Surface Quality of 3D-Printed Models as a Function of Various Printing Parameters

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Reliability

3.2. Ra Roughness within One Measurement Direction (X1 vs. X2, Y1 vs. Y2, Z1 vs. Z2)

3.3. Ra Roughness as a Function of the Measurement Direction (X vs. Y vs. Z)

3.4. Printing Speed

3.5. Support Structure/Inclination

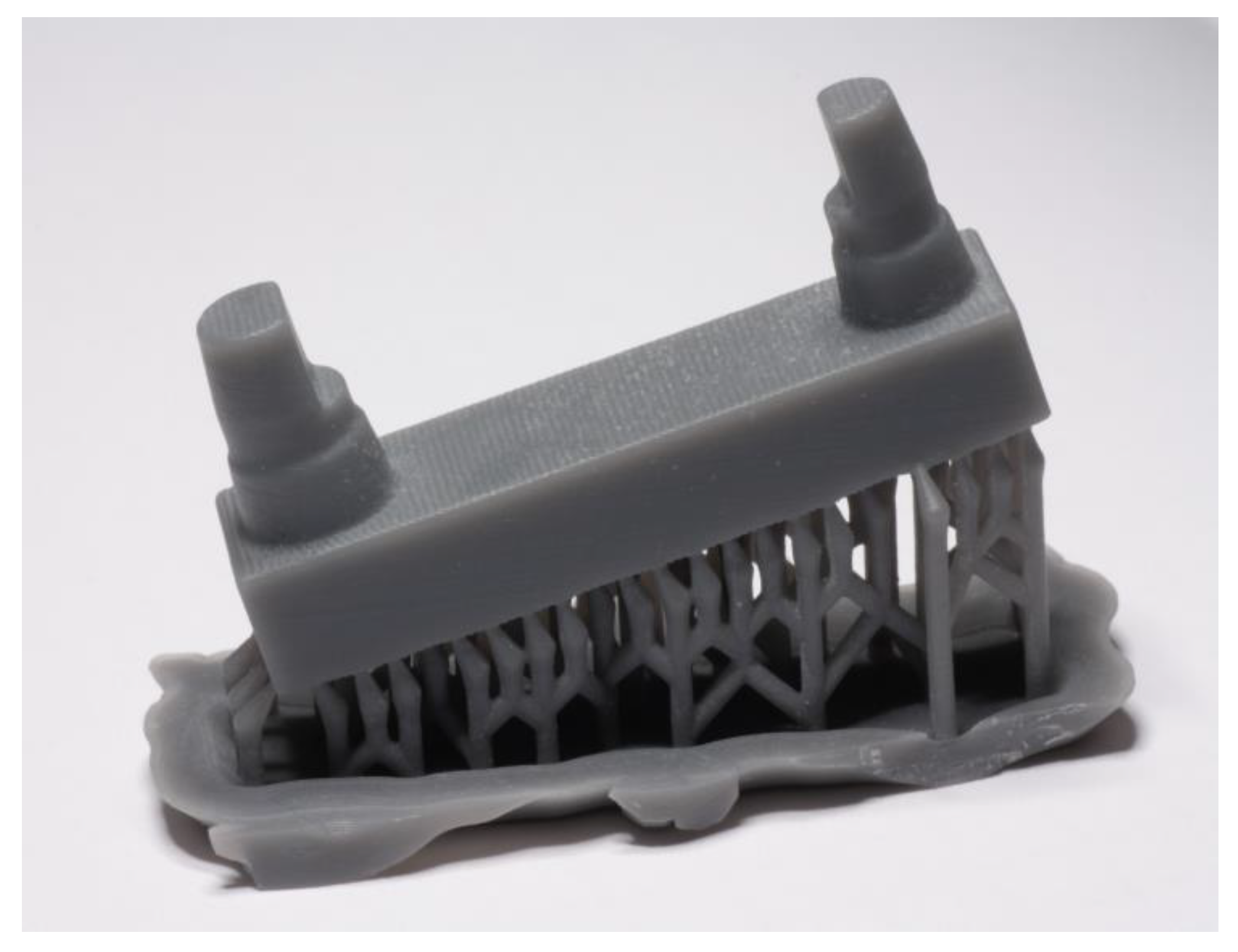

3.6. Model Structure

3.7. Model Base Orientation

3.8. Position Build Platform and Reprint

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alifui-Segbaya, F.; Bowman, J.; White, A.R.; Varma, S.; Lieschke, G.J.; George, R. Toxicological assessment of additively manufactured methacrylates for medical devices in dentistry. Acta Biomater. 2018, 15, 64–77. [Google Scholar] [CrossRef] [PubMed]

- Egan, P.F.; Bauer, I.; Shea, K.; Ferguson, S.J. Mechanics of three-dimensional printed lattices for biomedical devices. J. Mech. Des. 2019, 141, 031703. [Google Scholar] [CrossRef]

- Lin, M.; Firoozi, N.; Tsai, C.T.; Wallace, M.B.; Kang, Y. 3D-printed flexible polymer stents for potential applications in inoperable esophageal malignancies. Acta Biomater. 2019, 1, 119–129. [Google Scholar] [CrossRef] [PubMed]

- Torabi, K.; Farjood, E.; Hamedani, S.H. Rapid prototyping technologies and their applications in prosthodontics, a review of literature. J. Dent. 2015, 16, 1–9. [Google Scholar]

- Silva, N.R.F.A.; Witek, L.; Coelho, P.G.; Thompson, V.P.; Rekow, E.D.; Smay, J. Additive CAD/CAM process for dental prostheses. J. Prosthodont. 2011, 20, 93–96. [Google Scholar] [CrossRef] [PubMed]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Keuter, F.M.S.; Davidson, C.L. Surface roughness of dental stone casts from alginate impressions. J. Dent. 1986, 14, 23–28. [Google Scholar] [CrossRef]

- Chang, Y.C.; Yu, C.H.; Liang, W.M.; Tu, M.G.; Chen, S. Comparison of the surface roughness of gypsum models constructed using various impression materials and gypsum products. J. Dent. Sci. 2016, 11, 23–28. [Google Scholar] [CrossRef] [PubMed]

- Johnson, G.H.; Chellis, K.D.; Gordon, G.E.; Lepe, X. Dimensional stability and detail reproduction of irreversible hydrocolloid and elastomeric impressions disinfected by immersion. J. Prosthet. Dent. 1998, 79, 446–453. [Google Scholar] [CrossRef]

- Camardella, L.T.; Vilella, O.V.; van Hezel, M.M.; Breuning, K.H. Accuracy of stereolithographically printed digital models compared to plaster models. J. Orofac. Orthop. 2017, 78, 394–402. [Google Scholar] [CrossRef]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef] [PubMed]

- Kruth, J.P.; Leu, M.C.; Nakagawa, T. Progress in additive manufacturing and rapid prototyping. ClRP Ann. 1998, 47, 525–539. [Google Scholar] [CrossRef]

- Pham, D.T.; Dimov, S.S. Rapid prototyping and rapid tooling—The key enablers for rapid manufacturing. J. Mech. Eng. Sci. 2003, 217, 1–23. [Google Scholar] [CrossRef]

- Byun, H.-S.; Lee, K.H. Determination of the optimal build direction for different rapid prototyping process using multi-criterion decision making. Robot. Comput. Integr. Manuf. 2006, 22, 69–80. [Google Scholar] [CrossRef]

- Cheng, W.; Fuh, J.Y.H.; Nee, A.Y.C.; Wong, Y.S.; Loh, H.T.; Miyazawa, T. Multi-objective optimization of part-building orientation in stereolithography. Rapid. Prototyp. J. 1995, 1, 12–23. [Google Scholar] [CrossRef]

- Pandey, P.M.; Venkata Reddy, N.; Dhande, S.G. Part deposition orientation studies in layered manufacturing. J. Mater. Process. Technol. 2007, 185, 125–131. [Google Scholar] [CrossRef]

- Delfs, P.; Tows, M.; Schmid, H.-J. Optimized build orientation of additive manufactured parts for improved surface quality and build time. Addit. Manuf. 2016, 12, 314–320. [Google Scholar] [CrossRef]

- Pandey, P.M.; Reddy, N.V.; Dhande, S.G. Slicing procedures in layered manufacturing: A review. Rapid Prototyp. J. 2003, 9, 274–288. [Google Scholar] [CrossRef]

- Gadelmawla, E.S.; Koura, M.M.; Maksoud, T.M.A.; Elewa, I.M.; Soliman, H.H. Roughness parameters. J. Mater. Process. Technol. 2002, 123, 133–145. [Google Scholar] [CrossRef]

- Dahlberg, G. Statistical Methods for Medical and Biological Students; Interscience Publications: New York, NY, USA, 1940. [Google Scholar]

- Benardos, P.G.; Vosniakos, G.-C. Predicting surface roughness in machining: A review. Int. J. Mac. Tool. Manuf. 2002, 43, 833–844. [Google Scholar] [CrossRef]

- Arbizu, I.P.; Pérez, C.J.L. Surface roughness prediction by factorial design of experiments in turning processes. J. Mater. Process. Technol. 2003, 143–144, 390–396. [Google Scholar] [CrossRef]

- Kim, K.-B.; Kim, J.-H.; Kim, S.-H. Impact of surface roughness of gypsum materials on adaption of zirconia cores. J. Adv. Prosthodont. 2015, 7, 199–206. [Google Scholar] [CrossRef] [PubMed]

- Abdelaziz, K.M.; Combe, E.C.; Hodges, J.S. The effect of disinfectants on the properties of dental gypsum, part 2: Surface properties. J. Prosthodont. 2002, 11, 234–240. [Google Scholar] [CrossRef] [PubMed]

- Murata, H.; Hong, G.; Li, A.Y. Compatibility of tissue conditioners and dental stones: Effect on surface roughness. J. Prosthet. Dent. 2005, 93, 274–281. [Google Scholar] [CrossRef] [PubMed]

- Murata, H.; Kawamura, M.; Hamada, T.; Chimori, H.; Nikawa, H. Physical properties and compatibility with dental stones of current alginate impression materials. J. Oral Rehabil. 2004, 31, 1115–1122. [Google Scholar] [CrossRef] [PubMed]

- Jacobs, P.F. Rapid Prototyping and Manufacturing: Fundamentals of Stereo-Lithography; Society of Manufacturing Engineers: Southfield, MI, USA, 1992; pp. 160–162. [Google Scholar]

- Pincel, P.V.; Jiménez-Pérez, J.L.; Cruz-Orea, A.; Correa-Pacheco, Z.N.; Hernández, R.J. Photoacoustic study of curing time by UV laser radiation of a photoresin with different thickness. Thermochim. Acta 2015, 606, 53–57. [Google Scholar] [CrossRef]

- Xie, R.; Li, D.; Chao, S. An inexpensive stereolithography technology with high power UV-LED light. Rapid Prototyp. J. 2011, 17, 441–450. [Google Scholar] [CrossRef]

- Scarparo, M.A.F.; Kiel, A.; Zhiyao, Z.; Ferrari, C.A.; Chen, Q.J.; Miller, A.S.; Allen, S.D. Study of resin based materials using CO2 laser stereolithography. Polymer 1997, 38, 2175–2181. [Google Scholar] [CrossRef]

- FormLabs Support: Orienting a Model. Available online: https://support.formlabs.com/s/article/Model-Orientation?language=en_US (accessed on 11 June 2019).

- Dolenc, A.; Makela, I. Slicing procedures for layered manufacturing techniques. Comput. Aided Des. 1994, 26, 119–126. [Google Scholar] [CrossRef]

- Oropallo, W.; Piegl, L.A. Ten challenges in 3D printing. Eng. Comput. 2015, 32, 135–148. [Google Scholar] [CrossRef]

- Ma, W.; But, W.-C.; He, P. NURBS-based adaptive slicing for efficient rapid prototyping. Comput. Aided Des. 2004, 36, 1309–1325. [Google Scholar] [CrossRef]

- Sabourin, E.; Houser, S.A.; Bohn, J.A. Adaptive slicing using stepwise uniform refinement. Rapid Prototyp. J. 1996, 2, 20–26. [Google Scholar] [CrossRef]

- FormLabs Support: Standard Resin Tank: Maintenance and Care. Available online: https://support.formlabs.com/s/article/Standard-Resin-Tank-Maintenance-and-Care?language=en_US (accessed on 11 June 2019).

| Printing Parameters | Selected Settings |

|---|---|

| Printing speed (layer thickness) | 0.025 slow (layer thickness: 25 µm) [S1] |

| 0.05 standard (layer thickness: 50 µm) [S2] | |

| 0.1 fast (layer thickness: 100 µm) [S3] | |

| Inclination (support structure) | 0° (without support structure) |

| 15° (with support structure) | |

| (canine up, molar down) | |

| Model structure | hollow body [H] |

| solid (full) body [F] | |

| Model base orientation (see Figure 2) | model base: parallel to the front [P] |

| model base: across the front [A] | |

| Position build platform (see Figure 2) | front area (right, middle, left) |

| center area (right, middle, left) | |

| back area (right, middle, left) |

| Ingredient | % |

|---|---|

| Methacrylated oligomer | ≥75 ~ ≤90 |

| Methacrylated monomer | ≥25 ~ ≤50 |

| Diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide | ≥1 ~ <3 |

| Test-Series Sequences | Printing resolution/Support Structure Inclination | Number of Layers | Print Time |

|---|---|---|---|

| D1 and D4 | 25 µm/0° | 659 | 466 min |

| D3 and D6 | 50 µm/0° | 330 | 249 min |

| D2 and D5 | 100 µm/0° | 165 | 146 min |

| D8 and D11 | 25 µm/15° | 1036 | 620 min |

| D9 and D12 | 50 µm/15° | 564 | 381 min |

| D7 and D10 | 100 µm/15° | 314 | 285 min |

| Model Structure | Position Build Platform | Comparison Measuring Direction | D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 | D10 | D11 | D12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Full body | Back left | X/Y | 0.120 | 0.232 | 0.297 | 0.531 | 0.001 | 0.161 | 0.195 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| X/Z | 0.000 | 0.006 | 0.000 | 0.004 | 0.000 | 0.121 | 0.005 | 0.000 | 0.000 | 0.002 | 0.000 | 0.000 | ||

| Y/Z | 0.000 | 0.084 | 0.000 | 0.003 | 0.016 | 0.050 | 0.250 | 0.509 | 0.253 | 0.096 | 0.020 | 0.557 | ||

| Back right | X/Y | 0.912 | 0.001 | 0.285 | 0.493 | 0.016 | 0.128 | 0.002 | 0.008 | 0.000 | 0.024 | 0.000 | 0.000 | |

| X/Z | 0.003 | 0.008 | 0.001 | 0.000 | 0.007 | 0.001 | 0.006 | 0.000 | 0.000 | 0.004 | 0.015 | 0.000 | ||

| Y/Z | 0.011 | 0.510 | 0.001 | 0.000 | 0.178 | 0.001 | 0.778 | 0.069 | 0.331 | 0.703 | 0.092 | 0.137 | ||

| Center middle | X/Y | 0.394 | 0.009 | 0.130 | 0.682 | 0.023 | 0.610 | 0.021 | 0.001 | 0.000 | 0.000 | 0.000 | 0.000 | |

| X/Z | 0.001 | 0.001 | 0.001 | 0.000 | 0.000 | 0.029 | 0.00 | 0.000 | 0.000 | 0.000 | 0.003 | 0.000 | ||

| Y/Z | 0.000 | 0.208 | 0.000 | 0.000 | 0.007 | 0.033 | 0.676 | 0.025 | 0.328 | 0.100 | 0.381 | 0.041 | ||

| Front left | X/Y | 0.625 | 0.019 | 0.686 | 0.198 | 0.256 | 0.597 | 0.000 | 0.000 | 0.002 | 0.000 | 0.000 | 0.000 | |

| X/Z | 0.001 | 0.007 | 0.012 | 0.028 | 0.005 | 0.005 | 0.000 | 0.000 | 0.003 | 0.000 | 0.000 | 0.000 | ||

| Y/Z | 0.000 | 0.051 | 0.000 | 0.006 | 0.251 | 0.003 | 0.795 | 0.026 | 0.206 | 0.502 | 0.008 | 0.213 | ||

| Front right | X/Y | 0.503 | 0.011 | 0.119 | 0.896 | 0.046 | 0.357 | 0.056 | 0.000 | 0.000 | 0.000 | 0.001 | 0.000 | |

| X/Z | 0.000 | 0.003 | 0.000 | 0.130 | 0.008 | 0.021 | 0.000 | 0.000 | 0.000 | 0.000 | 0.001 | 0.000 | ||

| Y/Z | 0.000 | 0.205 | 0.006 | 0.129 | 0.041 | 0.013 | 0.082 | 0.867 | 0.052 | 0.711 | 0.002 | 0.009 | ||

| Back middle | X/Y | 0.365 | 0.004 | 0.196 | 0.292 | 0.115 | 0.254 | 0.024 | 0.000 | 0.000 | 0.000 | 0.001 | 0.002 | |

| X/Z | 0.000 | 0.015 | 0.001 | 0.055 | 0.034 | 0.000 | 0.001 | 0.000 | 0.000 | 0.004 | 0.000 | 0.000 | ||

| Y/Z | 0.001 | 0.699 | 0.000 | 0.036 | 0.134 | 0.000 | 0.633 | 0.212 | 0.007 | 0.474 | 0.003 | 0.074 | ||

| Left middle | X/Y | 0.701 | 0.006 | 0.765 | 0.104 | 0.070 | 0.231 | 0.008 | 0.557 | 0.000 | 0.000 | 0.004 | 0.001 | |

| X/Z | 0.000 | 0.014 | 0.016 | 0.002 | 0.003 | 0.002 | 0.028 | 0.618 | 0.002 | 0.014 | 0.015 | 0.000 | ||

| Y/Z | 0.001 | 0.084 | 0.006 | 0.001 | 0.300 | 0.033 | 0.673 | 0.882 | 0.382 | 0.132 | 0.135 | 0.017 | ||

| Right middle | X/Y | 0.167 | 0.173 | 0.831 | 0.374 | 0.001 | 0.451 | 0.001 | 0.132 | 0.000 | 0.000 | 0.001 | 0.000 | |

| X/Z | 0.008 | 0.006 | 0.005 | 0.000 | 0.068 | 0.285 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.003 | ||

| Y/Z | 0.007 | 0.463 | 0.001 | 0.001 | 0.846 | 0.429 | 0.628 | 0.134 | 0.125 | 0.350 | 0.008 | 0.437 | ||

| Front middle | X/Y | 0.188 | 0.014 | 0.039 | 0.636 | 0.415 | 0.711 | 0.036 | 0.002 | 0.000 | 0.121 | 0.000 | 0.001 | |

| X/Z | 0.005 | 0.004 | 0.001 | 0.000 | 0.000 | 0.025 | 0.003 | 0.010 | 0.000 | 0.001 | 0.000 | 0.000 | ||

| Y/Z | 0.002 | 0.158 | 0.000 | 0.000 | 0.221 | 0.022 | 0.593 | 0.124 | 0.071 | 0.320 | 0.004 | 0.017 | ||

| Hollow body | Back left | X/Y | 0.001 | 0.000 | 0.244 | 0.002 | 0.325 | 0.910 | 0.000 | 0.003 | 0.000 | 0.000 | 0.000 | 0.000 |

| X/Z | 0.002 | 0.002 | 0.002 | 0.004 | 0.004 | 0.001 | 0.002 | 0.000 | 0.000 | 0.005 | 0.000 | 0.000 | ||

| Y/Z | 0.000 | 0.867 | 0.000 | 0.002 | 0.047 | 0.003 | 0.176 | 0.001 | 0.063 | 0.189 | 0.590 | 0.374 | ||

| Back right | X/Y | 0.384 | 0.008 | 0.415 | 0.589 | 0.064 | 0.654 | 0.000 | 0.001 | 0.000 | 0.001 | 0.000 | 0.001 | |

| X/Z | 0.005 | 0.006 | 0.046 | 0.004 | 0.017 | 0.000 | 0.005 | 0.000 | 0.001 | 0.011 | 0.001 | 0.001 | ||

| Y/Z | 0.004 | 0.258 | 0.150 | 0.004 | 0.251 | 0.000 | 0.303 | 0.134 | 0.416 | 0.225 | 0.280 | 0.248 | ||

| Center middle | X/Y | 0.061 | 0.009 | 0.417 | 0.077 | 0.076 | 0.149 | 0.005 | 0.000 | 0.000 | 0.010 | 0.001 | 0.000 | |

| X/Z | 0.001 | 0.001 | 0.005 | 0.175 | 0.006 | 0.087 | 0.004 | 0.000 | 0.000 | 0.006 | 0.000 | 0.000 | ||

| Y/Z | 0.017 | 0.301 | 0.018 | 0.282 | 0.125 | 0.339 | 0.942 | 0.121 | 0.119 | 0.638 | 0.192 | 0.065 | ||

| Front left | X/Y | 0.202 | 0.005 | 0.019 | 0.151 | 0.030 | 0.913 | 0.001 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | |

| X/Z | 0.490 | 0.002 | 0.019 | 0.011 | 0.003 | 0.006 | 0.000 | 0.000 | 0.000 | 0.000 | 0.001 | 0.000 | ||

| Y/Z | 0.549 | 0.123 | 0.014 | 0.006 | 0.025 | 0.010 | 0.453 | 0.685 | 0.116 | 0.000 | 0.008 | 0.600 | ||

| Front right | X/Y | 0.491 | 0.011 | 0.412 | 0.783 | 0.000 | 0.727 | 0.000 | 0.000 | 0.000 | 0.000 | 0.002 | 0.000 | |

| X/Z | 0.001 | 0.001 | 0.102 | 0.001 | 0.003 | 0.062 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | ||

| Y/Z | 0.002 | 0.047 | 0.176 | 0.011 | 0.121 | 0.043 | 0.522 | 0.329 | 0.034 | 0.090 | 0.003 | 0.031 | ||

| Back middle | X/Y | 0.034 | 0.093 | 0.691 | 0.007 | 0.016 | 0.276 | 0.000 | 0.011 | 0.000 | 0.024 | 0.000 | 0.016 | |

| X/Z | 0.000 | 0.003 | 0.001 | 0.005 | 0.009 | 0.002 | 0.001 | 0.000 | 0.000 | 0.001 | 0.000 | 0.000 | ||

| Y/Z | 0.006 | 0.299 | 0.013 | 0.043 | 0.597 | 0.002 | 0.393 | 0.023 | 0.018 | 0.565 | 0.078 | 0.122 | ||

| Left middle | X/Y | 0.272 | 0.009 | 0.399 | 0.018 | 0.353 | 0.812 | 0.000 | 0.867 | 0.000 | 0.000 | 0.001 | 0.000 | |

| X/Z | 0.004 | 0.012 | 0.025 | 0.000 | 0.035 | 0.001 | 0.008 | 0.022 | 0.000 | 0.016 | 0.006 | 0.000 | ||

| Y/Z | 0.000 | 0.748 | 0.032 | 0.001 | 0.277 | 0.000 | 0.245 | 0.111 | 0.195 | 0.372 | 0.052 | 0.196 | ||

| Right middle | X/Y | 0.526 | 0.005 | 0.732 | 0.000 | 0.564 | 0.823 | 0.031 | 0.004 | 0.000 | 0.000 | 0.001 | 0.000 | |

| X/Z | 0.001 | 0.026 | 0.000 | 0.000 | 0.001 | 0.035 | 0.001 | 0.003 | 0.000 | 0.000 | 0.000 | 0.000 | ||

| Y/Z | 0.024 | 0.202 | 0.007 | 0.000 | 0.053 | 0.119 | 0.520 | 0.408 | 0,006 | 0.108 | 0.007 | 0.842 | ||

| Front middle | X/Y | 0.436 | 0.159 | 0.523 | 0.076 | 0.189 | 0.254 | 0.012 | 0.000 | 0.000 | 0.003 | 0.003 | 0.000 | |

| X/Z | 0.001 | 0.031 | 0.035 | 0.001 | 0.001 | 0.028 | 0.010 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | ||

| Y/Z | 0.004 | 0.100 | 0.061 | 0.000 | 0.072 | 0.092 | 0.774 | 0.334 | 0.001 | 0.847 | 0.047 | 0.050 |

| Combination of Printing Resolutions | 15° | 0° | ||||

|---|---|---|---|---|---|---|

| X | Y | Z | X | Y | Z | |

| 0.025 to 0.05 | 78% | 11% | 22% | 39% | 22% | 6% |

| 0.025 to 0.1 | 100% | 22% | 94% | 94% | 0% | 89% |

| 0.05 to 0.1 | 89% | 6% | 72% | 100% | 11% | 84% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arnold, C.; Monsees, D.; Hey, J.; Schweyen, R. Surface Quality of 3D-Printed Models as a Function of Various Printing Parameters. Materials 2019, 12, 1970. https://doi.org/10.3390/ma12121970

Arnold C, Monsees D, Hey J, Schweyen R. Surface Quality of 3D-Printed Models as a Function of Various Printing Parameters. Materials. 2019; 12(12):1970. https://doi.org/10.3390/ma12121970

Chicago/Turabian StyleArnold, Christin, Delf Monsees, Jeremias Hey, and Ramona Schweyen. 2019. "Surface Quality of 3D-Printed Models as a Function of Various Printing Parameters" Materials 12, no. 12: 1970. https://doi.org/10.3390/ma12121970

APA StyleArnold, C., Monsees, D., Hey, J., & Schweyen, R. (2019). Surface Quality of 3D-Printed Models as a Function of Various Printing Parameters. Materials, 12(12), 1970. https://doi.org/10.3390/ma12121970