Structural Properties and Damage Detection Capability of Carbon Nanotube Modified Mortars after Freeze-Thaw

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

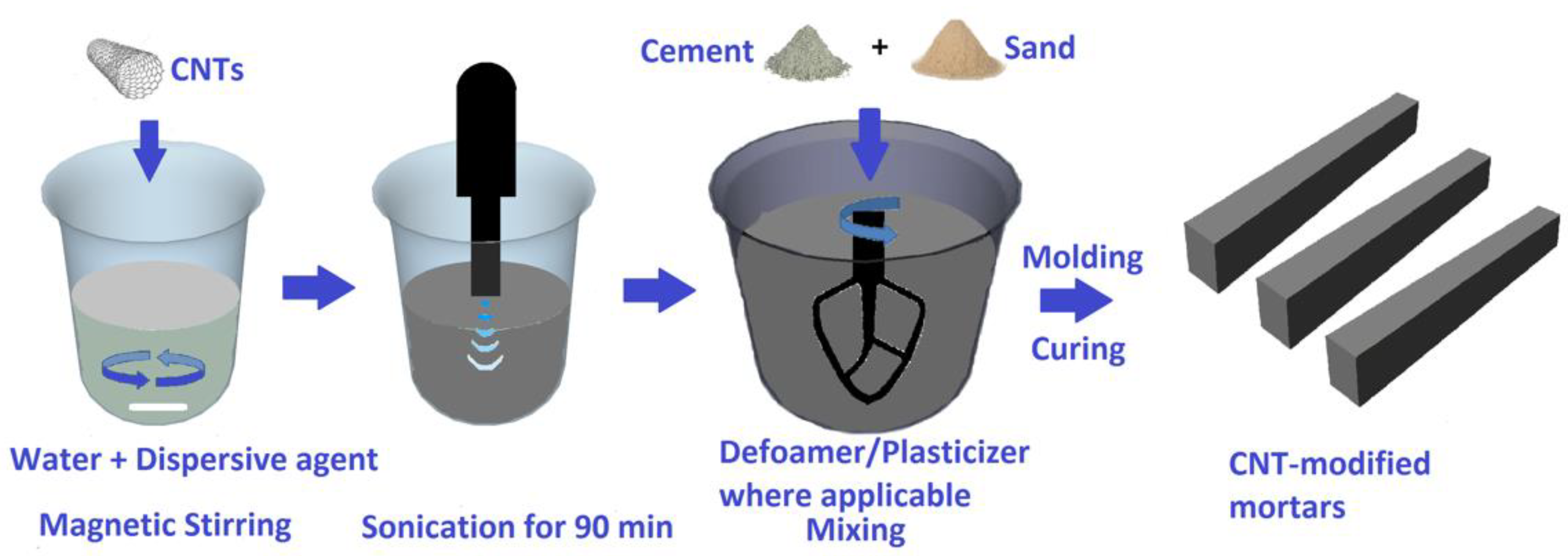

2.2. Preparation of Nano-Modified Mortars

2.3. Freeze-Thaw Cycling

2.4. Testing Procedure

3. Results

4. Conclusions

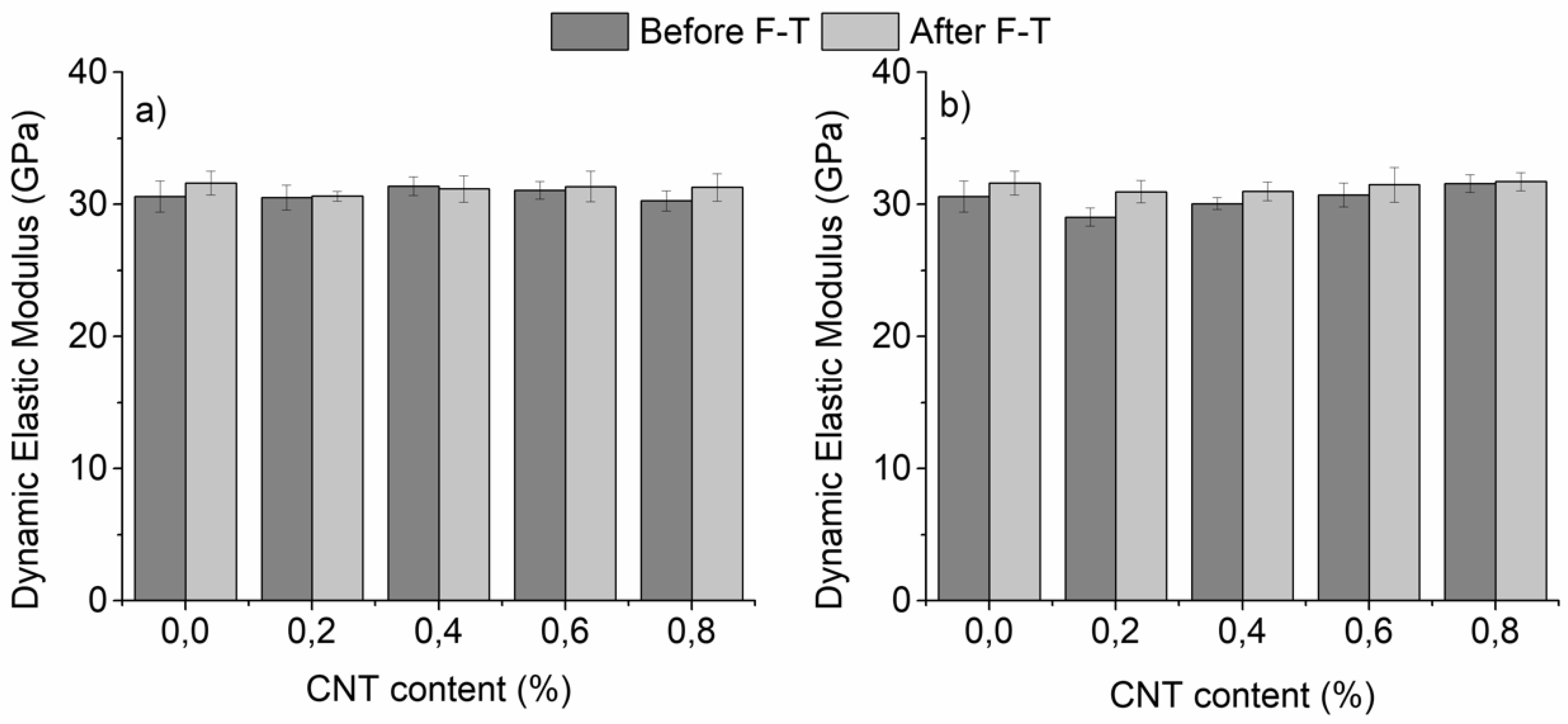

- F-T exposure slightly enhanced the dynamic elastic modulus of un-modified and CNT-modified mortars prepared with a surfactant as a dispersive agent, while those prepared with superplasticizer present minor variations before and after F-T. This has been associated with enhanced hydration and compaction in specimens prepared with superplasticizer as a dispersant.

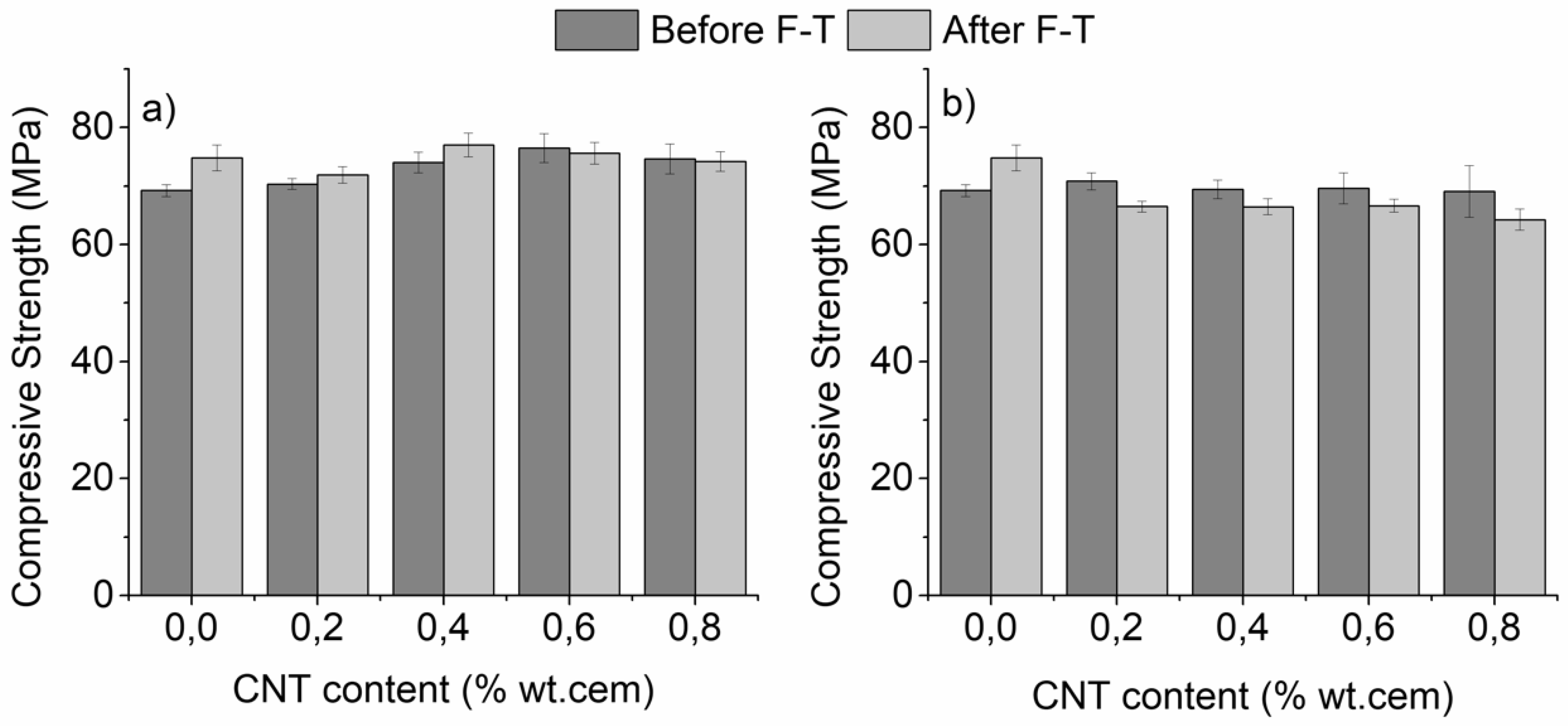

- F-T cycling did not significantly impact the compressive strength of CNT-modified specimens which was mainly determined by the microstructure of the specimens. The use of a superplasticizer as a dispersant facilitated the compaction of the specimens and enhanced their compressive strength prior and post F-T cycling.

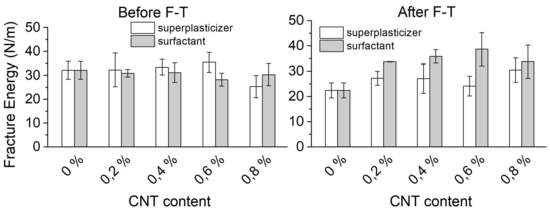

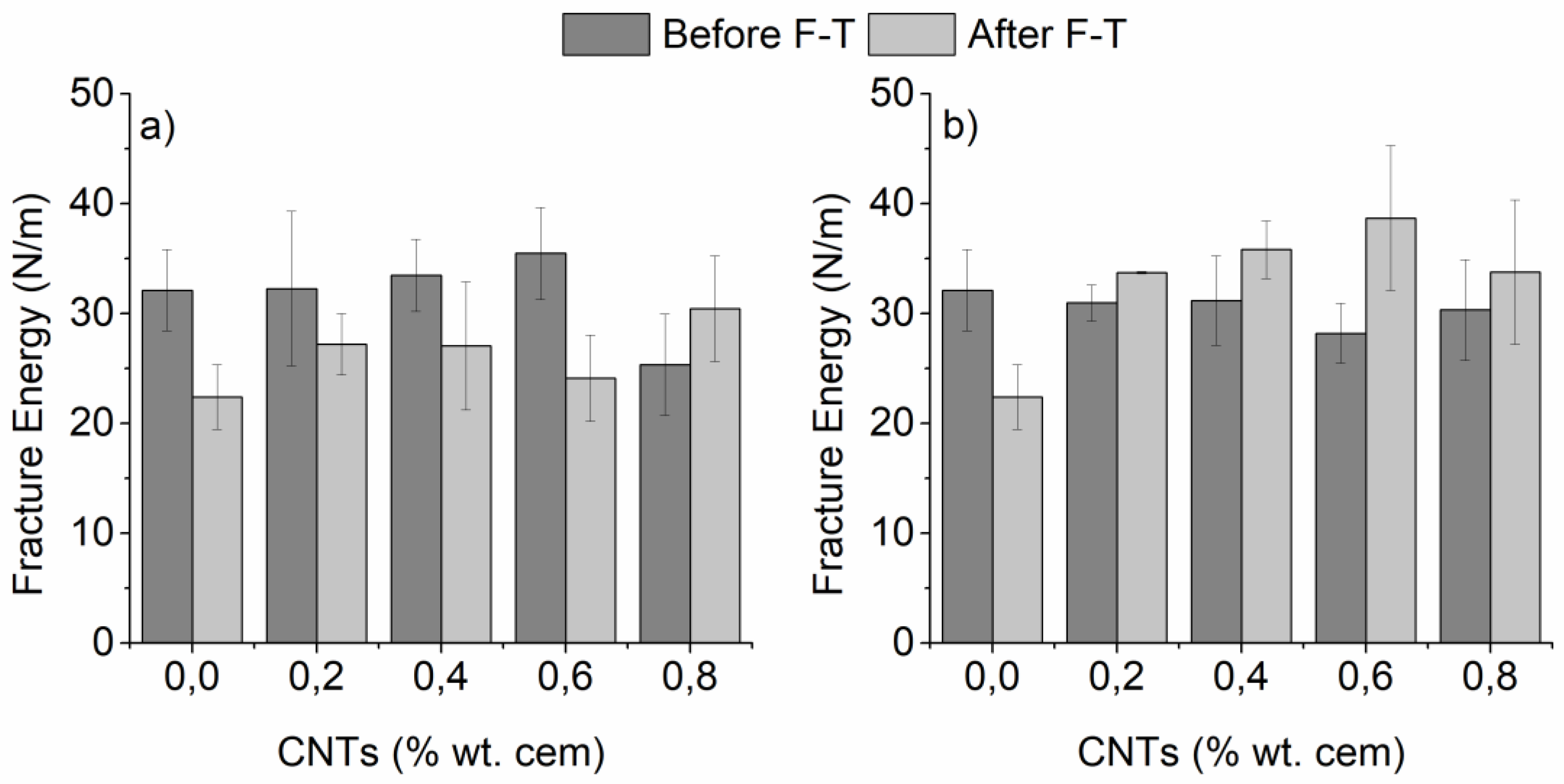

- Nano-modification was beneficial for the durability of cementitious mortars exposed to F-T conditions since it resulted in an up to 73% higher fracture energy. The level of improvement was, however, dictated not only by the CNT content and dispersion efficiency but also by the nature of the dispersive agents. The dispersive agents controlled the size of micro-pores, the level of pressure built and, in turn, the way microcracks developed during the F-T cycling.

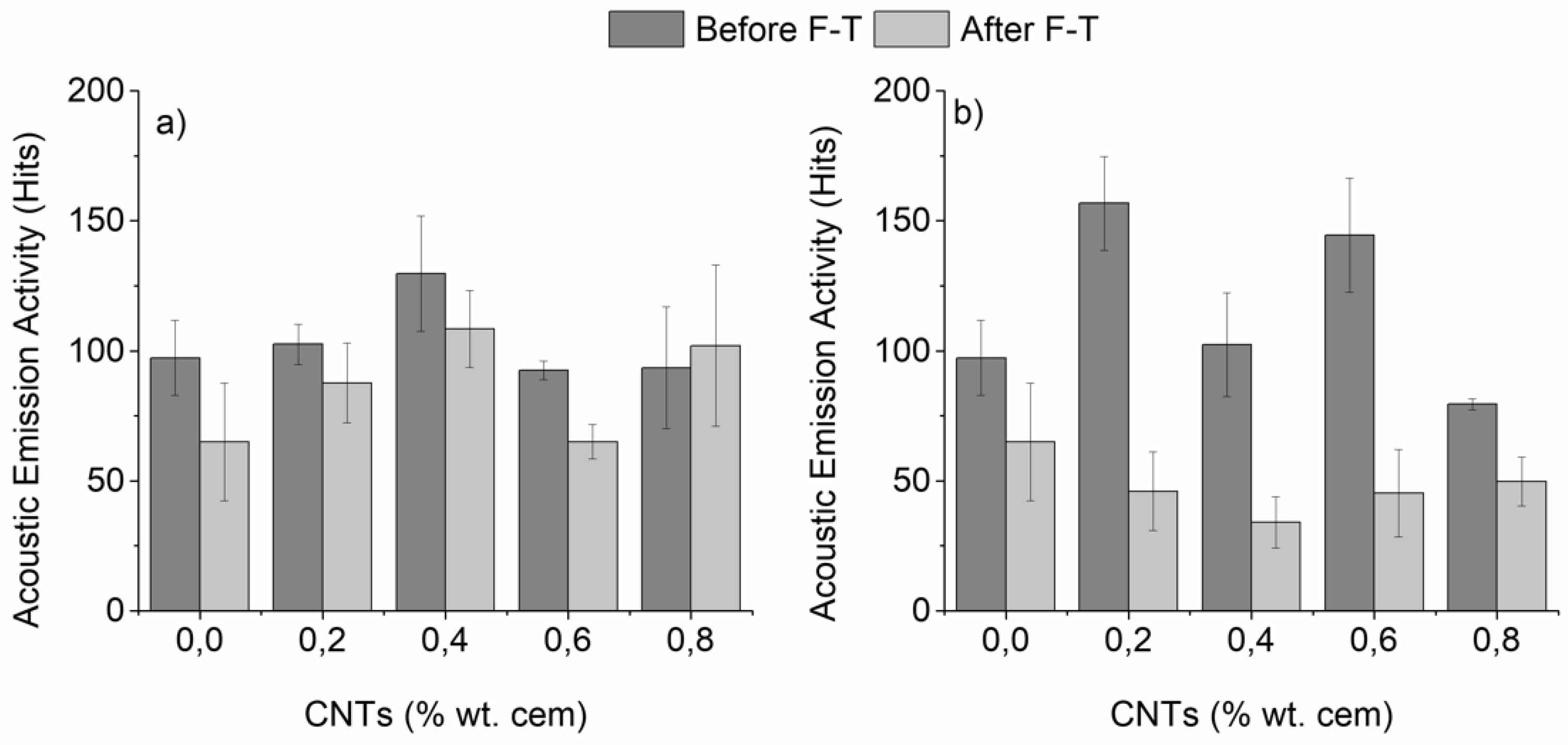

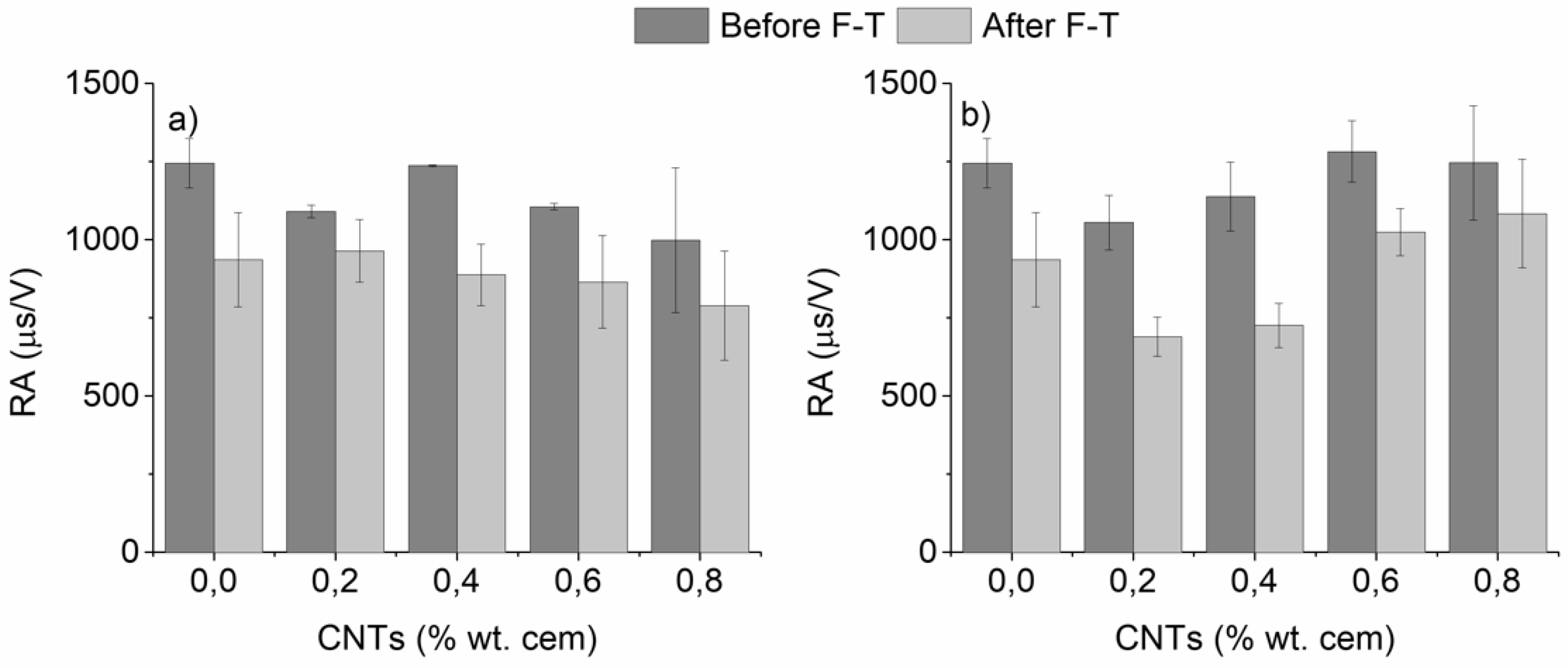

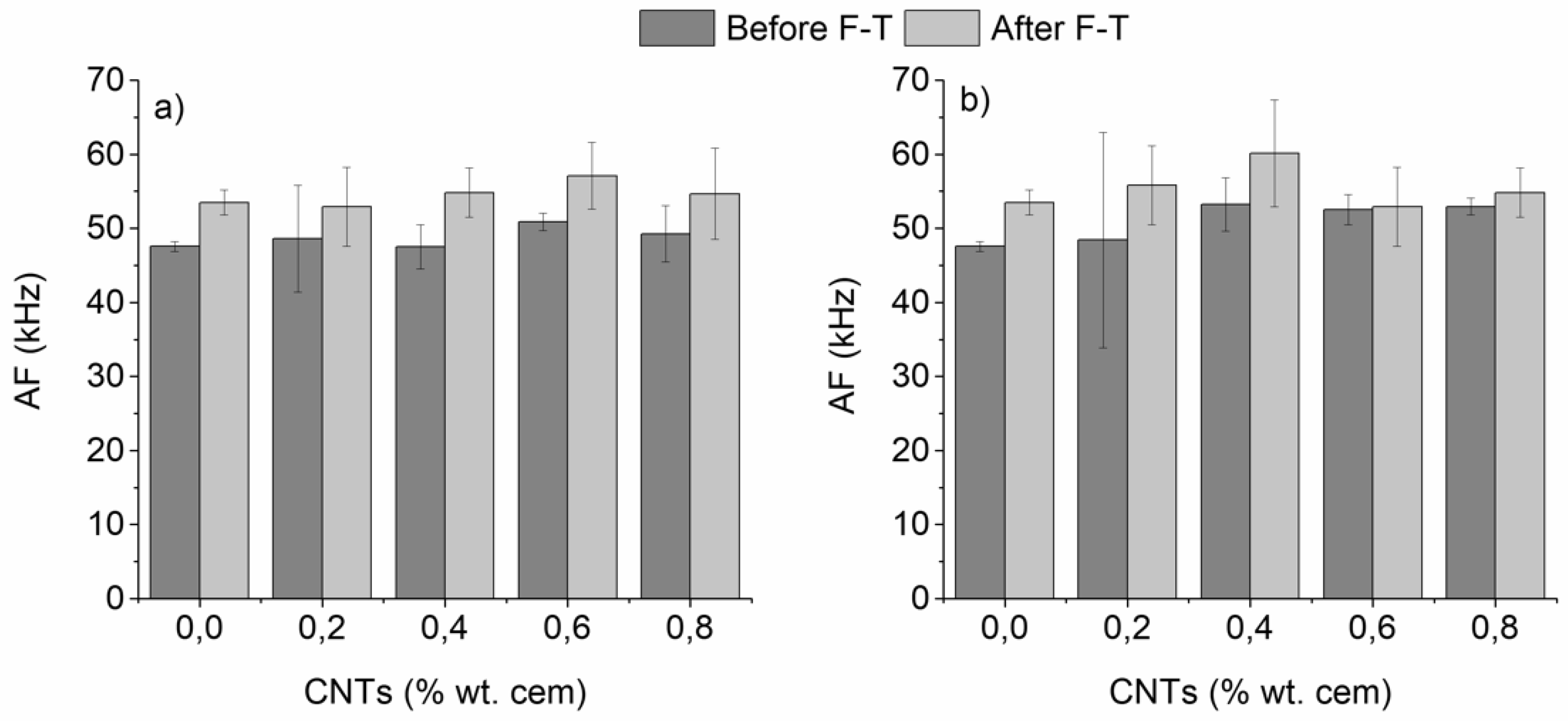

- Damage sensing activity was lower; however, it was still possible to identify a more tensile mode of fracture after F-T using critical AE indicators (RA and AF). This was more obvious in the case of nano-modified mortars with 0.4–0.6 wt.% CNTs. This fact was linked with better-dispersed nanotubes that supported pull-out/crack bridging mechanisms.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Han, B.; Wang, Y.; Dong, S.; Zhang, L.; Ding, S.; Yu, X.; Ou, J. Smart concretes and structures: A review. J. Intell. Mater. Syst. Struct. 2015, 26, 1303–1345. [Google Scholar] [CrossRef]

- Han, B.; Sun, S.; Ding, S.; Zhang, L.; Yu, X.; Ou, J. Review of nanocarbon-engineered multifunctional cementitious composites. Compos. Part A Appl. Sci. Manuf. 2015, 70, 69–81. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R. A Review on Nanomaterial Dispersion, Microstructure, and Mechanical Properties of Carbon Nanotube and Nanofiber Reinforced Cementitious Composites. J. Nanomater. 2013, 2013, 710175. [Google Scholar] [CrossRef]

- Manzur, T.; Yazdani, N.; Emon, A.B. Potential of Carbon Nanotube Reinforced Cement Composites as Concrete Repair Material. J. Nanomater. 2016, 2016, 1421959. [Google Scholar] [CrossRef]

- Chen, S.J.; Collins, F.G.; Macleod, A.J.N.; Pan, Z.; Duan, W.H.; Wang, C.M. Carbon nanotube-cement composites: A retrospect. IES J. Part A Civ. Struct. Eng. 2011, 4, 254–265. [Google Scholar] [CrossRef]

- Li, Q.; Liu, J.; Xu, S. Progress in Research on Carbon Nanotubes Reinforced Cementitious Composites. Adv. Mater. Sci. Eng. 2015, 2015, 307435. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Ou, J. Multifunctional and Smart Carbon Nanotube Reinforced Cement-Based Materials. Nanotechnol. Civ. Infrastruct. 2011, 1–47. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Pressure-sensitive properties and microstructure of carbon nanotube reinforced cement composites. Cem. Concr. Compos. 2007, 29, 377–382. [Google Scholar] [CrossRef]

- Dalla, P.T.; Dassios, K.G.; Tragazikis, I.K.; Exarchos, D.A.; Matikas, T.E. Carbon nanotubes and nanofibers as strain and damage sensors for smart cement. Mater. Today Commun 2016, 8, 2352–4928. [Google Scholar] [CrossRef]

- Abu Al-Rub, R.K.; Ashour, A.I.; Tyson, B.M. On the aspect ratio effect of multi-walled carbon nanotube reinforcements on the mechanical properties of cementitious nanocomposites. Constr. Build. Mater. 2012, 35, 647–655. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon N. Y. 2005, 43, 239–1245. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R.; Paiva, M.C. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem. Concr. Res. 2015, 73, 215–227. [Google Scholar] [CrossRef]

- Zohhadi, N.; Koohbor, B.; Matta, F.; Kidane, A. Characterization of Fracture Behavior of Multi-Walled Carbon Nanotube Reinforced Cement Paste Using Digital Image Correlation. Conf. Proc. Soc. Exp. Mech. Ser. 2015, 5, 73–79. [Google Scholar] [CrossRef]

- Sindu, B.S.; Sasmal, S. Properties of carbon nanotube reinforced cement composite synthesized using different types of surfactants. Constr. Build. Mater. 2017, 155, 389–399. [Google Scholar] [CrossRef]

- Wang, B.; Han, Y.; Liu, S. Effect of highly dispersed carbon nanotubes on the flexural toughness of cement-based composites. Constr. Build. Mater. 2013, 46, 8–12. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J.A.; Dias, A.P.S. On the mechanical and shrinkage behavior of cement mortars reinforced with carbon nanotubes. Constr. Build. Mater. 2018, 168, 459–470. [Google Scholar] [CrossRef]

- Zou, B.; Chen, S.J.; Korayem, A.H.; Collins, F.; Wang, C.M.; Duan, W.H. Effect of ultrasonication energy on engineering properties of carbon nanotube reinforced cement pastes. Carbon N. Y. 2015, 85, 212–220. [Google Scholar] [CrossRef]

- Tragazikis, I.K.; Dassios, K.G.; Exarchos, D.A.; Dalla, P.T.; Matikas, T.E. Acoustic emission investigation of the mechanical performance of carbon nanotube-modified cement-based mortars. Constr. Build. Mater. 2016, 122, 518–524. [Google Scholar] [CrossRef]

- Tragazikis, I.K.; Dassios, K.G.; Dalla, P.T.; Exarchos, D.A.; Matikas, T.E. Acoustic emission investigation of the effect of graphene on the fracture behavior of cement mortars. Eng. Fract. Mech. 2019, 210, 444–451. [Google Scholar] [CrossRef]

- Trofimov, B.Y.; Kramar, L.Y.; Schuldyakov, K.V. On Deterioration Mechanism of Concrete Exposed to Freeze-Thaw Cycles. IOP Conf. Ser. Mater. Sci. Eng. 2017, 262, 012019. [Google Scholar] [CrossRef]

- Powers, T.C. Freezing Effects in Concrete. Spec. Publ. 1975, 47, 1–12. [Google Scholar] [CrossRef]

- Zeng, Q.; Fen-Chong, T.; Dangla, P.; Li, K. A study of freezing behavior of cementitious materials by poromechanical approach. Int. J. Solids Struct. 2011, 48, 3267–3273. [Google Scholar] [CrossRef]

- Bjegovic, D.; Ukraincik, V. Theoretical Aspect and Methods of Testing Concrete Resistance to Freezing and Deicing Chemicals. Spec. Publ. 1987, 100, 947–972. [Google Scholar] [CrossRef]

- Li, W.; Pour-Ghaz, M.; Asce, M.; Castro, J.; Weiss, J. Water Absorption and Critical Degree of Saturation Relating to Freeze-Thaw Damage in Concrete Pavement Joints Background on the Problem of Joint Deterioration in Concrete Pavements. J. Mater. Civ. Eng. 2012, 24, 299–307. [Google Scholar] [CrossRef]

- Farnam, Y.; Bentz, D.; Hampton, A.; Weiss, W.J. Acoustic Emission and Low-Temperature Calorimetry Study of Freeze and Thaw Behavior in Cementitious Materials Exposed to Sodium Chloride Salt. Transp. Res. Rec. 2014, 2441, 81–90. [Google Scholar] [CrossRef]

- Nochaiya, T.; Chaipanich, A. Behavior of multi-walled carbon nanotubes on the porosity and microstructure of cement-based materials. Appl. Surf. Sci. 2011, 257, 1941–1945. [Google Scholar] [CrossRef]

- Yakovlev, G.I.; Skripkiunas, G.; Polianskich, I.S.; Lahayne, O.; Eberhardsteiner, J.; Urkhanova, L.A.; Pudova, I.A.; Sychugova, S.V.; Karpovaa, E.A.; Sen’kov, S.A. Modification of Cement Matrix Using Carbon Nanotube Dispersions and Nanosilica. Procedia Eng. 2017, 172, 1261–1269. [Google Scholar] [CrossRef]

- Han, B.; Yang, Z.; Shi, X.; Yu, X. Transport properties of carbon-nanotube/cement composites. J. Mater. Eng. Perform. 2013, 22, 184–189. [Google Scholar] [CrossRef]

- Mohammed, A.; Sanjayan, J.G.; Duan, W.H.; Nazari, A. Incorporating graphene oxide in cement composites: A study of transport properties. Constr. Build. Mater. 2015, 84, 341–347. [Google Scholar] [CrossRef]

- Du, H.; Pang, S.D. Enhancement of barrier properties of cement mortar with graphene nanoplatelet. Cem. Concr. Res. 2015, 76, 10–19. [Google Scholar] [CrossRef]

- Cwirzen, A.; Habermehl-Cwirzen, K. The Effect of Carbon Nano- and Microfibers on Strength and Residual Cumulative Strain of Mortars Subjected to Freeze-Thaw Cycles. J. Adv. Concr. Technol. 2013, 11, 80–88. [Google Scholar] [CrossRef]

- Yakovlev, G.; Pervushin, G.; Maeva, I.; Keriene, J.; Pudov, I.; Shaybadullina, A.; Buryanovc, A.; Korzhenko, A.; Senkov, S. Modification of construction materials with multi-walled carbon nanotubes. Procedia Eng. 2013, 57, 407–413. [Google Scholar] [CrossRef]

- Li, W.W.; Ji, W.M.; Wang, Y.C.; Liu, Y.; Shen, R.X.; Xing, F. Investigation on the mechanical properties of a cement-based material containing carbon nanotube under drying and freeze-thaw conditions. Materials 2015, 8, 8780–8792. [Google Scholar] [CrossRef]

- Wang, X.; Rhee, I.; Wang, Y.; Xi, Y. Compressive strength, chloride permeability, and freeze-thaw resistance of mwnt concretes under different chemical treatments. Sci. World J. 2014, 2014, 572102. [Google Scholar] [CrossRef]

- Kumar, S.; Kolay, P.; Malla, S.; Mishra, S. Effect of Multiwalled Carbon Nanotube in Cement Composite on Mechanical Strength and Freeze-Thaw Susceptibility. Adv. Civ. Eng. Mater. 2015, 4, 257–274. [Google Scholar] [CrossRef]

- Dassios, K.G.; Alafogianni, P.; Antiohos, S.K.; Leptokaridis, C.; Barkoula, N.M.; Matikas, T.E. Optimization of sonication parameters for homogeneous surfactant assisted dispersion of multiwalled carbon nanotubes in aqueous solutions. J. Phys. Chem. C 2015, 119, 7506–7516. [Google Scholar] [CrossRef]

- Alafogianni, P.; Dassios, K.; Tsakiroglou, C.D.; Matikas, T.E.; Barkoula, N.M. Effect of CNT addition and dispersive agents on the transport properties and microstructure of cement mortars. Constr. Build. Mater. 2018, 197, 251–261. [Google Scholar] [CrossRef]

- Al-Dahawi, A.; Sarwary, M.H.; Öztürk, O.; Yıldırım, G.; Akın, A.; Şahmaran, M.; Lachemi, M. Electrical percolation threshold of cementitious composites possessing self-sensing functionality incorporating different carbon-based materials. Smart Mater. Struct. 2016, 25, 105005. [Google Scholar] [CrossRef]

- Alafogianni, P.; Dassios, K.; Farmaki, S.; Antiohos, S.K.; Matikas, T.E.; Barkoula, N.M. On the efficiency of UV-vis spectroscopy in assessing the dispersion quality in sonicated aqueous suspensions of carbon nanotubes. Colloids Surf. A Physicochem. Eng. Asp. 2016, 495, 118–124. [Google Scholar] [CrossRef]

- American Society for Testing Materials. Committee C-9 on Concrete and Concrete Aggregates. In Standard Test Method Foe Resistance of Concrete to Rapid Freezing and Thawing; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- BS EN 196-1:2005. Methods Of Testing Cement—Part 1: Determination of Strength; British Standards Institution: London, UK, 2013. [Google Scholar]

- Matikas, T.E. Towards the Next Generation of Standards for Service Life of Cement-Based Materials and Structures; COST Action-TU1404; COST Association: Brussels, Belgium, 2016. [Google Scholar]

- Huang, H.; Qian, C.; Zhao, F.; Qu, J.; Guo, J.; Danzinger, M. Improvement on microstructure of concrete by polycarboxylate superplasticizer (PCE) and its influence on durability of concrete. Constr. Build. Mater. 2016, 110, 293–299. [Google Scholar] [CrossRef]

- Zhang, Y.; Kong, X. Influences of superplasticizer, polymer latexes and asphalt emulsions on the pore structure and impermeability of hardened cementitious materials. Constr. Build. Mater. 2014, 53, 392–402. [Google Scholar] [CrossRef]

- Shao, H.; Chen, B.; Li, B.; Tang, S.; Li, Z. Influence of dispersants on the properties of CNTs reinforced cement-based materials. Constr. Build. Mater. 2017, 131, 186–194. [Google Scholar] [CrossRef]

- Sobolkina, A.; Mechtcherine, V.; Khavrus, V.; Maier, D.; Mende, M.; Ritschel, M.; Leonhardt, A. Dispersion of carbon nanotubes and its influence on the mechanical properties of the cement matrix. Cem. Concr. Compos. 2012, 34, 1104–1113. [Google Scholar] [CrossRef]

- Ouyang, X.; Guo, Y.; Qiu, X. The feasibility of synthetic surfactant as an air entraining agent for the cement matrix. Constr. Build. Mater. 2008, 22, 1774–1779. [Google Scholar] [CrossRef]

- Tong, T.; Fan, Z.; Liu, Q.; Wang, S.; Tan, S.; Yu, Q. Investigation of the effects of graphene and graphene oxide nanoplatelets on the micro- and macro-properties of cementitious materials. Constr. Build. Mater. 2016, 106, 102–114. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Mpalaskas, A.C.; Matikas, T.E. Investigation of different fracture modes in cement-based materials by acoustic emission. Cem. Concr. Res. 2013, 48, 1–8. [Google Scholar] [CrossRef]

- Soulioti, D.; Barkoula, N.M.; Paipetis, A.; Matikas, T.E.; Shiotani, T.; Aggelis, D.G. Acoustic emission behavior of steel fibre reinforced concrete under bending. Constr. Build. Mater. 2009, 23, 3532–3536. [Google Scholar] [CrossRef]

- Ohtsu, M.; Shiotani, T.; Shigeishi, M.; Kamada, T.; Yuyama, S.; Watanabe, T.; Grosse, C.; Helmerich, R.; Forde, M.C.; Moczko, A.; et al. Recommendation of RILEM TC 212-ACD: Acoustic emission and related NDE techniques for crack detection and damage evaluation in concrete: Measurement method for acoustic emission signals in concrete. Mater. Struct. 2010, 43, 1187–1189. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alafogianni, P.; Tragazikis, I.; Balaskas, A.; Barkoula, N.-M. Structural Properties and Damage Detection Capability of Carbon Nanotube Modified Mortars after Freeze-Thaw. Materials 2019, 12, 1747. https://doi.org/10.3390/ma12111747

Alafogianni P, Tragazikis I, Balaskas A, Barkoula N-M. Structural Properties and Damage Detection Capability of Carbon Nanotube Modified Mortars after Freeze-Thaw. Materials. 2019; 12(11):1747. https://doi.org/10.3390/ma12111747

Chicago/Turabian StyleAlafogianni, Panagiota, Ilias Tragazikis, Anastasios Balaskas, and Nektaria-Marianthi Barkoula. 2019. "Structural Properties and Damage Detection Capability of Carbon Nanotube Modified Mortars after Freeze-Thaw" Materials 12, no. 11: 1747. https://doi.org/10.3390/ma12111747

APA StyleAlafogianni, P., Tragazikis, I., Balaskas, A., & Barkoula, N.-M. (2019). Structural Properties and Damage Detection Capability of Carbon Nanotube Modified Mortars after Freeze-Thaw. Materials, 12(11), 1747. https://doi.org/10.3390/ma12111747