Variation in Compressive Strength of Concrete aross Thickness of Placed Layer

Abstract

:1. Introduction

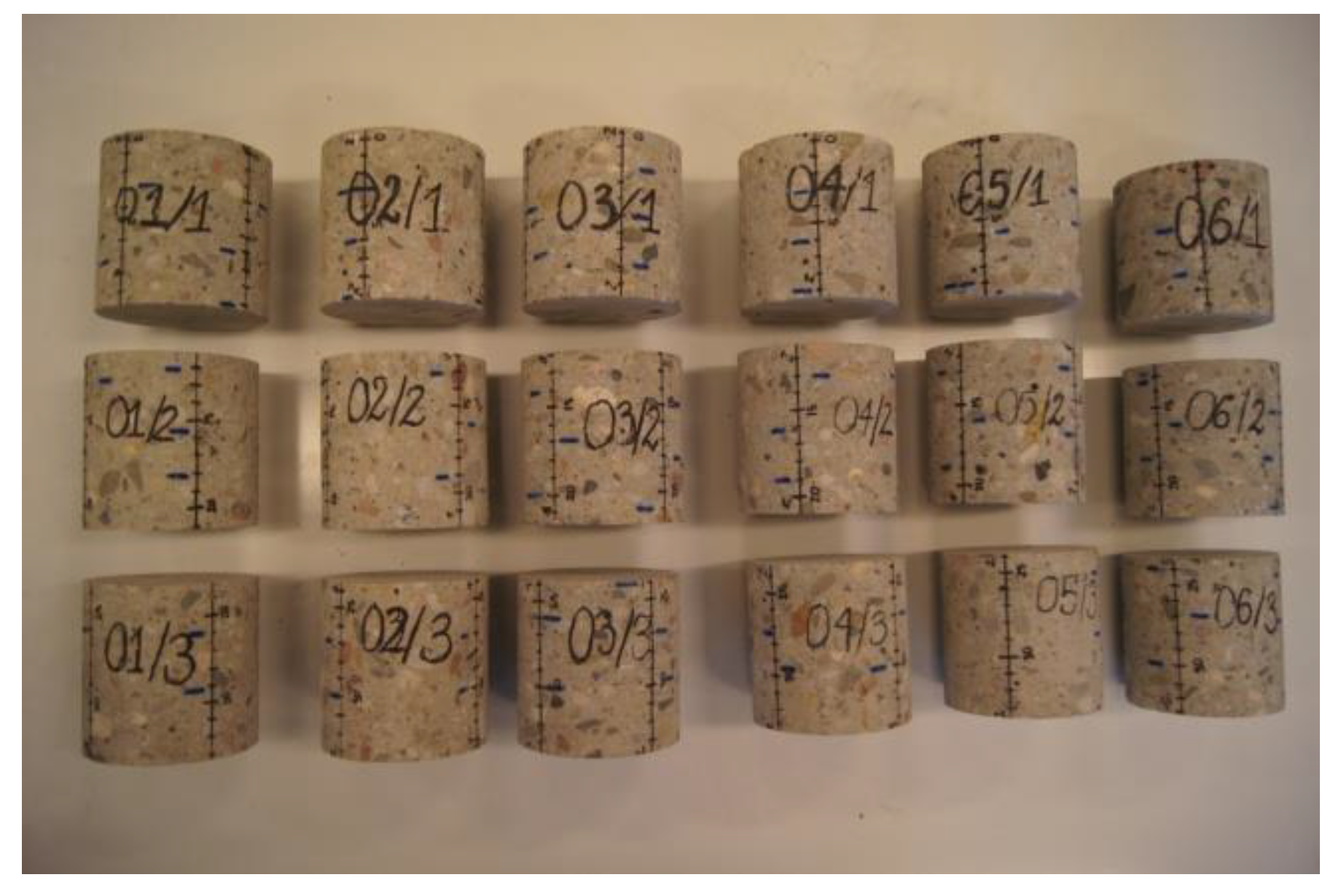

2. Description of Author’s Investigations

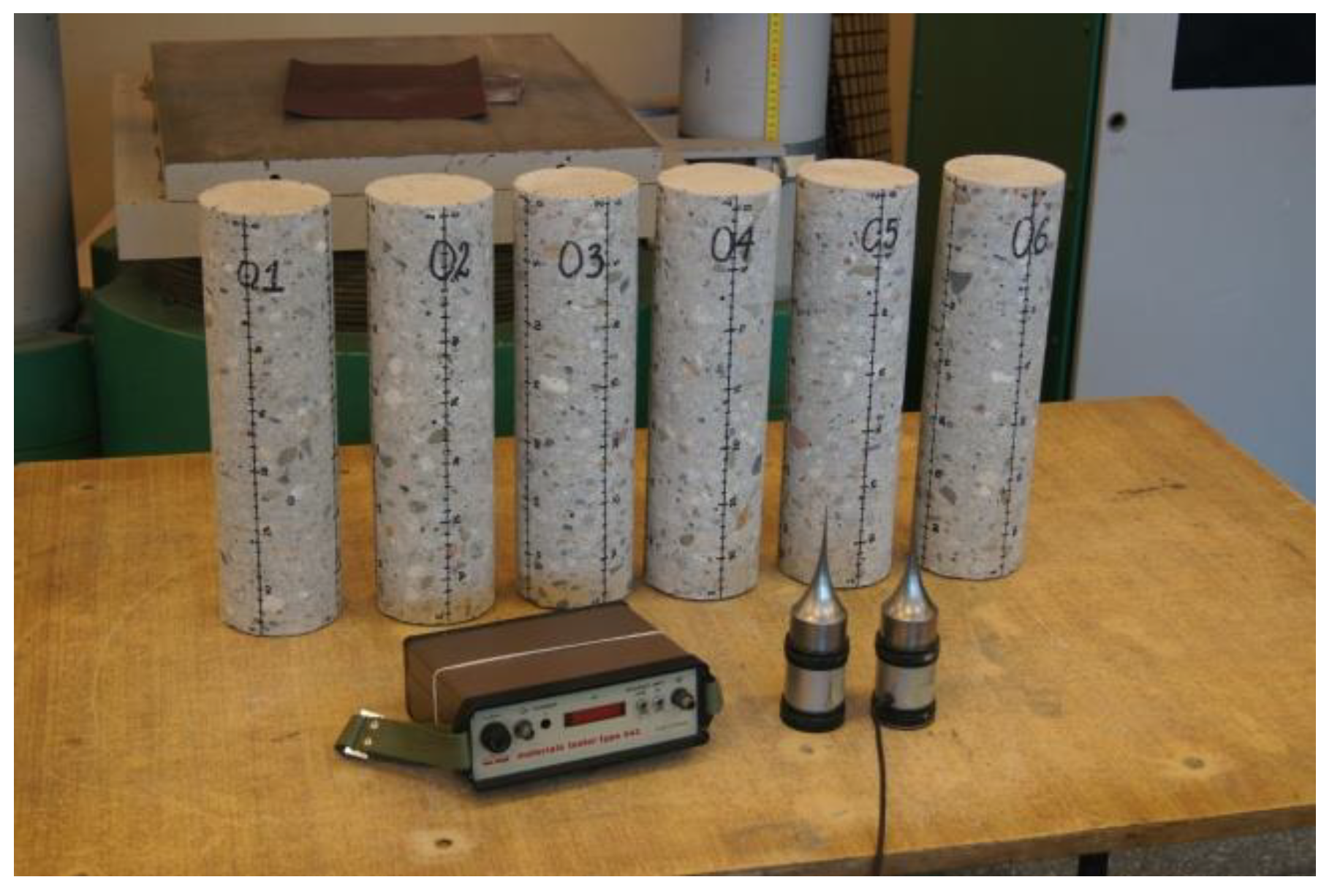

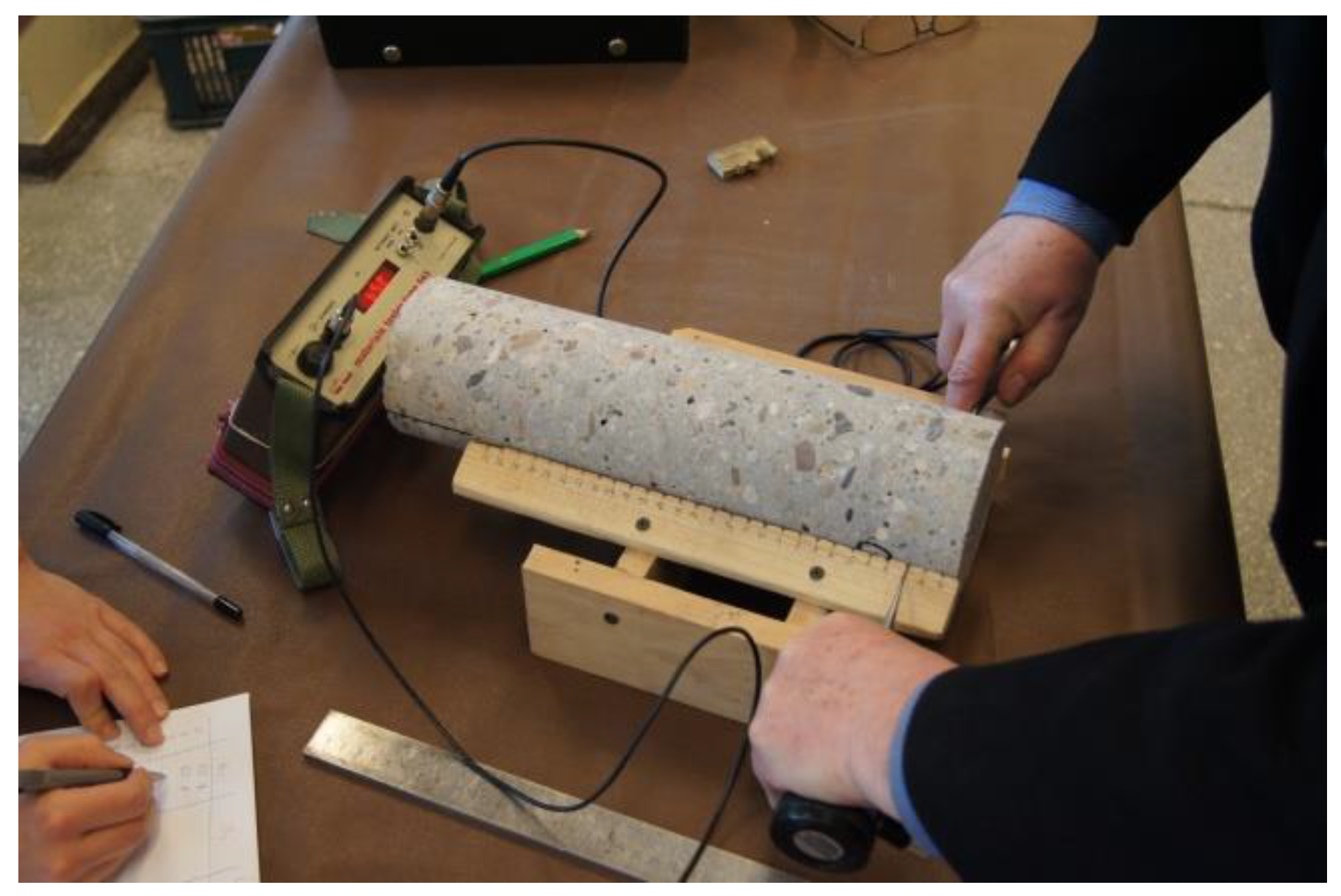

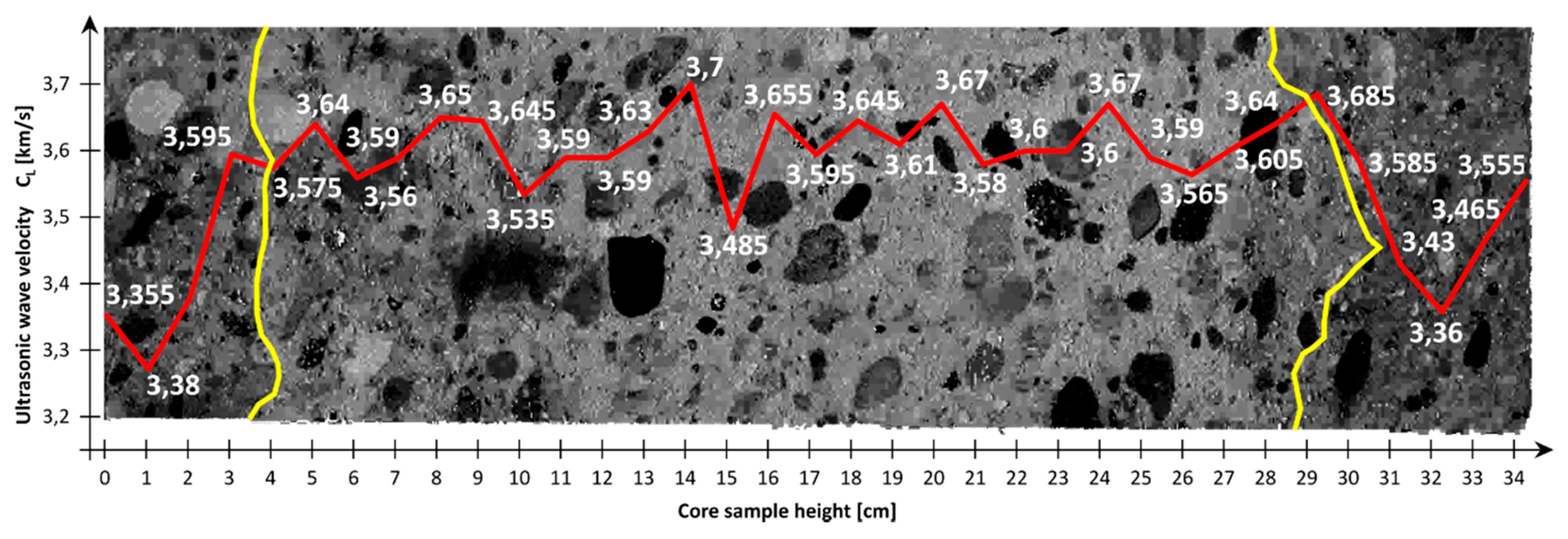

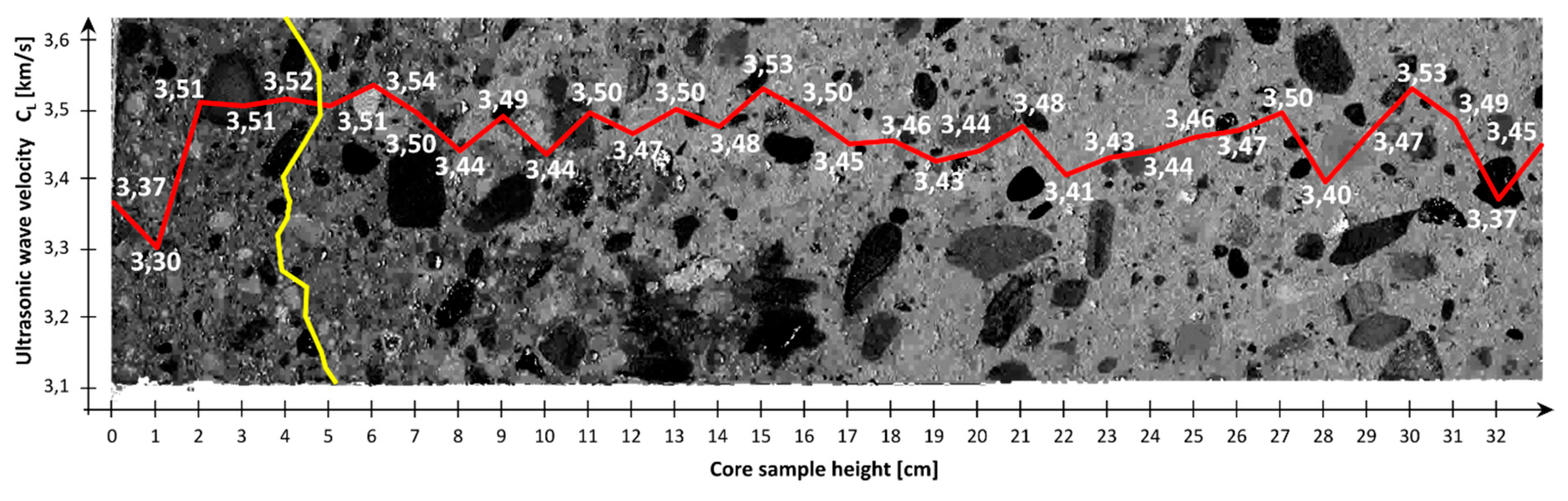

2.1. Ultrasonic Tests of Concrete

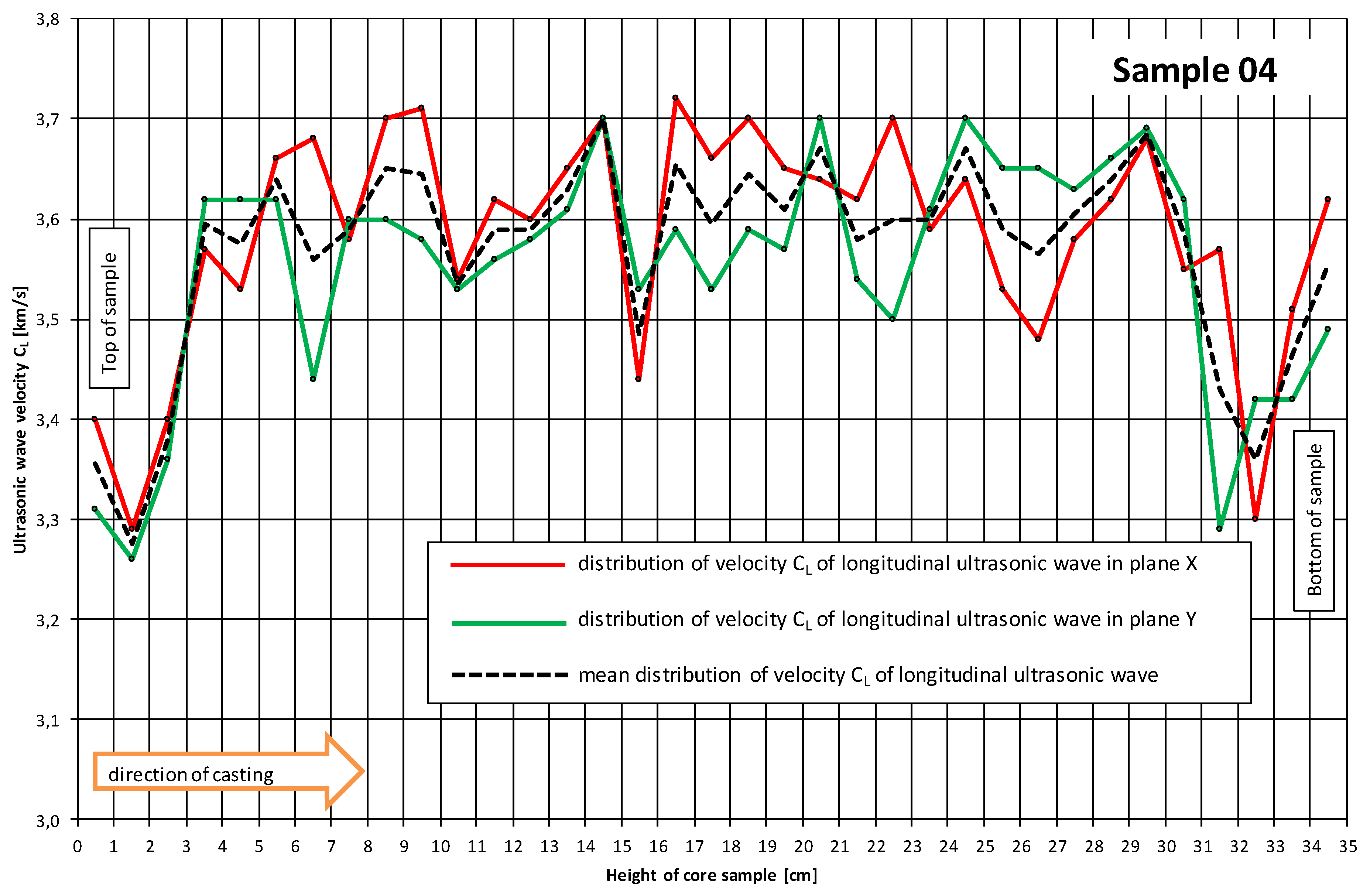

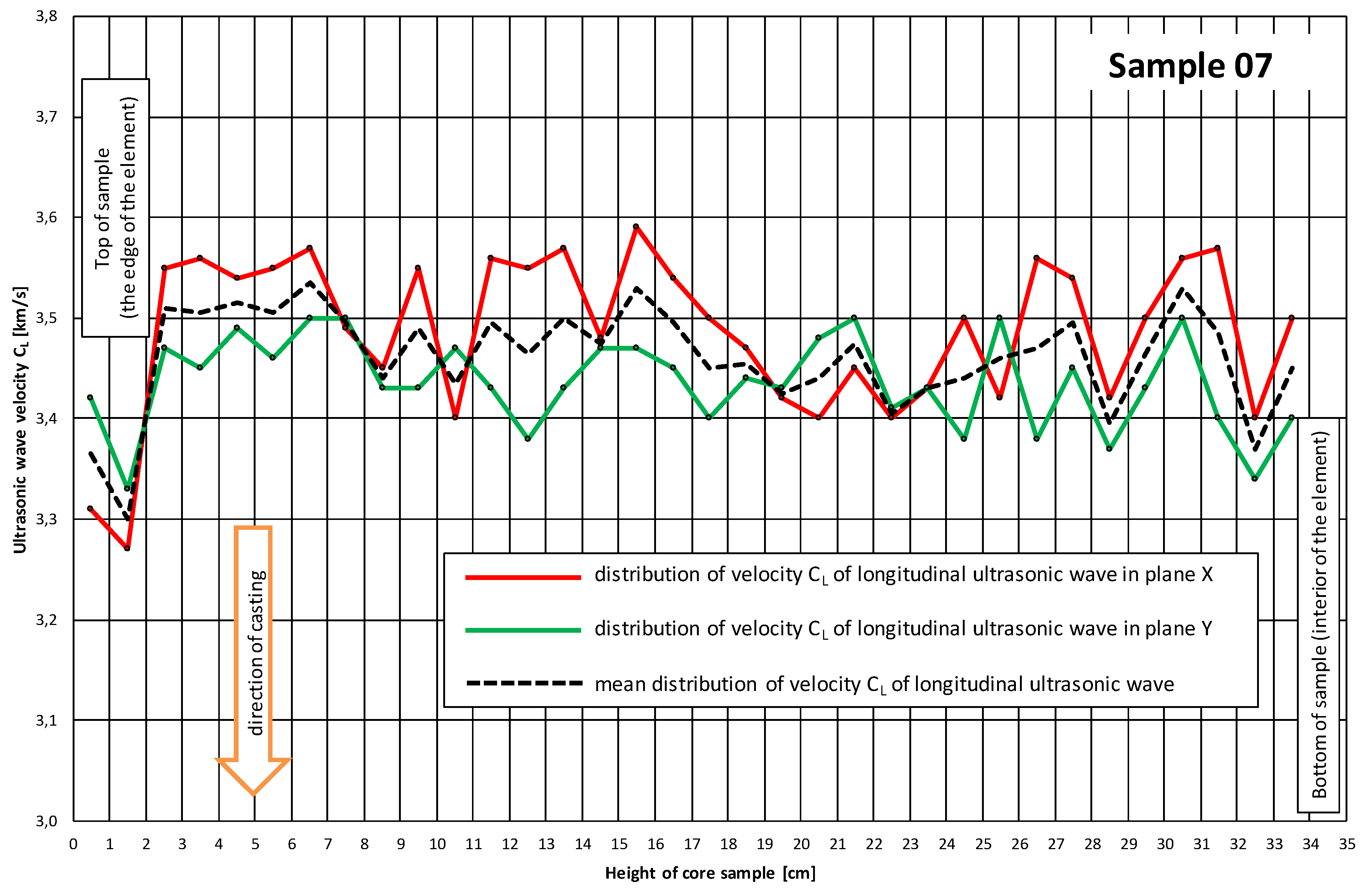

2.2. Ultrasonic Tests of Concrete

2.3. Scaling of Correlation Curve

η = [0.25 × 15.34]1/2 ÷ [0.25 × 16.33]1/2 = 0.97 > 0.75

νk = 100 × [(1/35)] × 0.12555]1/2 = 5.99% < 12%.

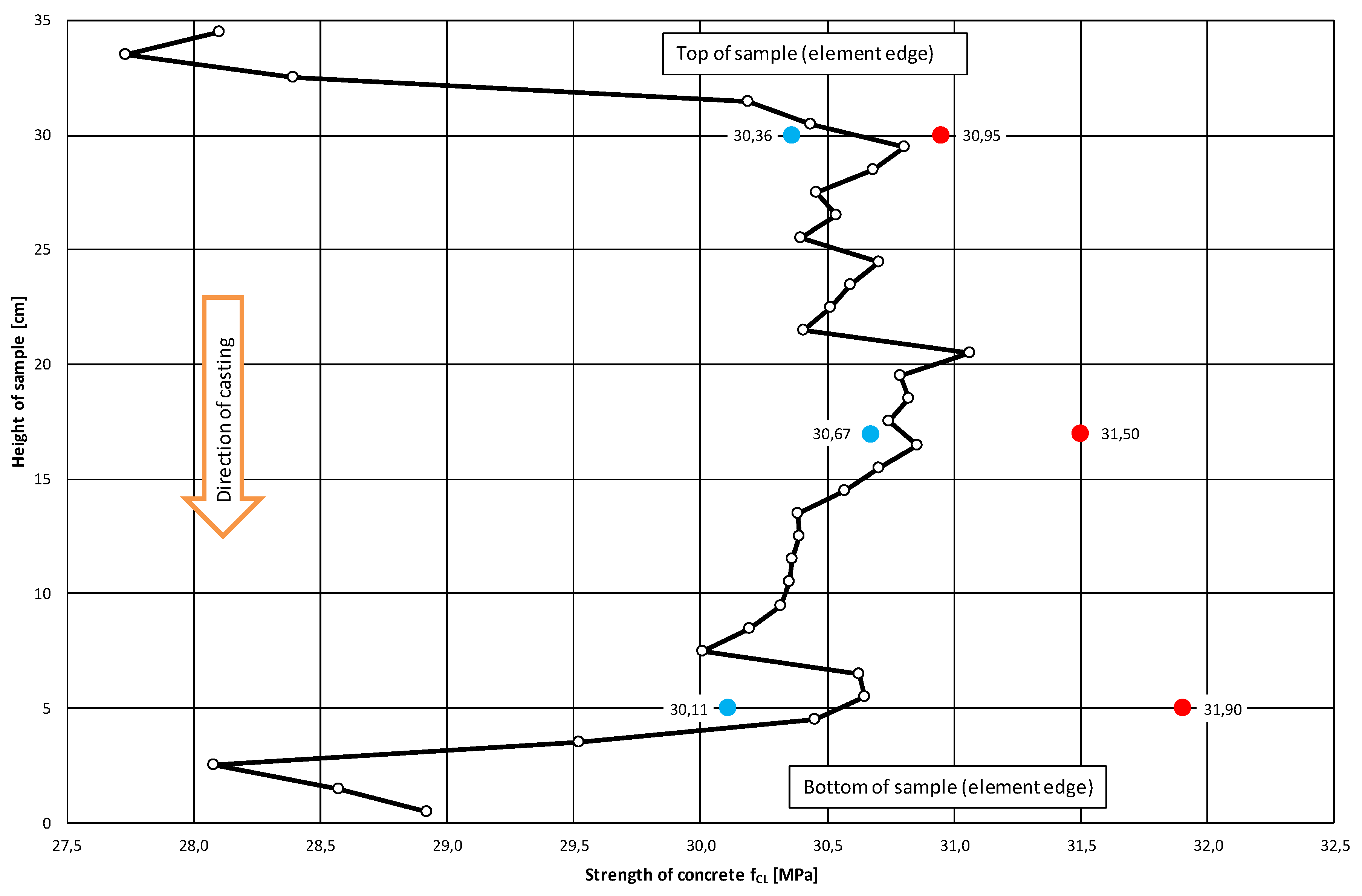

3. Analysis of Test Results

4. Conclusions

- The obtained compressive strength increments across the thickness of the placed layer of concrete do not corroborate Stawiski’s theses [1,2,3], but confirm the results reported in, [7,8,9]. Therefore, there can be agreement with Neville’s statement [10] that the slight increase in concrete compressive strength with depth below the top surface is a natural thing and need not to be taken into account in the evaluation of the strength of concrete in the structure.

- The concrete compressive strength determined on core samples only slightly depends on the depth of where the sample came from (provided the ingredients of the concrete do not segregate as it is being placed and compacted).

- The use of the ultrasonic method for testing concrete with point-contact exponential probes showed the variation in concrete strength along the height of the core sample could be quite accurately evaluated and areas of lower quality concrete could be indicated. This was mainly from the thick layer (approximately 30–40 mm) extending from the top edge and the thick layer (approximately 30–50 mm) extending from the bottom edge of the samples 01–06 taken perpendicularly to the upper plane of the element. Further, from the thick layer (approximately 20–80 mm) extending from the edge constituting the side plane of the slab for the samples taken parallel with the top plane of the element (samples 07–12). The decline in the strength of the concrete in the upper part of samples 01–06 is caused by the bleeding of water from the concrete mixture (the bleeding phenomenon [17]) and the sedimentation of the latter. While in the lower part of the samples, it is due to the improper vibration of the placed layer of concrete mixture. The decrease in concrete strength at the side edge of the slab in the case of samples 07–12 can be due to the wall effect [9,10].

- The ultrasonic method of testing concrete by means of point-contact exponential probes enables the accurate assessment of the quality of concrete (the segregation of concrete components, porosity, density, strength, etc.) along the height of a core sample drilled out perpendicularly to the placed layer.

Funding

Conflicts of Interest

References

- Stawiski, B. Ultrasonic Testing of Concrete and Mortar Using Point Probes; Wroclaw University of Technology: Wroclaw, Poland, 2009; p. 154. (In Polish) [Google Scholar]

- Stawiski, B. The heterogeneity of mechanical properties of concrete in formed constructions horizontally. Arch. Civ. Mech. Eng. 2012, 12, 90–94. [Google Scholar] [CrossRef]

- Stawiski, B. Concrete strength gradients in industrial floors. Mater. Bud. 2017, 543, 22–24. (In Polish) [Google Scholar]

- Hoła, J.; Sadowski, L.; Hoła, A.M. The effect of failure to comply with technological and technical requirements on the condition of newly built cement mortar floors. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 268–275. [Google Scholar] [CrossRef]

- Petersons, N. Should standard cube test specimens be replaced by test specimens taken from structures? Mater. Struct. 1968, 1, 425–435. [Google Scholar] [CrossRef]

- Dąbrowski, K.; Stachurski, W.; Zieliński, J.L. Concrete Constructions; Wydawnictwo Arkady: Warsaw, Poland, 1982. (In Polish) [Google Scholar]

- Yuan, R.L.; Ragab, M.; Hill, R.E.; Cook, J.E. Evaluation of core strength in high-strength concrete. Concr. Int. 1991, 13, 30–34. [Google Scholar]

- Suprenant, B.A. Core Strength Variation of in-Place Concrete; The Aberdeen Group: Boston, MA, USA, 1995. [Google Scholar]

- Neville, A. Core tests: Easy to perform, not easy to interpret. Concr. Int. 2001, 11, 59–68. [Google Scholar]

- Watanabe, S.; Hishikawa, K.; Kamae, K.; Namiki, S. Study on estimation of compressive strength of concrete in structure using ultrasonic method. J. Struct. Constr. Eng. 2016, 81, 191–198. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Polski Cement Sp. z o.o.: Cracow, Poland, 2000. (In Polish) [Google Scholar]

- PN-EN 12390-2:2011. Testing Hardened Concrete. Part 2. Making and Curing Specimens for Strength Tests; Polish Committee for Standardization: Warsaw, Poland, 2011. [Google Scholar]

- PN-EN 13791:2008. Assessment of In-Situ Compressive Strength in Structures and Precast Concrete Components; Polish Committee for Standardization: Warsaw, Poland, 2008. [Google Scholar]

- PN-EN 12390-3:2011. Testing Hardened Concrete. Part 3: Compressive Strength of Test Specimens; Polish Committee for Standardization: Warsaw, Poland, 2008. [Google Scholar]

- Gudra, T.; Stawiski, B. Non-destructive strength characterization of concrete using surface waves. NDT E Int. 2000, 33, 1–6. [Google Scholar] [CrossRef]

- Drobiec, L.; Jasiński, R.; Piekarczyk, A. Diagnosis of Reinforced Concrete Structures. Methodology, Field Tests, Laboratory Tests of Concrete and Steel; Wydawnictwo Naukowe PWN: Warsaw, Poland, 2010. (In Polish) [Google Scholar]

- Soshiroda, T. Effects of bleeding and segregation on the internal structure of hardened concrete. In Properties of Fresh Concrete; Taylor & Francis: Mild Park, UK, 1990; pp. 225–232. [Google Scholar]

- PN-EN 12390-4:2001. Testing Hardened Concrete. Part 4: Compressive Strength. Specification for Testing Machines; Polish Committee for Standardization: Warsaw, Poland, 2001. [Google Scholar]

- PN-EN 12504-1:2011. Testing Concrete in Structures. Part 1: Cored Specimens. Taking, Examining and Testing in Compression; Polish Committee for Standardization: Warsaw, Poland, 2011. [Google Scholar]

- Schabowicz, K. Ultrasonic tomography—The latest nondestructive technique for testing concrete members—Description, test methodology, application example. Arch. Civ. Mech. Eng. 2014, 14, 295–303. [Google Scholar] [CrossRef]

- Schabowicz, K.; Suvorov, V.A. Nondestructive testing of a bottom surface and construction of its profile by ultrasonic tomography. Russ. J. Nondestruct. Test. 2014, 50, 109–119. [Google Scholar] [CrossRef]

| Sample Number | dśr | hśr | m | V | ρ |

|---|---|---|---|---|---|

| mm | g | cm3 | g/cm3 | ||

| 01 | 98.7 | 351.7 | 6158.5 | 2691 | 2.29 |

| 02 | 98.5 | 351.4 | 6167.5 | 2680 | 2.30 |

| 03 | 98.6 | 351.5 | 6138.0 | 2682 | 2.29 |

| 04 | 98.6 | 351.4 | 6176.5 | 2682 | 2.30 |

| 05 | 98.5 | 350.0 | 6121.5 | 2669 | 2.29 |

| 06 | 98.6 | 350.2 | 6121.0 | 2675 | 2.29 |

| 07 | 98.6 | 350.0 | 6122.0 | 2672 | 2.29 |

| 08 | 98.7 | 351.3 | 6172.5 | 2688 | 2.30 |

| 09 | 98.5 | 351.4 | 6168.2 | 2678 | 2.30 |

| 10 | 98.5 | 350.0 | 6122.4 | 2667 | 2.30 |

| 11 | 98.6 | 351.5 | 6140.0 | 2684 | 2.29 |

| 12 | 98.5 | 351.4 | 6137.6 | 2678 | 2.29 |

| Measuring Place Distance from Sample Top | Sample 01 | Sample 02 | Sample 03 | Sample 04 | Sample 05 | Sample 06 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CL 1 | CL 2 | CL 1 | CL 2 | CL 1 | CL 2 | CL 1 | CL 2 | CL 1 | CL 2 | CL 1 | CL 2 | |

| cm | km/s | |||||||||||

| 0.5 | 3.19 | 3.39 | 3.49 | 3.18 | 3.32 | 3.44 | 3.40 | 3.31 | 3.36 | 3.36 | 3.23 | 3.29 |

| 1.5 | 3.18 | 3.35 | 3.48 | 3.02 | 3.28 | 3.38 | 3.29 | 3.26 | 3.35 | 3.30 | 3.22 | 3.33 |

| 2.5 | 3.30 | 3.41 | 3.49 | 3.48 | 3.31 | 3.37 | 3.40 | 3.36 | 3.28 | 3.33 | 3.27 | 3.36 |

| 3.5 | 3.58 | 3.63 | 3.62 | 3.57 | 3.43 | 3.54 | 3.57 | 3.62 | 3.33 | 3.54 | 3.55 | 3.65 |

| 4.5 | 3.60 | 3.68 | 3.60 | 3.61 | 3.49 | 3.52 | 3.53 | 3.62 | 3.53 | 3.52 | 3.61 | 3.63 |

| 5.5 | 3.51 | 3.66 | 3.64 | 3.54 | 3.66 | 3.62 | 3.66 | 3.62 | 3.62 | 3.67 | 3.57 | 3.61 |

| 6.5 | 3.60 | 3.68 | 3.70 | 3.52 | 3.57 | 3.67 | 3.68 | 3.44 | 3.47 | 3.66 | 3.60 | 3.63 |

| 7.5 | 3.53 | 3.59 | 3.62 | 3.48 | 3.64 | 3.58 | 3.58 | 3.60 | 3.53 | 3.62 | 3.62 | 3.58 |

| 8.5 | 3.46 | 3.60 | 3.72 | 3.61 | 3.57 | 3.50 | 3.70 | 3.60 | 3.54 | 3.61 | 3.56 | 3.58 |

| 9.5 | 3.53 | 3.57 | 3.74 | 3.57 | 3.26 | 3.62 | 3.71 | 3.58 | 3.44 | 3.59 | 3.60 | 3.65 |

| 10.5 | 3.61 | 3.59 | 3.70 | 3.57 | 3.57 | 3.63 | 3.54 | 3.53 | 3.47 | 3.58 | 3.67 | 3.79 |

| 11.5 | 3.58 | 3.59 | 3.62 | 3.66 | 3.60 | 3.62 | 3.62 | 3.56 | 3.50 | 3.58 | 3.58 | 3.62 |

| 12.5 | 3.56 | 3.65 | 3.62 | 3.65 | 3.55 | 3.65 | 3.60 | 3.58 | 3.52 | 3.62 | 3.41 | 3.62 |

| 13.5 | 3.32 | 3.63 | 3.61 | 3.60 | 3.57 | 3.49 | 3.65 | 3.61 | 3.57 | 3.57 | 3.57 | 3.70 |

| 14.5 | 3.38 | 3.65 | 3.72 | 3.66 | 3.55 | 3.63 | 3.70 | 3.70 | 3.63 | 3.62 | 3.66 | 3.76 |

| 15.5 | 3.45 | 3.67 | 3.73 | 3.57 | 3.65 | 3.63 | 3.44 | 3.53 | 3.61 | 3.65 | 3.73 | 3.68 |

| 16.5 | 3.60 | 3.66 | 3.73 | 3.58 | 3.62 | 3.51 | 3.72 | 3.59 | 3.50 | 3.61 | 3.62 | 3.65 |

| 17.5 | 3.53 | 3.68 | 3.72 | 3.53 | 3.53 | 3.62 | 3.66 | 3.53 | 3.54 | 3.61 | 3.65 | 3.70 |

| 18.5 | 3.68 | 3.67 | 3.64 | 3.49 | 3.62 | 3.53 | 3.70 | 3.59 | 3.54 | 3.66 | 3.61 | 3.70 |

| 19.5 | 3.58 | 3.72 | 3.66 | 3.59 | 3.47 | 3.48 | 3.65 | 3.57 | 3.62 | 3.66 | 3.63 | 3.62 |

| 20.5 | 3.59 | 3.68 | 3.63 | 3.47 | 3.57 | 3.39 | 3.64 | 3.70 | 3.43 | 3.70 | 3.62 | 3.66 |

| 21.5 | 3.62 | 3.57 | 3.57 | 3.58 | 3.53 | 3.56 | 3.62 | 3.54 | 3.54 | 3.62 | 3.48 | 3.65 |

| 22.5 | 3.40 | 3.61 | 3.62 | 3.61 | 3.55 | 3.45 | 3.70 | 3.50 | 3.54 | 3.61 | 3.58 | 3.70 |

| 23.5 | 3.45 | 3.64 | 3.62 | 3.65 | 3.68 | 3.59 | 3.59 | 3.61 | 3.40 | 3.37 | 3.58 | 3.65 |

| 24.5 | 3.35 | 3.62 | 3.51 | 3.62 | 3.52 | 3.58 | 3.64 | 3.70 | 3.48 | 3.53 | 3.62 | 3.65 |

| 25.5 | 3.55 | 3.66 | 3.65 | 3.48 | 3.53 | 3.50 | 3.53 | 3.65 | 3.46 | 3.57 | 3.64 | 3.57 |

| 26.5 | 3.38 | 3.71 | 3.69 | 3.61 | 3.57 | 3.32 | 3.48 | 3.65 | 3.44 | 3.61 | 3.58 | 3.58 |

| 27.5 | 3.54 | 3.55 | 3.62 | 3.55 | 3.54 | 3.43 | 3.58 | 3.63 | 3.37 | 3.58 | 3.54 | 3.49 |

| 28.5 | 3.54 | 3.61 | 3.52 | 3.57 | 3.56 | 3.59 | 3.62 | 3.66 | 3.57 | 3.66 | 3.62 | 3.65 |

| 29.5 | 3.61 | 3.65 | 3.63 | 3.58 | 3.60 | 3.59 | 3.68 | 3.69 | 3.48 | 3.54 | 3.57 | 3.57 |

| 30.5 | 3.57 | 3.62 | 3.64 | 3.57 | 3.57 | 3.57 | 3.55 | 3.62 | 3.57 | 3.53 | 3.61 | 3.54 |

| 31.5 | 3.45 | 3.61 | 3.58 | 3.52 | 3.45 | 3.48 | 3.57 | 3.29 | 3.57 | 3.50 | 3.27 | 3.51 |

| 32.5 | 3.24 | 3.20 | 3.52 | 3.25 | 3.13 | 3.34 | 3.30 | 3.42 | 3.48 | 3.26 | 3.43 | 3.34 |

| 33.5 | 3.33 | 3.25 | 3.57 | 3.22 | 3.28 | 3.20 | 3.51 | 3.42 | 3.54 | 3.41 | 3.42 | 3.42 |

| 34.5 | 3.39 | 3.29 | 3.59 | 3.23 | 3.47 | 3.04 | 3.62 | 3.49 | 3.49 | 3.49 | 3.40 | 3.49 |

| Measuring Place Distance from Sample Top | Sample 07 | Sample 08 | Sample 09 | Sample 10 | Sample 11 | Sample 12 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CL 1 | CL 2 | CL 1 | CL 2 | CL 1 | CL 2 | CL 1 | CL 2 | CL 1 | CL 2 | CL 1 | CL 2 | |

| cm | km/s | |||||||||||

| 0.5 | 3.31 | 3.42 | 3.60 | 3.40 | 3.34 | 3.60 | 3.60 | 3.35 | 3.30 | 3.28 | 3.50 | 3.38 |

| 1.5 | 3.27 | 3.33 | 3.50 | 3.28 | 3.25 | 3.30 | 3.32 | 3.34 | 3.29 | 3.26 | 3.40 | 3.31 |

| 2.5 | 3.55 | 3.47 | 3.31 | 3.60 | 3.36 | 3.56 | 3.41 | 3.51 | 3.32 | 3.41 | 3.45 | 3.33 |

| 3.5 | 3.56 | 3.45 | 3.25 | 3.46 | 3.59 | 3.42 | 3.62 | 3.53 | 3.52 | 3.54 | 3.43 | 3.59 |

| 4.5 | 3.54 | 3.49 | 3.54 | 3.42 | 3.45 | 3.55 | 3.50 | 3.51 | 3.40 | 3.41 | 3.46 | 3.56 |

| 5.5 | 3.55 | 3.46 | 3.46 | 3.60 | 3.40 | 3.50 | 3.48 | 3.44 | 3.41 | 3.55 | 3.42 | 3.36 |

| 6.5 | 3.57 | 3.50 | 3.41 | 3.45 | 3.51 | 3.44 | 3.41 | 3.44 | 3.28 | 3.38 | 3.46 | 3.37 |

| 7.5 | 3.49 | 3.50 | 3.57 | 3.42 | 3.51 | 3.53 | 3.44 | 3.45 | 3.39 | 3.50 | 3.56 | 3.43 |

| 8.5 | 3.45 | 3.43 | 3.56 | 3.60 | 3.47 | 3.54 | 3.55 | 3.41 | 3.49 | 3.51 | 3.51 | 3.49 |

| 9.5 | 3.55 | 3.43 | 3.60 | 3.52 | 3.44 | 3.57 | 3.48 | 3.51 | 3.50 | 3.44 | 3.45 | 3.50 |

| 10.5 | 3.40 | 3.47 | 3.49 | 3.50 | 3.45 | 3.50 | 3.40 | 3.45 | 3.41 | 3.49 | 3.39 | 3.39 |

| 11.5 | 3.56 | 3.43 | 3.46 | 3.51 | 3.54 | 3.46 | 3.41 | 3.55 | 3.36 | 3.46 | 3.44 | 3.50 |

| 12.5 | 3.55 | 3.38 | 3.42 | 3.50 | 3.54 | 3.46 | 3.42 | 3.47 | 3.52 | 3.55 | 3.43 | 3.43 |

| 13.5 | 3.57 | 3.43 | 3.38 | 3.46 | 3.51 | 3.56 | 3.37 | 3.40 | 3.39 | 3.50 | 3.55 | 3.51 |

| 14.5 | 3.48 | 3.47 | 3.41 | 3.55 | 3.57 | 3.51 | 3.38 | 3.40 | 3.51 | 3.55 | 3.46 | 3.52 |

| 15.5 | 3.59 | 3.47 | 3.55 | 3.51 | 3.43 | 3.59 | 3.42 | 3.41 | 3.48 | 3.58 | 3.44 | 3.45 |

| 16.5 | 3.54 | 3.45 | 3.56 | 3.46 | 3.42 | 3.46 | 3.38 | 3.38 | 3.41 | 3.45 | 3.56 | 3.40 |

| 17.5 | 3.50 | 3.40 | 3.53 | 3.35 | 3.57 | 3.56 | 3.49 | 3.44 | 3.40 | 3.38 | 3.41 | 3.39 |

| 18.5 | 3.47 | 3.44 | 3.46 | 3.47 | 3.49 | 3.45 | 3.40 | 3.36 | 3.42 | 3.39 | 3.38 | 3.40 |

| 19.5 | 3.42 | 3.43 | 3.41 | 3.55 | 3.45 | 3.43 | 3.40 | 3.46 | 3.42 | 3.50 | 3.43 | 3.54 |

| 20.5 | 3.40 | 3.48 | 3.47 | 3.46 | 3.44 | 3.50 | 3.44 | 3.43 | 3.38 | 3.40 | 3.38 | 3.55 |

| 21.5 | 3.45 | 3.50 | 3.50 | 3.39 | 3.42 | 3.42 | 3.44 | 3.56 | 3.48 | 3.44 | 3.44 | 3.49 |

| 22.5 | 3.40 | 3.41 | 3.41 | 3.42 | 3.46 | 3.42 | 3.40 | 3.44 | 3.50 | 3.43 | 3.42 | 3.43 |

| 23.5 | 3.43 | 3.43 | 3.41 | 3.45 | 3.54 | 3.41 | 3.41 | 3.49 | 3.33 | 3.50 | 3.37 | 3.41 |

| 24.5 | 3.50 | 3.38 | 3.53 | 3.50 | 3.38 | 3.42 | 3.49 | 3.42 | 3.52 | 3.38 | 3.51 | 3.50 |

| 25.5 | 3.42 | 3.50 | 3.51 | 3.38 | 3.40 | 3.57 | 3.46 | 3.40 | 3.46 | 3.41 | 3.45 | 3.53 |

| 26.5 | 3.56 | 3.38 | 3.45 | 3.36 | 3.44 | 3.37 | 3.45 | 3.25 | 3.55 | 3.45 | 3.49 | 3.44 |

| 27.5 | 3.54 | 3.45 | 3.51 | 3.47 | 3.39 | 3.31 | 3.30 | 3.36 | 3.36 | 3.43 | 3.41 | 3.46 |

| 28.5 | 3.42 | 3.37 | 3.55 | 3.46 | 3.40 | 3.38 | 3.48 | 3.36 | 3.37 | 3.37 | 3.50 | 3.55 |

| 29.5 | 3.50 | 3.43 | 3.46 | 3.34 | 3.43 | 3.36 | 3.44 | 3.35 | 3.43 | 3.35 | 3.53 | 3.50 |

| 30.5 | 3.56 | 3.50 | 3.42 | 3.43 | 3.45 | 3.45 | 3.44 | 3.53 | 3.50 | 3.37 | 3.37 | 3.32 |

| 31.5 | 3.57 | 3.40 | 3.55 | 3.33 | 3.44 | 3.43 | 3.46 | 3.50 | 3.40 | 3.37 | 3.37 | 3.45 |

| 32.5 | 3.40 | 3.34 | 3.40 | 3.53 | 3.40 | 3.41 | 3.50 | 3.56 | 3.40 | 3.45 | 3.45 | 3.44 |

| 33.5 | 3.50 | 3.40 | 3.59 | 3.51 | 3.47 | 3.45 | 3.42 | 3.49 | 3.51 | 3.40 | 3.44 | 3.47 |

| Samp. No. | dm | hm | m | Ac | Vc | ρ | Fis | fis | Samp. No. | dm | hm | m | Ac | Vc | ρ | Fis | fis |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | g | cm2 | cm3 | g/cm3 | kN | MPa | mm | g | cm2 | cm3 | g/cm3 | kN | MPa | ||||

| 01/1 | 98.7 | 99.9 | 1725 | 76.51 | 764 | 2.26 | 236 | 30.85 | 07/1 | 98.6 | 100.0 | 1760 | 76.36 | 764 | 2.30 | 226 | 29.60 |

| 01/2 | 98.7 | 99.8 | 1743 | 76.51 | 764 | 2.28 | 240 | 31.37 | 07/2 | 98.6 | 99.9 | 1751 | 76.36 | 763 | 2.30 | 231 | 30.25 |

| 01/3 | 98.7 | 99.8 | 1765 | 76.51 | 764 | 2.31 | 242 | 31.63 | 07/3 | 98.6 | 99.8 | 1746 | 76.36 | 762 | 2.29 | 232 | 30.38 |

| 02/1 | 98.5 | 100.0 | 1724 | 76.20 | 762 | 2.26 | 236 | 30.97 | 08/1 | 98.7 | 99.9 | 1755 | 76.51 | 764 | 2.30 | 230 | 30.06 |

| 02/2 | 98.5 | 99.8 | 1761 | 76.20 | 760 | 2.32 | 238 | 31.23 | 08/2 | 98.7 | 99.9 | 1761 | 76.51 | 764 | 2.30 | 235 | 30.71 |

| 02/3 | 98.5 | 99.9 | 1762 | 76.20 | 761 | 2.31 | 243 | 31.89 | 08/3 | 98.7 | 99.9 | 1757 | 76.51 | 764 | 2.30 | 237 | 30.98 |

| 03/1 | 98.5 | 99.8 | 1711 | 76.20 | 760 | 2.25 | 233 | 30.58 | 09/1 | 98.5 | 99.7 | 1744 | 76.20 | 760 | 2.30 | 234 | 30.71 |

| 03/2 | 98.5 | 99.9 | 1741 | 76.20 | 761 | 2.29 | 241 | 31.63 | 09/2 | 98.5 | 99.9 | 1740 | 76.20 | 761 | 2.29 | 238 | 31.23 |

| 03/3 | 98.6 | 99.6 | 1768 | 76.36 | 761 | 2.32 | 248 | 32.48 | 09/3 | 98.5 | 100.0 | 1760 | 76.20 | 762 | 2.31 | 243 | 31.89 |

| 04/1 | 98.5 | 99.9 | 1731 | 76.20 | 761 | 2.27 | 237 | 31.10 | 10/1 | 98.5 | 99.6 | 1754 | 76.20 | 759 | 2.31 | 239 | 31.36 |

| 04/2 | 98.5 | 99.9 | 1755 | 76.20 | 761 | 2.31 | 240 | 31.50 | 10/2 | 98.5 | 99.8 | 1742 | 76.20 | 760 | 2.29 | 245 | 32.15 |

| 04/3 | 98.5 | 99.8 | 1779 | 76.20 | 760 | 2.34 | 240 | 31.50 | 10/3 | 98.5 | 99.8 | 1748 | 76.20 | 760 | 2.30 | 248 | 32.55 |

| 05/1 | 98.5 | 99.9 | 1717 | 76.20 | 761 | 2.26 | 234 | 30.71 | 11/1 | 98.6 | 99.7 | 1741 | 76.36 | 761 | 2.29 | 237 | 31.04 |

| 05/2 | 98.5 | 99.9 | 1745 | 76.20 | 761 | 2.29 | 240 | 31.50 | 11/2 | 98.6 | 99.7 | 1747 | 76.36 | 761 | 2.29 | 232 | 30.38 |

| 05/3 | 98.5 | 99.9 | 1769 | 76.20 | 761 | 2.32 | 242 | 31.76 | 11/3 | 98.6 | 99.9 | 1750 | 76.36 | 763 | 2.29 | 238 | 31.17 |

| 06/1 | 98.5 | 99.9 | 1716 | 76.20 | 761 | 2.25 | 240 | 31.50 | 12/1 | 98.5 | 99.9 | 1766 | 76.20 | 761 | 2.32 | 240 | 31.50 |

| 06/2 | 98.5 | 99.9 | 1741 | 76.20 | 761 | 2.29 | 242 | 31.76 | 12/2 | 98.5 | 99.8 | 1754 | 76.20 | 760 | 2.31 | 243 | 31.89 |

| 06/3 | 98.5 | 99.9 | 1762 | 76.20 | 761 | 2.31 | 245 | 32.15 | 12/3 | 98.5 | 100.1 | 1750 | 76.20 | 763 | 2.29 | 245 | 32.15 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michałek, J. Variation in Compressive Strength of Concrete aross Thickness of Placed Layer. Materials 2019, 12, 2162. https://doi.org/10.3390/ma12132162

Michałek J. Variation in Compressive Strength of Concrete aross Thickness of Placed Layer. Materials. 2019; 12(13):2162. https://doi.org/10.3390/ma12132162

Chicago/Turabian StyleMichałek, Jarosław. 2019. "Variation in Compressive Strength of Concrete aross Thickness of Placed Layer" Materials 12, no. 13: 2162. https://doi.org/10.3390/ma12132162

APA StyleMichałek, J. (2019). Variation in Compressive Strength of Concrete aross Thickness of Placed Layer. Materials, 12(13), 2162. https://doi.org/10.3390/ma12132162