Synergistic Enhancement of Thermal Conductivity and Dielectric Properties in Al2O3/BaTiO3/PP Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PP Powders

2.3. Preparation of Composite Sample

2.4. Characterizations

3. Results and Discussion

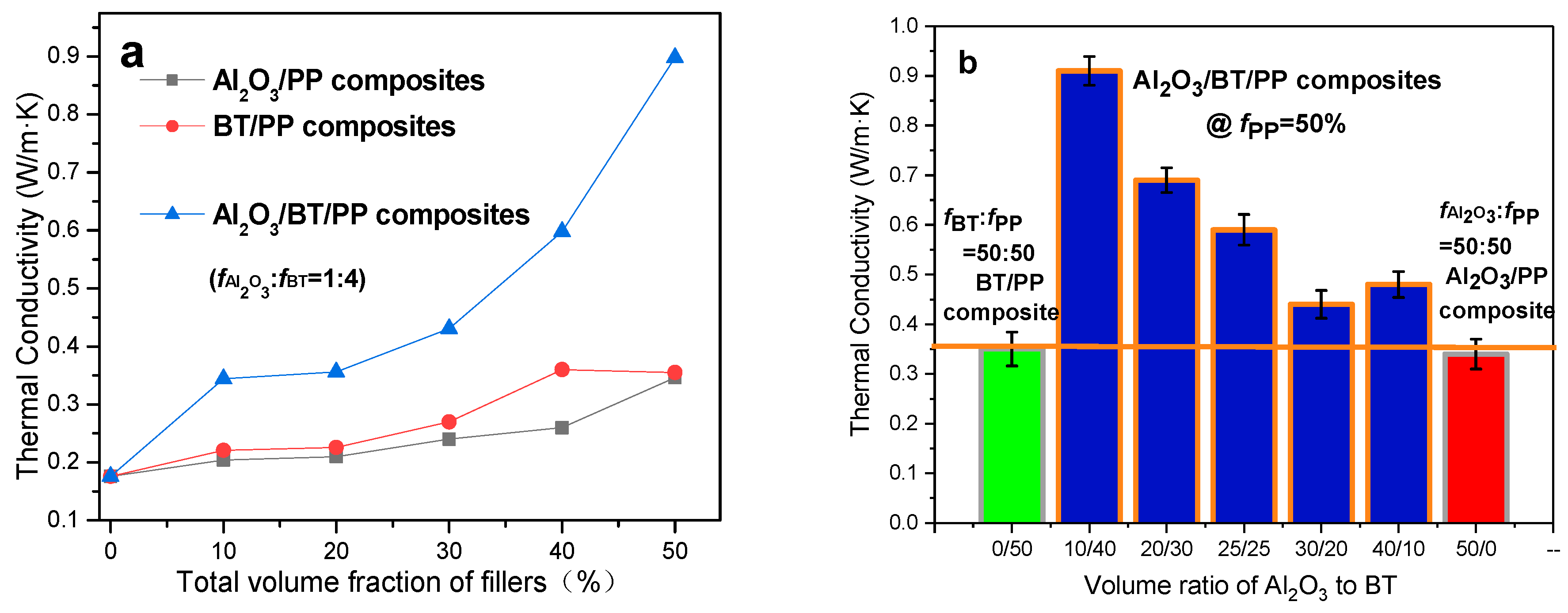

3.1. Thermal Conductivity of the Composites

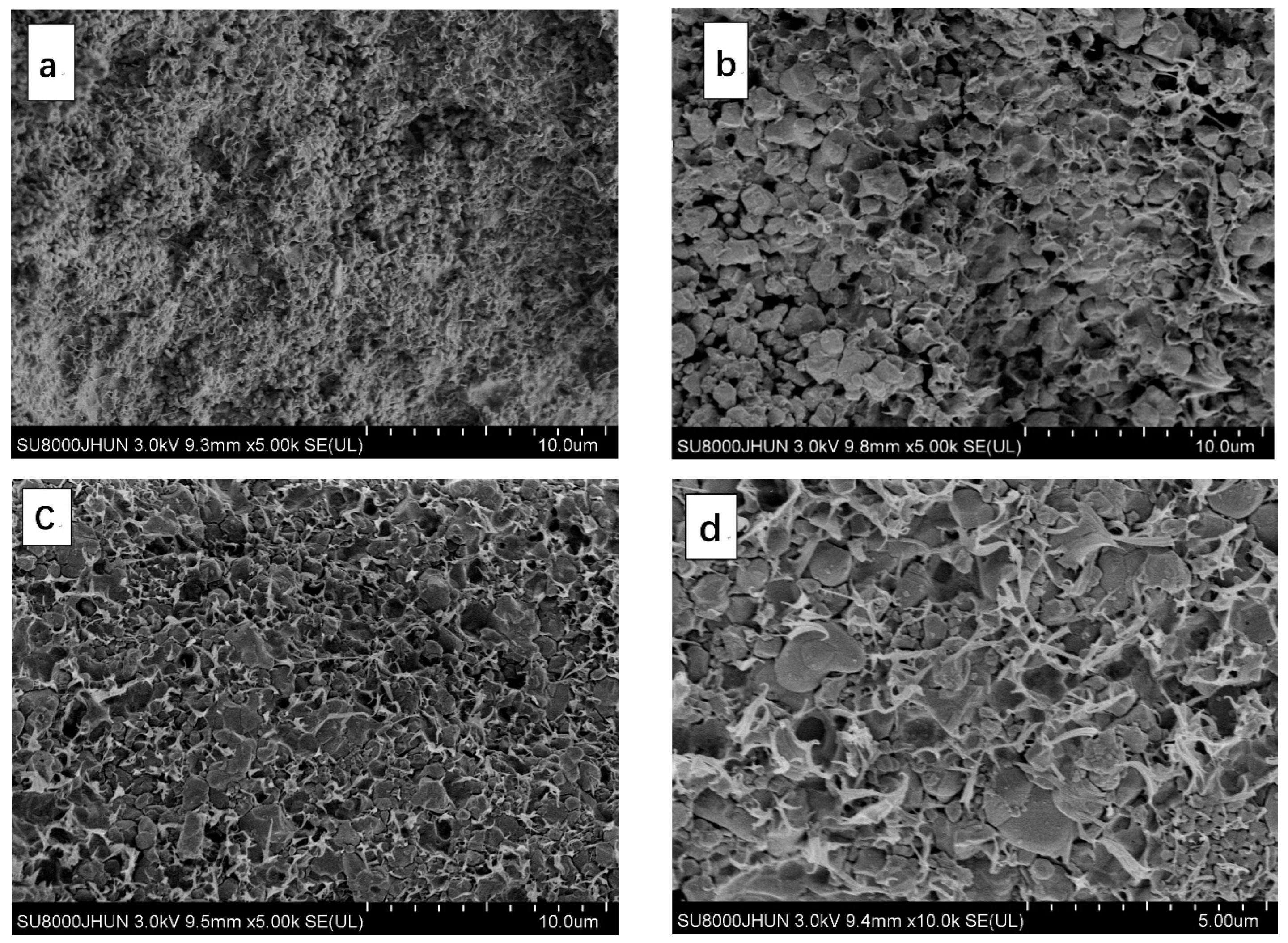

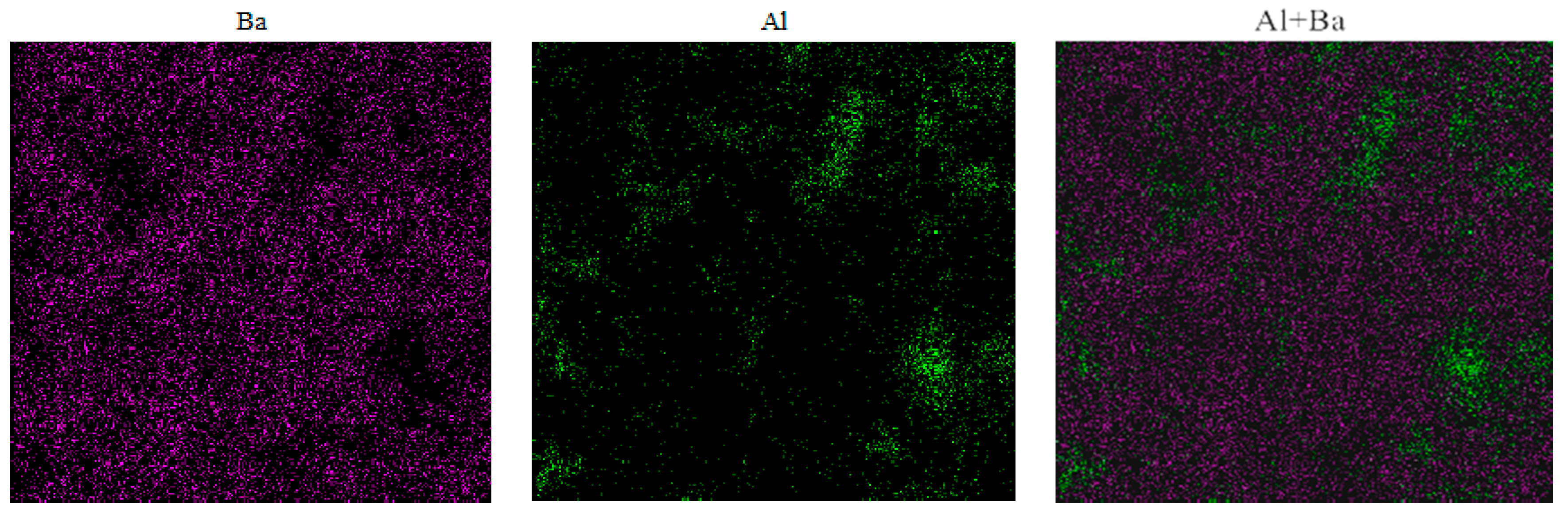

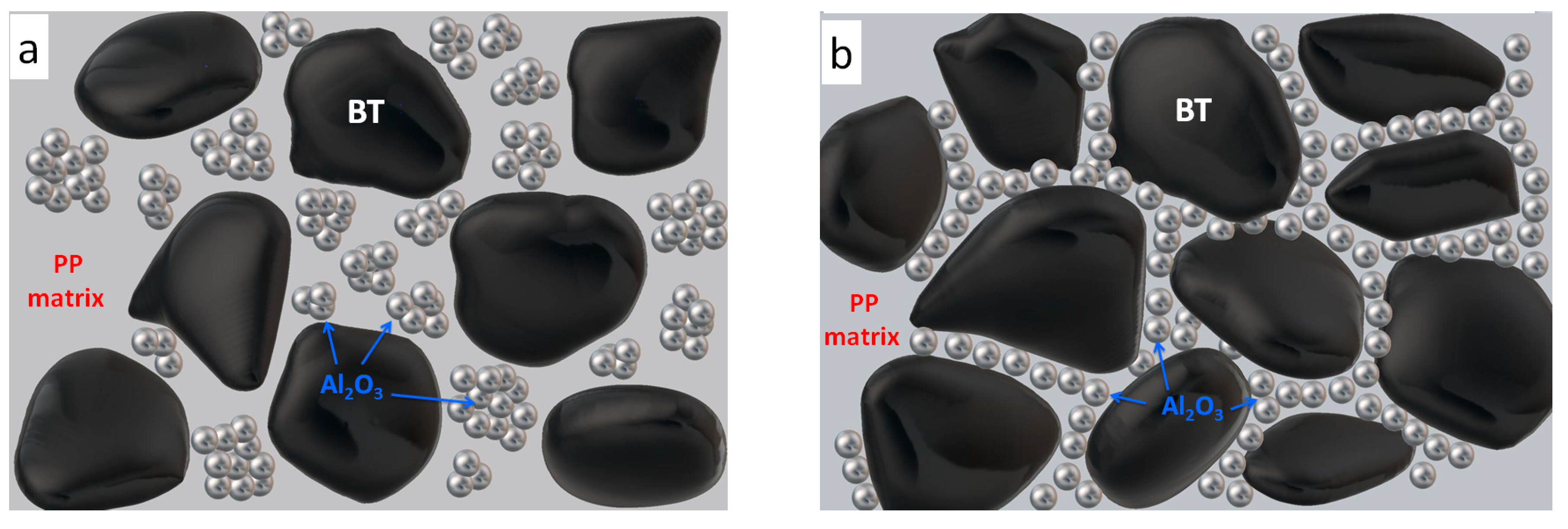

3.2. The Micrographs of Al2O3/BT/PP, Al2O3/PP and BT/PP Composites

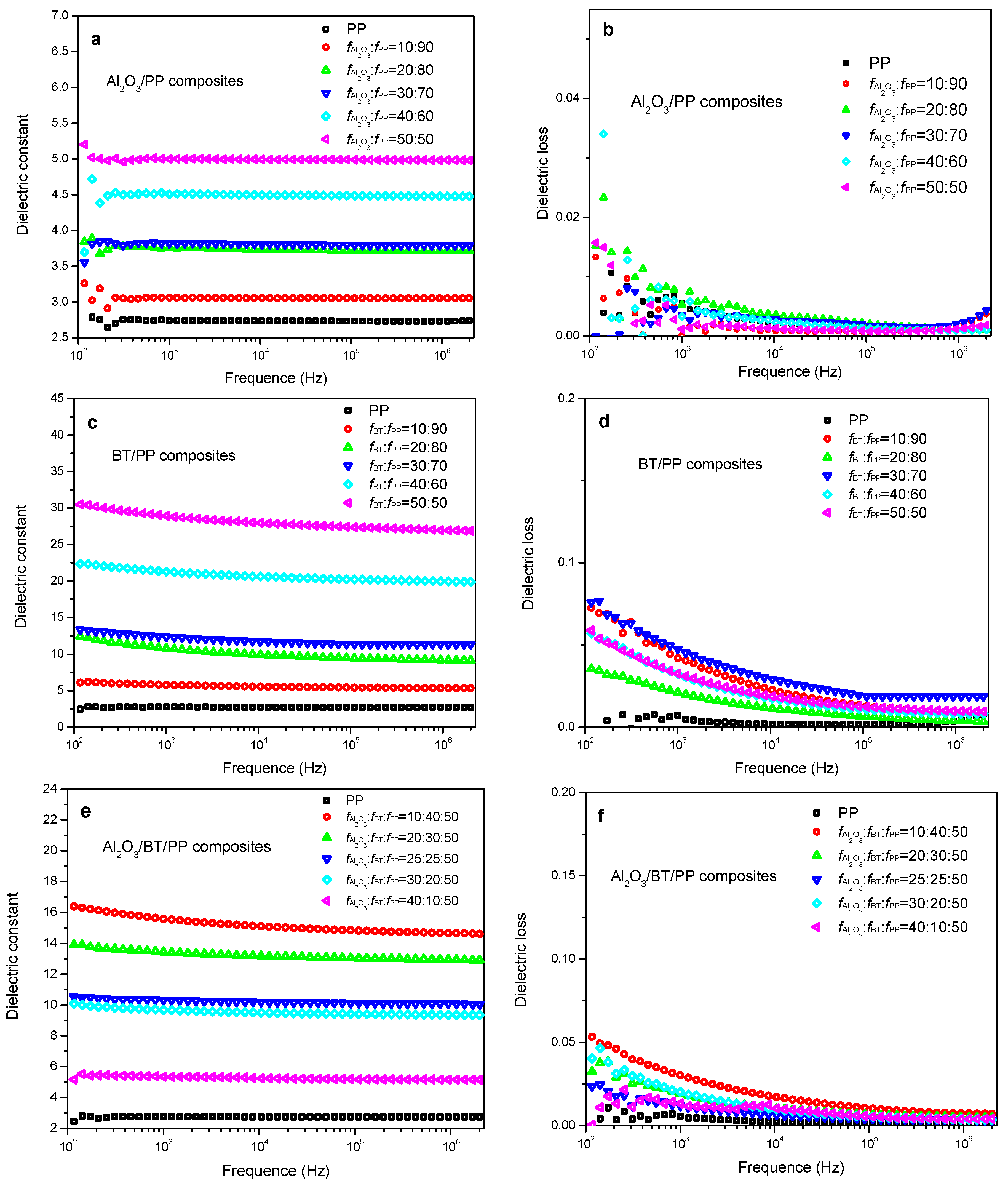

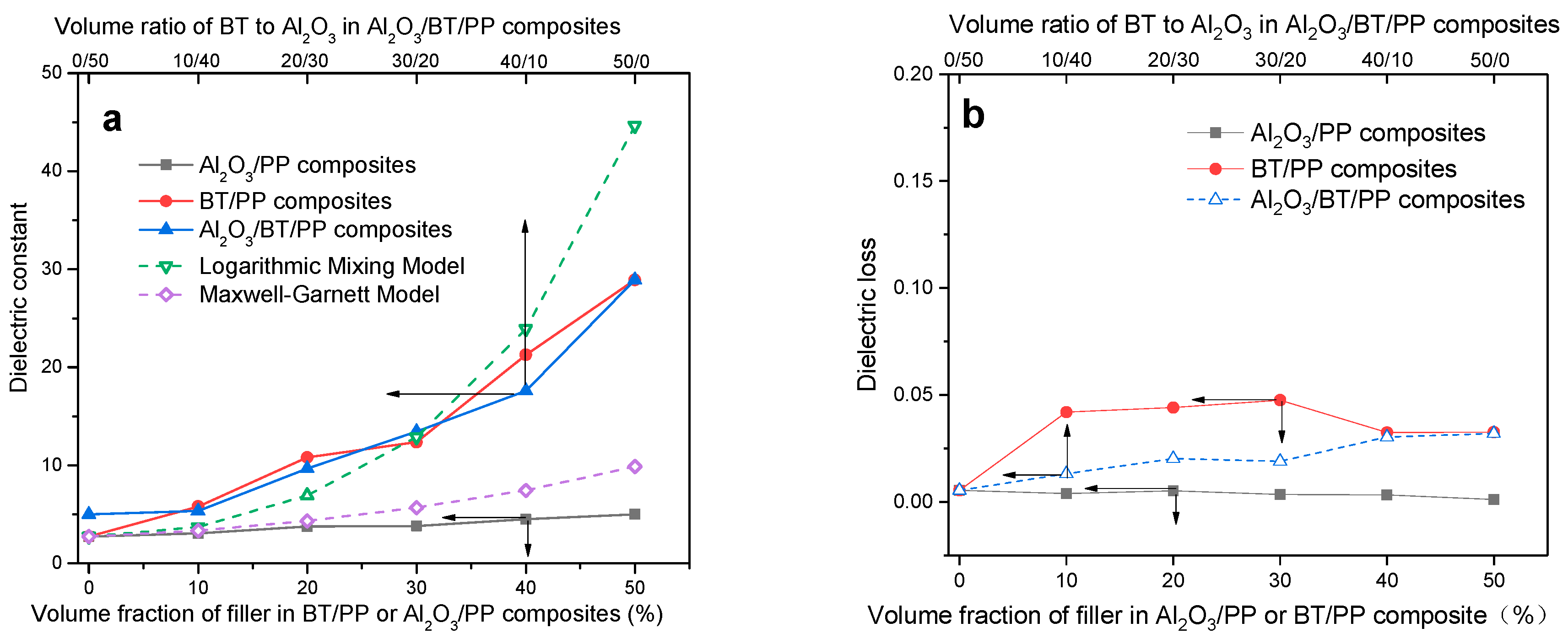

3.3. Dielectric Properties of the Composites

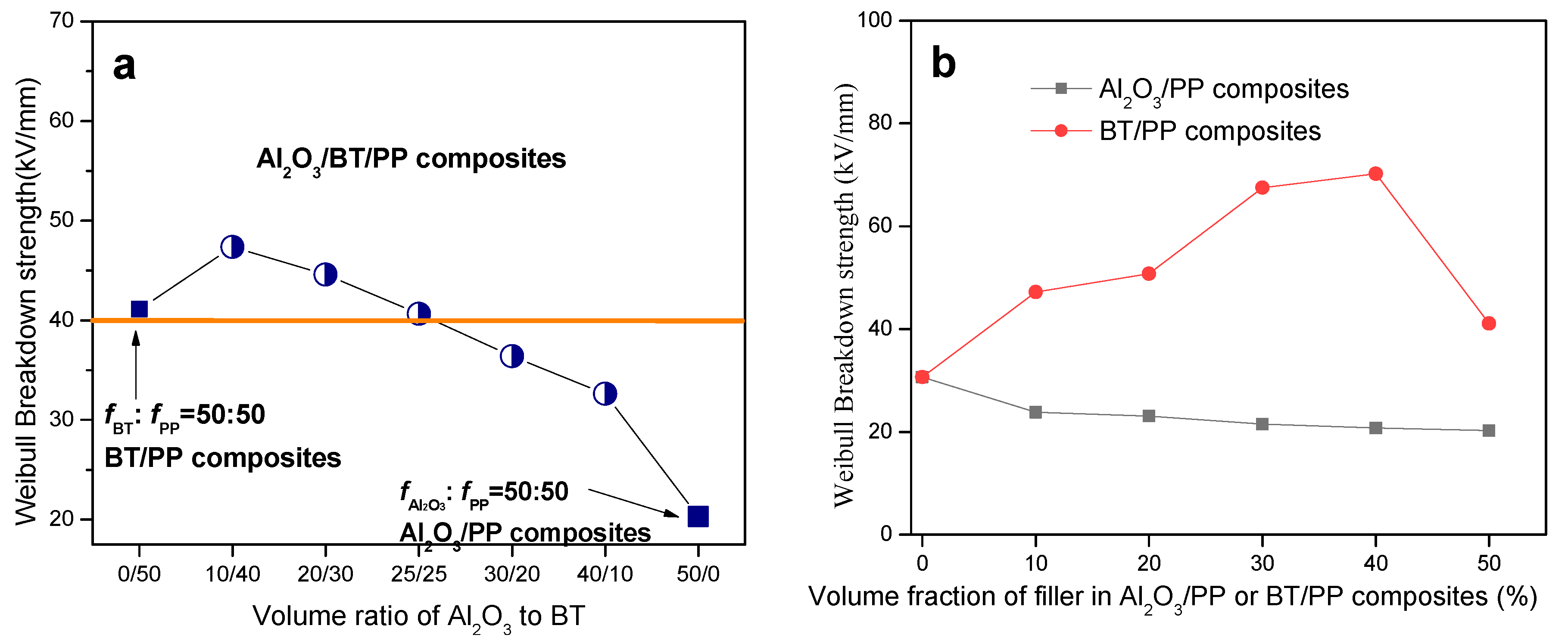

3.4. Breakdown Strength of the Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, Q.; Chen, L.; Gadinski, M.R.; Zhang, S.; Zhang, G.; Li, U.; Iagodkine, E.; Haque, A.; Chen, L.Q.; Jackson, N.; et al. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 2015, 523, 576–579. [Google Scholar] [CrossRef] [PubMed]

- Abdalla, S.; Al-Marzouki, F.; Obaid, A.; Gamal, S. Effect of addition of colloidal silica to films of polyimide, polyvinylpyridine, polystyrene, and polymethylmethacrylate nano-composites. Materials 2016, 9, 104. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Liu, F.H.; Yang, T.N.; Gadinski, M.R.; Zhang, G.Z.; Chen, L.Q.; Wang, Q. Sandwich-structured polymer nanocomposites with high energy density and great charge-discharge efficiency at elevated temperatures. Proc. Natl. Acad. Sci. USA 2016, 113, 9995–10000. [Google Scholar] [CrossRef] [PubMed]

- Yao, J.L.; Xiong, C.X.; Dong, L.J.; Chen, C.; Lei, Y.A.; Chen, L.; Li, R.; Zhu, Q.M.; Liu, X.F. Enhancement of dielectric constant and piezoelectric coefficient of ceramic-polymer composites by interface chelation. J. Mater. Chem. 2009, 19, 2817–2821. [Google Scholar] [CrossRef]

- Han, S.; Yang, X.; Zhuang, X.; Yu, J.; Li, L. Tailoring the dielectric layer structure for enhanced performance of organic field-effect transistors: The use of a sandwiched polar dielectric layer. Materials 2016, 9, 545. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Yao, J.; Liu, Y.; Tuo, X.; Da, Y.; Zeng, X.; Li, L. 3D nanostructured polypyrrole/sodium alginate conducting hydrogel from self-assembly with high supercapacitor performance. J. Macromol. Sci. B 2017, 56, 532–540. [Google Scholar] [CrossRef]

- Huang, H.B.; Yao, J.L.; Li, L.; Zhu, F.; Liu, Z.T.; Zeng, X.P.; Yu, X.H.; Huang, Z.L. Reinforced polyaniline/polyvinyl alcohol conducting hydrogel from a freezing-thawing method as self-supported electrode for supercapacitors. J. Mater. Sci. 2016, 51, 8728–8736. [Google Scholar] [CrossRef]

- Barshaw, E.J.; White, J.; Chait, M.J.; Cornette, J.B.; Bustamante, J.; Folli, F.; Biltchick, D.; Borelli, G.; Picci, G.; Rabuffi, M. High energy density (HED) biaxially-oriented poly-propylene (BOPP) capacitors for pulse power applications. IEEE Trans. Magn. 2007, 43, 223–225. [Google Scholar] [CrossRef]

- Azizi, A.; Gadinski, M.R.; Li, Q.; AlSaud, M.A.; Wang, J.; Wang, Y.; Wang, B.; Liu, F.; Chen, L.-Q.; Alem, N.; et al. High-performance polymers sandwiched with chemical vapor deposited hexagonal boron nitrides as scalable high-temperature dielectric materials. Adv. Mater. 2017, 29, 1701864. [Google Scholar] [CrossRef] [PubMed]

- Chung, J.Y.; Lee, J.G.; Baek, Y.K.; Shin, P.W.; Kim, Y.K. Magnetic field-induced enhancement of thermal conductivities in polymer composites by linear clustering of spherical particles. Compos. Part B 2018, 136, 215–221. [Google Scholar] [CrossRef]

- Liu, F.; Li, Q.; Cui, J.; Li, Z.; Yang, G.; Liu, Y.; Dong, L.; Xiong, C.; Wang, H.; Wang, Q. High-energy-density dielectric polymer nanocomposites with trilayered architecture. Adv. Funct. Mater. 2017, 27, 1606292. [Google Scholar] [CrossRef]

- Kim, P.; Jones, S.C.; Hotchkiss, P.J.; Haddock, J.N.; Kippelen, B.; Marder, S.R.; Perry, J.W. Phosphonic acid-modified barium titanate polymer nanocomposites with high permittivity and dielectric strength. Adv. Mater. 2007, 19, 1001–1005. [Google Scholar] [CrossRef]

- Tan, D.; Zhang, L.L.; Chen, Q.; Irwin, P. High-temperature capacitor polymer films. J. Electron. Mater. 2014, 43, 4569–4575. [Google Scholar] [CrossRef]

- Ouyang, Y.; Hou, G.; Bai, L.; Li, B.; Yuan, F. Constructing continuous networks by branched alumina for enhanced thermal conductivity of polymer composites. Compos. Sci. Technol. 2018, 165, 307–313. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhai, Z.; Drummer, D. Thermal conductivity of aluminosilicate- and aluminum oxide-filled thermosets for injection molding: Effect of filler content, filler size and filler geometry. Polymers 2018, 10, 457. [Google Scholar] [CrossRef]

- Liu, F.H.; Li, Q.; Li, Z.Y.; Liu, Y.; Dong, L.J.; Xiong, C.X.; Wang, Q. Poly(methyl methacrylate)/boron nitride nanocomposites with enhanced energy density as high temperature dielectrics. Compos. Sci. Technol. 2017, 142, 139–144. [Google Scholar] [CrossRef]

- Terao, T.; Zhi, C.Y.; Bando, Y.; Mitome, M.; Tang, C.C.; Golberg, D. Alignment of boron nitride nanotubes in polymeric composite films for thermal conductivity improvement. J. Phys. Chem. C 2010, 114, 4340–4344. [Google Scholar] [CrossRef]

- Hu, J.T.; Huang, Y.; Yao, Y.M.; Pan, G.R.; Sun, J.J.; Zeng, X.L.; Sun, R.; Xu, J.B.; Song, B.; Wong, C.P. Polymer composite with improved thermal conductivity by constructing a hierarchically ordered three-dimensional interconnected network of BN. ACS Appl. Mater. Interfaces 2017, 9, 13544–13553. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Zhao, H.; He, D.; Hu, C.; Chen, H.; Bai, J. Carbon coated boron nitride nanosheets for polymer nanocomposites with enhanced dielectric performance. Materials 2017, 10, 741. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.M.; Wang, X.H.; Luo, B.C.; Li, L.T. Hierarchical-structured dielectric permittivity and breakdown performances of polymer-ceramic nanocomposites. Ceram. Int. 2018, 44, 843–848. [Google Scholar] [CrossRef]

- Ruan, M.N.; Yang, D.; Guo, W.L.; Zhang, L.Q.; Li, S.X.; Shang, Y.W.; Wu, Y.B.; Zhang, M.; Wang, H. Improved dielectric properties, mechanical properties, and thermal conductivity properties of polymer composites via controlling interfacial compatibility with bio-inspired method. Appl. Surf. Sci. 2018, 439, 186–195. [Google Scholar] [CrossRef]

- Yang, C.T.; Hsiang, H.I.; Huang, T.S.; Huang, P.C.; Han, Y.K. Thermal conductivity and dielectric properties of PEDOT: PSS-AlN filler reinforced water-soluble polymer composites. Ceram. Int. 2017, 43, 710–716. [Google Scholar] [CrossRef]

- Rajeshwari, P.; Dey, T.K. Finite element modelling and experimental investigation on effective thermal conductivity of AIN (nano) particles reinforced HDPE polymer nanocomposites. Thermochim. Acta 2016, 638, 103–112. [Google Scholar] [CrossRef]

- Ali, A.F.; Hassan, M.L.; Ward, A.A.; El-Giar, E.M. Processing, dynamic mechanical thermal analysis, and dielectric properties of barium titanate/cellulosic polymer nanocomposites. Polym. Compos. 2017, 38, 893–907. [Google Scholar] [CrossRef]

- Li, R.; Zhou, J.; Liu, H.; Pei, J. Effect of polymer matrix on the structure and electric properties of piezoelectric lead zirconatetitanate/polymer composites. Materials 2017, 10, 945. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Zeng, X.; Guo, K.; Sun, R.; Xu, J.-b. The effect of interfacial state on the thermal conductivity of functionalized Al2O3 filled glass fibers reinforced polymer composites. Compos. Part A Appl. Sci. Manuf. 2015, 69, 49–55. [Google Scholar] [CrossRef]

- Liang, S.; Chong, S.R.; Giannelis, E.P. Barium titanate/epoxy composite dielectric materials for integrated thin film capacitors. In Proceedings of the 48th Electronic Components and Technology Conference (Cat. No.98CH36206), Seattle, WA, USA, 25–28 May 1998; pp. 171–175. [Google Scholar]

- Leung, S.N. Thermally conductive polymer composites and nanocomposites: Processing-structure-property relationships. Compos. Part B 2018, 150, 78–92. [Google Scholar] [CrossRef]

- Chen, H.Y.; Ginzburg, V.V.; Yang, J.; Yang, Y.F.; Liu, W.; Huang, Y.; Du, L.B.; Chen, B. Thermal conductivity of polymer-based composites: Fundamentals and applications. Prog. Polym. Sci. 2016, 59, 41–85. [Google Scholar] [CrossRef]

- Huang, C.; Qian, X.; Yang, R. Thermal conductivity of polymers and polymer nanocomposites. Mater. Sci. Eng. R 2018, 132, 1–22. [Google Scholar] [CrossRef]

- Ye, X.; Jin, L.; Caglayan, H.; Chen, J.; Xing, G.; Zheng, C.; Doan-Nguyen, V.; Kang, Y.; Engheta, N.; Kagan, C.R. Improved size-tunable synthesis of monodisperse gold nanorods through the use of aromatic additives. ACS Nano 2012, 6, 2804–2817. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.L.; Zha, J.W.; Li, W.K.; Li, C.Q.; Wang, S.J.; Wen, Y.Q.; Dang, Z.M. Enhanced thermal conductivity and mechanical property through boron nitride hot string in polyvinylidene fluoride fibers by electrospinning. Compos. Sci. Technol. 2018, 156, 1–7. [Google Scholar] [CrossRef]

- Yu, J.; Choi, H.K.; Kim, H.S.; Kim, S.Y. Synergistic effect of hybrid graphene nanoplatelet and multi-walled carbon nanotube fillers on the thermal conductivity of polymer composites and theoretical modeling of the synergistic effect. Compos. Part A 2016, 88, 79–85. [Google Scholar] [CrossRef]

- Bian, Y.; Wu, C.; Li, H.; Zhai, J. A tunable metamaterial dependent on electric field at terahertz with barium strontium titanate thin film. Appl. Phys. Lett. 2014, 104, 563–597. [Google Scholar] [CrossRef]

- Noel, K.M.; Pearson, A.M.; Curry, R.D.; O’Connor, K.A. High frequency properties of high voltage barium titanate-ferrite multiferroic metamaterial composites. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2965–2969. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, S.J.; Park, H.; Lee, B. Metamaterials and metasurfaces for sensor applications. Sensors 2017, 17, 1726. [Google Scholar] [CrossRef] [PubMed]

- Perez-Medina, J.C.; Waldo-Mendoza, M.A.; Cruz-Delgado, V.J.; Quinones-Jurado, Z.V.; Gonzalez-Morones, P.; Ziolo, R.F.; Martinez-Colunga, J.G.; Soriano-Corral, F.; Avila-Orta, C.A. Metamaterial behavior of polymer nanocomposites based on polypropylene/multi-walled carbon nanotubes fabricated by means of ultrasound-assisted extrusion. Materials 2016, 9, 923. [Google Scholar] [CrossRef] [PubMed]

- Liberal, I.; Engheta, N. Near-zero refractive index photonics. Nat. Photonics 2017, 11, 149–158. [Google Scholar] [CrossRef]

- Bao, D.; Rajab, K.Z.; Hao, Y.; Kallos, E.; Tang, W.; Argyropoulos, C.; Piao, Y.; Yang, S. All-dielectric invisibility cloaks made of BaTiO3-loaded polyurethane foam. New J. Phys. 2011, 13, 103023. [Google Scholar] [CrossRef]

- Mulle, M.; Wafai, H.; Yudhanto, A.; Lubineau, G.; Yaldiz, R.; Schijve, W.; Verghese, N. Process monitoring of glass reinforced polypropylene laminates using fiber bragg gratings. Compos. Sci. Technol. 2016, 123, 143–150. [Google Scholar] [CrossRef]

- Zemouli, S.; Chaabi, A.; Talbi, H.S. Design of a compact and high sensitivity temperature sensor using metamaterial. Int. J. Antennas Propag. 2015, 2015, 1–7. [Google Scholar] [CrossRef][Green Version]

- Iovine, R.; Spada, L.L.; Vegni, L. Nanoparticle device for biomedical and optoelectronics applications. Compel 2013, 32, 1596–1608. [Google Scholar] [CrossRef]

- Spada, L.L.; Iovine, R. Electromagnetic modeling of ellipsoidal nanoparticles for sensing applications. Opt. Eng. 2013, 52, 051205. [Google Scholar] [CrossRef]

- Homberger, M.; Simon, U. On the application potential of gold nanoparticles in nanoelectronics and biomedicine. Philos. Trans. R. Soc. A 2010, 368, 1405–1453. [Google Scholar] [CrossRef] [PubMed]

- Spada, L.L.; Iovine, R.; Tarparelli, R.; Vegni, L. Conical nanoparticles for blood disease detection. Adv. Nanopart. 2013, 2, 259–265. [Google Scholar] [CrossRef]

- Liu, Y.; Hao, Y.; Li, K.; Gong, S. Radar cross section reduction of a microstrip antenna based on polarization conversion metamaterial. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 80–83. [Google Scholar] [CrossRef]

- Walker, E.L.; Wang, Z.; Neogi, A. Radio-frequency actuated polymer-based phononic meta-materials for control of ultrasonic waves. NPG Asia Mater. 2017, 9, 350. [Google Scholar] [CrossRef]

- Spada, L.L.; Haq, S.; Hao, Y. Modeling and design for electromagnetic surface wave devices. Radio Sci. 2017, 52, 1049–1057. [Google Scholar] [CrossRef]

- Cai, W.; Chettiar, U.K.; Kildishev, A.V.; Shalaev, V.M. Optical cloaking with metamaterials. Nat. Photonics 2007, 1, 224–227. [Google Scholar] [CrossRef]

- Qin, F.; Ding, L.; Zhang, L.; Monticone, F.; Chan, C.C.; Deng, J.; Mei, S.; Li, Y.; Teng, J.; Hong, M. Hybrid bilayer plasmonic metasurface efficiently manipulates visible light. Sci. Adv. 2016, 2, 1501168. [Google Scholar] [CrossRef] [PubMed]

- Popielarz, R.; Chiang, C.K.; Nozaki, R.; Obrzut, J. Dielectric properties of polymer/ferroelectric ceramic composites from 100 Hz to 10 GHz. Macromolecules 2001, 34, 5910–5915. [Google Scholar] [CrossRef]

- Jayasundere, N.; Smith, B.V. Dielectric constant for binary piezoelectric 0-3 composites. J. Appl. Phys. 1993, 73, 2462–2466. [Google Scholar] [CrossRef]

- Chiang, C.K.; Popielarz, R. Polymer composites with high dielectric constant. Ferroelectrics 2002, 275, 1–9. [Google Scholar] [CrossRef]

- Feng, Y.Z.; He, C.G.; Wen, Y.F.; Zhou, X.P.; Xie, X.L.; Ye, Y.S.; Mai, Y.W. Multi-functional interface tailoring for enhancing thermal conductivity, flame retardancy and dynamic mechanical property of epoxy/Al2O3 composites. Compos. Sci. Technol. 2018, 160, 42–49. [Google Scholar] [CrossRef]

- Cai, Z.M.; Wang, X.H.; Luo, B.C.; Hong, W.; Wu, L.W.; Li, L.T. Dielectric response and breakdown behavior of polymer-ceramic nanocomposites: The effect of nanoparticle distribution. Compos. Sci. Technol. 2017, 145, 105–113. [Google Scholar] [CrossRef]

- Neese, B.; Chu, B.J.; Lu, S.G.; Wang, Y.; Furman, E.; Zhang, Q.M. Large electrocaloric effect in ferroelectric polymers near room temperature. Science 2008, 321, 821–823. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Zhang, G.Z.; Liu, F.H.; Han, K.; Gadinski, M.R.; Xiong, C.X.; Wang, Q. Solution-processed ferroelectric terpolymer nanocomposites with high breakdown strength and energy density utilizing boron nitride nanosheets. Energy Environ. Sci. 2015, 8, 922–931. [Google Scholar] [CrossRef]

| Materials | Average Particle Size (μm) | Density (g/cm3) | Dielectric Constant @ 1000 Hz | Breakdown Strength (kV/mm) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|---|

| Al2O3 | 0.1 | 4.00 | 10 | 15 | 42 |

| BT | 3 | 5.85 | 1000 | 3 | 6.2 |

| PP | - | 0.92 | 2.5 | 30 | 0.14 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, J.; Hu, L.; Zhou, M.; You, F.; Jiang, X.; Gao, L.; Wang, Q.; Sun, Z.; Wang, J. Synergistic Enhancement of Thermal Conductivity and Dielectric Properties in Al2O3/BaTiO3/PP Composites. Materials 2018, 11, 1536. https://doi.org/10.3390/ma11091536

Yao J, Hu L, Zhou M, You F, Jiang X, Gao L, Wang Q, Sun Z, Wang J. Synergistic Enhancement of Thermal Conductivity and Dielectric Properties in Al2O3/BaTiO3/PP Composites. Materials. 2018; 11(9):1536. https://doi.org/10.3390/ma11091536

Chicago/Turabian StyleYao, Junlong, Li Hu, Min Zhou, Feng You, Xueliang Jiang, Lin Gao, Qing Wang, Zhengguang Sun, and Jun Wang. 2018. "Synergistic Enhancement of Thermal Conductivity and Dielectric Properties in Al2O3/BaTiO3/PP Composites" Materials 11, no. 9: 1536. https://doi.org/10.3390/ma11091536

APA StyleYao, J., Hu, L., Zhou, M., You, F., Jiang, X., Gao, L., Wang, Q., Sun, Z., & Wang, J. (2018). Synergistic Enhancement of Thermal Conductivity and Dielectric Properties in Al2O3/BaTiO3/PP Composites. Materials, 11(9), 1536. https://doi.org/10.3390/ma11091536