Finite Element Prediction of Residual Stress and Deformation Induced by Double-Pass TIG Welding of Al 2219 Plate

Abstract

1. Introduction

2. Materials and Methods

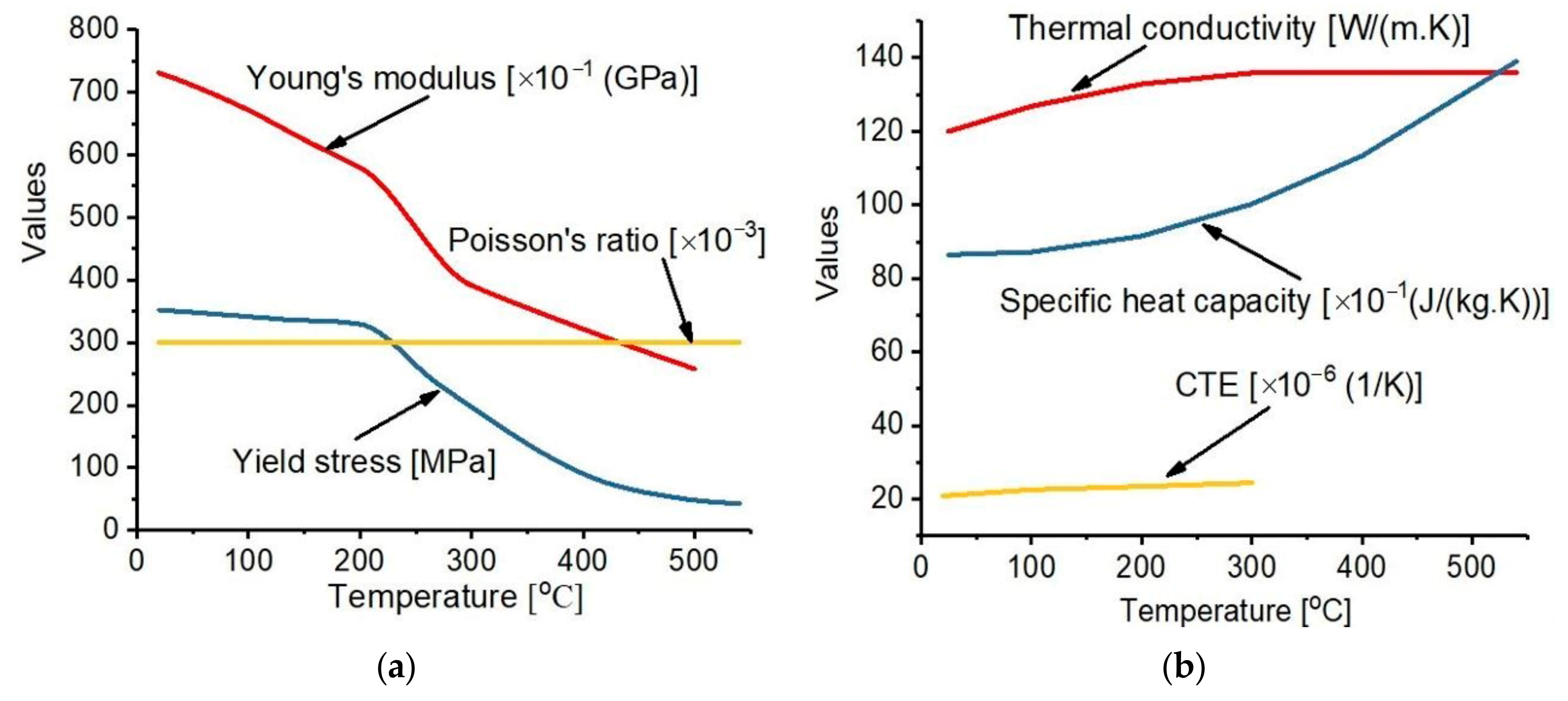

2.1. Material

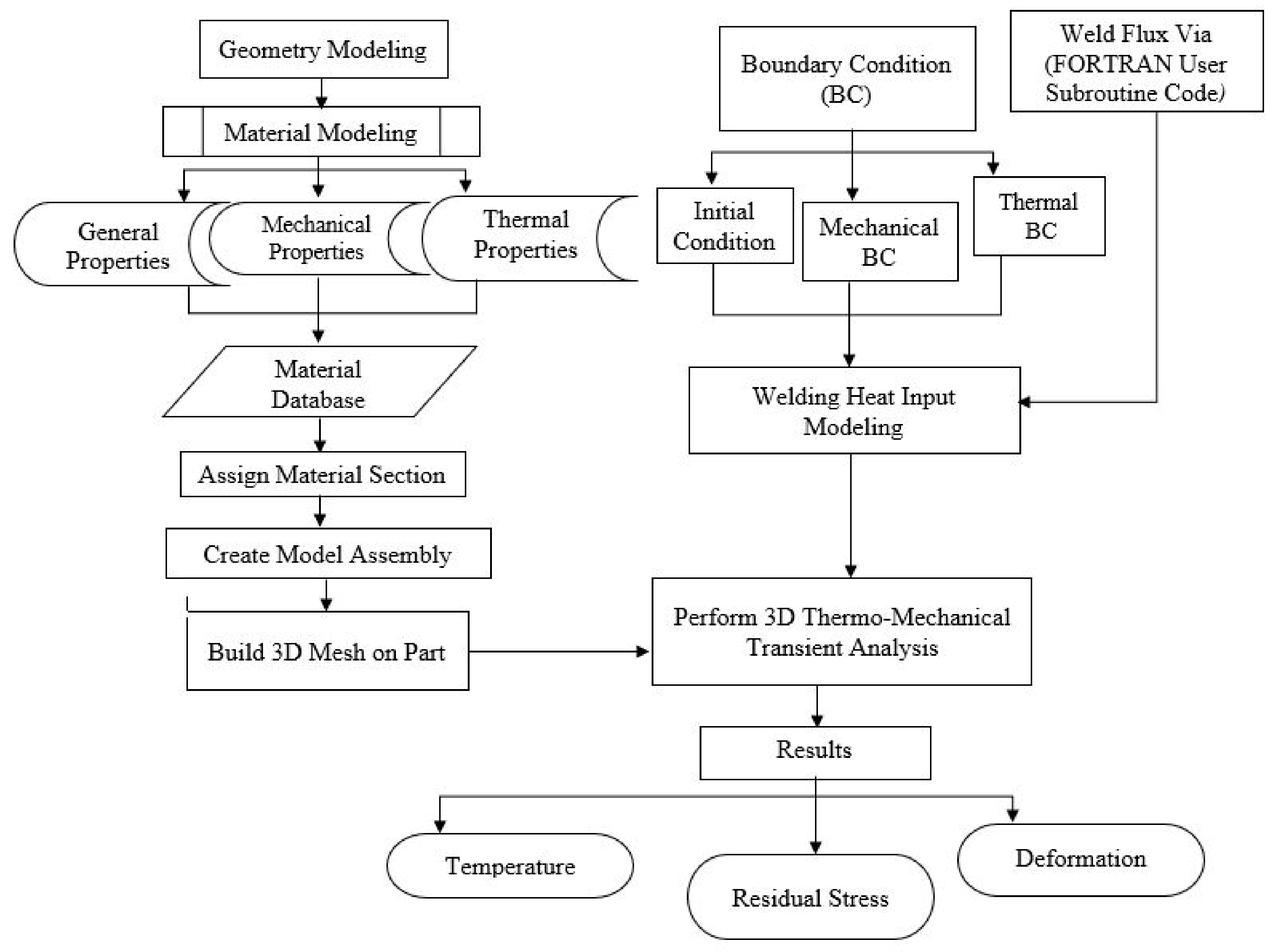

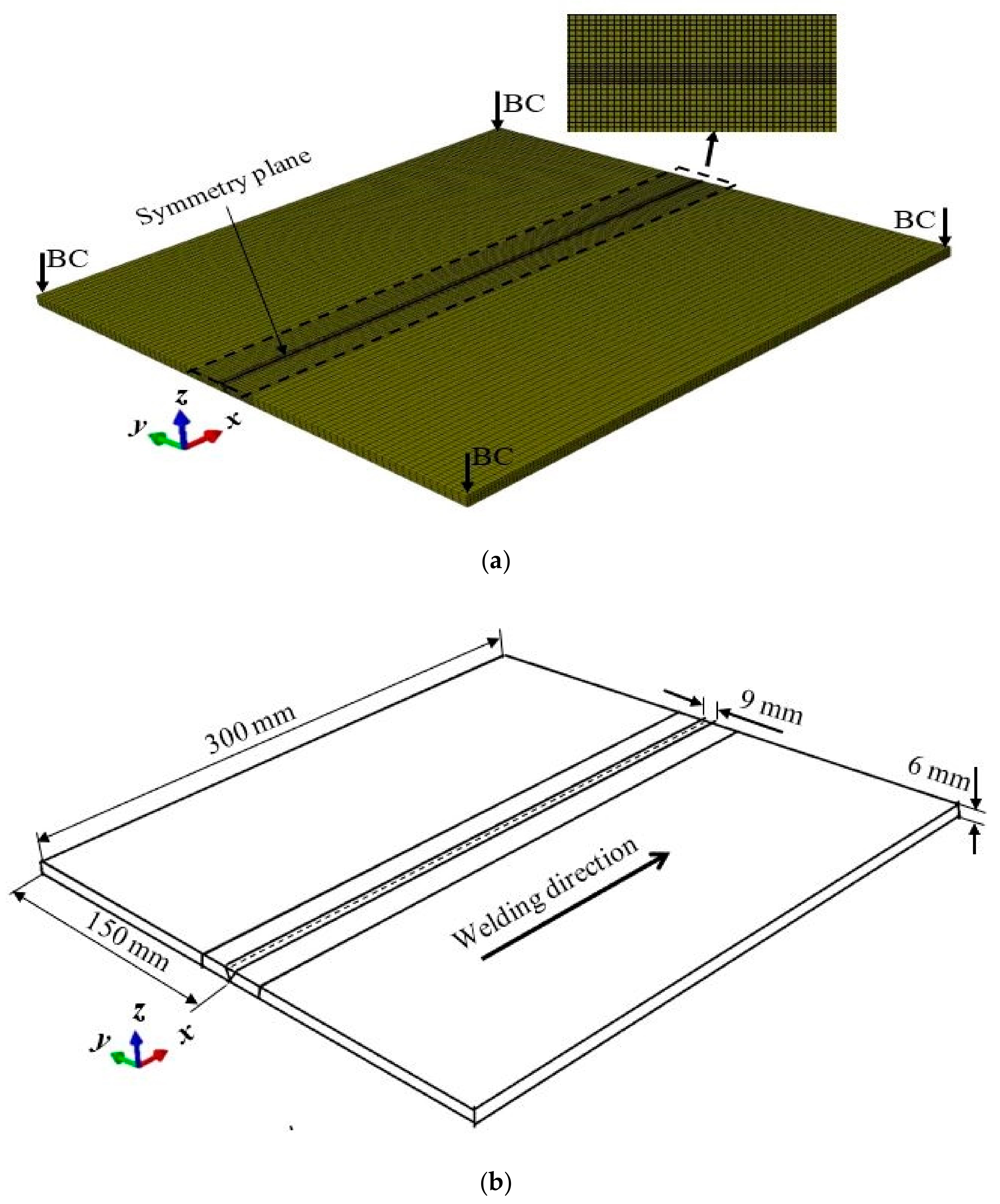

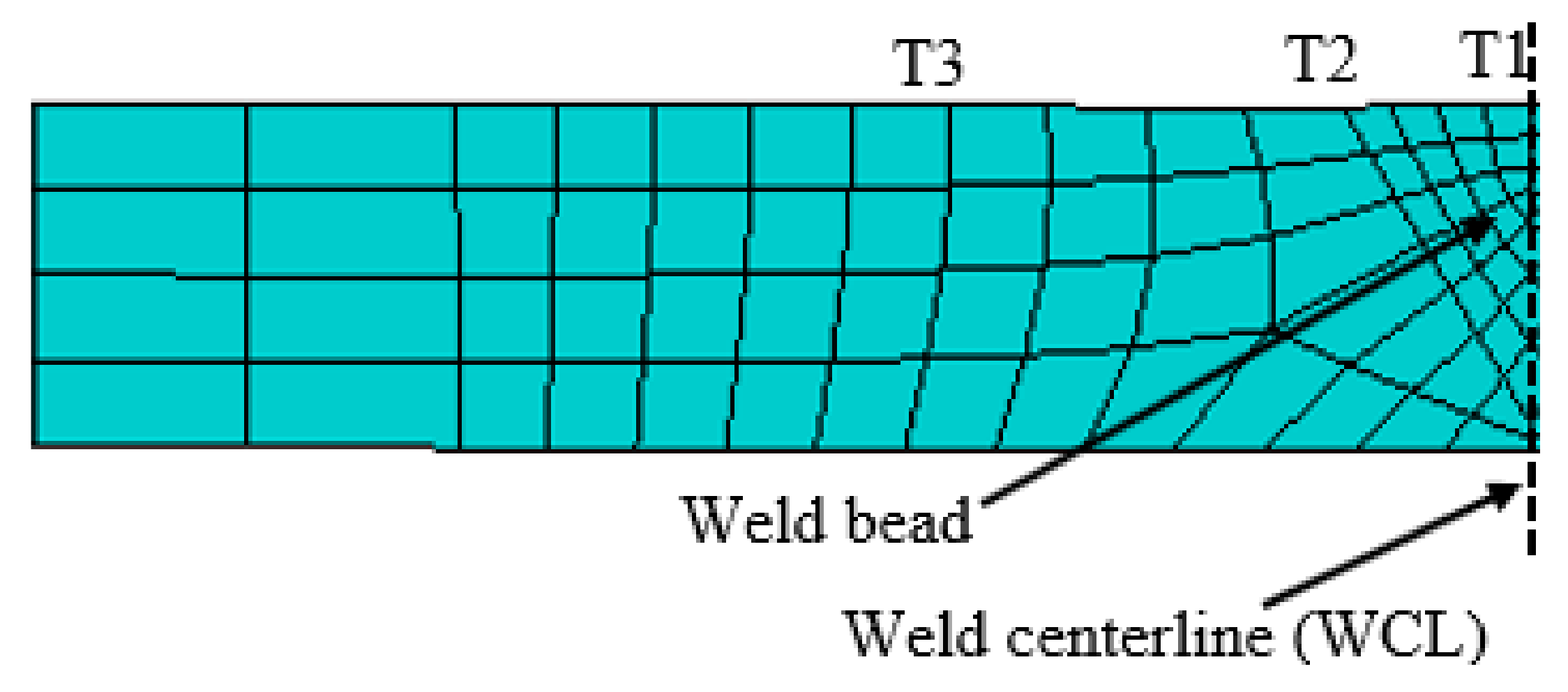

2.2. FE Modelling and Simulation of TIG Welding

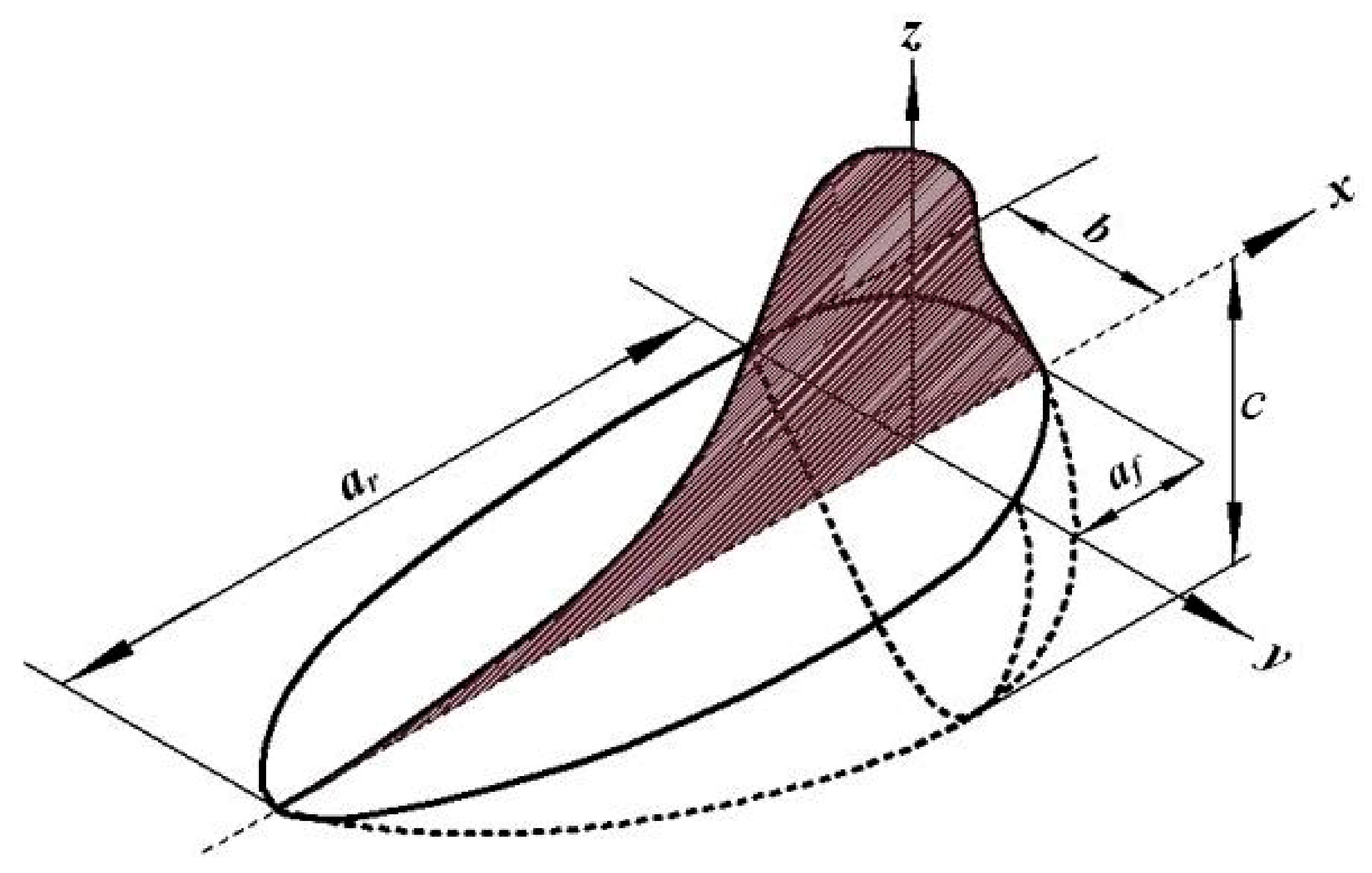

2.2.1. Thermal Analysis

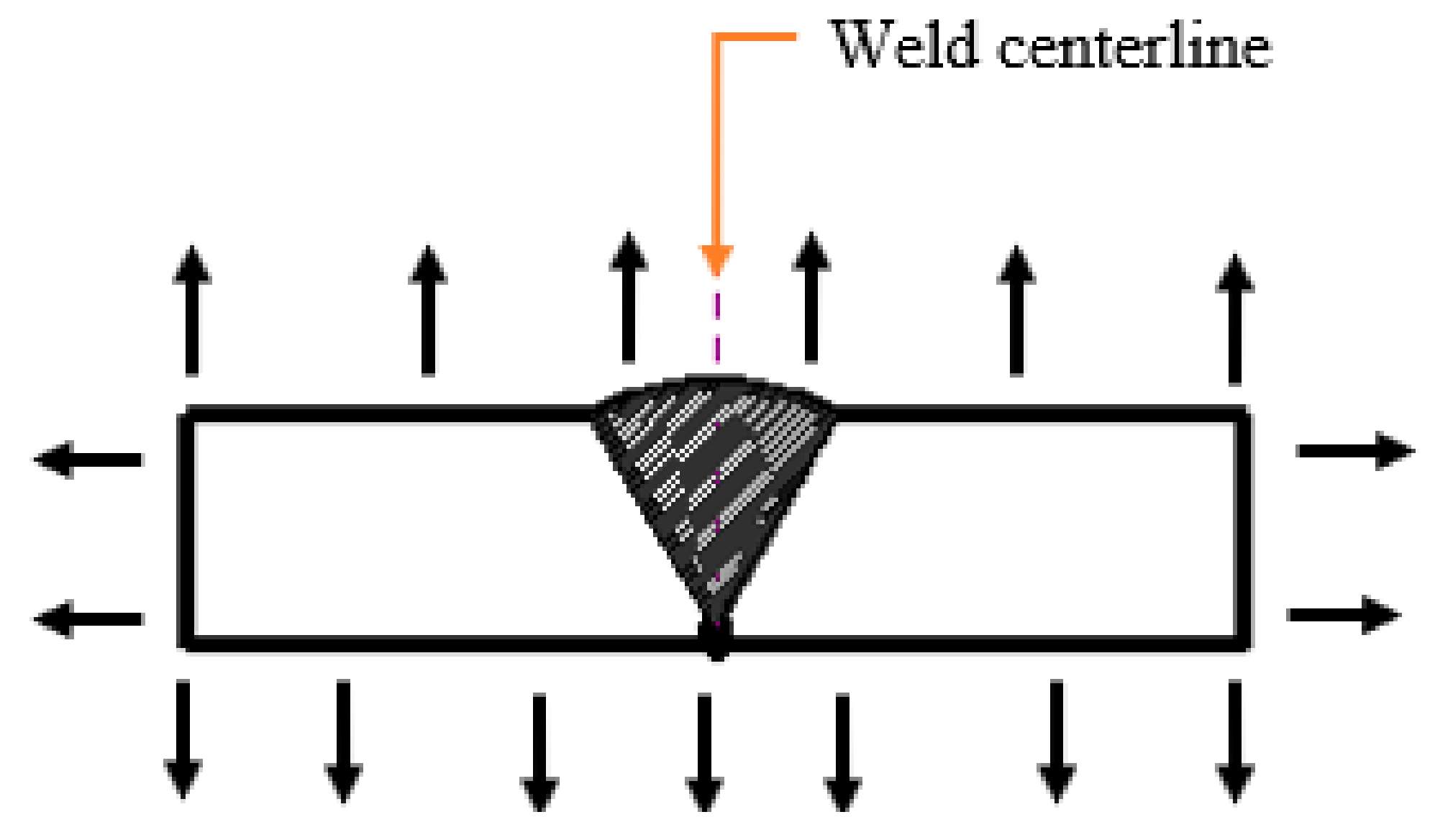

2.2.2. Mechanical Analysis

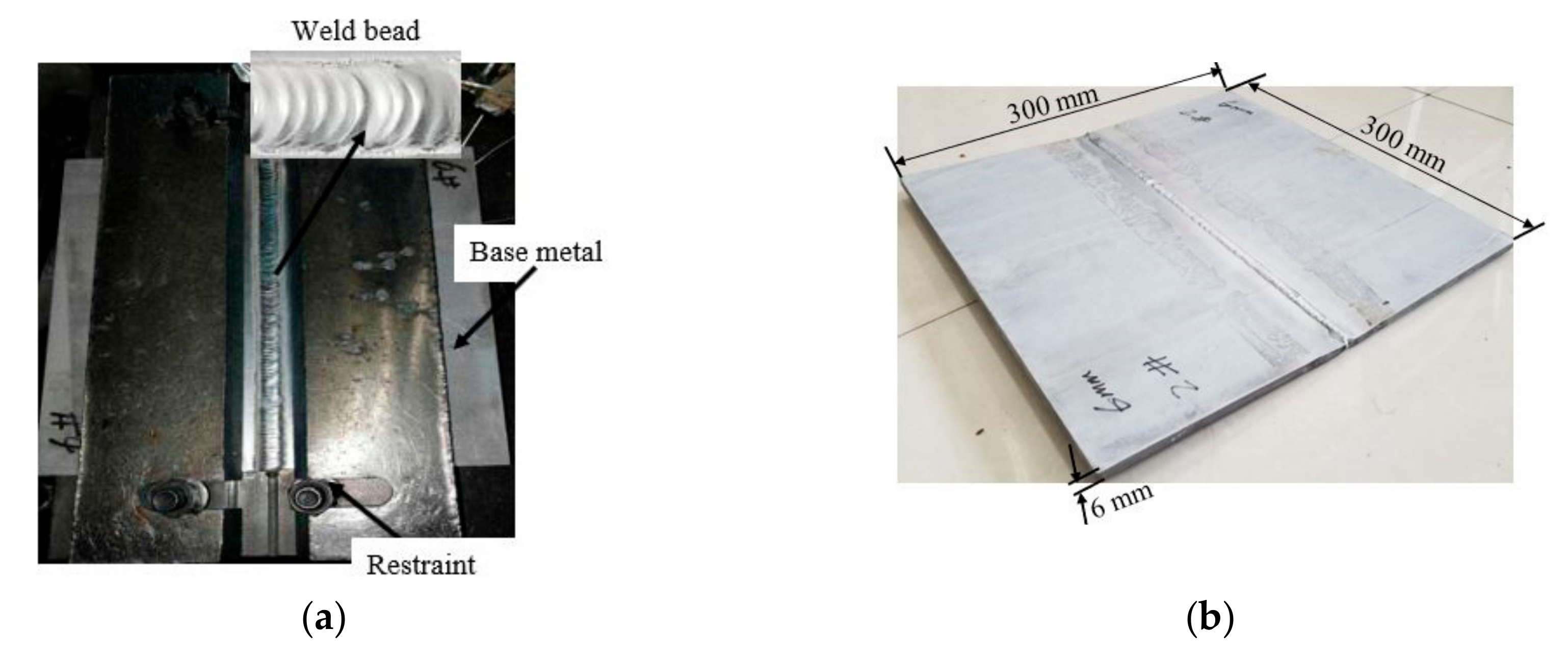

2.3. Experimental Validation

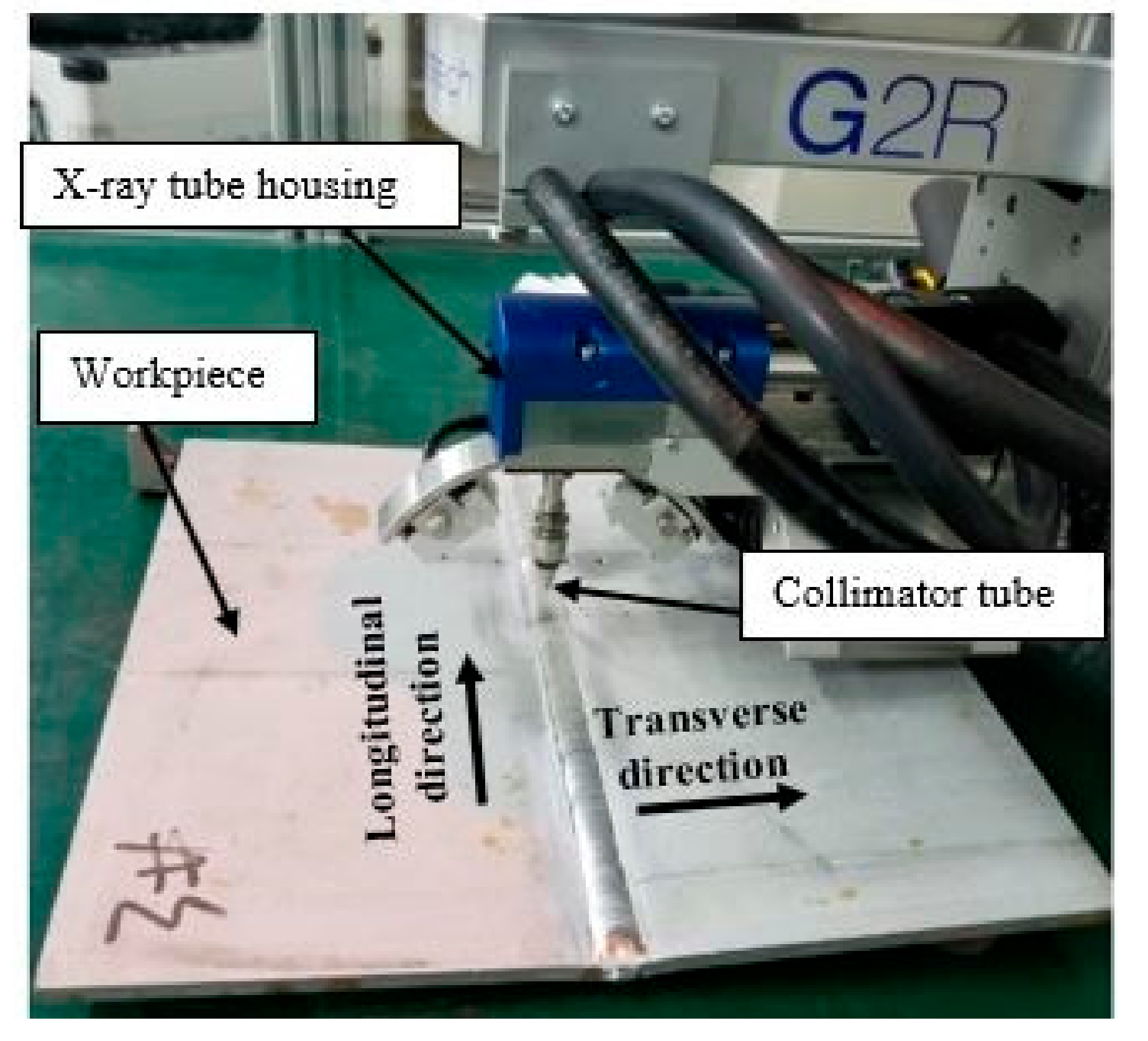

2.4. Residual Stress Measurement Using X-ray Diffractometer (XRD)

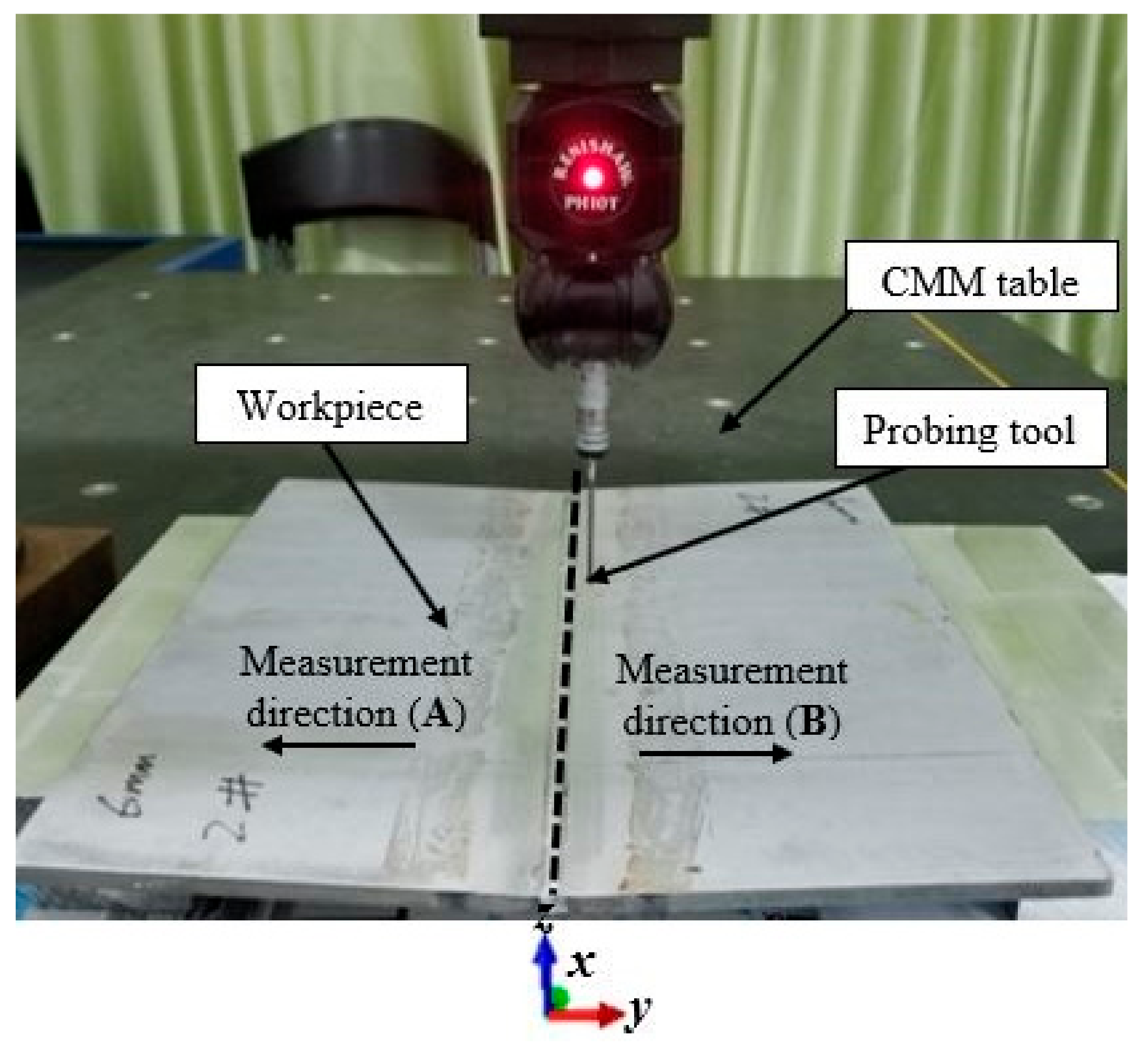

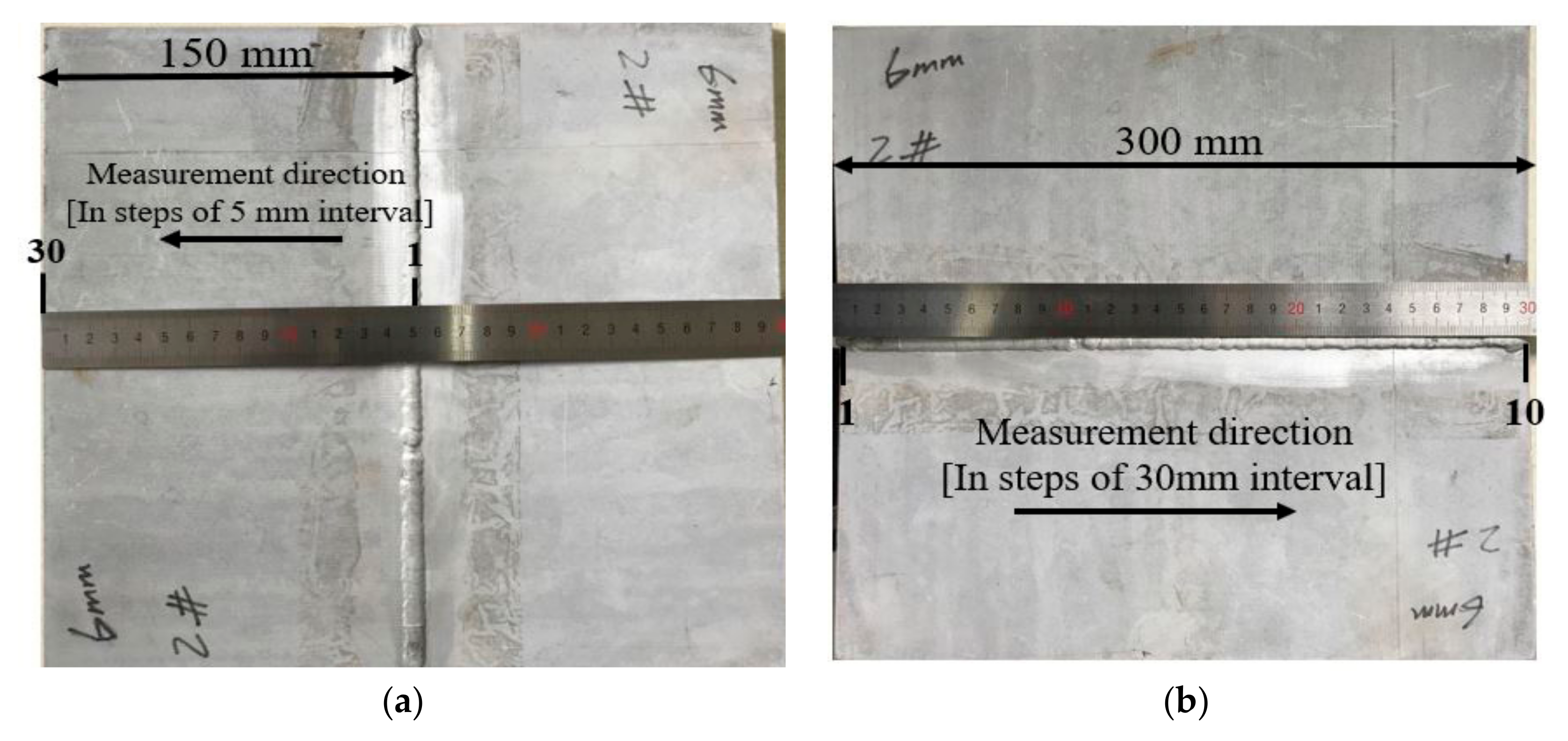

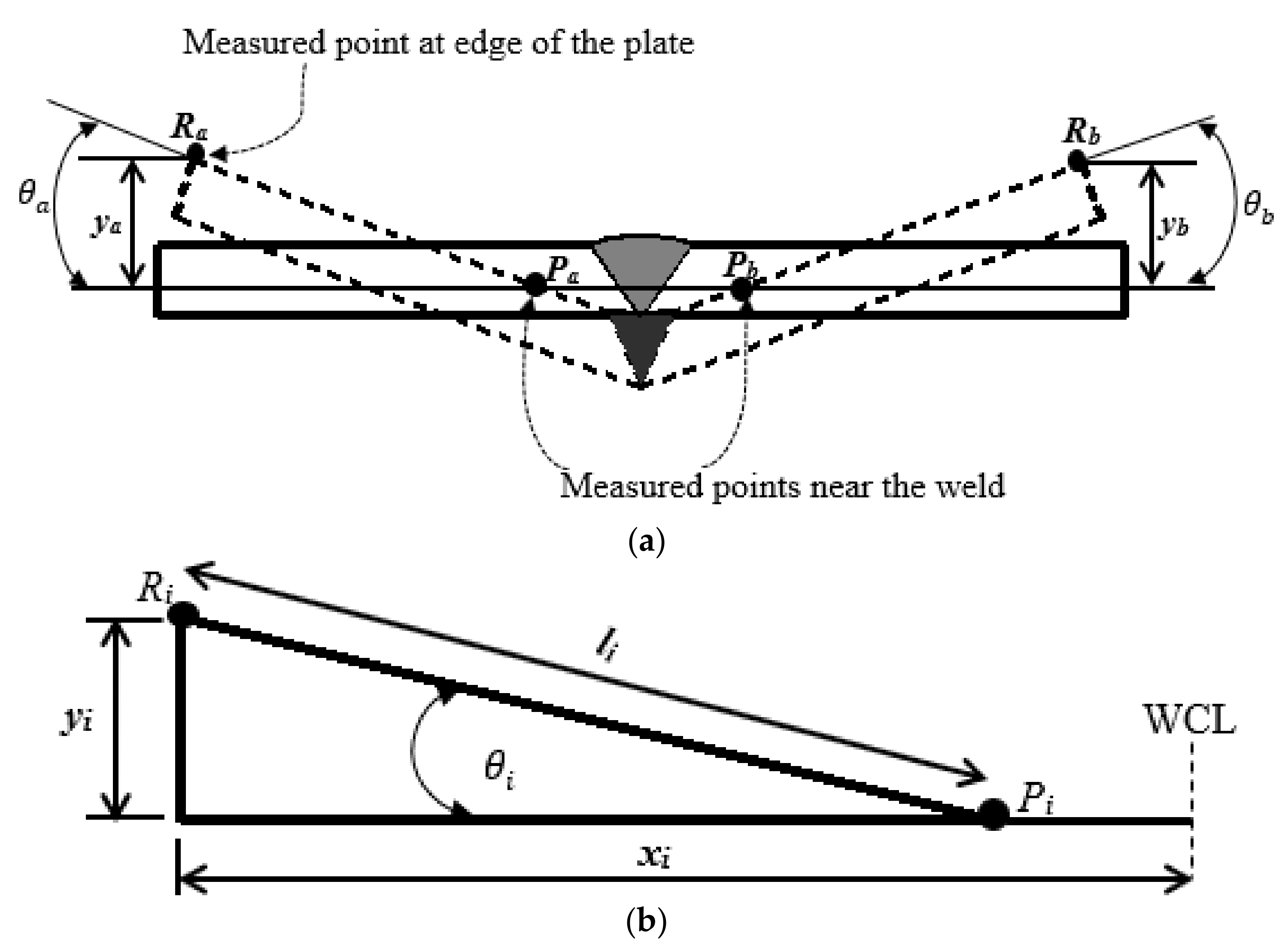

2.5. Measurement of Welding Deformation Using Coordinate Measuring Machine (CMM)

3. Results and Discussions

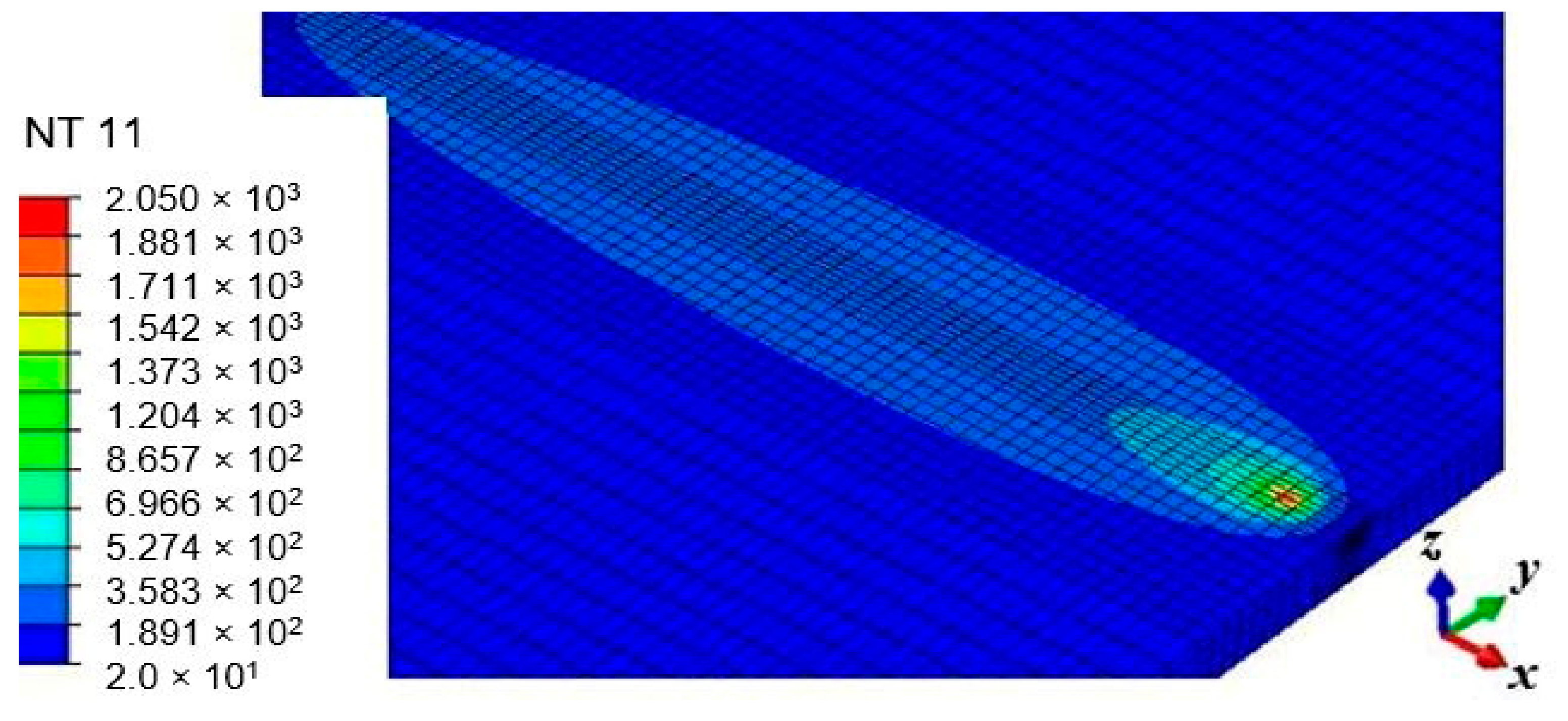

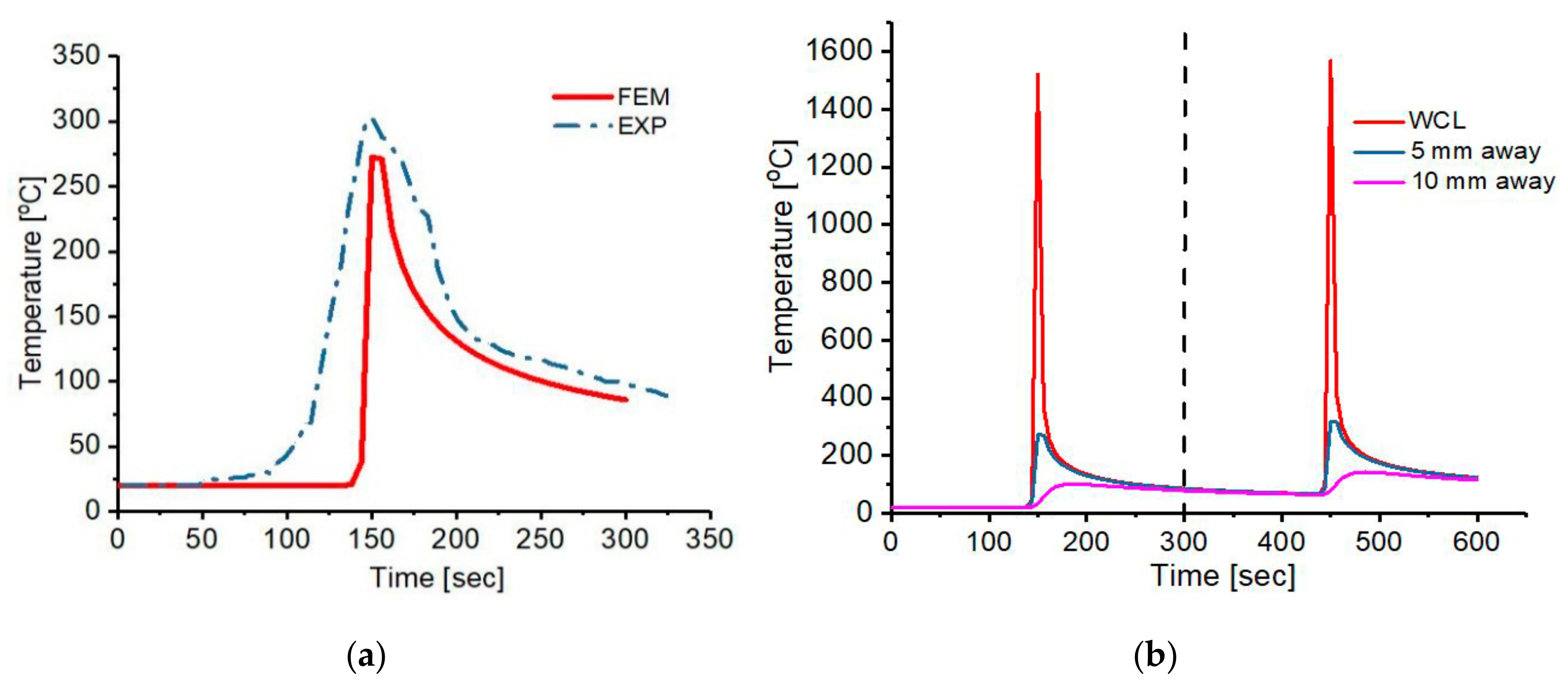

3.1. Thermal Field Induced by the Two-Pass Butt-Welding

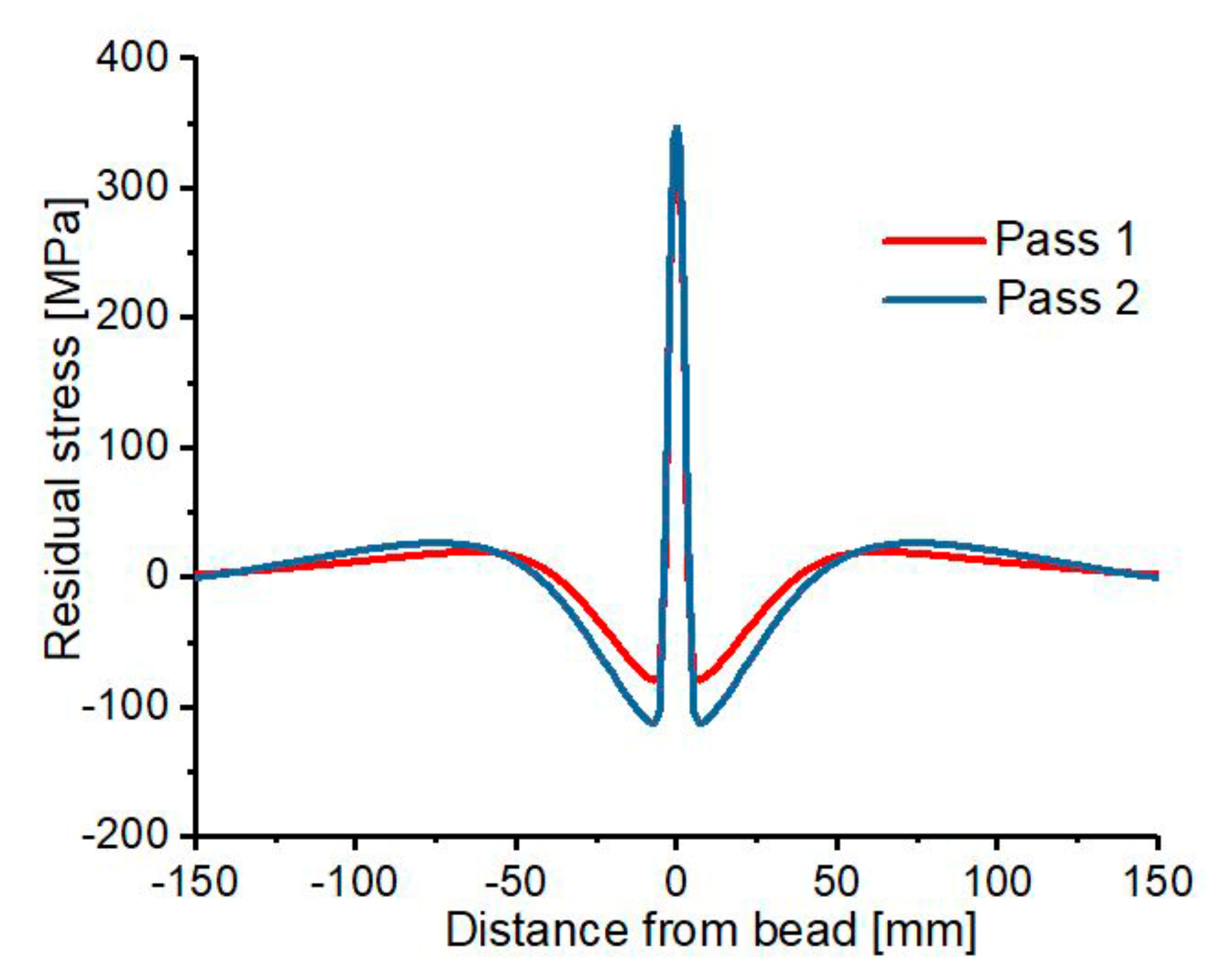

3.2. Comparison of Residual Stresses Between FEA and Experiment

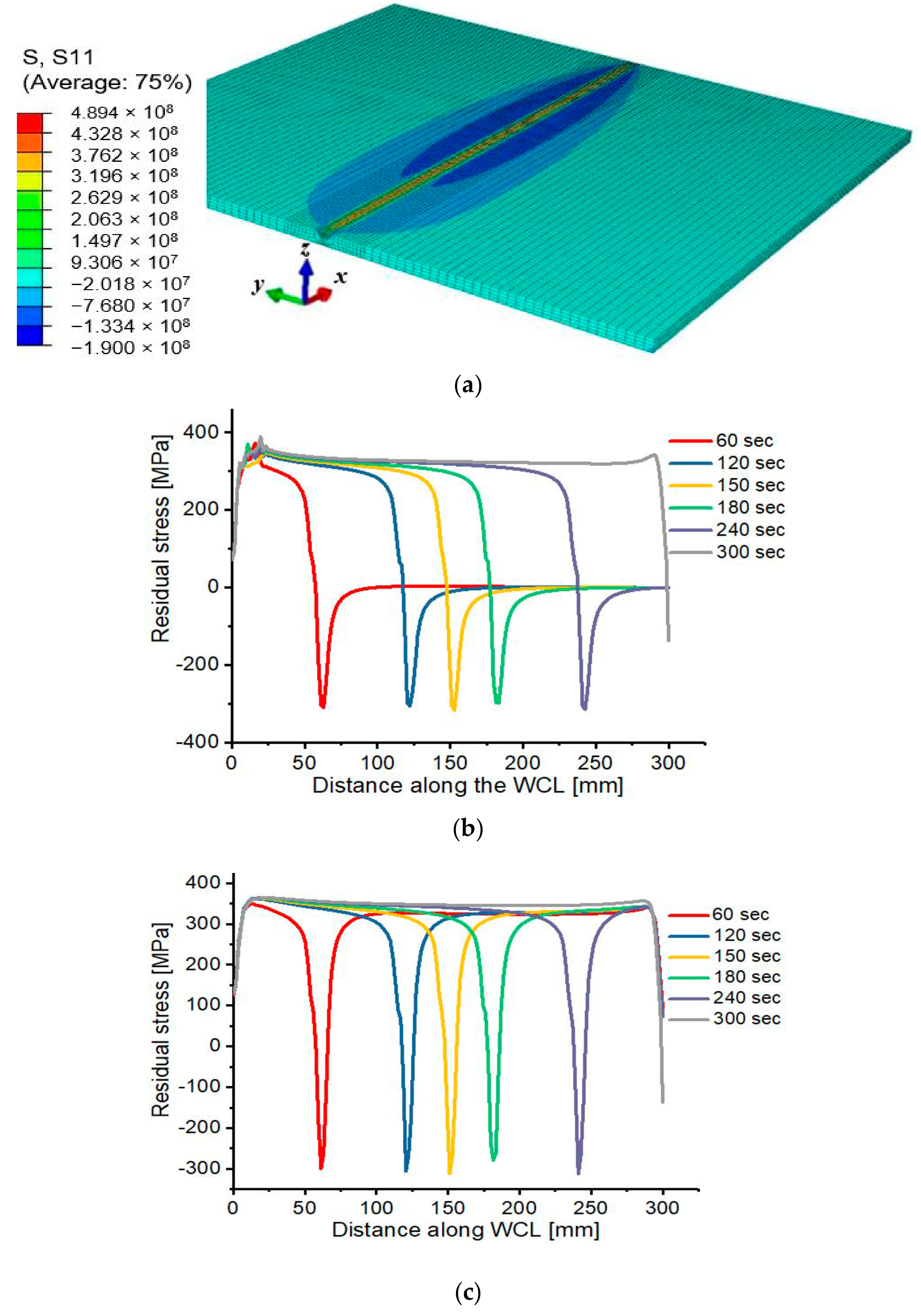

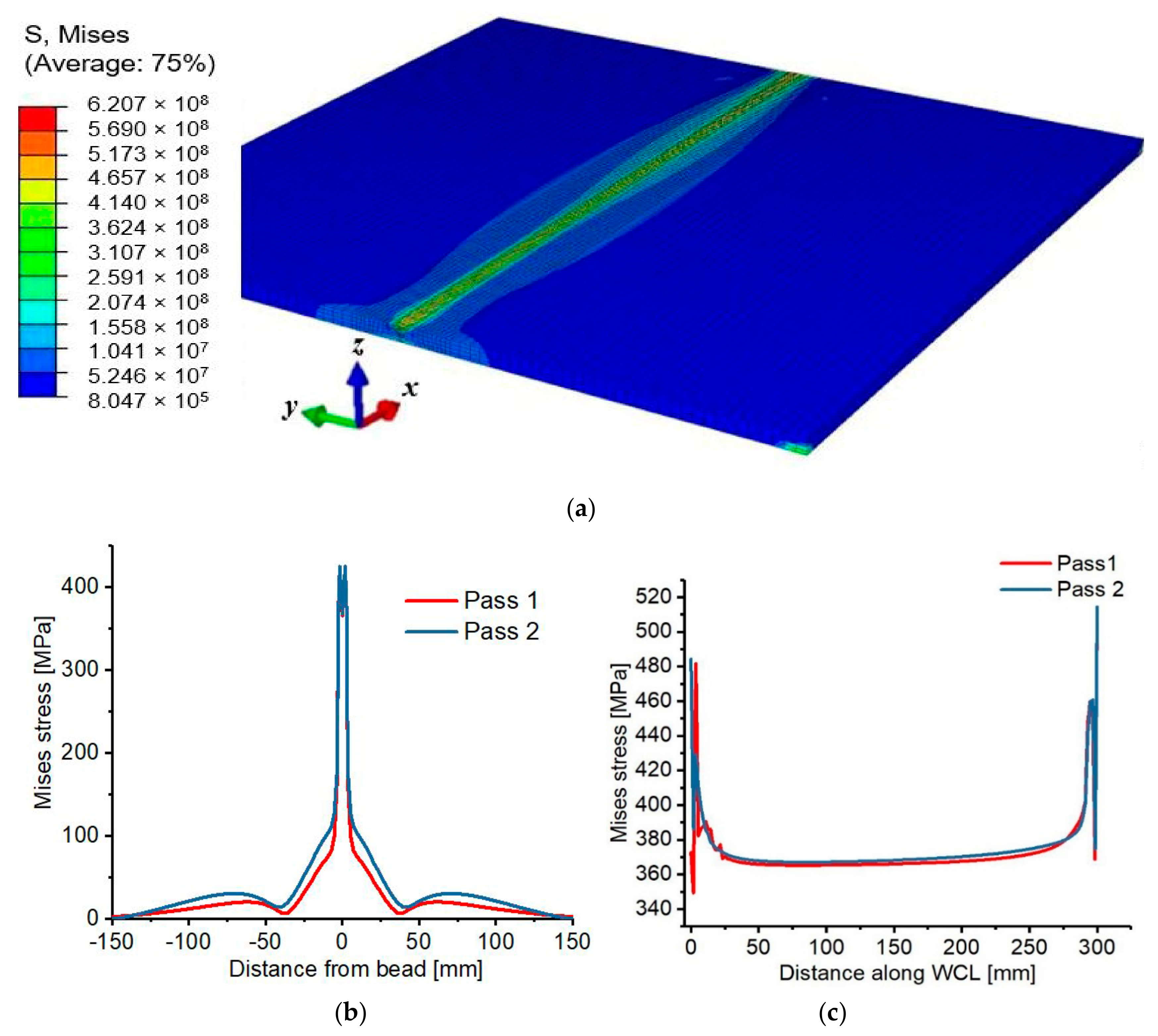

3.3. Residual Stress Evolution

3.4. Comparison Between FEA and Experimental Distortion

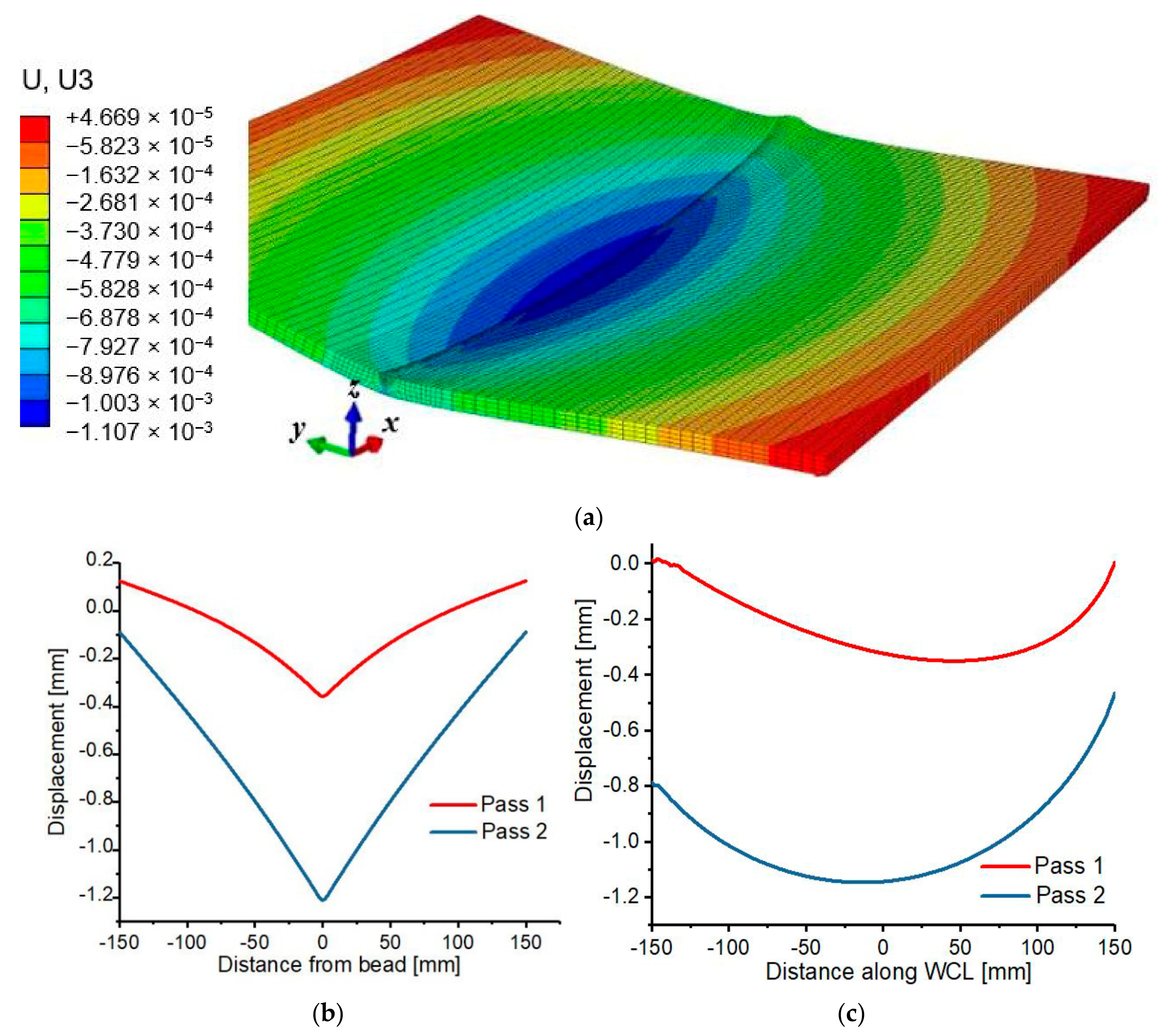

3.5. Welding Deformation and Shrinkage

4. Conclusions

- (1)

- Based on the experimental validation performed, the implemented FE model is feasible and reliable for computing the thermal field, residual stresses, and deformation induced by two-pass TIG welding on Al 2219 plate.

- (2)

- A very high residual stress which is up to 0.788 of the Von Mises stress and 0.81 of the material’s yield strength is induced at the vicinity of the weld zone, consequently resulting in the noticeable deformation observed. The residual stress is so high that reduction is necessary to enhance the mechanical performance of the weld plate.

- (3)

- The observed experimental distortion is significant that the plate may require repair or rework, thus resulting in higher manufacturing cost.

- (4)

- High inter-pass temperature can develop on the workpiece from the previous pass, which may lead to hot cracking of weld during the subsequent passes. Therefore, an inter-pass cooling is recommended after completing each weld pass.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dean, D. FEM prediction of welding residual stress and distortion in carbon steel considering phase transformation effects. Mater. Des. 2009, 30, 359–366. [Google Scholar]

- Diogo, F.; Almeida, R.F.; Martins, J.B. Cardoso. Numerical simulation of residual stresses induced by TIG butt-welding of a thin plate made of AISI 3I6L stainless steel. Procedia. Struct. Integr. Procedia 2017, 5, 633–639. [Google Scholar]

- Webster, G.A.; Wimpory, R.C. Non-destructive measurement of residual stress by neutron diffraction. J. Mater. Process. Technol. 2001, 117, 395–399. [Google Scholar] [CrossRef]

- Akira, M.; Atsushi, K.; Hisashi, S.; Hidekazu, M. Fast three-dimensional multipass welding simulation using an iterative substructure method. J. Mater. Process. Technol. 2015, 215, 30–41. [Google Scholar]

- Rong, Y.; Zhang, G.; Huang, Y. Study of welding distortion and residual stress considering nonlinear yield stress curves and multi-constraint equations. JMEPEG 2016, 25, 4484–4494. [Google Scholar] [CrossRef]

- Deng, D.; Murakawa, H.; Liang, W. Prediction of welding distortion in a curved plate structure by means of elastic Finite Element Method. J. Mater. Process. Technol. 2008, 203, 252–266. [Google Scholar] [CrossRef]

- Yupiter, H.P.; Manurung, A.; Robert, N.L.; Rahim, M.R.; Zakaria, M.Y.; Redza, M.R.; Sulaiman, M.S.; Ghalib, T.S.; Abas, K. Welding distortion analysis of multipass joint combination with different sequences using 3D FEM and experiment. Int. J. Press. Vessel. Pip. 2013, 111–112, 89–98. [Google Scholar]

- Sim, W.M. Challenges of residual stress and part distortion in the civil airframe industry. Int. J. Microstruct. Mater. Prop. 2010, 5, 446. [Google Scholar] [CrossRef]

- Hafiz, W.A.; Jeong, H.H.; Ju, H.L.; Dong, H.B. Welding Residual Stress Analysis and Fatigue Strength Assessment of Multi-Pass Dissimilar Material Welded Joint between Alloy 617 and 12Cr Steel. Metals 2018, 8, 21. [Google Scholar] [CrossRef]

- Obeid, O.; Giulio, A.; Hamid, B.; Hussam, J. Numerical simulation of thermal and residual stress fields induced by lined pipe welding. Therm. Sci. Eng. Progr. 2018, 5, 1–14. [Google Scholar] [CrossRef]

- Abburi Venkata, K.; Truman, C.E.; Wimpory, R.C.; Pirling, T. Numerical simulation of a three-pass TIG welding using a finite element with validation from measurements. Int. J. Press. Vessel. Pip. 2018, 164, 68–79. [Google Scholar] [CrossRef]

- Luigi, A.C.; Filippis, D.; Livia, M.S.; Francesco, F.; Giovanni, M.; Antonio, D.L. Prediction of the Vickers Microhardness and Ultimate Tensile Strength of AA5754 H111 Friction Stir Welding Butt Joints Using Artificial Neural Network. Materials 2016, 9, 915. [Google Scholar] [CrossRef]

- Giuseppe, A.; Arnesano, F.; Facchini, C.; Lossaco, A.M.; Maurizio, P.; Cesare, B. Statistical Analysis and Modelling of Yb: KGW Femtosecond Laser Micro-drilling Process. Proceedia CIRP 2017, 62, 275–280. [Google Scholar]

- Sukhomay, P.; Surjya, P.; Arun, K.; Samantaray, K. Artificial neural network modeling of weld joint strength prediction of a pulsed metal inert gas welding process using arc signals. J. Mat. Proc. Technol. 2008, 202, 464–474. [Google Scholar]

- Li, T.; Liu, G.; Xu, M.; Wang, B.; Fu, T.; Wang, Z.; Raja, D.; Kumar, M. Flow Stress Prediction and Hot Deformation Mechanisms in Ti-44Al-5Nb–(Mo, V, B) Alloy. Materials 2018, 11, 2044. [Google Scholar] [CrossRef]

- George, E.; Cook, R.; Barnett, J.; Andersen, K.; Alvin, M.S. Weld Modelling and Control Using Artificial Neural Network. IEEE. Trans. Ind. Appl. 1995, 31, 1484–1491. [Google Scholar]

- Mohd, I.; Shah, I.; Okamoto, Y.; Okada, A. Neural Network Modeling for Prediction of Weld Bead Geometry in Laser Microwelding. Adv. Opt. Technol. 2013, 2013, 1–7. [Google Scholar]

- Wu, C.T.; Bui, T.Q.; Wu, Y.; Luo, T.L.; Wang, M.; Liao, C.C.; Chen, Y.; Lai, Y.S. Numerical and experimental validation of a particle Galerkin method for metal grinding simulation. Comput. Mech. 2018, 61, 365–383. [Google Scholar] [CrossRef]

- Wu, C.T.; Wu, Y.; Lyu, D.; Pan, X.; Hu, W. The momentum-consistent smoothed particle Galerkin (MC-SPG) method for simulating the extreme thread forming in the flow drill screw-driving process. Comput. Part. Mech. 2019, 1–15. [Google Scholar] [CrossRef]

- Hu, Y.; Feng, G.; Lia, S.; Sheng, W.; Zhang, C. Numerical modeling of ductile fracture in steel plates with non-ordinary state-based peridynamics. Eng. Fract. Mech. 2019. [Google Scholar] [CrossRef]

- Pan, X.; Wu, C.T.; Hu, W.; Wu, Y. A momentum-consistent stabilization algorithm for Lagrangian particle methods in the thermo-mechanical friction drilling analysis. Comput. Mech. 2019, 1–20. [Google Scholar] [CrossRef]

- Liu, L.; Wu, Y.; Gong, H.; Li, S.; Ahmad, A.S. A Physically Based Constitutive Model and Continuous Dynamic Recrystallization Behavior Analysis of 2219 Aluminum Alloy during Hot Deformation Process. Matericals 2018, 11, 1443. [Google Scholar] [CrossRef]

- Liu, L.; Wu, Y.; Gong, H. Effects of Deformation Parameters on Microstructural Evolution of 2219 Aluminum Alloy during Intermediate Thermo-Mechanical Treatment Process. Materials 2018, 11, 1496. [Google Scholar] [CrossRef]

- Park, J.U.; An, G.; Lee, H.W. Effect of external load on angular distortion in fillet welding. Mater. Des. 2012, 42, 403–410. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Cai, C.; Gao, L.; Wu, L. Fundamental studies on in-process controlling angular distortion in asymmetrical double-sided arc welding. J. Mater. Process. Technol. 2008, 205, 214–223. [Google Scholar] [CrossRef]

- Lidam, R.H.; Yupiter, M.R.; Rahim, M.; Sulaiman, M.; Zakaria, M.; Tham, G.; Abasa, S.; Haruman, E.; Chau, C.Y. Simulation study on multi-passed welding distortion of combined joint types using thermo-elastic-plastic FEM. J. Eng. Res. 2012, 9, 1–6. [Google Scholar] [CrossRef]

- ABAQUS Documentation, Release 14; Dassault Systemes: Providence, RI, USA, 2014.

- Attarha, M.J.; Sattari-Far, I. Study on welding temperature distribution in thin welded plates through experimental measurements and finite element simulation. J. Mater. Process. Technol. 2011, 211, 688–694. [Google Scholar] [CrossRef]

- Goldak, J.; Chakravarti, A.; Bibby, M. A New Finite Element Model for Welding Heat Sources. Metall. Trans. B. 1984, 15B, 299. [Google Scholar] [CrossRef]

- Obeid, O.; Alfano, G.; Bahai, H. Thermo-Mechanical Analysis of a Single-Pass Weld Overlay and Girth Welding in Lined Pipe. JMEPEG 2017, 26, 3861–3876. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, L.; Liu, Y.; Ma, Z.; Li, H.; Liu, C.; Wu, J.; Ma, J.; Li, Z. Analysis of the Effect of Tungsten Inert Gas Welding Sequences on Residual Stress and Distortion of CFETR Vacuum Vessel Using Finite Element Simulations. Metals 2018, 8, 912. [Google Scholar] [CrossRef]

- Duan, Y.G.; Vincent, Y.; Boitout, F.; Leblond, J.B.; Bergheau, J.M. Prediction of welding residual distortions of large structures using a local/global approach. J. Mech. Sci. Technol. 2007, 21, 1700–1706. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhang, P.; Hou, Z.G.; Li, C.Z. Inherent strain method and thermal elastic-plastic analysis of welding deformation of a thin-wall beam. J. Mech. 2008, 24, 301–309. [Google Scholar] [CrossRef]

- Dai, J.; Xi, S.; Li, D. Numerical Analysis of Curing Residual Stress and Deformation in Thermosetting Composite Laminates with Comparison between Different Constitutive Models. Materials 2019, 12, 572. [Google Scholar] [CrossRef]

- Ahmad, A.S.; Wu, Y.; Gong, H.; Liu, L. Determination of the Effect of Cold Working Compression on Residual Stress Reduction in Quenched Aluminum Alloy 2219 Block. SV- JME 2019, 65, 311–318. [Google Scholar] [CrossRef]

| Weight % | Al | Si | Fe | Cu | Mn | Mg | Zn | Ti | Others |

|---|---|---|---|---|---|---|---|---|---|

| Al 2219 | Balance | 0.20Max | 0.30Max | 5.80–6.80 | 0.20–0.40 | 0.02 Max | 0.10 Max | 0.02–0.10 | Max 0.050 each Max 0.15 total |

| Parameters | Values |

|---|---|

| Efficiency (η) | 0.7 |

| Current (I) | 12 A |

| Voltage (U) | 200 V |

| af | 6.0 mm |

| ar | 12 mm |

| b | 3.5 mm |

| c | 5.0 mm |

| ff | 1.33 |

| fr | 0.67 |

| Parameters. | Values |

|---|---|

| Efficiency (η) | 0.7 |

| Current (I) | 12 A |

| Voltage (U) | 200 V |

| Ambient Temperature | 19 °C |

| Welding Speed (pass 1) | 2.6 mm/s |

| Welding speed (pass 2) | 2.8 mm/s |

| (pass 1) | 0.646 |

| (pass 2) | 0.600 |

| X-ray Diffraction Parameters | Specification/Values |

|---|---|

| Tube type | Cr |

| Max. Current | 9 A |

| Max. Power | 270 W |

| Supplied current during the experiment | 6.7 A |

| Supplied voltage during the experiment | 30 V |

| Exposure time for the calibration | 8 s |

| Exposure time for measurement | 10 s |

| Collimator diameter | 3 mm |

| Collimator distance | 10.390 mm |

| Detector distance | 50 mm |

| Tilt angle | −45° to 45° |

| Number of tilts | 5/5 |

| Rotation angle | 0° to 90° |

| Number of rotations | 2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, A.S.; Wu, Y.; Gong, H.; Nie, L. Finite Element Prediction of Residual Stress and Deformation Induced by Double-Pass TIG Welding of Al 2219 Plate. Materials 2019, 12, 2251. https://doi.org/10.3390/ma12142251

Ahmad AS, Wu Y, Gong H, Nie L. Finite Element Prediction of Residual Stress and Deformation Induced by Double-Pass TIG Welding of Al 2219 Plate. Materials. 2019; 12(14):2251. https://doi.org/10.3390/ma12142251

Chicago/Turabian StyleAhmad, Abdulrahaman Shuaibu, Yunxin Wu, Hai Gong, and Lin Nie. 2019. "Finite Element Prediction of Residual Stress and Deformation Induced by Double-Pass TIG Welding of Al 2219 Plate" Materials 12, no. 14: 2251. https://doi.org/10.3390/ma12142251

APA StyleAhmad, A. S., Wu, Y., Gong, H., & Nie, L. (2019). Finite Element Prediction of Residual Stress and Deformation Induced by Double-Pass TIG Welding of Al 2219 Plate. Materials, 12(14), 2251. https://doi.org/10.3390/ma12142251