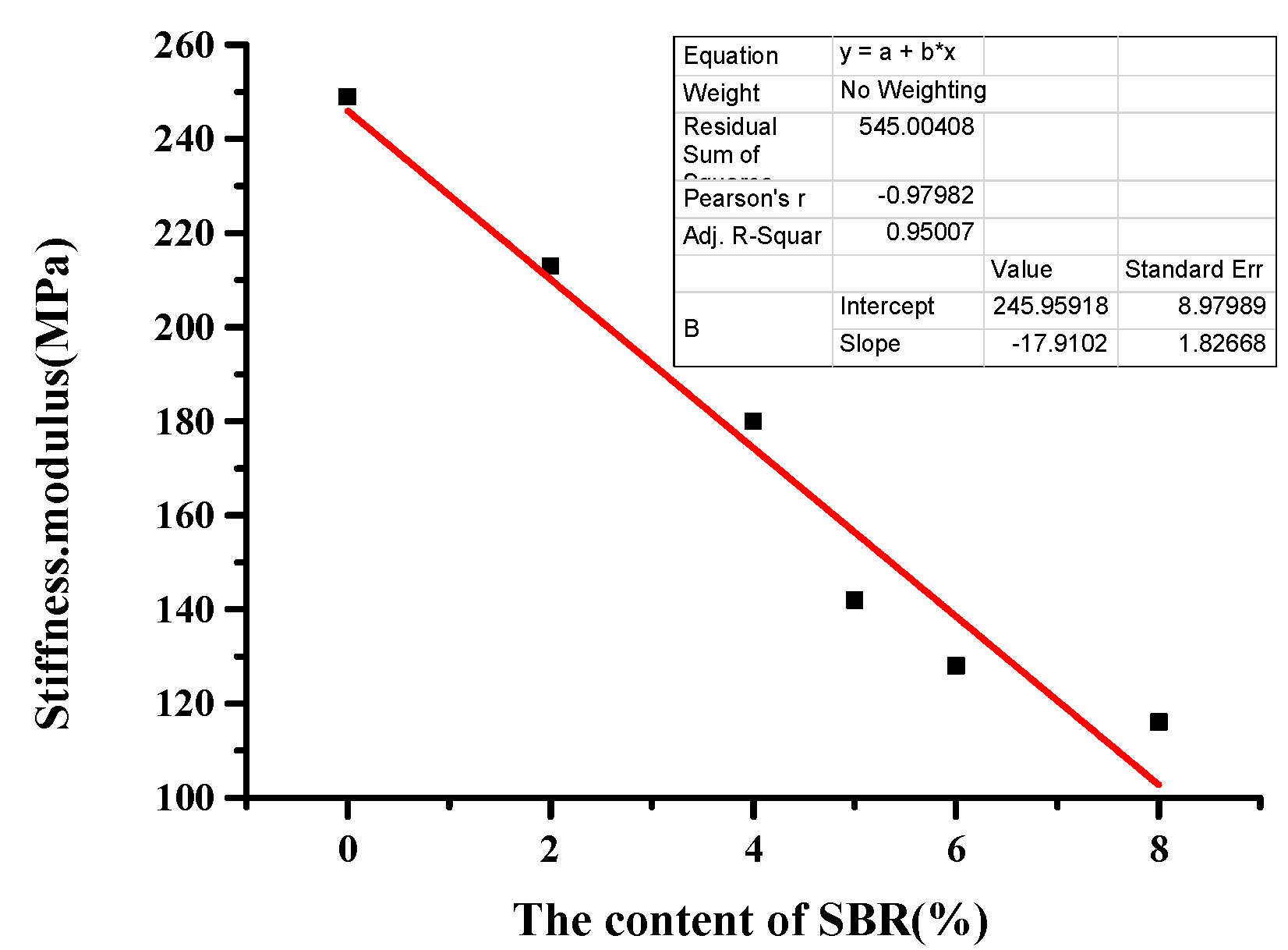

Figure 8.

Fitting curves of SBR content and stiffness modulus.

Figure 8.

Fitting curves of SBR content and stiffness modulus.

Figure 9.

Fitting curves of SBR content and equivalent brittle point.

Figure 9.

Fitting curves of SBR content and equivalent brittle point.

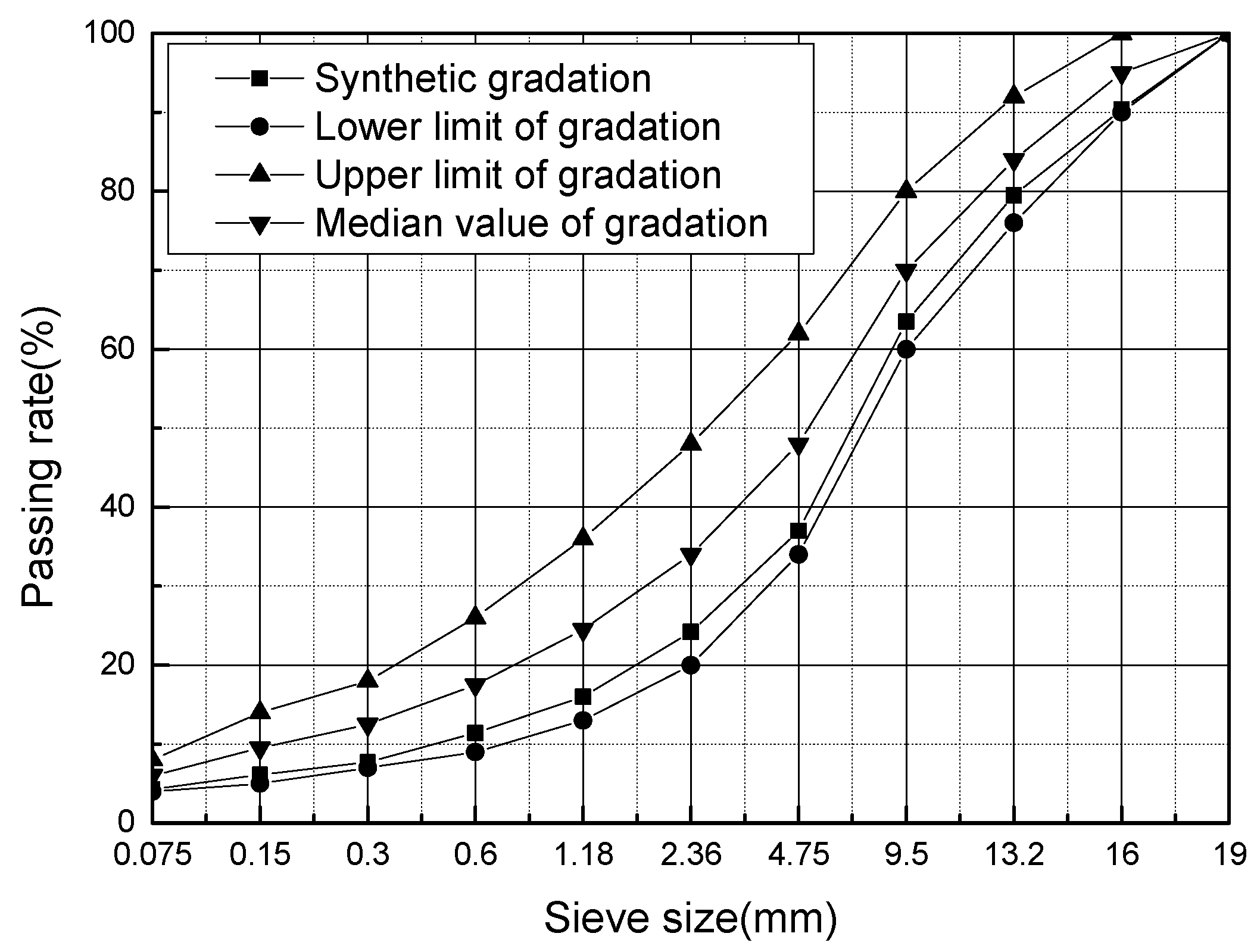

Figure 10.

The aggregate gradation of AC-16C.

Figure 10.

The aggregate gradation of AC-16C.

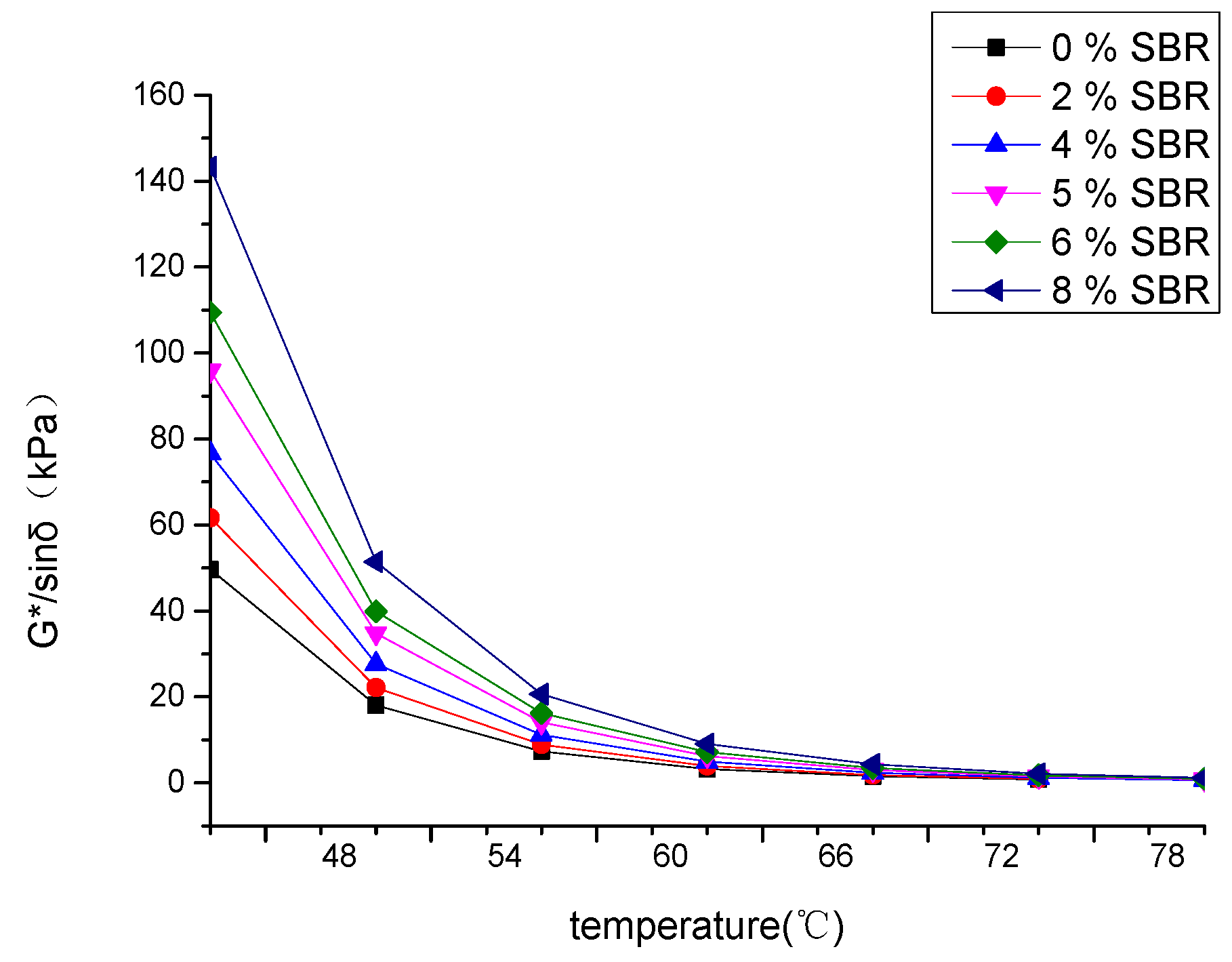

Figure 11.

Rutting factor G*/sinδ with different temperatures.

Figure 11.

Rutting factor G*/sinδ with different temperatures.

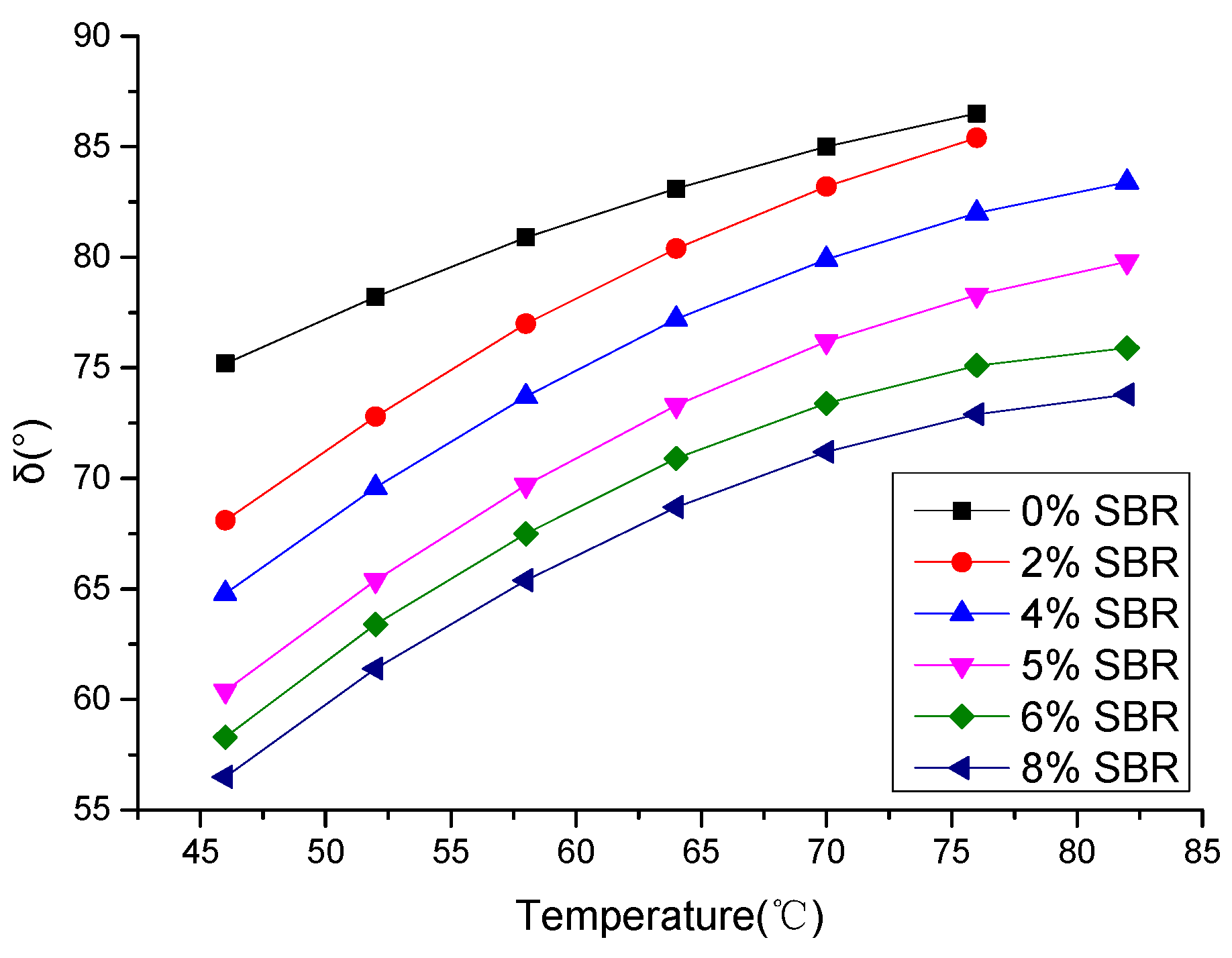

Figure 12.

Phase angle δ with different temperatures.

Figure 12.

Phase angle δ with different temperatures.

Table 1.

Technical properties of 70# neat asphalt.

Table 1.

Technical properties of 70# neat asphalt.

| Technical Indicators | Industry Standard | Test Results |

|---|

| Penetration (25 °C,100 g, 5 s) (0.1 mm) | 60–80 | 68.2 |

| Ductility (5 cm/min, 15 °C) (cm) | ≥100 | >100 |

| Softening point (°C) | ≥46 | 49.1 |

| Density (15 °C) (g/cm−3) | - | 1.03 |

Table 2.

Main technical indexes of Buton rock asphalt.

Table 2.

Main technical indexes of Buton rock asphalt.

| Technical Indicators | Industry Standard | Test Results |

|---|

| Appearance | Brown Powder | Brown Powder |

|---|

| Ash content (%) | <75 | 74.14 |

| Solubility (%) | >25 | 25.86 |

| Water content (%) | <2 | 0.97 |

| Particle size range (%) | 4.75 mm | 100 | 100 |

| 2.36 mm | 90–100 | 100 |

| 0.6 mm | 10–60 | 100 |

Table 3.

Technical performance of styrene-butadiene rubber (SBR) latex.

Table 3.

Technical performance of styrene-butadiene rubber (SBR) latex.

| Property | Test Result | Specification of Experimental Methods |

|---|

| Appearance | White Latex | - |

| Molecular weight | 50,000 | GB/T12005.10-1992 |

| Mooney viscosity (mPa·s) | 4000 | GB/T1231.1 |

Table 4.

Buton rock asphalt (BRA) and BRA ash content comparison table.

Table 4.

Buton rock asphalt (BRA) and BRA ash content comparison table.

| BRA Content | BRA Ash Content |

|---|

| 0.19 | 0.14 |

| 0.39 | 0.29 |

| 0.58 | 0.43 |

| 0.77 | 0.57 |

| 0.97 | 0.72 |

Table 5.

Test conditions of low-temperature creep bending test.

Table 5.

Test conditions of low-temperature creep bending test.

| Test Conditions | Specimen Size | Temperature | Loading Frequency |

| 250 mm × 30 mm × 35 mm | −10 °C | 50 mm/min |

Table 6.

Test results of BRA-modified asphalt.

Table 6.

Test results of BRA-modified asphalt.

| Property | Unit | BRA (%) |

|---|

| 0 | 19 | 39 | 58 | 77 | 97 |

|---|

| Penetration | 15 °C | 0.1 mm | 25.1 | 20.5 | 18.7 | 15.6 | 13.7 | 11.2 |

| 25 °C | 68.2 | 53.7 | 46.9 | 39.0 | 33.9 | 28.2 |

| 30 °C | 114.4 | 87.5 | 79.4 | 64.5 | 54.5 | 41.1 |

| PI | | −0.602 | −0.321 | −0.258 | −0.149 | 0.019 | 0.346 |

| T1.2 | °C | −15.09 | −14.34 | −13.58 | −12.16 | −11.48 | −10.67 |

Table 7.

Penetration test results of the BRA ash asphalt mortar.

Table 7.

Penetration test results of the BRA ash asphalt mortar.

| Property | Unit | The Content of BRA Ash (%) |

|---|

| 0 | 14 | 29 | 43 | 57 | 72 |

|---|

| Penetration | 15 °C | 0.1 mm | 25.1 | 23.9 | 21.7 | 19.8 | 18.2 | 16.8 |

| 25 °C | 68.2 | 63.9 | 58.2 | 51.5 | 46.8 | 40.8 |

| 30 °C | 114.4 | 107.5 | 96.2 | 85.3 | 77.3 | 70.4 |

| PI | | −0.602 | −0.539 | −0.488 | −0.35 | −0.284 | −0.174 |

| T1.2 | °C | −15.09 | −14.88 | −14.17 | −13.83 | −13.24 | −12.76 |

Table 8.

Percentage of penetration of different components in BRA.

Table 8.

Percentage of penetration of different components in BRA.

| BRA Content (%) | BRA Ash Content (%) | Penetration (15 °C) | The Proportion of Ash and Pure Asphalt in the Difference between the Penetration of BRA Modified Asphalt and Neat Asphalt |

|---|

| BRA Modified Asphalt | BRA Ash Asphalt Mortar | Ash (%) | Pure Asphalt (%) |

|---|

| 0 | 0 | 25.1 | 25.1 | 0 | 0 |

| 19 | 14 | 20.5 | 22.5 | 57 | 43 |

| 39 | 29 | 18.7 | 21.7 | 53 | 47 |

| 58 | 43 | 15.6 | 19.8 | 56 | 44 |

| 77 | 57 | 13.7 | 18.2 | 61 | 39 |

| 97 | 72 | 11.2 | 16.8 | 60 | 40 |

Table 9.

Percentage of equivalent brittle point of different components in BRA.

Table 9.

Percentage of equivalent brittle point of different components in BRA.

| BRA Content (%) | BRA Ash Content (%) | T1.2 (°C) | The Proportion of Ash and Pure Asphalt in the Difference between the Equivalent Brittle Point of BRA Modified Asphalt and Neat Asphalt |

|---|

| BRA Modified Asphalt | BRA Ash Asphalt Mortar | Ash (%) | Pure Asphalt (%) |

|---|

| 0 | 0 | −15.09 | −15.09 | 0 | 0 |

| 19 | 14 | −14.34 | −14.88 | 28 | 72 |

| 39 | 29 | −13.58 | −14.57 | 66 | 34 |

| 58 | 43 | −12.16 | −13.83 | 43 | 57 |

| 77 | 57 | −11.48 | −13.64 | 40 | 60 |

| 97 | 72 | −10.67 | −12.98 | 48 | 52 |

Table 10.

Penetration of BRA-SBR composite modified asphalt.

Table 10.

Penetration of BRA-SBR composite modified asphalt.

| Property | Unit | The Content of SBR (%) (The Content of BRA is 58%) |

|---|

| 0 | 2 | 4 | 5 | 6 | 8 |

|---|

| Penetration | 15 °C | 0.1 mm | 15.6 | 17.6 | 18.5 | 20.4 | 22.5 | 24.8 |

| 25 °C | 39 | 41.4 | 43.4 | 48 | 57.5 | 63.8 |

| 30 °C | 64.5 | 69.1 | 71.9 | 79 | 84.3 | 89.3 |

| PI | | −0.149 | 0.127 | 0.173 | 0.185 | 0.239 | 0.406 |

| T1.2 | °C | −12.16 | −14.58 | −15.35 | −16.51 | −18.12 | −20.15 |

Table 11.

Force ductility test result of BRA-modified asphalt.

Table 11.

Force ductility test result of BRA-modified asphalt.

| BRA Content (%) | Ductility (cm) | FMax (N) | Compliance in Extension | A (J) |

|---|

| 0 | 24.34 | 52.48 | 0.464 | 1265.708 |

| 19 | 7.05 | 84.56 | 0.083 | 269.8131 |

| 39 | 6.51 | 105.74 | 0.062 | 247.9926 |

| 58 | 5.14 | 119.96 | 0.043 | 170.0564 |

| 77 | 3.07 | 177.5 | 0.017 | 73.96904 |

| 97 | 0.60 | 298.56 | 0.002 | 1.63564 |

Table 12.

Force ductility test result of BRA ash asphalt mortar.

Table 12.

Force ductility test result of BRA ash asphalt mortar.

| BRA Ash Content (%) | Ductility (cm) | FMax (N) | Compliance in Extension | A (J) |

|---|

| 0 | 24.34 | 52.48 | 0.464 | 1265.708 |

| 14 | 14.09 | 71.36 | 0.197 | 685.8082 |

| 29 | 12.28 | 83.3 | 0.147 | 553.6637 |

| 43 | 7.02 | 92.42 | 0.076 | 263.8006 |

| 57 | 5.28 | 105.12 | 0.05 | 185.625 |

| 72 | 2.85 | 140.8 | 0.02 | 73.196 |

Table 13.

Percentage of ductility of different components in BRA.

Table 13.

Percentage of ductility of different components in BRA.

| BRA Content (%) | BRA Ash Content (%) | Ductility (cm) | The Proportion of Ash and Pure Asphalt in the Difference between the Ductility of BRA Modified Asphalt and Neat Asphalt |

|---|

| BRA Modified Asphalt | BRA Ash Asphalt Mortar | Ash (%) | Pure Asphalt (%) |

|---|

| 0 | 0 | 24.34 | 24.34 | 0 | 0 |

| 19 | 14 | 7.05 | 14.09 | 59 | 41 |

| 39 | 29 | 6.51 | 12.28 | 68 | 32 |

| 58 | 43 | 5.14 | 7.02 | 90 | 10 |

| 77 | 57 | 3.07 | 5.28 | 90 | 10 |

| 97 | 72 | 0.60 | 2.85 | 91 | 9 |

Table 14.

Results of 10 °C ductility test of BRA-SBR composite modified asphalt.

Table 14.

Results of 10 °C ductility test of BRA-SBR composite modified asphalt.

| SBR Content (%) | Ductility (cm) | FMax (N) | Compliance in Extension | A (J) |

|---|

| 0 | 5.14 | 119.96 | 0.043 | 170.0564 |

| 2 | 9.73 | 97.48 | 0.100 | 212.8536 |

| 4 | 13.18 | 84.98 | 0.155 | 258.7621 |

| 5 | 16.87 | 76.35 | 0.221 | 325.4685 |

| 6 | 19.45 | 65.12 | 0.299 | 512.5346 |

| 8 | 20.61 | 58.32 | 0.353 | 623.851 |

Table 15.

Beam bending rheometer (BBR) test results of BRA-modified asphalt.

Table 15.

Beam bending rheometer (BBR) test results of BRA-modified asphalt.

| T (°C) | Test Results | Amount of BRA (%) |

|---|

| 0 | 19 | 39 | 58 | 77 | 97 |

|---|

| −6 | S (MPa) | 74.9 | 115 | 186 | 249 | 328 | 437 |

| m | 0.497 | 0.439 | 0.346 | 0.301 | 0.245 | 0.215 |

| −12 | S (MPa) | 161 | 270 | 406 | 522 | 663 | 885 |

| m | 0.427 | 0.379 | 0.284 | 0.253 | 0.215 | 0.204 |

Table 16.

BBR test results of BRA ash asphalt mortar.

Table 16.

BBR test results of BRA ash asphalt mortar.

| T (°C) | Test Results | Amount of BRA Ash (%) |

|---|

| 0 | 14 | 29 | 43 | 57 | 72 |

|---|

| −6 | S (MPa) | 74.9 | 94.2 | 141 | 179 | 208 | 264 |

| m | 0.497 | 0.461 | 0.388 | 0.346 | 0.340 | 0.316 |

| −12 | S (MPa) | 161 | 208 | 266 | 347 | 485 | 637 |

| m | 0.427 | 0.404 | 0.356 | 0.306 | 0.278 | 0.258 |

Table 17.

Percentage of stiffness modulus of different components in BRA at −6 °C.

Table 17.

Percentage of stiffness modulus of different components in BRA at −6 °C.

| BRA Content (%) | BRA Ash Content (%) | Creep Rate | The Proportion of Ash and Pure Asphalt in the Difference between the Stiffness Modulus of BRA Modified Asphalt and Neat Asphalt |

|---|

| BRA Modified Asphalt | BRA Ash Asphalt Mortar | Ash (%) | Pure Asphalt (%) |

|---|

| 0 | 0 | 0.497 | 0.497 | 0 | 0 |

| 19 | 14 | 0.439 | 0.461 | 62 | 38 |

| 39 | 29 | 0.346 | 0.388 | 72 | 28 |

| 58 | 43 | 0.301 | 0.346 | 77 | 23 |

| 77 | 57 | 0.245 | 0.340 | 62 | 38 |

| 97 | 72 | 0.215 | 0.316 | 64 | 36 |

Table 18.

Percentage of stiffness modulus of different components in BRA at −12 °C.

Table 18.

Percentage of stiffness modulus of different components in BRA at −12 °C.

| BRA Content (%) | BRA Ash Content (%) | Creep Rate | The Proportion of Ash and Pure Asphalt in the Difference between the Stiffness Modulus of BRA Modified Asphalt and Neat Asphalt |

|---|

| BRA Modified Asphalt | BRA Ash Asphalt Mortar | Ash (%) | Pure Asphalt (%) |

|---|

| 0 | 0 | 0.427 | 0.427 | 0 | 0 |

| 19 | 14 | 0.329 | 0.404 | 23 | 77 |

| 39 | 29 | 0.284 | 0.356 | 50 | 50 |

| 58 | 43 | 0.253 | 0.306 | 70 | 30 |

| 77 | 57 | 0.215 | 0.278 | 70 | 30 |

| 97 | 72 | 0.204 | 0.258 | 76 | 23 |

Table 19.

BBR test results of BRA-SBR compound modified asphalt.

Table 19.

BBR test results of BRA-SBR compound modified asphalt.

| Amount of SBR (%) | 0 | 2 | 4 | 5 | 6 | 8 |

|---|

| S (MPa) | −6 °C | 249 | 213 | 180 | 142 | 128 | 116 |

| −12 °C | 522 | 436 | 376 | 297 | 265 | 247 |

| m | −6 °C | 0.301 | 0.327 | 0.344 | 0.367 | 0.388 | 0.409 |

| −12 °C | 0.253 | 0.265 | 0.290 | 0.327 | 0.333 | 0.346 |

| m/S (MP−1) | −6 | 0.001209 | 0.001535 | 0.001911 | 0.002585 | 0.003031 | 0.003526 |

| −12 | 0.000485 | 0.000608 | 0.000771 | 0.001101 | 0.001257 | 0.001401 |

Table 20.

Performance Index of BRA–SBR composite modified asphalt.

Table 20.

Performance Index of BRA–SBR composite modified asphalt.

| Type of Asphalt | Penetration 25 °C, 100 g, 5 s (0.1 mm) | Softening Point TR&B (°C) | Ductility 10 °C (cm) | Relative Density |

|---|

| neat asphalt | 68.2 | 49.1 | 24.34 | 1.029 |

| BRA modified asphalt | 39.0 | 61.4 | 5.14 | 1.045 |

| BRA-SBR compound modified asphalt | 48.0 | 63.2 | 16.87 | 1.036 |

Table 21.

Marshall test results at optimal asphalt content.

Table 21.

Marshall test results at optimal asphalt content.

| | Optimal Asphalt Content (%) | Bulk Specific Gravity (g·cm−3) | The Volume of Air Voids VV (%) | Voids Filled with Asphalt VFA (%) | Voids in Mineral Aggregate VMA/% | Marshall Stability (kN) | Flow Value (mm) |

|---|

| neat asphalt mixture | 5.2 | 2.469 | 4.3 | 69.3 | 14 | 16.21 | 3.2 |

| BRA modified asphalt mixture | 4.7% | 7.8 | 15.0 | 45.1 | 16.26 | 2.8 | 2.536 |

| BRA-SBR compound modified asphalt mixture | 4.7% | 6.5 | 13.7 | 52.8 | 16.63 | 3.1 | 2.401 |

Table 22.

Creep bending test results of BRA–SBR compound modified asphalt mixture.

Table 22.

Creep bending test results of BRA–SBR compound modified asphalt mixture.

| Property | Specimen | Flexural Tensile Strength (MPa) | Average Value (MPa) | Failure Strain (με) | Average Value (με) | Stiffness Modulus (MPa) |

|---|

| neat asphalt mixture | 1 | 7.12 | 7.27 | 2158 | 2164.3 | 3823.8 |

| 2 | 7.17 | 2238 |

| 3 | 7.51 | 2097 |

| BRA modified asphalt | 1 | 8.91 | 8.75 | 1544 | 1484.0 | 5898.5 |

| 2 | 8.52 | 1413 |

| 3 | 8.83 | 1495 |

| BRA-SBR compound modified asphalt mixture | 1 | 9.98 | 9.49 | 2675 | 2692.7 | 4014.6 |

Table 23.

Brookfield rotary viscosity of BRA-SBR compound modified asphalt (Pa·s).

Table 23.

Brookfield rotary viscosity of BRA-SBR compound modified asphalt (Pa·s).

| T/°C | Amount of SBR (%) | Neat Asphalt |

|---|

| 0 | 2 | 4 | 5 | 6 | 8 |

|---|

| 135 | 0.638 | 0.625 | 0.617 | 0.591 | 0.562 | 0.584 | 0.601 |

| 145 | 0.385 | 0.357 | 0.339 | 0.318 | 0.297 | 0.284 | 0.320 |

| 165 | 0.169 | 0.143 | 0.135 | 0.126 | 0.117 | 0.106 | 0.130 |

| 175 | 0.119 | 0.112 | 0.106 | 0.097 | 0.085 | 0.092 | 0.102 |