Improving the Thermoelectric Properties of the Half-Heusler Compound VCoSb by Vanadium Vacancy

Abstract

1. Introduction

2. Experimental Details

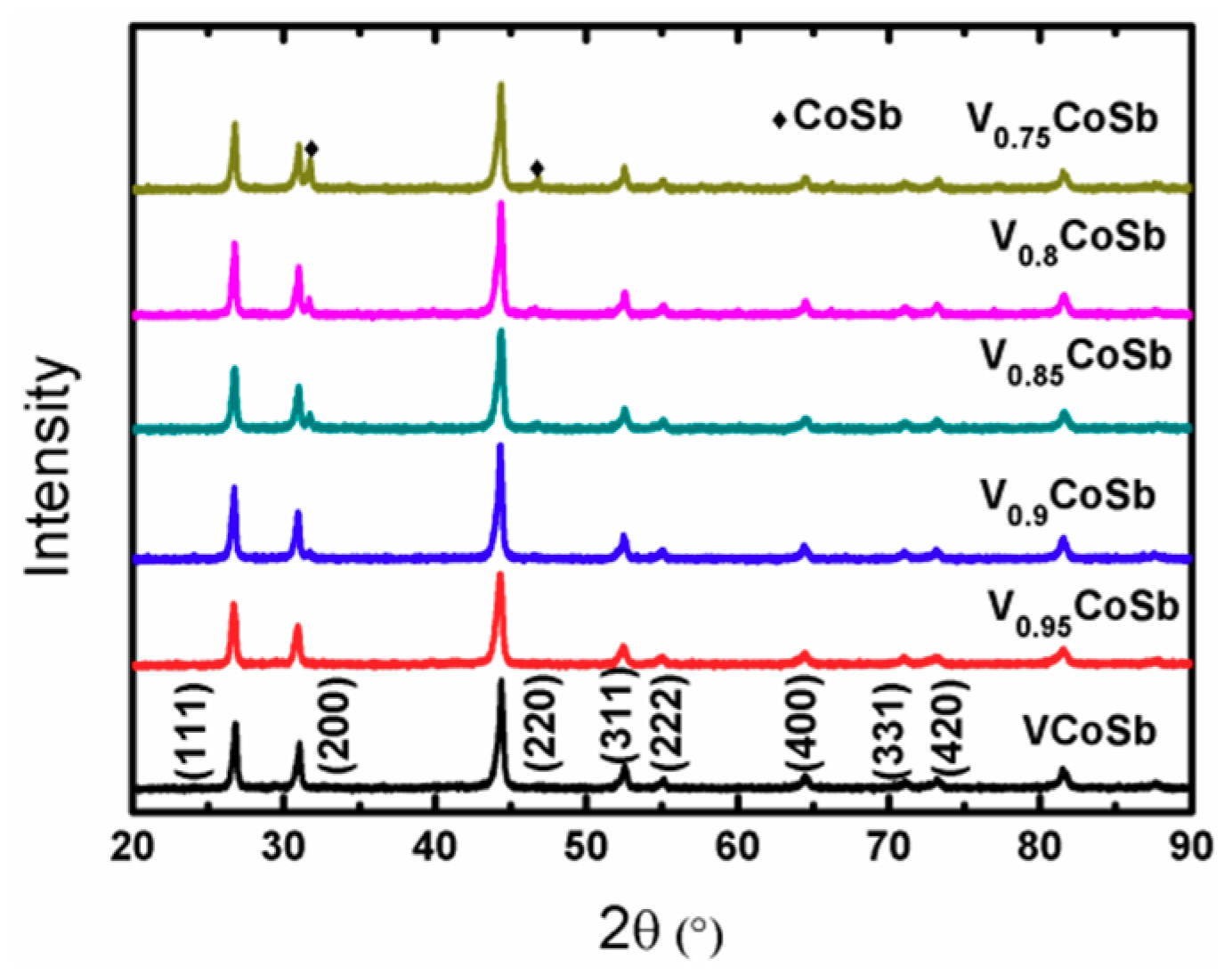

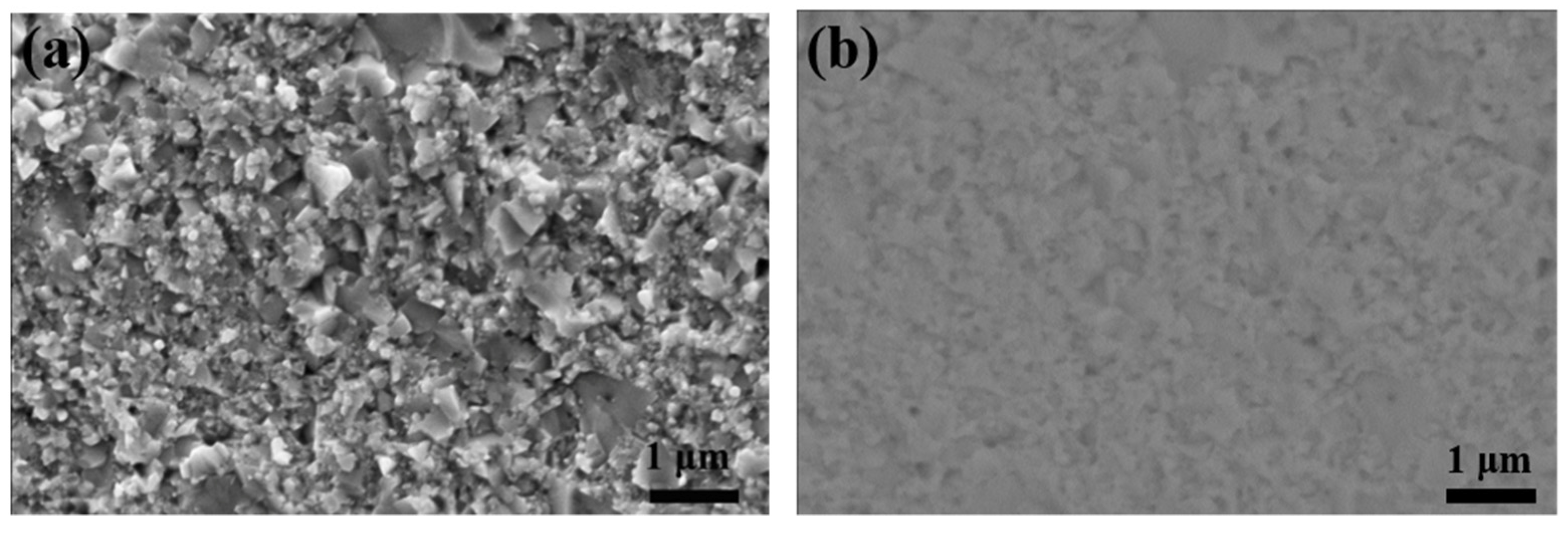

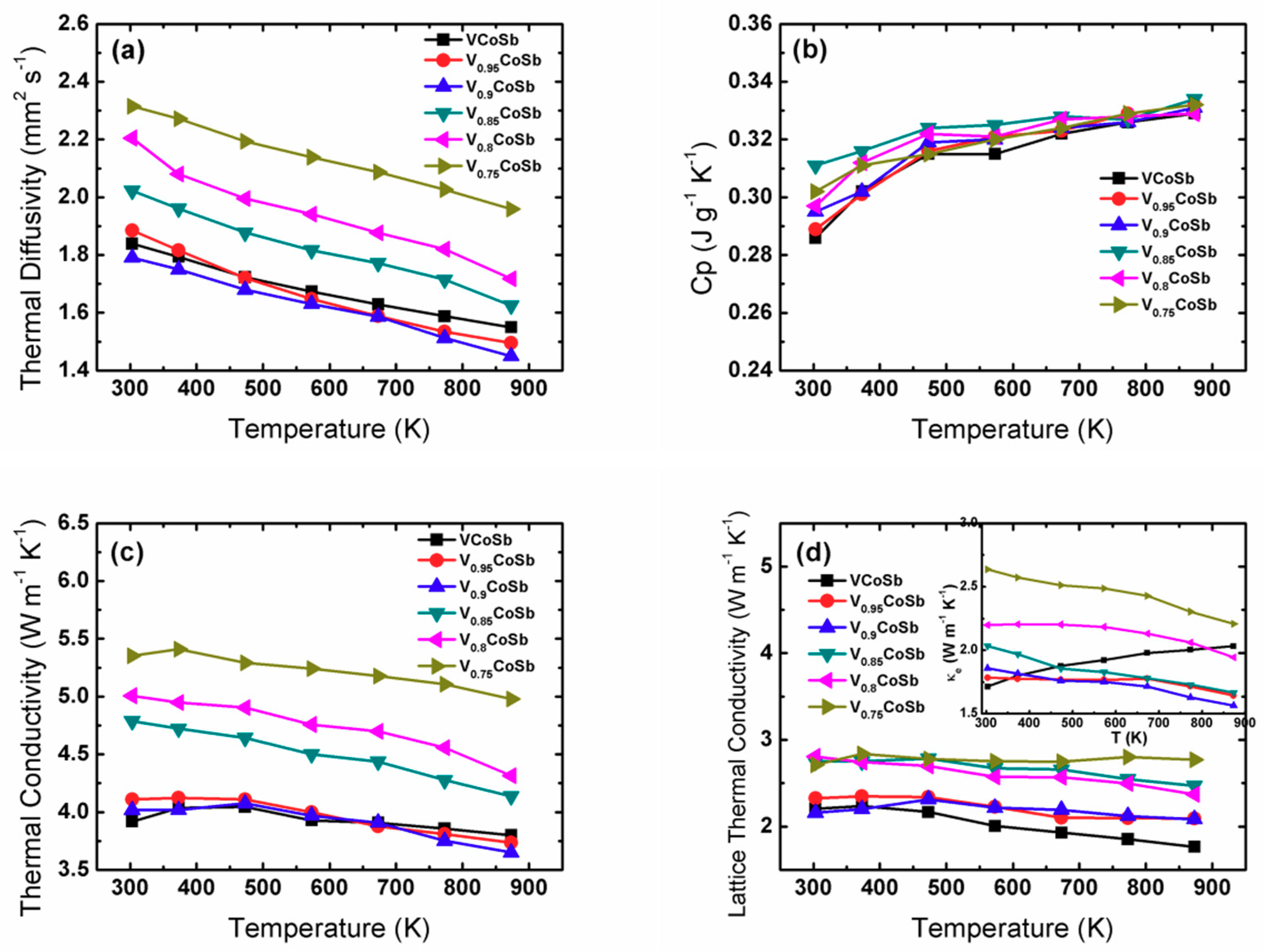

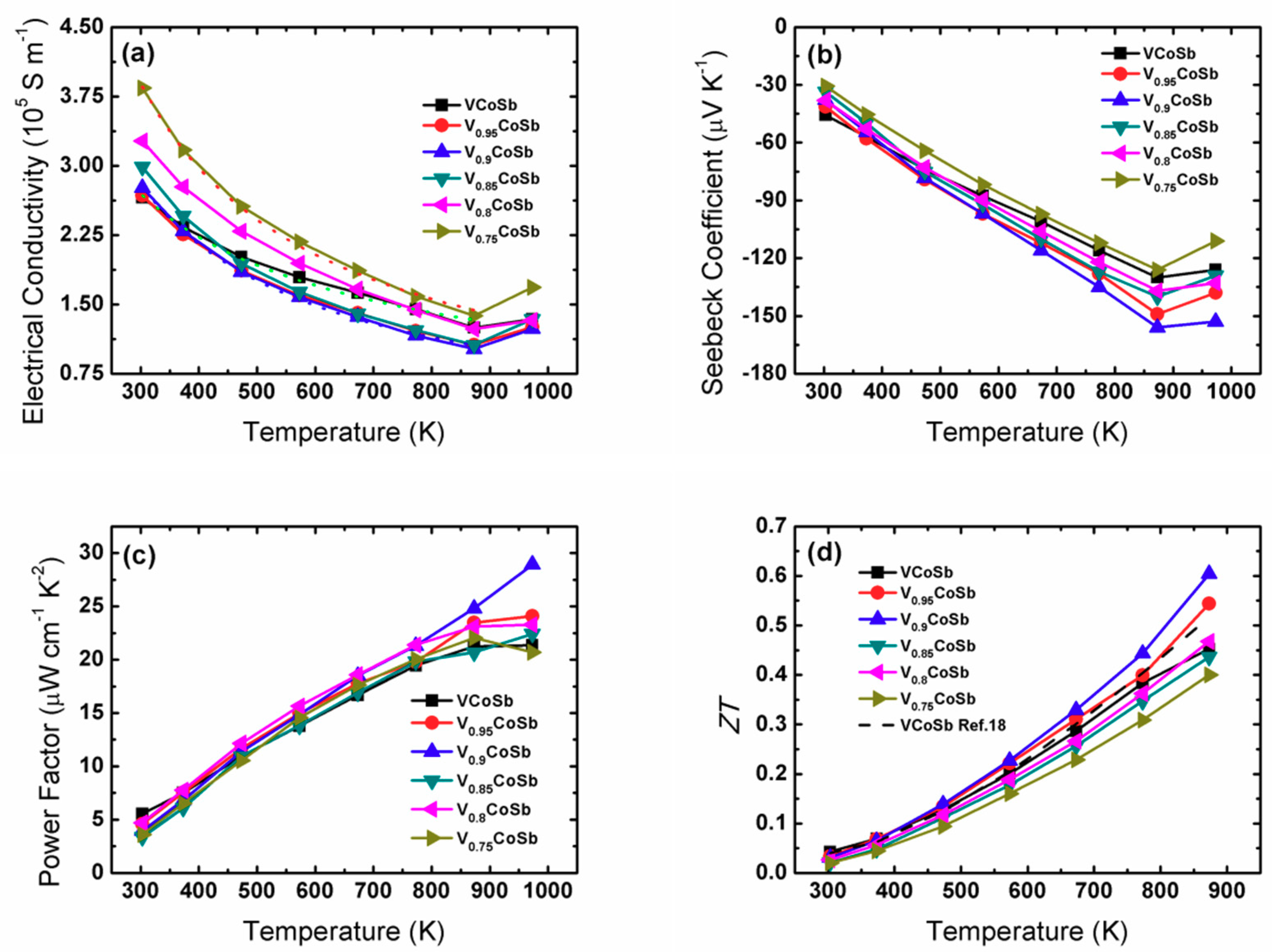

3. Results and Discussion

4. Conclusion

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Su, X.L.; Hao, S.Q.; Bailey, T.P.; Wang, S.; Hadar, I.; Tan, G.J.; Song, T.B.; Zhang, Q.J.; Uher, C.; Wolverton, C.; et al. Weak electron phonon coupling and deep level impurity for high thermoelectric performance Pb1−xGaxTe. Adv. Energy Mater. 2018, 8, 1800659. [Google Scholar] [CrossRef]

- Tan, G.J.; Zeier, W.G.; Shi, F.Y.; Wang, P.L.; Snyder, G.J.; Dravid, V.P.; Kanatzidis, M.G. High thermoelectric performance SnTe-In2Te3 solid solutions enabled by resonant levels and strong vacancy phonon scattering. Chem. Mater. 2015, 27, 7801–7811. [Google Scholar] [CrossRef]

- Liu, W.; Tan, X.J.; Yin, K.; Liu, H.J.; Tang, X.F.; Shi, J.; Zhang, Q.J.; Uher, C. Convergence of conduction bands as a means of enhancing thermoelectric performance of n-type Mg2Si1−xSnx solid solutions. Phys. Rev. Lett. 2012, 108, 166601. [Google Scholar] [CrossRef]

- Pei, Y.Z.; LaLonde, A.D.; Wang, H.; Snyder, J.G. Low effective mass leading to high thermoelectric performance. Energy Environ. Sci. 2012, 5, 7963–7969. [Google Scholar] [CrossRef]

- Shuai, J.; Mao, J.; Song, S.W.; Zhu, Q.; Sun, J.F.; Wang, Y.M.; He, R.; Zhou, J.W.; Chen, G.; Singh, D.J.; et al. Tuning the carrier scattering mechanism to effectively improve the thermoelectric properties. Energy Environ. Sci. 2017, 10, 799–807. [Google Scholar] [CrossRef]

- Yu, J.J.; Fu, C.G.; Liu, Y.T.; Xia, K.Y.; Aydemir, U.; Chasapis, T.C.; Snyder, G.J.; Zhao, X.B.; Zhu, T.J. Unique role of refractory Ta alloying in enhancing the figure of merit of NbFeSb thermoelectric materials. Adv. Energy Mater. 2017, 1701313, 1–8. [Google Scholar] [CrossRef]

- Chai, Y.W.; Oniki, T.; Kenjo, T.; Kimura, Y. The effect of an isoelectronic Ti-Zr substitution on Heusler nanoprecipitation and the thermoelectric properties of a (Ti0.2,Zr0.8)Ni1.1Sn half-Heusler alloy. J. Alloy Compd. 2016, 662, 566–577. [Google Scholar] [CrossRef]

- Zhao, L.D.; Lo, S.H.; Zhang, Y.S.; Sun, H.; Tan, G.J.; Uher, C.; Wolverton, C.; Dravid, V.P.; Kanatzidis, M.G. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature 2014, 508, 373–377. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Parker, D.; Singh, D.J. Importance of non-parabolic band effects in the thermoelectric properties of semiconductors. Sci. Rep. 2013, 3, 3168. [Google Scholar] [CrossRef]

- Zhu, T.J.; Fu, C.G.; Liu, X.H.; Liu, Y.T.; Zhao, X.B. High efficiency half-Heusler thermoelectric materials for energy harvesting. Adv. Energy Mater. 2015, 5, 1500588. [Google Scholar] [CrossRef]

- Rausch, E.; Balke, B.; Stahlhofen, J.M.; Ouardi, S.; Burkhardt, U.; Felser, C. Fine tuning of thermoelectric performance in phase-separated half-Heusler compounds. J. Mater. Chem. C 2015, 3, 10409–10414. [Google Scholar] [CrossRef]

- Zhu, T.J.; Liu, Y.T.; Fu, C.G.; Heremans, J.P.; Snyder, J.G.; Zhao, X.B. Compromise and synergy in high-efficiency thermoelectric materials. Adv. Mater. 2017, 1605884, 1–26. [Google Scholar]

- Zhang, H.; Wang, Y.M.; Dahal, K.; Mao, J.; Huang, L.H.; Zhang, Q.Y.; Ren, Z.F. Thermoelectric properties of n-type half-Heusler compounds (Hf0.25Zr0.75)1−xNbxNiSn. Acta Mater. 2016, 113, 41–47. [Google Scholar] [CrossRef]

- He, R.; Huang, L.H.; Wang, Y.M.; Samsonidze, G.; Kozinsky, B.; Zhang, Q.Y.; Ren, Z.F. Enhanced thermoelectric properties of n-type NbCoSn half-Heusler by improving phase purity. Appl. Mater. 2016, 4, 104804. [Google Scholar] [CrossRef]

- Fu, C.G.; Zhu, T.J.; Liu, Y.T.; Xie, H.H.; Zhao, X.B. Band engineering of high performance p-type FeNbSb based half-Heusler thermoelectric materials for figure of merit ZT > 1. Energy Environ. Sci. 2015, 8, 216–220. [Google Scholar] [CrossRef]

- Liu, W.S.; Kim, H.S.; Chen, S.; Jie, Q.; Lv, B.; Yao, M.L.; Ren, Z.S.; Opeil, C.P.; Wilson, S.; Chu, C.W.; et al. N-type thermoelectric material Mg2Sn0.75Ge0.25 for high power generation. PNAS 2015, 112, 3269. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Liu, Y.M.; He, J.; Tritt, T.M.; Poon, S.J. High thermoelectric figure of merit by resonant dopant in half-Heusler alloys. AIP Adv. 2017, 7, 065208. [Google Scholar] [CrossRef]

- Silpawilawan, W.; Kurosaki, K.; Ohishi, Y.; Muta, H.; Yamanaka, S. FeNbSb p-type half-Heusler compound: Beneficial thermomechanical properties and high-temperature stability for thermoelectrics. J. Mater. Chem. C 2017, 5, 6677–6681. [Google Scholar] [CrossRef]

- Fu, C.G.; Bai, S.Q.; Liu, Y.T.; Tang, Y.S.; Chen, L.D.; Zhao, X.B.; Zhu, T.J. Realizing high figure of merit in heavy-band p-type half-Heusler thermoelectric materials. Nat. Commun. 2015, 6, 8144–8150. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.G.; Zuo, M.; Bo, L.; Wang, Y.P. Synthesis and thermoelectric properties of Pb-Doped ZrCoBi Half-heusler compounds. Materials 2018, 11, 728. [Google Scholar] [CrossRef]

- Yan, Y.G.; Geng, W.Q.; Qiu, J.H.; Ke, H.Q.; Luo, C.; Yang, J.H.; Uher, C.; Tang, X.F. Thermoelectric properties of n-type ZrNiSn prepared by rapid non-equilibrium laser processing. RSC Adv. 2018, 8, 15796–15803. [Google Scholar] [CrossRef]

- Dow, H.; Kim, W.; Shin, W.G. Effect of C and N addition on thermoelectric properties of TiNiSn half-Heusler compounds. Materials 2018, 11, 262. [Google Scholar] [CrossRef]

- Huang, L.H.; He, R.; Chen, S.; Zhang, H.; Dahal, K.S.; Zhou, H.Q.; Wang, H.; Zhang, Q.Y.; Ren, Z.F. A new n-type half-Heusler thermoelectric material NbCoSb. Mater. Res. Bull. 2015, 70, 773–778. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Huang, L.; Chen, S.; Dahal, H.; Wang, D.; Ren, Z. Synthesis and thermoelectric properties of n-type half-Heusler compound VCoSb with valence electron count of 19. J. Alloy Compd. 2016, 654, 321–326. [Google Scholar] [CrossRef]

- Huang, L.H.; Wang, Y.M.; Shuai, J.; Zhang, H.; Yang, S.Q.; Zhang, Q.Y.; Ren, Z.F. Thermal conductivity reduction by isoelectronic elements V and Ta for partial substitution of Nb in half-Heusler Nb(1−x)/2V(1−x)/2TaxCoSb. RSC Adv. 2015, 5, 102469–102476. [Google Scholar] [CrossRef]

- Huang, L.H.; Zhang, Q.Y.; Wang, Y.M.; He, R.; Shuai, J.; Zhang, J.J.; Wang, C.; Ren, Z.F. The effect of Sn doping on thermoelectric performance of n-type half-Heusler NbCoSb. Phys. Chem. Chem. Phys. 2017, 19, 25683–25690. [Google Scholar] [CrossRef]

- Huang, L.H.; Wang, J.C.; Chen, X.; He, R.; Shuai, J.; Zhang, J.J.; Zhang, Q.Y.; Ren, Z.F. The effects of excess Co on the phase composition and thermoelectric properties of half-Heusler NbCoSb. Materials 2018, 11, 773. [Google Scholar] [CrossRef]

- Zeier, W.G.; Anand, S.; Huang, L.; He, R.; Zhang, H.; Ren, Z.; Wolverton, C.; Snyder, G.J. Using the 18-electron rule to understand the nominal 19-electron half-Heusler NbCoSb with Nb vacancies. Chem. Mater. 2017, 29, 1210–1217. [Google Scholar] [CrossRef]

- Xia, K.Y.; Liu, Y.T.; Anand, S.; Snyder, G.J.; Xin, J.Z.; Yu, J.J.; Zhao, X.B.; Zhu, T.J. Enhanced thermoelectric performance in 18-electron Nb0.8CoSb half-Heusler compound with intrinsic Nb vacancies. Adv. Funct. Mater. 2018, 28, 1705845. [Google Scholar] [CrossRef]

- Ibanez, M.; Luo, Z.S.; Genc, A.; Piveteau, L.; Ortega, S.; Cadavid, D.; Dobrozhan, O.; Liu, Y.; Nachtegaal, M.; Zebarjadi, M.; et al. High-performance thermoelectric nanocomposites from nanocrystal building blocks. Nat. Commun. 2016, 7, 10766. [Google Scholar] [CrossRef]

- Xie, H.H.; Wang, H.; Pei, Y.Z.; Fu, C.G.; Liu, X.H.; Snyder, G.J.; Zhao, X.B.; Zhu, T.J. Beneficial contribution of alloy disorder to electron and phonon transport in half-Heusler thermoelectric materials. Adv. Funct. Mater. 2013, 23, 5123–5130. [Google Scholar] [CrossRef]

- Fu, C.G.; Zhu, T.J.; Pei, Y.Z.; Xie, H.H.; Wang, H.; Snyder, G.J.; Liu, Y.; Liu, Y.T.; Zhao, X.B. High band degeneracy contributes to high thermoelectric performance in p-type half-Heusler compounds. Adv. Energy Mater. 2014, 4, 1400600. [Google Scholar] [CrossRef]

- Li, J.H.; Tan, Q.; Li, J.F.; Liu, D.W.; Li, F.; Li, Z.Y.; Zou, M.M.; Wang, K. BiSbTe-based nanocomposites with high ZT: The effect of SiC nano dispersion on thermoelectric properties. Adv. Funct. Mater. 2013, 23, 4317–4323. [Google Scholar] [CrossRef]

- Jiang, Q.H.; Yang, J.Y.; Xin, J.W.; Zhou, Z.W.; Zhang, D.; Yan, H.X. Carriers concentration tailoring and phonon scattering from n-type zinc oxide (ZnO) nanoinclusion in p- and n-type bismuth telluride (Bi2Te3): Leading to ultralow thermal conductivity and excellent thermoelectric properties. J. Alloy Compd. 2017, 694, 864–868. [Google Scholar] [CrossRef]

| Nominal Composition | Lattice Parameter (nm) | Density (g/cm3) | Relative Density (%) | |

|---|---|---|---|---|

| Theoretical | Experimental | |||

| VCoSb | 0.5772 | 7.45 | 8.01 | 93.01 |

| V0.95CoSb | 0.5772 | 7.53 | 7.87 | 95.67 |

| V0.9CoSb | 0.5771 | 7.6 | 7.79 | 97.56 |

| V0.85CoSb | 0.5770 | 7.62 | 7.73 | 98.57 |

| V0.8CoSb | 0.5770 | 7.63 | 7.68 | 99.35 |

| V0.75CoSb | 0.5769 | 7.64 | 7.66 | 99.74 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Wang, J.; Mo, X.; Lei, X.; Ma, S.; Wang, C.; Zhang, Q. Improving the Thermoelectric Properties of the Half-Heusler Compound VCoSb by Vanadium Vacancy. Materials 2019, 12, 1637. https://doi.org/10.3390/ma12101637

Huang L, Wang J, Mo X, Lei X, Ma S, Wang C, Zhang Q. Improving the Thermoelectric Properties of the Half-Heusler Compound VCoSb by Vanadium Vacancy. Materials. 2019; 12(10):1637. https://doi.org/10.3390/ma12101637

Chicago/Turabian StyleHuang, Lihong, Junchen Wang, Xiaobo Mo, Xiaobo Lei, Sude Ma, Chao Wang, and Qinyong Zhang. 2019. "Improving the Thermoelectric Properties of the Half-Heusler Compound VCoSb by Vanadium Vacancy" Materials 12, no. 10: 1637. https://doi.org/10.3390/ma12101637

APA StyleHuang, L., Wang, J., Mo, X., Lei, X., Ma, S., Wang, C., & Zhang, Q. (2019). Improving the Thermoelectric Properties of the Half-Heusler Compound VCoSb by Vanadium Vacancy. Materials, 12(10), 1637. https://doi.org/10.3390/ma12101637