VOC Emissions from Spruce Strands and Hemp Shive: In Search for a Low Emission Raw Material for Bio-Based Construction Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

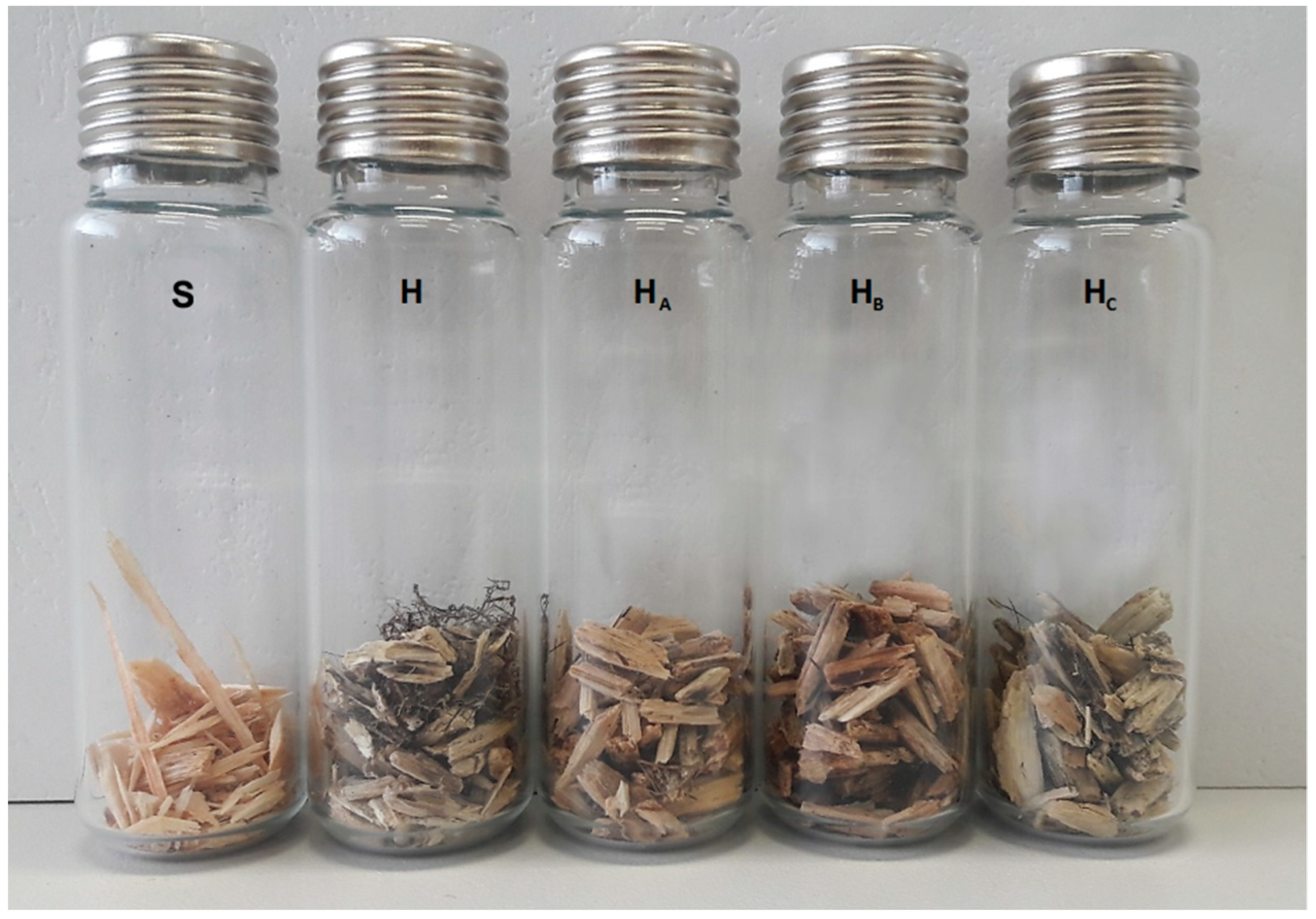

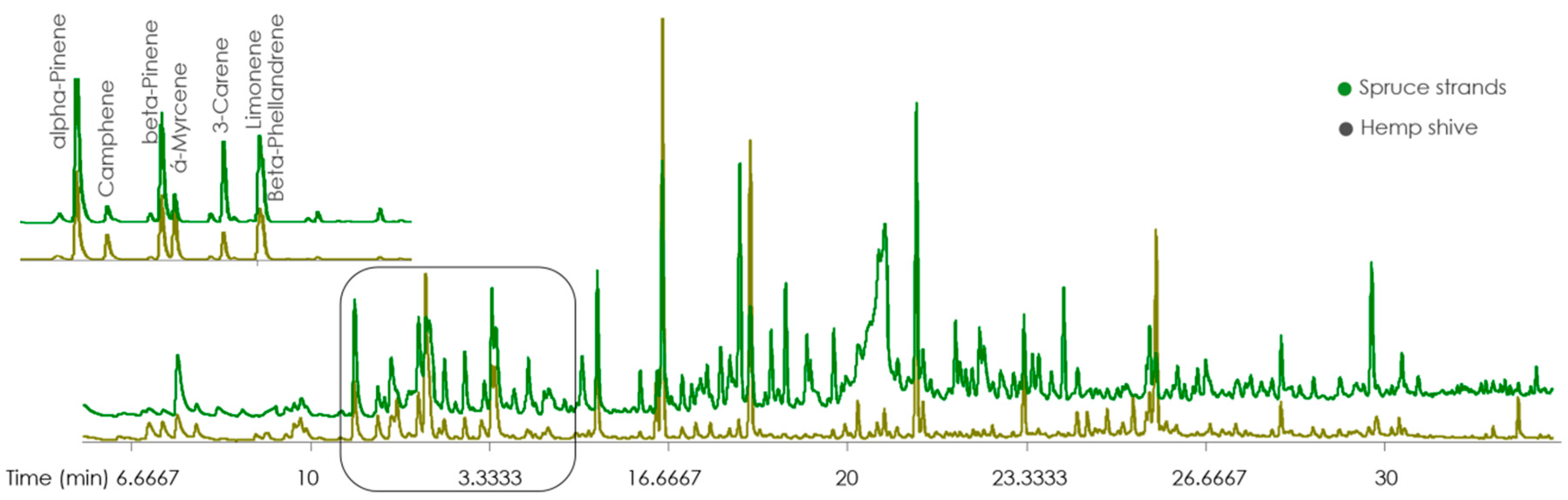

2.2. Samples

2.3. Chemical Treatment

2.4. Extraction of Volatiles, GC–MS Analysis and Data Processing

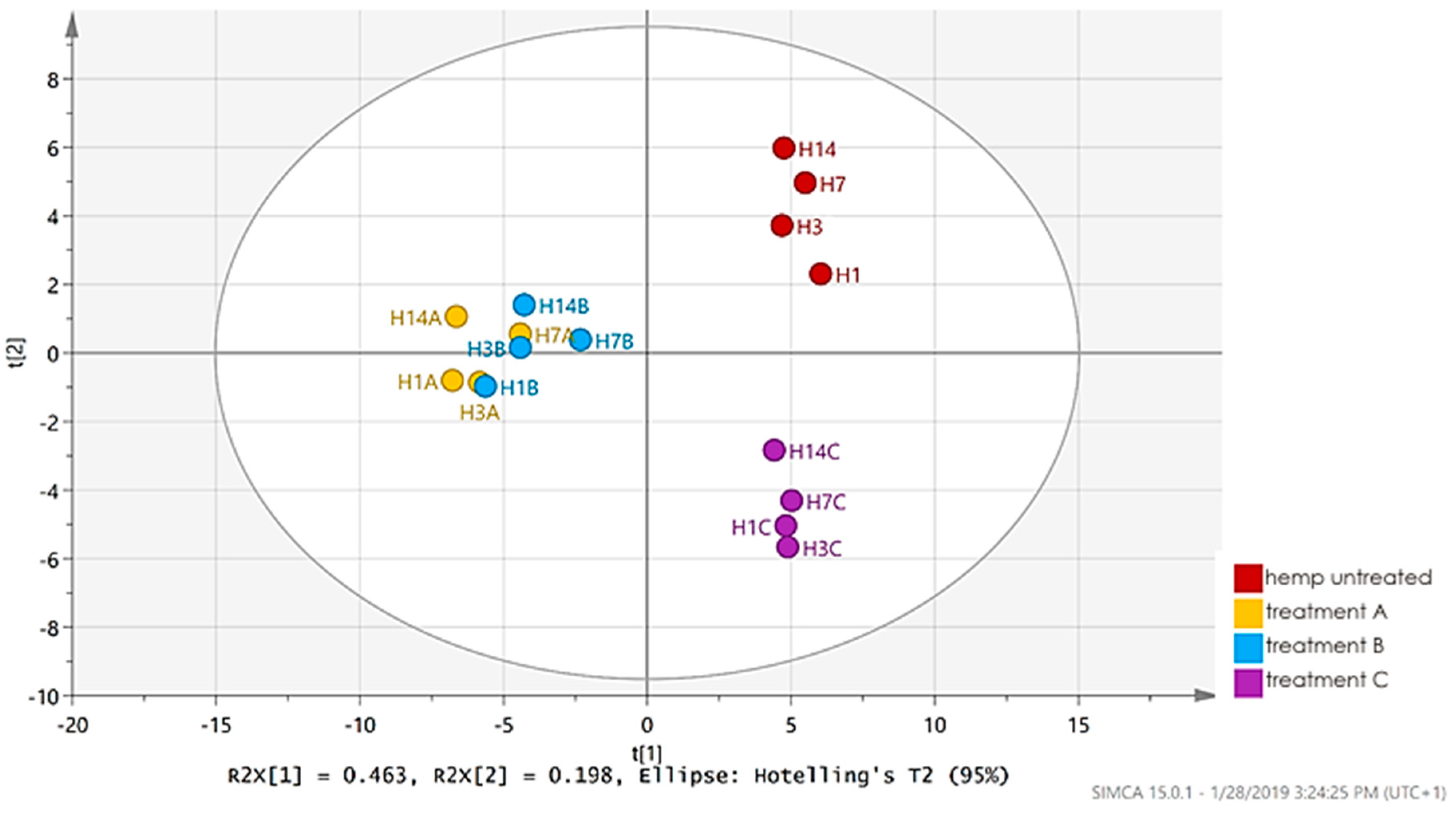

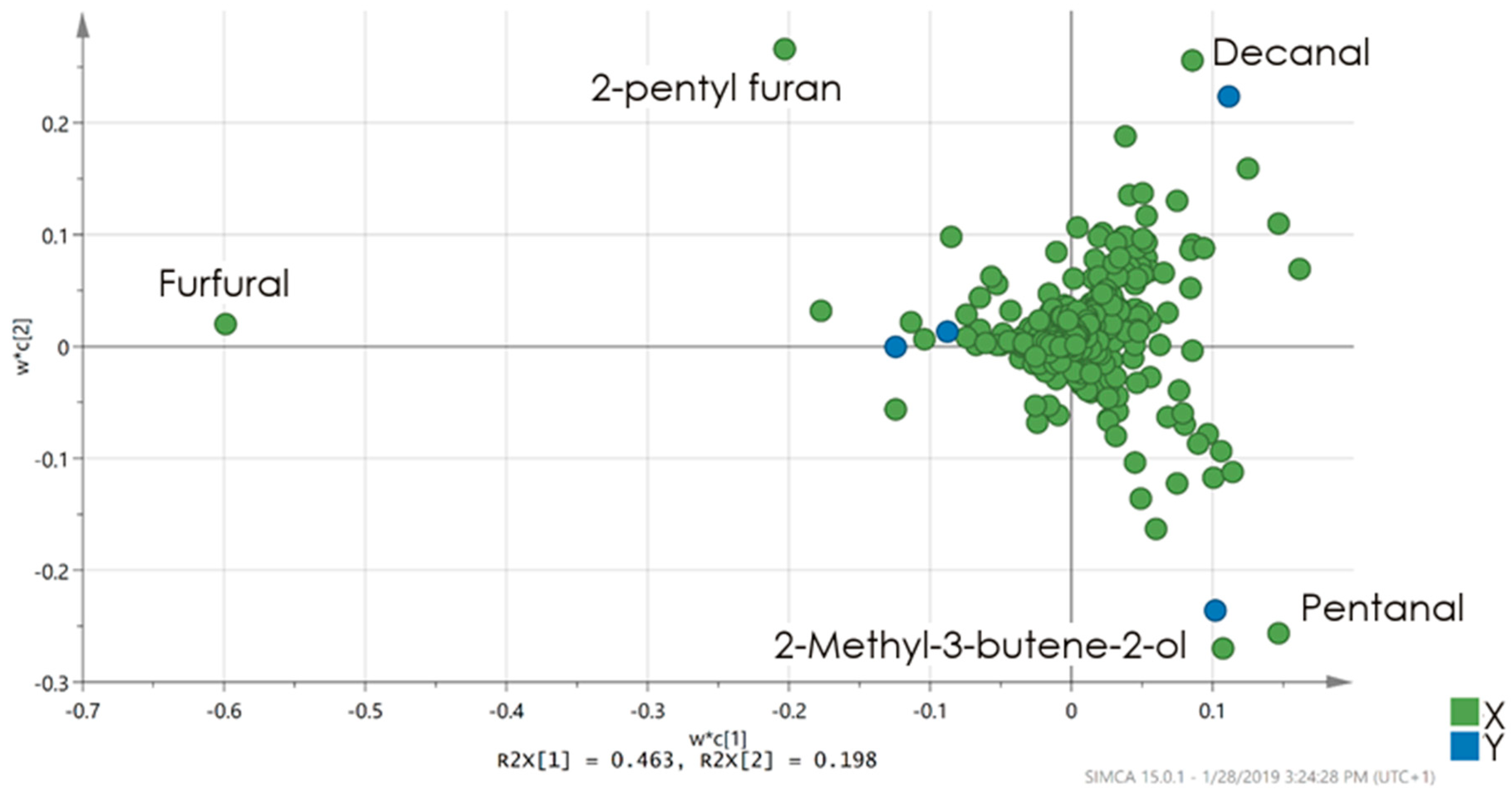

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Matsubara, E.; Kawai, S. VOCs emitted from Japanese cedar (Cryptomeria japonica) interior walls induce physiological relaxation. Build. Environ. 2014, 72, 125–130. [Google Scholar] [CrossRef]

- An, J.-Y.; Kim, S.; Kim, H.-J. Formaldehyde and TVOCs emission behaviour of laminate flooring by structure of laminate flooring and heating condition. J. Hazard. Mater. 2011, 187, 44–51. [Google Scholar] [CrossRef] [PubMed]

- Tanaka-Kagawa, T.; Uchiyama, S.; Matsushima, E.; Sasaki, A.; Kobayashi, H.; Kobayashi, H.; Yagi, M.; Tsuno, M.; Arao, M.; Ikemoto, K.; et al. Survey of volatile organic compounds found in indoor and outdoor air samples from Japan. Bull. Natl. Inst. Health Sci. 2005, 123, 27–31. [Google Scholar]

- Maskell, D.; da Silva, C.F.; Mower, K.; Cheta, R.; Dengel, A.; Ball, R.; Ansell, M.; Walker, P.; Shea, A. Properties of bio-based insulation materials and their potential impact on indoor air quality. In Proceedings of the First International Conference on Bio-Based Building Materials, Clermont-Ferrand, France, 22–24 June 2015. [Google Scholar]

- Skov, H.; Hansen, A.B.; Lorenzen, G.; Andersen, H.V.; Lofstrom, P.; Christensen, C.S. Benzene exposure and the effect of traffic pollution in Copenhagen Denmark. Atmos. Environ. 2001, 35, 2463–2471. [Google Scholar] [CrossRef]

- Liu, Y.; Shen, J.; Zhu, X. Influence of processing parameters on VOC emission from particleboards. Environ. Monit. Assess. 2010, 171, 249–254. [Google Scholar] [CrossRef]

- Xi, Z.; Zhiwei, L.; Wu, Y. Human physiological responses to wooden indoor environment. Physiol. Behav. 2017, 174, 27–34. [Google Scholar]

- Irle, M.; Barbu, M.C. Wood-Based Panel Technology. In Wood-Based Panels: An Introduction for Specialists; Thoemen, H., Irle, M., Sernek, M., Eds.; Brunel University Press: London, UK, 2010; pp. 1–55. ISBN 978-1-902316-82-6. [Google Scholar]

- Grand View Research; Low-Volatile Organic Compounds (VOC) Coating Additives Market Analysis, Market Size, Application Analysis, Regional Outlook, Competitive Strategies, and Forecasts, 2015–2022. Available online: https://www.grandviewresearch.com/industry-analysis/low-volatile-organic-compounds-coating-additives-market (accessed on 1 February 2019).

- Liu, Y.; Zhu, X. Measurement of formaldehyde and VOCs emissions from wood based panels with nanomaterial added melamine impregnated paper. Constr. Build. Mater. 2014, 66, 132–137. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, Y.; Qi, Y.; Yu, Y.; Yu, W. Identification of odorous constituents of bamboo during thermal treatment. Constr. Build. Mater. 2019, 203, 104–110. [Google Scholar] [CrossRef]

- He, Z.; Zhang, Y.; Wei, W. Formaldehyde and VOC emissions at different manufacturing stages of wood based panels. Build. Environ. 2012, 47, 197–204. [Google Scholar] [CrossRef]

- da Silva, C.F.; Cheta, R.; Maskell, R.; Dengel, A.; Ansell, M.P.; Ball, R. Influence of eco-materials on indoor air quality. Green Mater. 2016, 4, 72–80. [Google Scholar] [CrossRef] [Green Version]

- Sumin, K. The reduction of indoor air pollutant from wood-based composite by adding pozzolan for building materials. Constr. Build. Mater. 2009, 23, 2319–2323. [Google Scholar] [CrossRef]

- Stachowiak-Wencek, A.; Pradzyński, W. Emission of volatile organic compounds from wood of exotic species. For. Wood Technol. 2014, 86, 215–219. [Google Scholar]

- Wolkoff, P. How to measure and evaluate volatile organic compound emissions from building products. A perspective. Sci. Total Environ. 1999, 227, 197–213. [Google Scholar] [CrossRef]

- Chen, H. Biotechnology of Lignocellulose: Theory and Practice; Chemical Industry Press: Beijing, China, 2014; ISBN 978-94-007-6898-7. [Google Scholar]

- Hill, C.A.S. Wood Modification: Chemical, Thermal and other Processes; Wiley-Blackwell: Chichester, UK, 2006; pp. 25–30. ISBN 0-470-02172-1. [Google Scholar]

- Roffael, E. Significance of wood extractives for wood bonding. Appl. Microbiol. Biotechnol. 2016, 100, 1589–1596. [Google Scholar] [CrossRef] [PubMed]

- Summerscales, J.; Dissanayake, N.; Hall, W.; Virk, A.S. A review of bast fibres and their composites. Part 1: Fibres as reinforcements. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1329–1335. [Google Scholar] [CrossRef]

- Koivula, M.; Kymäläinen, H.R.; Virta, J.; Hakkarainen, H.; Hussein, T.; Komulainen, J.; Koponen, H.; Hautala, M.; Hämeri, K.; Kanerva, P.; et al. Emissions from thermal insulations—Part 2: Evaluation of emissions from organic and inorganic insulations. Build. Environ. 2005, 40, 803–814. [Google Scholar] [CrossRef]

- Çomak, B.; Bideci, A.; Bideci, Ö.S. Effects of hemp fibers on characteristics of cement based mortar. Constr. Build. Mater. 2018, 169, 794–799. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Jiang, Y.; Lawrence, M.; Ansell, M.P.; Hussain, A. Cell wall microstructure, pore size distribution and absolute density of hemp shiv. R. Soc. Open Sci. 2018, 5, 171945. [Google Scholar] [CrossRef] [Green Version]

- Donatelli, A.; Cuna, D.; Tagliente, M.A.; Protopapa, M.L.; Mevoli, A.; Aversa, P.; Blasi, C.; Capodieci, L.; Luprano, V.A.M. Effect of treatments on the aging behaviour of hemp fibres for building construction in the Mediterranean Area. J. Build. Eng. 2017, 11, 37–47. [Google Scholar] [CrossRef]

- Hussain, A.; Calabria-Holley, J.; Lawrence, M.; Ansell, M.P.; Jiang, Y.; Schorr, D.; Blanchet, P. Development of novel building composites based on hemp and multi-functional silica matrix. Compos. Part B Eng. 2019, 156, 266–273. [Google Scholar] [CrossRef]

- Brzyski, P.; Łagód, G. Physical and mechanical properties of composites based on hemp shiv and lime. In SOLINA 2018—VII Conference SOLINA Sustainable Development: Architecture—Building Construction—Environmental Engineering and Protection Innovative Energy-Efficient Technologies—Utilization of Renewable Energy Sources, Proceedings of the Meeting SOLINA 2018, Polanczyk, Poland, 19–23 June 2018; Lichołai, L., Dębska, B., Miąsik, P., Szyszka, J., Krasoń, J., Szlachta, A., Eds.; EDP Sciences: Les Ulis, France, 2018; Volume 49, p. 00010. [Google Scholar]

- Brzyski, P.; Barnat-Hunek, D.; Suchorab, Z.; Łagód, G. Composite materials based on hemp and flax for low-energy buildings. Materials 2017, 10, 510. [Google Scholar] [CrossRef] [PubMed]

- Wilke, O.; Brozowski, F.; Wiegner, K.; Brauer, F. Bestimmung der VOC-Emissionen aus Grobspanplatten (OSB-Platten) und ihre Bewertung nach dem AgBB-Schema. Umwelt und Mensch Informationsdienst 2013, 1, 5–11. [Google Scholar]

- Fiore, V.; Scalici, T.; Nicoletti, F.; Vitale, G.; Prestipino, M.; Valenza, A. A new eco-friendly chemical treatment of natural fibres: Effect of sodium bicarbonate on properties of sisal fibre and its epoxy composites. Compos. Part B Eng. 2016, 85, 150–160. [Google Scholar] [CrossRef]

- ISO 16000-6:2011. Indoor Air—Part 6: Determination of Volatile Organic Compounds in Indoor and Test Chambre Air by Active Sampling on Tenax TA ® Sorbent, Thermal Desorption and Ga\s Chromatography Using MS or MS-FID; ISO/TC 146; Technical Committee: Geneva, Switzerland, 2011. [Google Scholar]

- NIOSH Pocket Guide to Chemical Hazards, Appendix: Aldehydes and NIOSH 2018: Aliphatic Aldehydes. Available online: http://www.cdc.gov/niosh/npg/npgd0652.html (accessed on 10 February 2019).

- Risholm-Sundman, M.; Lundgren, M.; Vestin, E.; Herder, P. Emissions of acetic acid and other volatile organic compounds from different species of solid wood. Holz als Roh-und Werkstoff 1998, 56, 125–129. [Google Scholar] [CrossRef]

- Ernstgård, L.; Iregren, A.; Sjögren, B.; Svedberg, U.; Johanson, G. Acute effects of exposure to hexanal vapors in humans. J. Occup. Environ. Med. 2006, 48, 573–580. [Google Scholar] [CrossRef] [PubMed]

- Salthammer, T.; Fuhrmann, F. Release of acetic acid and furfural from cork products. Indoor Air 2000, 10, 133–134. [Google Scholar] [CrossRef]

- Eseyin, A.E.; Steele, P.H. An overview of the applications of furfural and its derivatives. Int. J. Adv. Chem. 2015, 3, 42–47. [Google Scholar] [CrossRef]

- Api, A.M.; Belsito, D.; Bhatia, S.; Bruze, M.; Calow, P.; Dagli, M.L.; Dekant, W.; Fryer, A.D.; Kromidas, L.; La Cava, S.; et al. RIFM fragrance ingredient safety assessment, 2-methyl-3-buten-2-ol, CAS Registry Number 115-18-4. Food Chem. Toxicol. 2015, 84, S50–S56. [Google Scholar] [CrossRef]

| SAMPLE/Designation | Spruce Hemp | ||||

|---|---|---|---|---|---|

| S | H | HA | HB | HC | |

| Treatment | - | - | Tartaric acid | Citric acid | Sodium bicarbonate |

| Solution concentration (wt.%) | - | - | 6 | 6 | 6 |

| Soaking time (h) | - | - | 24 | 24 | 24 |

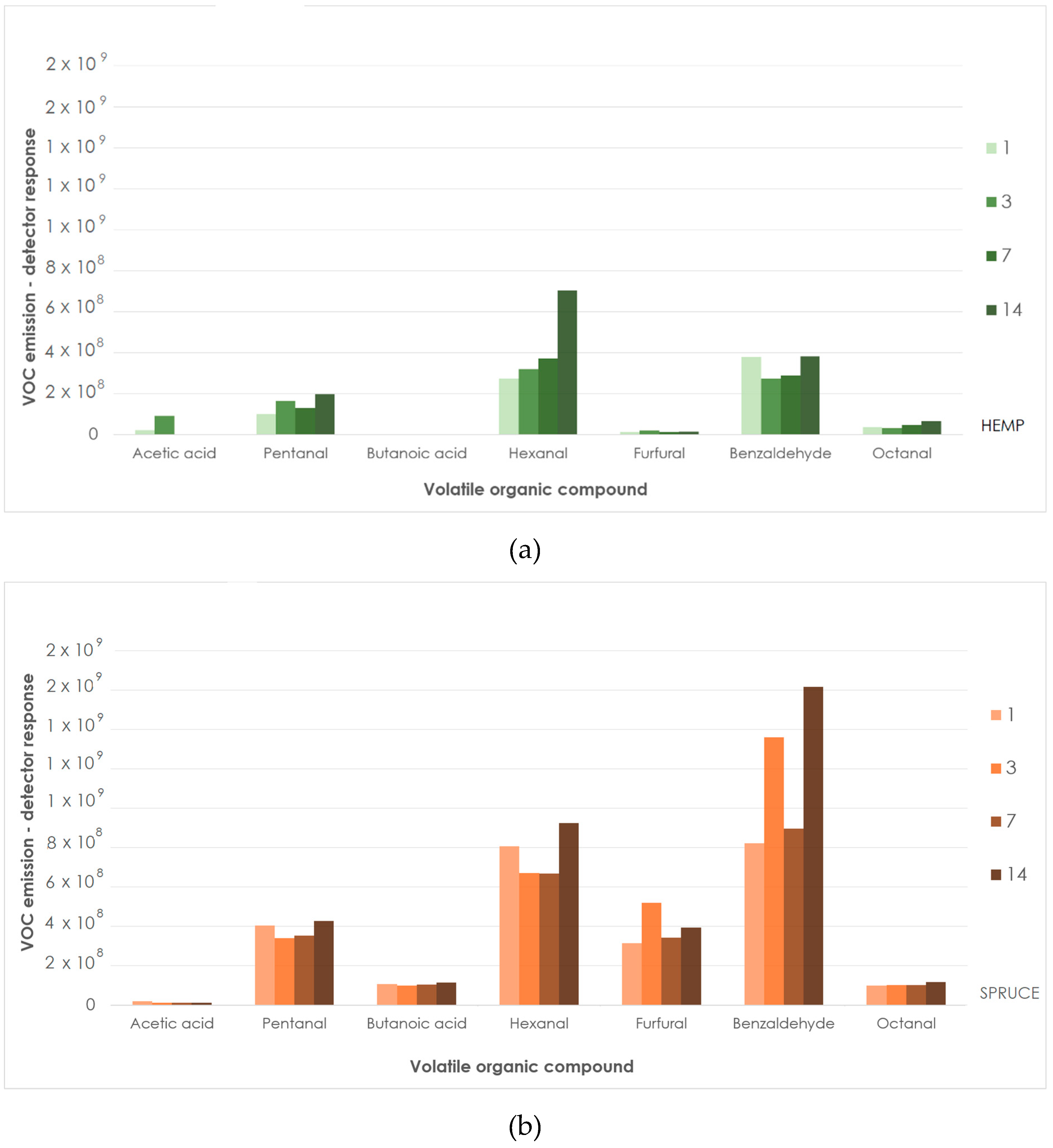

| SAMPLES & SAMPLING DAYS | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| COMPOUND | S | H | HA | HB | HC | |||||||||||||||

| 1 | 3 | 7 | 14 | 1 | 3 | 7 | 14 | 1 | 3 | 7 | 14 | 1 | 3 | 7 | 14 | 1 | 3 | 7 | 14 | |

| Acetic acid | 20 | 12 | 12 | 1 | 23 | 90 | 2 | 2 | 90 | 62 | 38 | 38 | 177 | 68 | 44 | 35 | 6 | 6 | 3 | 1 |

| Pentanal | 403 | 340 | 352 | 428 | 100 | 165 | 131 | 198 | 192 | 180 | 149 | 183 | 237 | 214 | 179 | 191 | 1275 | 1073 | 615 | 554 |

| Butanoic acid | 105 | 98 | 103 | 113 | / | / | / | / | 20 | 20 | 22 | 26 | 22 | 23 | 25 | 26 | / | / | / | / |

| Hexanal | 805 | 669 | 668 | 925 | 273 | 320 | 372 | 704 | 606 | 582 | 650 | 798 | 577 | 554 | 607 | 787 | 379 | 356 | 408 | 375 |

| Furfural | 315 | 520 | 342 | 394 | 12 | 19 | 12 | 16 | 10638 | 9191 | 5609 | 6672 | 8427 | 5639 | 2557 | 2419 | 92 | 86 | 59 | 61 |

| alpha-Pinene | 1377 | 7345 | 2815 | 4872 | 666 | 285 | 244 | 24 | 697 | 729 | 594 | 279 | 679 | 572 | 639 | 253 | 887 | 782 | 883 | 303 |

| Camphene | 120 | 145 | 63 | 113 | 190 | 83 | 68 | 3 | 224 | 233 | 181 | 89 | 247 | 192 | 202 | 82 | 265 | 236 | 259 | 87 |

| Benzaldehyde | 821 | 1360 | 897 | 1619 | 379 | 274 | 287 | 381 | 791 | 676 | 560 | 467 | 697 | 704 | 558 | 540 | 952 | 873 | 682 | 579 |

| beta-Pinene | 761 | 1066 | 271 | 2189 | 441 | 197 | 172 | / | 409 | 440 | 391 | 196 | 291 | 286 | 385 | 177 | 649 | 612 | 646 | 233 |

| 3-Octanone | / | / | / | 3 | / | 2 | 2 | 1 | / | / | / | 2 | 3 | / | / | / | 4 | 4 | 3 | 2 |

| beta-Myrcene | 176 | 212 | 88 | 147 | 381 | 149 | 142 | 7 | 388 | 365 | 312 | 148 | 382 | 293 | 345 | 141 | 525 | 491 | 501 | 164 |

| Octanal | 98 | 100 | 100 | 116 | 36 | 31 | 46 | 65 | 92 | 87 | 81 | 90 | 71 | 76 | 80 | 82 | 41 | 456 | 44 | 51 |

| Limonene | 818 | 896 | 503 | 147 | 475 | 191 | 190 | 89 | 490 | 500 | 500 | 203 | 585 | 426 | 459 | 194 | 602 | 605 | 593 | 214 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adamová, T.; Hradecký, J.; Prajer, M. VOC Emissions from Spruce Strands and Hemp Shive: In Search for a Low Emission Raw Material for Bio-Based Construction Materials. Materials 2019, 12, 2026. https://doi.org/10.3390/ma12122026

Adamová T, Hradecký J, Prajer M. VOC Emissions from Spruce Strands and Hemp Shive: In Search for a Low Emission Raw Material for Bio-Based Construction Materials. Materials. 2019; 12(12):2026. https://doi.org/10.3390/ma12122026

Chicago/Turabian StyleAdamová, Tereza, Jaromír Hradecký, and Marek Prajer. 2019. "VOC Emissions from Spruce Strands and Hemp Shive: In Search for a Low Emission Raw Material for Bio-Based Construction Materials" Materials 12, no. 12: 2026. https://doi.org/10.3390/ma12122026

APA StyleAdamová, T., Hradecký, J., & Prajer, M. (2019). VOC Emissions from Spruce Strands and Hemp Shive: In Search for a Low Emission Raw Material for Bio-Based Construction Materials. Materials, 12(12), 2026. https://doi.org/10.3390/ma12122026