Surface Quality of 3D-Printed Models as a Function of Various Printing Parameters

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Reliability

3.2. Ra Roughness within One Measurement Direction (X1 vs. X2, Y1 vs. Y2, Z1 vs. Z2)

3.3. Ra Roughness as a Function of the Measurement Direction (X vs. Y vs. Z)

3.4. Printing Speed

3.5. Support Structure/Inclination

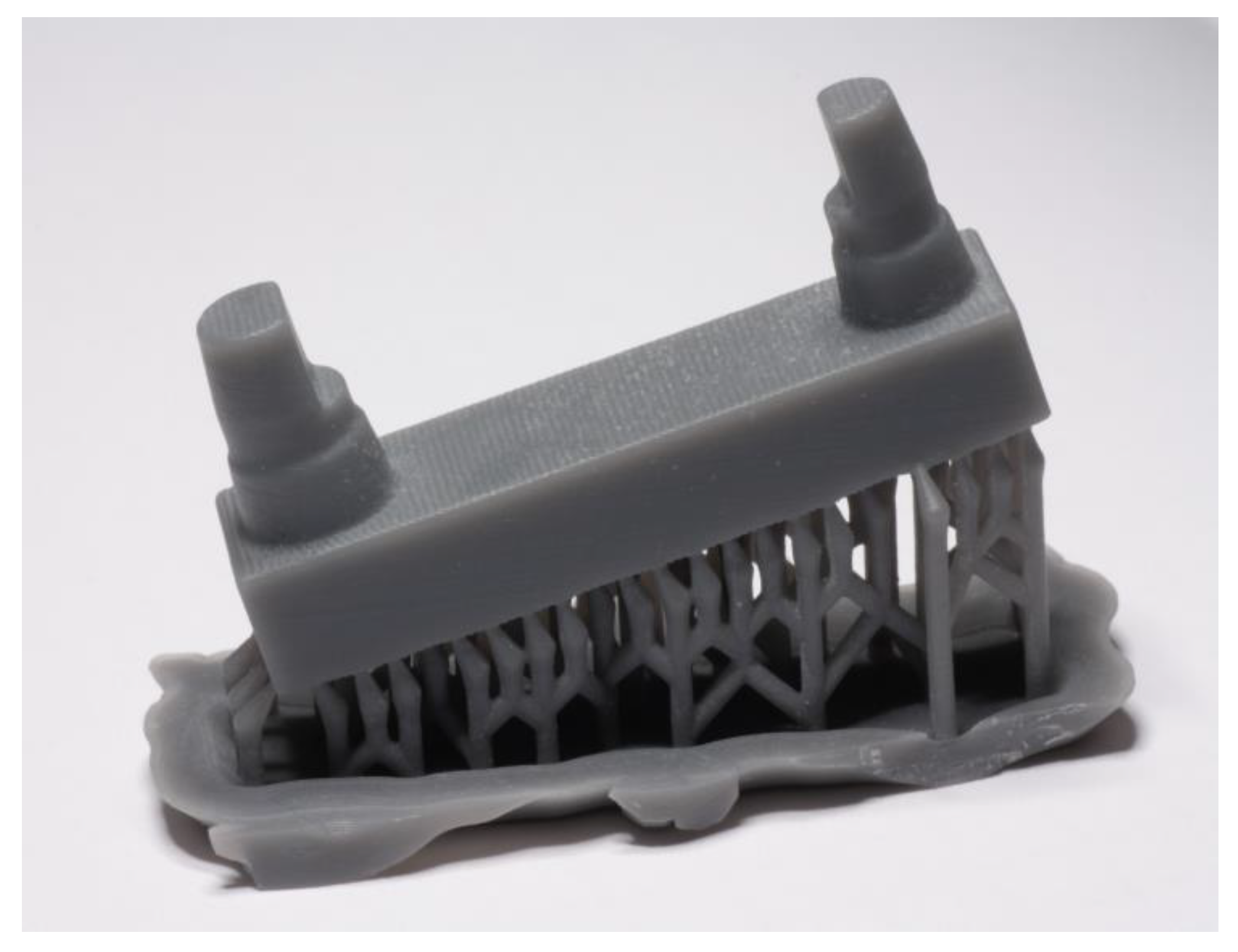

3.6. Model Structure

3.7. Model Base Orientation

3.8. Position Build Platform and Reprint

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alifui-Segbaya, F.; Bowman, J.; White, A.R.; Varma, S.; Lieschke, G.J.; George, R. Toxicological assessment of additively manufactured methacrylates for medical devices in dentistry. Acta Biomater. 2018, 15, 64–77. [Google Scholar] [CrossRef] [PubMed]

- Egan, P.F.; Bauer, I.; Shea, K.; Ferguson, S.J. Mechanics of three-dimensional printed lattices for biomedical devices. J. Mech. Des. 2019, 141, 031703. [Google Scholar] [CrossRef]

- Lin, M.; Firoozi, N.; Tsai, C.T.; Wallace, M.B.; Kang, Y. 3D-printed flexible polymer stents for potential applications in inoperable esophageal malignancies. Acta Biomater. 2019, 1, 119–129. [Google Scholar] [CrossRef] [PubMed]

- Torabi, K.; Farjood, E.; Hamedani, S.H. Rapid prototyping technologies and their applications in prosthodontics, a review of literature. J. Dent. 2015, 16, 1–9. [Google Scholar]

- Silva, N.R.F.A.; Witek, L.; Coelho, P.G.; Thompson, V.P.; Rekow, E.D.; Smay, J. Additive CAD/CAM process for dental prostheses. J. Prosthodont. 2011, 20, 93–96. [Google Scholar] [CrossRef] [PubMed]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Keuter, F.M.S.; Davidson, C.L. Surface roughness of dental stone casts from alginate impressions. J. Dent. 1986, 14, 23–28. [Google Scholar] [CrossRef]

- Chang, Y.C.; Yu, C.H.; Liang, W.M.; Tu, M.G.; Chen, S. Comparison of the surface roughness of gypsum models constructed using various impression materials and gypsum products. J. Dent. Sci. 2016, 11, 23–28. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Johnson, G.H.; Chellis, K.D.; Gordon, G.E.; Lepe, X. Dimensional stability and detail reproduction of irreversible hydrocolloid and elastomeric impressions disinfected by immersion. J. Prosthet. Dent. 1998, 79, 446–453. [Google Scholar] [CrossRef]

- Camardella, L.T.; Vilella, O.V.; van Hezel, M.M.; Breuning, K.H. Accuracy of stereolithographically printed digital models compared to plaster models. J. Orofac. Orthop. 2017, 78, 394–402. [Google Scholar] [CrossRef]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kruth, J.P.; Leu, M.C.; Nakagawa, T. Progress in additive manufacturing and rapid prototyping. ClRP Ann. 1998, 47, 525–539. [Google Scholar] [CrossRef]

- Pham, D.T.; Dimov, S.S. Rapid prototyping and rapid tooling—The key enablers for rapid manufacturing. J. Mech. Eng. Sci. 2003, 217, 1–23. [Google Scholar] [CrossRef]

- Byun, H.-S.; Lee, K.H. Determination of the optimal build direction for different rapid prototyping process using multi-criterion decision making. Robot. Comput. Integr. Manuf. 2006, 22, 69–80. [Google Scholar] [CrossRef]

- Cheng, W.; Fuh, J.Y.H.; Nee, A.Y.C.; Wong, Y.S.; Loh, H.T.; Miyazawa, T. Multi-objective optimization of part-building orientation in stereolithography. Rapid. Prototyp. J. 1995, 1, 12–23. [Google Scholar] [CrossRef]

- Pandey, P.M.; Venkata Reddy, N.; Dhande, S.G. Part deposition orientation studies in layered manufacturing. J. Mater. Process. Technol. 2007, 185, 125–131. [Google Scholar] [CrossRef]

- Delfs, P.; Tows, M.; Schmid, H.-J. Optimized build orientation of additive manufactured parts for improved surface quality and build time. Addit. Manuf. 2016, 12, 314–320. [Google Scholar] [CrossRef]

- Pandey, P.M.; Reddy, N.V.; Dhande, S.G. Slicing procedures in layered manufacturing: A review. Rapid Prototyp. J. 2003, 9, 274–288. [Google Scholar] [CrossRef]

- Gadelmawla, E.S.; Koura, M.M.; Maksoud, T.M.A.; Elewa, I.M.; Soliman, H.H. Roughness parameters. J. Mater. Process. Technol. 2002, 123, 133–145. [Google Scholar] [CrossRef]

- Dahlberg, G. Statistical Methods for Medical and Biological Students; Interscience Publications: New York, NY, USA, 1940. [Google Scholar]

- Benardos, P.G.; Vosniakos, G.-C. Predicting surface roughness in machining: A review. Int. J. Mac. Tool. Manuf. 2002, 43, 833–844. [Google Scholar] [CrossRef]

- Arbizu, I.P.; Pérez, C.J.L. Surface roughness prediction by factorial design of experiments in turning processes. J. Mater. Process. Technol. 2003, 143–144, 390–396. [Google Scholar] [CrossRef]

- Kim, K.-B.; Kim, J.-H.; Kim, S.-H. Impact of surface roughness of gypsum materials on adaption of zirconia cores. J. Adv. Prosthodont. 2015, 7, 199–206. [Google Scholar] [CrossRef] [PubMed]

- Abdelaziz, K.M.; Combe, E.C.; Hodges, J.S. The effect of disinfectants on the properties of dental gypsum, part 2: Surface properties. J. Prosthodont. 2002, 11, 234–240. [Google Scholar] [CrossRef] [PubMed]

- Murata, H.; Hong, G.; Li, A.Y. Compatibility of tissue conditioners and dental stones: Effect on surface roughness. J. Prosthet. Dent. 2005, 93, 274–281. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Murata, H.; Kawamura, M.; Hamada, T.; Chimori, H.; Nikawa, H. Physical properties and compatibility with dental stones of current alginate impression materials. J. Oral Rehabil. 2004, 31, 1115–1122. [Google Scholar] [CrossRef] [PubMed]

- Jacobs, P.F. Rapid Prototyping and Manufacturing: Fundamentals of Stereo-Lithography; Society of Manufacturing Engineers: Southfield, MI, USA, 1992; pp. 160–162. [Google Scholar]

- Pincel, P.V.; Jiménez-Pérez, J.L.; Cruz-Orea, A.; Correa-Pacheco, Z.N.; Hernández, R.J. Photoacoustic study of curing time by UV laser radiation of a photoresin with different thickness. Thermochim. Acta 2015, 606, 53–57. [Google Scholar] [CrossRef]

- Xie, R.; Li, D.; Chao, S. An inexpensive stereolithography technology with high power UV-LED light. Rapid Prototyp. J. 2011, 17, 441–450. [Google Scholar] [CrossRef]

- Scarparo, M.A.F.; Kiel, A.; Zhiyao, Z.; Ferrari, C.A.; Chen, Q.J.; Miller, A.S.; Allen, S.D. Study of resin based materials using CO2 laser stereolithography. Polymer 1997, 38, 2175–2181. [Google Scholar] [CrossRef]

- FormLabs Support: Orienting a Model. Available online: https://support.formlabs.com/s/article/Model-Orientation?language=en_US (accessed on 11 June 2019).

- Dolenc, A.; Makela, I. Slicing procedures for layered manufacturing techniques. Comput. Aided Des. 1994, 26, 119–126. [Google Scholar] [CrossRef]

- Oropallo, W.; Piegl, L.A. Ten challenges in 3D printing. Eng. Comput. 2015, 32, 135–148. [Google Scholar] [CrossRef]

- Ma, W.; But, W.-C.; He, P. NURBS-based adaptive slicing for efficient rapid prototyping. Comput. Aided Des. 2004, 36, 1309–1325. [Google Scholar] [CrossRef]

- Sabourin, E.; Houser, S.A.; Bohn, J.A. Adaptive slicing using stepwise uniform refinement. Rapid Prototyp. J. 1996, 2, 20–26. [Google Scholar] [CrossRef]

- FormLabs Support: Standard Resin Tank: Maintenance and Care. Available online: https://support.formlabs.com/s/article/Standard-Resin-Tank-Maintenance-and-Care?language=en_US (accessed on 11 June 2019).

| Printing Parameters | Selected Settings |

|---|---|

| Printing speed (layer thickness) | 0.025 slow (layer thickness: 25 µm) [S1] |

| 0.05 standard (layer thickness: 50 µm) [S2] | |

| 0.1 fast (layer thickness: 100 µm) [S3] | |

| Inclination (support structure) | 0° (without support structure) |

| 15° (with support structure) | |

| (canine up, molar down) | |

| Model structure | hollow body [H] |

| solid (full) body [F] | |

| Model base orientation (see Figure 2) | model base: parallel to the front [P] |

| model base: across the front [A] | |

| Position build platform (see Figure 2) | front area (right, middle, left) |

| center area (right, middle, left) | |

| back area (right, middle, left) |

| Ingredient | % |

|---|---|

| Methacrylated oligomer | ≥75 ~ ≤90 |

| Methacrylated monomer | ≥25 ~ ≤50 |

| Diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide | ≥1 ~ <3 |

| Test-Series Sequences | Printing resolution/Support Structure Inclination | Number of Layers | Print Time |

|---|---|---|---|

| D1 and D4 | 25 µm/0° | 659 | 466 min |

| D3 and D6 | 50 µm/0° | 330 | 249 min |

| D2 and D5 | 100 µm/0° | 165 | 146 min |

| D8 and D11 | 25 µm/15° | 1036 | 620 min |

| D9 and D12 | 50 µm/15° | 564 | 381 min |

| D7 and D10 | 100 µm/15° | 314 | 285 min |

| Model Structure | Position Build Platform | Comparison Measuring Direction | D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 | D10 | D11 | D12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Full body | Back left | X/Y | 0.120 | 0.232 | 0.297 | 0.531 | 0.001 | 0.161 | 0.195 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| X/Z | 0.000 | 0.006 | 0.000 | 0.004 | 0.000 | 0.121 | 0.005 | 0.000 | 0.000 | 0.002 | 0.000 | 0.000 | ||

| Y/Z | 0.000 | 0.084 | 0.000 | 0.003 | 0.016 | 0.050 | 0.250 | 0.509 | 0.253 | 0.096 | 0.020 | 0.557 | ||

| Back right | X/Y | 0.912 | 0.001 | 0.285 | 0.493 | 0.016 | 0.128 | 0.002 | 0.008 | 0.000 | 0.024 | 0.000 | 0.000 | |

| X/Z | 0.003 | 0.008 | 0.001 | 0.000 | 0.007 | 0.001 | 0.006 | 0.000 | 0.000 | 0.004 | 0.015 | 0.000 | ||

| Y/Z | 0.011 | 0.510 | 0.001 | 0.000 | 0.178 | 0.001 | 0.778 | 0.069 | 0.331 | 0.703 | 0.092 | 0.137 | ||

| Center middle | X/Y | 0.394 | 0.009 | 0.130 | 0.682 | 0.023 | 0.610 | 0.021 | 0.001 | 0.000 | 0.000 | 0.000 | 0.000 | |

| X/Z | 0.001 | 0.001 | 0.001 | 0.000 | 0.000 | 0.029 | 0.00 | 0.000 | 0.000 | 0.000 | 0.003 | 0.000 | ||

| Y/Z | 0.000 | 0.208 | 0.000 | 0.000 | 0.007 | 0.033 | 0.676 | 0.025 | 0.328 | 0.100 | 0.381 | 0.041 | ||

| Front left | X/Y | 0.625 | 0.019 | 0.686 | 0.198 | 0.256 | 0.597 | 0.000 | 0.000 | 0.002 | 0.000 | 0.000 | 0.000 | |

| X/Z | 0.001 | 0.007 | 0.012 | 0.028 | 0.005 | 0.005 | 0.000 | 0.000 | 0.003 | 0.000 | 0.000 | 0.000 | ||

| Y/Z | 0.000 | 0.051 | 0.000 | 0.006 | 0.251 | 0.003 | 0.795 | 0.026 | 0.206 | 0.502 | 0.008 | 0.213 | ||

| Front right | X/Y | 0.503 | 0.011 | 0.119 | 0.896 | 0.046 | 0.357 | 0.056 | 0.000 | 0.000 | 0.000 | 0.001 | 0.000 | |

| X/Z | 0.000 | 0.003 | 0.000 | 0.130 | 0.008 | 0.021 | 0.000 | 0.000 | 0.000 | 0.000 | 0.001 | 0.000 | ||

| Y/Z | 0.000 | 0.205 | 0.006 | 0.129 | 0.041 | 0.013 | 0.082 | 0.867 | 0.052 | 0.711 | 0.002 | 0.009 | ||

| Back middle | X/Y | 0.365 | 0.004 | 0.196 | 0.292 | 0.115 | 0.254 | 0.024 | 0.000 | 0.000 | 0.000 | 0.001 | 0.002 | |

| X/Z | 0.000 | 0.015 | 0.001 | 0.055 | 0.034 | 0.000 | 0.001 | 0.000 | 0.000 | 0.004 | 0.000 | 0.000 | ||

| Y/Z | 0.001 | 0.699 | 0.000 | 0.036 | 0.134 | 0.000 | 0.633 | 0.212 | 0.007 | 0.474 | 0.003 | 0.074 | ||

| Left middle | X/Y | 0.701 | 0.006 | 0.765 | 0.104 | 0.070 | 0.231 | 0.008 | 0.557 | 0.000 | 0.000 | 0.004 | 0.001 | |

| X/Z | 0.000 | 0.014 | 0.016 | 0.002 | 0.003 | 0.002 | 0.028 | 0.618 | 0.002 | 0.014 | 0.015 | 0.000 | ||

| Y/Z | 0.001 | 0.084 | 0.006 | 0.001 | 0.300 | 0.033 | 0.673 | 0.882 | 0.382 | 0.132 | 0.135 | 0.017 | ||

| Right middle | X/Y | 0.167 | 0.173 | 0.831 | 0.374 | 0.001 | 0.451 | 0.001 | 0.132 | 0.000 | 0.000 | 0.001 | 0.000 | |

| X/Z | 0.008 | 0.006 | 0.005 | 0.000 | 0.068 | 0.285 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.003 | ||

| Y/Z | 0.007 | 0.463 | 0.001 | 0.001 | 0.846 | 0.429 | 0.628 | 0.134 | 0.125 | 0.350 | 0.008 | 0.437 | ||

| Front middle | X/Y | 0.188 | 0.014 | 0.039 | 0.636 | 0.415 | 0.711 | 0.036 | 0.002 | 0.000 | 0.121 | 0.000 | 0.001 | |

| X/Z | 0.005 | 0.004 | 0.001 | 0.000 | 0.000 | 0.025 | 0.003 | 0.010 | 0.000 | 0.001 | 0.000 | 0.000 | ||

| Y/Z | 0.002 | 0.158 | 0.000 | 0.000 | 0.221 | 0.022 | 0.593 | 0.124 | 0.071 | 0.320 | 0.004 | 0.017 | ||

| Hollow body | Back left | X/Y | 0.001 | 0.000 | 0.244 | 0.002 | 0.325 | 0.910 | 0.000 | 0.003 | 0.000 | 0.000 | 0.000 | 0.000 |

| X/Z | 0.002 | 0.002 | 0.002 | 0.004 | 0.004 | 0.001 | 0.002 | 0.000 | 0.000 | 0.005 | 0.000 | 0.000 | ||

| Y/Z | 0.000 | 0.867 | 0.000 | 0.002 | 0.047 | 0.003 | 0.176 | 0.001 | 0.063 | 0.189 | 0.590 | 0.374 | ||

| Back right | X/Y | 0.384 | 0.008 | 0.415 | 0.589 | 0.064 | 0.654 | 0.000 | 0.001 | 0.000 | 0.001 | 0.000 | 0.001 | |

| X/Z | 0.005 | 0.006 | 0.046 | 0.004 | 0.017 | 0.000 | 0.005 | 0.000 | 0.001 | 0.011 | 0.001 | 0.001 | ||

| Y/Z | 0.004 | 0.258 | 0.150 | 0.004 | 0.251 | 0.000 | 0.303 | 0.134 | 0.416 | 0.225 | 0.280 | 0.248 | ||

| Center middle | X/Y | 0.061 | 0.009 | 0.417 | 0.077 | 0.076 | 0.149 | 0.005 | 0.000 | 0.000 | 0.010 | 0.001 | 0.000 | |

| X/Z | 0.001 | 0.001 | 0.005 | 0.175 | 0.006 | 0.087 | 0.004 | 0.000 | 0.000 | 0.006 | 0.000 | 0.000 | ||

| Y/Z | 0.017 | 0.301 | 0.018 | 0.282 | 0.125 | 0.339 | 0.942 | 0.121 | 0.119 | 0.638 | 0.192 | 0.065 | ||

| Front left | X/Y | 0.202 | 0.005 | 0.019 | 0.151 | 0.030 | 0.913 | 0.001 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | |

| X/Z | 0.490 | 0.002 | 0.019 | 0.011 | 0.003 | 0.006 | 0.000 | 0.000 | 0.000 | 0.000 | 0.001 | 0.000 | ||

| Y/Z | 0.549 | 0.123 | 0.014 | 0.006 | 0.025 | 0.010 | 0.453 | 0.685 | 0.116 | 0.000 | 0.008 | 0.600 | ||

| Front right | X/Y | 0.491 | 0.011 | 0.412 | 0.783 | 0.000 | 0.727 | 0.000 | 0.000 | 0.000 | 0.000 | 0.002 | 0.000 | |

| X/Z | 0.001 | 0.001 | 0.102 | 0.001 | 0.003 | 0.062 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | ||

| Y/Z | 0.002 | 0.047 | 0.176 | 0.011 | 0.121 | 0.043 | 0.522 | 0.329 | 0.034 | 0.090 | 0.003 | 0.031 | ||

| Back middle | X/Y | 0.034 | 0.093 | 0.691 | 0.007 | 0.016 | 0.276 | 0.000 | 0.011 | 0.000 | 0.024 | 0.000 | 0.016 | |

| X/Z | 0.000 | 0.003 | 0.001 | 0.005 | 0.009 | 0.002 | 0.001 | 0.000 | 0.000 | 0.001 | 0.000 | 0.000 | ||

| Y/Z | 0.006 | 0.299 | 0.013 | 0.043 | 0.597 | 0.002 | 0.393 | 0.023 | 0.018 | 0.565 | 0.078 | 0.122 | ||

| Left middle | X/Y | 0.272 | 0.009 | 0.399 | 0.018 | 0.353 | 0.812 | 0.000 | 0.867 | 0.000 | 0.000 | 0.001 | 0.000 | |

| X/Z | 0.004 | 0.012 | 0.025 | 0.000 | 0.035 | 0.001 | 0.008 | 0.022 | 0.000 | 0.016 | 0.006 | 0.000 | ||

| Y/Z | 0.000 | 0.748 | 0.032 | 0.001 | 0.277 | 0.000 | 0.245 | 0.111 | 0.195 | 0.372 | 0.052 | 0.196 | ||

| Right middle | X/Y | 0.526 | 0.005 | 0.732 | 0.000 | 0.564 | 0.823 | 0.031 | 0.004 | 0.000 | 0.000 | 0.001 | 0.000 | |

| X/Z | 0.001 | 0.026 | 0.000 | 0.000 | 0.001 | 0.035 | 0.001 | 0.003 | 0.000 | 0.000 | 0.000 | 0.000 | ||

| Y/Z | 0.024 | 0.202 | 0.007 | 0.000 | 0.053 | 0.119 | 0.520 | 0.408 | 0,006 | 0.108 | 0.007 | 0.842 | ||

| Front middle | X/Y | 0.436 | 0.159 | 0.523 | 0.076 | 0.189 | 0.254 | 0.012 | 0.000 | 0.000 | 0.003 | 0.003 | 0.000 | |

| X/Z | 0.001 | 0.031 | 0.035 | 0.001 | 0.001 | 0.028 | 0.010 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | ||

| Y/Z | 0.004 | 0.100 | 0.061 | 0.000 | 0.072 | 0.092 | 0.774 | 0.334 | 0.001 | 0.847 | 0.047 | 0.050 |

| Combination of Printing Resolutions | 15° | 0° | ||||

|---|---|---|---|---|---|---|

| X | Y | Z | X | Y | Z | |

| 0.025 to 0.05 | 78% | 11% | 22% | 39% | 22% | 6% |

| 0.025 to 0.1 | 100% | 22% | 94% | 94% | 0% | 89% |

| 0.05 to 0.1 | 89% | 6% | 72% | 100% | 11% | 84% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arnold, C.; Monsees, D.; Hey, J.; Schweyen, R. Surface Quality of 3D-Printed Models as a Function of Various Printing Parameters. Materials 2019, 12, 1970. https://doi.org/10.3390/ma12121970

Arnold C, Monsees D, Hey J, Schweyen R. Surface Quality of 3D-Printed Models as a Function of Various Printing Parameters. Materials. 2019; 12(12):1970. https://doi.org/10.3390/ma12121970

Chicago/Turabian StyleArnold, Christin, Delf Monsees, Jeremias Hey, and Ramona Schweyen. 2019. "Surface Quality of 3D-Printed Models as a Function of Various Printing Parameters" Materials 12, no. 12: 1970. https://doi.org/10.3390/ma12121970

APA StyleArnold, C., Monsees, D., Hey, J., & Schweyen, R. (2019). Surface Quality of 3D-Printed Models as a Function of Various Printing Parameters. Materials, 12(12), 1970. https://doi.org/10.3390/ma12121970