Effects of a Short Heat Treatment Period on the Pullout Resistance of Shape Memory Alloy Fibers in Mortar

Abstract

1. Introduction

Shape Memory Alloy Fiber-Reinforced Cementitious Composites (SMA-FRCCs)

2. Experiments

2.1. Materials and Sample Preparation

2.2. Test Setup and Procedure

3. Results and Discussion

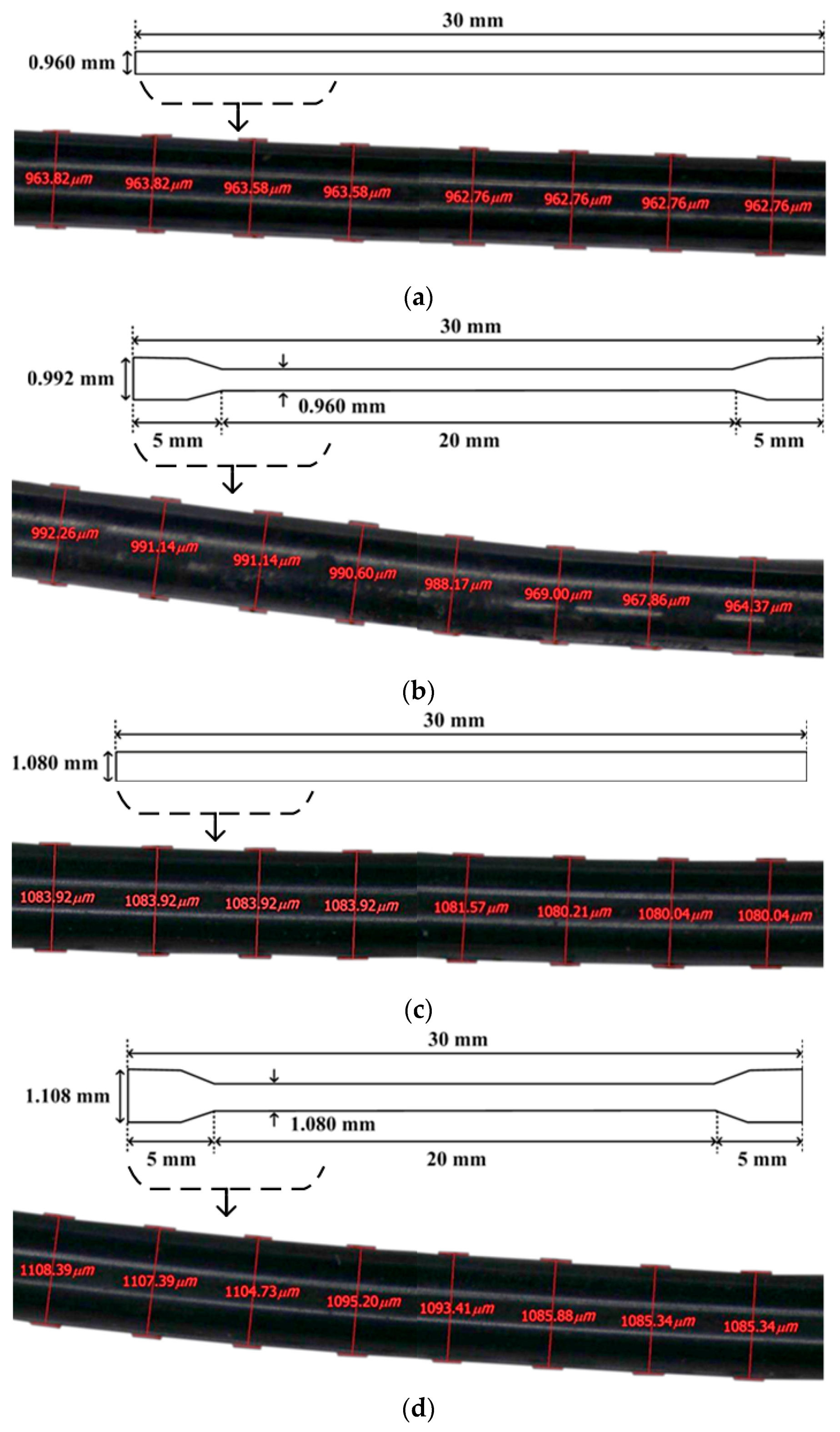

3.1. Length and Diameter of Cold-Drawn SMA Fibers during the Short Heat Treatment Period

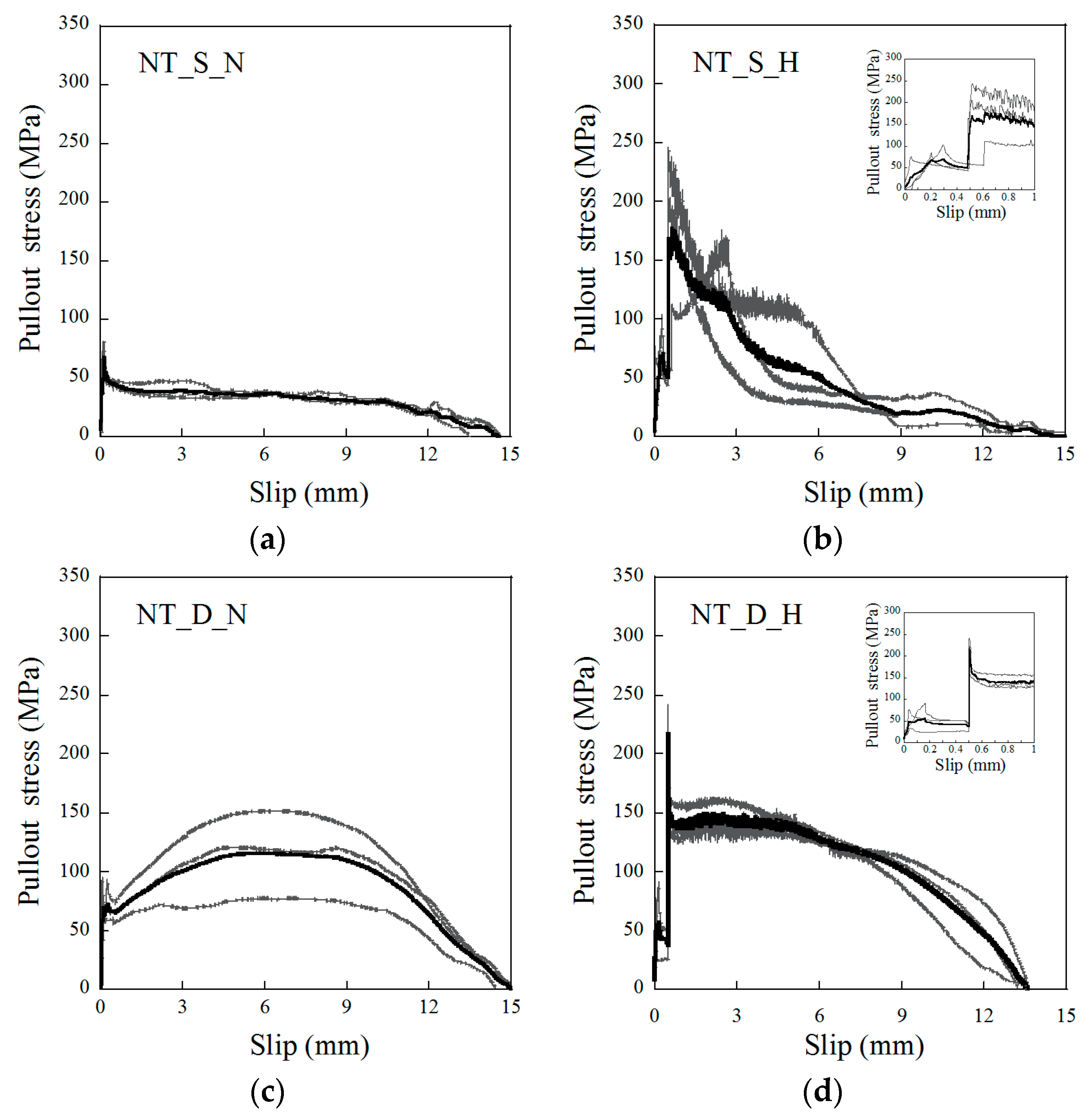

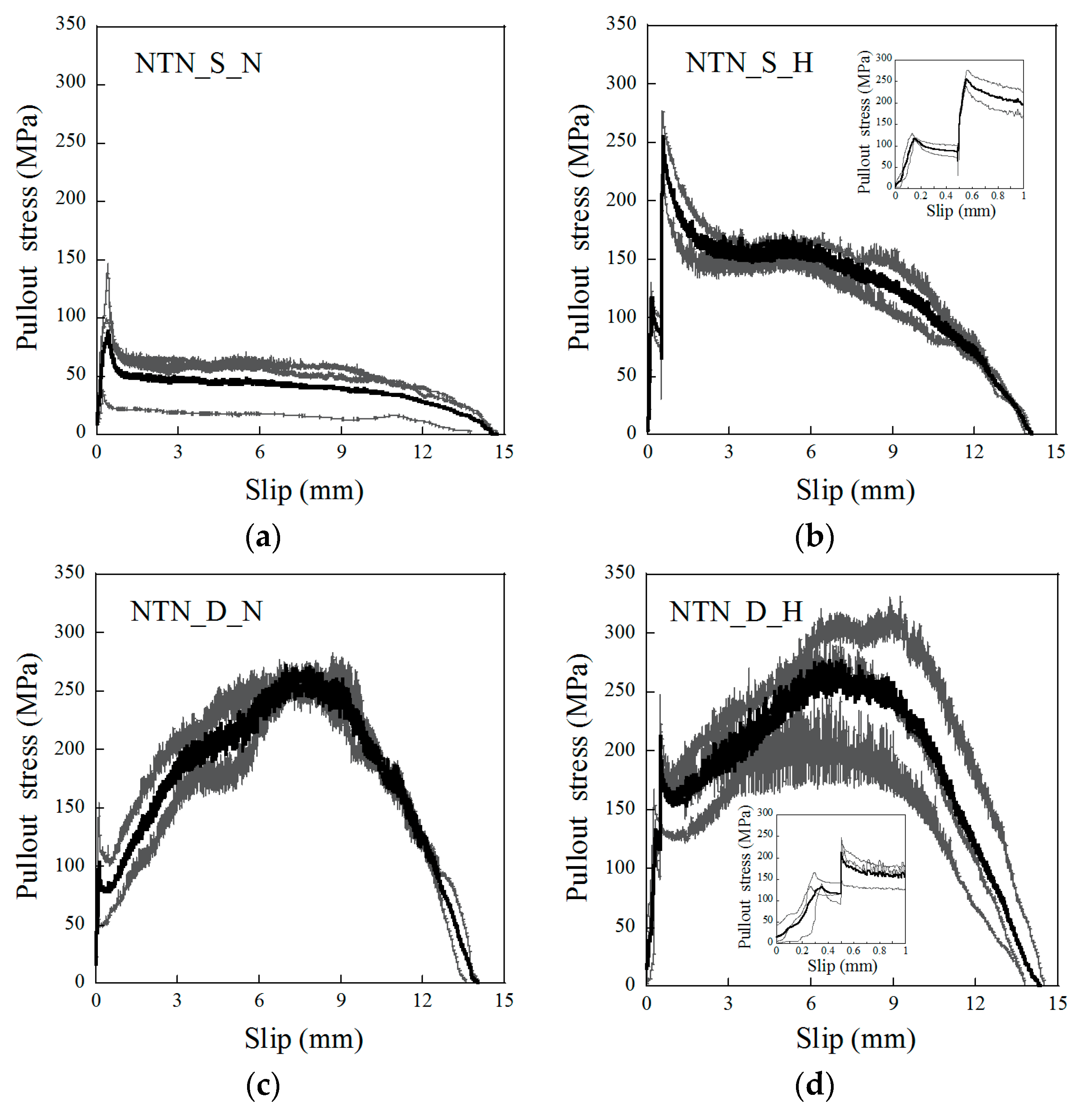

3.2. Pullout Stress Versus Slip Response

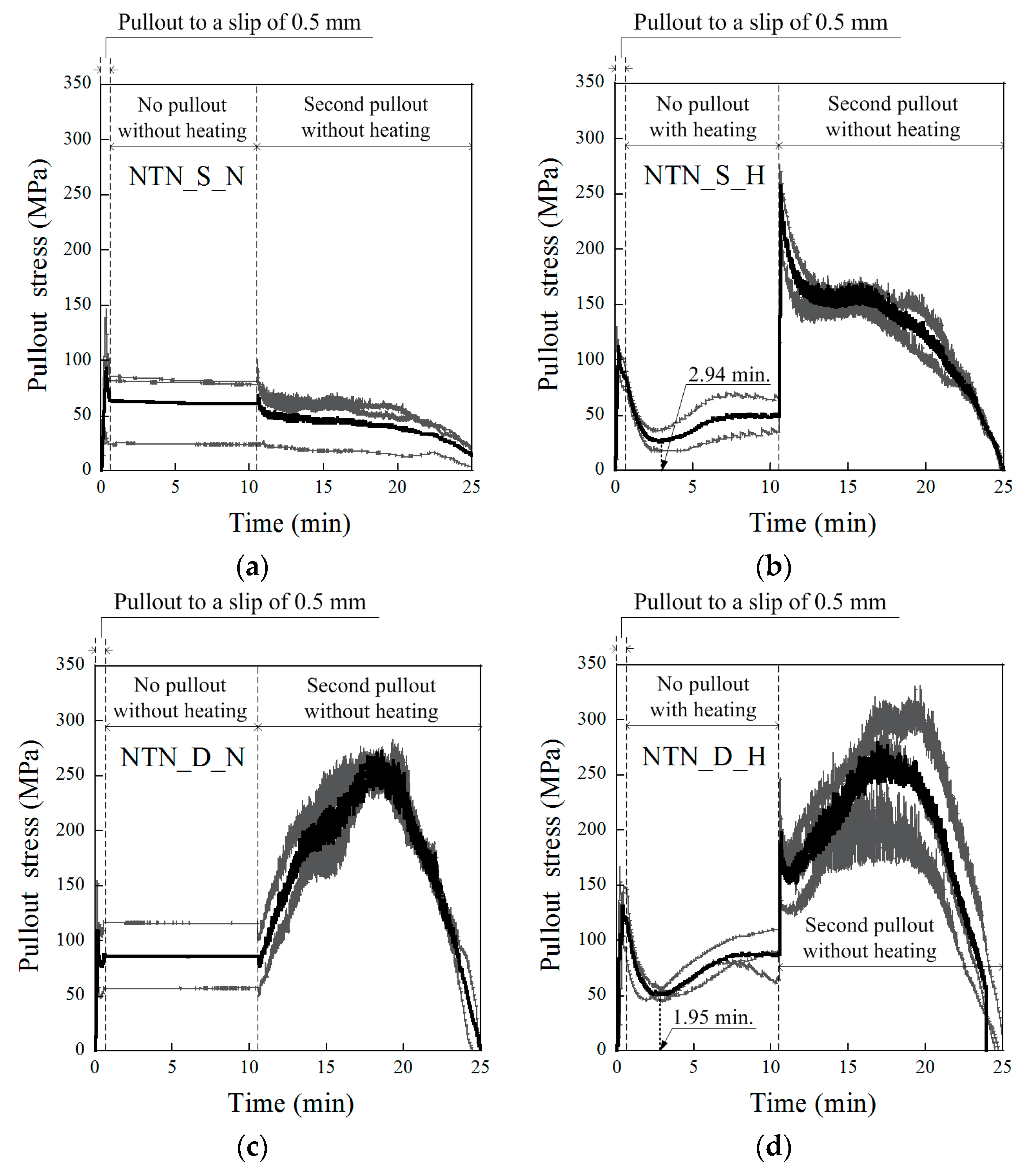

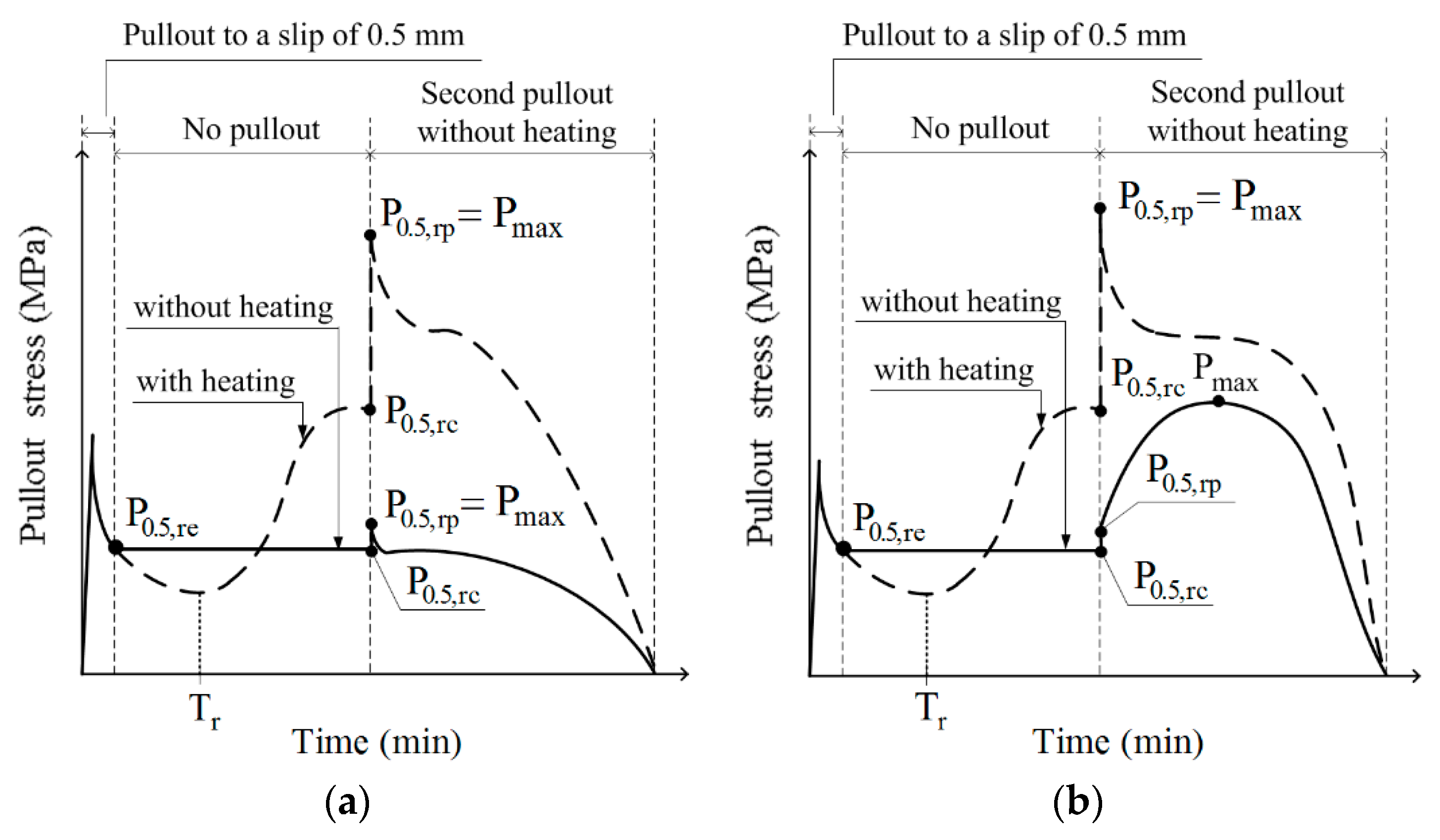

3.3. Pullout Resistance during the Short Heat Treatment Period

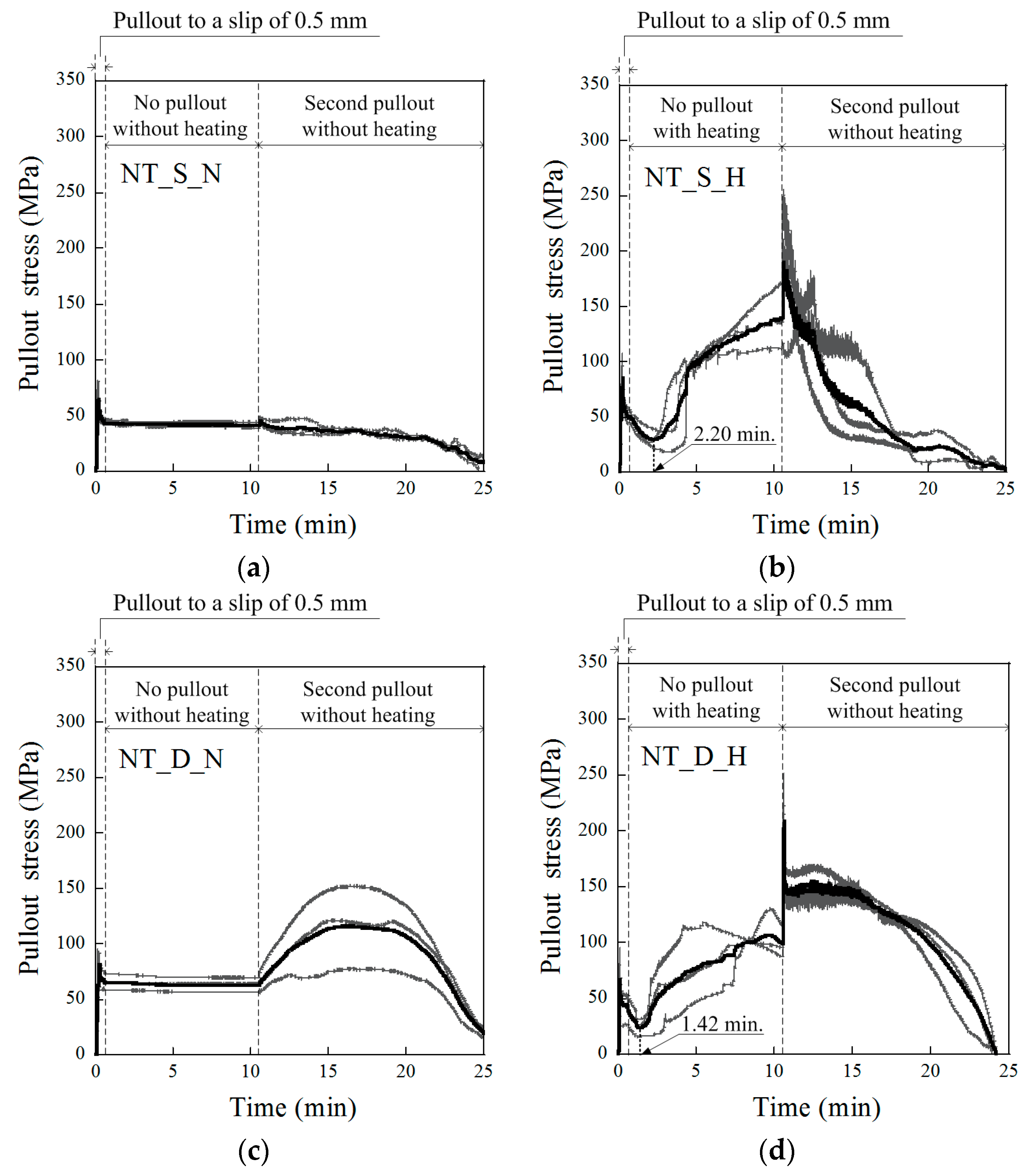

3.4. Pullout Stress Recovery Starting Time (Tr) during the Heat Treatment

3.5. Pullout Stress Recovery Ratios

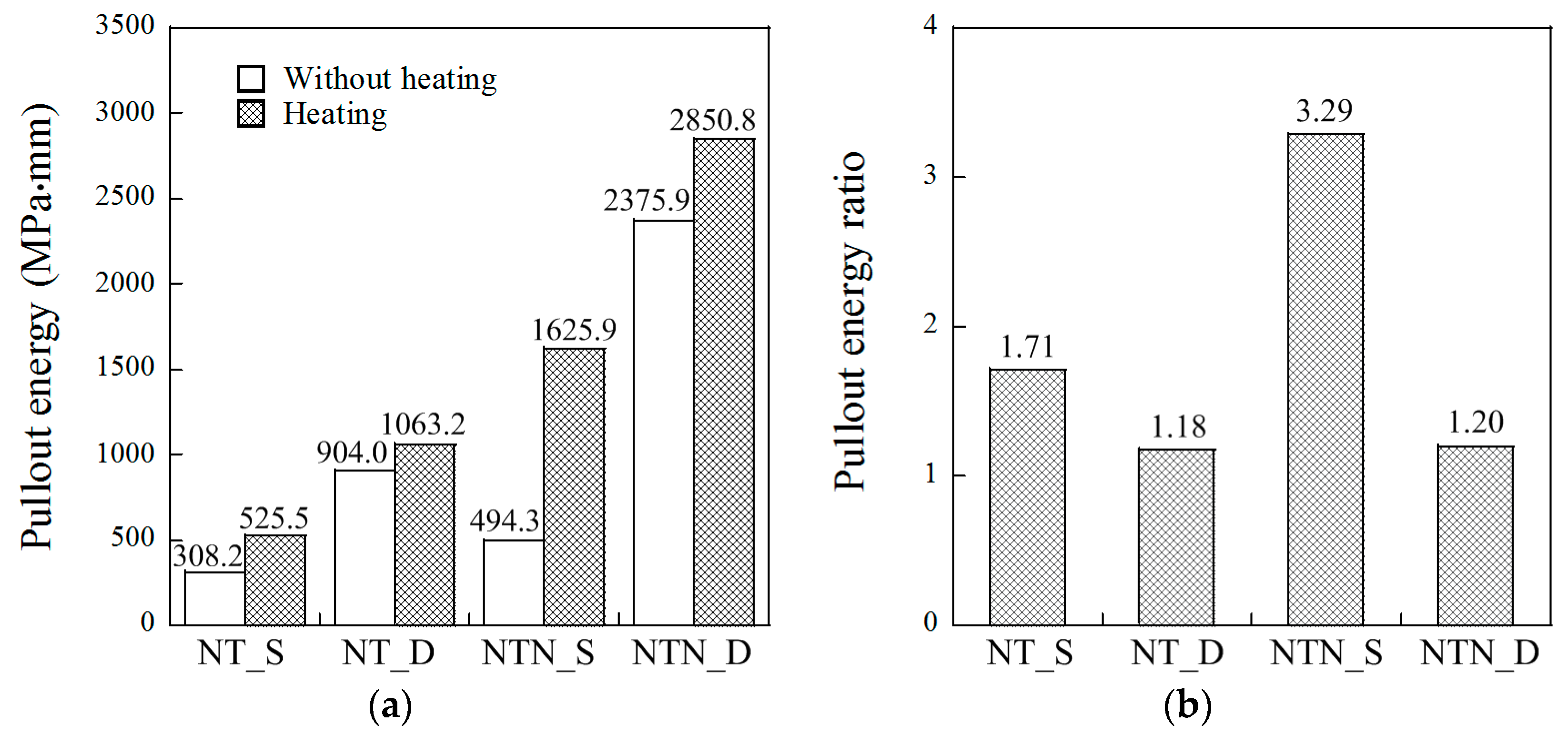

3.6. Pullout Energy Ratios

4. Conclusions

- During the short heat treatment period, the length of the cold-drawn SMA fibers clearly decreased, whereas their diameter expanded due to the shape memory effect. The NiTi fibers generally showed greater shape memory effects in both diameter and length than the NiTiNb fibers, while the smooth geometry SMA fibers had greater shape memory effects than the dog-bone-shaped geometry fibers;

- SMA fibers with a dog-bone-shaped geometry generally showed higher pullout resistances than those with a smooth geometry;

- The short heat treatment period noticeably increased the pullout stress, although the degree of enhancement varied, relative to the SMA fiber alloy and geometry: (1) the NiTi fibers generally produced a faster pullout stress recovery than the NiTiNb fibers, while the SMA fibers with dog-bone-shaped geometries showed a faster recovery than those with a smooth geometry; (2) the NiTi fibers revealed higher pullout stress ratios during and after the heat treatment than the NiTiNb fibers; and (3) the SMA fibers with dog-bone-shaped geometries generated a larger amount of pullout energy (PE), which is favorable for faster crack closing.

Author Contributions

Funding

Conflicts of Interest

References

- Naaman, A.E.; Reinhardt, H.W. Characterization of high performance fiber reinforced cementitious composites-HPFRCC. In Proceedings of the Second International Workshop on High Performance Fiber Reinforced Cement Composites (HPFRCC2), Ann Arbor, MI, USA, 11–14 June 1995; pp. 1–24. [Google Scholar]

- Orange, G.; Acker, P.; Vernet, C. A new generation of UHPConcrete: DUCTAL damage resistance and micro mechanical analysis. In Proceedings of the Third International Workshop on High Performance Fiber Reinforced Cement Composites (HPFRCC3), Mainz, Germany, 16–19 May 1999; pp. 101–112. [Google Scholar]

- Rossi, P. High performance multimodal fiber reinforced cement composites (HPMFRCC): The LCPC experience. ACI Mater. J. 1997, 94, 478–483. [Google Scholar]

- Rossi, P.; Arca, A.; Parant, E.; Fakhri, P. Bending and compressive behavior of a new cement composite. Cem. Concr. Res. 2005, 35, 27–33. [Google Scholar] [CrossRef]

- Ahn, T.H.; Kishi, T. Crack self-healing behavior of cementitious composites incorporating various mineral admixtures. J. Adv. Concr. Technol. 2010, 8, 171–186. [Google Scholar] [CrossRef]

- Li, M.; Li, V.C. Cracking and healing of engineered cementitious composites under chloride environment. ACI Mater. J. 2011, 108, 333–340. [Google Scholar]

- Kim, D.J.; El-Tawil, S.; Naaman, A.E. Rate-dependent tensile behavior of high performance fiber reinforced cementitious composites. Mat. Struct. 2009, 42, 399–414. [Google Scholar] [CrossRef]

- Blanco, A.; Pujadas, P.; Fuente, D.; Cavalaro, S.H.P.; Aguado, A. Influence of the type of fiber on the structural response and design of FRC slabs. J. Struct. Eng. 2016, 142, 04016054. [Google Scholar] [CrossRef]

- Edvardsen, C. Water permeability and autogenous healing of cracks in concrete. ACI Mater. J. 1999, 96, 448–455. [Google Scholar]

- Kim, D.J.; Kim, H.A.; Chung, Y.-S.; Choi, E. Pullout resistance of straight NiTi SMA fibers in cement mortar after cold drawing process and heat treatment. Compos. Part B Eng. 2014, 67, 588–594. [Google Scholar] [CrossRef]

- Kim, D.J.; Kim, H.A.; Chung, Y.-S.; Choi, E. Pullout resistance of deformed shape memory alloy fibers embedded in cement mortar. J. Intell. Mat. Syst. Str. 2014, 27, 1–12. [Google Scholar] [CrossRef]

- Kim, M.K.; Kim, D.J.; Chung, Y.-S.; Choi, E. Direct tensile behavior of shape-memory alloy fiber-reinforced cement composites. Constr. Build. Mater. 2016, 102, 462–470. [Google Scholar] [CrossRef]

- Choi, E.; Nam, T.-H.; Cho, S.-C.; Chung, Y.-S.; Park, T. The behavior of concrete cylinders confined by shape memory alloy wires. Smart Mater. Struct. 2008, 17, 065032. [Google Scholar] [CrossRef]

- Choi, E.; Chung, Y.-S.; Choi, J.-H.; Kim, H.-T.; Lee, H. The confining effectiveness of NiTiNb and NiTi SMA wire jackets for concrete. Smart Mater. Struct. 2010, 19, 035024. [Google Scholar] [CrossRef]

- Choi, E.; Kim, Y.-W.; Chung, Y.-S.; Yang, K.-T. Bond strength of concrete confined by SMA wire jackets. Phys. Procedia 2010, 10, 210–215. [Google Scholar] [CrossRef][Green Version]

- Tran, H.; Balandraud, X.; Destrebecq, J.F. Improvement of the mechanical performances of concrete cylinders confined actively or passively by means of SMA wires. Arch. Civ. Mech. Eng. 2015, 15, 292–299. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Kikuchi, T.; Ogawa, K.; Kajiwara, S.; Ikeo, Y.; Kojima, M.; Ogawa, T. Development of prestressed concrete using Fe-Mn-Si-based shape memory alloys containing NbC. Mater. Trans. 2006, 41, 580–583. [Google Scholar] [CrossRef]

- Umezaki, E. Improvement in separation of SMA from matrix in SMA embedded smart structures. Mat. Sci. Eng. A Struct. 2000, 285, 363–369. [Google Scholar] [CrossRef]

- Lee, K.-J.; Lee, J.-H.; Jung, C.-Y.; Choi, E. Crack-closing performance of NiTi and NiTiNb fibers in cement mortar beams using shape memory effects. Compos. Struct. 2018, 202, 710–718. [Google Scholar] [CrossRef]

- Lee, J.-H.; Lee, K.-J.; Choi, E. Flexural capacity and crack-closing performance of NiTi and NiTiNb shape-memory alloy fibers randomly distributed in mortar beams. Compos. Part B Eng. 2018, 153, 264–276. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, L.; Wang, Z.; Huang, H.; Ye, L. Analysis of internal stresses induced by strain recovery in a single SMA fiber-matrix composite. Comp. Part B Eng. 2011, 42, 1135–1143. [Google Scholar] [CrossRef]

- Watanabe, Y.; Miyazaki, E.; Okada, H. Enhanced mechanical properties of Fe-Mn-Si-Cr shape memory fiber/plaster smart composite. Mater. Trans. 2002, 43, 974–983. [Google Scholar] [CrossRef][Green Version]

- Kuang, Y.; Ou, J. Self-repairing performance of concrete beams strengthened using superelastic SMA wires in combination with adhesives released from hollow fiber. Smart Mater. Struct. 2008, 17, 025020. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Sultan, M.A. Effect of temperature on thermal properties of high strength concrete. J. Mater. Civil Eng. 2003, 15, 101–107. [Google Scholar] [CrossRef]

- Kim, J.; Lee, G.-P.; Moon, D.Y. Evaluation of mechanical properties of steel-fibre-reinforced concrete exposed to high temperatures by double punch test. Constr. Build. Mater. 2015, 79, 182–191. [Google Scholar] [CrossRef]

- Pujadas, P.; Blanco, A.; Cavalaro, S.H.P.; Fuente, A.; Aguado, A. Multidirectional double punch test to assess the post-cracking behaviour and fibre orientation of FRC. Constr. Build. Mater. 2014, 58, 214–224. [Google Scholar] [CrossRef]

| Alloy | Fiber Diameter (mm) a | Shape | Heat Treatment | Notation |

|---|---|---|---|---|

| NiTi | 1.0 → 0.96 | Smooth | No | NT_S_N |

| Yes | NT_S_H | |||

| Dog-bone shaped | No | NT_D_N | ||

| Yes | NT_D_H | |||

| NiTiNb | 1.12 → 1.08 | Smooth | No | NTN_S_N |

| Yes | NTN_S_H | |||

| Dog-bone shaped | No | NTN_D_N | ||

| Yes | NTN_D_H |

| Cement (Type 3) | Fly Ash | Silica Sand | High-Range Water-Reducing Admixture | Water | f′ck (MPa) |

|---|---|---|---|---|---|

| 1.00 | 0.15 | 1.00 | 0.009 | 0.35 | 55 |

| Notation | Length (mm) | Diameter (mm) | Young’s Modulus (GPa) | Tensile Strength (MPa) | Transformation Temperature (°C) a | |||

|---|---|---|---|---|---|---|---|---|

| Mf | Ms | As | Af | |||||

| NT_S | 30 | 0.96 | 41 | 973 | 0.7 | 36.7 | 43.2 | 62.8 |

| NT_D | ||||||||

| NTN_S | 30 | 1.08 | 21 | 1270 | − | −100≥ | −100≤ | − |

| NTN_D | ||||||||

| Notation | Sample | P0.5,re (MPa) | P0.5,rc (MPa) | P0.5,rp (MPa) | Pmax (MPa) | PE (MPa-mm) |

|---|---|---|---|---|---|---|

| NT_S_N | SP1 | 41.5 | 39.5 | 43.6 | 43.6 | 272.2 |

| SP2 | 46.2 | 44.2 | 48.8 | 48.8 | 335.2 | |

| SP3 | 43.2 | 42.1 | 46.1 | 46.1 | 317.1 | |

| Aver. a | 43.7 | 41.9 | 45.7 | 45.7 | 308.2 | |

| STD b | 1.9 | 1.9 | 2.1 | 2.1 | 26.5 | |

| NT_S_H | SP1 | 56.6 | 112.5 | 181.9 | 181.9 | 471.3 |

| SP2 | 44.5 | 171.2 | 214.5 | 214.5 | 382.9 | |

| SP3 | 49.9 | 136.1 | 254.9 | 254.9 | 658.0 | |

| Aver. | 50.3 | 139.9 | 190.6 | 190.6 | 525.5 | |

| STD | 4.9 | 24.1 | 29.9 | 29.9 | 114.7 | |

| NT_D_N | SP1 | 58.7 | 56.0 | 58.1 | 94.4 | 578.7 |

| SP2 | 73.5 | 69.1 | 47.9 | 152.3 | 1137.0 | |

| SP3 | 64.2 | 64.2 | 65.8 | 121.2 | 959.1 | |

| Aver. | 65.6 | 63.1 | 65.7 | 116.4 | 904.0 | |

| STD | 6.4 | 5.4 | 7.3 | 23.7 | 232.9 | |

| NT_D_H | SP1 | 51.2 | 95.0 | 251.0 | 251.0 | 1123.9 |

| SP2 | 53.2 | 87.6 | 232.3 | 232.3 | 959.7 | |

| SP3 | 26.3 | 115.2 | 193.7 | 193.7 | 1106.7 | |

| Aver. | 43.6 | 99.3 | 208.8 | 208.8 | 1063.2 | |

| STD | 12.2 | 11.7 | 23.9 | 23.9 | 73.7 | |

| NTN_S_N | SP1 | 23.9 | 23.9 | 26.3 | 26.3 | 181.5 |

| SP2 | 85.9 | 81.0 | 85.5 | 85.5 | 641.8 | |

| SP3 | 81.6 | 78.3 | 99.8 | 99.8 | 652.3 | |

| Aver. | 63.8 | 61.1 | 69.3 | 69.3 | 494.3 | |

| STD | 28.3 | 26.3 | 31.8 | 31.8 | 219.5 | |

| NTN_S_H | SP1 | 73.1 | 33.7 | 239.4 | 239.4 | 1472.1 |

| SP2 | 95.9 | 66.4 | 276.6 | 276.6 | 1780.3 | |

| Aver. | 84.5 | 50.0 | 257.5 | 257.5 | 1625.9 | |

| STD | 11.4 | 16.4 | 18.6 | 18.6 | 154.1 | |

| NTN_D_N | SP1 | 57.2 | 57.1 | 57.4 | 273.8 | 2073.3 |

| SP2 | 115.8 | 115.8 | 116.3 | 282.2 | 2358.4 | |

| Aver. | 84.8 | 84.5 | 86.7 | 271.8 | 2375.9 | |

| STD | 29.3 | 29.4 | 29.5 | 4.2 | 142.6 | |

| NTN_D_H | SP1 | 148.0 | 63.8 | 247.0 | 296.1 | 2600.0 |

| SP2 | 92.8 | 109.9 | 154.7 | 330.4 | 2865.0 | |

| SP3 | 120.9 | 115.1 | 236.2 | 269.0 | 2031.1 | |

| Aver. | 120.3 | 96.6 | 198.3 | 280.1 | 2850.8 | |

| STD | 22.5 | 23.1 | 41.2 | 25.1 | 347.9 |

| Notation | Sample | Tr (min.) |

|---|---|---|

| NT_S_H | SP1 | 3.35 |

| SP2 | 1.93 | |

| SP3 | 3.17 | |

| Average | 2.20 | |

| NT_D_H | SP1 | 1.47 |

| SP2 | 1.51 | |

| SP3 | 1.42 | |

| Average | 1.42 | |

| NTN_S_H | SP1 | 4.20 |

| SP2 | 2.77 | |

| Average | 2.94 | |

| NTN_D_H | SP1 | 3.14 |

| SP2 | 1.93 | |

| SP3 | 1.95 | |

| Average | 1.95 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.K.; Kim, D.J.; Chung, Y.-S.; Choi, E. Effects of a Short Heat Treatment Period on the Pullout Resistance of Shape Memory Alloy Fibers in Mortar. Materials 2019, 12, 2278. https://doi.org/10.3390/ma12142278

Kim MK, Kim DJ, Chung Y-S, Choi E. Effects of a Short Heat Treatment Period on the Pullout Resistance of Shape Memory Alloy Fibers in Mortar. Materials. 2019; 12(14):2278. https://doi.org/10.3390/ma12142278

Chicago/Turabian StyleKim, Min Kyoung, Dong Joo Kim, Young-Soo Chung, and Eunsoo Choi. 2019. "Effects of a Short Heat Treatment Period on the Pullout Resistance of Shape Memory Alloy Fibers in Mortar" Materials 12, no. 14: 2278. https://doi.org/10.3390/ma12142278

APA StyleKim, M. K., Kim, D. J., Chung, Y.-S., & Choi, E. (2019). Effects of a Short Heat Treatment Period on the Pullout Resistance of Shape Memory Alloy Fibers in Mortar. Materials, 12(14), 2278. https://doi.org/10.3390/ma12142278