Dislocation Densities and Velocities within the γ Channels of an SX Superalloy during In Situ High-Temperature Creep Tests

Abstract

1. Introduction

2. Materials and Methods

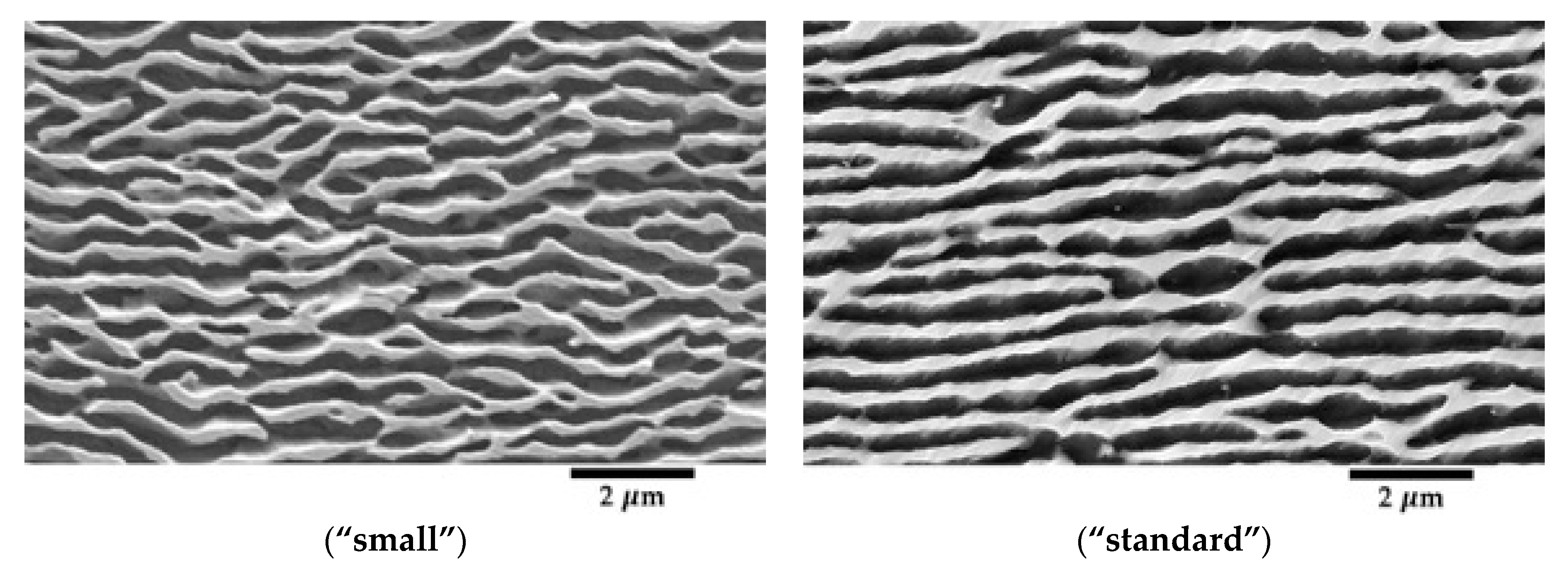

2.1. Materials

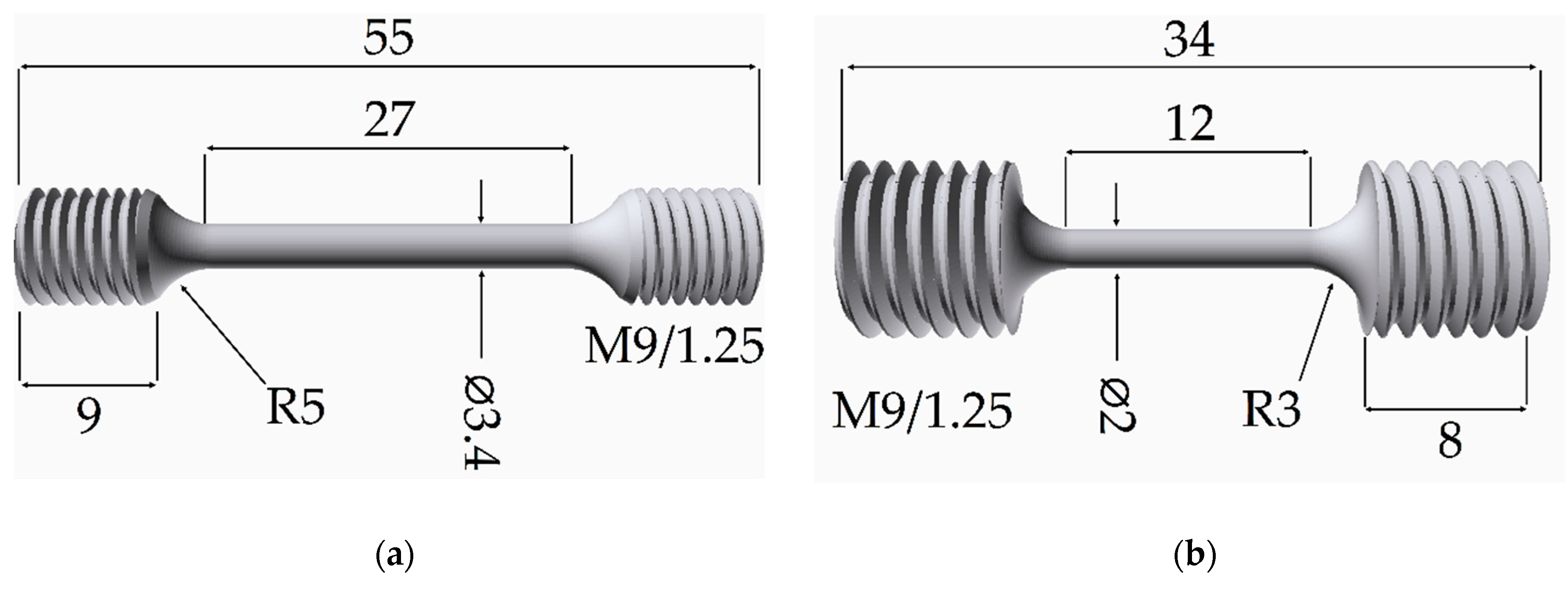

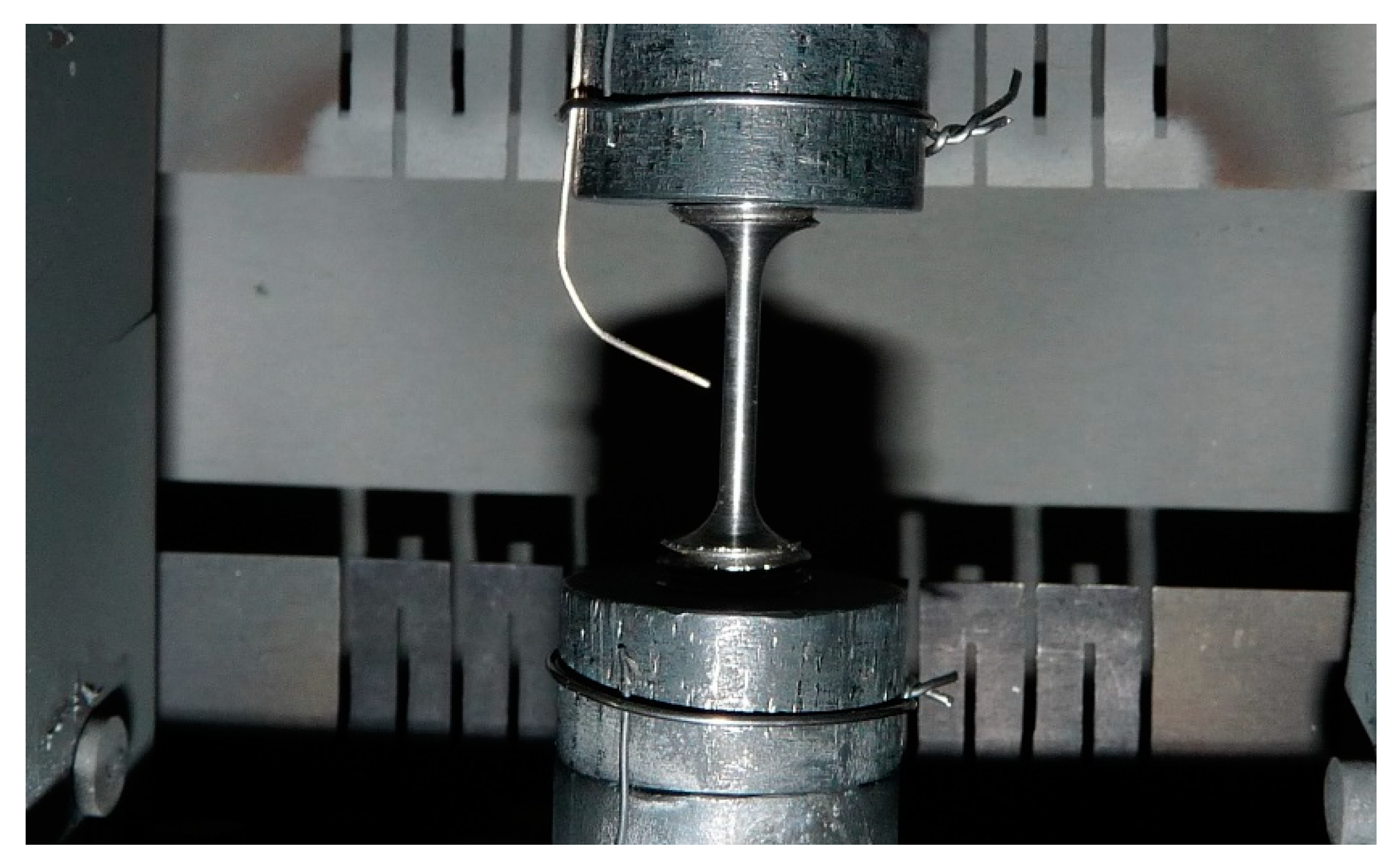

2.2. High-Temperature Straining Device

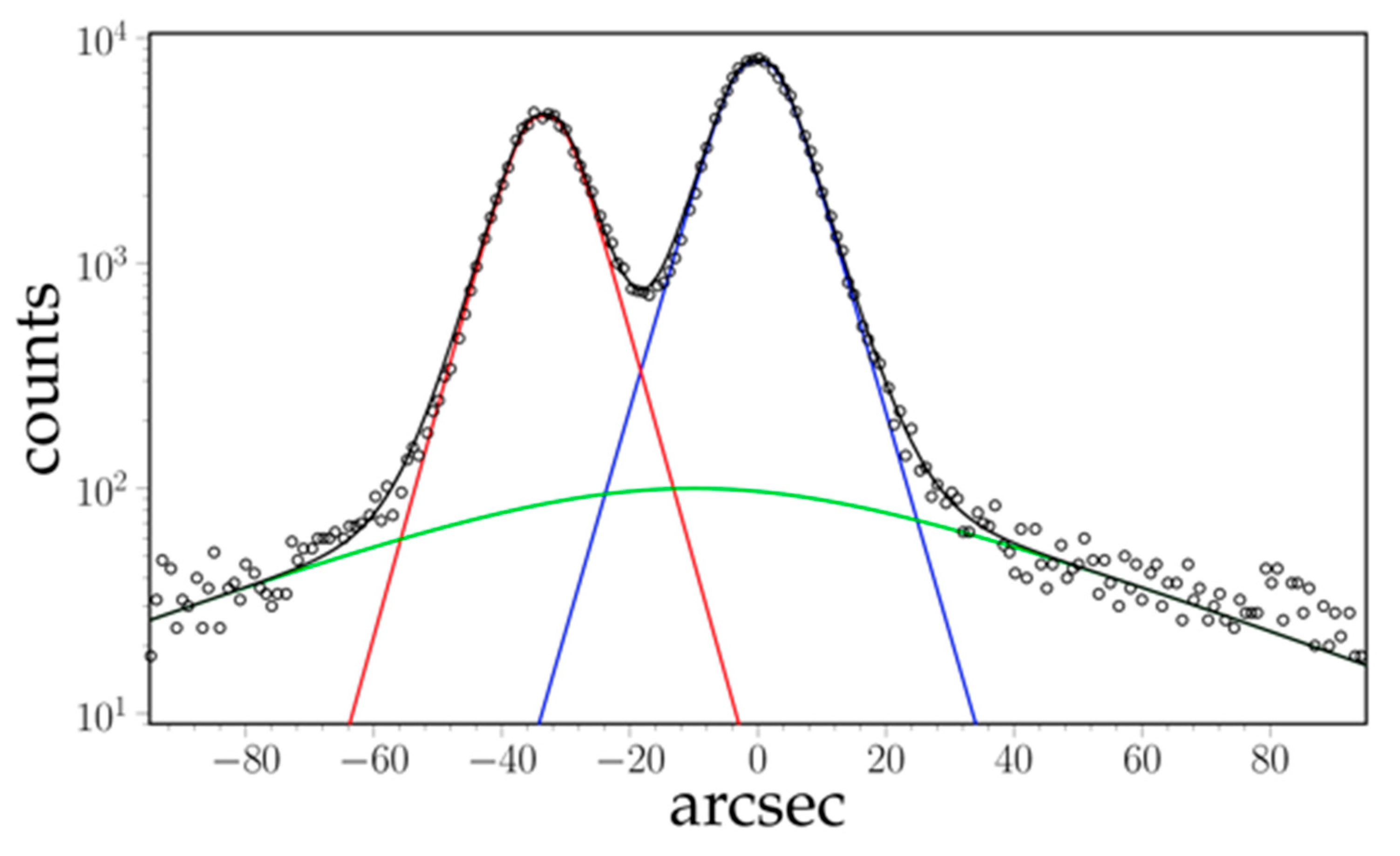

2.3. In Situ XRD

2.4. Post Mortem TEM and SEM Studies

2.5. Data Analysis

- homogenous and isotropic phases

- same Poisson coefficient [4]

- distinct Young’s moduli:

- symmetric stress tensors (i.e., ).

3. Results

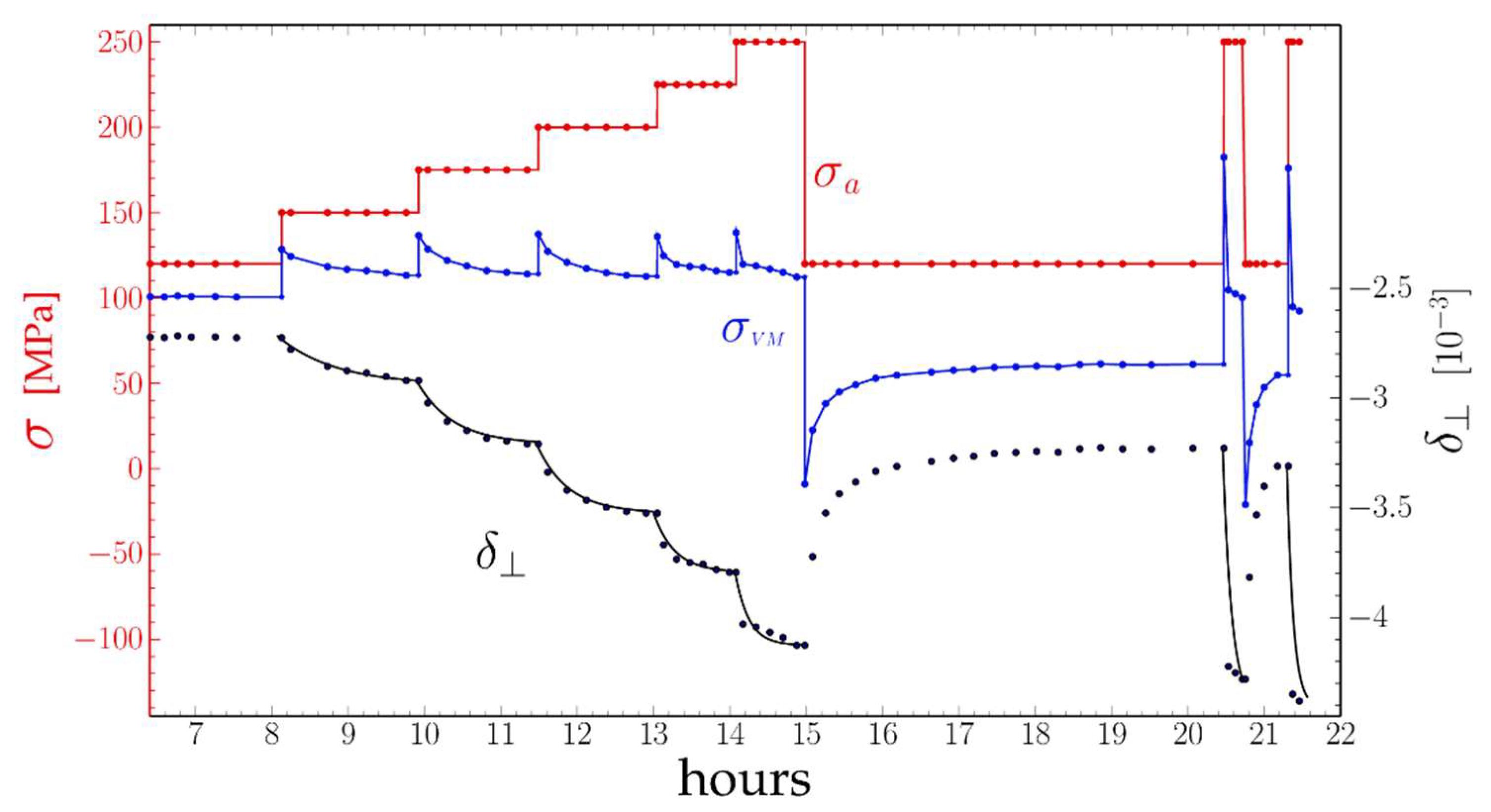

3.1. Real-Time Experiment with Far-Field Diffractometry

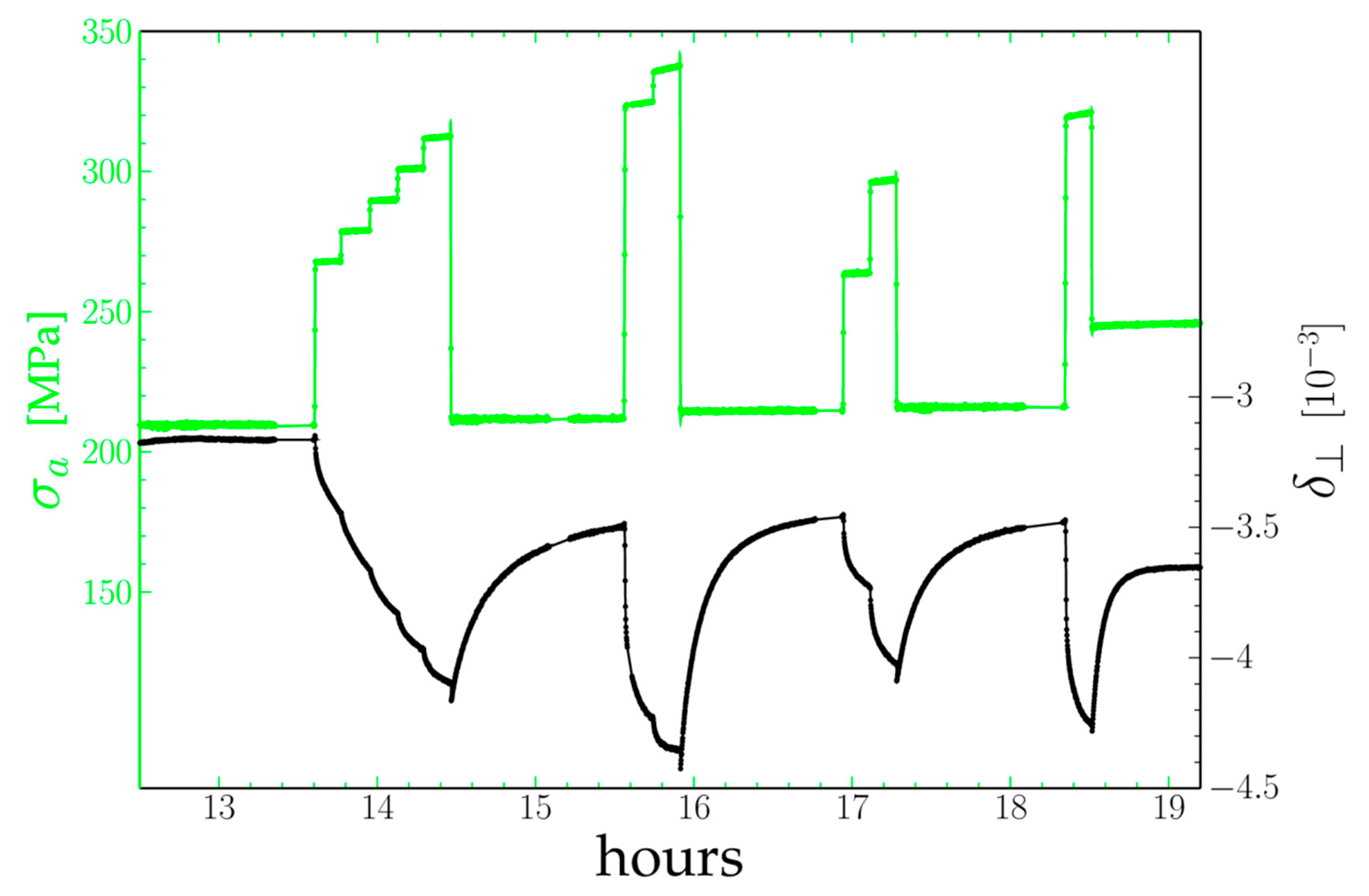

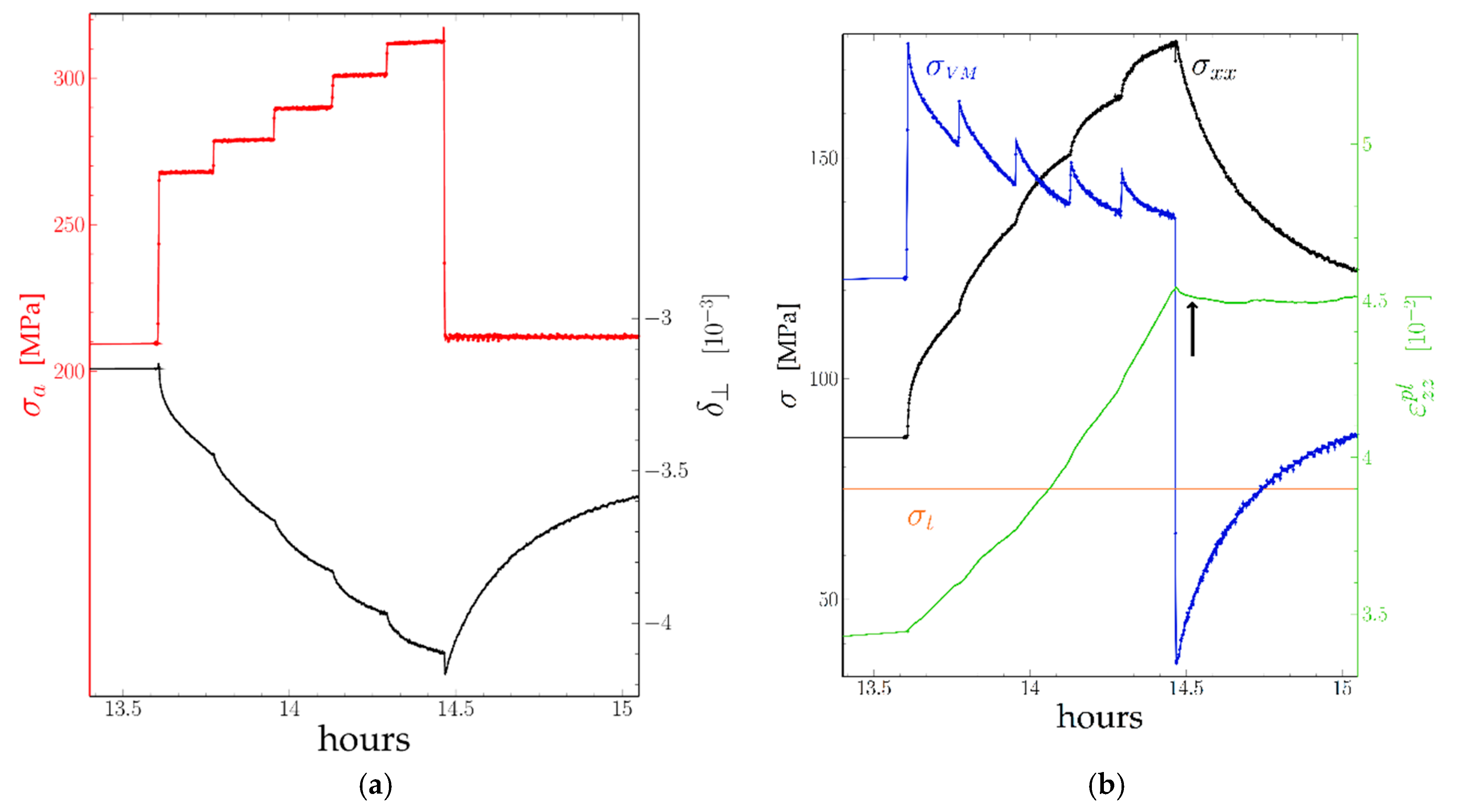

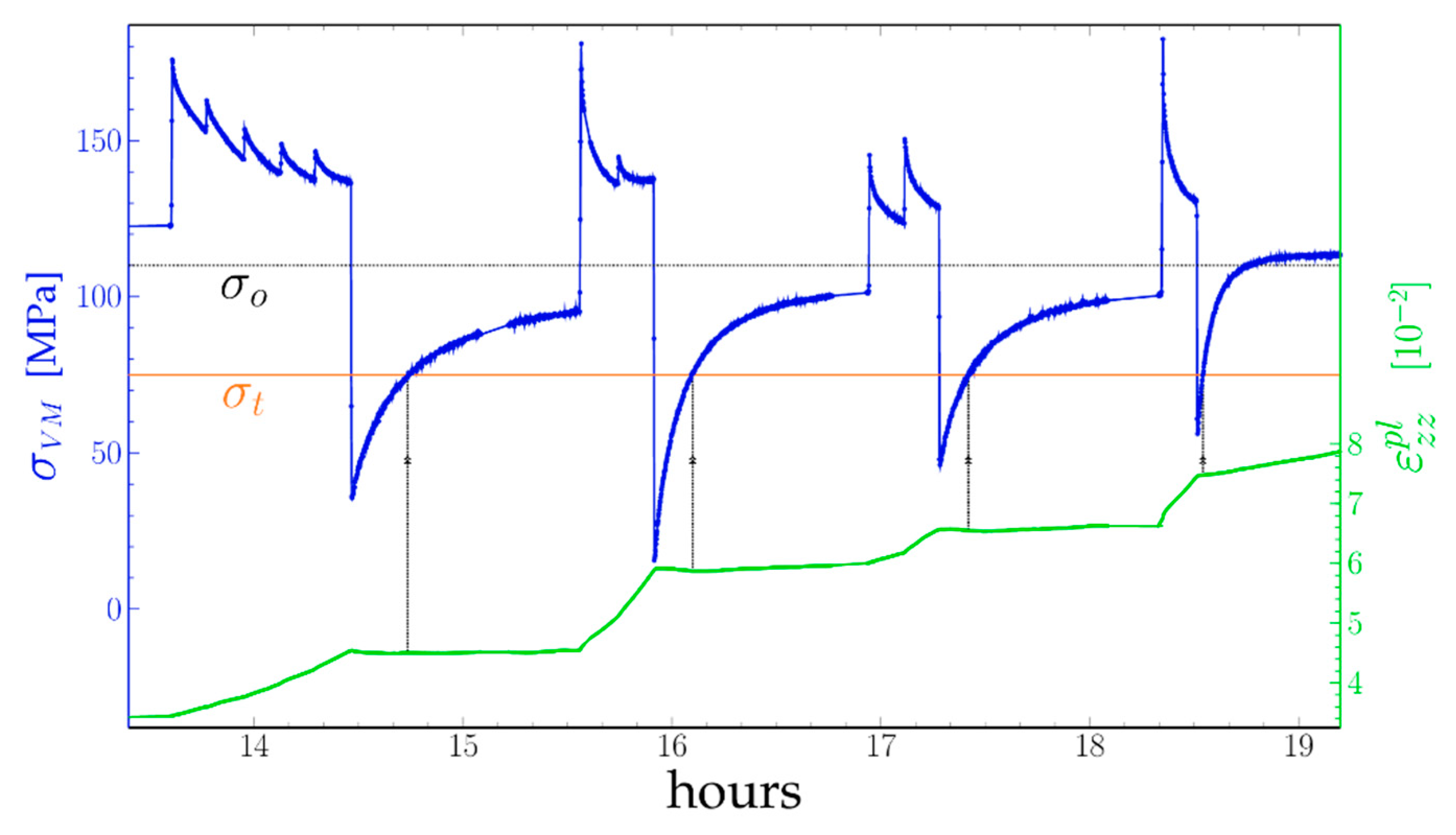

3.2. Successive Relaxation Tests

4. Analysis of the Experimental Results

4.1. Base of Modelling

4.2. Determination of the Threshold Stress

4.3. Dislocation Velocities and Densities

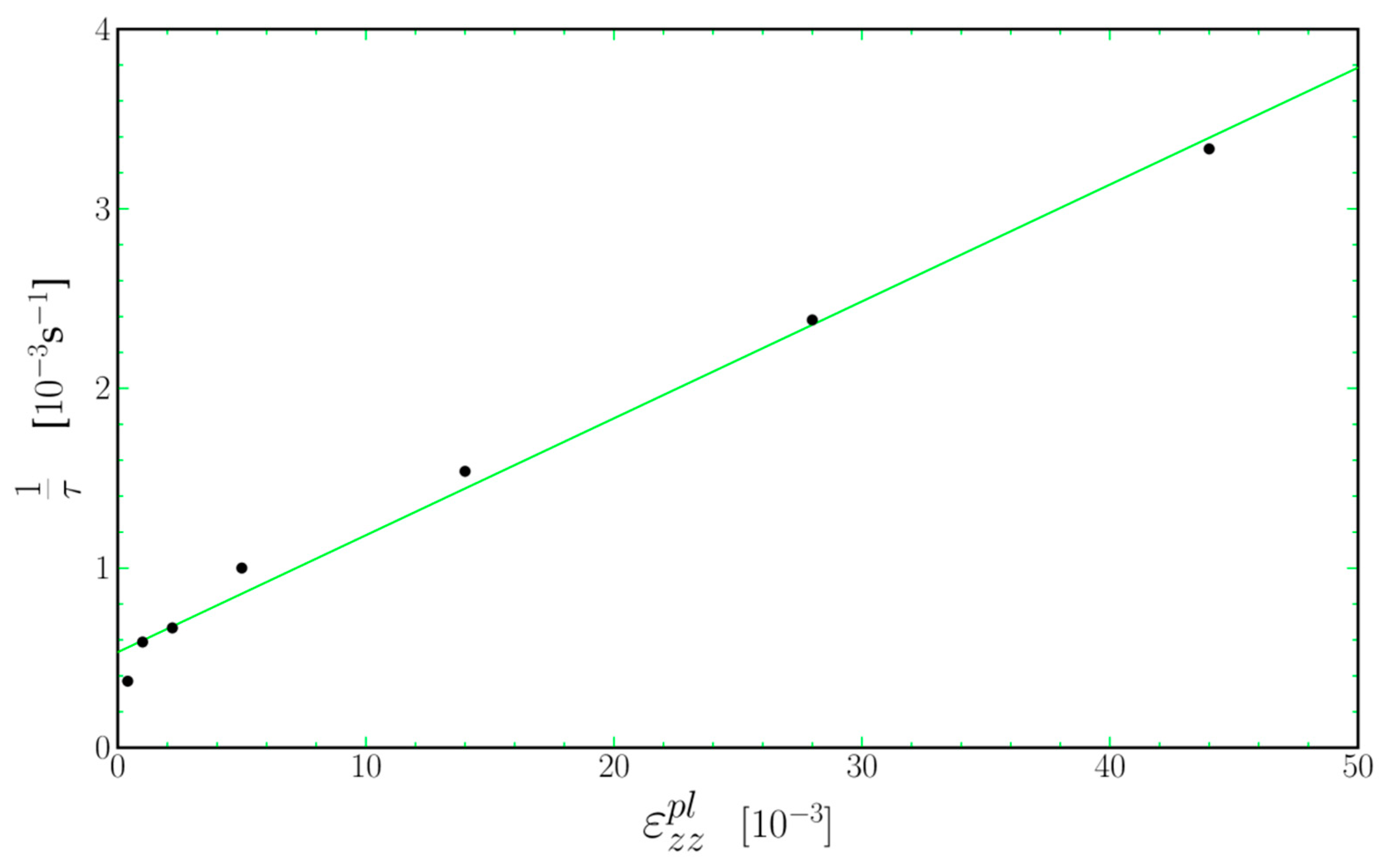

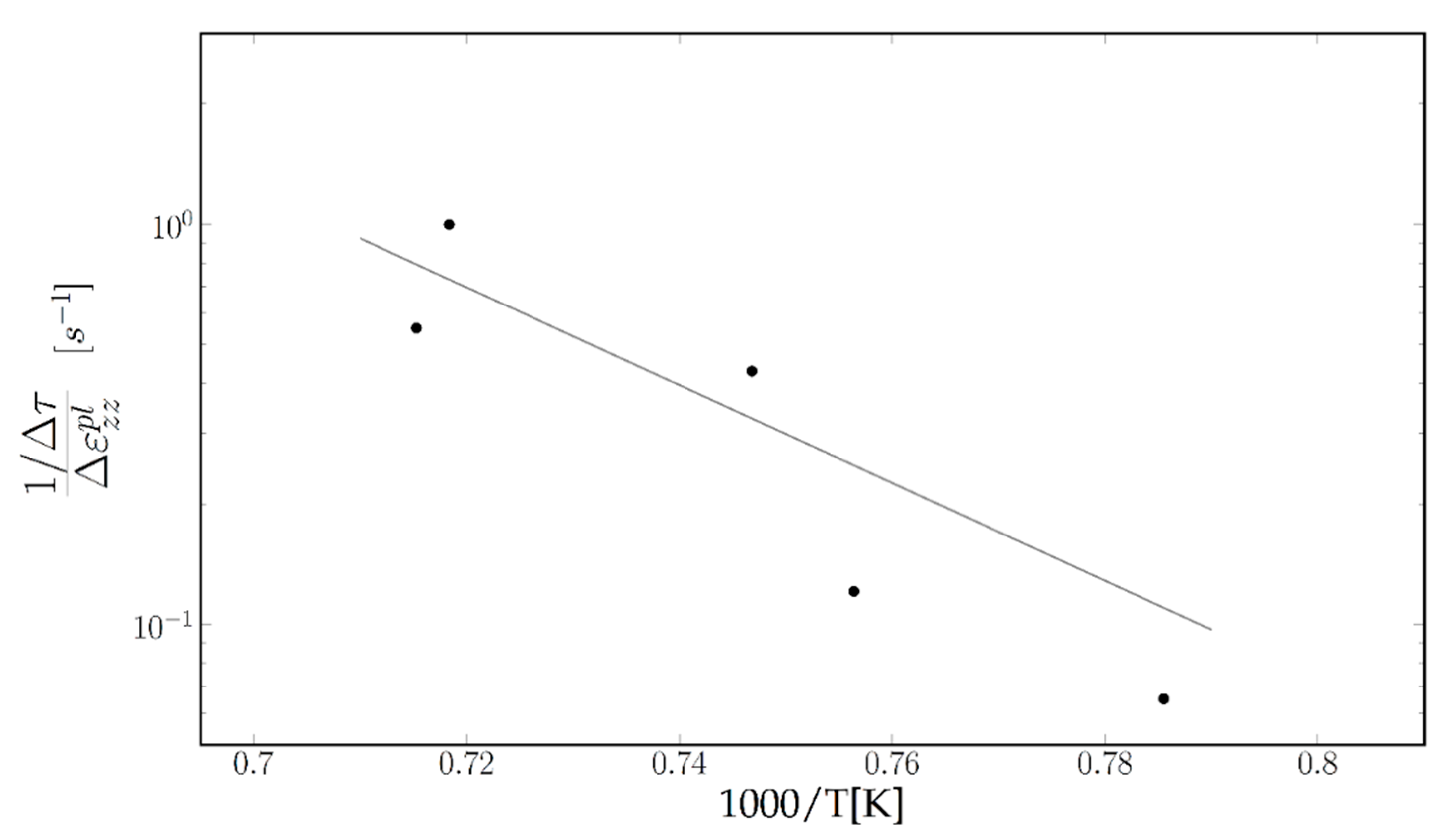

4.4. Successive Stress Relaxations and Activation Energy

5. Discussion

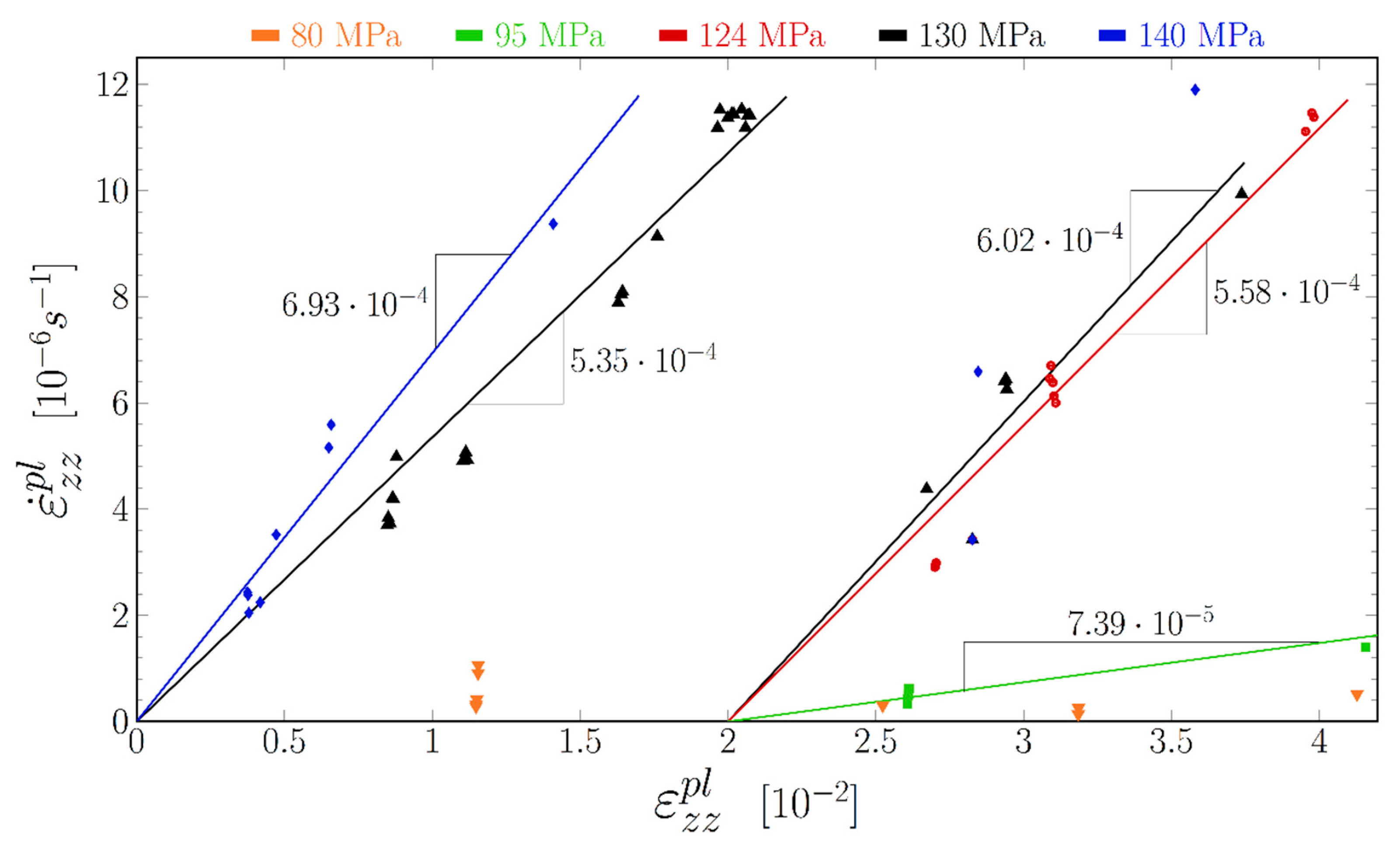

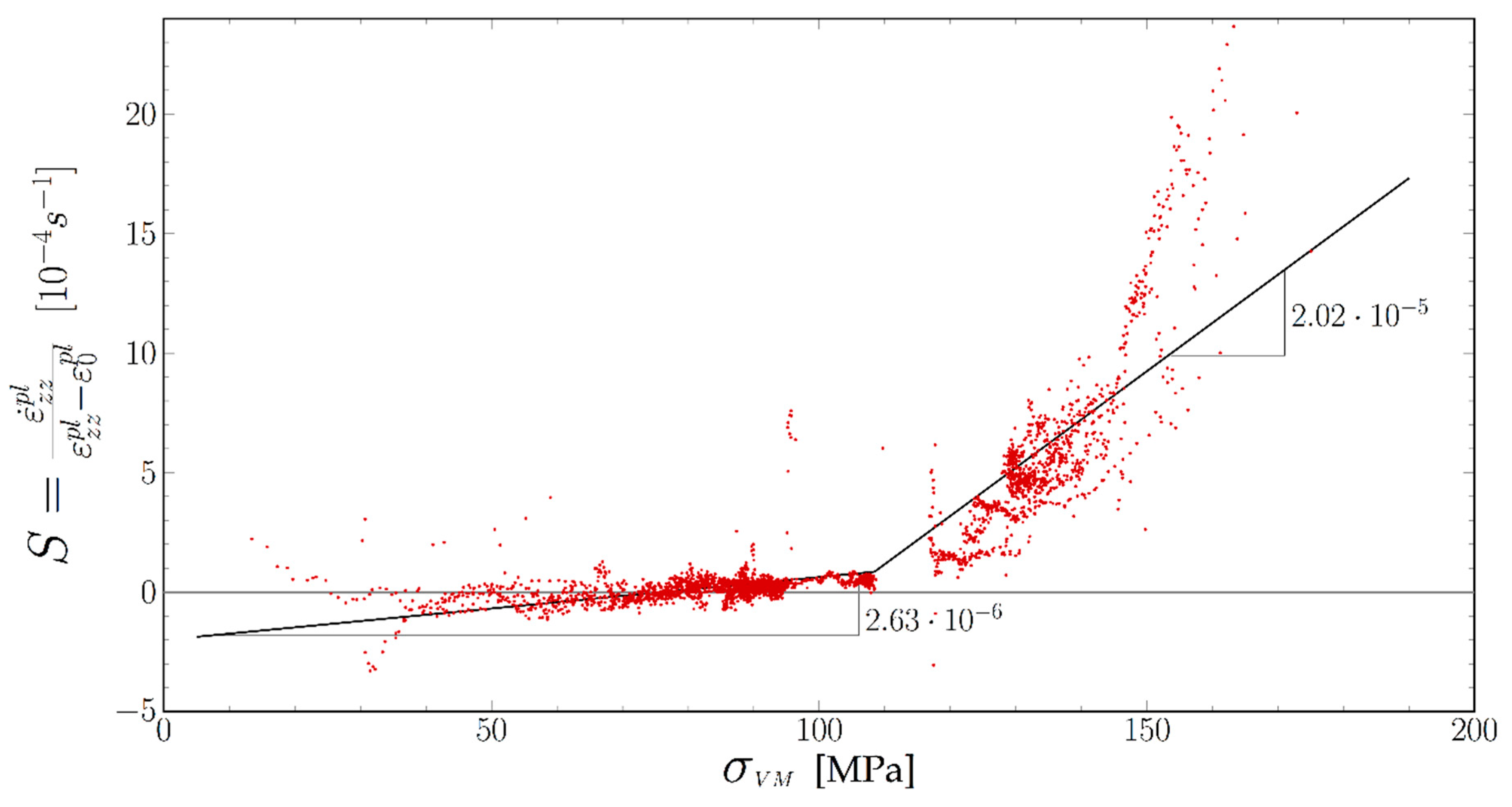

5.1. Dislocation Velocity Law

5.2. Dislocation Multiplication and Annihilation

6. Conclusions

- The mobile dislocation density increases proportionately with the strain. This is consistent with a multiplication mechanism of the scolopendra type. However, as the dislocation distribution is uneven (there is probably a waiting time before dislocations enter the channel) usual annihilation laws do not apply and the main annihilation events take place during drops in the Von Mises stress.

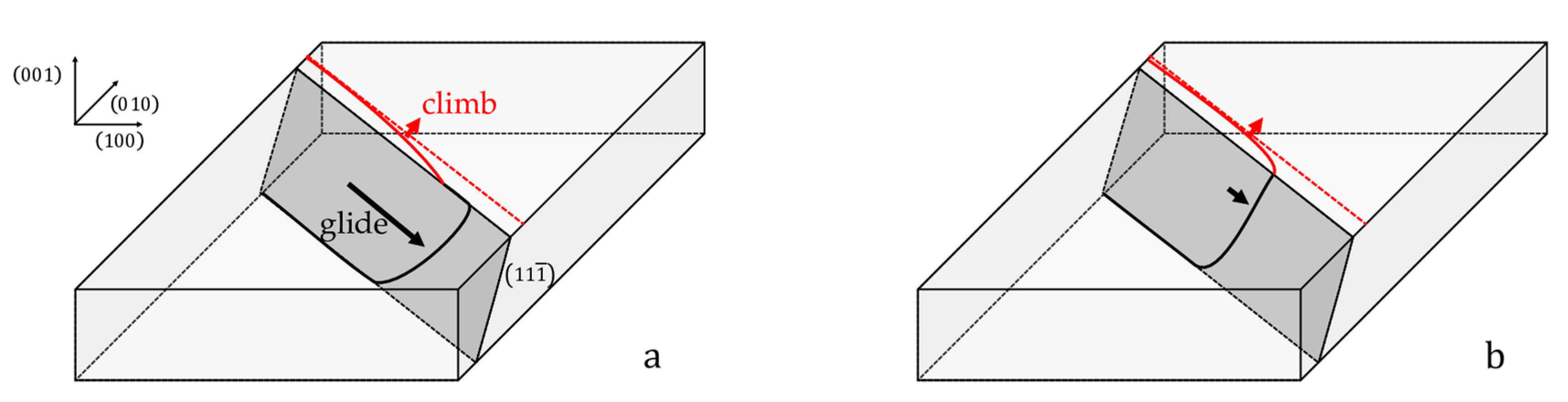

- Two different velocity laws for high and low Von Mises stresses seem to operate. In the first case (Von Mises stress larger than the Orowan stress), the velocity is proportional to and the dislocation mobility is thermally activated a ~3 eV activation energy. At Von Mises stresses lower than the Orowan stress, dislocations can still glide within the rafts without needing to trail one dislocation at each γ/γ′ interface. This mechanism is probably controlled by dislocation climb within the interface.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Reed, R.C.; Rae, C.M.F. 22—Physical Metallurgy of the Nickel-Based Superalloys. In Physical Metallurgy, 5th ed.; Laughlin, D.E., Hono, K., Eds.; Elsevier: Oxford, UK, 2014; pp. 2215–2290. ISBN 978-0-444-53770-6. [Google Scholar]

- Pollock, T.M.; Argon, A.S. Creep resistance of CMSX-3 nickel base superalloy single crystals. Acta Metall. Mater. 1992, 40, 1–30. [Google Scholar] [CrossRef]

- Miyazaki, T.; Nakamura, K.; Mori, H. Experimental and theoretical investigations on morphological changes of γ′ precipitates in Ni-Al single crystals during uniaxial stress-annealing. J. Mater. Sci. 1979, 14, 1827–1837. [Google Scholar] [CrossRef]

- Pollock, T.M.; Argon, A.S. Directional coarsening in nickel-base single crystals with high volume fractions of coherent precipitates. Acta Metall. Mater. 1994, 42, 1859–1874. [Google Scholar] [CrossRef]

- Buffiere, J.Y.; Ignat, M. A dislocation based criterion for the raft formation in nickel-based superalloys single crystals. Acta Metall. Mater. 1995, 43, 1791–1797. [Google Scholar] [CrossRef]

- Véron, M.; Bréchet, Y.; Louchet, F. Directional coarsening of Ni-based superalloys: Computer simulation at the mesoscopic level. Acta Mater. 1996, 44, 3633–3641. [Google Scholar] [CrossRef]

- Srinivasan, R.; Eggeler, G.; Mills, M. γ′-cutting as rate-controlling recovery process during high-temperature and low-stress creep of superalloy single crystals. Acta Mater. 2000, 48, 4867–4878. [Google Scholar] [CrossRef]

- Huang, M.; Zhuo, L.; Xiong, J.; Li, J.; Zhu, J. Core structure of a<100> superdislocations in a single-crystal superalloy during high-temperature and low-stress creep. Philos. Mag. Lett. 2015, 95, 496–503. [Google Scholar] [CrossRef]

- Jacques, A.; Tréhorel, R.; Schenk, T. High temperature dislocation climb in the γ′ rafts of Single Crystal Superalloys: The hypothesis of a control by dislocation entry into the rafts. Metall. Mater. Trans. A 2018, 49, 4110–4125. [Google Scholar] [CrossRef]

- Nabarro, F.R.N.; Frank, R.N.; De Villiers, H.L.; Heidi, L. The Physics of Creep: Creep and Creep-Resistant Alloys; Taylor & Francis: London, UK, 1995; ISBN 0850668522. [Google Scholar]

- Jacques, A.; Dirand, L.; Chateau, J.P.; Schenk, T.; Ferry, O.; Bastie, P. In Situ Measurement of Internal Stresses and Strain Rates by High Energy X-ray Diffraction during High Temperature Mechanical Testing. Adv. Mater. Res. 2011, 278, 48–53. [Google Scholar] [CrossRef]

- Hantcherli, M.; Pettinari-Sturmel, F.; Viguier, B.; Douin, J.; Coujou, A. Evolution of interfacial dislocation network during anisothermal high-temperature creep of a nickel-based superalloy. Scr. Mater. 2012, 66, 143–146. [Google Scholar] [CrossRef]

- Bouchard, R.; Hupfeld, D.; Lippmann, T.; Neuefeind, J.; Neumann, H.B.; Poulsen, H.F.; Rütt, U.; Schmidt, T.; Schneider, J.R.; Süssenbach, J.; et al. A triple-crystal diffractometer for high-energy synchrotron radiation at the HASYLAB high-field wiggler beamline BW5. J. Synchrotron Radiat. 1998, 5, 90–101. [Google Scholar] [CrossRef] [PubMed]

- Tréhorel, R.; Ribarik, G.; Jacques, A.; Schenk, T. Real time study of transients during high temperature creep of a Ni-based superalloy by far field high energy synchrotron X-rays diffraction. J. Appl. Crystallogr. 2018. submitted. [Google Scholar] [CrossRef]

- Dirand, L.; Jacques, A.; Chateau-Cornu, J.P.; Schenk, T.; Ferry, O.; Bastie, P. Phase-specific high temperature creep behaviour of a pre-rafted Ni-based superalloy studied by X-ray synchrotron diffraction. Philos. Mag. 2013, 93, 1384–1412. [Google Scholar] [CrossRef]

- Royer, A.; Bastie, P.; Veron, M. In situ determination of γ′ phase volume fraction and of relations between lattice parameters and precipitate morphology in Ni-based single crystal superalloy. Acta Mater. 1998, 46, 5357–5368. [Google Scholar] [CrossRef]

- Diologent, F.; Caron, P.; D’Almeida, T.; Jacques, A.; Bastie, P. The γ/γ′ mismatch in Ni based superalloys: In situ measurements during a creep test. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms. 2003, 200, 346–351. [Google Scholar] [CrossRef]

- Jacques, A.; Bastie, P. The evolution of the lattice parameter mismatch of a nickel-based superalloy during a high-temperature creep test. Philos. Mag. 2003, 83, 3005–3027. [Google Scholar] [CrossRef]

- Jacques, A.; Diologent, F.; Bastie, P. In situ measurement of the lattice parameter mismatch of a nickel-base single-crystalline superalloy under variable stress. Mater. Sci. Eng. A 2004, 387–389, 944–949. [Google Scholar] [CrossRef]

- Jacques, A.; Diologent, F.; Caron, P.; Bastie, P. Mechanical behavior of a superalloy with a rafted microstructure: In situ evaluation of the effective stresses and plastic strain rates of each phase. Mater. Sci. Eng. A 2008, 483, 568–571. [Google Scholar] [CrossRef]

- Dirand, L.; Cormier, J.; Jacques, A.; Chateau-Cornu, J.P.; Schenk, T.; Ferry, O.; Bastie, P. Measurement of the effective gamma/gamma’ lattice mismatch during high temperature creep of Ni-based single crystal superalloy. Mater. Charact. 2013, 77, 32–46. [Google Scholar] [CrossRef]

- Caron, P.; Khan, T. Improvement of Creep strength in a nickel-base single-crystal superalloy by heat treatment. Mater. Sci. Eng. 1983, 61, 173–184. [Google Scholar] [CrossRef]

- Fredholm, A.; Khan, T.; Theret, J.M.C.F.; Davidson, J.H. Alliage Monocristallin à Matrice à Base de Nickel. EP0149942, 1985. [Google Scholar]

- Testing of Metallic Materials—Tensile Test Pieces. Available online: https://www.din.de/de/mitwirken/normenausschuesse/nmp/normen/wdc-beuth:din21:262241217 (accessed on 7 August 2018).

- Feiereisen, J.P.; Ferry, O.; Jacques, A.; George, A. Mechanical testing device for in situ experiments on reversibility of dislocation motion in silicon. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2003, 200, 339–345. [Google Scholar] [CrossRef]

- Tréhorel, R. Comportement Mécanique Haute Température du Superalliage Monocristallin AM1: Étude In Situ Par Une Nouvelle Technique de Diffraction en Rayonnement Synchrotron. Ph.D. Thesis, Université de Lorraine, Vandœuvre-lès-Nancy, France, 2018. [Google Scholar]

- Epishin, A.; Link, T. Mechanisms of high-temperature creep of nickel-based superalloys under low applied stresses. Philos. Mag. 2004, 84, 1979–2000. [Google Scholar] [CrossRef]

- Dirand, L. Fluage à Haute Température d’un Superalliage Monocristallin: Expérimentation In Situ en Rayonnement Synchrotron; INPL Nancy: Vandœuvre-lès-Nancy, France, 2011. [Google Scholar]

- Carry, C.; Strudel, J.L. Apparent and effective creep parameters in single crystals of a nickel base superalloy-I Incubation period. Acta Metall. 1977, 25, 767–777. [Google Scholar] [CrossRef]

- Ma, A.; Dye, D.; Reed, R.C. A model for the creep deformation behaviour of single-crystal superalloy CMSX-4. Acta Mater. 2008, 56, 1657–1670. [Google Scholar] [CrossRef]

- Louchet, F.; Doisneau-Cottignies, B.; Bréchet, Y. Specific dislocation multiplication mechanisms and mechanical properties in nanoscaled multilayers: The example of pearlite. Philos. Mag. A Phys. Condens. Matter Struct. Defects Mech. Prop. 2000, 80, 1605–1619. [Google Scholar] [CrossRef]

- Essmann, U.; Mughrabi, H. Annihilation of dislocations during tensile and cyclic deformation and limits of dislocation densities. Philos. Mag. A 1979, 40, 731–756. [Google Scholar] [CrossRef]

- Brown, L.M. Dislocation bowing and passing in persistent slip bands. Philos. Mag. 2006, 86, 4055–4068. [Google Scholar] [CrossRef]

| Jump nº | |||||

|---|---|---|---|---|---|

| 1 | 150 | 2.9406 | 0.4 | 3.0 × 10−8 | 2700 |

| 2 | 175 | 3.2091 | 1 | 7.0 × 10−8 | 1700 |

| 3 | 200 | 3.52515 | 2.2 | 3.0 × 10−7 | 1500 |

| 4 | 225 | 3.79425 | 5 | 1.24 × 10−6 | 1000 |

| 5 | 250 | 4.12654 | 14 | 5.0 × 10−6 | 650 |

| 6 | 250 | 4.40814 | 28 | 1.2 × 10−5 | 420 |

| 7 | 250 | 4.40813 | 44 | 1.50 × 10−5 | 300 |

| Sample | 5A1 | 4L2 | 5C1 | 1C2 | 4R2 |

|---|---|---|---|---|---|

| T | 1000 | 1049 | 1066 | 1119 | 1125 |

| slope | 0.0651 | 0.121 | 0.43 | 1 | 0.55 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schenk, T.; Trehorel, R.; Dirand, L.; Jacques, A. Dislocation Densities and Velocities within the γ Channels of an SX Superalloy during In Situ High-Temperature Creep Tests. Materials 2018, 11, 1527. https://doi.org/10.3390/ma11091527

Schenk T, Trehorel R, Dirand L, Jacques A. Dislocation Densities and Velocities within the γ Channels of an SX Superalloy during In Situ High-Temperature Creep Tests. Materials. 2018; 11(9):1527. https://doi.org/10.3390/ma11091527

Chicago/Turabian StyleSchenk, Thomas, Roxane Trehorel, Laura Dirand, and Alain Jacques. 2018. "Dislocation Densities and Velocities within the γ Channels of an SX Superalloy during In Situ High-Temperature Creep Tests" Materials 11, no. 9: 1527. https://doi.org/10.3390/ma11091527

APA StyleSchenk, T., Trehorel, R., Dirand, L., & Jacques, A. (2018). Dislocation Densities and Velocities within the γ Channels of an SX Superalloy during In Situ High-Temperature Creep Tests. Materials, 11(9), 1527. https://doi.org/10.3390/ma11091527