Effects of Dislocation Density Evolution on Mechanical Behavior of OFHC Copper during High-Speed Machining

Abstract

1. Introduction

2. Simulation and experimentation

2.1. Simulation

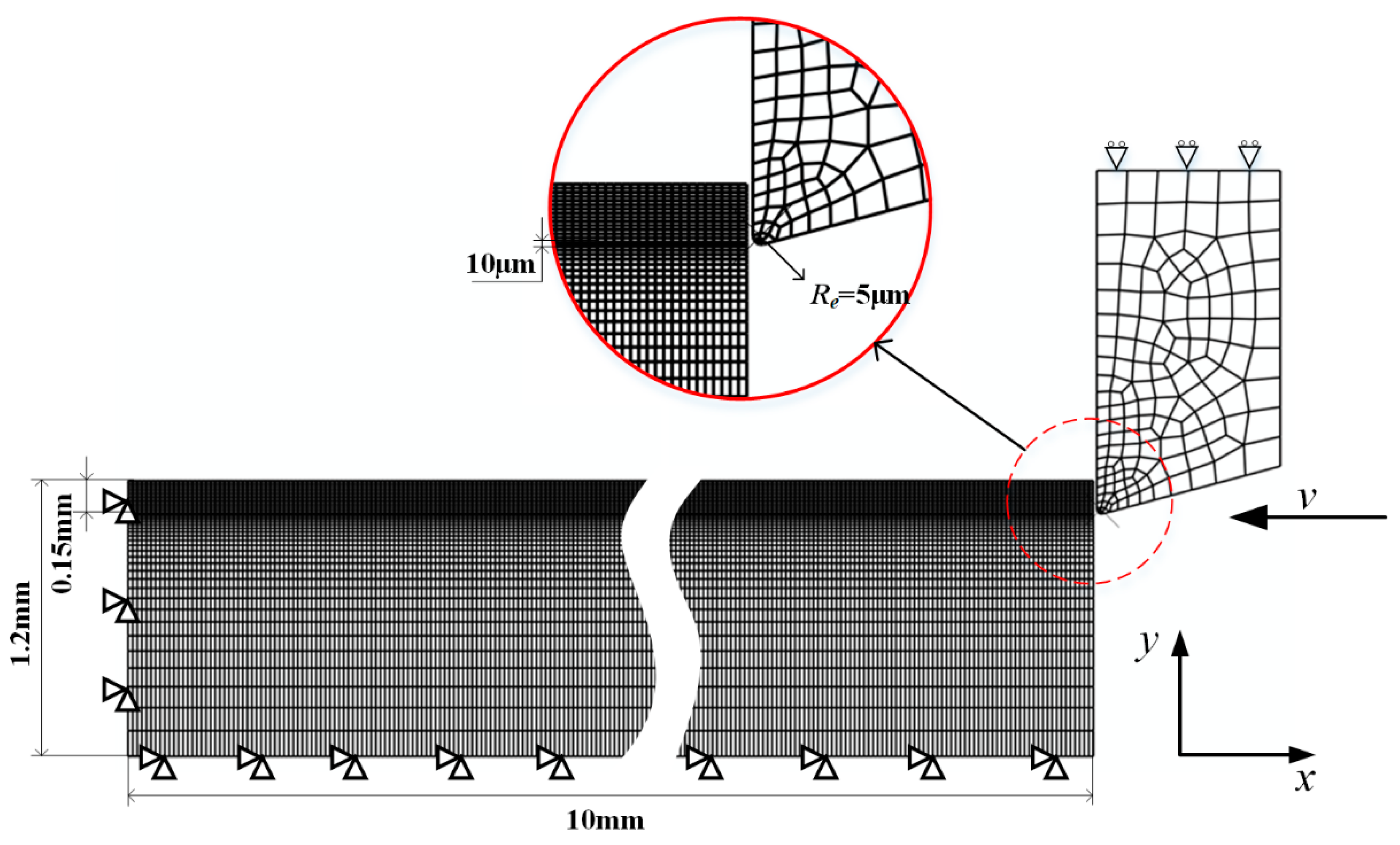

2.1.1. FEM Model Set-up

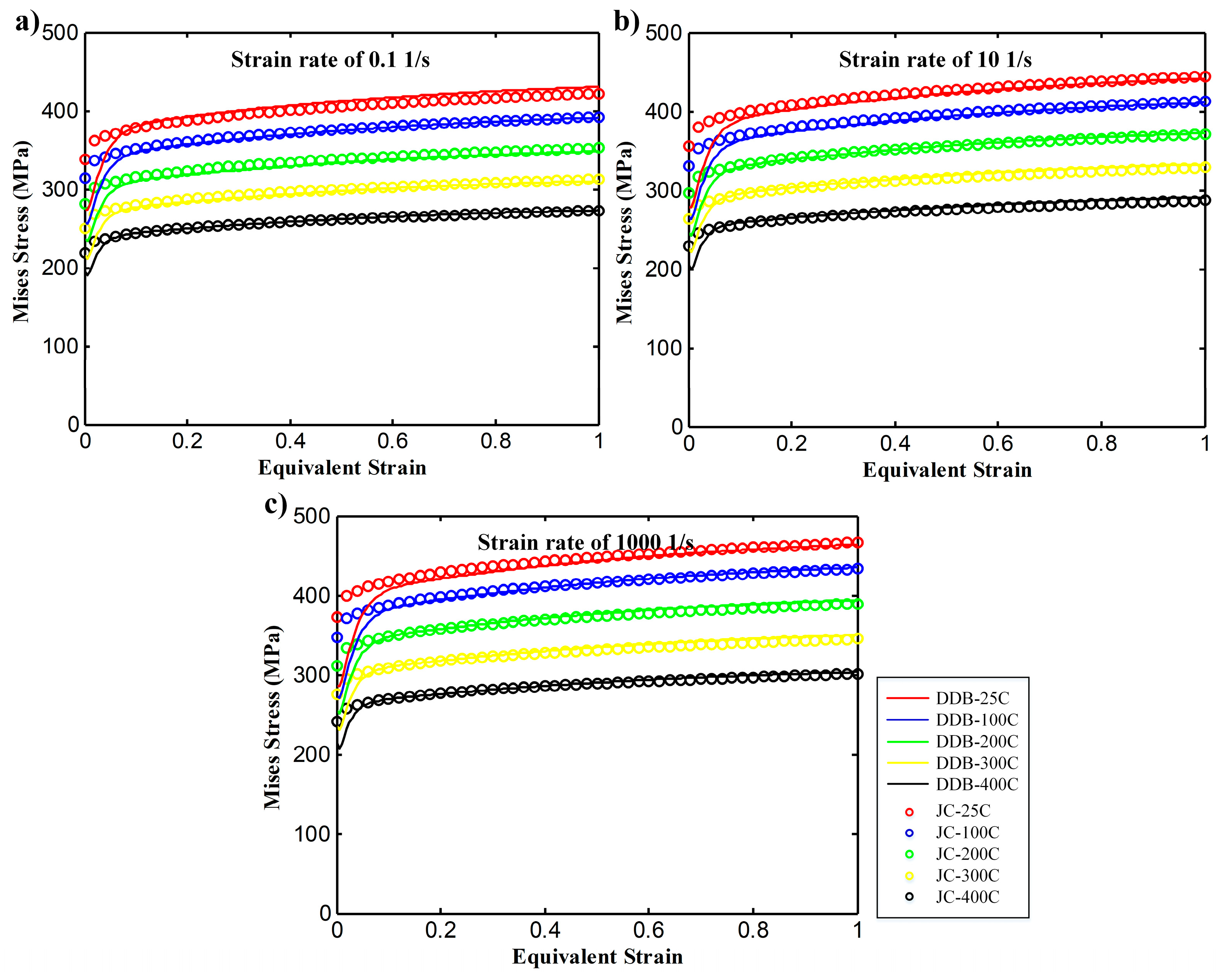

2.1.2. Constitutive Relationship

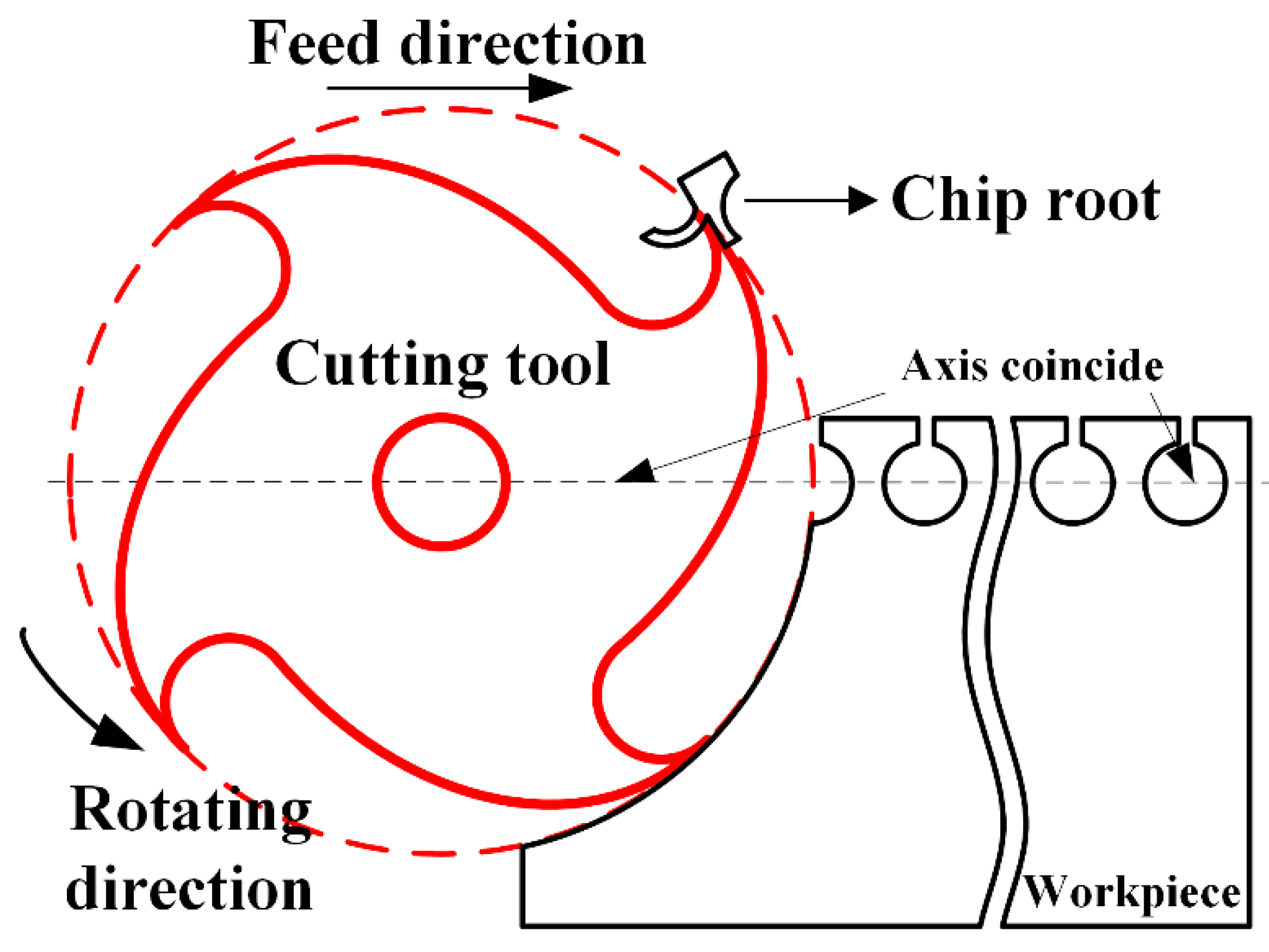

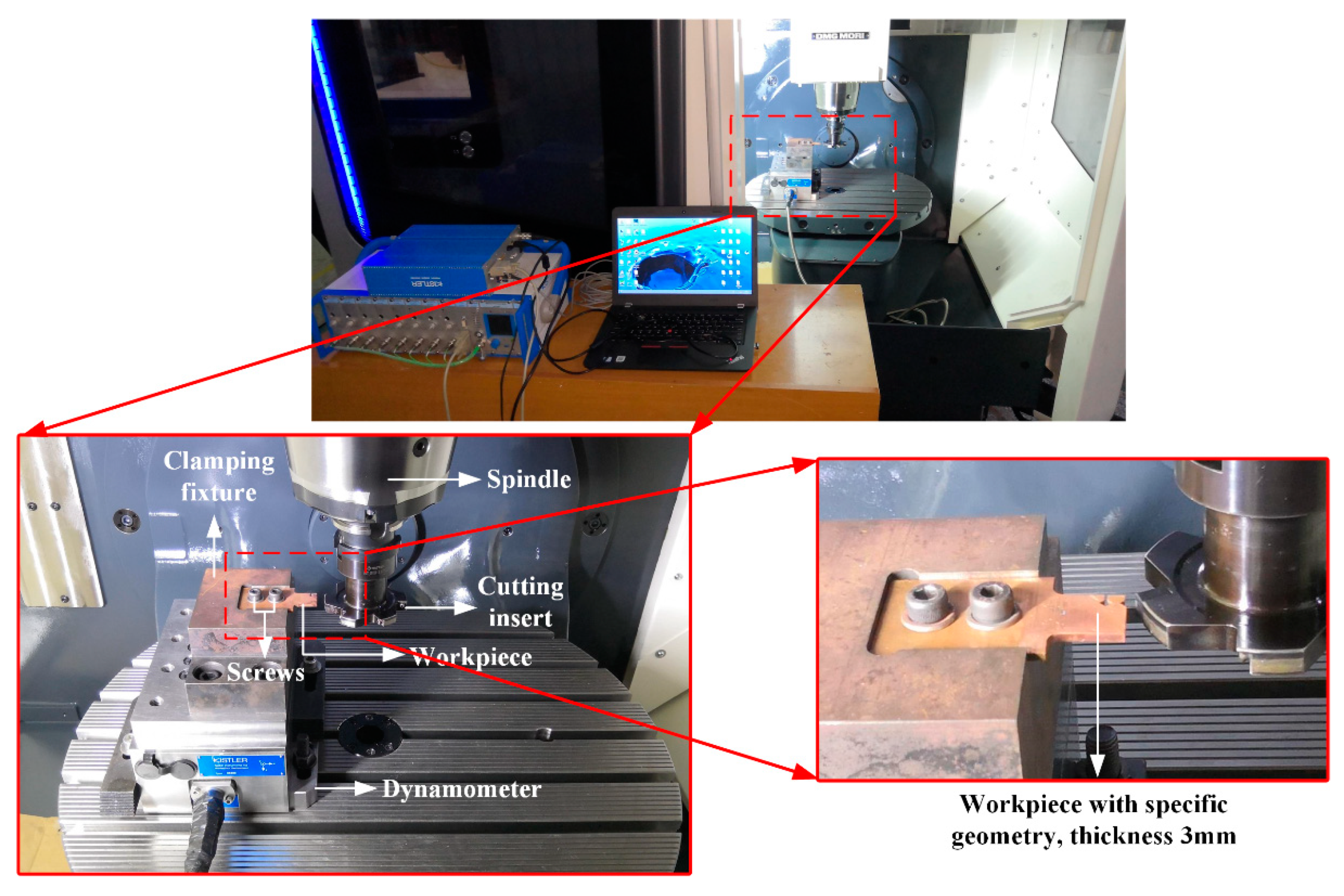

2.2. Experimentation

3. Results and Discussion

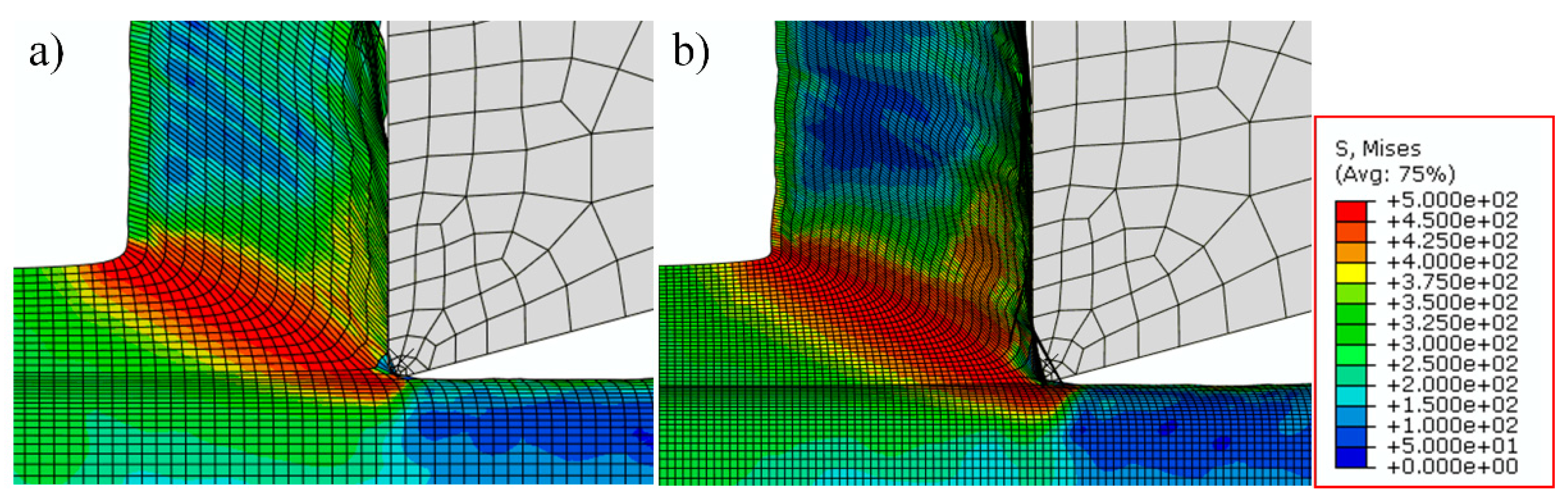

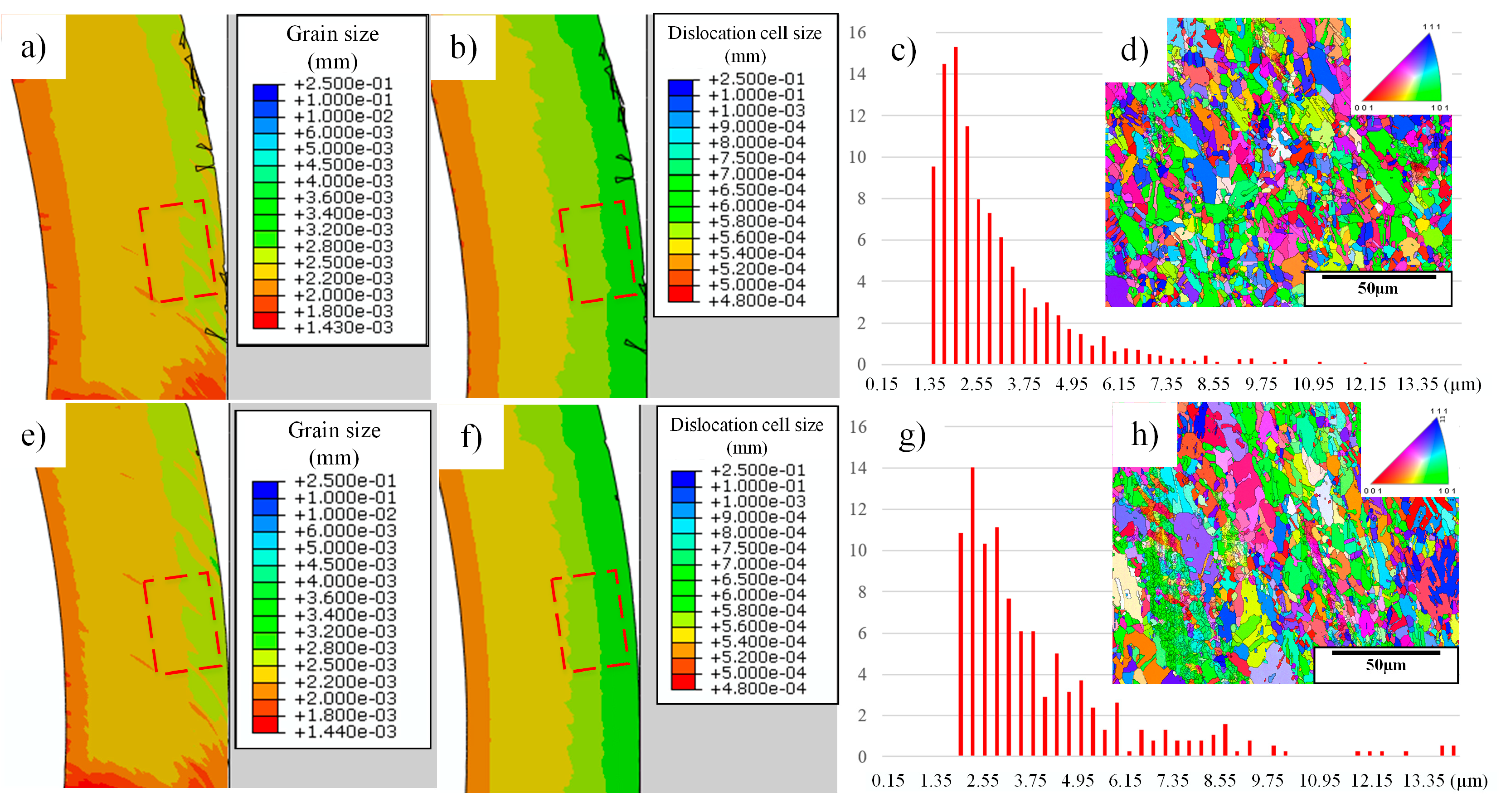

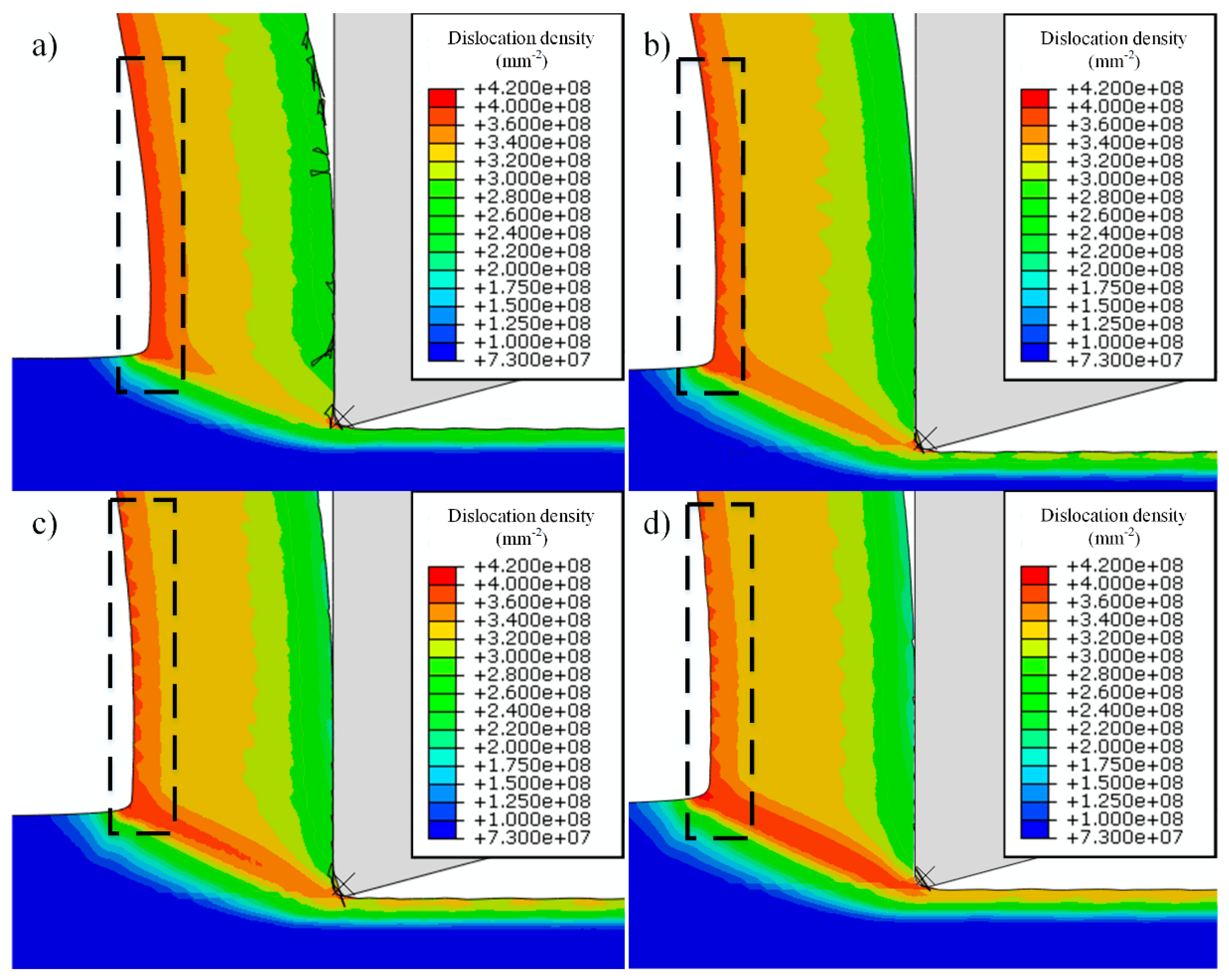

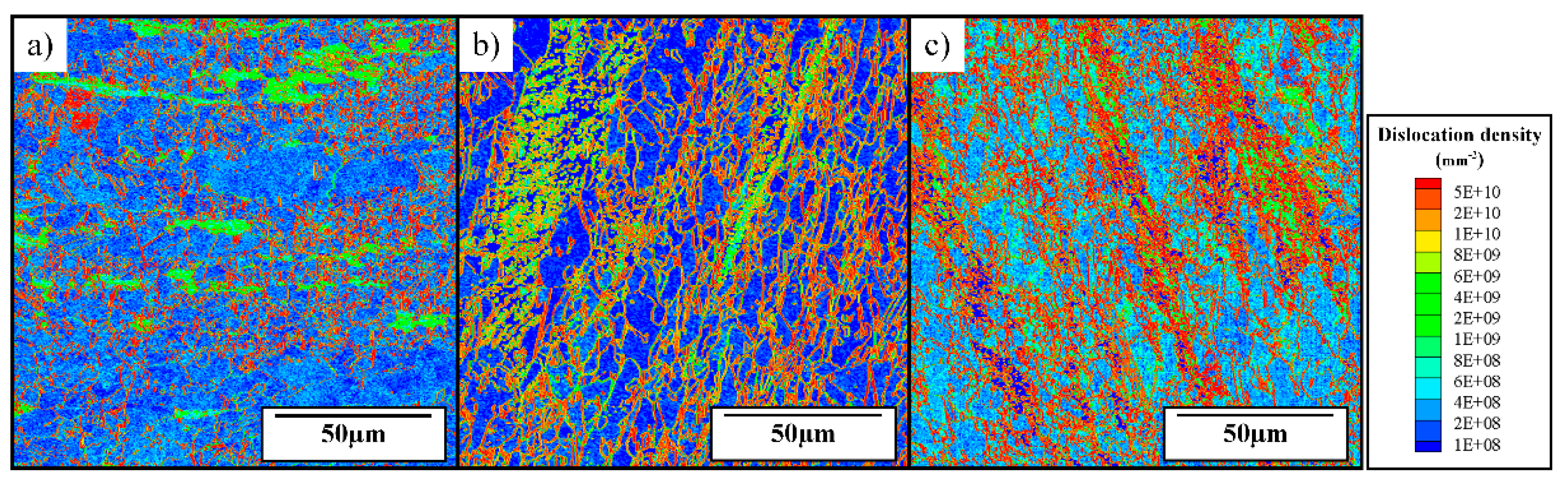

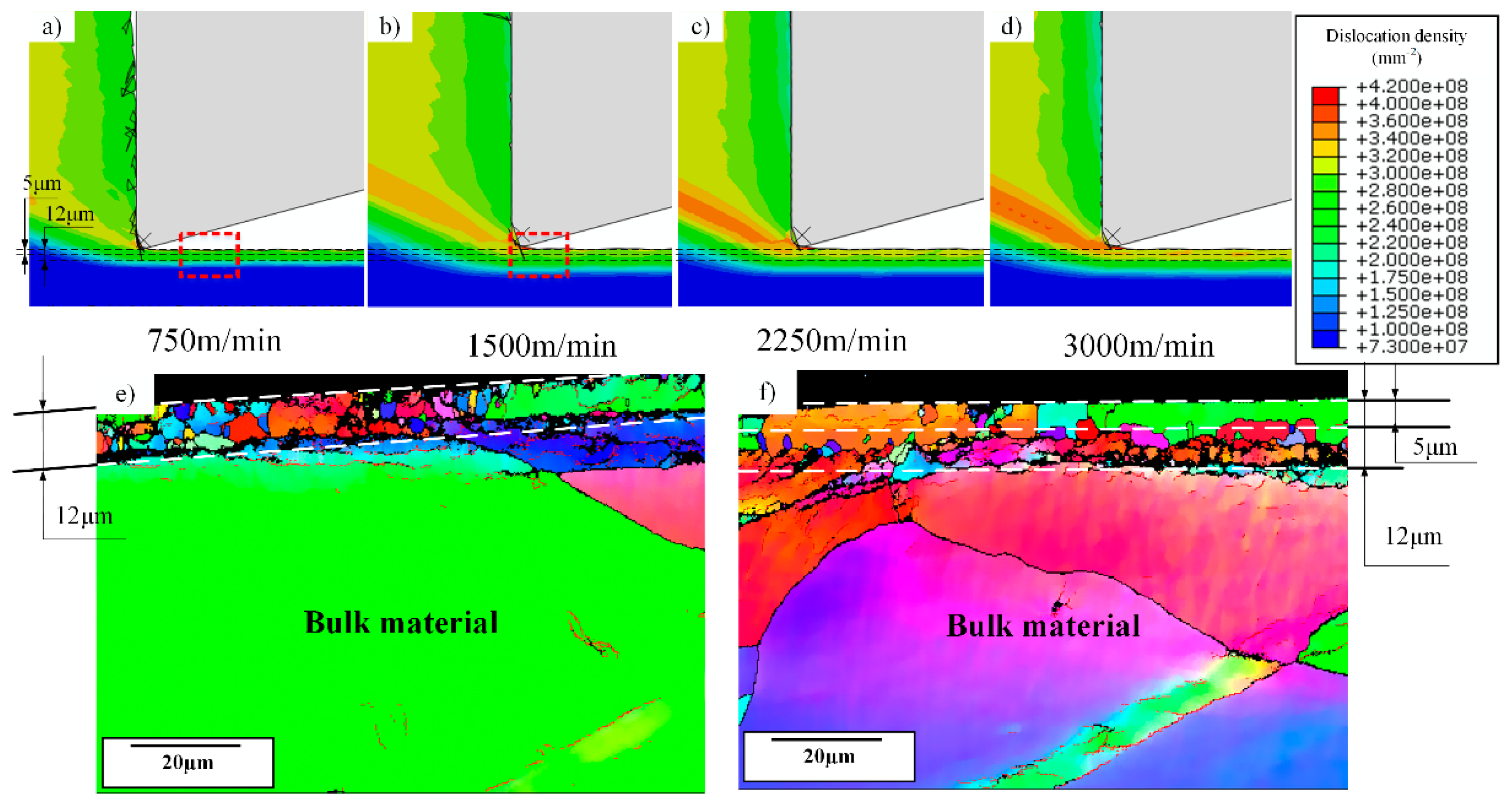

3.1. Dislocation Density-Related Microstructure Evolution under High-speed Cutting Conditions

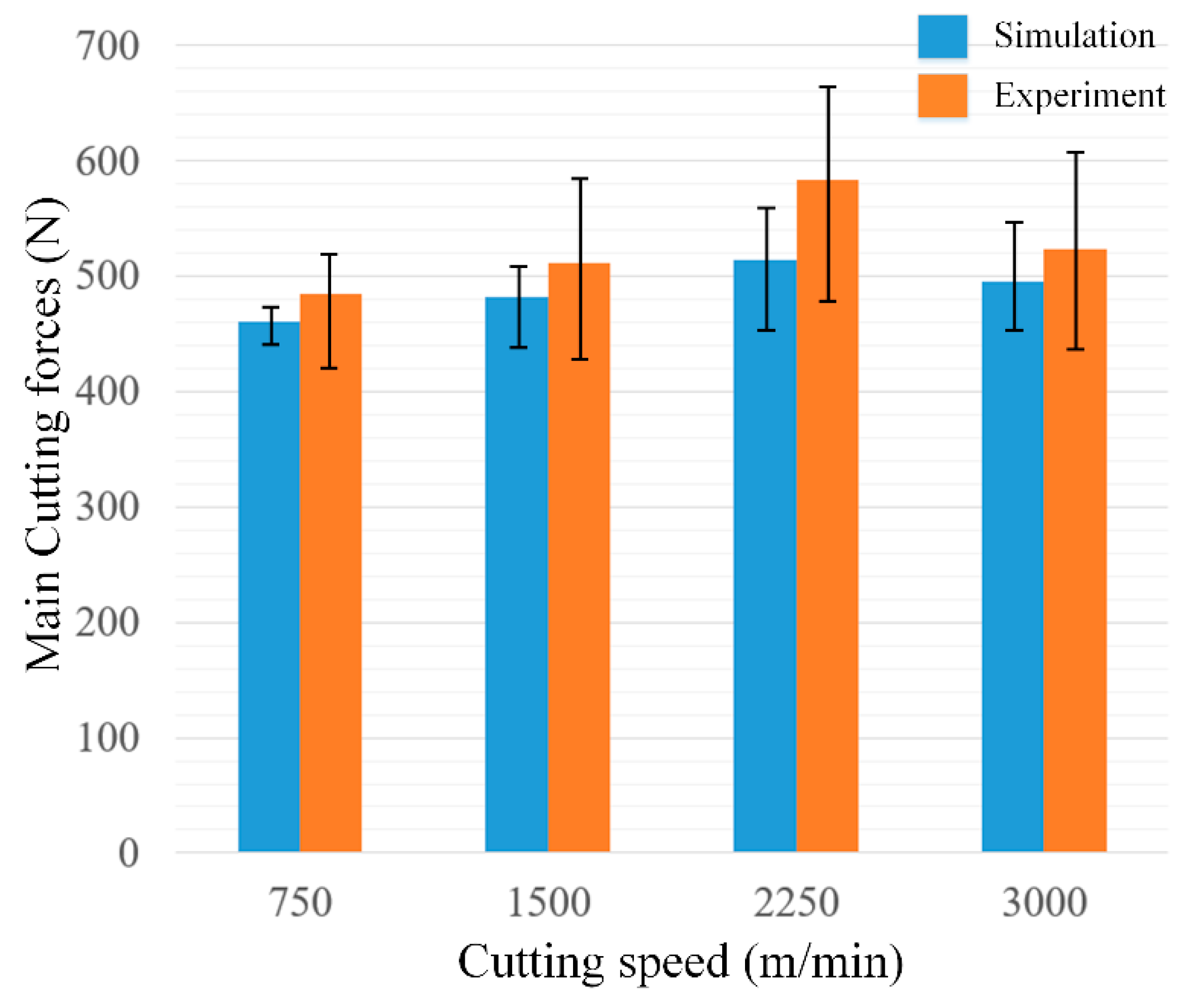

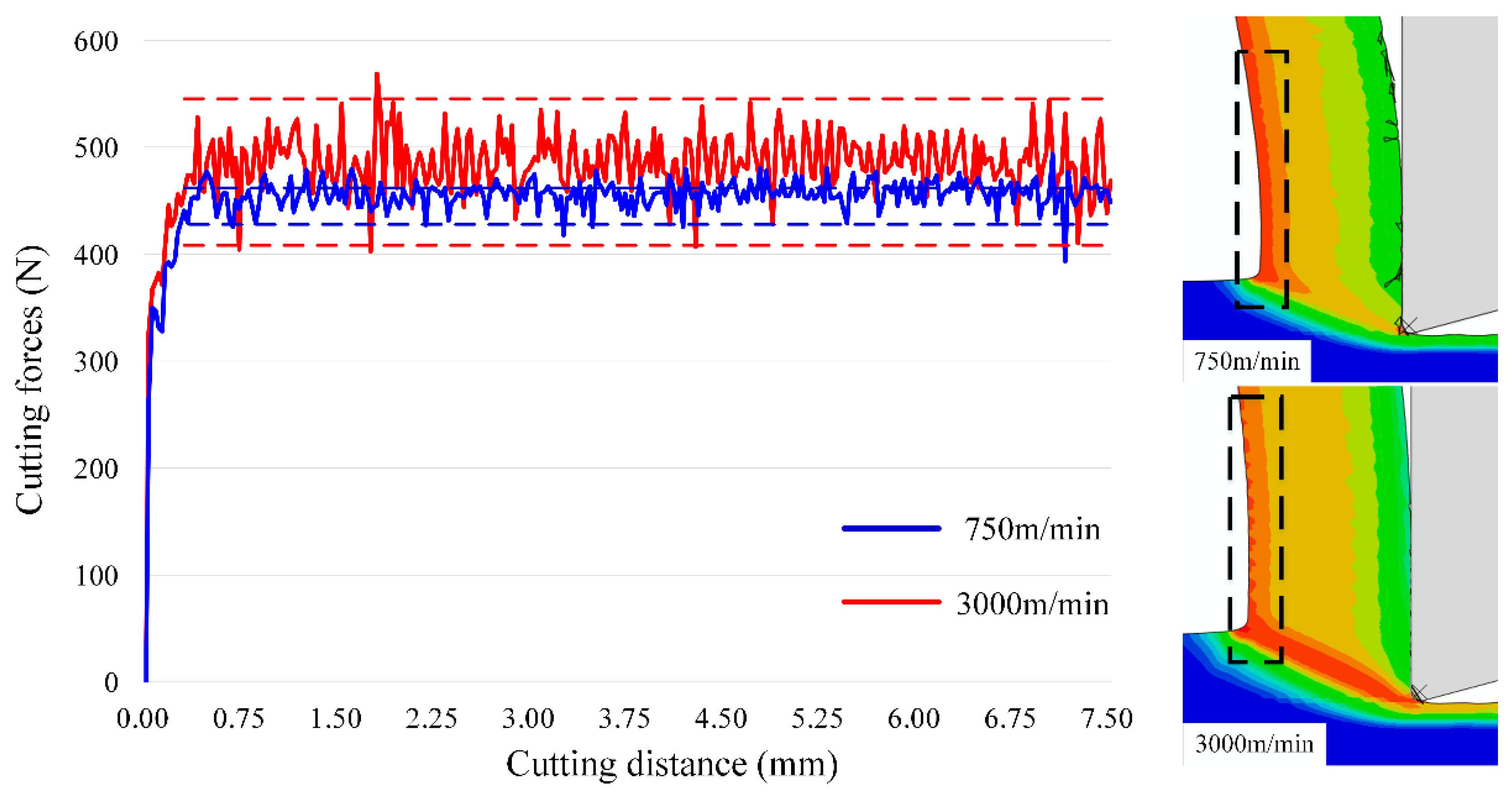

3.2. Dislocation Density Evolution-Induced Fluctuation of Cutting Forces

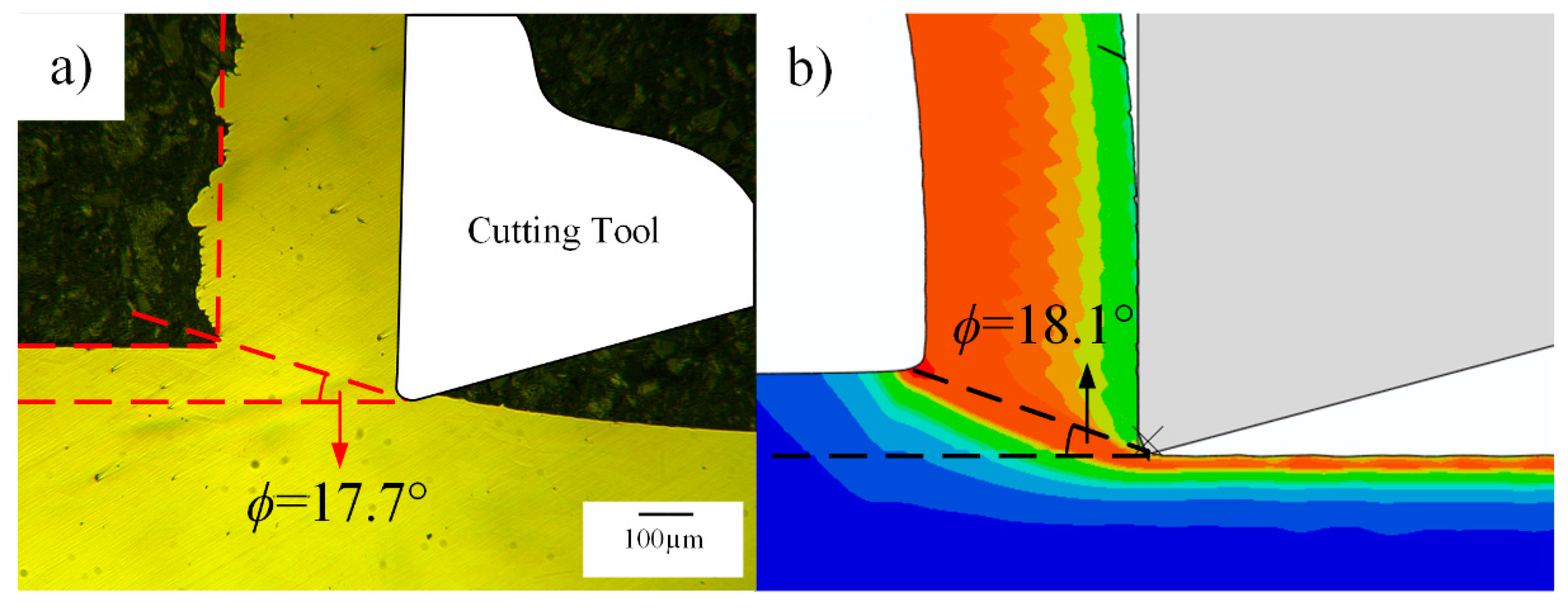

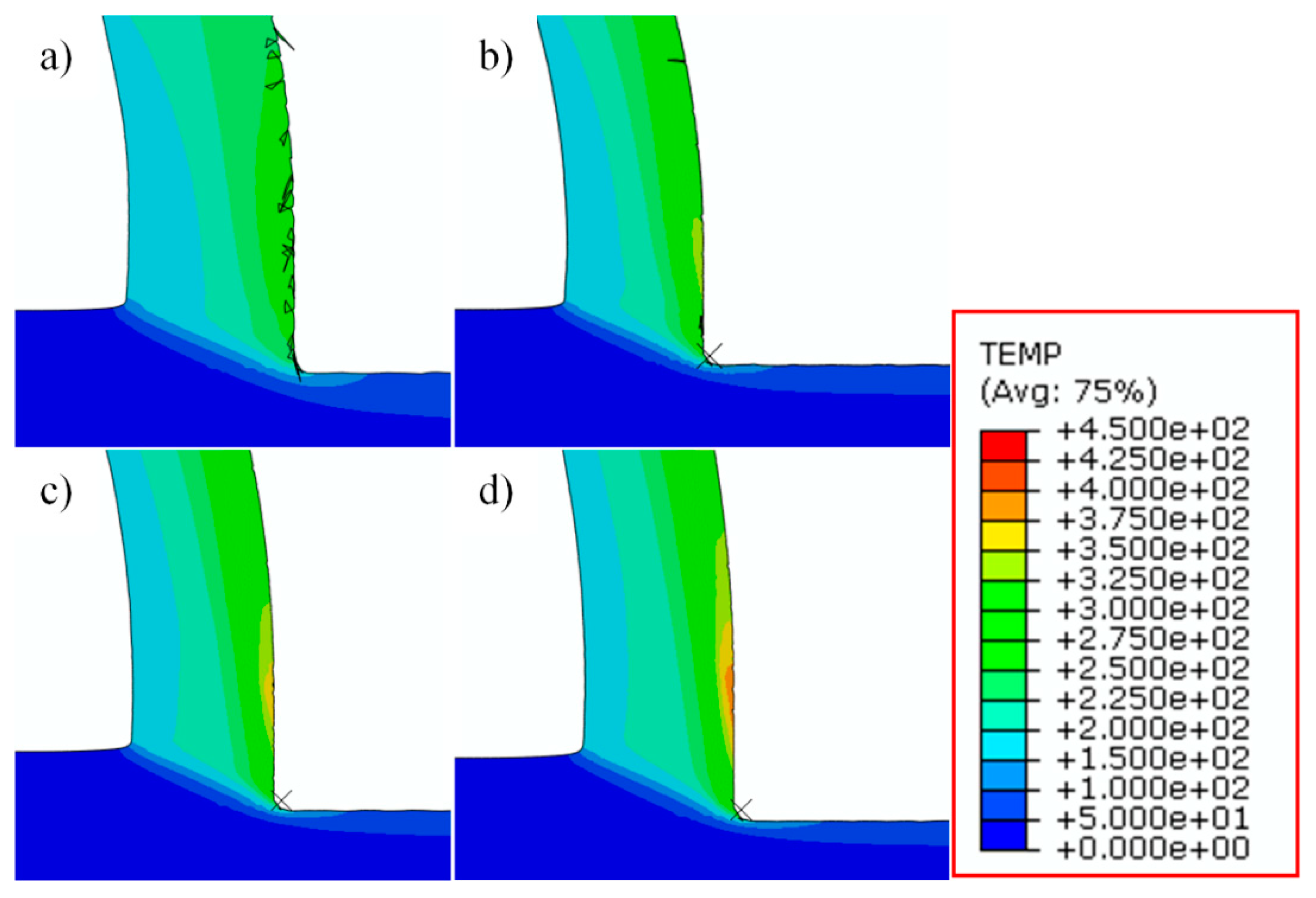

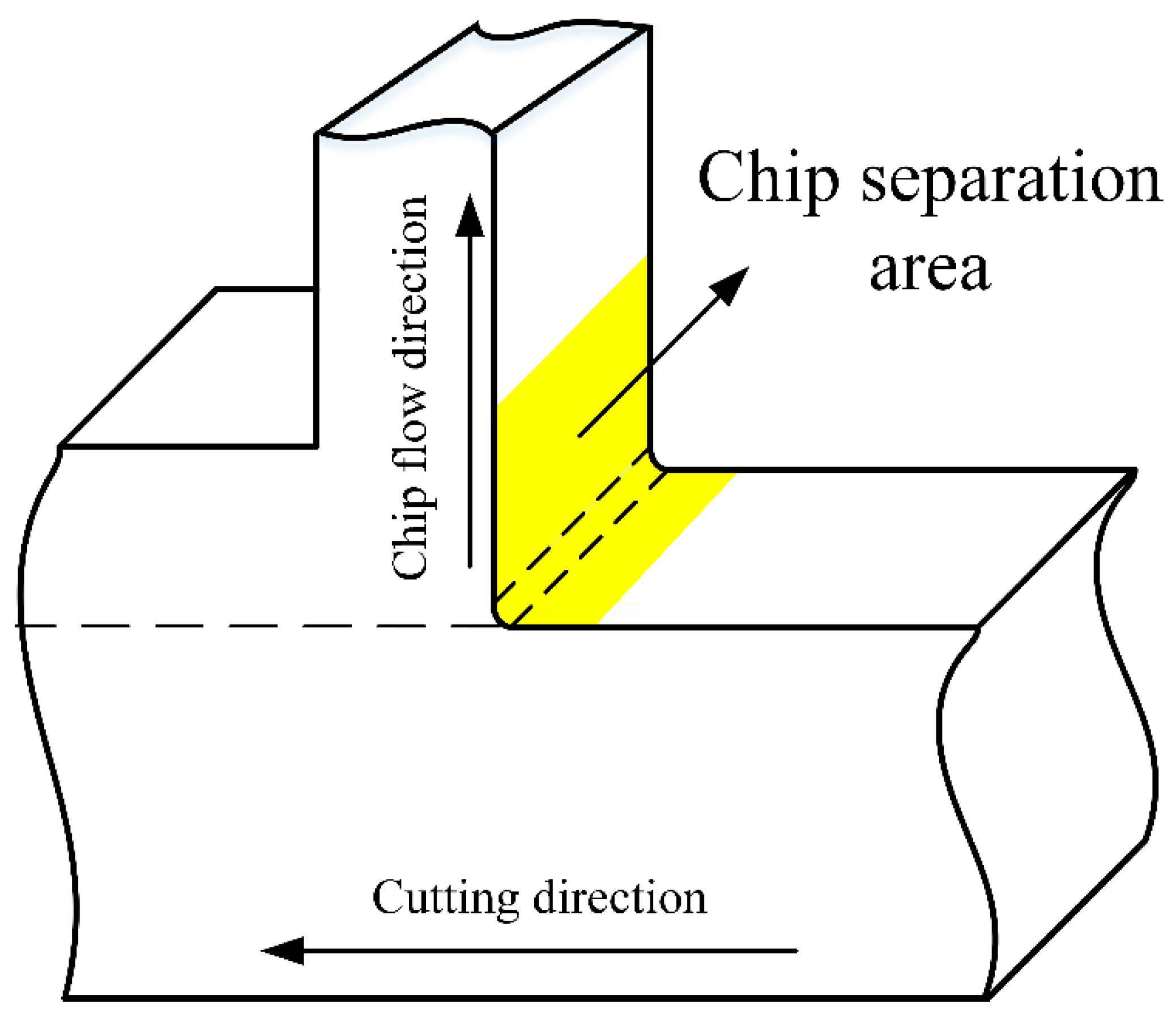

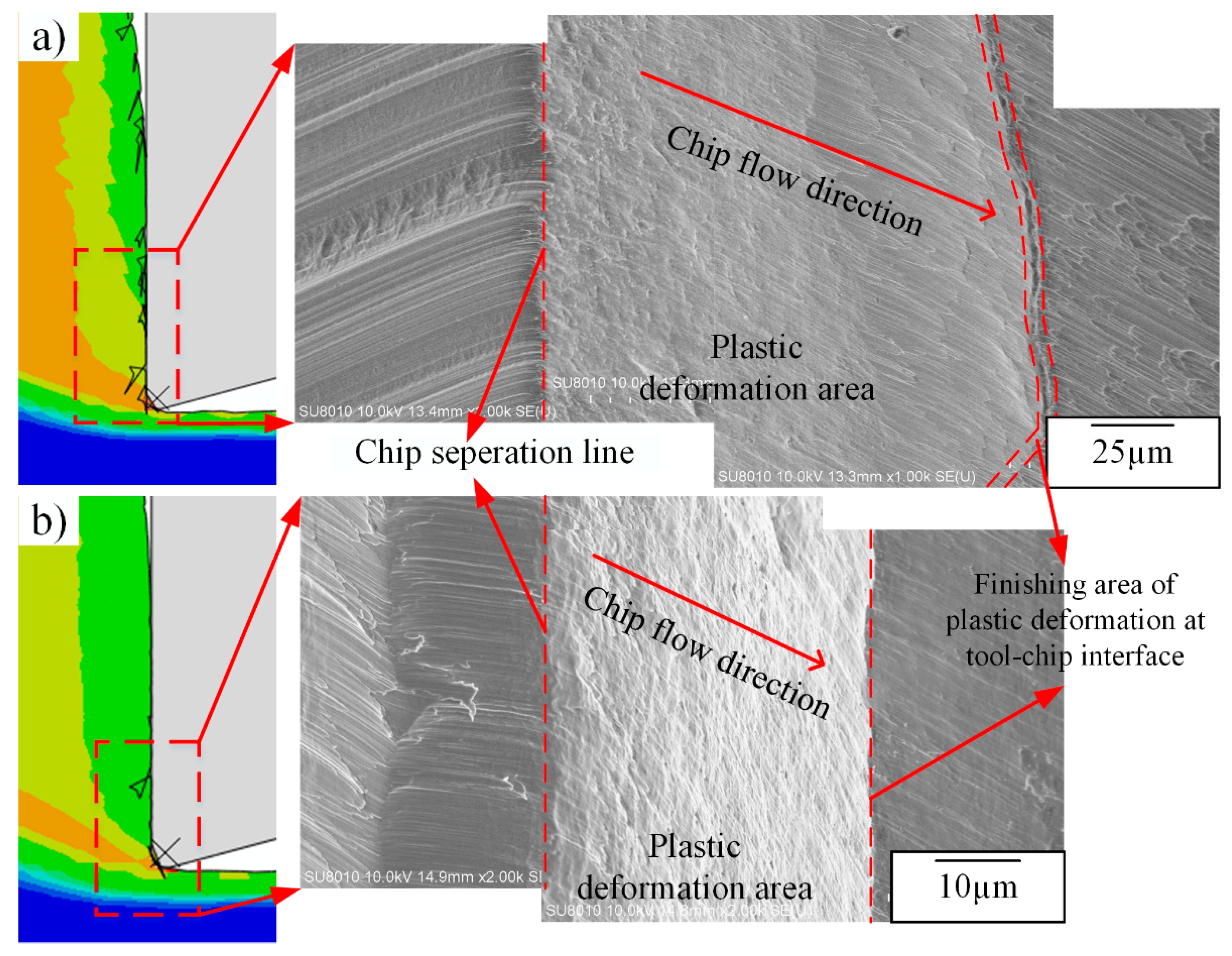

3.3. Effects of the Dislocation Density Evolution on Surface Formation and Chip Separation

4. Conclusions

- Dislocation is the carrier of plastic deformation in the cutting process, and the fluctuation of the cutting forces is induced by its evolution and distribution. Both SSDs and GNDs are introduced to describe this phenomenon. The distribution of SSDs is simulated by the DDB model, which has shown a discontinuous distribution inside the chips when the cutting forces begin to fluctuate at high cutting speeds. The GNDs are used for supplementary illustration of the dislocation effects, which are obtained through the EBSD technique, which is also a key factor for the variation of the cutting forces with respect to the cutting speeds, and the values increase with the increase of cutting speeds, especially at grain boundaries due to the heterogeneity of materials.

- The periodical distribution of the dislocation densities appears in both the chips and machined surfaces with the increase of the cutting speeds. This layer in the machined surface has a certain thickness of about 12 μm, and the value of the dislocation densities decreases in the chips while an increase in machined surfaces is seen as the cutting speeds become higher, which is also related to the fluctuation of the cutting forces.

- With the increase of cutting speeds, the dislocation densities around the tool-chip interface decrease, meanwhile, the area of the plastic deformation during the chip separation decreases with fewer burrs formed.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ulutan, D.; Ozel, T. Machining induced surface integrity in titanium and nickel alloys: A review. Int. J. Mach. Tools Manuf. 2011, 51, 250–280. [Google Scholar] [CrossRef]

- Guo, Y.; Saldana, C.; Dale Compton, W.; Chandrasekar, S. Controlling deformation and microstructure on machined surfaces. Acta Mater. 2011, 59, 4538–4547. [Google Scholar] [CrossRef]

- Pan, Z.; Shih, D.S.; Tabei, A.; Garmestani, H.; Liang, S.Y. Modeling of Ti-6Al-4V machining force considering material microstructure evolution. Int. J. Adv. Manuf. Technol. 2017, 91, 2673–2680. [Google Scholar] [CrossRef]

- Yang, D.; Liu, Z. Quantification of microstructural features and prediction of mechanical properties of a dual-phase Ti-6Al-4V alloy. Materials 2016, 9, 628. [Google Scholar] [CrossRef] [PubMed]

- Li, A.; Pang, J.; Zhao, J.; Zang, J.; Wang, F. FEM-simulation of machining induced surface plastic deformation and microstructural texture evolution of Ti-6Al-4V alloy. Int. J. Mech. Sci. 2017, 123, 214–223. [Google Scholar] [CrossRef]

- Shyha, I.; Gariani, S.; El-Sayed, M.; Huo, D. Analysis of Microstructure and Chip Formation When Machining Ti-6Al-4V. Metals 2018, 8, 185. [Google Scholar] [CrossRef]

- Sutter, G.; List, G. Very high speed cutting of Ti-6Al-4V titanium alloy–change in morphology and mechanism of chip formation. Int. J. Mach. Tools Manuf. 2013, 66, 37–43. [Google Scholar] [CrossRef]

- Duan, C.Z.; Zhang, L.C. Adiabatic shear banding in AISI 1045 steel during high speed machining: Mechanisms of microstructural evolution. Mater. Sci. Eng. A 2012, 532, 111–119. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z.; Su, G.; Song, Q.; Ai, X. Investigations of critical cutting speed and ductile-to-brittle transition mechanism for workpiece material in ultra-high speed machining. Int. J. Mech. Sci. 2015, 104, 44–59. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, Z.; Wang, B.; Song, Q.; Wan, Y. Evolutions of grain size and micro-hardness during chip formation and machined surface generation for Ti-6Al-4V in high-speed machining. Int. J. Adv. Manuf. Technol. 2016, 82, 1725–1736. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z.; Hou, X.; Zhao, J. Influences of Cutting Speed and Material Mechanical Properties on Chip Deformation and Fracture during High-Speed Cutting of Inconel 718. Materials 2018, 11, 461. [Google Scholar] [CrossRef] [PubMed]

- Childs, T.H.; Arrazola, P.J.; Aristimuno, P.; Garay, A.; Sacristan, I. Ti6Al4V metal cutting chip formation experiments and modelling over a wide range of cutting speeds. J. Mater. Process. Technol. 2018, 255, 898–913. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Nieslony, P.; Wojciechowski, S.; Michalski, M.; Legutko, S. The influence of the cooling conditions on the cutting tool wear and the chip formation mechanism. J. Manuf. Process. 2016, 24, 107–115. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Michalski, M.; Nieslony, P.; Wojciechowski, S. Structural and microhardness changes after turning of the AISI 1045 steel for minimum quantity cooling lubrication. J. Mater. Eng. Perform. 2017, 26, 431–438. [Google Scholar] [CrossRef]

- Calamaz, M.; Coupard, D.; Girot, F. A new material model for 2D numerical simulation of serrated chip formation when machining titanium alloy Ti-6Al-4V. Int. J. Mach. Tools Manuf. 2008, 48, 275–288. [Google Scholar] [CrossRef]

- Sima, M.; Özel, T. Modified material constitutive models for serrated chip formation simulations and experimental validation in machining of titanium alloy Ti-6Al-4V. Int. J. Mach. Tools Manuf. 2010, 50, 943–960. [Google Scholar] [CrossRef]

- Ding, H.; Shen, N.; Shin, Y.C. Modeling of grain refinement in aluminum and copper subjected to cutting. Comput. Mater. Sci. 2011, 50, 3016–3025. [Google Scholar] [CrossRef]

- Denguir, L.A.; Outeiro, J.C.; Fromentin, G.; Vignal, V.; Besnard, R. A physical-based constitutive model for surface integrity prediction in machining of OFHC copper. J. Mater. Process. Technol. 2017, 248, 143–160. [Google Scholar] [CrossRef]

- Atmani, Z.; Haddag, B.; Nouari, M.; Zenasni, M. Combined microstructure-based flow stress and grain size evolution models for multi-physics modelling of metal machining. Int. J. Mech. Sci. 2016, 118, 77–90. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Estrin, Y.; Tóth, L.S.; Molinari, A.; Bréchet, Y. A dislocation-based model for all hardening stages in large strain deformation. Acta Mater. 1998, 46, 5509–5522. [Google Scholar] [CrossRef]

- Tóth, L.S.; Molinari, A.; Estrin, Y. Strain Hardening at Large Strains as Predicted by Dislocation Based Polycrystal Plasticity Model. J. Eng. Mater. Technol. 2002, 124, 71. [Google Scholar] [CrossRef]

- Steinmetz, D.R.; Jäpel, T.; Wietbrock, B.; Eisenlohr, P.; Gutierrez-Urrutia, I.; Saeed–Akbari, A.; Hickel, T.; Roters, F.; Raabe, D. Revealing the strain-hardening behavior of twinning-induced plasticity steels: Theory, simulations, experiments. Acta Mater. 2013, 61, 494–510. [Google Scholar] [CrossRef]

- Derby, B. The dependence of grain size on stress during dynamic recrystallisation. Acta Metall. Mater. 1991, 39, 955–962. [Google Scholar] [CrossRef]

- Andrade, U.; Meyers, M.A.; Vecchio, K.S.; Chokshi, A.H. Dynamic recrystallization in high-strain, high-strain-rate plastic deformation of copper. Acta Metall. Mater. 1994, 42, 3183–3195. [Google Scholar] [CrossRef]

- Liu, Y.; Varghese, S.; Ma, J.; Yoshino, M.; Lu, H.; Komanduri, R. Orientation effects in nanoindentation of single crystal copper. Int. J. Plast. 2008, 24, 1990–2015. [Google Scholar] [CrossRef]

- Meyers, M.A.; Andrade, U.R.; Chokshi, A.H. The effect of grain size on the high-strain, high-strain-rate behavior of copper. Metall. Mater. Trans. A 1995, 26, 2881–2893. [Google Scholar] [CrossRef]

- Buda, J. New methods in the study of plastic deformation in the cutting zone. CIRP Ann. 1972, 21, 17–18. [Google Scholar]

- Liu, H.; Zhang, J.; Xu, X.; Jiang, Y.; He, Y.; Zhao, W. Effect of microstructure evolution on chip formation and fracture during high-speed cutting of single phase metals. Int. J. Adv. Manuf. Technol. 2017, 91, 823–833. [Google Scholar] [CrossRef]

- Roters, F.; Eisenlohr, P.; Hantcherli, L.; Tjahjanto, D.D.; Bieler, T.R.; Raabe, D. Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications. Acta Mater. 2010, 58, 1152–1211. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, J.; Liu, H.; Qi, Y.; Liu, Z.; Zhao, W. Effect of morphological evolution of serrated chips on surface formation during high speed cutting Ti6Al4V. Procedia CIRP 2018, 77, 147–150. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J.; Xu, X.; Zhao, W. Experimental study on fracture mechanism transformation in chip segmentation of Ti-6Al-4V alloys during high-speed machining. J. Mater. Process. Technol. 2018, 257, 132–140. [Google Scholar] [CrossRef]

- Ding, H.; Shin, Y.C. Multi-physics modeling and simulations of surface microstructure alteration in hard turning. J. Mater. Process. Technol. 2013, 213, 877–886. [Google Scholar] [CrossRef]

- Toth, L.S.; Gu, C. Ultrafine-grain metals by severe plastic deformation. Mater. Charact. 2014, 92, 1–14. [Google Scholar] [CrossRef]

- Jorge-Badiola, D.; Iza-Mendia, A.; Gutierrez, I. Study by EBSD of the development of the substructure in a hot deformed 304 stainless steel. Mater. Sci. Eng. A 2005, 394, 445–454. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, J.; Liu, H.; He, Y.; Zhao, W. Grain refinement mechanism under high strain-rate deformation in machined surface during high speed machining Ti6Al4V. Mater. Sci. Eng. A 2019, 752, 167–179. [Google Scholar] [CrossRef]

- Hashimura, M.; Chang, Y.P.; Dornfeld, D. Analysis of burr formation mechanism in orthogonal cutting. Trans.-Am. Soc. Mech. Eng. J. Manuf. Sci. Eng. 1999, 121, 1–7. [Google Scholar] [CrossRef]

- Ko, S.L.; Dornfeld, D.A. A study on burr formation mechanism. J. Eng. Mater. Technol. 1991, 113, 75–87. [Google Scholar] [CrossRef]

| Parameter | d1 | d2 | d3 | d4 | d5 |

|---|---|---|---|---|---|

| Value | 0.54 | 4.89 | −3.03 | 0.014 | 1.12 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| τ0 | 30 MPa | K | 10 |

| α* | 0.04 | d0 | 200 μm |

| β* | 0.01 | 4000 s−1 | |

| f0 | 0.25 | G | 48 GPa |

| f∞ | 0.165 | A | 30,000 |

| ρw,0 | 1 × 107 mm−2 | B | 14,900 |

| ρc,0 | 1 × 108 mm−2 | M | 3.06 |

| b | 0.256 nm |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| p00 | 9.72 | p02 | −1.701 × 10−5 |

| p10 | 0.2124 | p30 | 4.266 × 10−4 |

| p01 | 0.006083 | p21 | 9.068 × 10−5 |

| p20 | −0.01218 | p12 | 2.898 × 10−6 |

| p11 | −3.54 × 10−4 | p03 | 3.255 × 10−8 |

| Material | A (MPa) | B (MPa) | C | n | m | Tr (°C) | Tm (°C) | έ (1/s) |

|---|---|---|---|---|---|---|---|---|

| OFHC | 320 | 80 | 0.012 | 0.324 | 1 | 25 | 1083 | 0.001 |

| Cutting Speed (m/min) | Experimental Results | Simulation (°) | ||

|---|---|---|---|---|

| Shear Angle (°) | Thickness (mm) | Shear Angle (°) | Thickness (mm) | |

| 750 | 12.8 | 0.62–0.68 | 14.4 | 0.58 |

| 1500 | 14.5 | 0.55–0.58 | 16.7 | 0.5 |

| 2250 | 17.7 | 0.45–0.48 | 18.4 | 0.45 |

| 3000 | 18.3 | 0.44–0.46 | 19.0 | 0.44 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Zhang, J.; Xu, X.; Qi, Y.; Liu, Z.; Zhao, W. Effects of Dislocation Density Evolution on Mechanical Behavior of OFHC Copper during High-Speed Machining. Materials 2019, 12, 2348. https://doi.org/10.3390/ma12152348

Liu H, Zhang J, Xu X, Qi Y, Liu Z, Zhao W. Effects of Dislocation Density Evolution on Mechanical Behavior of OFHC Copper during High-Speed Machining. Materials. 2019; 12(15):2348. https://doi.org/10.3390/ma12152348

Chicago/Turabian StyleLiu, Hongguang, Jun Zhang, Xiang Xu, Yutong Qi, Zhechao Liu, and Wanhua Zhao. 2019. "Effects of Dislocation Density Evolution on Mechanical Behavior of OFHC Copper during High-Speed Machining" Materials 12, no. 15: 2348. https://doi.org/10.3390/ma12152348

APA StyleLiu, H., Zhang, J., Xu, X., Qi, Y., Liu, Z., & Zhao, W. (2019). Effects of Dislocation Density Evolution on Mechanical Behavior of OFHC Copper during High-Speed Machining. Materials, 12(15), 2348. https://doi.org/10.3390/ma12152348