Microstructure and Selective Corrosion of Alloy 625 Obtained by Means of Laser Powder Bed Fusion

Abstract

1. Introduction

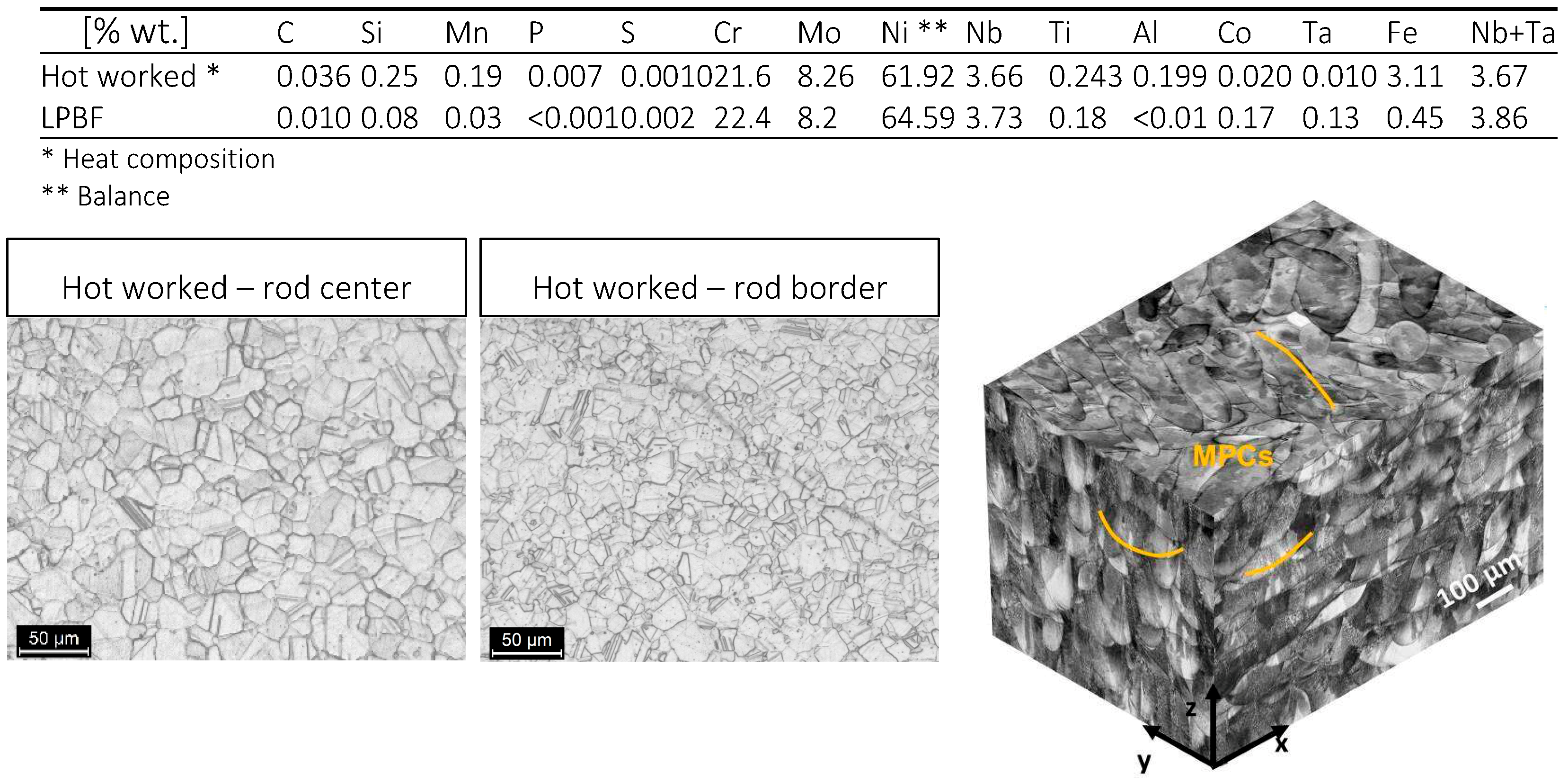

2. Materials and Methods

2.1. Specimens

2.2. Corrosion Tests

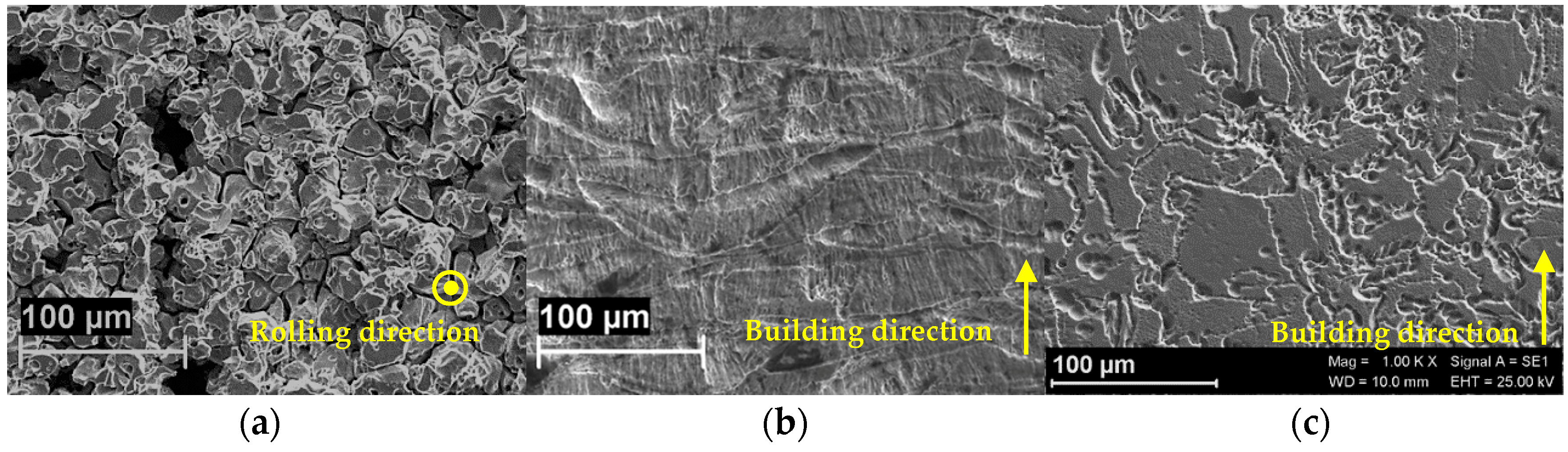

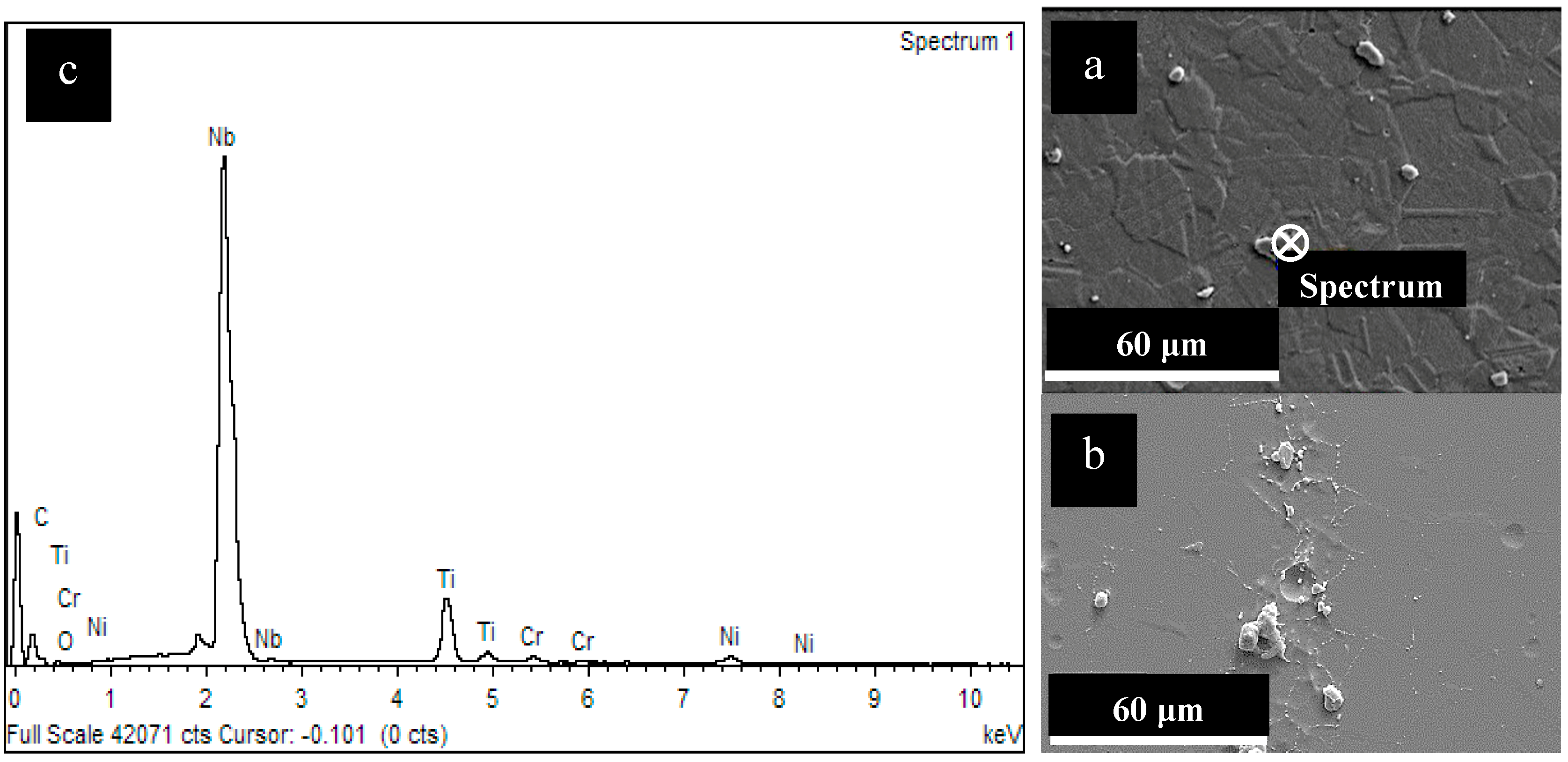

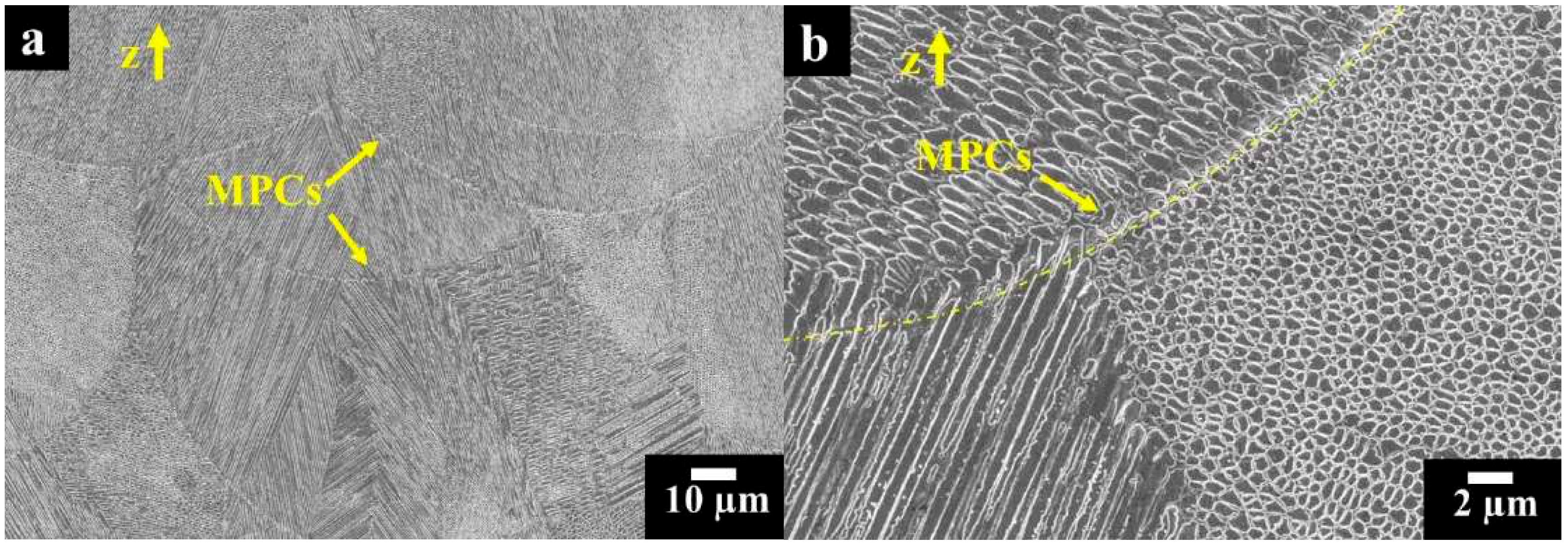

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Eiselstein, H.; Tillack, D. The Invention and Definition of Alloy 625. Superalloys 1991. [Google Scholar] [CrossRef]

- Radavich, J.F.; Fort, A. Effects of Long Time Exposure in Alloy 625 at 1200°F, 1400°F and 1600°F. Superalloys 1994, 718, 635–647. [Google Scholar]

- Rai, S.K.; Kumar, A.; Shankar, V.; Jayakumar, T.; Rao, K.B.S.; Raj, B. Characterization of microstructures in Inconel 625 using X-ray diffraction peak broadening and lattice parameter measurements. Scr. Mater. 2004, 51, 59–63. [Google Scholar] [CrossRef]

- Kolts, J.; Wu, J.B.C.; Manning, P.E.; Asphahani, A.I. Highly Alloyed Austenitic Material for Corrosion Resistance. Corros. Rev. 1986, 6, 279–326. [Google Scholar]

- Metals Handbook, 9th ed.; ASM International: Metals Park, Geauga, OH, USA, 1987.

- Shankar, V.; Bhanu Sankara Rao, K.; Mannan, S. Microstructure and mechanical properties of Inconel 625 superalloy. J. Nucl. Mater. 2001, 288, 222–232. [Google Scholar] [CrossRef]

- Harris, J.A.; Scarberry, R.C. Effect of metallurgical reactions in INCONEL nickel-chromium-molybdenum alloy 625 on corrosion resistance in nitric acid. JOM 1971, 23, 45–49. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Amato, K.N.; Gaytan, S.M.; Hernandez, J.; Ramirez, D.A.; Shindo, P.W.; Medina, F.; Wicker, R.B. Fabrication of metal and alloy components by additive manufacturing: Examples of 3D materials science. J. Mater. Res. Technol. 2012, 1, 42–54. [Google Scholar] [CrossRef]

- Dinda, G.P.; Dasgupta, A.K.; Mazumder, J. Laser aided direct metal deposition of Inconel 625 superalloy: Microstructural evolution and thermal stability. Mater. Sci. Eng. A 2009, 509, 98–104. [Google Scholar] [CrossRef]

- Paul, C.P.; Ganesh, P.; Mishra, S.K.; Bhargava, P.; Negi, J.; Nath, A.K. Investigating laser rapid manufacturing for Inconel-625 components. Opt. Laser Technol. 2007, 39, 800–805. [Google Scholar] [CrossRef]

- Witkin, D.B.; Adams, P.; Albright, T. Microstructural evolution and mechanical behavior of nickel-based superalloy 625 made by selective laser melting. In Proceedings of the SPIE, San Francisco, CA, USA, 16 March 2015. [Google Scholar]

- Yadroitsev, I.; Gusarov, A.; Yadroitsava, I.; Smurov, I. Single track formation in selective laser melting of metal powders. J. Mater. Process. Technol. 2010, 210, 1624–1631. [Google Scholar] [CrossRef]

- Keller, T.; Lindwall, G.; Ghosh, S.; Ma, L.; Lane, B.M.; Zhang, F.; Kattner, U.R.; Lass, E.A.; Heigel, J.C.; Idell, Y.; Williams, M.E.; Allen, A.J.; Guyer, J.E.; Levine, L.E. Application of finite element, phase-field, and CALPHAD-based methods to additive manufacturing of Ni-based superalloys. Acta Mater. 2017, 139, 244–253. [Google Scholar] [CrossRef]

- Marchese, G.; Garmendia Colera, X.; Calignano, F.; Lorusso, M.; Biamino, S.; Minetola, P.; Manfredi, D. Characterization and Comparison of Inconel 625 Processed by Selective Laser Melting and Laser Metal Deposition. Adv. Eng. Mater. 2017, 19, 1600635. [Google Scholar] [CrossRef]

- Suave, L.M.; Cormier, J.; Villechaise, P.; Soula, A.; Hervier, Z.; Bertheau, D.; Laigo, J. Microstructural evolutions during thermal aging of alloy 625: Impact of temperature and forming process. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2014, 45, 2963–2982. [Google Scholar] [CrossRef]

- Petrzak, P.; Kowalski, K.; Blicharski, M. Analysis of phase transformations in Inconel 625 alloy during annealing. Acta Phys. Pol. A 2016, 130, 1043–1044. [Google Scholar] [CrossRef]

- Dupont, J.N.; Robino, C.V.; Marder, A.R.; Notis, M.R. Solidification of Nb-bearing superalloys: Part II. Pseudoternary solidification surfaces. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 1998, 29, 2797–2806. [Google Scholar] [CrossRef]

- Xu, F.; Lv, Y.; Liu, Y.; Xu, B.; He, P. Effect of heat treatment on microstructure and mechanical properties of Inconel 625 alloy fabricated by pulsed plasma arc deposition. Phys. Procedia 2013, 50, 48–54. [Google Scholar] [CrossRef]

- Li, S.; Wei, Q.; Shi, Y.; Zhu, Z.; Zhang, D. Microstructure Characteristics of Inconel 625 Superalloy Manufactured by Selective Laser Melting. J. Mater. Sci. Technol. 2015, 31, 946–952. [Google Scholar] [CrossRef]

- Dai, N.; Zhang, L.-C.; Zhang, J.; Chen, Q.; Wu, M. Corrosion behavior of selective laser melted Ti-6Al-4V alloy in NaCl solution. Corros. Sci. 2016, 102, 484–489. [Google Scholar] [CrossRef]

- Yang, J.; Yang, H.; Yu, H.; Wang, Z.; Zeng, X. Corrosion Behavior of Additive Manufactured Ti-6Al-4V Alloy in NaCl Solution. Metall. Mater. Trans. A 2017, 48, 3583–3593. [Google Scholar] [CrossRef]

- Liu, L.; He, M.; Xu, X.; Zhao, C.; Gan, Y.; Lin, J.; Luo, J.; Lin, J. Preliminary study on the corrosion resistance, antibacterial activity and cytotoxicity of selective-laser-melted Ti6Al4V-xCu alloys. Mater. Sci. Eng. C 2017, 72, 631–640. [Google Scholar] [CrossRef]

- Ziętala, M.; Durejko, T.; Polański, M.; Kunce, I.; Płociński, T.; Zieliński, W.; Łazińska, M.; Stępniowski, W.; Czujko, T.; Kurzydłowski, K.J.; et al. The microstructure, mechanical properties and corrosion resistance of 316 L stainless steel fabricated using laser engineered net shaping. Mater. Sci. Eng. A 2016, 677, 1–10. [Google Scholar] [CrossRef]

- Trelewicz, J.R.; Halada, G.P.; Donaldson, O.K.; Manogharan, G. Microstructure and Corrosion Resistance of Laser Additively Manufactured 316L Stainless Steel. JOM 2016, 68, 850–859. [Google Scholar] [CrossRef]

- Sander, G.; Thomas, S.; Cruz, V.; Jurg, M.; Birbilis, N.; Gao, X.; Brameld, M.; Hutchinson, C.R. On The Corrosion and Metastable Pitting Characteristics of 316L Stainless Steel Produced by Selective Laser Melting. J. Electrochem. Soc. 2017, 164, C250–C257. [Google Scholar] [CrossRef]

- Schmidt, D.P.; Jelis, E.; Clemente, M.P.; Ravindra, N.M. Corrosion of 3D Printed Steel. Available online: https://www.researchgate.net/publication/283346384_CORROSION_OF_3D_PRINTED_STEEL (accessed on 28 May 2019).

- Tuna, S.H.; Özçiçek Pekmez, N.; Kürkçüoğlu, I. Corrosion resistance assessment of Co-Cr alloy frameworks fabricated by CAD/CAM milling, laser sintering, and casting methods. J. Prosthet. Dent. 2015, 114, 725–734. [Google Scholar] [CrossRef]

- Puskar, T.; Jevremovic, D.; Williams, R.J.; Eggbeer, D.; Vukelic, D.; Budak, I. A comparative analysis of the corrosive effect of artificial saliva of variable pH on DMLS and cast Co-Cr-Mo dental alloy. Materials 2014, 7, 6486–6501. [Google Scholar] [CrossRef]

- Cabrini, M.; Lorenzi, S.; Pastore, T.; Pellegrini, S.; Ambrosio, E.P.; Calignano, F.; Manfredi, D.; Pavese, M.; Fino, P. Effect of heat treatment on corrosion resistance of DMLS AlSi10Mg alloy. Electrochim. Acta 2016, 206, 346–355. [Google Scholar] [CrossRef]

- Cabrini, M.; Lorenzi, S.; Pastore, T.; Pellegrini, S.; Testa, C.; Manfredi, D.; Calignano, F.; Fino, P.; Cattano, G. Evaluation of corrosion resistance of aluminum silicon alloys manufactured by LPBF | Valutazione della resistenza a corrosione di leghe di alluminio-silicio ottenute per LPBF. Metall. Ital. 2017, 109, 123–126. [Google Scholar]

- Cabrini, M.; Lorenzi, S.; Pastore, T.; Testa, C.; Manfredi, D.; Lorusso, M.; Calignano, F.; Pavese, M.; Andreatta, F. Corrosion behavior of AlSi10Mg alloy produced by laser powder bed fusion under chloride exposure. Corros. Sci. 2019, 152, 101–108. [Google Scholar] [CrossRef]

- Cabrini, M.; Calignano, F.; Fino, P.; Lorenzi, S.; Lorusso, M.; Manfredi, D.; Testa, C.; Pastore, T. Corrosion Behavior of Heat-Treated AlSi10Mg Manufactured by Laser Powder Bed Fusion. Materials 2018, 11, 1051. [Google Scholar] [CrossRef]

- Cabrini, M.; Lorenzi, S.; Pastore, T.; Testa, C.; Manfredi, D.; Cattano, G.; Calignano, F. Corrosion resistance in chloride solution of the AlSi10Mg alloy obtained by means of LPBF. Surf. Interface Anal. 2016, 48, 818–826. [Google Scholar] [CrossRef]

- Cabrini, M.; Lorenzi, S.; Testa, C.; Pastore, T.; Manfredi, D.; Lorusso, M.; Calignano, F.; Fino, P. Statistical approach for electrochemical evaluation of the effect of heat treatments on the corrosion resistance of AlSi10Mg alloy by laser powder bed fusion. Electrochim. Acta 2019, 305, 459–466. [Google Scholar] [CrossRef]

- Marchese, G.; Lorusso, M.; Calignano, F.; Ambrosio, E.P.; Manfredi, D.; Pavese, M.; Biamino, S.; Ugues, D.; Fino, P. Inconel 625 by direct metal laser sintering: Effects of the process parameters and heat treatments on microstructure and hardness. In Proceedings of the 13th International Symposium of Superalloys, Seven Springs, PA, USA, 11–15 September 2016. [Google Scholar]

- Kim, J.S.; Lee, H.W. A study on effect of intergranular corrosion by heat input on Inconel 625 overlay weld metal. Int. J. Electrochem. Sci. 2015, 10, 6454–6464. [Google Scholar]

- Corrieu, J.; Vernot-Loier, C.; Cortial, F. Influence of Heat Treatments on Corrosion Behavior of Alloy 625 Forged Rod. Superalloys 1994. [Google Scholar] [CrossRef]

- Cortial, F.; Corrieu, J.M; Vernot-Loier, C. Influence of heat treatments on microstructure, mechanical properties, and corrosion resistance of weld alloy 625. Metall. Mater. Trans. A 1995, 26, 1273–1286. [Google Scholar] [CrossRef]

- Tawancy, H.M.; Allam, I.M.; Abbas, N.M. Effect of Ni3Nb precipitation on the corrosion resistance of Inconel alloy 625. J. Mater. Sci. Lett. 1990, 9, 343–347. [Google Scholar] [CrossRef]

- Manfredi, D.; Calignano, F.; Krishnan, M.; Canali, R.; Ambrosio, E.P.; Atzeni, E. From powders to dense metal parts: Characterization of a commercial AlSi10Mg alloy processed through direct metal laser sintering. Materials 2013, 6, 856–869. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Turenne, S. Elevated temperature mechanical behavior of IN625 alloy processed by laser powder-bed fusion. Mater. Sci. Eng. A 2017, 700, 540–553. [Google Scholar] [CrossRef]

- Antonsson, T.; Fredriksson, H. The effect of cooling rate on the solidification of INCONEL 718. Metall. Mater. Trans. B-Process Metall. Mater. Process. Sci. 2005, 36, 85–96. [Google Scholar] [CrossRef]

- Marchese, G.; Lorusso, M.; Parizia, S.; Bassini, E.; Lee, J.W.; Calignano, F.; Manfredi, D.; Terner, M.; Hong, H.U.; Ugues, D.; Lombardi, M.; Biamino, S. Influence of heat treatments on microstructure evolution and mechanical properties of Inconel 625 processed by laser powder bed fusion. Mater. Sci. Eng. A 2018, 729, 64–95. [Google Scholar] [CrossRef]

- Harrison, N.J.; Todd, I.; Mumtaz, K. Reduction of micro-cracking in nickel superalloys processed by Selective Laser Melting: A fundamental alloy design approach. Acta Mater. 2015, 94, 59–68. [Google Scholar] [CrossRef]

- Tobergte, D.R.; Curtis, S. Modeling and Experimental validation of Nickel-based super alloy (Inconel 625) made using Selective Laser Melting. Solid Free. Fabr. 2013. [Google Scholar] [CrossRef]

- Anam, M.A.; Dilip, J.J.S.; Pal, D.; Stucker, B. Effect of scan pattern on the microstructural evolution of Inconel 625 during selective laser melting. In Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014. [Google Scholar]

- Floreen, S.; Fuchs, G.E.; Yang, W.J. The Metallurgy of Alloy 625. In Superalloys 718, 625, 706 and Various Derivatives; Minerals, Metals and Materials Society: Pittsburgh, PA, USA, 1994; pp. 13–39. [Google Scholar]

| Metallurgical Condition | Specimens | Exposed Surface [cm2] | Initial Mass * [g] | Final Mass * [g] | Mass Variation [g] | Corrosion Rate [mdd] |

|---|---|---|---|---|---|---|

| Hot worked bar/Grade 1 annealing | HW1 | 6.05 | 6.73923 | 6.63074 | 0.10849 | 359 |

| HW2 | 6.13 | 7.16643 | 7.06459 | 0.10184 | 332 | |

| LPBF as built | LPBF NHT1 | 13.50 | 28.23744 | 28.12392 | 0.11352 | 168.2 |

| LPBF NHT2 | 13.35 | 27.03907 | 26.92816 | 0.11091 | 166.2 | |

| LPBF/Grade 1 annealing | LPBF HT1 | 13.06 | 28.24230 | 28.16770 | 0.0746 | 114.2 |

| LPBF HT2 | 13.12 | 28.34171 | 28.26959 | 0.07212 | 109.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cabrini, M.; Lorenzi, S.; Testa, C.; Brevi, F.; Biamino, S.; Fino, P.; Manfredi, D.; Marchese, G.; Calignano, F.; Pastore, T. Microstructure and Selective Corrosion of Alloy 625 Obtained by Means of Laser Powder Bed Fusion. Materials 2019, 12, 1742. https://doi.org/10.3390/ma12111742

Cabrini M, Lorenzi S, Testa C, Brevi F, Biamino S, Fino P, Manfredi D, Marchese G, Calignano F, Pastore T. Microstructure and Selective Corrosion of Alloy 625 Obtained by Means of Laser Powder Bed Fusion. Materials. 2019; 12(11):1742. https://doi.org/10.3390/ma12111742

Chicago/Turabian StyleCabrini, Marina, Sergio Lorenzi, Cristian Testa, Fabio Brevi, Sara Biamino, Paolo Fino, Diego Manfredi, Giulio Marchese, Flaviana Calignano, and Tommaso Pastore. 2019. "Microstructure and Selective Corrosion of Alloy 625 Obtained by Means of Laser Powder Bed Fusion" Materials 12, no. 11: 1742. https://doi.org/10.3390/ma12111742

APA StyleCabrini, M., Lorenzi, S., Testa, C., Brevi, F., Biamino, S., Fino, P., Manfredi, D., Marchese, G., Calignano, F., & Pastore, T. (2019). Microstructure and Selective Corrosion of Alloy 625 Obtained by Means of Laser Powder Bed Fusion. Materials, 12(11), 1742. https://doi.org/10.3390/ma12111742