This section is separated into two parts. In the first part of this section, we investigate the geometrical stiffening effect caused by a polymeric coating. To this end, we consider macroscopic samples of nanoporous gold with and without a coating and analyze it under the assumption that we can apply bulk material values for the gold ligaments and the polymer coating. To find out the orthotropic material parameters of such samples and to quantify the stiffening effect caused by the coating, we perform a homogenization by means of the window method.

The second part of this section is related to the comparison of numerical computations on NPG-PPy-composites with a ligament diameter of

and a coating thickness of

to experimental investigations on NPG-PPy samples with a ligament diameter of

and a PPy coating thickness of

. Under the assumption of self-similarity of these structures, which was shown in [

28,

44], we aim to solve the inverse problem, meaning to find the material parameters of the polymer coating such that numerically and experimentally obtained stress–strain curves coincide. The self-similarity properties of NPG were also studied in [

45].

4.1. Linear Elastic Properties

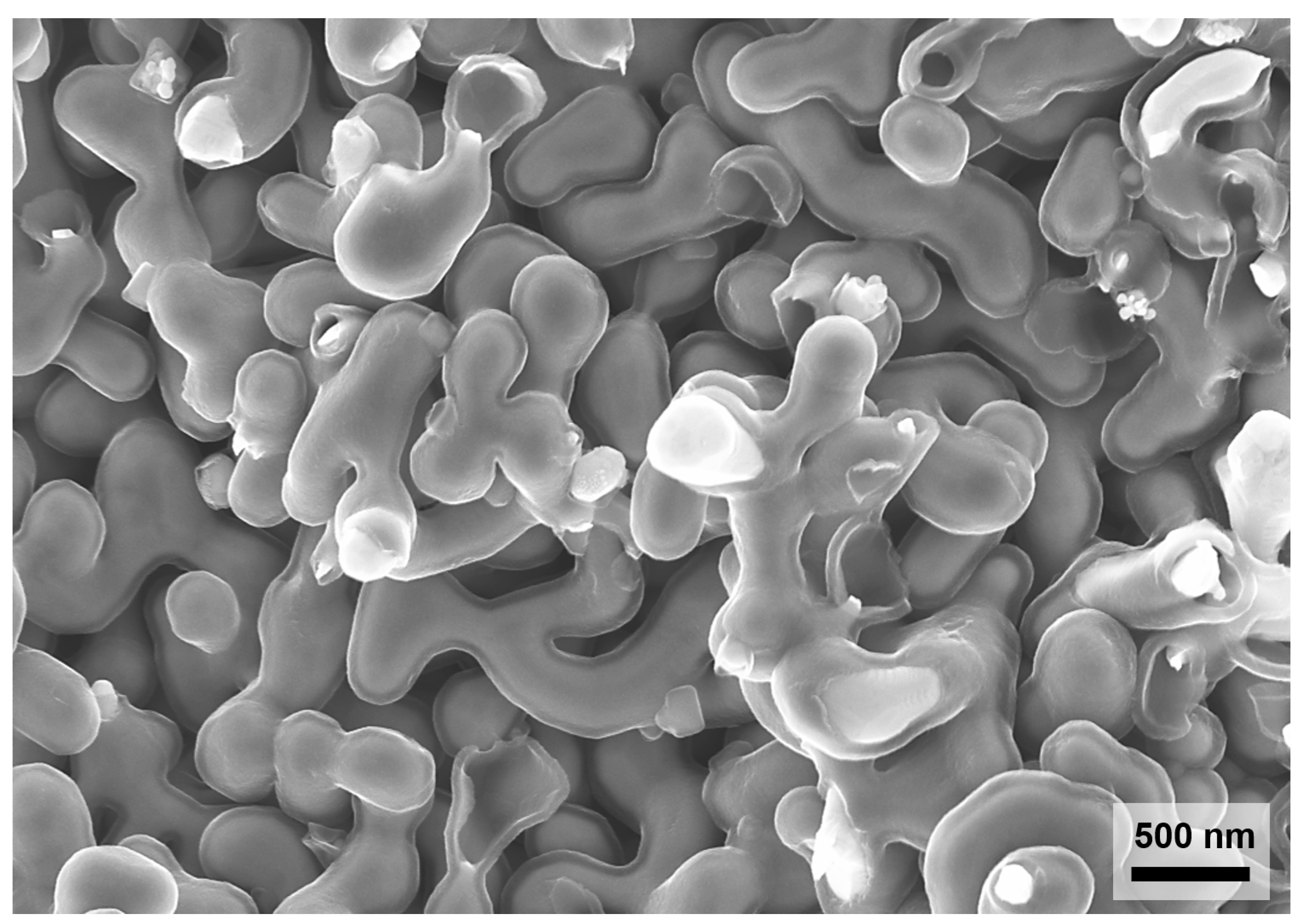

The starting point for our investigation of the elastic properties of nanoporous gold with a mean ligament diameter of

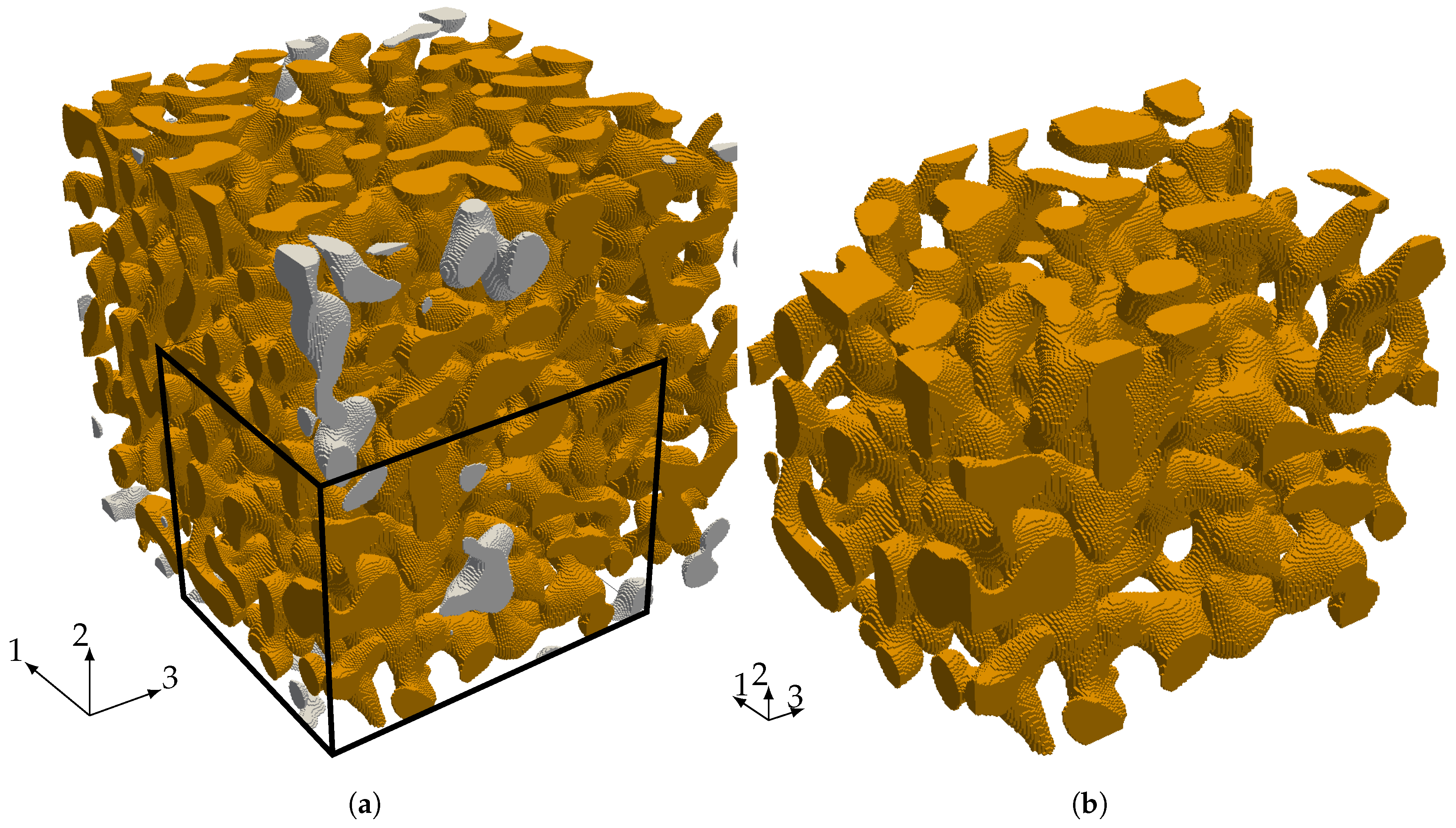

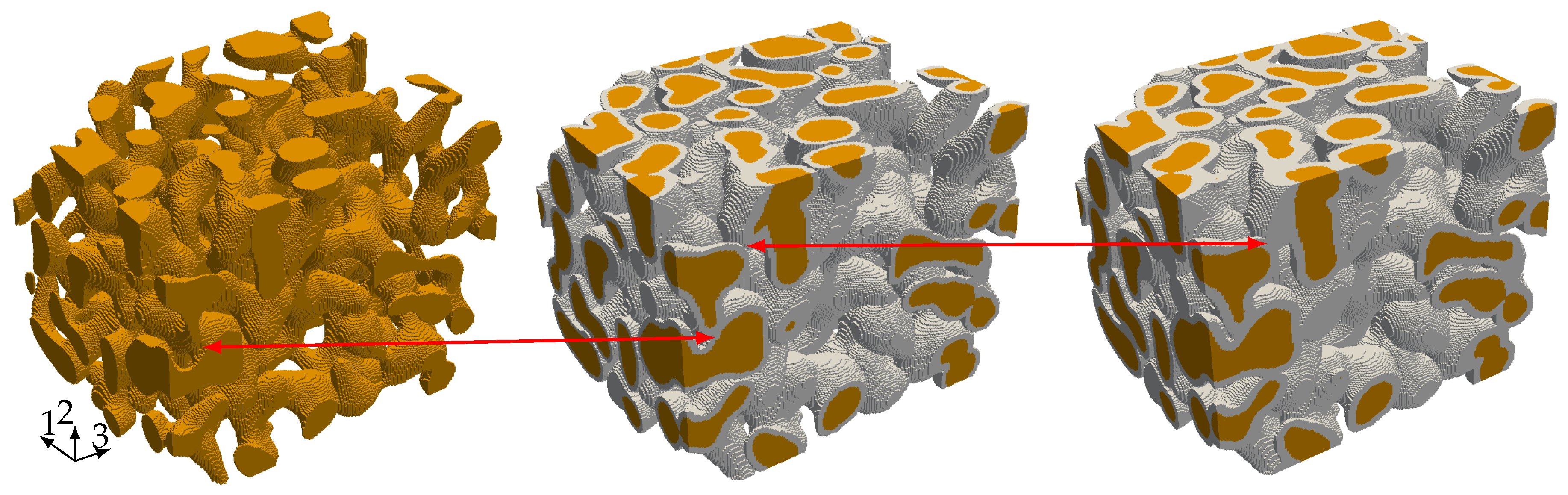

is a voxel model of a representative sample—see

Figure 6a. The data was obtained by 3D focused ion beam-scanning electron microscope (FIB-SEM) tomography undertaken by [

28,

46]. The solid fraction of the sample is 32%. For details on the tomography and data analysis in terms of structural and mechanical properties, see [

28,

29,

44]. The model preparation requires only little pre-processing effort. Disconnected regions—made visible by gray color—bear no loads and are removed from the model. In order to detect these isolated regions, we make use of a seed-fill algorithm [

47]. In a second step, we extracted a sub-sample from the full model that is small enough to be analyzed on a computer in a reasonable time and large enough to carry all characteristic information of the microstructure (see

Figure 6b).

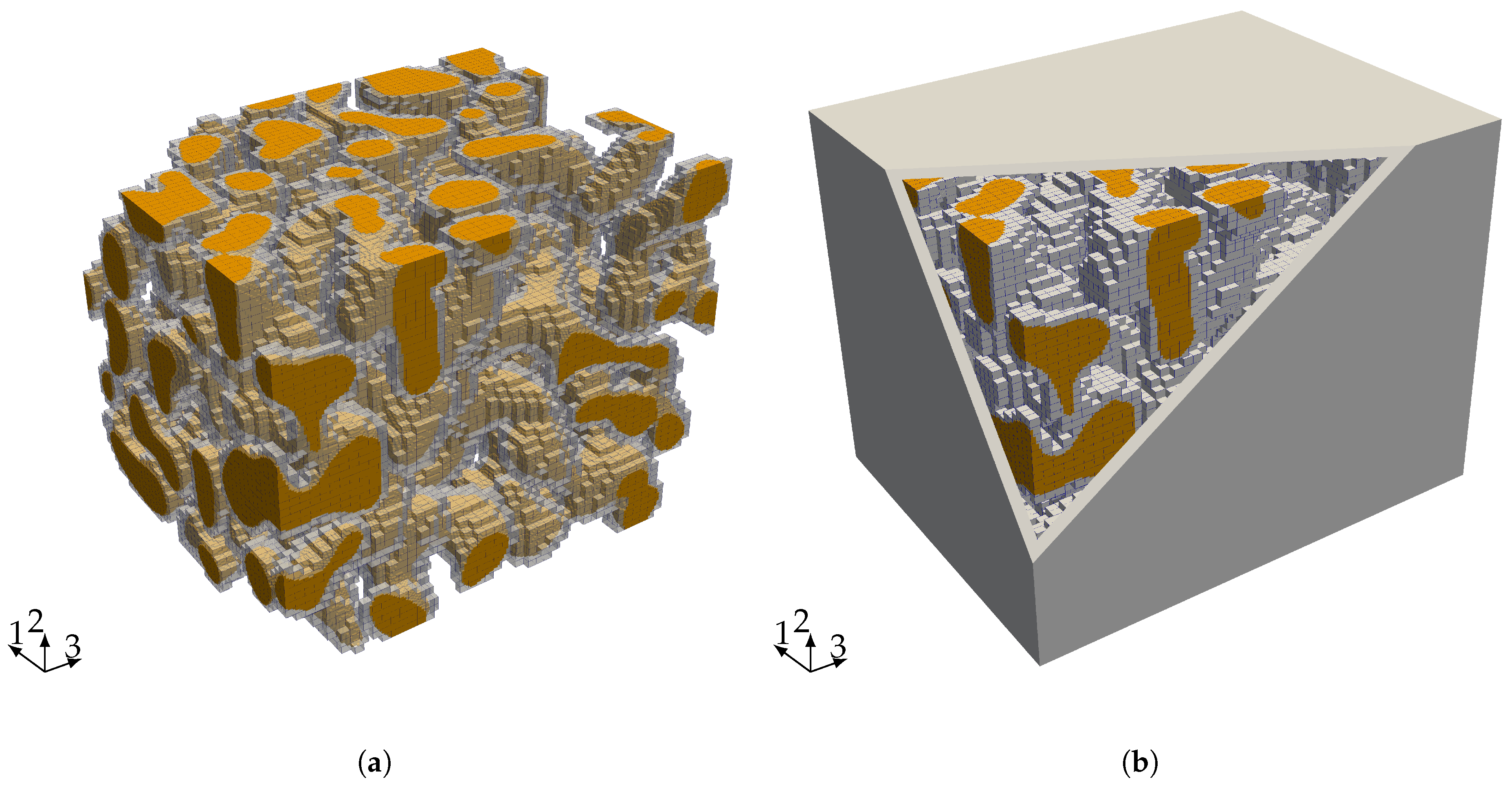

We discretize the sub-sample by finite cells where each cell contains four voxels per direction—see

Figure 7a. The refinement of the spatial discretization is carried out by increasing the polynomial degree of the shape functions (

p-refinement) and not by reducing the element size (

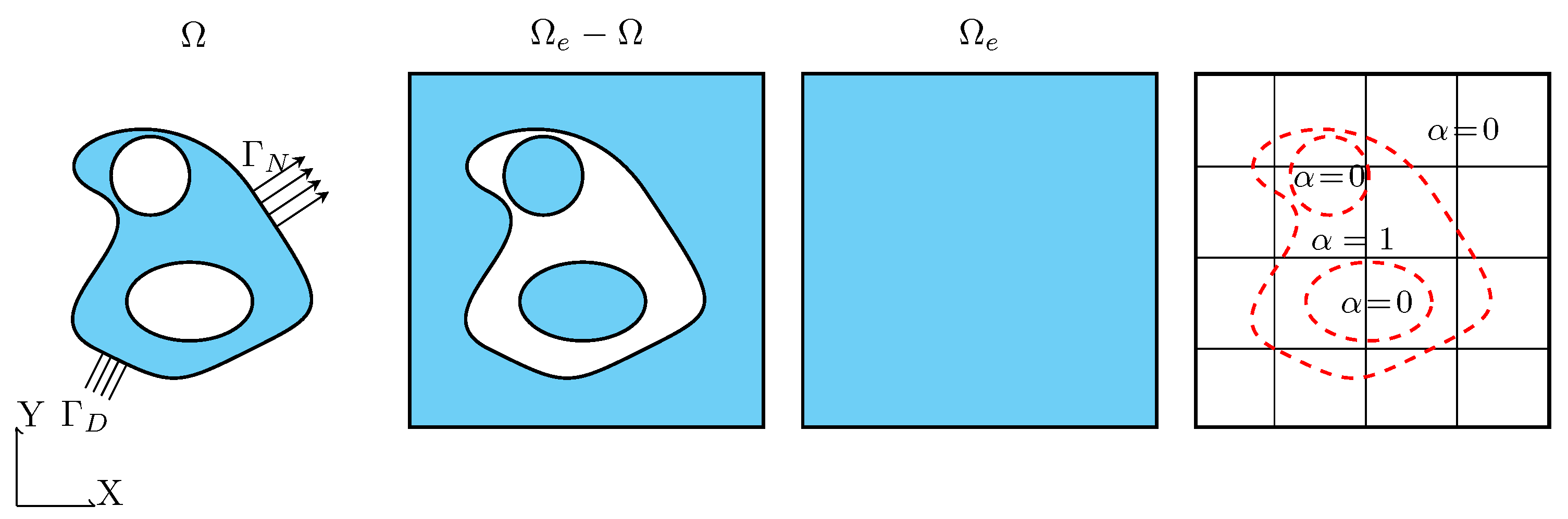

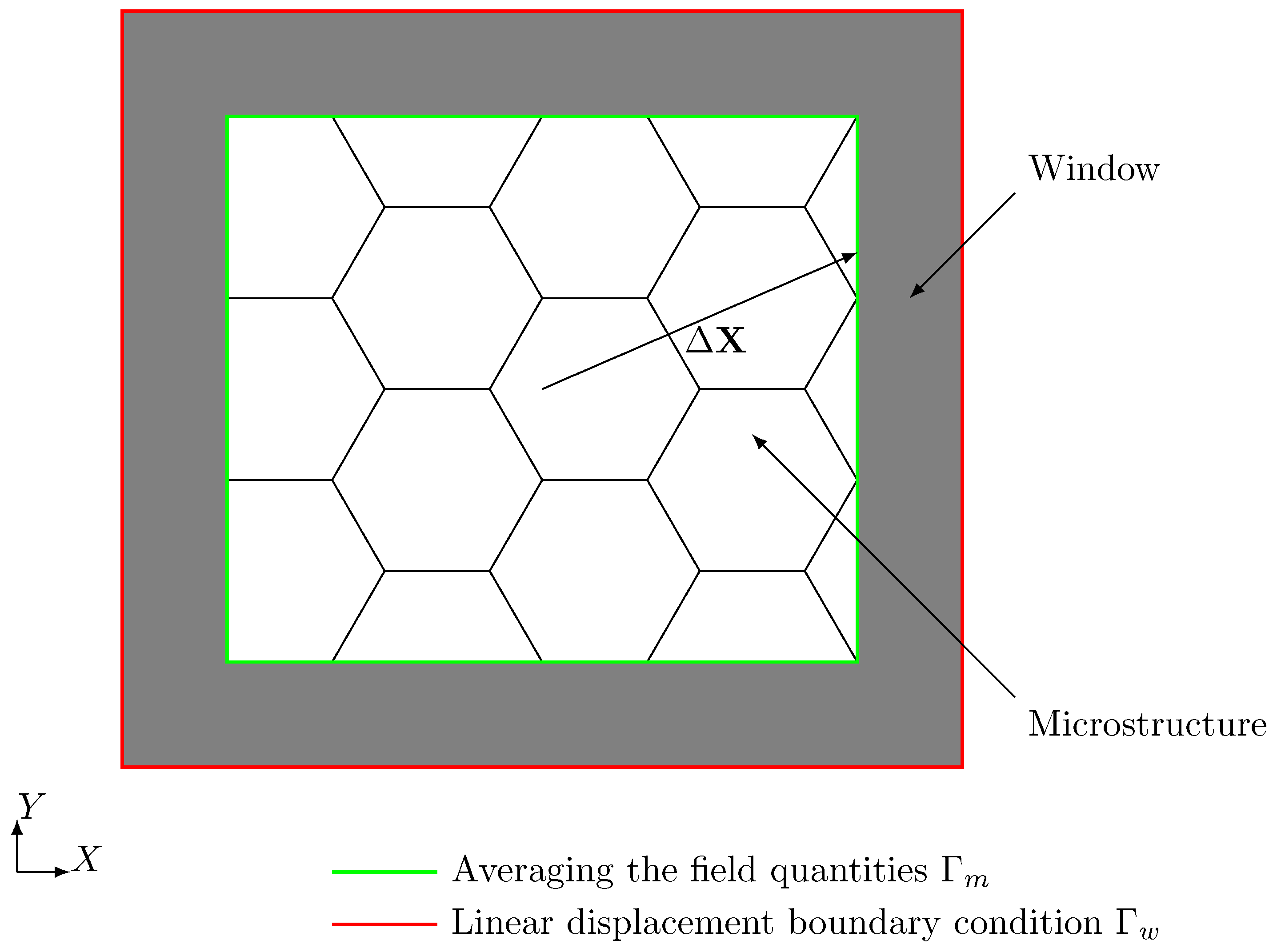

h-refinement). The application of the window method requires to embed the sample of nanoporous gold into a so-called window as depicted in

Figure 7b. Determining all elastic properties of the microstructure requires solving different load-cases. The window serves to apply the corresponding displacement boundary conditions not directly to the microstructure but to the window and by this lowers the influence of the boundary conditions. The window layer itself is composed of one layer of finite cells and is adjustable in thickness to model different types of boundary conditions. For a large window thickness, the boundary conditions resemble a Neumann boundary, while, for a small window thickness, they correspond to Dirichlet boundary conditions.

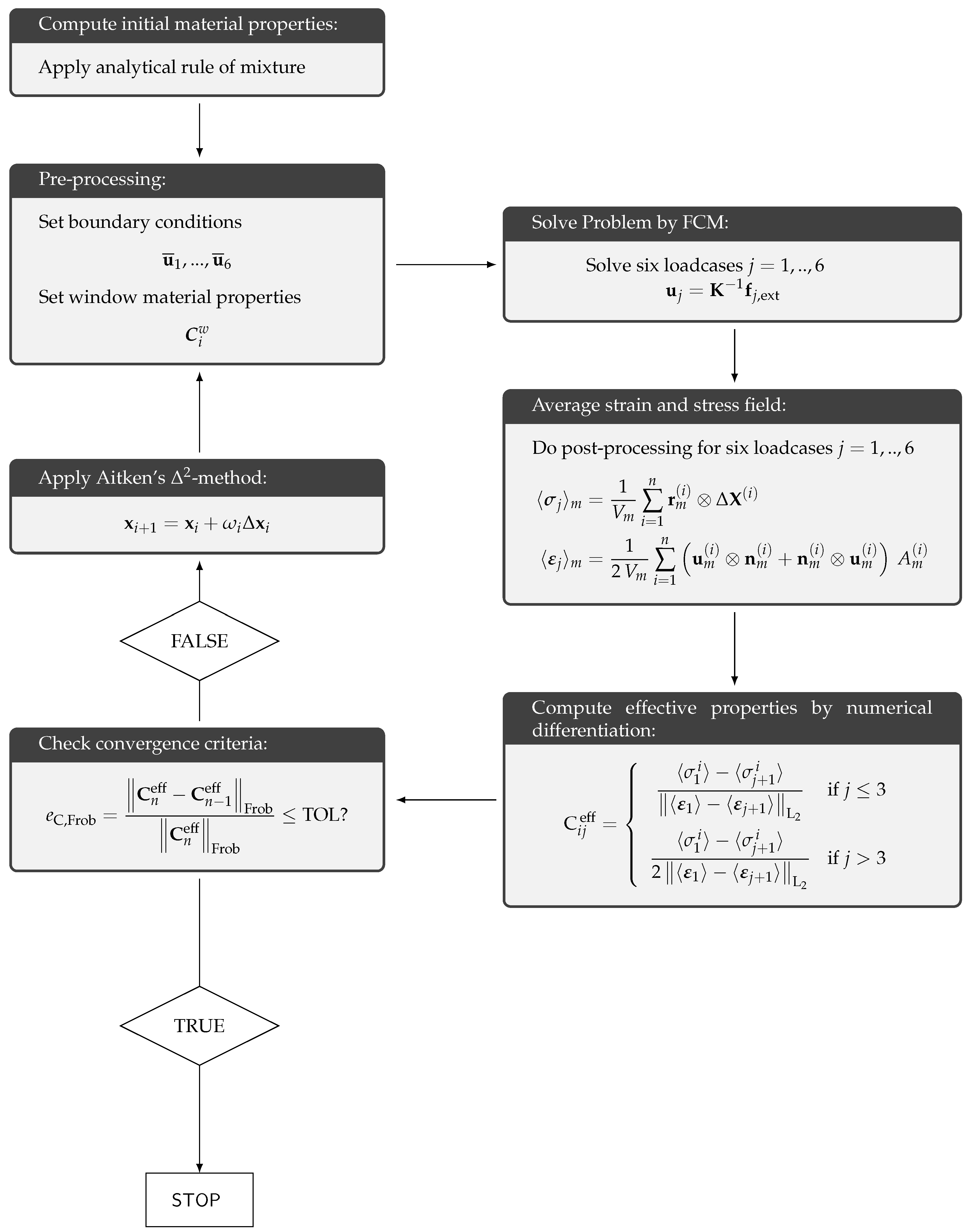

By changing the window thickness (

) and its material properties, the surroundings of the sub-sample are modeled in a self consistent way and different results are obtained for different sizes of the window. The procedure regarding how to adjust the material properties is explained in more detail in

Section 3.3. The material properties of the bulk gold material applied in the simulations chosen according to [

15] are given in

Table 1.

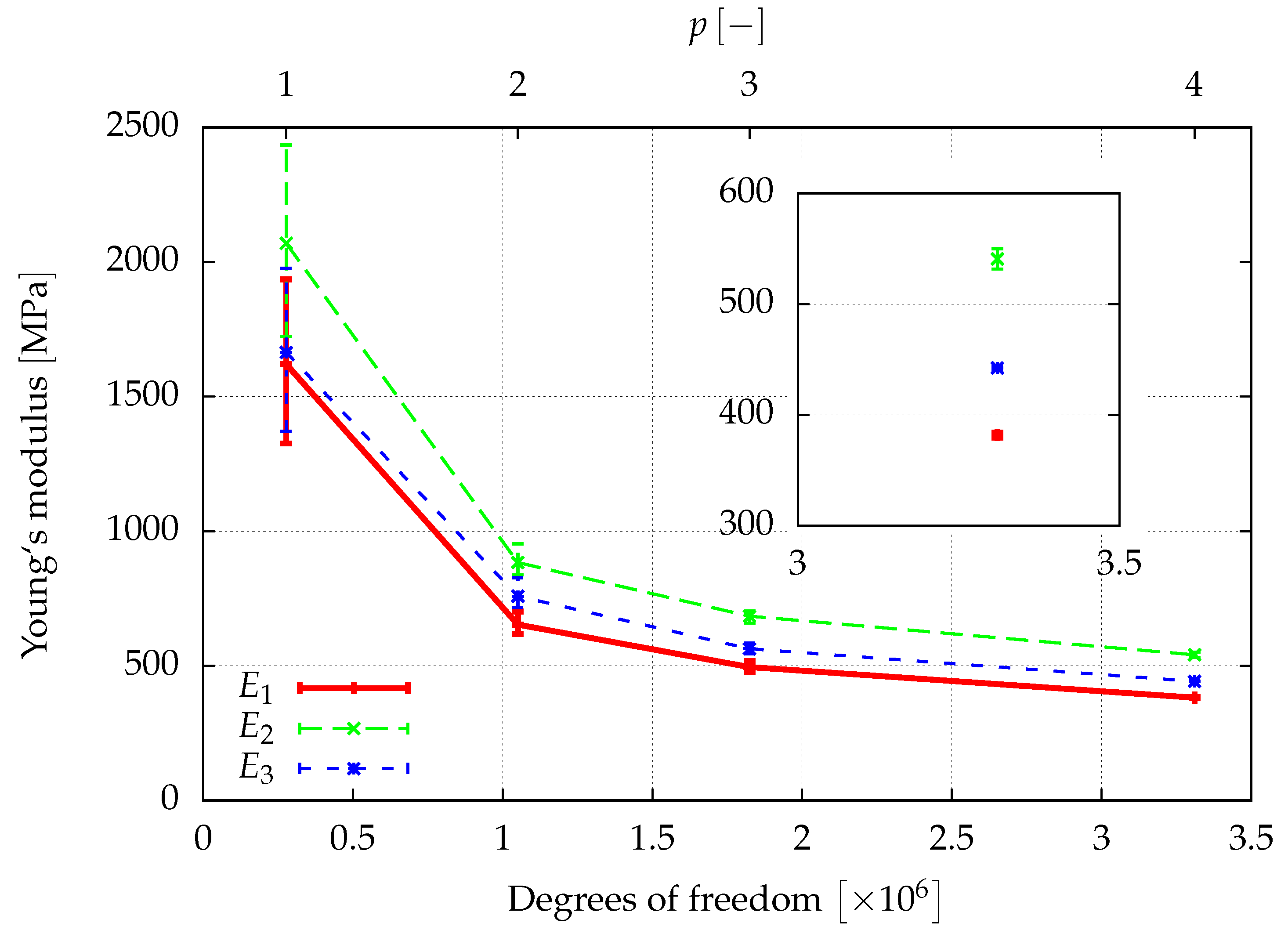

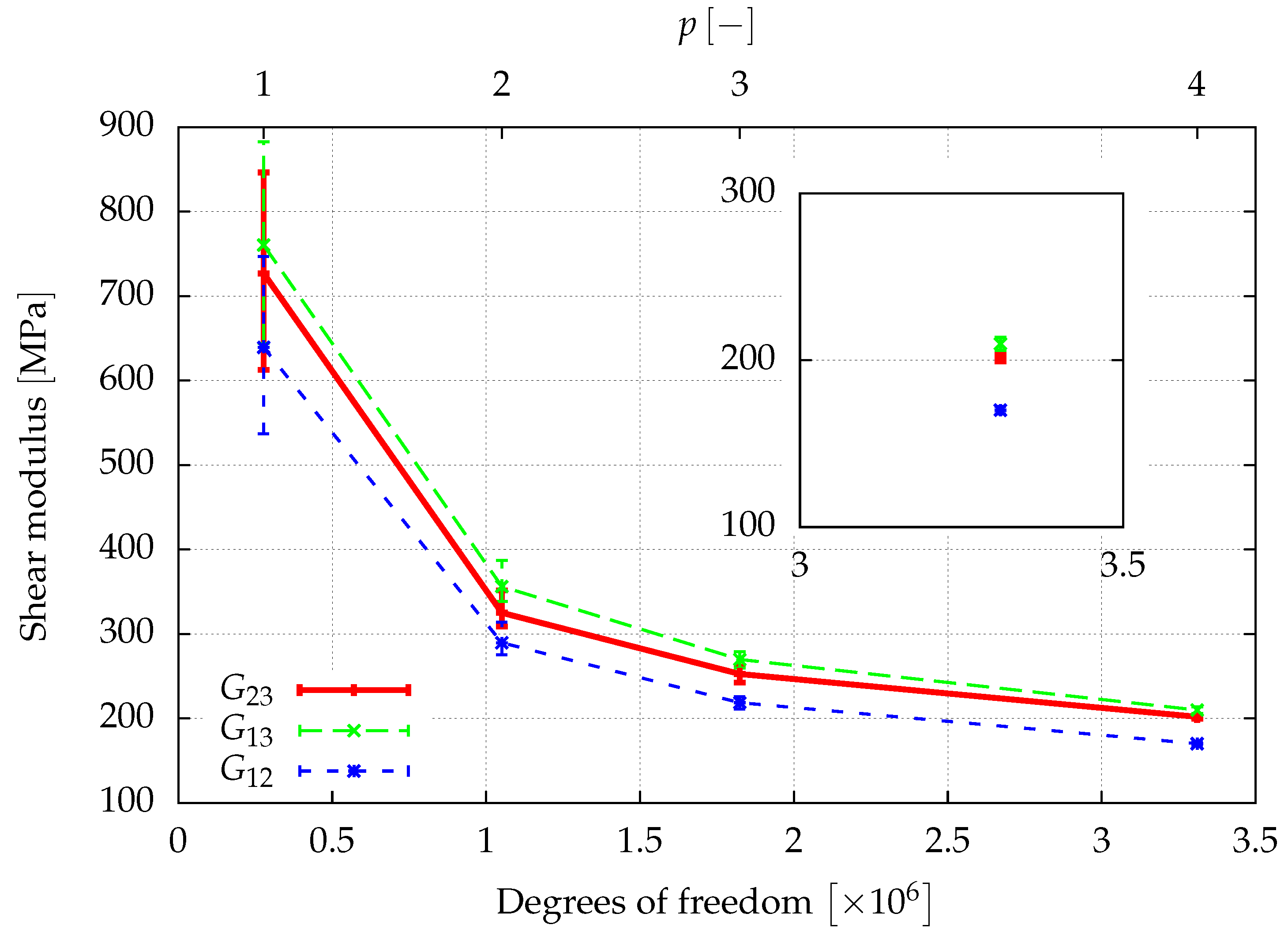

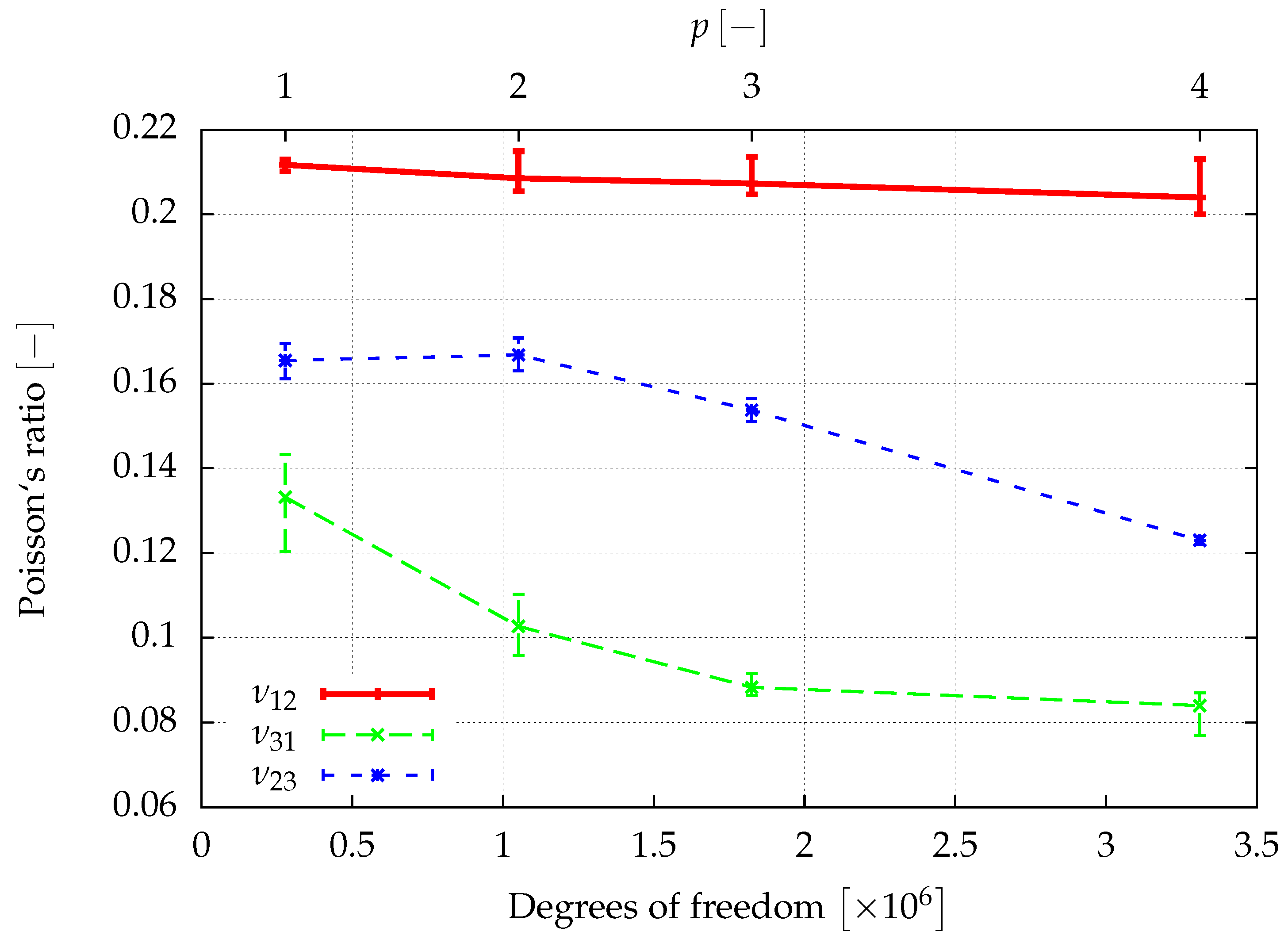

The window method allows for finding the full anisotropic material properties of the sample as explained in

Section 3.3. Assuming an orthotropic material behavior, the directional Young’s moduli,

, the shear moduli,

, and the Poisson ratios

, can be determined from a least squares fit of the obtained elasticity matrix. The results of a first investigation of the elastic properties are given in

Figure 8,

Figure 9 and

Figure 10, where the convergence of the elastic parameters against the degrees of freedom for a uniform increase of the polynomial degree of the shape functions of all cells is plotted. The error-bars include the results obtained for different sizes of the window. With an increasing spatial resolution, the differences in the results obtained for different window sizes are more or less reduced and will be neglected in the further considerations. In summary, the obtained results are in the same range of the data already presented in [

46] for a sample of the same size.

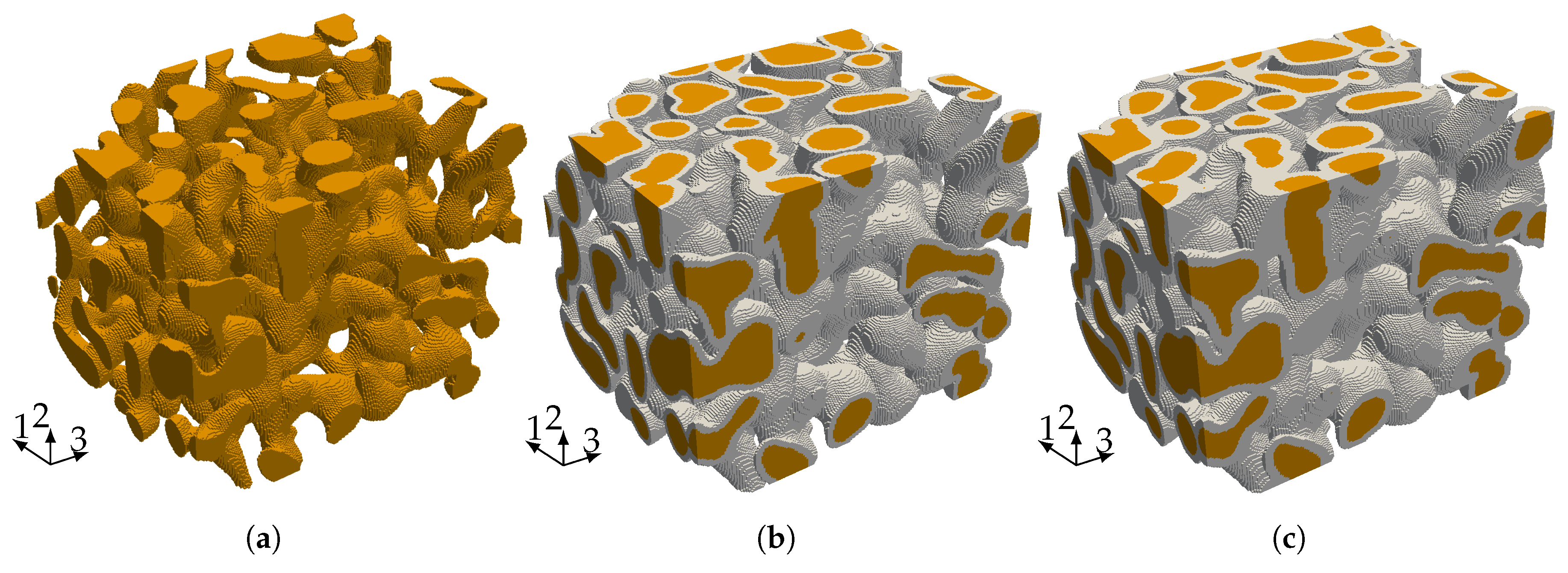

For our second investigation, we apply a homogeneous polymer coating of

(

Figure 11b), resp.

(

Figure 11c) to the voxel model depicted in

Figure 11a. The voxel spacing is not equal in each direction, so the coating thickness varies from

to

, resp. from

to

. A Cartesian mesh with 85,388, respectively 117,683 cells, is generated for the composites in the same fashion as for the nanoporous gold microstructure. The interface between the different materials is not resolved by cell interfaces, but considered during the integration of the stiffness matrix. To this end, we apply the adaptive Gaussian quadrature as explained in

Section 3.1 to capture the material interface by means of an octree refinement.

For this study, we assume the properties of epoxy, which will also serve as starting values for the calibration of the polymer properties of PPy in

Section 4.2. The material properties for the polymer used in the second investigation are taken from [

46] and listed in

Table 2.

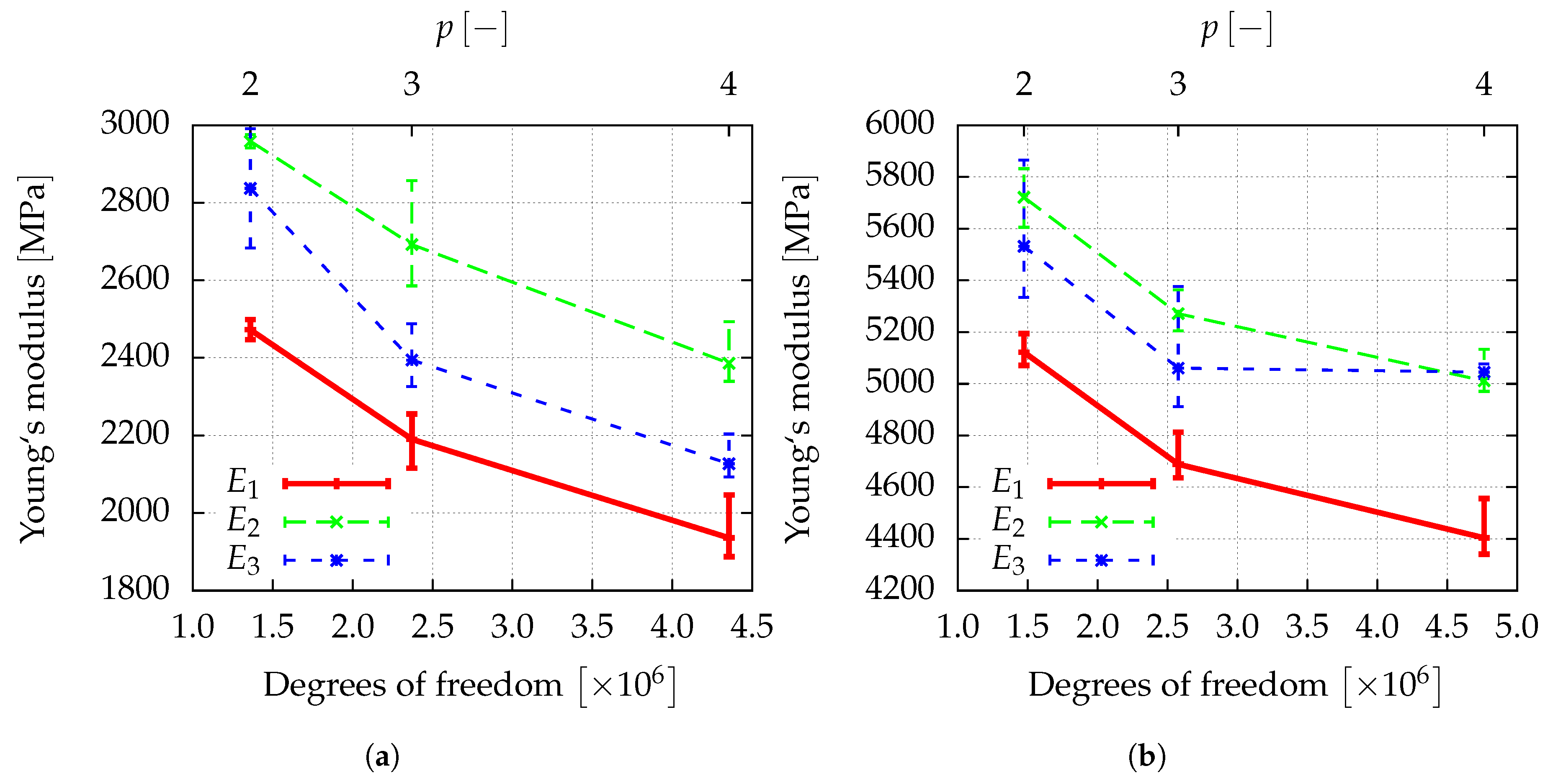

Figure 12a,b show the convergence of the macroscopic elastic properties of the composite obtained from homogenization for a

p-refinement, where

.

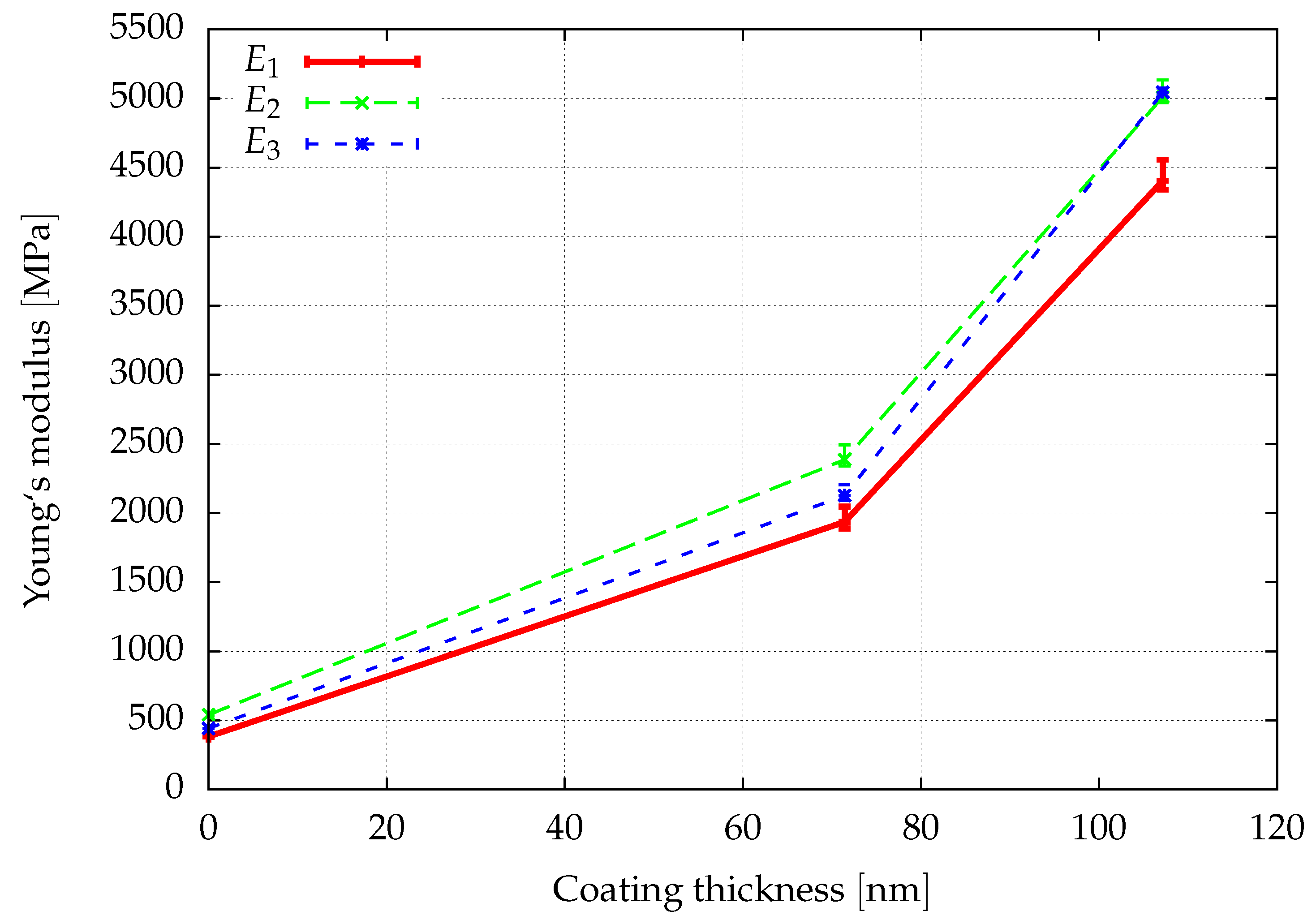

By comparing the Young’s modulus for the finest discretization (

) in

Figure 13, it is observed that the application of a polymer layer significantly increases the stiffness of the composite by up to a factor of 10, although the thickness of the polymer coating is below the ligament diameter and the Young’s modulus is only 6% of gold.

If the coating was not a polymer but had the bulk properties of gold, one could simply estimate that, under bending dominated deformation of cylindrical ligaments [

15], the geometrical increase in stiffness would scale with the area moment of inertia by a factor of

. In tensile loading conditions, the increase in geometrical stiffness would scale by the area of the ligament

. When considering that the real coating is a polymer which is more compliant than gold, the real stiffening effect would be even less than given by these two estimates. However, both scaling relations still underestimate the real increase in stiffness. This indicates that the dominant stiffening effect of the additional coating has other origins among which the forming of new connections between neighboring ligaments is one mechanism—see

Figure 14.

4.2. Investigation of Elastoplastic Properties

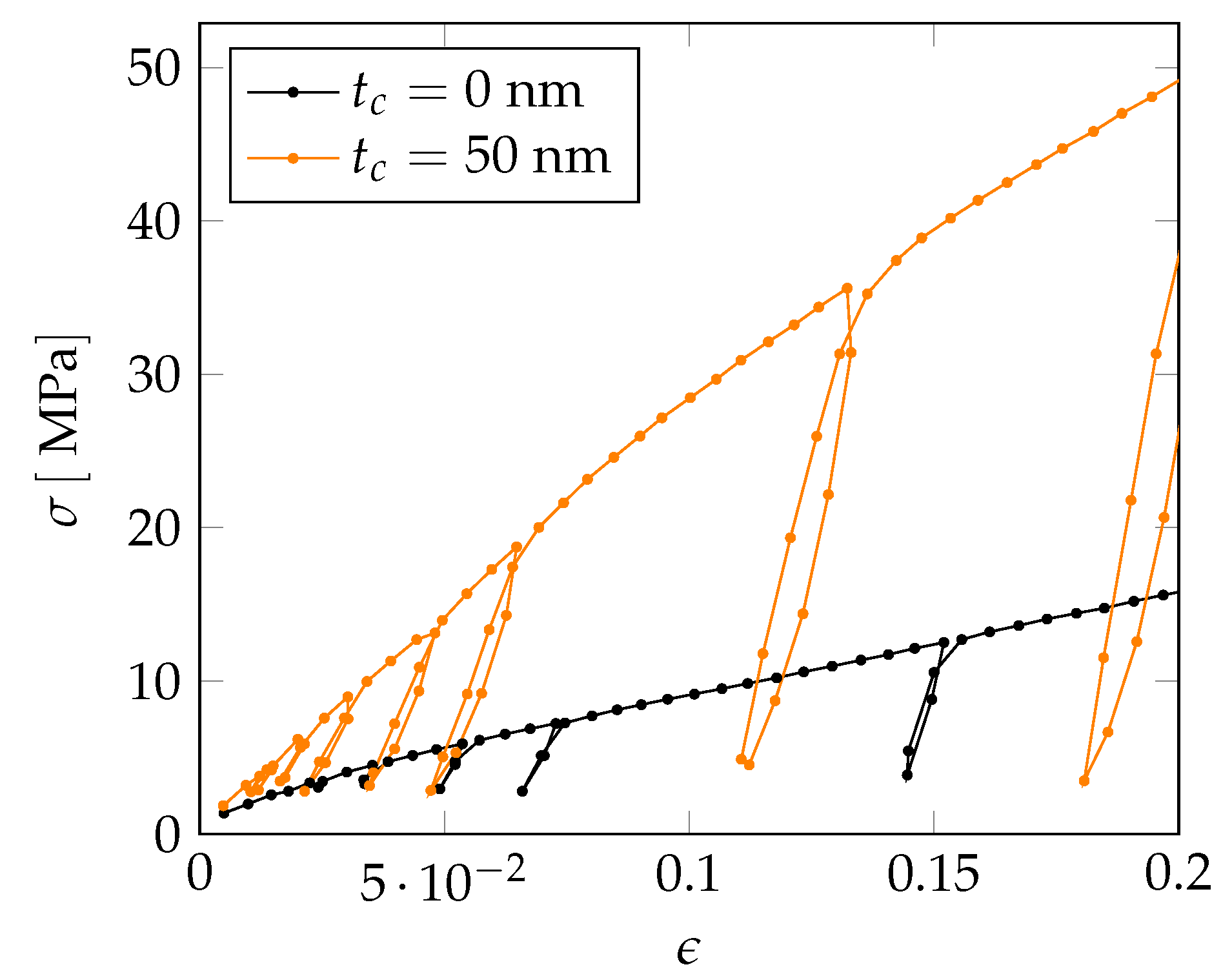

In a next step, we extend our investigations to the nonlinear regime by also considering the plastic behavior of the NPG-PPy nanocomposite. In order to relate the computations to experiments, we consider experimentally obtained true stress–strain curves on nanoporous gold samples with a ligament diameter of

and NPG samples coated by a PPy layer with a thickness of

—see

Figure 15. An important assumption that allows us to apply the tomography data of a NPG sample with

to a smaller ligament diameter is the self-similarity of the NPG which holds for structures with a ligament diameter

. The self-similarity of NPG has been intensively investigated for a large range of ligament sizes in [

28,

44].

The deformation behavior of the non-coated NPG under compression is comparable to previous studies of NPG specimens with similar ligament size [

8,

9,

33]. Here, we also find an absence of the initial elastic regime and an early yielding along with weak work hardening at higher strains. In contrast, an NPG-PPy nanocomposite exhibits the enhanced flow stress and work hardening, although the elastic-plastic transition is still ill defined. The effective elastic moduli as inferred from the first unloading cycles for both samples differ by less than

—see

Table 3. The presence of the

thick PPy layer marginally stiffens NPG, by about

. The influence of the polymer coating on the plastic flow, however, is more significant. For instance, at

strain, there is a nearly 4-fold increase in the flow stress of the nanocomposite.

In order to fit the numerical stress–strain curve to the one of the NPG-composite, we follow a two-step approach. In a first step, we adjust the properties of the nanoporous gold such that we meet the experimental curve of nanoporous gold. In a second step, we take the fitted properties of the nanoporous gold and apply bulk polymer material properties of epoxy as starting values and adjust the polymer parameters until we meet the experimental NPG-composite stress–strain curve.

The values for the macroscopic yield stress as well as the macroscopic elastic modulus determined from the first unloading are given in

Table 3. To have a unique definition for the yield stress, we took the offset yield point where

plastic deformation occurs.

In order to simulate the coating, we added a homogeneous layer of polymer with

—see

Figure 11c. These values correspond to the same ratio

vs.

as for the experimentally tested samples. As a starting point, we take bulk values for the material properties from [

46] which are listed in

Table 4 and apply them to the sample of nanoporous gold that is shown in

Figure 11a.

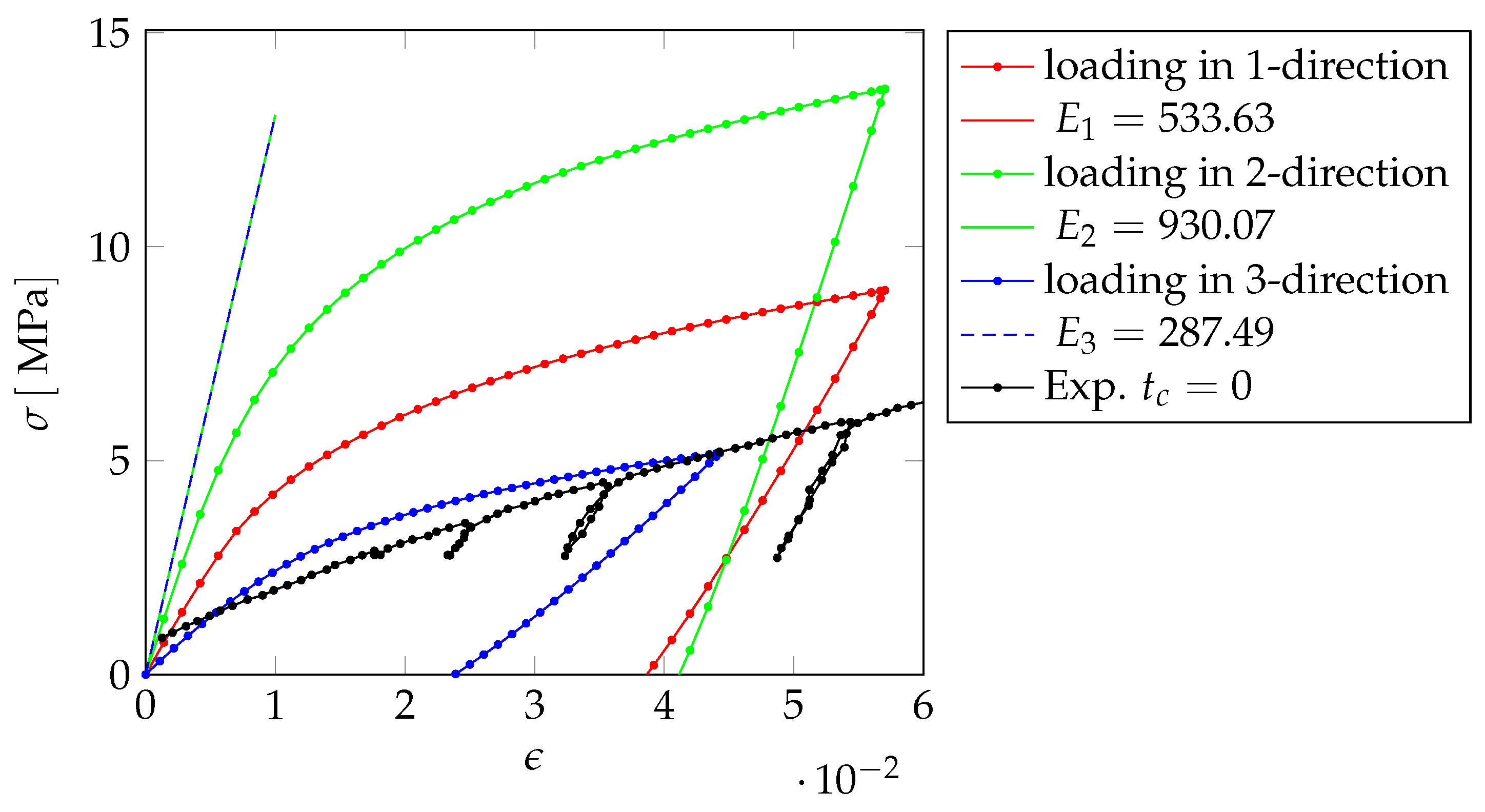

In order to analyze the anisotropic behavior of the nanoporous gold, we apply three different compressive loadings in 1-, 2- and 3-direction by clamping the lower side of the sample and prescribing a displacement on the upper side. The discretization consists of 130,114 cells with a size of .

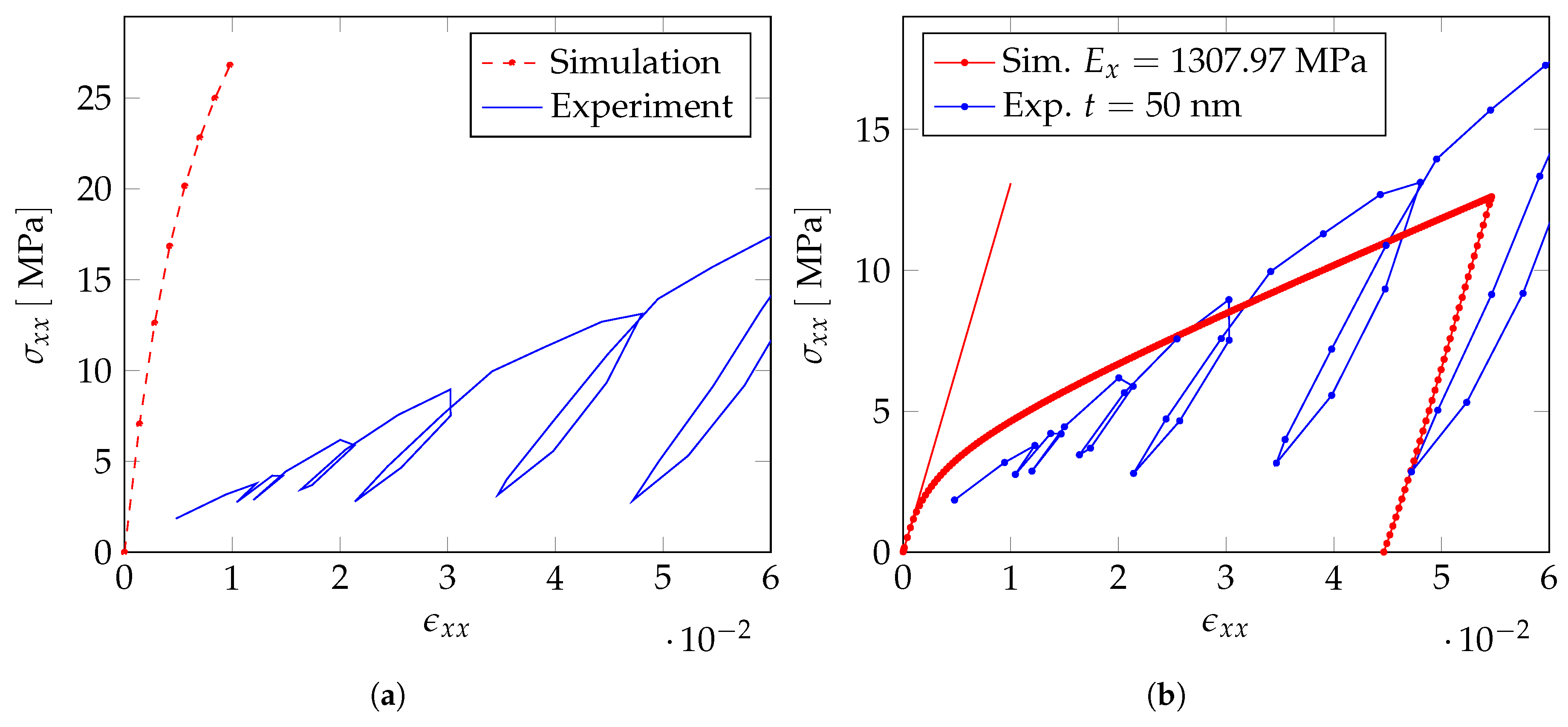

Figure 16 shows the comparison of the numerical results of this first investigation to the experimental results.

Since the slopes of the elastic unloading fit best for the 1-direction and also fit to the results for the homogenization, we consider this loading direction for our further investigations.

In a next step, we change the initial yield stress

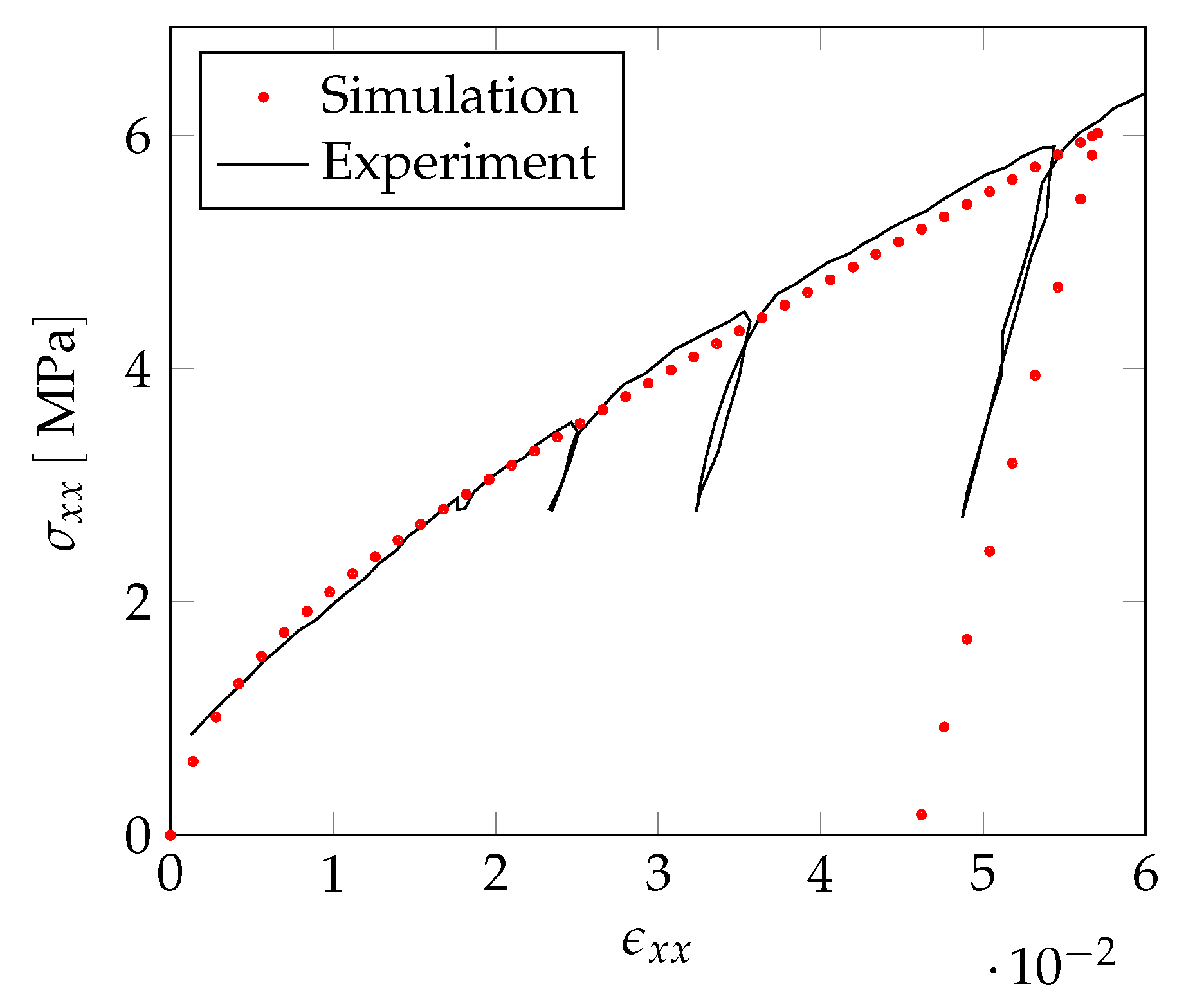

and the hardening modulus of the gold, such that the numerical stress–strain curve fits the experimental one.

Figure 17 shows the stress–strain curve after fitting the material parameters of the gold. The Young’s modulus of the sample is

and the initial yield stress

, yielding a sufficiently close fit to the experimental values listed in

Table 3.

The fitted material parameters for gold are given in

Table 5. The initial yield stress compares very well with the values determined by [

10] for ligaments of

which ranged from

to

, but the hardening modulus is much higher by about an order of magnitude compared to the values found by [

15,

28] who used a work hardening rate of

.

In a next step, we analyze a coated sample using the material parameters of the nanoporous gold obtained from the fit together with material parameters for the polymer for which we use properties of epoxy as starting values—see

Table 6.

Applying these material parameters, the polymer has a much more pronounced stiffening effect on the stress–strain curve than determined from the experiments—see

Figure 18a.

Therefore, in a next step, we also adjust the material parameters of the polymer in our numerical computations, such that the stress–strain curve fits to the experiments—see

Figure 18b. For the fitted material parameters, which are given in

Table 7, the computed Young’s modulus of the macroscopic sample is

and the initial yield stress is

. Both are still slightly higher than the values measured from the experimental stress–strain curve. In order to fully align the numerical computations with the experiments, a further reduction of the Young’s modulus and the initial yield stress of the polymer coating is required. However, the further reduction of these material parameters yields to a very poor conditioning of the resulting stiffness matrix which causes convergence problems of the Newton–Raphson method.

Our numerical investigations of nanoporous gold samples with a ligament diameter of

and a polymer coating of

indicate an enormous increase of the macroscopic stiffness by a factor of ten if a polymer coating such as epoxy resin with bulk material values could be applied—see

Figure 13. In line with our expectations from the experimental results, the increase in stiffness entailed by coating the gold ligaments with the softer polymer such as PPy is ten times smaller. Our numerical computations capture the stress–strain behavior of the NPG-PPy nanocomposite and predict the mechanical properties of PPy. The Young’s modulus and yield stress of PPy which need to be applied in the numerical computations in order to match the stress–strain curve of the experiments have been found to be

and

, respectively. The values match well to the experimental data available in the literature, where the elastic moduli have been reported in the range of 100–4300

[

48,

49,

50,

51,

52,

53,

54] and the yield strength between 2.4–5.3

[

49]. Significant variations in the mechanical parameters of the bulk PPy in the literature have been attributed to the sensitivity of the PPy morphology and structure to synthesis conditions [

55]. Among other factors, a type of the dopant counterions used for electropolymerization can strongly affect PPy mechanical characteristics. For the perchlorate anion employed as a dopant during synthesis of PPy in our work, the reported values of elastic modulus are in the range 100–300

[

48], and agree well with the predictions from our simulations. The good agreement underlines the high sensitivity of the approach for calibration of the material parameters for PPy using the numerical model. Starting the calibration with much larger values taken from bulk epoxy, the solution rapidly converged to the much lower and much more realistic values of PPy within a few iterations. In this way, there is now a set of material parameters for PPy available that includes the yield stress and hardening rate for the given synthesis conditions on NPG.