Quality Index Charts of Al-Si-Mg Semi Solid Alloys Subjected to Multiple Temperatures Aging Treatments and Different Quenching Media

Abstract

:1. Introduction

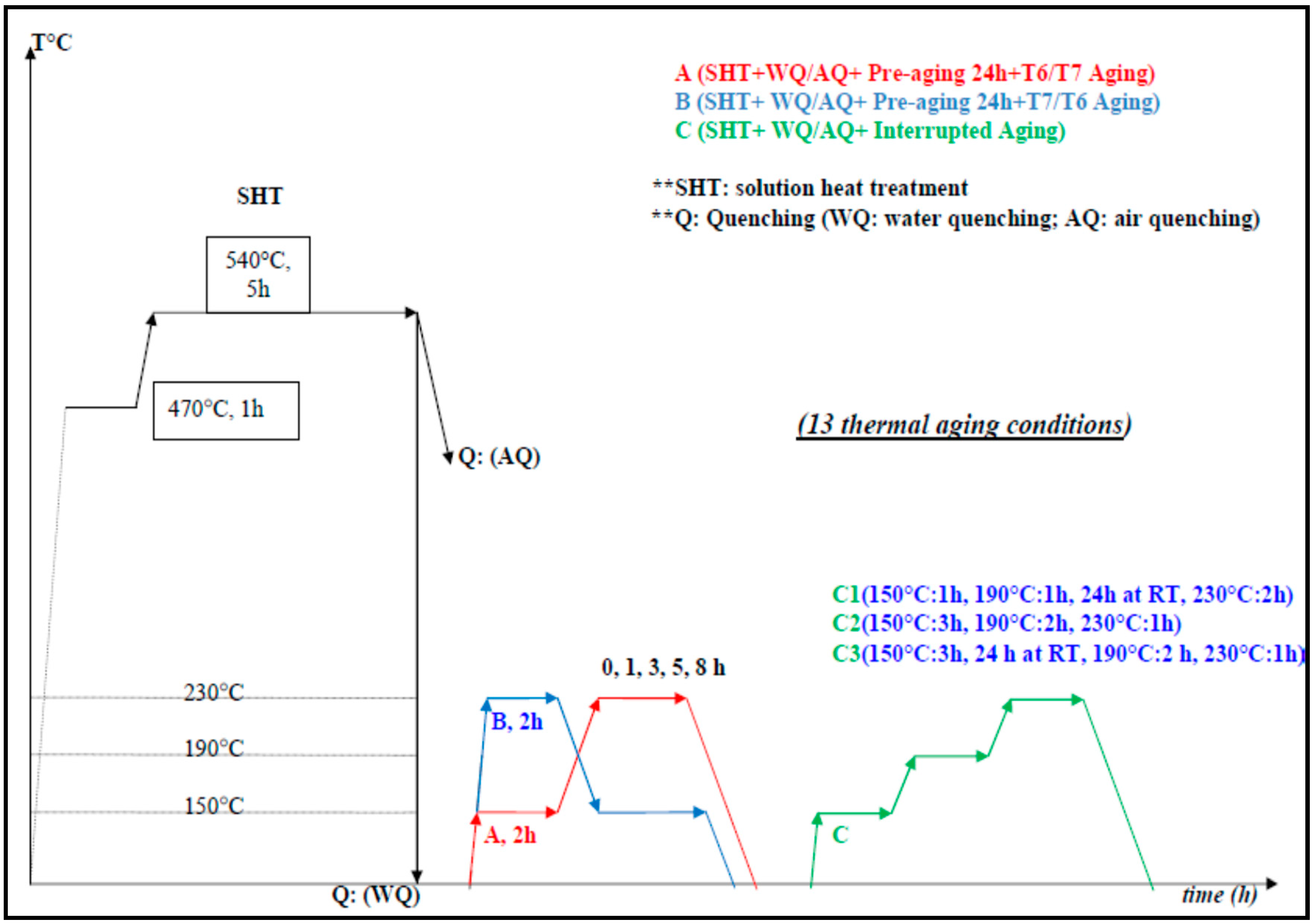

2. Materials and Methods

3. Results and Discussions

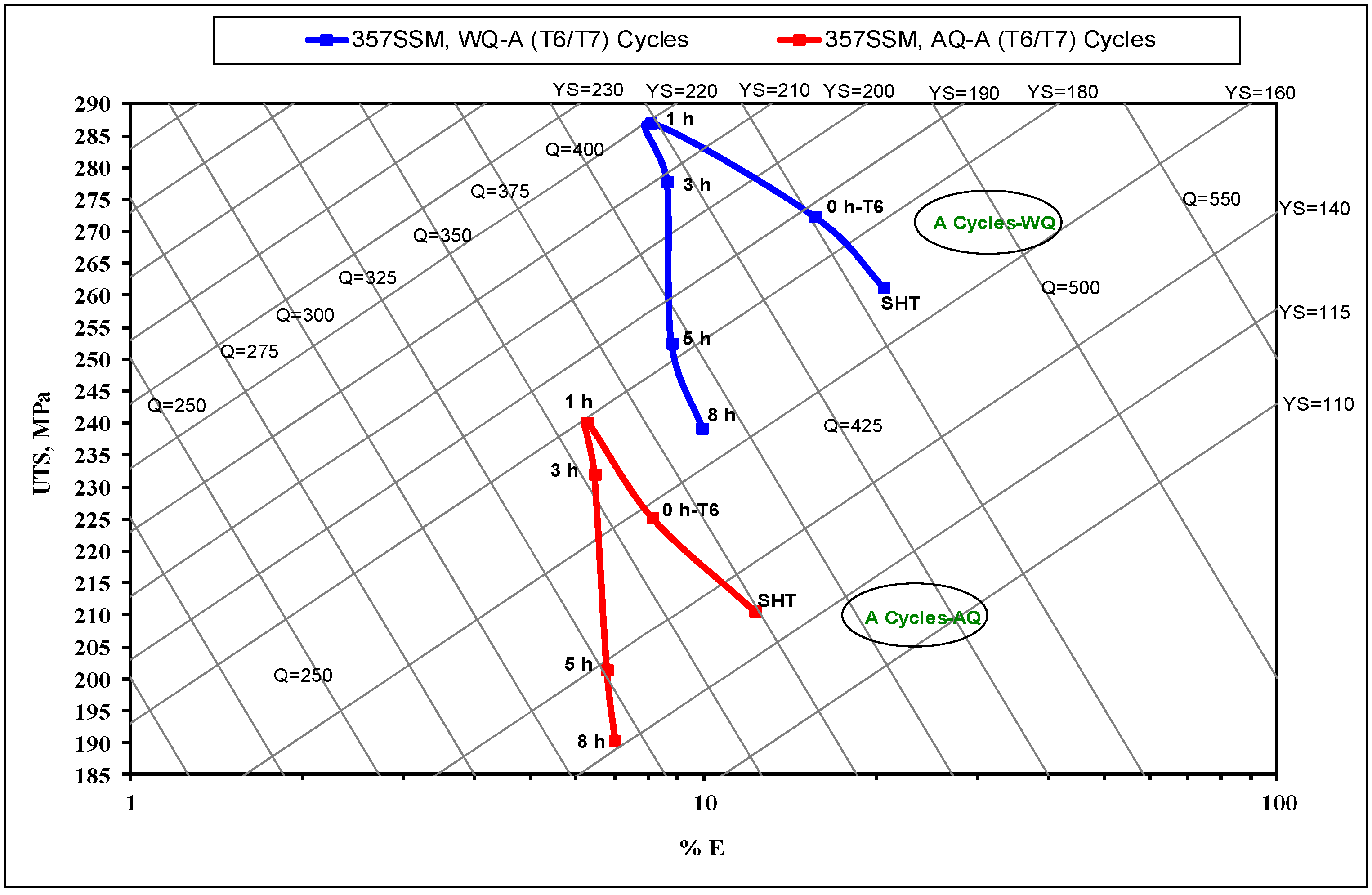

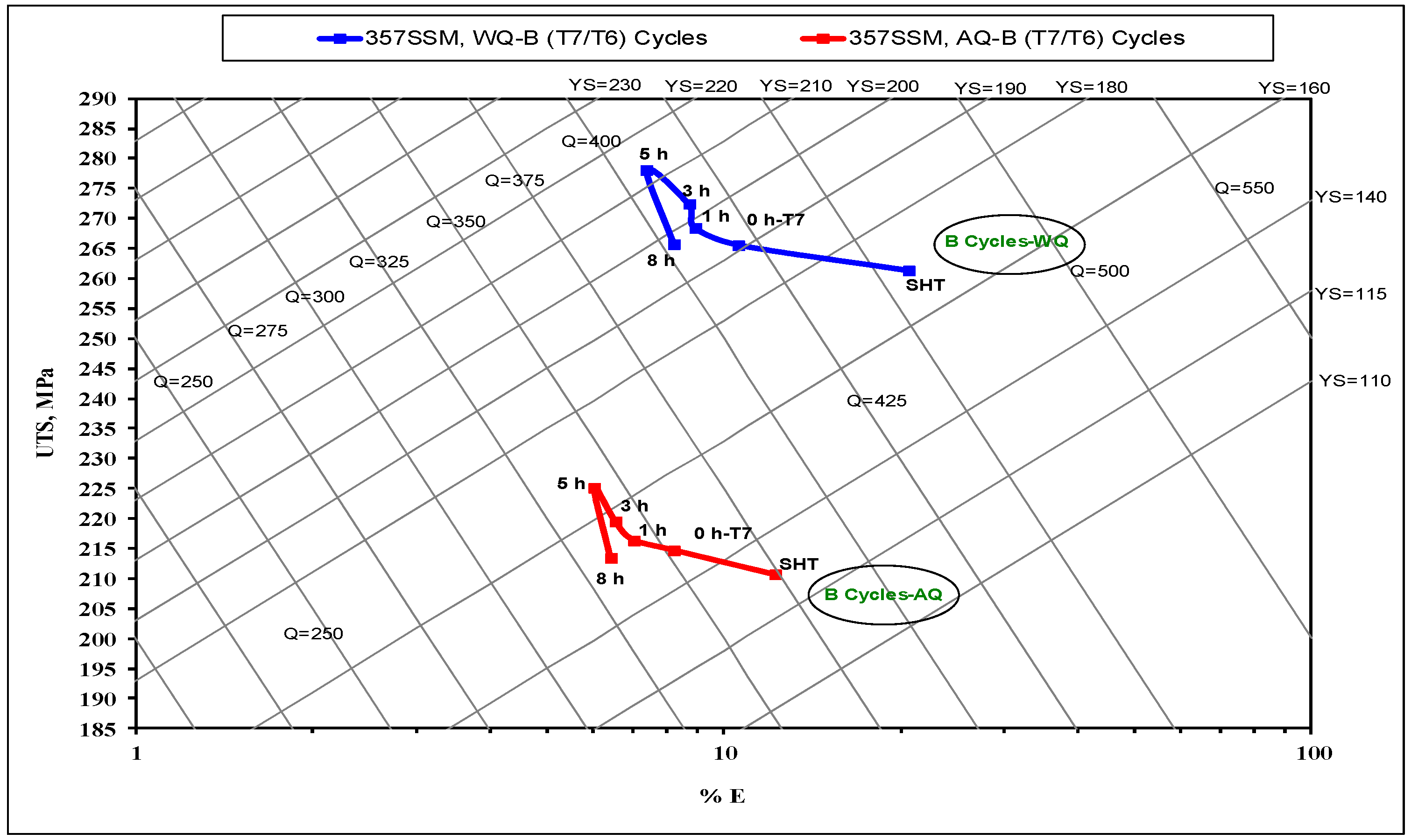

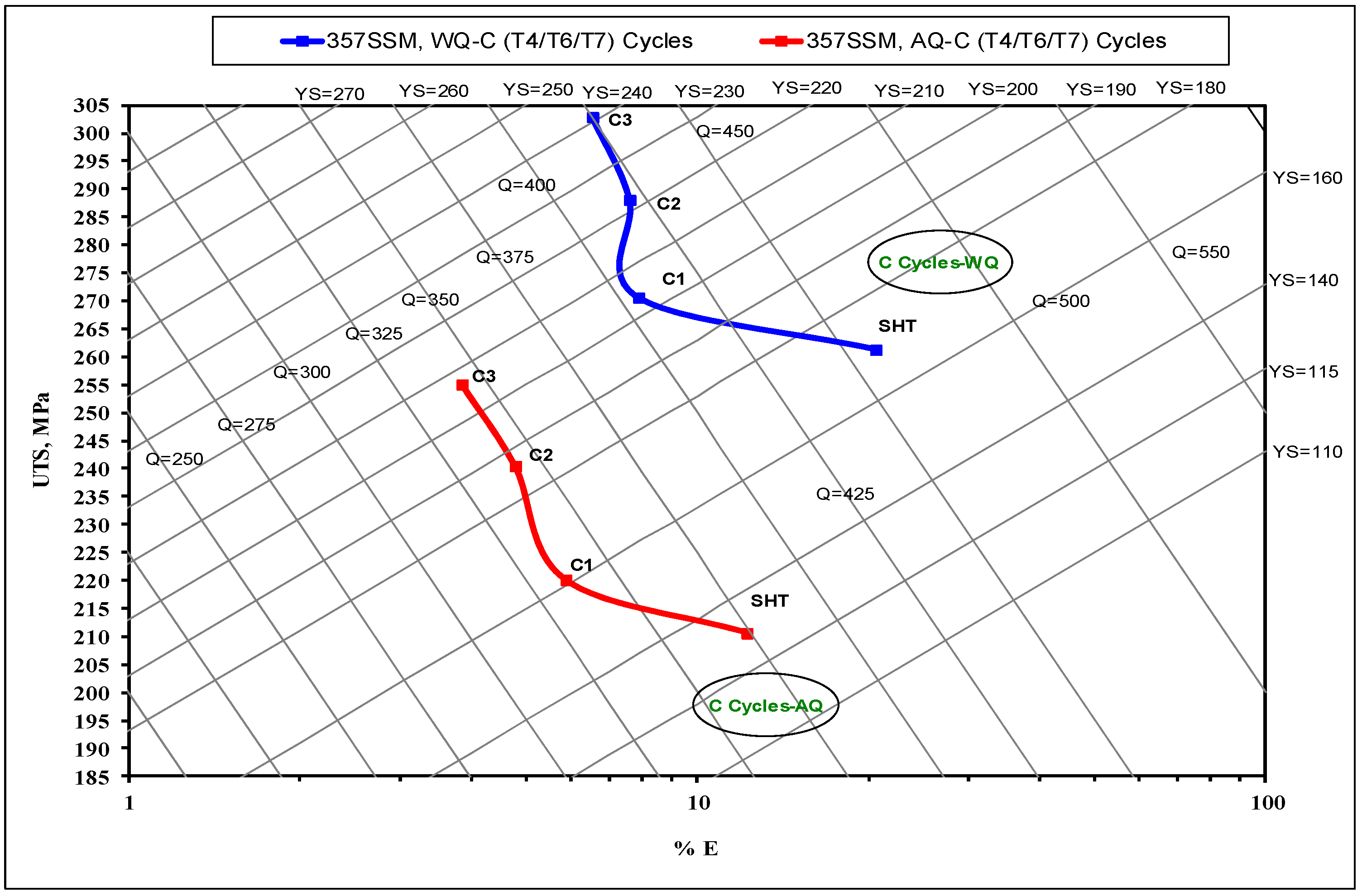

3.1. Quality Index Charts

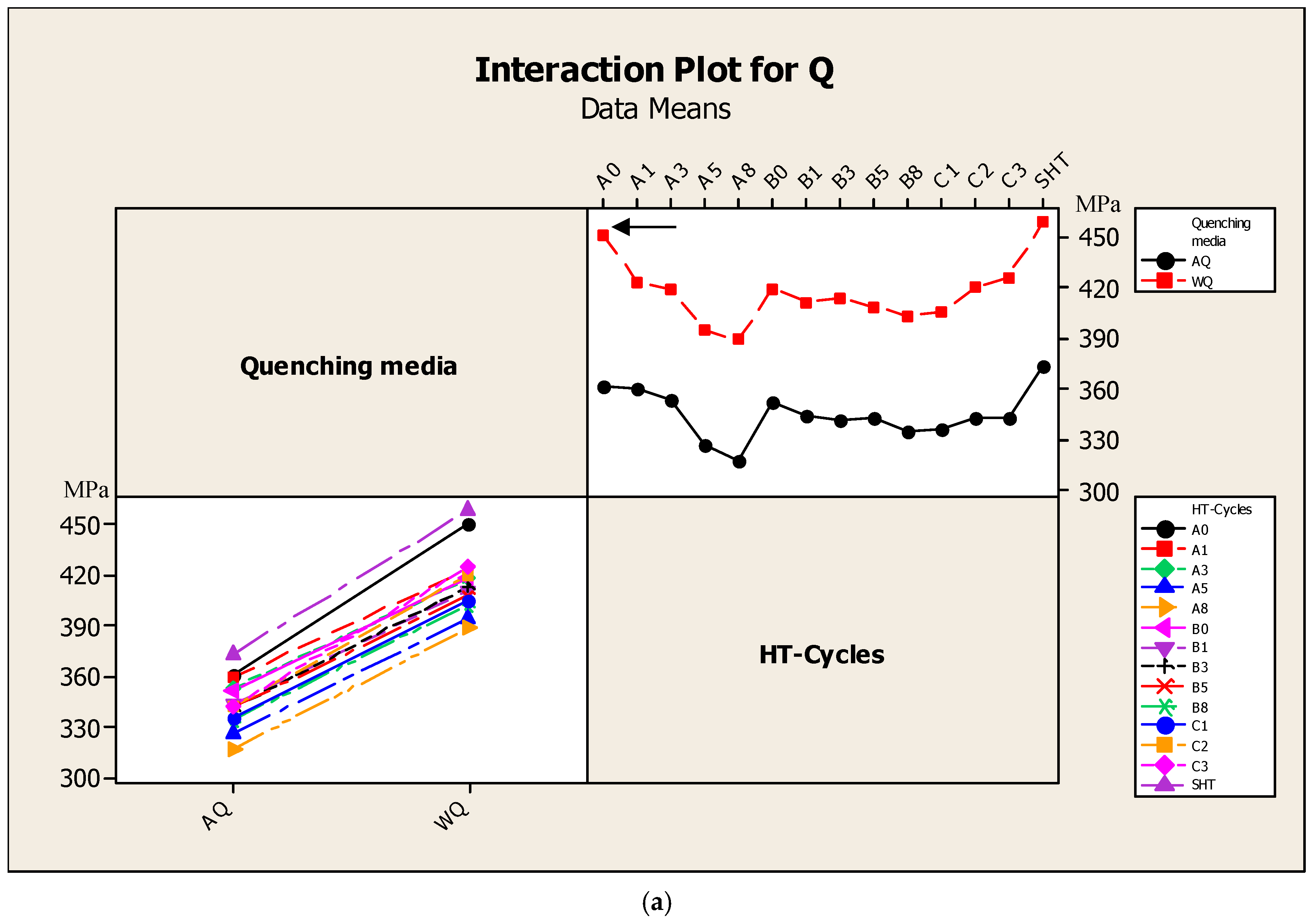

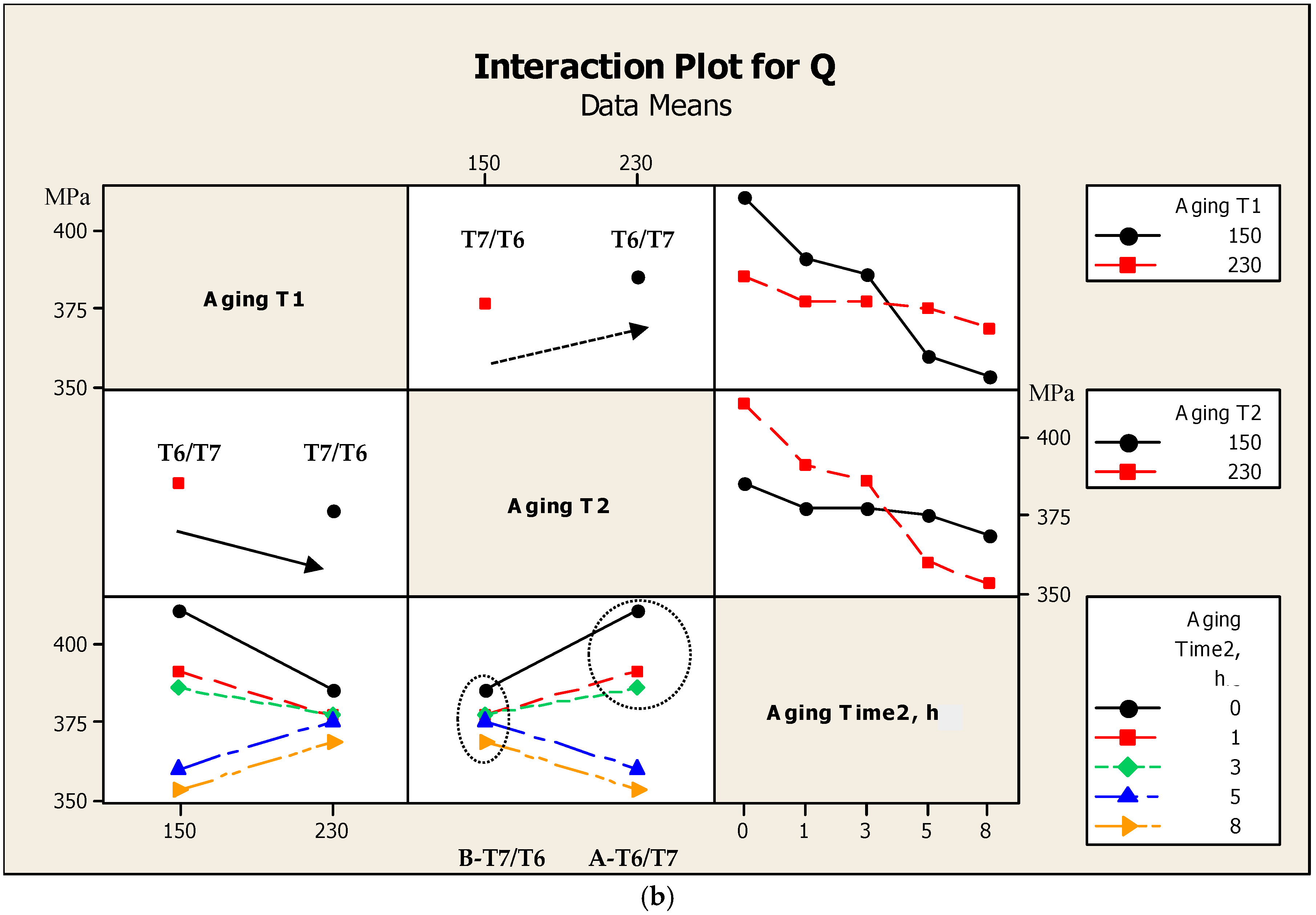

3.2. Statistical Analysis

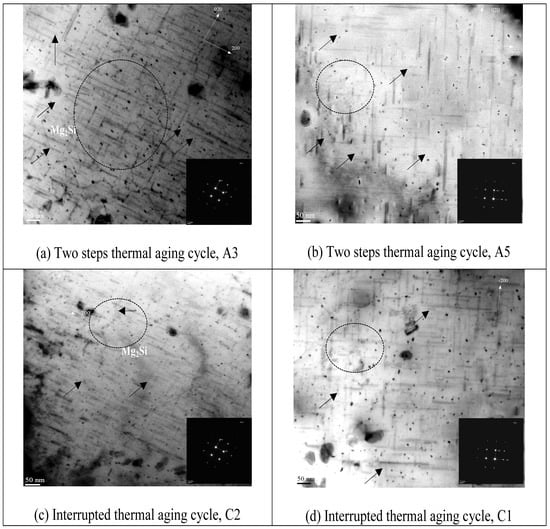

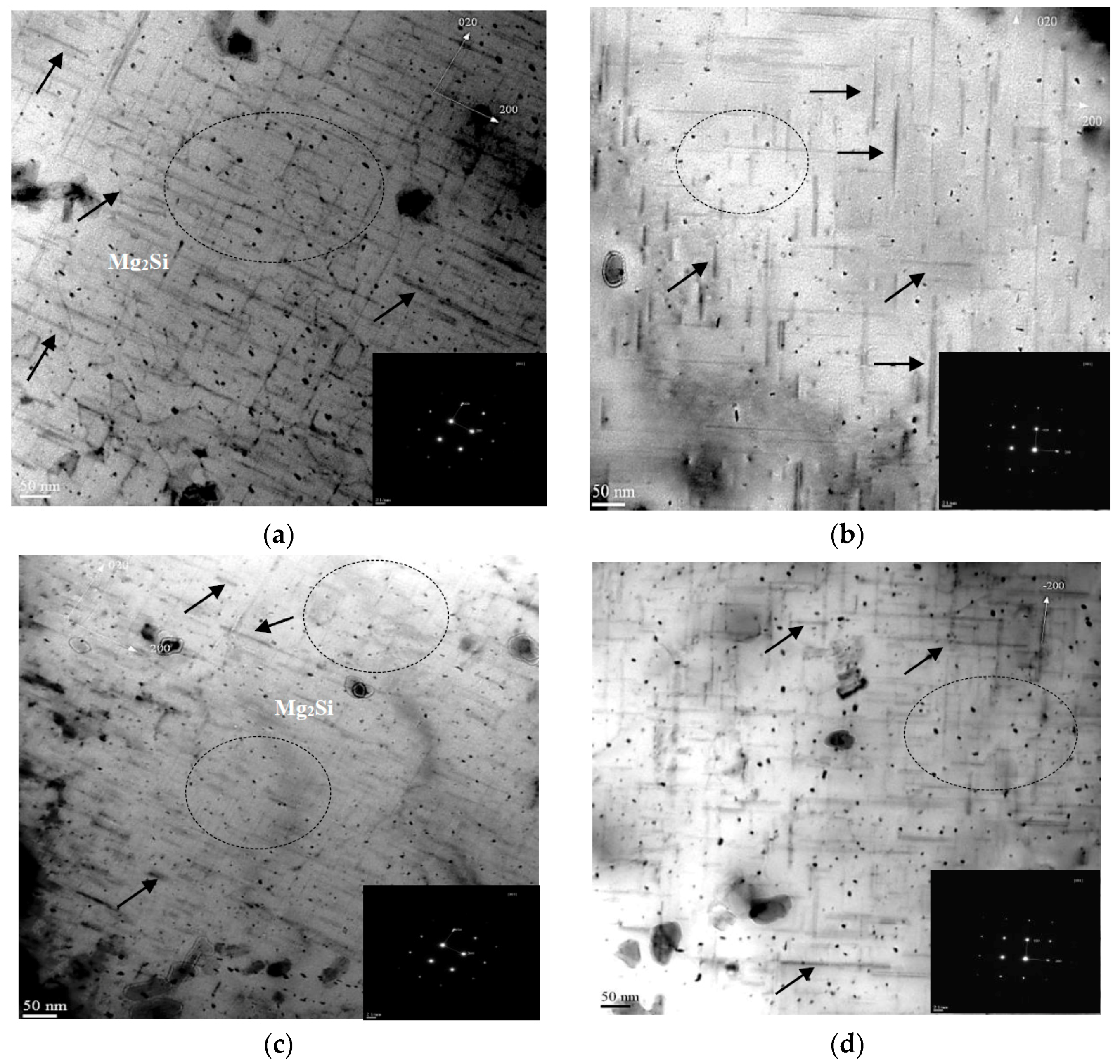

3.3. Precipitates Evolution

4. Conclusions

- The water quenching alloys showed better quality index values obtained for all thermal aging cycles compared to air quenching ones.

- The application of multiple thermal aging parameters of T6/T7-A1,3,5,8 cycle conditions indicates a significant negative effect on the UTS strength values (for T7 aging times of 1 h–8 h) compared to the aging conditions of B and C cycles.

- The optimum quality index values obtained by this study were achieved by the application of the aging condition of A0-T6 cycle and C2,3-interrupted aging cycles. This may be related to the ductility enhancement of alloys investigated for such thermal treatment conditions.

- With regard to regression models for quality results, the mean quality values of A357 alloys are significantly sensitive to quenching media compared to other independent variables of thermal aging parameters. In addition, the ductility variable had a significant positive impact on the quality index values compared to the strength factor. This may explain the highest quality values after thermal aging condition of T6-A0 cycle.

- With respect to the statistical analysis using DOE for thermal aging parameters, the optimum mean quality index values were obtained by the application of the aging conditions of A0 and C3 cycles. The interrupted thermal aging cycles of C2 and C3 arrive at the optimum UTS strength (285–300 MPa) and high-quality index (425 MPa) compared to the other aging parameters applied in this study.

- The application of interrupted aging conditions of the C2 cycle led to the formation of finer and denser precipitates of various sizes compared to the two-steps aging of A3,5 cycles. Such finer precipitates of various sizes induced a significant increase in the strength and quality index values for thermal aging cycles of C conditions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fridlyander, I.N.; Sister, V.G.; Grushko, O.E.; Berstenev, V.V.; Sheveleva, L.M.; Ivanova, L.A. Aluminum alloys: Promising materials in the automotive industry. Met. Sci. Heat Treat. 2002, 44, 365–370. [Google Scholar] [CrossRef]

- Alexopoulos, N.D. Generation of quality maps to support material selection by exploiting the quality indices concept of cast aluminum alloys. Mate. Des. 2007, 28, 534–543. [Google Scholar] [CrossRef]

- Davis, J.R. ASM Specialty Handbook: Aluminum and Aluminum Alloys; ASM International: Materials Park, OH, USA, 1993. [Google Scholar]

- Davies, G. Materials for Automobile Bodies; Butterworth-Heinemann: Oxford, UK, 2003; pp. 61–90. [Google Scholar]

- Wang, Q.G.; Davidson, C.J. Solidification and precipitation behaviour of Al-Si-Mg casting alloys. J. Mater. Sci. 2001, 36, 739–750. [Google Scholar] [CrossRef]

- Langlais, J.; Lemieux, A. The SEED technology for semi-solid processing of aluminum alloys: A metallurgical and process overview. Solid State Phenom. 2006, 116, 472–477. [Google Scholar] [CrossRef]

- Ragab, K.A.; Bouaicha, A.; Bouazara, M. Optimization of Casting Design Parameters on Fabrication of Reliable Semi-Solid Aluminum Suspension Control Arm. J. Mater. Eng. Perform. 2017, 26, 4450–4461. [Google Scholar] [CrossRef]

- Ragab, K.A.; Bouazara, M.; Bouaicha, A.; Allaoui, O. Microstructural and mechanical features of aluminium semi-solid alloys made by rheocasting technique. Mater. Sci. Technol. 2017, 33, 646–655. [Google Scholar] [CrossRef]

- Ragab, K.A.; Bouazara, M.; Chen, X.G. Influence of Thermal Aging Parameters on the Characteristics of Aluminum Semi-Solid Alloys. Metals 2018, 8, 746. [Google Scholar] [CrossRef]

- Martin, J.W. Precipitation Hardening; Butterworth-Heinemann: Oxford, UK, 1998; p. 215. [Google Scholar]

- Shivkumar, S.; Keller, C.; Apelian, D. Aging behavior in cast Al-Si-Mg alloys. AFS Trans. 1990, 98, 905–911. [Google Scholar]

- Abdulwahab, M.; Madugu, I.A.; Yaro, S.A. Effects of temper conditions and step-quenching-ageing on the hardness characteristics and yield strength of A356.0-type Al-Si-Mg alloy. Silicon 2012, 4, 137–143. [Google Scholar] [CrossRef]

- Andersen, S.J.; Marioara, C.D.; Vissers, R.; Frøseth, A.; Zandbergen, H.W. The structural relation between precipitates in Al-Mg-Si alloys, the Al-matrix and diamond silicon, with emphasis on the trigonal phase U1-MgAl2Si2. Mater. Sci. Eng. A 2007, 444, 157–169. [Google Scholar] [CrossRef]

- Matsumoto, K.; Komatsu, S.-Y.; Ikeda, M.; Verlinden, B.; Ratchev, P. Quantification of volume fraction of precipitates in an aged Al-1.0 mass% Mg2Si alloy. Mater. Trans. 2000, 41, 1275–1281. [Google Scholar] [CrossRef]

- Ding, L.P.; Jia, Z.H.; Nie, J.F.; Weng, Y.Y.; Cao, L.F.; Chen, H.W.; Wu, X.Z.; Liu, Q. The structural and compositional evolution of precipitates in Al-Mg-Si-Cu alloy. Acta Mater. 2018, 145, 437–450. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Pantelakis, S.G. Quality assessment of artificially aged A357 aluminum alloy cast ingots by introducing approximate expressions of the quality index Q. Metall. Trans. A 2004, 35, 3079–3089. [Google Scholar] [CrossRef]

- Cáceres, C.H. Microstructure design and heat treatment selection for casting alloys using the quality index. J. Mater. Eng. Perform. 2000, 9, 215–221. [Google Scholar] [CrossRef]

- Ragab, C.H; Barresi, J. Selection of temper and Mg content to optimise the quality index of Al-7Si-Mg casting alloys. Int. J. Cast Met. Res. 2000, 12, 377–384. [Google Scholar]

- Montgomery, D.C. Experiments with a single factor: the analysis of variance. Design and Analysis of Experiments; SAS Institute Inc.: Cary, NC, USA, 1991; pp. 87–89. [Google Scholar]

- Steinberg, D.M; Hunter, W.G. Experimental design: Review and comments. Technometrics 1984, 26, 71–97. [Google Scholar] [CrossRef]

- Drouzy, M.; Jacob, S.; Richard, M. Interpretation of tensile results by means of quality index and probable yield strength-application to Al-Si7 Mg foundry alloys-France. Int. Cast Met. J. 1980, 5, 43–50. [Google Scholar]

- Cáceres, C.H. A phenomenological approach to the Quality Index of Al-Si-Mg casting alloys. Int. J. Cast Met. Res. 2000, 12, 367–375. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Staley, J.T.; Campbell, J. Evaluating structural integrity of cast Al–7% Si–Mg alloys via work hardening characteristics: II. A new quality index. Mater. Sci. Eng. A 2004, 368, 231–238. [Google Scholar] [CrossRef]

- Ravi, C.; Wolverton, C. First-principles study of crystal structure and stability of Al-Mg-Si-(Cu) precipitates. Acta Mater. 2004, 52, 4213–4227. [Google Scholar] [CrossRef]

- Abubakre, O.K.; Mamaki, U.P.; Muriana, R.A. Investigation of the quenching properties of selected media on 6061 aluminum alloy. J. Min. Mater. Charact. Eng. 2009, 8, 303–315. [Google Scholar] [CrossRef]

- Gupta, A.K.; Lloyd, D.J. Precipitation hardening in Al-Mg-Si alloys with and without excess Si. Mater. Sci. Eng. A 2001, 316, 11–17. [Google Scholar] [CrossRef]

- Lumley, R.N.; Polmear, I.J.; Et Morton, A.J. Development of mechanical properties during secondary aging in aluminium alloys. Mater. Sci. Technol. 2005, 21, 1025–1032. [Google Scholar] [CrossRef]

- Babu, G.D.; Rao, M.N. Effect of Non-Conventional Aging Treatments on the Tensile Properties of Non-Hipped Castings of Aluminum Alloy 354. Adv. Mat. Res. 2014, 875, 1397–1405. [Google Scholar] [CrossRef]

- Ding, L.P.; Jia, Z.H.; Zhang, Z.Q.; Sanders, R.E.; Liu, Q.; Yang, G. The natural aging and precipitation hardening behavior of Al-Mg-Si-Cu alloys with different Mg/Si ratios and Cu additions. Mater. Sci. Eng. A 2015, 627, 119–126. [Google Scholar] [CrossRef]

- Aruga, Y.; Kozuka, M.; Takaki, Y.; Sato, T. Formation and reversion of clusters during natural aging and subsequent artificial aging in an Al–Mg–Si alloy. Mater. Sci. Eng. A 2015, 631, 86–96. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ragab, K.A.; Bouazara, M.; Chen, X.-G. Quality Index Charts of Al-Si-Mg Semi Solid Alloys Subjected to Multiple Temperatures Aging Treatments and Different Quenching Media. Materials 2019, 12, 1834. https://doi.org/10.3390/ma12111834

Ragab KA, Bouazara M, Chen X-G. Quality Index Charts of Al-Si-Mg Semi Solid Alloys Subjected to Multiple Temperatures Aging Treatments and Different Quenching Media. Materials. 2019; 12(11):1834. https://doi.org/10.3390/ma12111834

Chicago/Turabian StyleRagab, Khaled Ahmed, Mohamed Bouazara, and X.-Grant Chen. 2019. "Quality Index Charts of Al-Si-Mg Semi Solid Alloys Subjected to Multiple Temperatures Aging Treatments and Different Quenching Media" Materials 12, no. 11: 1834. https://doi.org/10.3390/ma12111834

APA StyleRagab, K. A., Bouazara, M., & Chen, X.-G. (2019). Quality Index Charts of Al-Si-Mg Semi Solid Alloys Subjected to Multiple Temperatures Aging Treatments and Different Quenching Media. Materials, 12(11), 1834. https://doi.org/10.3390/ma12111834