The Influence of Exposure Energy Density on Porosity and Microhardness of the SLM Additive Manufactured Elements

Abstract

:1. Introduction

- High-dimensional accuracy of the manufactured elements;

- Relatively low anisotropy of mechanical properties;

- A significant number of available materials;

- Low porosity of the manufactured elements.

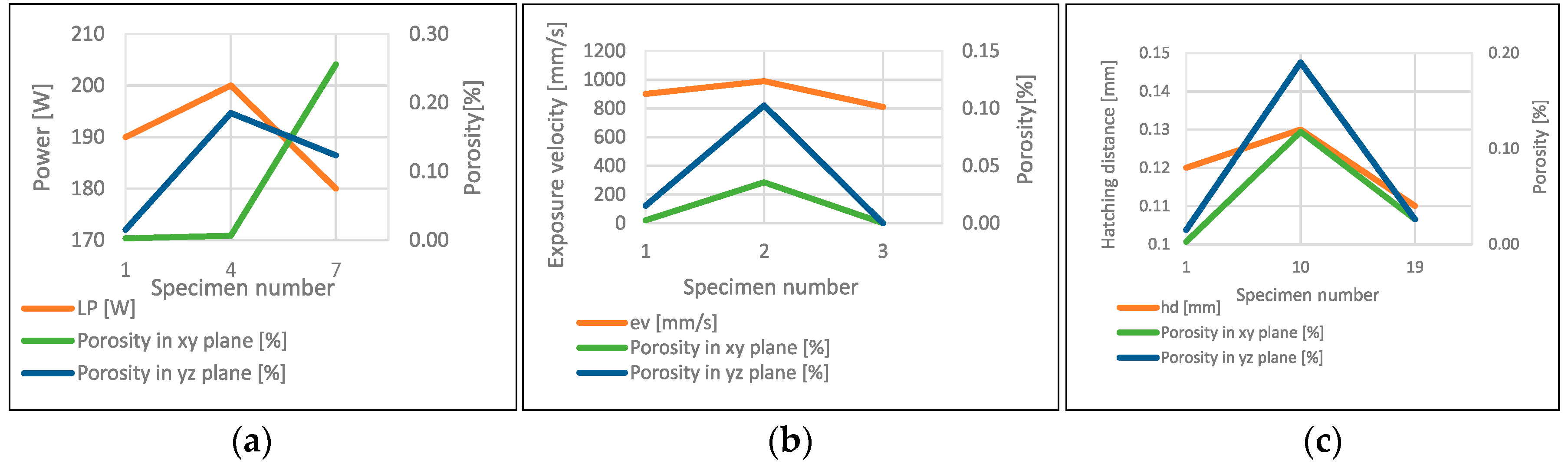

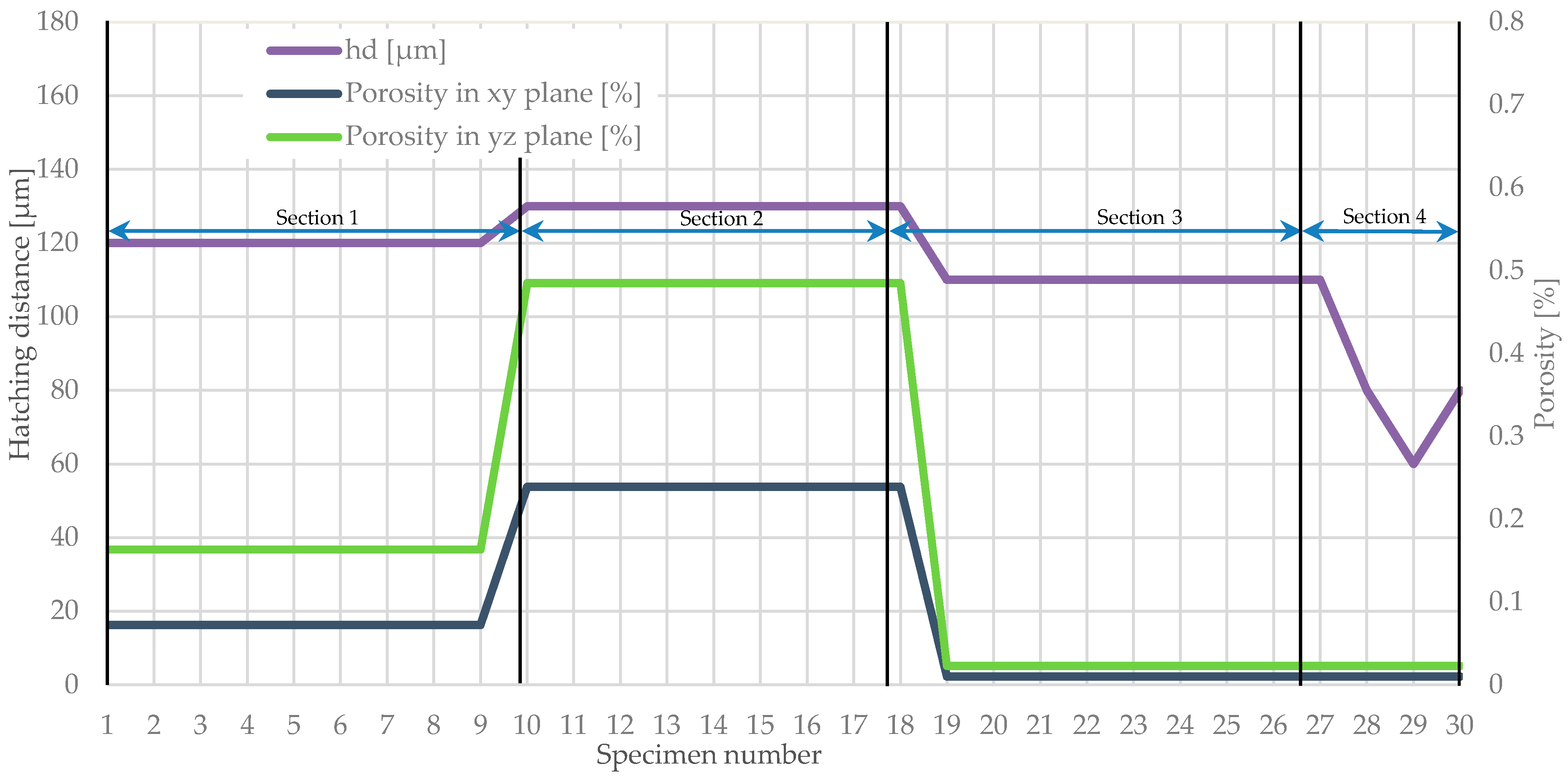

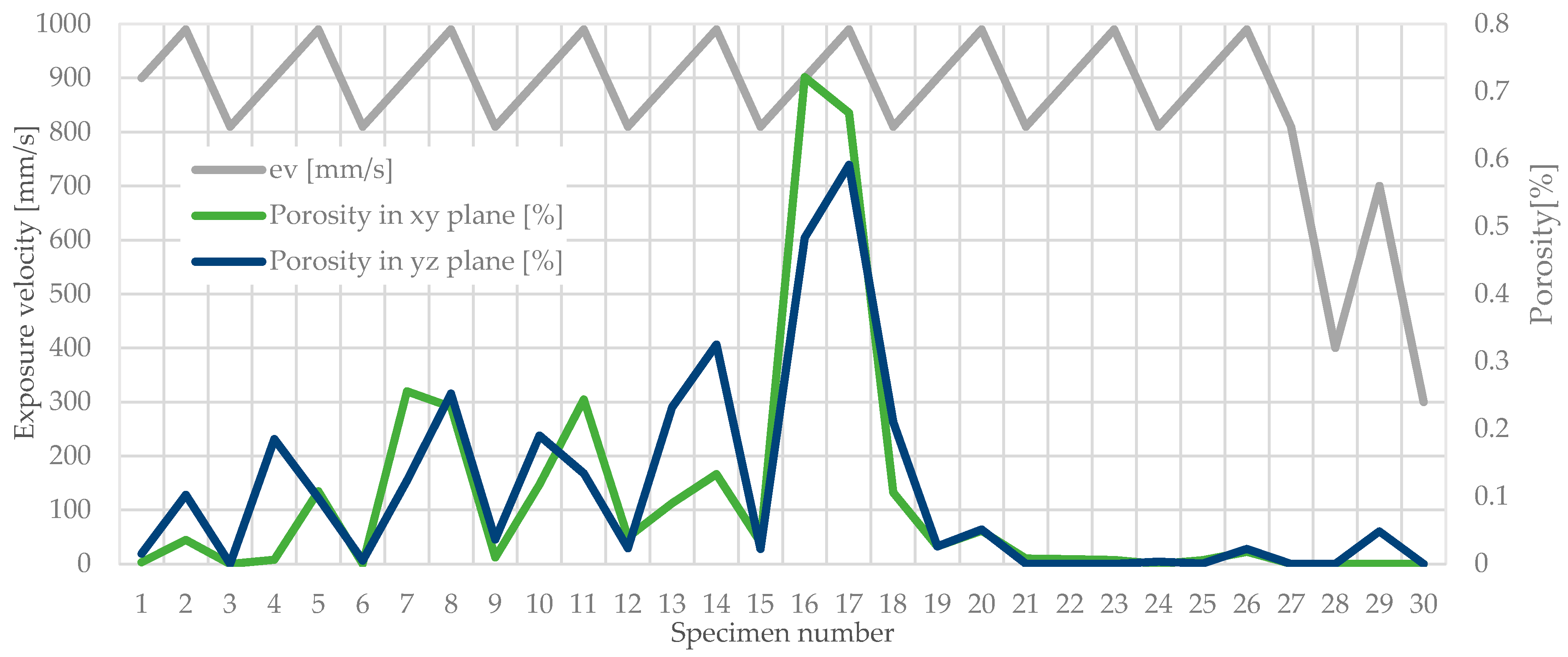

- Laser power;

- Exposure velocity;

- Hatching distance.

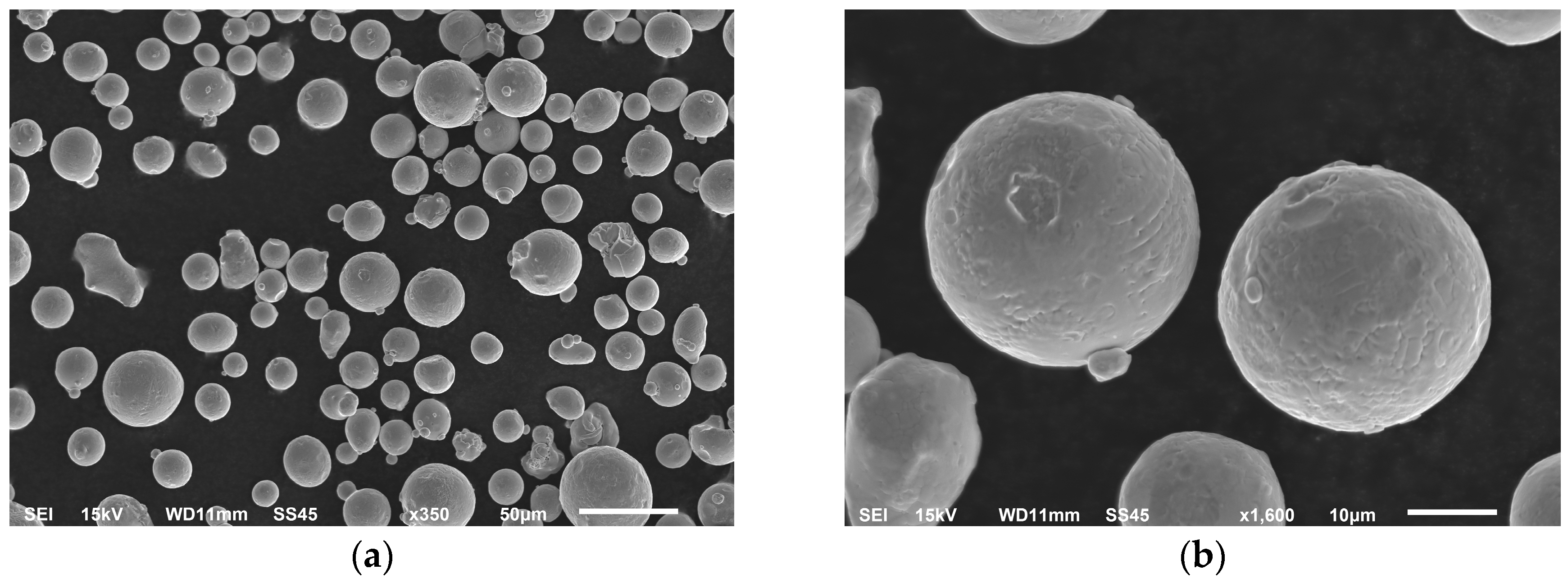

2. Material

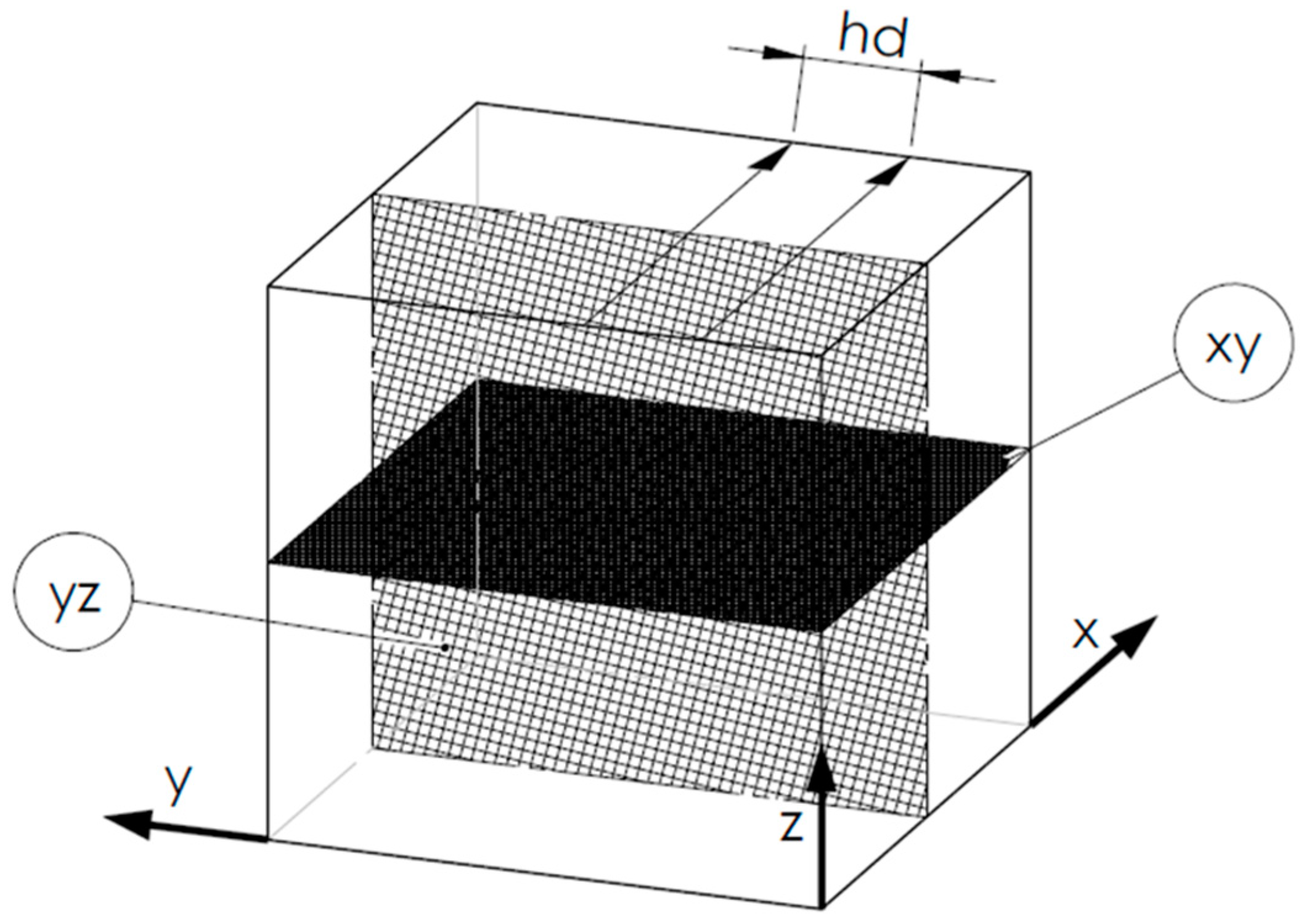

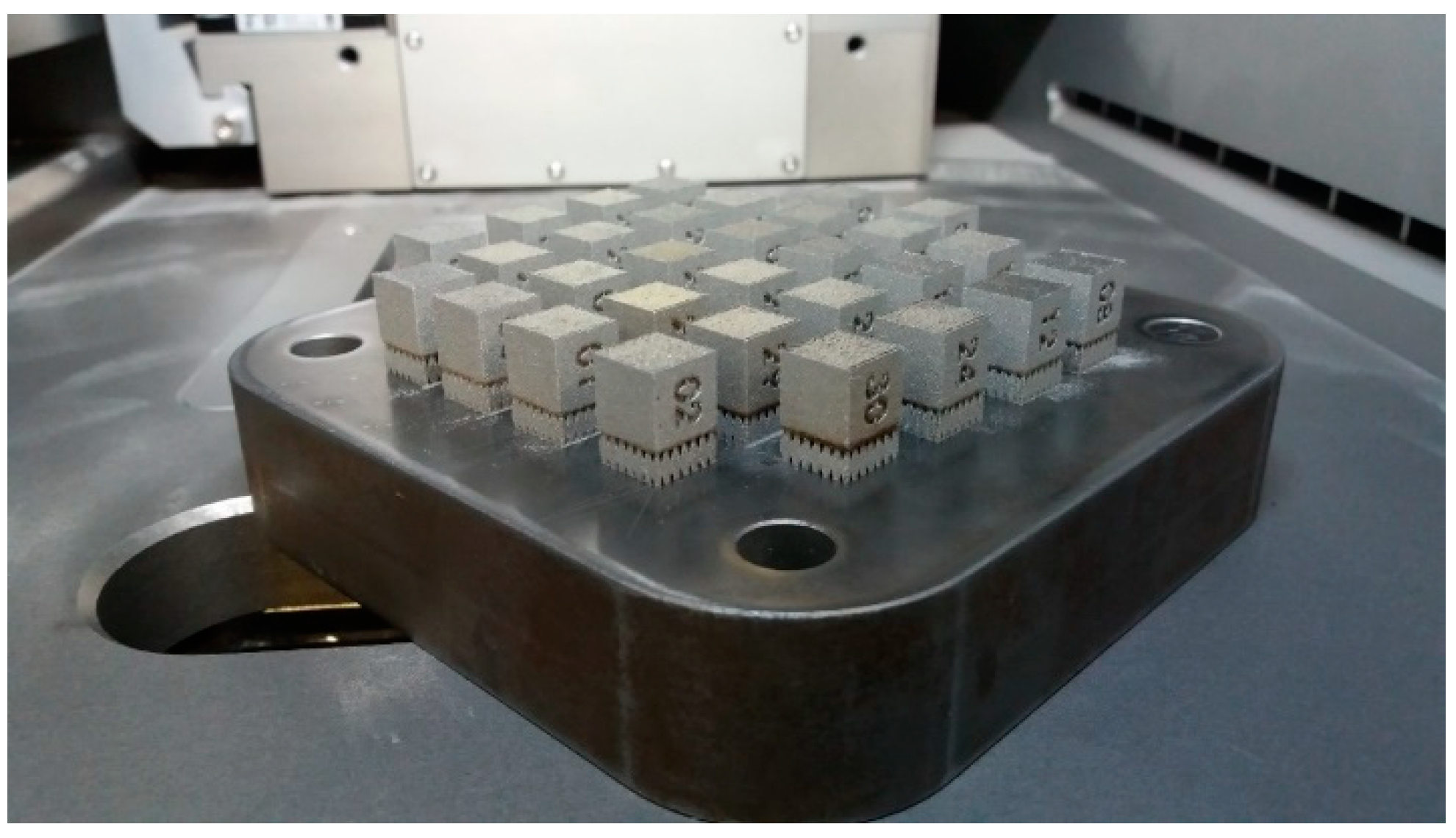

3. Experiments

- LP—laser power [W];

- ev—exposure velocity [mm/s];

- hd—hatching distance [mm];

- lt—layer thickness [mm].

- Proper calibration of the powder reservoir (recouter);

- Inert gas flow speed;

- Clearance in the worm gear in the building platform leveling mechanism.

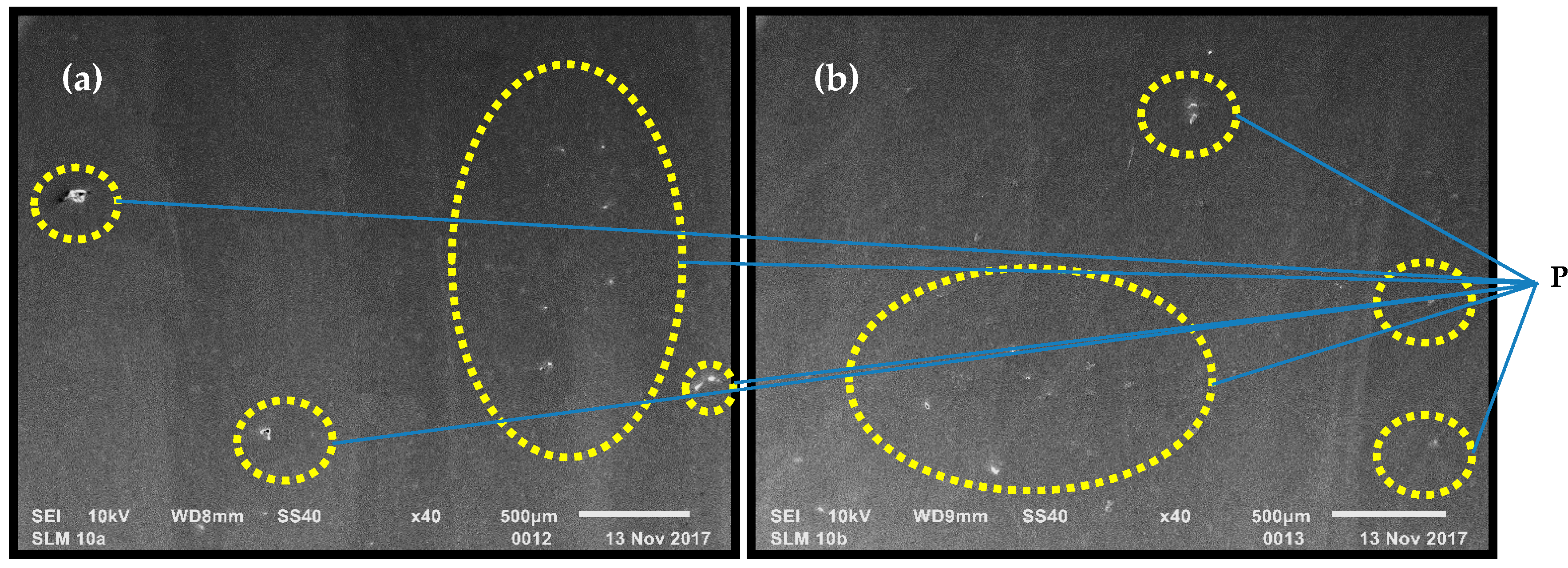

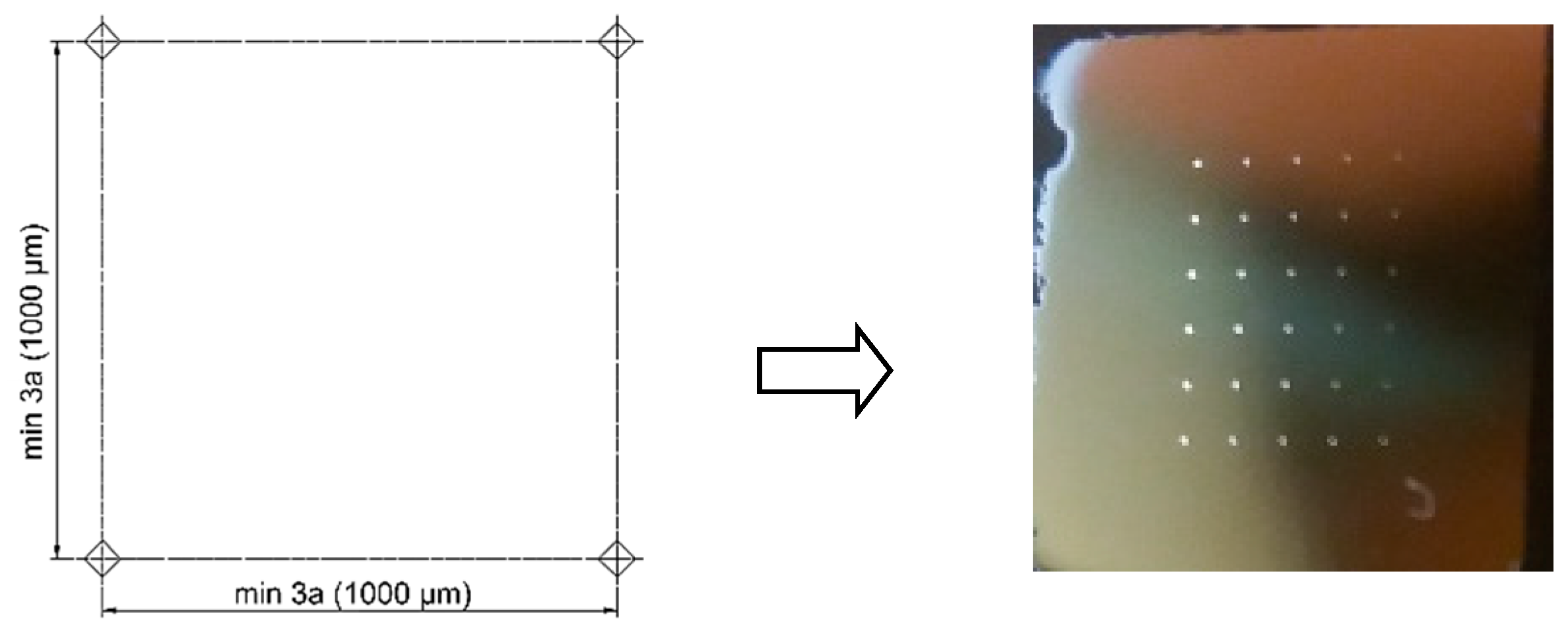

4. Porosity Analysis Results and Discussion

- Lp—number of pixels in the contoured pores;

- Lc—number of pixels of the image entire area.

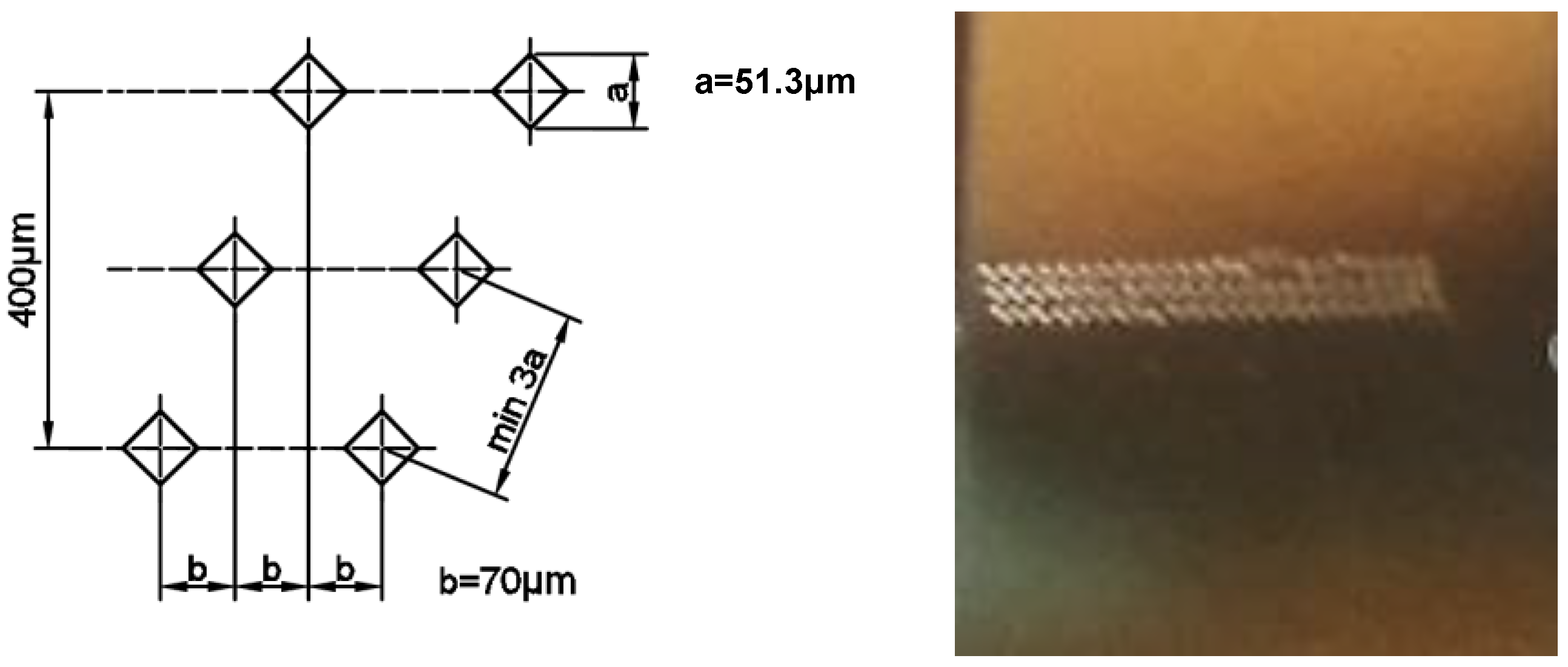

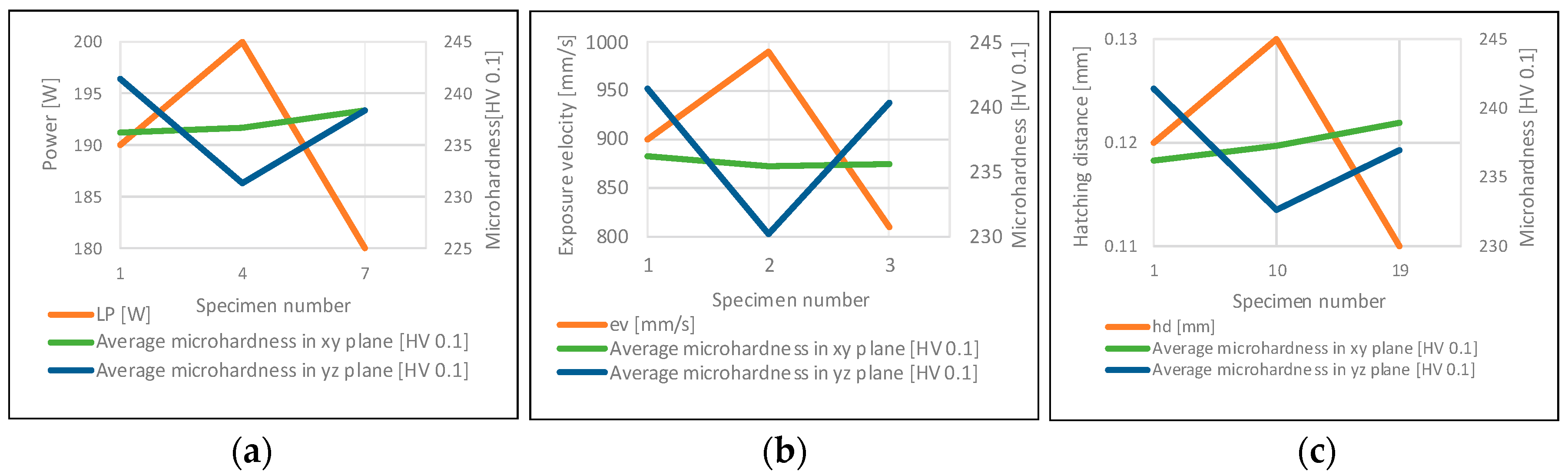

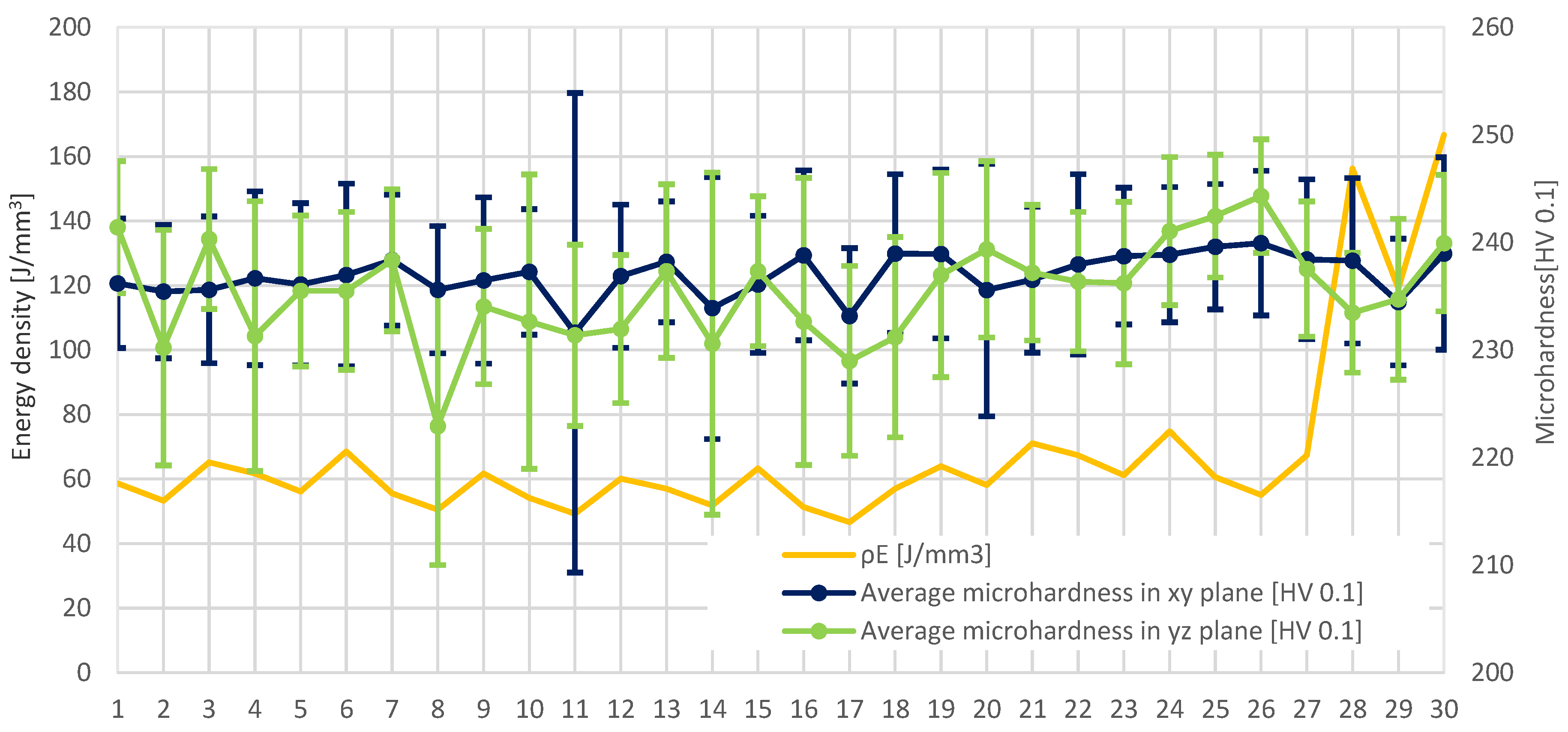

5. Microhardness Analysis Results and Discussion

6. Final Conclusions

- There are no significant differences in microhardness and porosity measurement results in the planes perpendicular and parallel to the machine building platform surface. The main reason for the lack of visible changes of microhardness is to the low range of the changed parameters: laser power and exposure velocity;

- The hatching distance has a significant influence on the porosity of the manufactured elements. As the hatching distance increases, the microstructure porosity of this element increases;

- Exposure velocity changes affect the additive manufactured element’s porosity. Lowering the exposure velocity cause the porosity to decrease;

- The relationship between exposure energy density changes and microhardness was identified. In the range of ±10% of the nominal value of the parameters, an increase of microhardness with an increase of the exposure energy density was observed. The microhardness increase is connected with the combined effect of grain refinement strengthening (Hall–Petch relation) and grain boundary strengthening [22];

- Conducted analyses of porosity and microhardness allowed for the selection of 5 groups of parameters which will be used to produce specimens for further research.

Author Contributions

Funding

Conflicts of Interest

References

- Siemiński, P.; Budzik, G. Additive Manufacturing. 3D Printing. 3D Printers; Warsaw University of Technology Publishing House: Warsaw, Poland, 2015. (In Polish) [Google Scholar]

- Badiru, A.B.; Valencia, V.V.; Liu, D. Additive Manufacturing Handbook: Product Development for the Defense Industry, 1st ed.; CRC Press: Baca Raton, FL, USA, 24 May 2017. [Google Scholar]

- Zadpoor, A.A. Frontiers of additively manufactured metallic materials. Materials 2018, 11, 1566. [Google Scholar] [CrossRef] [PubMed]

- Sayeed Ahmed, G.; Algarni, S. Development and FE thermal analysis of a radially grooved brake disc developed through direct metal laser sintering. Materials 2018, 11, 1211. [Google Scholar] [CrossRef] [PubMed]

- Demir, A.G.; Previtali, B. Additive manufacturing of cardiovascular CoCr stents by selective laser melting. Mater. Des. 2017, 119, 338–350. [Google Scholar] [CrossRef]

- Fousova, M.; Dvorsky, D.; Vronka, M.; Vojtech, D.; Lejcek, P. The use of selective laser melting to increase the performance of AlSi9Cu3Fe alloy. Materials 2018, 11, 1918. [Google Scholar] [CrossRef] [PubMed]

- AlMangour, B.; Grzesiak, D.; Yang, J.M. In-situ formation of novel TiC-particle-reinforced 316L stainless steel bulk-form composites by selective laser melting. J. Alloy Compd. 2017, 706, 409–418. [Google Scholar] [CrossRef]

- Han, X.; Sawada, T.; Schille, C.; Schweizer, E.; Scheideler, L.; Geis-Gerstorfer, J.; Rupp, F.; Spintzyk, S. Comparative analysis of mechanical properties and metal-ceramic bond strength of Co-Cr dental alloy fabricated by different manufacturing processes. Materials 2018, 11, 1801. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Kustov, S.; Van Humbeeck, J. A short review on the microstructure, transformation behavior and functional properties of NiTi shape memory alloys fabricated by selective laser melting. Materials 2018, 11, 1683. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Y.; Liu, L.; Wikman, S.; Cui, D.; Shen, Z. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J. Nucl. Mater. 2016, 470, 170–178. [Google Scholar] [CrossRef]

- Lu, Y.; Gan, Y.; Lin, J.; Guo, S.; Wu, S.; Lin, J. Effect of laser speeds on the mechanical property and corrosion resistance of CoCrW alloy fabricated by SLM. Rapid Prototyp. J. 2017, 23, 28–33. [Google Scholar] [CrossRef]

- Riemer, A.; Leuders, S.; Thöne, M.; Richard, H.A.; Tröster, T.; Niendorf, T. On the fatigue crack growth behavior in 316L stainless steel manufactured by selective laser melting. Eng. Fract. Mech. 2014, 120, 15–25. [Google Scholar] [CrossRef]

- Fousova, M.; Vojtech, D.; Doubrava, K.; Daniel, M.; Lin, C.F. Influence of inherent surface and internal defects on mechanical properties of additively manufactured Ti6Al4V alloy: Comparison between selective laser melting and electron beam melting. Materials 2018, 11, 537. [Google Scholar] [CrossRef] [PubMed]

- Bassoli, E.; Denti, L. Assay of secondary anisotropy in additively manufactured alloys for dental applications. Materials 2018, 11, 1831. [Google Scholar] [CrossRef] [PubMed]

- AlMangour, B.; Grzesiak, D.; Cheng, J.; Ertas, Y. Thermal behavior of the molten pool, microstructural evolution, and tribological performance during selective laser melting of TiC/316L stainless steel nanocomposites: Experimental and simulation methods. J. Mater. Process. Technol. 2018, 257, 288–301. [Google Scholar] [CrossRef]

- Metelkova, J.; Kinds, Y.; Kempen, K.; de Formanoir, C.; Witvrouw, A.; Van Hooreweder, B. On the influence of laser defocusing in Selective Laser Melting of 316L. Addit. Manuf. 2018, 23, 161–169. [Google Scholar] [CrossRef]

- Yasa, E.; Kruth, J.P. Microstructural investigation of selective laser melting 316L stainless steel parts exposed to laser re-melting. Procedia Eng. 2011, 19, 389–395. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Z.; Yang, Y.; Wang, D. Research on the microstructure and properties of the overhanging structure formed by selective laser melting. Rapid Prototyp. J. 2017, 23, 904–910. [Google Scholar] [CrossRef]

- Morgan, R.; Sutcliffe, C.J.; O’Neill, W. Density analysis of direct metal laser re-melted 316L stainless steel cubic primitives. J. Mater. Sci. 2004, 39, 1195–1205. [Google Scholar] [CrossRef]

- Mahmoudi, M.; Elwany, A.; Yadollahi, A.; Thompson, S.M.; Bian, L.; Shamsaei, N. Mechanical properties and microstructural characterization of selective laser melted 17-4 PH stainless steel. Rapid Prototyp. J. 2017, 23, 280–294. [Google Scholar] [CrossRef]

- Delgado, J.; Ciurana, J.; Rodríguez, C.A. Influence of process parameters on part quality and mechanical properties for DMLS and SLM with iron-based materials. Int. J. Adv. Manuf. Technol. 2012, 60, 601–610. [Google Scholar] [CrossRef]

- Kluczyński, J. Strength Properties Analysis of Additive Manufactured Elements SLM Technology. In Proceedings of the Knowledge and Innovations materals from the 3rd Young Scientists Conference, Warsaw, Poland, November 2015. [Google Scholar]

- Lu, Y.; Zhang, Y.; Cong, M.; Li, X.; Xu, W.; Song, L. Microstructures, mechanical and corrosion properties of the extruded AZ31-xCaO alloys. Materials 2018, 11, 1467. [Google Scholar] [CrossRef] [PubMed]

- Yadollahi, A.; Sjamsaei, N.; Thompson, S.M.; Seely, D.W. Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Mater. Sci. Eng. A 2015, 644, 171–183. [Google Scholar] [CrossRef]

- Zhu, Y.; Peng, T.; Jia, G.; Zhang, H.; Xu, S.; Yang, H. Electrical energy consumption and mechanical properties of selective-laser-melting-produced 316L stainless steel samples using various processing parameters. J. Clean. Prod. 2019, 208, 77–85. [Google Scholar] [CrossRef]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Borkar, T.; Yang, J.M. Densification behavior, microstructural evolution, and mechanical properties of TiC/316L stainless steel nanocomposites fabricated by selective laser melting. Mater. Des. 2018, 138, 119–128. [Google Scholar] [CrossRef]

- Alsalla, H.H.; Smith, C.; Hao, L. Effect of build orientation on the surface quality, microstructure and mechanical properties of selective laser melting 316L stainless steel. Rapid Prototyp. J. 2018, 24, 9–17. [Google Scholar] [CrossRef] [Green Version]

- Huang, C.; Lin, X.; Yang, H.; Liu, F.; Huang, W. Microstructure and tribological properties of laser forming repaired 34CrNiMo6 steel. Materials 2018, 11, 1722. [Google Scholar] [CrossRef] [PubMed]

- Bültmann, J.; Merkt, S.; Hammer, C.; Hinke, C.; Prahl, U. Scalability of the mechanical properties of selective laser melting produced micro-struts. J. Laser Appl. 2015, 27, S29206. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Y.; Yang, Y.; Xiao, D. Theoretical and experimental study on Surface roughness of 316L stainless steel metal parts obtained through selective laser melting. Rapid Prototyp. J. 2016, 22, 706–716. [Google Scholar] [CrossRef]

| C | Mn | Si | P | S | N | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| wt.% | ||||||||

| max. 0.03 | max. 2.00 | max. 0.75 | max. 0.04 | max. 0.03 | max. 0.10 | 16.00–18.00 | 2.00–3.00 | 10.00–14.00 |

| Parameters Set | LP [W] | ev [mm/s] | hd [mm] | ρE [J/mm3] |

|---|---|---|---|---|

| 1 | 190 | 900 | 0.12 | 58.64 |

| 2 | 190 | 990 | 0.12 | 53.31 |

| 3 | 190 | 810 | 0.12 | 65.16 |

| 4 | 200 | 900 | 0.12 | 61.73 |

| 5 | 200 | 990 | 0.12 | 56.12 |

| 6 | 200 | 810 | 0.12 | 68.59 |

| 7 | 180 | 900 | 0.12 | 55.56 |

| 8 | 180 | 990 | 0.12 | 50.51 |

| 9 | 180 | 810 | 0.12 | 61.73 |

| 10 | 190 | 900 | 0.13 | 54.13 |

| 11 | 190 | 990 | 0.13 | 49.21 |

| 12 | 190 | 810 | 0.13 | 60.15 |

| 13 | 200 | 900 | 0.13 | 56.98 |

| 14 | 200 | 990 | 0.13 | 51.80 |

| 15 | 200 | 810 | 0.13 | 63.31 |

| 16 | 180 | 900 | 0.13 | 51.28 |

| 17 | 180 | 990 | 0.13 | 46.62 |

| 18 | 180 | 810 | 0.13 | 56.98 |

| 19 | 190 | 900 | 0.11 | 63.97 |

| 20 | 190 | 990 | 0.11 | 58.16 |

| 21 | 190 | 810 | 0.11 | 71.08 |

| 22 | 200 | 900 | 0.11 | 67.34 |

| 23 | 200 | 990 | 0.11 | 61.22 |

| 24 | 200 | 810 | 0.11 | 74.82 |

| 25 | 180 | 900 | 0.11 | 60.61 |

| 26 | 180 | 990 | 0.11 | 55.10 |

| 27 | 180 | 810 | 0.11 | 67.34 |

| 28 | 150 | 400 | 0.08 | 156.25 |

| 29 | 150 | 700 | 0.06 | 119.05 |

| 30 | 120 | 300 | 0.08 | 166.67 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kluczyński, J.; Śnieżek, L.; Grzelak, K.; Mierzyński, J. The Influence of Exposure Energy Density on Porosity and Microhardness of the SLM Additive Manufactured Elements. Materials 2018, 11, 2304. https://doi.org/10.3390/ma11112304

Kluczyński J, Śnieżek L, Grzelak K, Mierzyński J. The Influence of Exposure Energy Density on Porosity and Microhardness of the SLM Additive Manufactured Elements. Materials. 2018; 11(11):2304. https://doi.org/10.3390/ma11112304

Chicago/Turabian StyleKluczyński, Janusz, Lucjan Śnieżek, Krzysztof Grzelak, and Janusz Mierzyński. 2018. "The Influence of Exposure Energy Density on Porosity and Microhardness of the SLM Additive Manufactured Elements" Materials 11, no. 11: 2304. https://doi.org/10.3390/ma11112304

APA StyleKluczyński, J., Śnieżek, L., Grzelak, K., & Mierzyński, J. (2018). The Influence of Exposure Energy Density on Porosity and Microhardness of the SLM Additive Manufactured Elements. Materials, 11(11), 2304. https://doi.org/10.3390/ma11112304