Synthesis, Characterization, Corrosion Resistance and In-Vitro Bioactivity Behavior of Biodegradable Mg–Zn–Mn–(Si–HA) Composite for Orthopaedic Applications

Abstract

1. Introduction

2. Materials and Methods

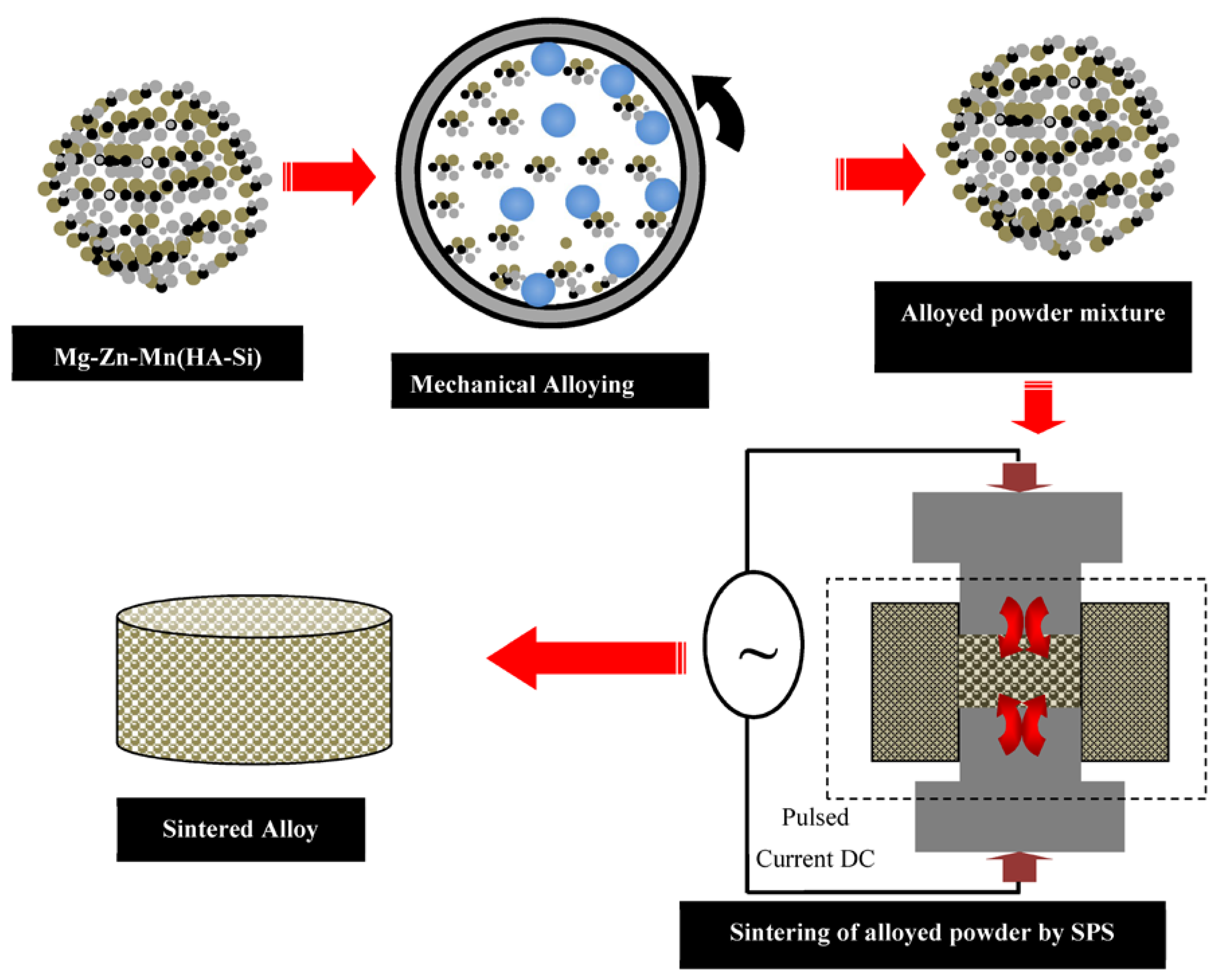

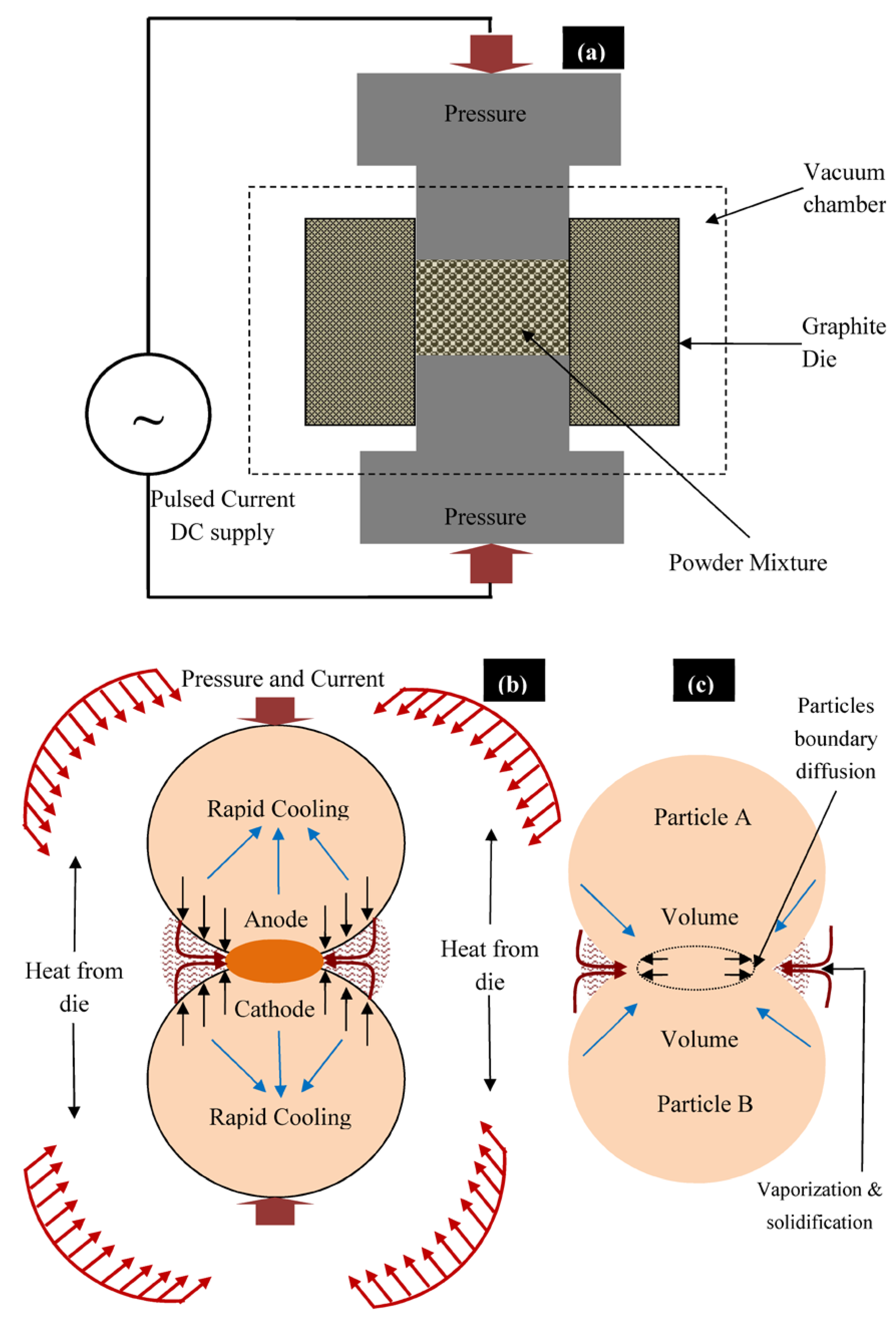

2.1. Mechanical Alloying and Consolidation of Spark Plasma Sintering

2.2. Metallurgical and Mechanical Characteristics

2.3. Potentiodynamic Corrosion and Degradation Test

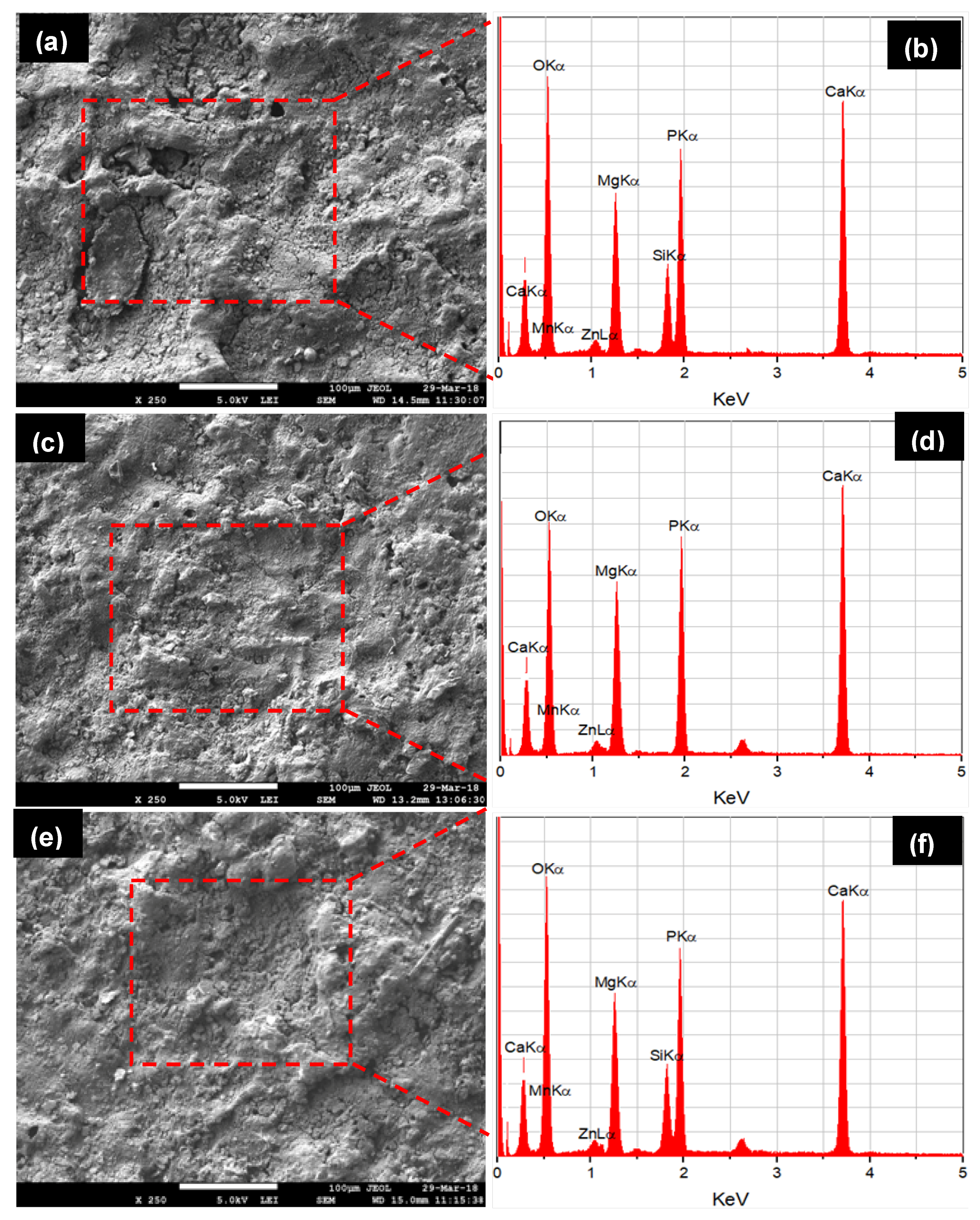

2.4. In Vitro Bioactivity Test

3. Results and Discussion

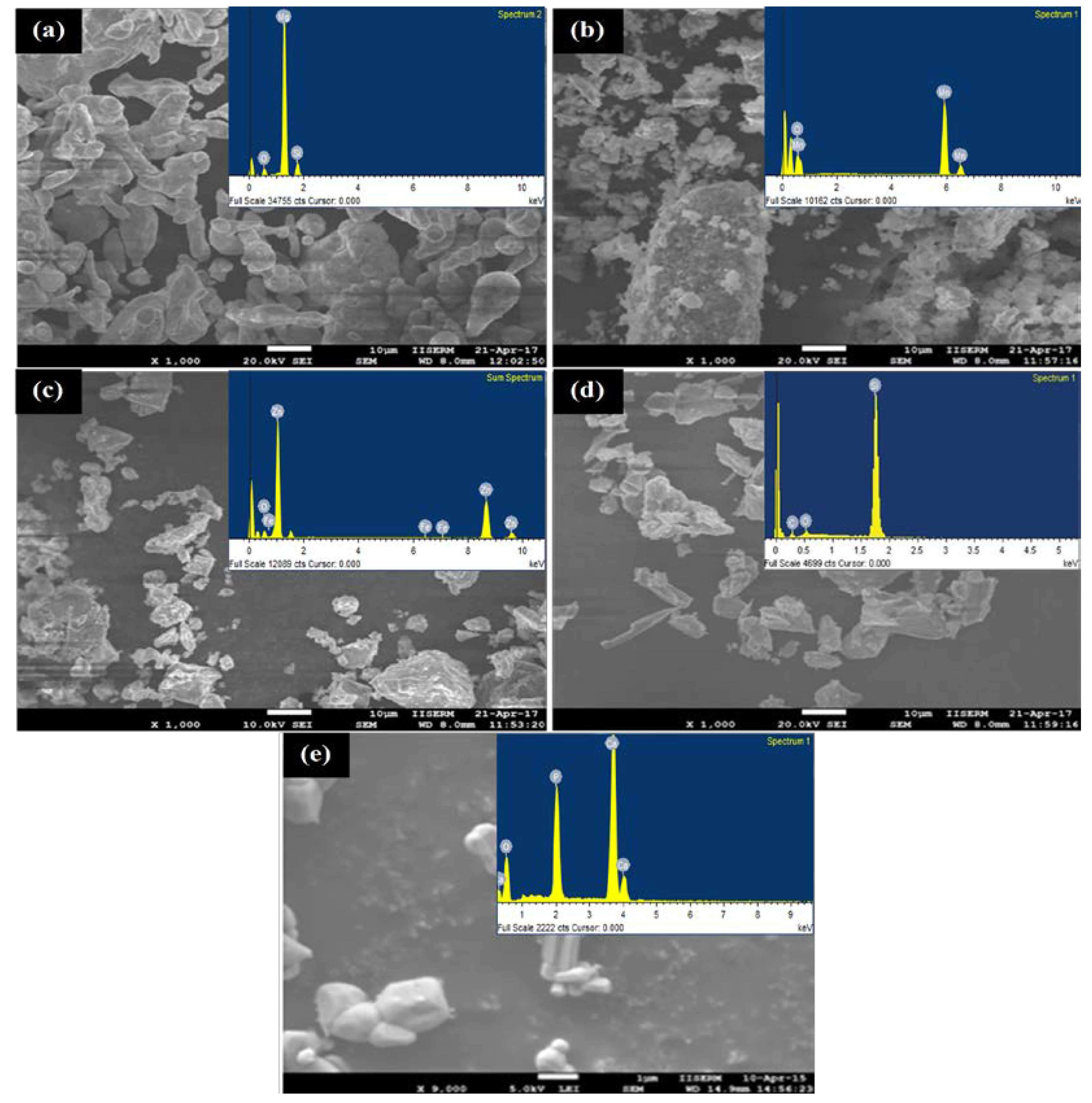

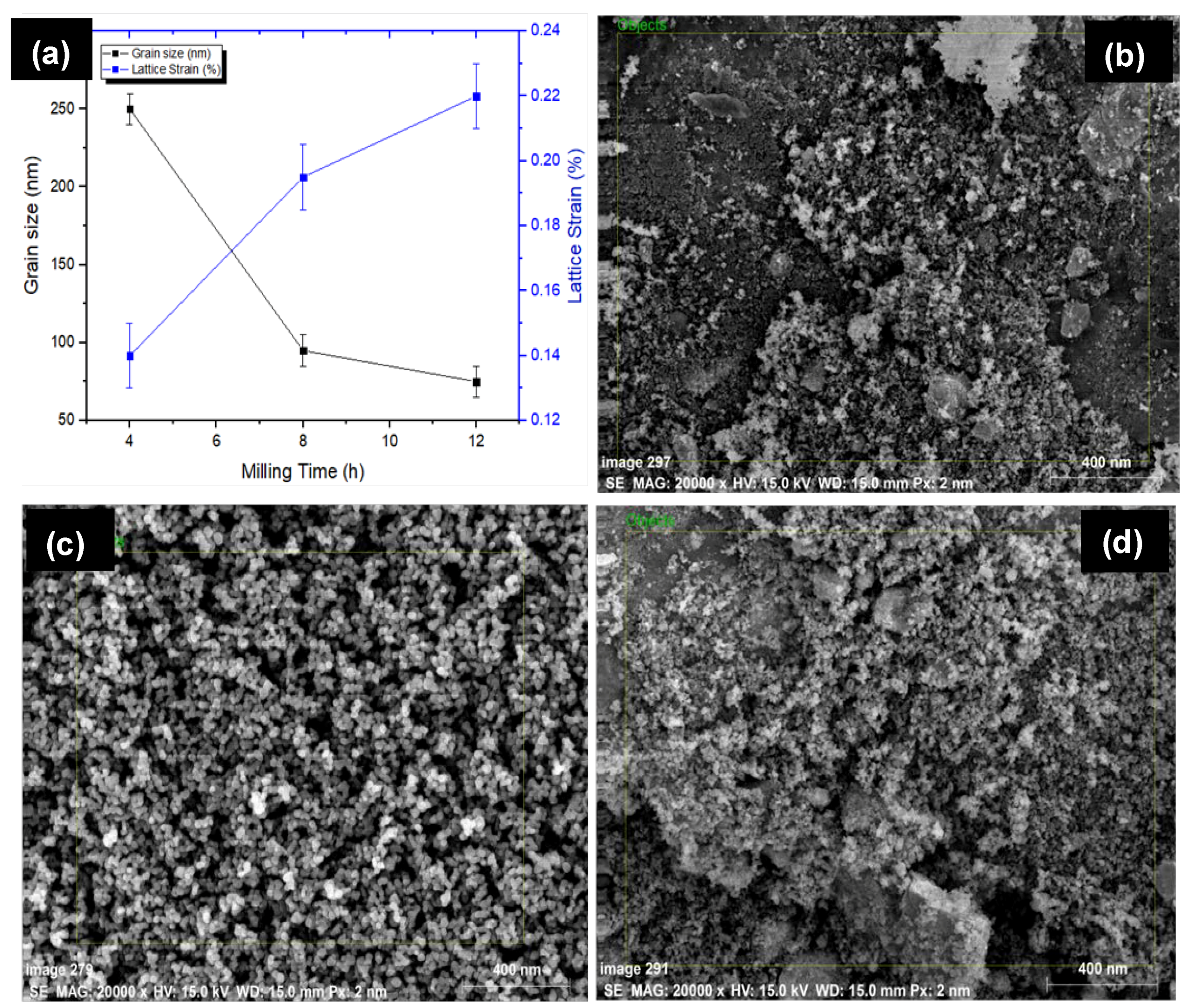

3.1. Powder Morphology

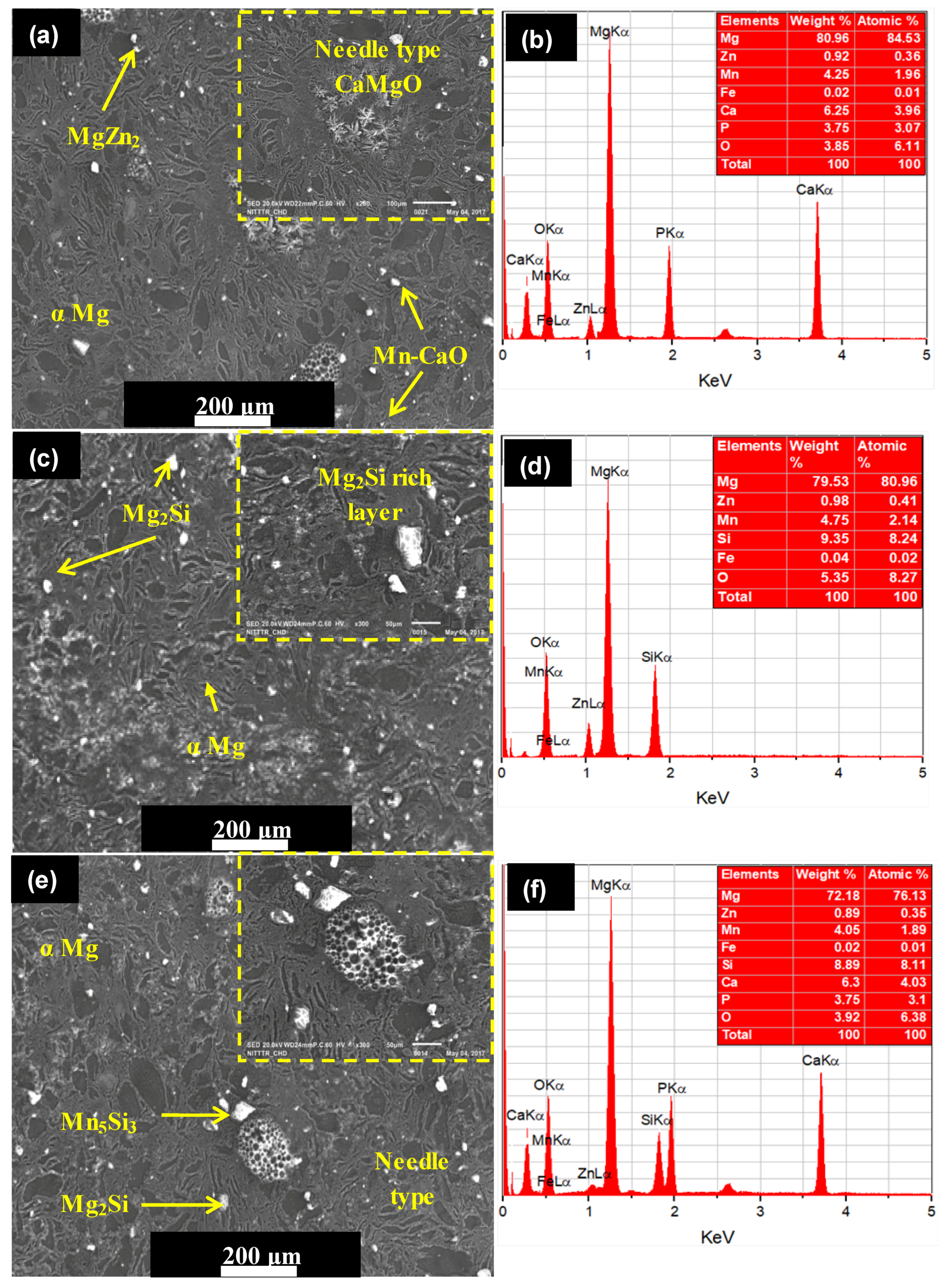

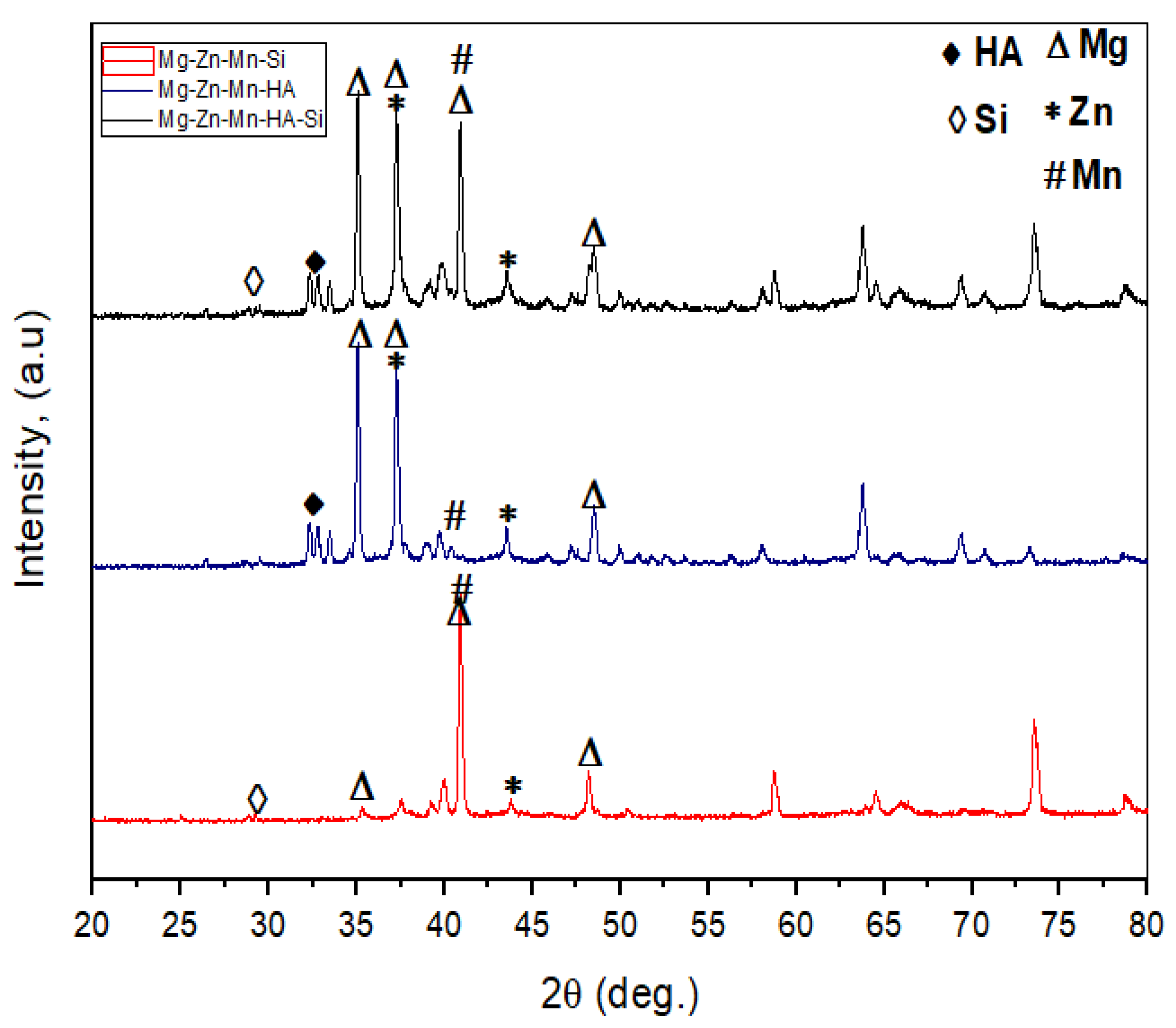

3.2. Microstructure

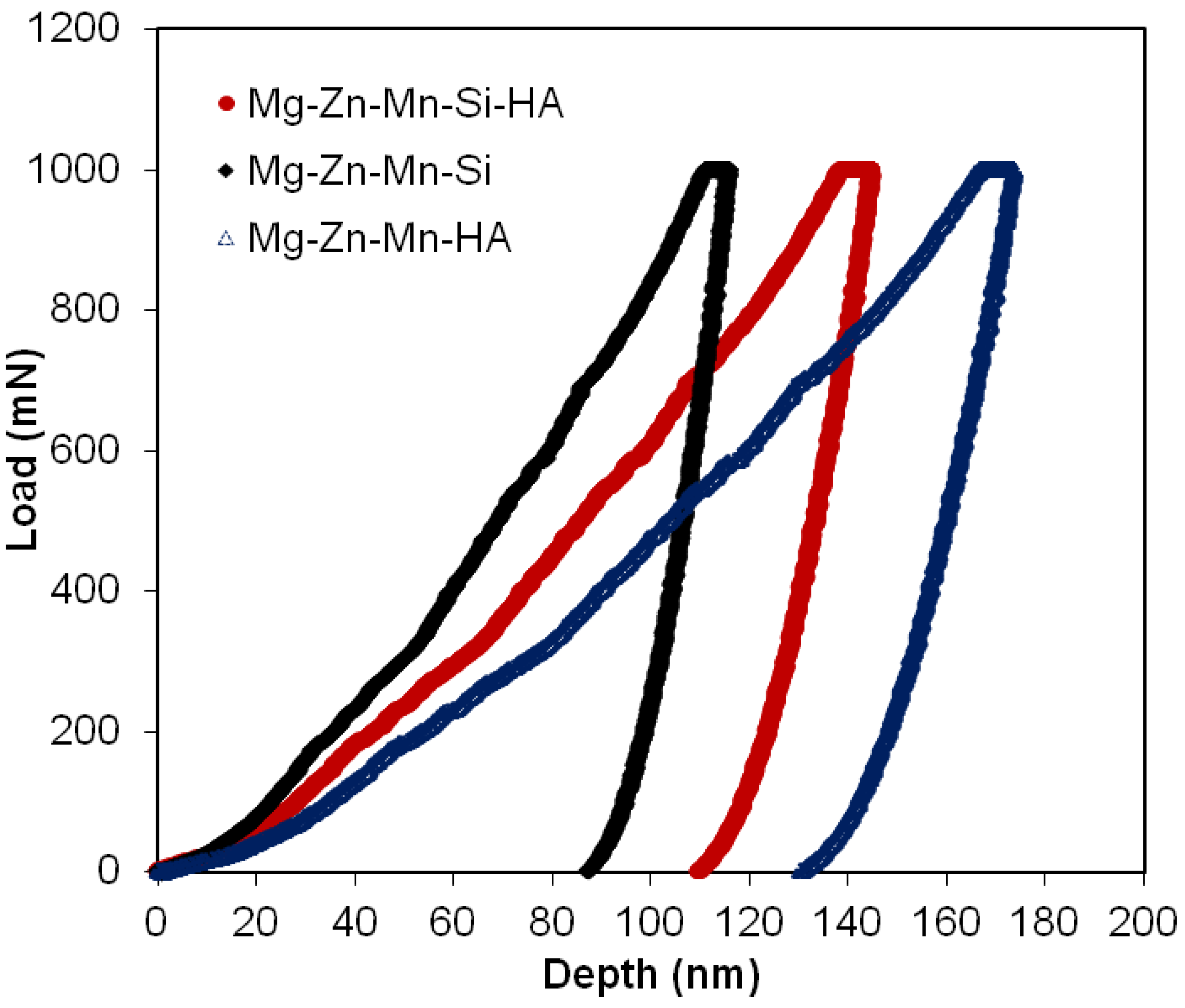

3.3. Mechanical Properties

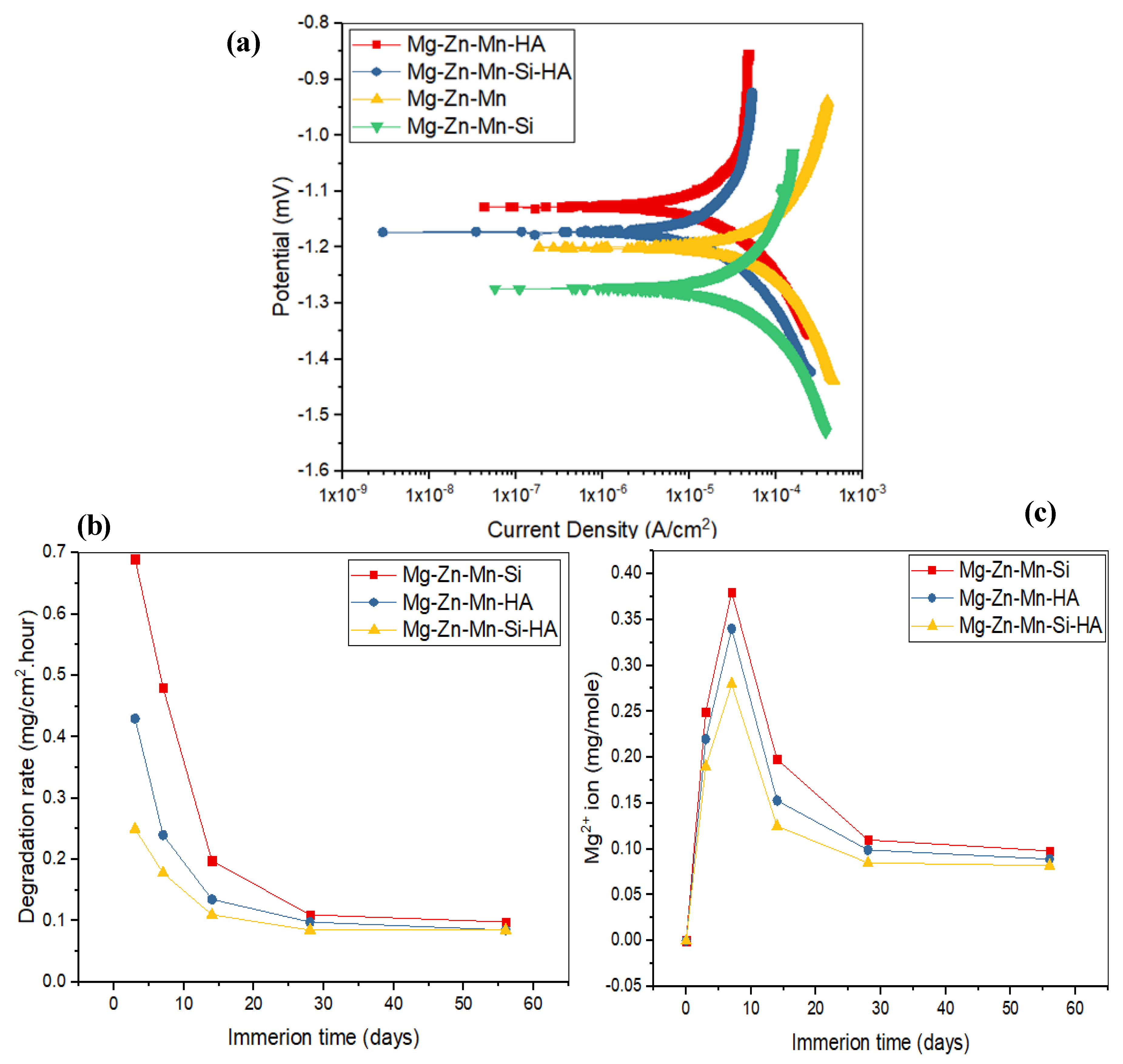

3.4. In Vitro Corrosion and Degradation Analysis

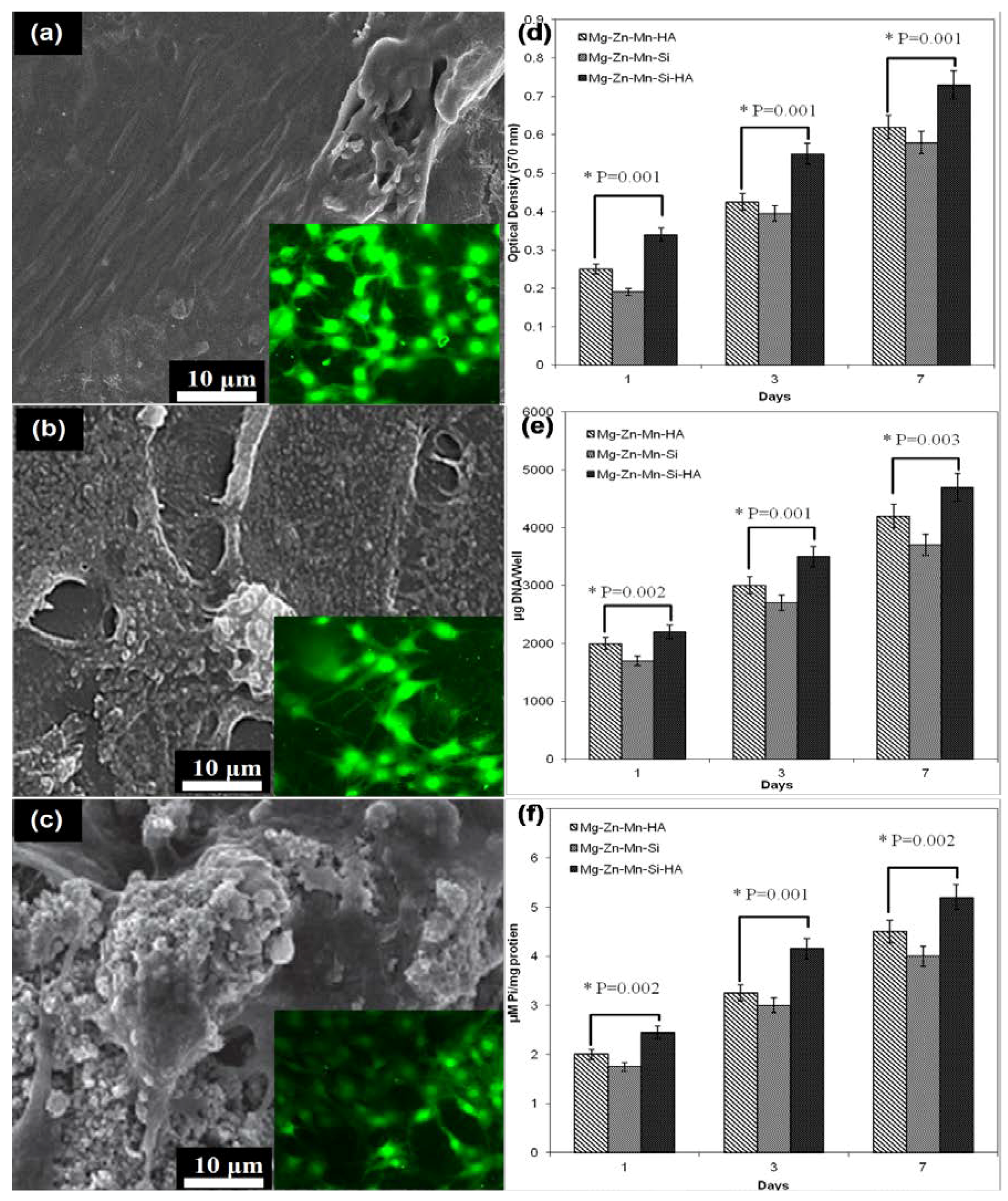

3.5. In Vitro Biocompatibility Assessment

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Prakash, C.; Kansal, H.K.; Pabla, B.S.; Puri, S.; Aggarwal, A. Electric discharge machining—A potential choice for surface modification of metallic implants for orthopedic applications: A review. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2016, 230, 331–353. [Google Scholar] [CrossRef]

- Spoerke, E.D.; Murray, N.G.; Li, H.; Brinson, L.C.; Dunand, D.C.; Stupp, S.I. A bioactive titanium foam scaffold for bone repair. Acta Biomater. 2005, 1, 523–533. [Google Scholar] [CrossRef] [PubMed]

- Staiger, M.P.; Pietak, A.M.; Huadmai, J.; Dias, G. Magnesium and its alloys as orthopedic biomaterials: A review. Biomaterials 2006, 27, 1728–1734. [Google Scholar] [CrossRef] [PubMed]

- Song, G.L.; Atrens, A. Corrosion mechanisms of magnesium alloys. Adv. Eng. Mater. 1999, 1, 11–33. [Google Scholar] [CrossRef]

- Song, G.; Atrens, A. Understanding magnesium corrosion—A framework for improved alloy performance. Adv. Eng. Mater. 2003, 5, 837–858. [Google Scholar] [CrossRef]

- Uddin, M.S.; Hall, C.; Murphy, P. Surface treatments for controlling corrosion rate of biodegradable Mg and Mg-based alloy implants. Sci. Technol. Adv. Mater. 2015, 16, 053501. [Google Scholar] [CrossRef] [PubMed]

- Abidin, N.I.Z.; Rolfe, B.; Owen, H.; Malisano, J.; Martin, D.; Hofstetter, J.; Uggowitzer, P.J.; Atrens, A. The in vivo and in vitro corrosion of high-purity magnesium and magnesium alloys WZ21 and AZ91. Corros. Sci. 2013, 75, 354–366. [Google Scholar] [CrossRef]

- Uddin, M.S.; Rosman, H.; Hall, C.; Murphy, P. Enhancing the corrosion resistance of biodegradable Mg-based alloy by machining-induced surface integrity: Influence of machining parameters on surface roughness and hardness. Int. J. Adv. Manuf. Technol. 2017, 90, 2095–2108. [Google Scholar] [CrossRef]

- Zhang, E.; Yin, D.; Xu, L.; Yang, L.; Yang, K. Microstructure, mechanical and corrosion properties and biocompatibility of Mg–Zn–Mn alloys for biomedical application. Mater. Sci. Eng. C 2009, 29, 987–993. [Google Scholar] [CrossRef]

- Atrens, A.; Song, G.L.; Liu, M.; Shi, Z.M.; Cao, F.Y.; Dargusch, M.S. Review of recent developments in the field of magnesium corrosion. Adv. Eng. Mater. 2015, 17, 400–453. [Google Scholar] [CrossRef]

- Atrens, A.; Song, G.L.; Cao, F.Y.; Shi, Z.M.; Bowen, P.K. Advances in Mg corrosion and research suggestions. J. Magnes. Alloys 2013, 1, 177–200. [Google Scholar] [CrossRef]

- Radha, R.; Sreekanth, D. Insight of magnesium alloys and composites for orthopedic implant alications—A review. J. Magnes. Alloys 2017, 5, 286–312. [Google Scholar] [CrossRef]

- Huang, X.; Han, G.; Huang, W. T6 Treatment and Its Effects on Corrosion Properties of an Mg–4Sn–4Zn–2Al Alloy. Materials 2018, 11, 628. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Jiang, W.; Guo, S.; Li, Y.; Ma, Y. The Effect of Rod-Shaped Long-Period Stacking Ordered Phases Evolution on Corrosion Behavior of Mg95. 33Zn2Y2. 67 Alloy. Materials 2018, 11, 815. [Google Scholar] [CrossRef] [PubMed]

- Gavras, S.; Buzolin, R.H.; Subroto, T.; Stark, A.; Tolnai, D. The Effect of Zn Content on the Mechanical Properties of Mg–4Nd–xZn Alloys (x = 0, 3, 5 and 8 wt %). Materials 2018, 11, 1103. [Google Scholar] [CrossRef] [PubMed]

- Cheng, W.; Zhang, Y.; Ma, S.; Arthanari, S.; Cui, Z.; Wang, H.X.; Wang, L. Tensile Properties and Corrosion Behavior of Extruded Low-Alloyed Mg-1Sn-1Al-1Zn Alloy: The Influence of Microstructural Characteristics. Materials 2018, 11, 1157. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, P.C.; Piai, K.D.A.; Takayanagui, A.M.M.; Segura-Muñoz, S.I. Aluminum as a risk factor for Alzheimer’s disease. Rev. Latinoam. Enfermagem. 2008, 16, 51–157. [Google Scholar] [CrossRef]

- Shingde, M.; Hughes, J.; Boadle, R.; Wills, E.J.; Pamphlett, R. Macrophagic myofasciitis associated with vaccine-derived aluminium. Med. J. Aust. 2005, 183, 145–146. [Google Scholar] [PubMed]

- Luo, L.; Liu, Y.; Duan, M. Phase Formation of Mg–Zn–Gd Alloys on the Mg-rich Corner. Materials 2018, 11, 1351. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.X.; Li, J.; Song, Y.; Zhao, C.L.; Zhang, X.N.; Xie, C.Y.; Zhang, Y.; Tao, H.R.; He, Y.H.; Jiang, Y.; et al. In vitro degradation, hemolysis and MC3T3-E1 cell adhesion of biodegradable Mg–Zn alloy. Mater. Sci. Eng. C 2009, 29, 1907–1912. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Yuan, G.; Xue, Y. Improvement of mechanical properties and corrosion resistance of biodegradable Mg–Nd–Zn–Zr alloys by double extrusion. Mater. Sci. Eng. B 2012, 177, 1113–1119. [Google Scholar] [CrossRef]

- Li, Z.; Gu, X.; Lou, S.; Zheng, Y. The development of binary Mg-Ca alloys for use as biodegradable materials within bone. Biomaterials 2009, 29, 1329–1344. [Google Scholar] [CrossRef] [PubMed]

- Ben-Hamu, G.; Eliezer, D.; Shin, K.S. The role of Si and Ca on new wrought Mg–Zn–Mn based alloy. Mater. Sci. Eng. A 2007, 447, 35–43. [Google Scholar] [CrossRef]

- Sunil, B.R.; Ganapathy, C.; Kumar, T.S.; Chakkingal, U. Processing and mechanical behavior of lamellar structured degradable magnesium–hydroxyapatite implants. J. Mech. Behav. Biomed. Mater. 2014, 40, 178–189. [Google Scholar] [CrossRef] [PubMed]

- Zheng, B.L.; Ertorer, O.; Li, Y.; Zhou, Y.Z.; Mathaudhu, S.N.; Tsao, C.Y.A.; Lavernia, E.J. High strength, nano-structured Mg–Al–Zn alloy. Mater. Sci. Eng. A 2017, 528, 2180–2191. [Google Scholar] [CrossRef]

- Zhang, E.; Yang, L.; Xu, J.; Chen, H. Microstructure, mechanical properties and bio-corrosion properties of Mg–Si (–Ca, Zn) alloy for biomedical application. Acta Biomater. 2010, 6, 1756–1762. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.; Liu, K.; Du, W.; Wang, Z.; Li, S.; Du, X. Microstructure and mechanical properties of the as-cast Mg–Zn–Mn–Ca alloys. IOP Conf. Ser. Mater. Sci. Eng. 2016, 182, 012053. [Google Scholar] [CrossRef]

- Singh, B.P.; Singh, R.; Mehta, J.S.; Prakash, C. Fabrication of Biodegradable Low Elastic Porous Mg–Zn–Mn–HA Alloy by Spark Plasma Sintering for Orthopaedic Applications. IOP Conf. Ser. Mater. Sci. Eng. 2017, 225, 012050. [Google Scholar] [CrossRef]

- Prakash, C.; Singh, S.; Verma, K.; Sidhu, S.S.; Singh, S. Synthesis and characterization of Mg–Zn–Mn–HA composite by spark plasma sintering process for orthopedic applications. Vacuum 2018, 155, 578–584. [Google Scholar] [CrossRef]

- Prakash, C.; Singh, S.; Sidhu, S.S.; Pabla, B.S.; Uddin, M.S. Bio-inspired Low Elastic Biodegradable Mg–Zn–Mn–Si–HA Alloy Fabricated by Spark Plasma Sintering. Mater. Manuf. 2018. [Google Scholar] [CrossRef]

- Zheng, R.X.; Ma, F.M.; Xiao, W.L.; Ameyama, K.; Ma, C.L. Achieving enhanced strength in ultrafine lamellar structured Al2024 alloy via mechanical milling and spark plasma sintering. Mater. Sci. Eng. A 2017, 687, 155–163. [Google Scholar] [CrossRef]

- Cullity, B.D. Elements of X-Ray Diffraction. Am. J. Phys. 1957, 25, 394. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Prakash, C.; Uddin, M.S. Surface modification of β-phase Ti implant by hydroaxyapatite mixed electric discharge machining to enhance the corrosion resistance and in-vitro bioactivity. Surf. Coat. Technol. 2017, 326, 134–145. [Google Scholar] [CrossRef]

- Prakash, C.; Singh, S.; Pabla, B.S.; Uddin, M.S. Synthesis, characterization, corrosion and bioactivity investigation of nano-HA coating deposited on biodegradable Mg–Zn–Mn alloy. Surf. Coat. Technol. 2018, 346, 9–18. [Google Scholar] [CrossRef]

- Shi, Z.; Liu, M.; Atrens, A. Measurement of the corrosion rate of magnesium alloys using Tafel extrapolation. Corros. Sci. 2010, 52, 579–588. [Google Scholar] [CrossRef]

- Jaiswal, S.; Kumar, R.M.; Gupta, P.; Kumaraswamy, M.; Roy, P.; Lahiri, D. Mechanical, corrosion and biocompatibility behaviour of Mg-3Zn-HA biodegradable composites for orthopaedic fixture accessories. J. Mech. Behav. Biomed. Mater. 2018, 78, 442–454. [Google Scholar] [CrossRef] [PubMed]

- Prakash, C.; Kansal, H.K.; Pabla, B.S.; Puri, S. Processing and characterization of novel biomimetic nanoporous bioceramic surface on β-Ti implant by powder mixed electric discharge machining. J. Mater. Eng. Perform. 2015, 24, 3622–3633. [Google Scholar] [CrossRef]

- Furko, M.; Havasi, V.; Kónya, Z.; Grünewald, A.; Detsch, R.; Boccaccini, A.R.; Balázsi, C. Development and characterization of multi-element doped hydroxyapatite bioceramic coatings on metallic implants for orthopedic applications. Bol. Soc. Esp. Ceram. Vidr. 2018, 57, 55–65. [Google Scholar] [CrossRef]

- Gittens, R.A.; McLachlan, T.; Olivares-Navarrete, R.; Cai, Y.; Berner, S.; Tannenbaum, R.; Schwartz, Z.; Sandhage, K.H.; Boyan, B.D. The effects of combined micron-/submicron-scale surface roughness and nanoscale features on cell proliferation and differentiation. Biomaterials 2011, 32, 3395–3403. [Google Scholar] [CrossRef] [PubMed]

| Composite | Composition | Alloying Element Composition, wt % | ||||

|---|---|---|---|---|---|---|

| Zn | Mn | Si | HA | Mg | ||

| Type-I | Mg–Zn–Mn–HA | 1 | 5 | 10 | Bal. | |

| Type-II | Mg–Zn–Mn–Si | 1 | 5 | 10 | Bal. | |

| Type-III | Mg–Zn–Mn–HA–Si | 1 | 5 | 10 | 10 | Bal. |

| Process Parameters | Symbol | Units | Levels |

|---|---|---|---|

| Type of alloying element | Ae | HA, Si, Si–HA | |

| Milling time, h | Tm | h | 4, 8, 12 |

| Sintering pressure | Ps | MPa | 30, 40, 50 |

| Sintering temperature | Ts | °C | 350, 400, 450 |

| Heating rate | °C/min | 50 | |

| Holding time | Min | 5 | |

| Atmosphere | Argon |

| Mg Alloys | Mechanical Properties | |||

|---|---|---|---|---|

| Elastic Modulus, E (GPa) | Hardness, H (GPa) | |||

| Mean of Sample Group | Standard Deviation | Mean of Sample Group | Standard Deviation | |

| Mg–Zn–Mn–HA | 32 | 1.58 | 0.54 | 0.02 |

| Mg–Zn–Mn–Si | 45 | 2.64 | 1.97 | 0.03 |

| Mg–Zn–Mn–Si–HA | 39 | 1.98 | 1.18 | 0.02 |

| Parameters | Mg Alloys | |||

|---|---|---|---|---|

| Mg–Zn–Mn | Mg–Zn–Mn–Si | Mg–Zn–Mn–HA | Mg–Zn–Mn–Si–HA | |

| Icorr (µA/cm2) | 22.7 | 7.7 | 3.3 | 0.98 |

| Ecorr (mV ) | −1.27 | −1.27 | −1.13 | −1.17 |

| CR (mm/year) | 1.98 | 1.45 | 0.97 | 0.15 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prakash, C.; Singh, S.; Gupta, M.K.; Mia, M.; Królczyk, G.; Khanna, N. Synthesis, Characterization, Corrosion Resistance and In-Vitro Bioactivity Behavior of Biodegradable Mg–Zn–Mn–(Si–HA) Composite for Orthopaedic Applications. Materials 2018, 11, 1602. https://doi.org/10.3390/ma11091602

Prakash C, Singh S, Gupta MK, Mia M, Królczyk G, Khanna N. Synthesis, Characterization, Corrosion Resistance and In-Vitro Bioactivity Behavior of Biodegradable Mg–Zn–Mn–(Si–HA) Composite for Orthopaedic Applications. Materials. 2018; 11(9):1602. https://doi.org/10.3390/ma11091602

Chicago/Turabian StylePrakash, Chander, Sunpreet Singh, Munish Kumar Gupta, Mozammel Mia, Grzegorz Królczyk, and Navneet Khanna. 2018. "Synthesis, Characterization, Corrosion Resistance and In-Vitro Bioactivity Behavior of Biodegradable Mg–Zn–Mn–(Si–HA) Composite for Orthopaedic Applications" Materials 11, no. 9: 1602. https://doi.org/10.3390/ma11091602

APA StylePrakash, C., Singh, S., Gupta, M. K., Mia, M., Królczyk, G., & Khanna, N. (2018). Synthesis, Characterization, Corrosion Resistance and In-Vitro Bioactivity Behavior of Biodegradable Mg–Zn–Mn–(Si–HA) Composite for Orthopaedic Applications. Materials, 11(9), 1602. https://doi.org/10.3390/ma11091602