Early Compressive Deformation of Closed-Cell Aluminum Foam Based on a Three-Dimensional Realistic Structure

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimens Preparation

2.2. Synchrotron Radiation X-ray Tomography

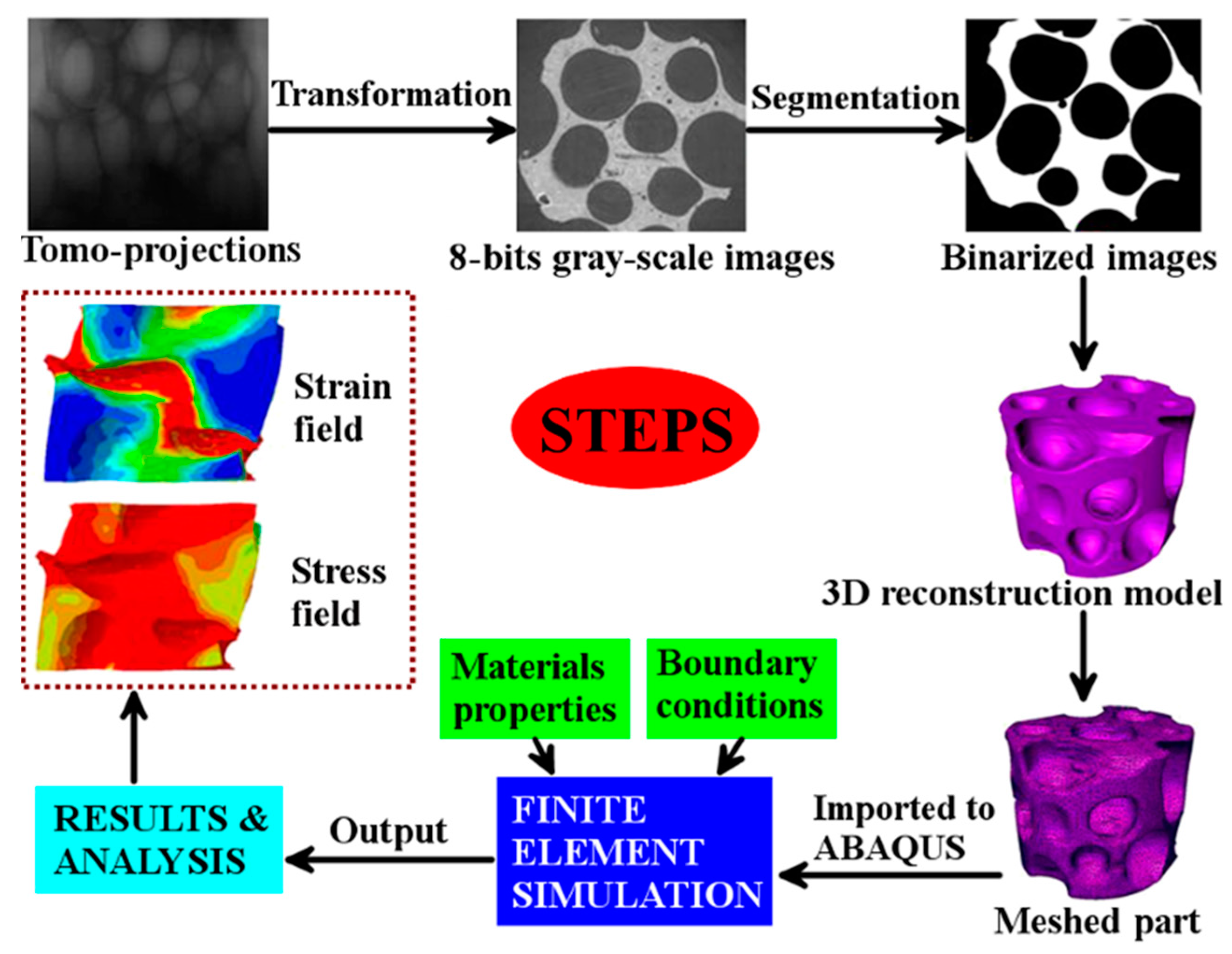

2.3. Real 3D Model Reconstruction

2.4. Simulation of Compression

2.5. Compression Experiment

3. Results and Discussion

3.1. Simulation Results and Initial Deformation Behavior

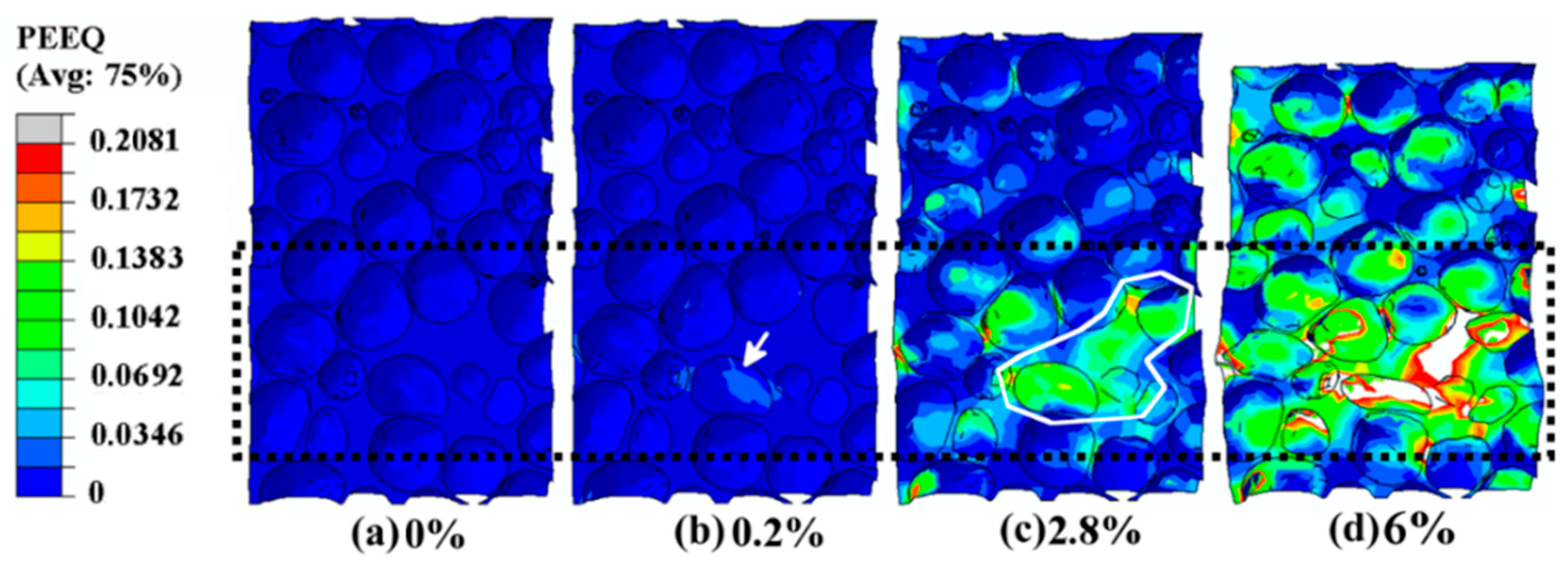

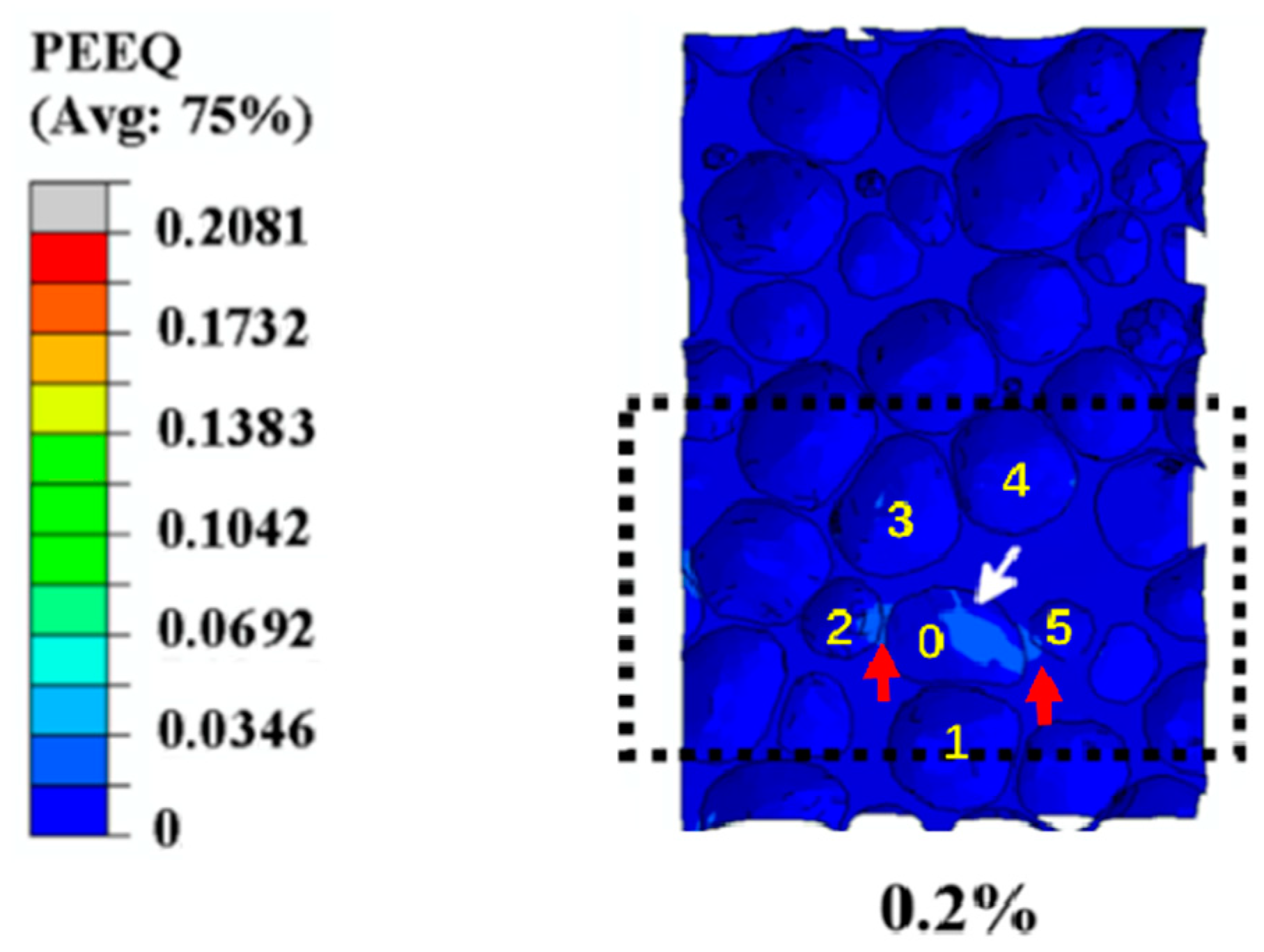

3.1.1. Initiation of Plastic Strain in the Simulation Results

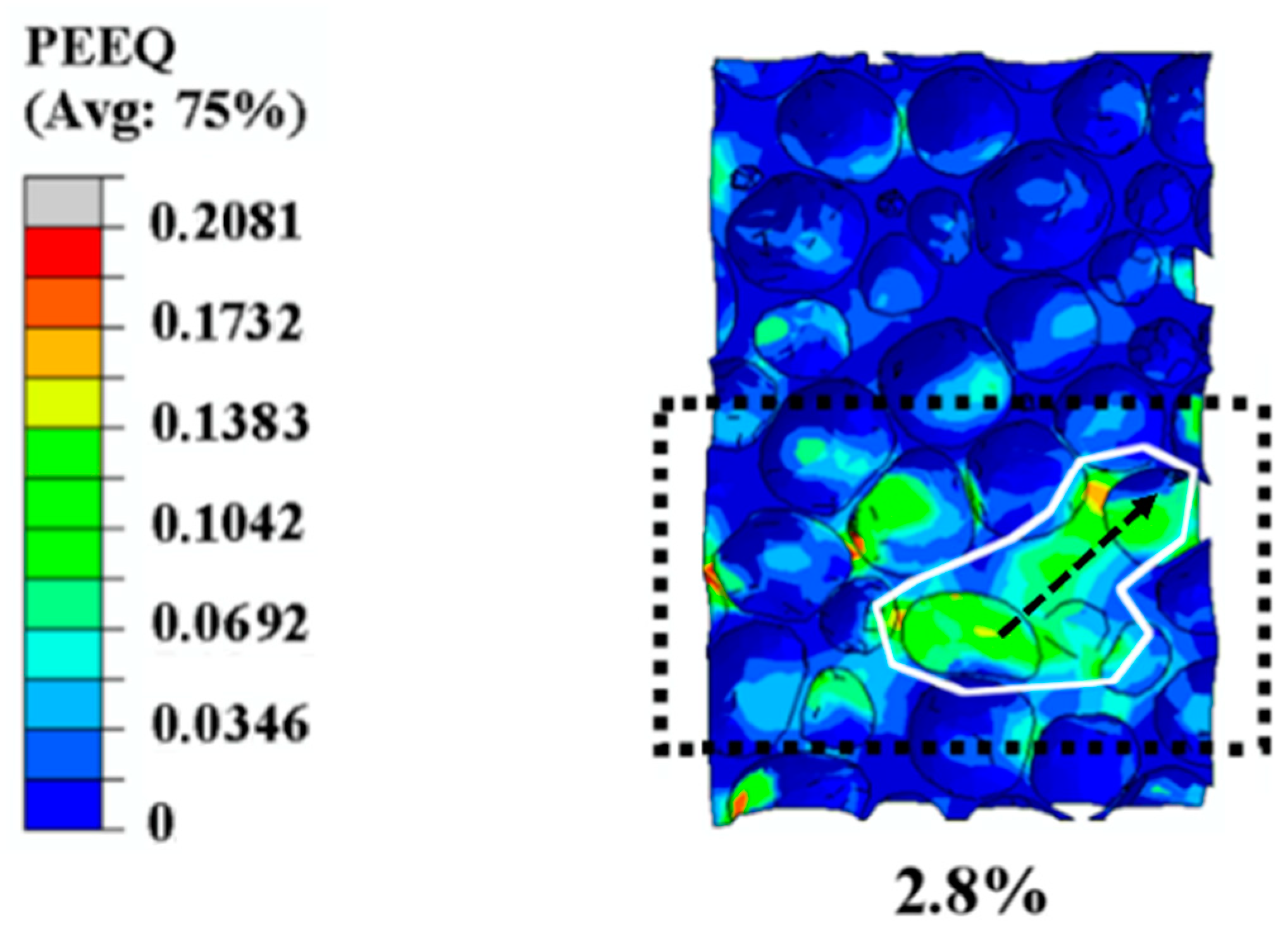

3.1.2. Propagation of the Plastic Strain Band in Simulation Results

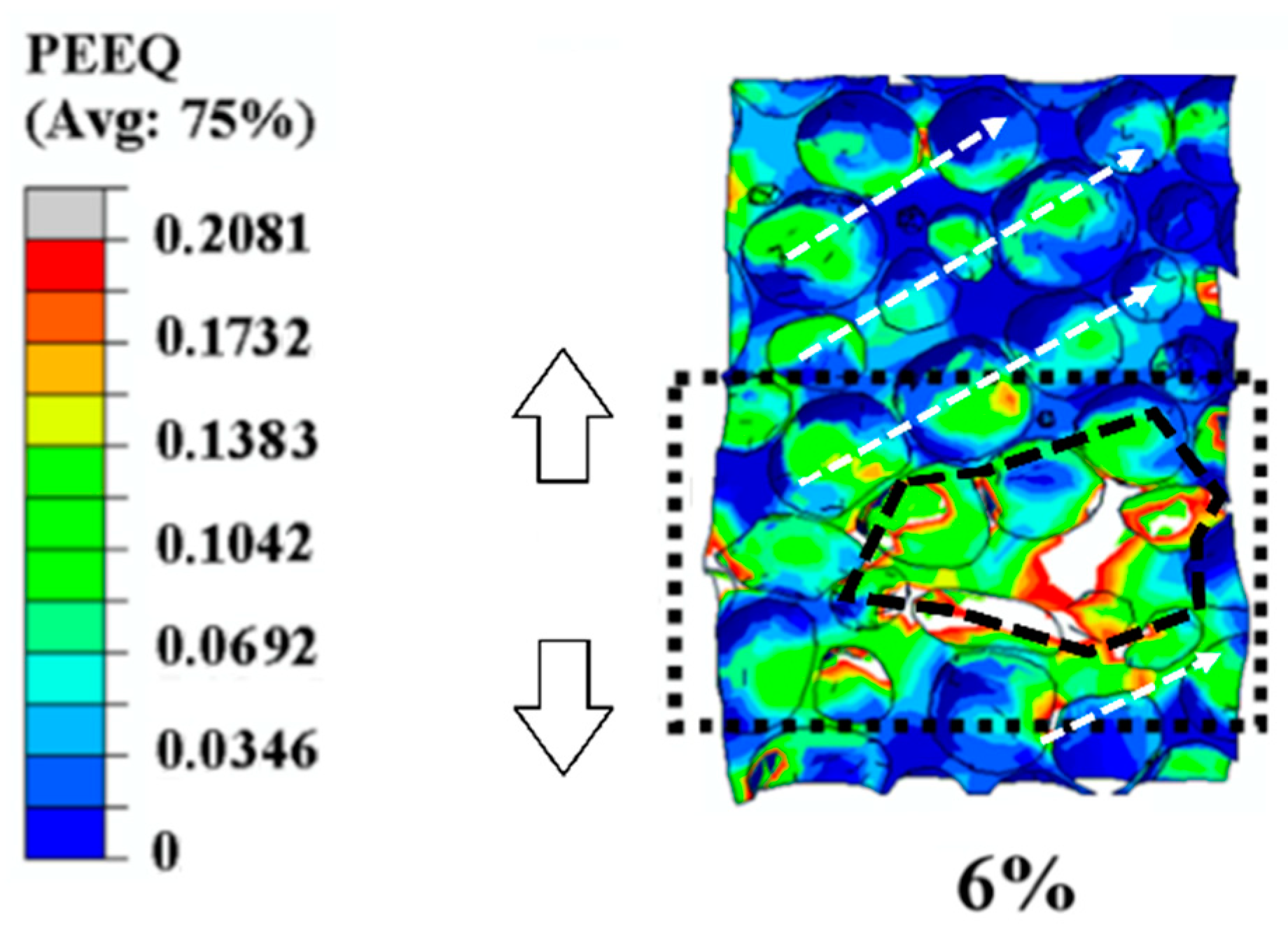

3.1.3. Formation of the Collapse Band in Simulation Results

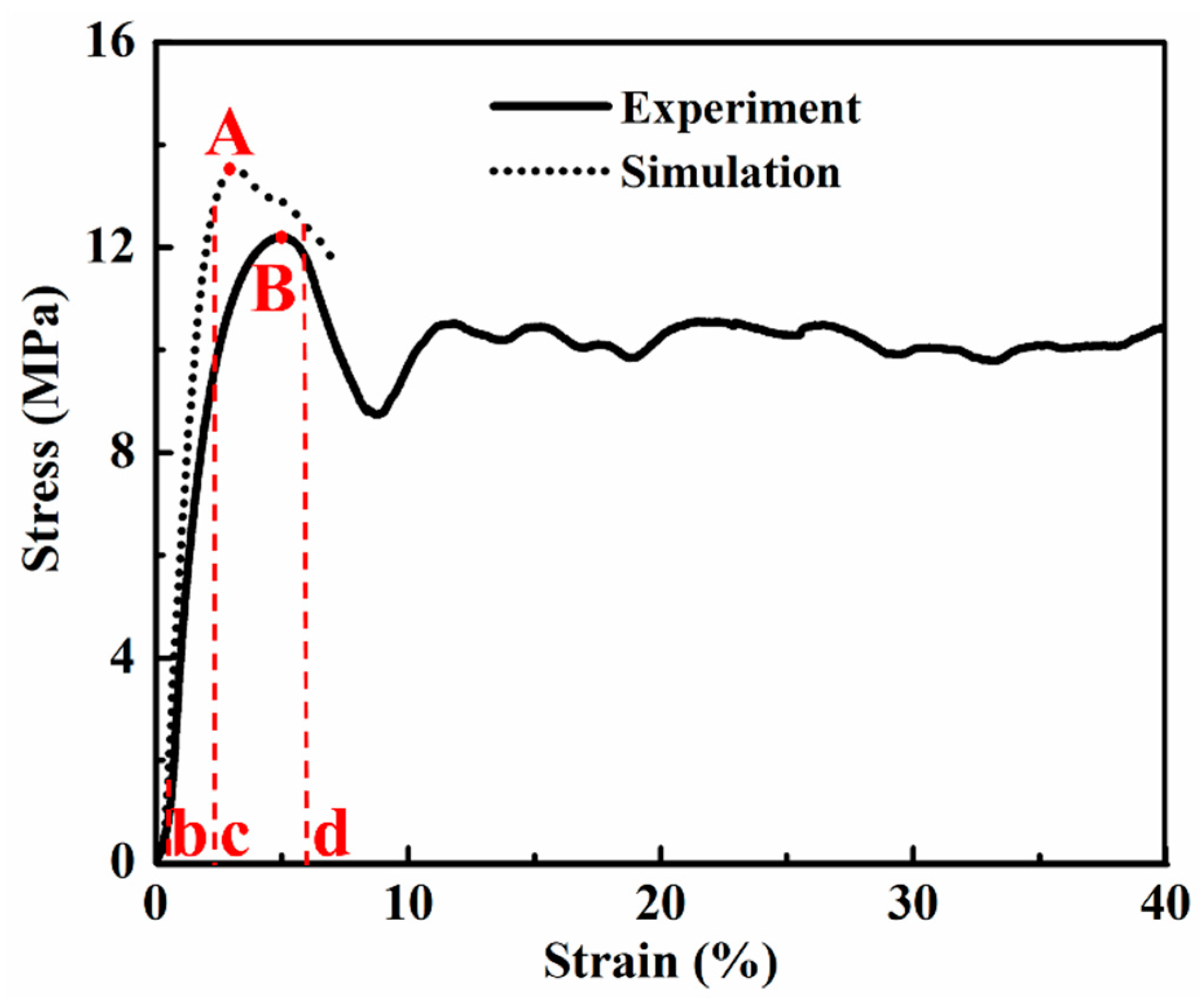

3.2. Comparison of the Compression Test Results between Simulation and Experiment

4. Conclusions

- The whole process of obtaining the finite-element model based on the real 3D structure was discussed using the synchrotron radiation X-ray tomography and 3D model reconstruction.

- Different strain levels (0.2%, 2.8%, and 6%) were chosen to discuss the evolution of plastic strain in early compressive deformation. The curvature, anisotropy, and distribution of the volume around cells were found to be important for the initiation of the plastic strain at the lower overall strain level (0.2%). Furthermore, the plastic strain band propagated along the direction aligned 45° with respect to the loading direction, and the width of the plastic strain band increased gradually till the formation of the collapse band in the other two strain levels (2.8% and 6%, corresponding to the levels of propagation of the plastic strain band and formation of the collapse band).

- The numerical and experimental results matched well. Meanwhile, three different strain levels were further demonstrated to exist in the early compressive deformation stage in the stress–strain curves, establishing a correlation between the evolution of the plastic strain among the cells and their global compressive deformation behavior.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tekoglu, C.; Gibson, L.J.; Pardoen, T.; Onck, P.R. Size effects in foams: Experiments and modeling. Prog. Mater. Sci. 2011, 56, 109–138. [Google Scholar] [CrossRef]

- Bart-Smith, H.; Bastawros, A.F.; Mumm, D.R.; Evans, A.G.; Sypeck, D.J.; Wadley, H.N.G. Compressive deformation and yielding mechanisms in cellular Al alloys determined using X-ray tomography and surface strain mapping. Acta Mater. 1998, 46, 3583–3592. [Google Scholar] [CrossRef]

- Jeon, I.; Asahina, T. The effect of structural defects on the compressive behavior of closed-cell Al foam. Acta Mater. 2005, 53, 3415–3423. [Google Scholar] [CrossRef]

- Sugimura, Y.; Meyer, J.; He, M.Y.; BartSmith, H.; Grenstedt, J.; Evans, A.G. On the mechanical performance of closed cell Al alloy foams. Acta Mater. 1997, 45, 5245–5259. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Lin, Y.F.; Li, S.; Zhai, D.X.; Wu, G.H. Quasi-static and high strain rates compressive behavior of aluminum matrix syntactic foams. Compos. Part B Eng. 2016, 98, 288–296. [Google Scholar] [CrossRef]

- Saadatfar, M.; Mukherjee, M.; Madadi, M.; Schröder-Turk, G.E.; Garcia-Moreno, F.; Schaller, F.M.; Hutzler, S.; Sheppard, A.P.; Banhart, J.; Ramamurty, U. Structure and deformation correlation of closed-cell aluminium foam subject to uniaxial compression. Acta Mater. 2012, 60, 3604–3615. [Google Scholar] [CrossRef]

- Banhart, J. Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Gama, B.A.; Bogetti, T.A.; Fink, B.K.; Yu, C.J.; Claar, T.D.; Eifert, H.H.; Gillespie, J.W. Aluminum foam integral armor: A new dimension in armor design. Compos. Struct. 2001, 52, 381–395. [Google Scholar] [CrossRef]

- Gibson, L.J. Mechanical behavior of metallic foams. Annu. Rev. Mater. Sci. 2000, 30, 191–227. [Google Scholar] [CrossRef]

- Simone, A.E.; Gibson, L.J. The effects of cell face curvature and corrugations on the stiffness and strength of metallic foams. Acta Mater. 1998, 46, 3929–3935. [Google Scholar] [CrossRef]

- Sun, Y.; Li, Q.M.; Lowe, T.; McDonald, S.A.; Withers, P.J. Investigation of strain-rate effect on the compressive behaviour of closed-cell aluminium foam by 3D image-based modelling. Mater. Des. 2016, 89, 215–224. [Google Scholar] [CrossRef]

- McCullough, K.Y.G.; Fleck, N.A.; Ashby, M.F. Uniaxial stress-strain behaviour of aluminium alloy foams. Acta Mater. 1999, 47, 2323–2330. [Google Scholar] [CrossRef]

- Balch, D.K.; Dunand, D.C. Load partitioning in aluminum syntactic foams containing ceramic microspheres. Acta Mater. 2006, 54, 1501–1511. [Google Scholar] [CrossRef]

- Szlancsik, A.; Katona, B.; Dombóvári, Z.; Orbulov, I.N. On the effective Young’s modulus of metal matrix syntactic foams. Mater. Sci. Technol. 2017, 33, 2283–2289. [Google Scholar] [CrossRef]

- Li, Y.G.; Wei, Y.H.; Hou, L.F.; Guo, C.-L.; Yang, S.-Q. Fabrication and compressive behaviour of an aluminium foam composite. J. Alloys Compd. 2015, 649, 76–81. [Google Scholar] [CrossRef]

- Yang, D.H.; Wang, H.; Guo, S.S.; Chen, J.Q.; Xu, Y.M.; Lei, D.; Sun, J.P.; Wang, L.; Jiang, J.H.; Ma, A.B. Coupling Effect of Porosity and Cell Size on the Deformation Behavior of Al Alloy Foam under Quasi-Static Compression. Materials 2019, 12, 951. [Google Scholar] [CrossRef]

- Markaki, A.E.; Clyne, T.W. The effect of cell wall microstructure on the deformation and fracture of aluminium-based foams. Acta Mater. 2001, 49, 1677–1686. [Google Scholar] [CrossRef]

- Ulbin, M.; Vesenjak, M.; Borovinšek, M.; Duarte, I.; Higa, Y.; Shimojima, K.; Ren, Z. Detailed Analysis of Closed-Cell Aluminum Alloy Foam Internal Structure Changes during Compressive Deformation. Adv. Eng. Mater. 2018, 20, 1800164. [Google Scholar] [CrossRef]

- Nammi, S.K.; Myler, P.; Edwards, G. Finite element analysis of closed-cell aluminium foam under quasi-static loading. Mater. Des. 2010, 31, 712–722. [Google Scholar] [CrossRef]

- Kádár, C.; Maire, E.; Borbély, A.; Peix, G.; Lendvai, J.; Rajkovits, Z. X-ray tomography and finite element simulation of the indentation behavior of metal foams. Mater. Sci. Eng. A 2004, 387, 321–325. [Google Scholar] [CrossRef]

- Yuan, W.W.; Chen, X.; Liu, Y.; Li, Y.X. Research on Key Technologies for Batch Preparation of Aluminum Foam Slabs by Melt Foaming Process. Rare Met. Mater. Eng. 2009, 38, 306–310. [Google Scholar]

- McDonald, S.A.; Mummery, P.M.; Johnson, G.; Withers, P.J. Characterization of the three-dimensional structure of a metallic foam during compressive deformation. J. Microsc. 2006, 223, 150–158. [Google Scholar] [CrossRef]

- Santosa, S.; Wierzbicki, T. On the modeling of crush behavior of a closed-cell aluminum foam structure. J. Mech. Phys. Solids 1998, 46, 645–669. [Google Scholar] [CrossRef]

- Mu, Y.L.; Yao, G.C.; Luo, H.J. Effect of cell shape anisotropy on the compressive behavior of closed-cell aluminum foams. Mater. Des. 2010, 31, 1567–1569. [Google Scholar] [CrossRef]

- Cady, C.M.; Gray, G.T.; Liu, C.; Lovato, M.L.; Mukai, T. Compressive properties of a closed-cell aluminum foam as a function of strain rate and temperature. Mater. Sci. Eng. A 2009, 525, 1–6. [Google Scholar] [CrossRef]

- Yu, J.L.; Li, J.R.; Hu, S.S. Strain-rate effect and micro-structural optimization of cellular metals. Mech. Mater. 2006, 38, 160–170. [Google Scholar] [CrossRef]

- Bastawros, A.F.; Bart-Smith, H.; Evans, A.G. Experimental analysis of deformation mechanisms in a closed-cell aluminum alloy foam. J. Mech. Phys. Solids 2000, 48, 301–322. [Google Scholar] [CrossRef]

- Wang, D.Q.; Xue, W.W.; Meng, X.J.; Shi, Z.Y. Cell structure and compressive behavior of an aluminum foam. J. Mater. Sci. 2005, 40, 3475–3480. [Google Scholar]

- Sun, Y.; Zhang, X.; Shao, Z.; Li, Q.M. Image-based correlation between the meso-scale structure and deformation of closed-cell foam. Mater. Sci. Eng. A 2017, 688, 27–39. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, X.; Zhu, K.; Xu, Y.; Han, B.; Jing, T. Early Compressive Deformation of Closed-Cell Aluminum Foam Based on a Three-Dimensional Realistic Structure. Materials 2019, 12, 1792. https://doi.org/10.3390/ma12111792

Wan X, Zhu K, Xu Y, Han B, Jing T. Early Compressive Deformation of Closed-Cell Aluminum Foam Based on a Three-Dimensional Realistic Structure. Materials. 2019; 12(11):1792. https://doi.org/10.3390/ma12111792

Chicago/Turabian StyleWan, Xiong, Kai Zhu, Yanjin Xu, Baoshuai Han, and Tao Jing. 2019. "Early Compressive Deformation of Closed-Cell Aluminum Foam Based on a Three-Dimensional Realistic Structure" Materials 12, no. 11: 1792. https://doi.org/10.3390/ma12111792

APA StyleWan, X., Zhu, K., Xu, Y., Han, B., & Jing, T. (2019). Early Compressive Deformation of Closed-Cell Aluminum Foam Based on a Three-Dimensional Realistic Structure. Materials, 12(11), 1792. https://doi.org/10.3390/ma12111792