The Effect of Crystal Defects on 3D High-Resolution Diffraction Peaks: A FFT-Based Method

Abstract

1. Introduction

2. Fast Fourier Transform (FFT)-Based Numerical Calculation of the Displacement Field and Periodized Green Operators

2.1. FFT-Based Algorithm and Mechanical Fields

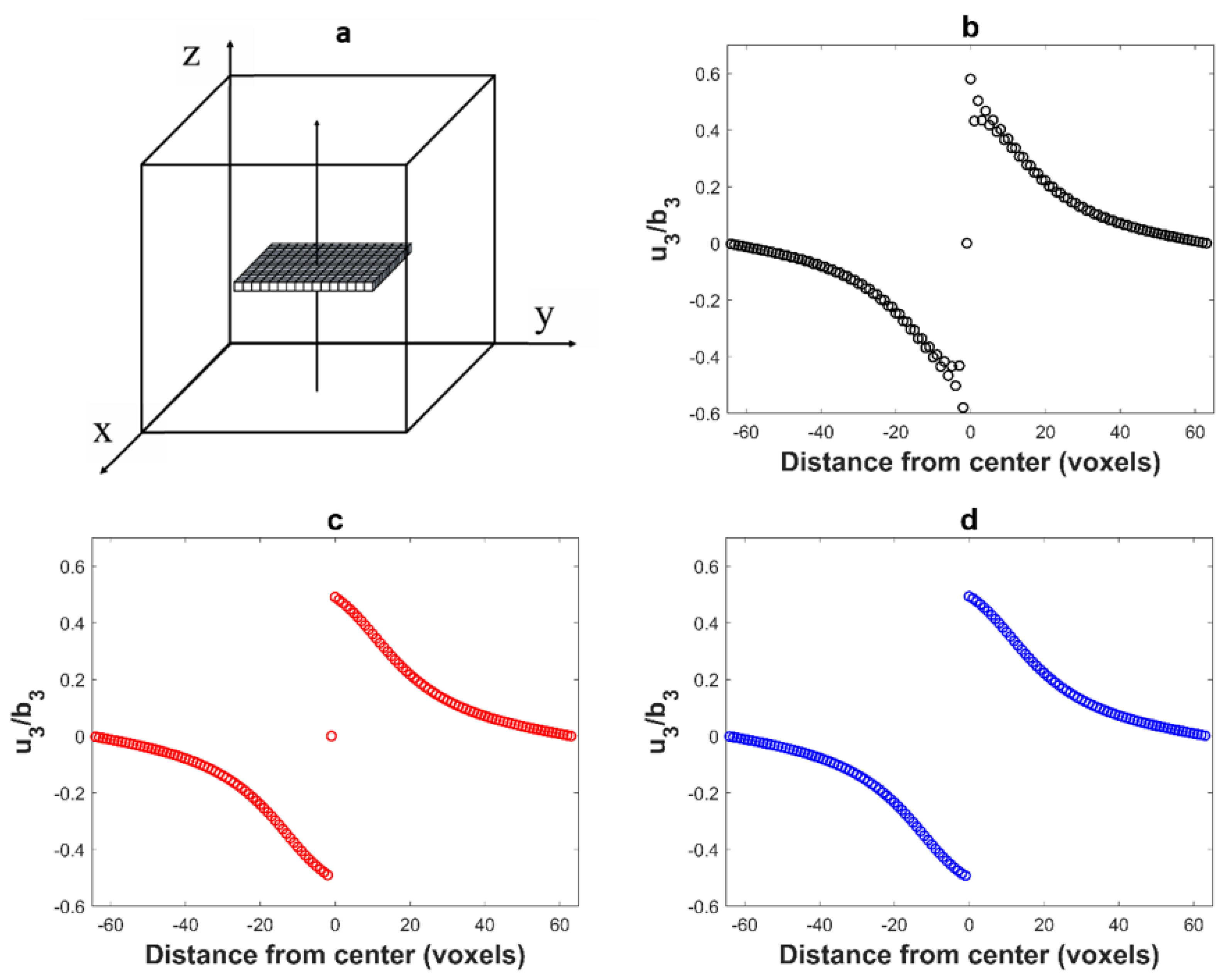

2.2. Numerical Examples

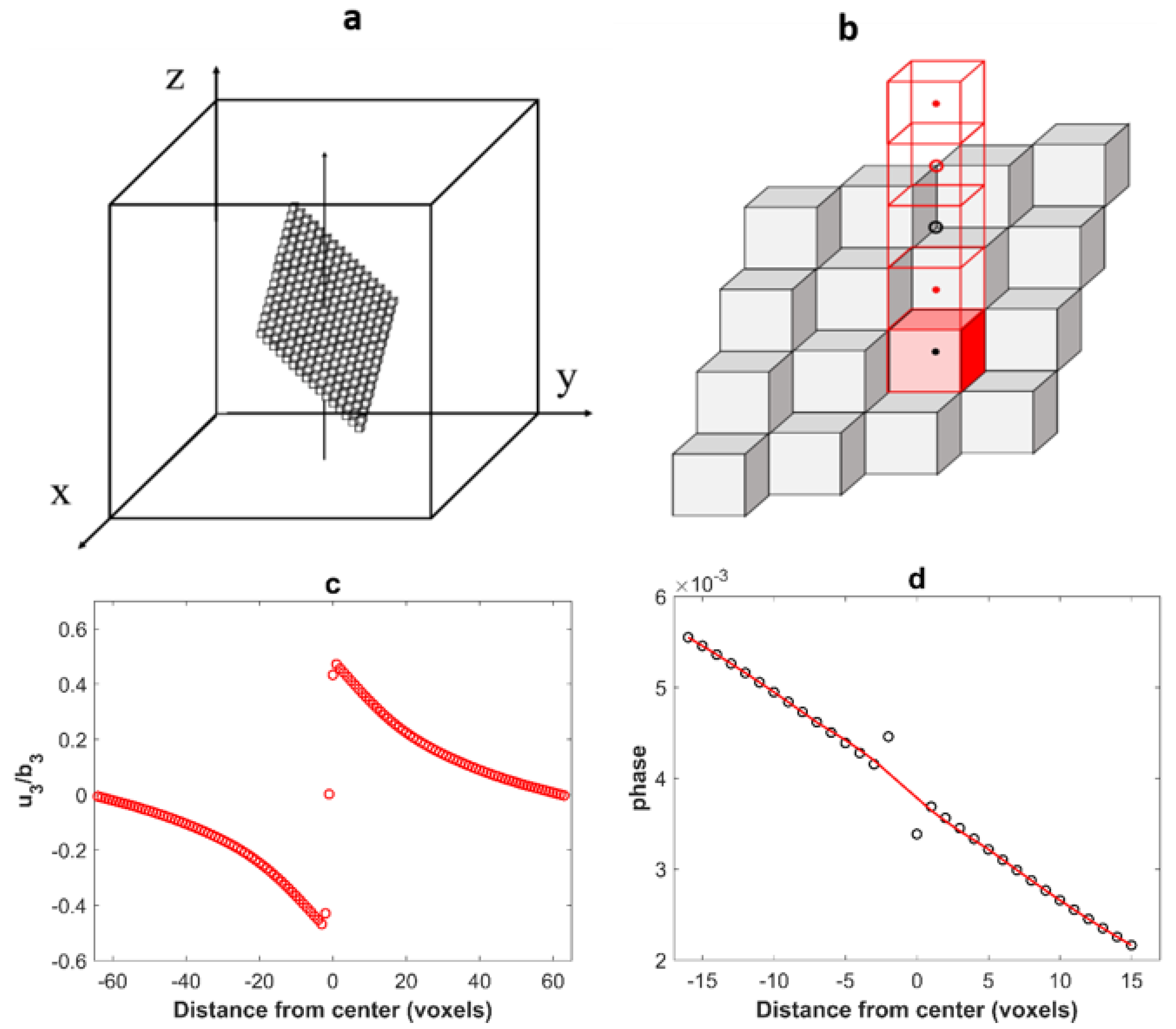

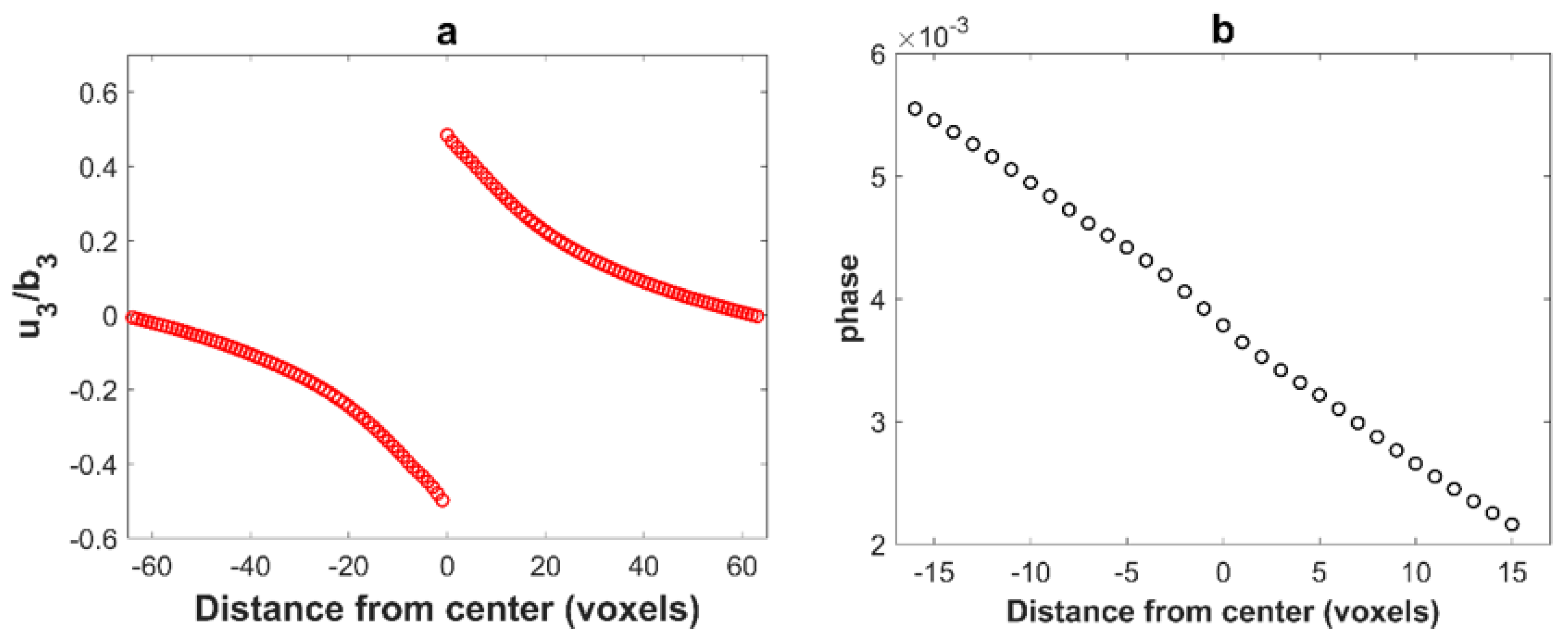

2.3. Voxelization Effect on the Displacement Field

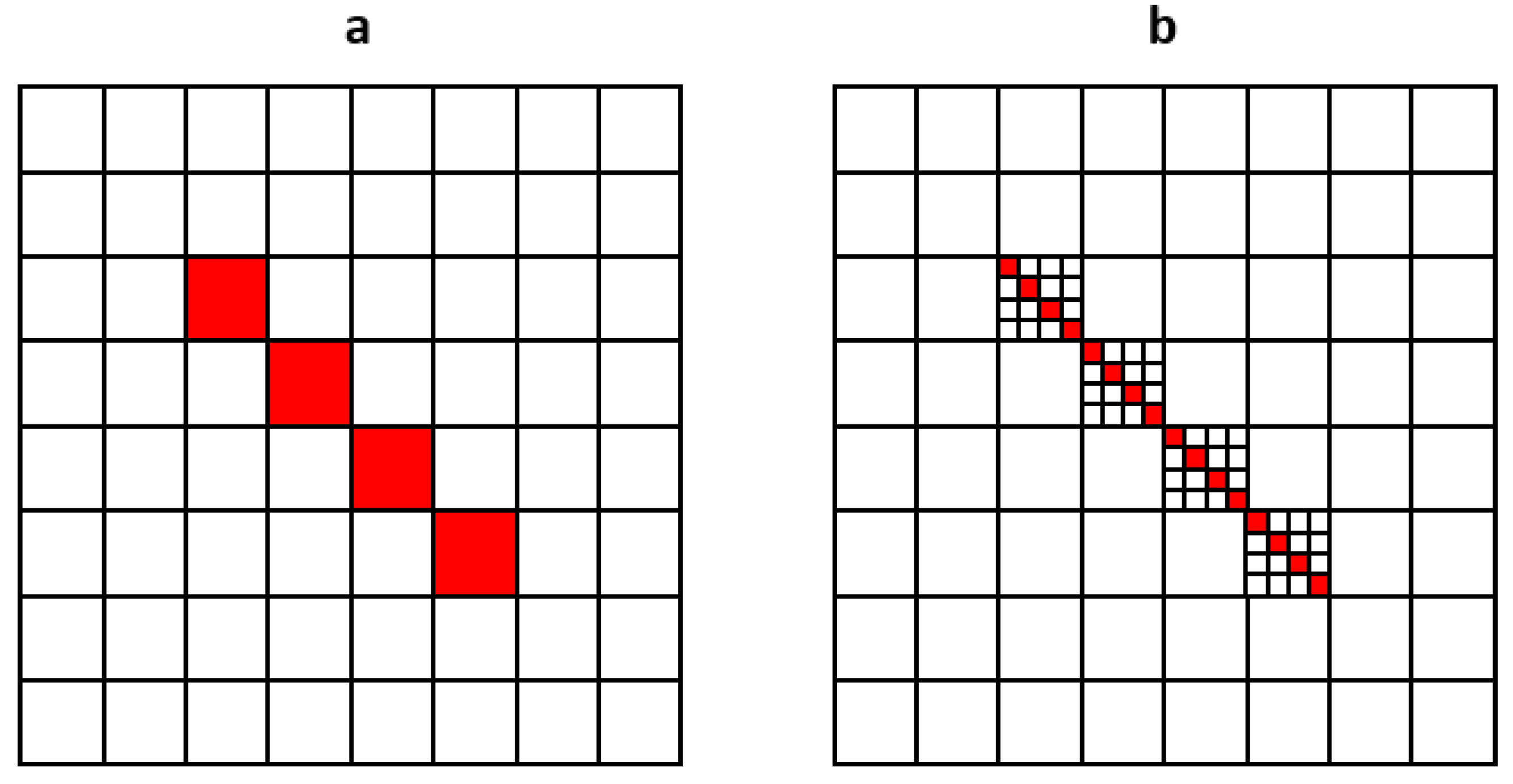

3. Sub-Voxelization Method to Correct Voxelization Artifacts

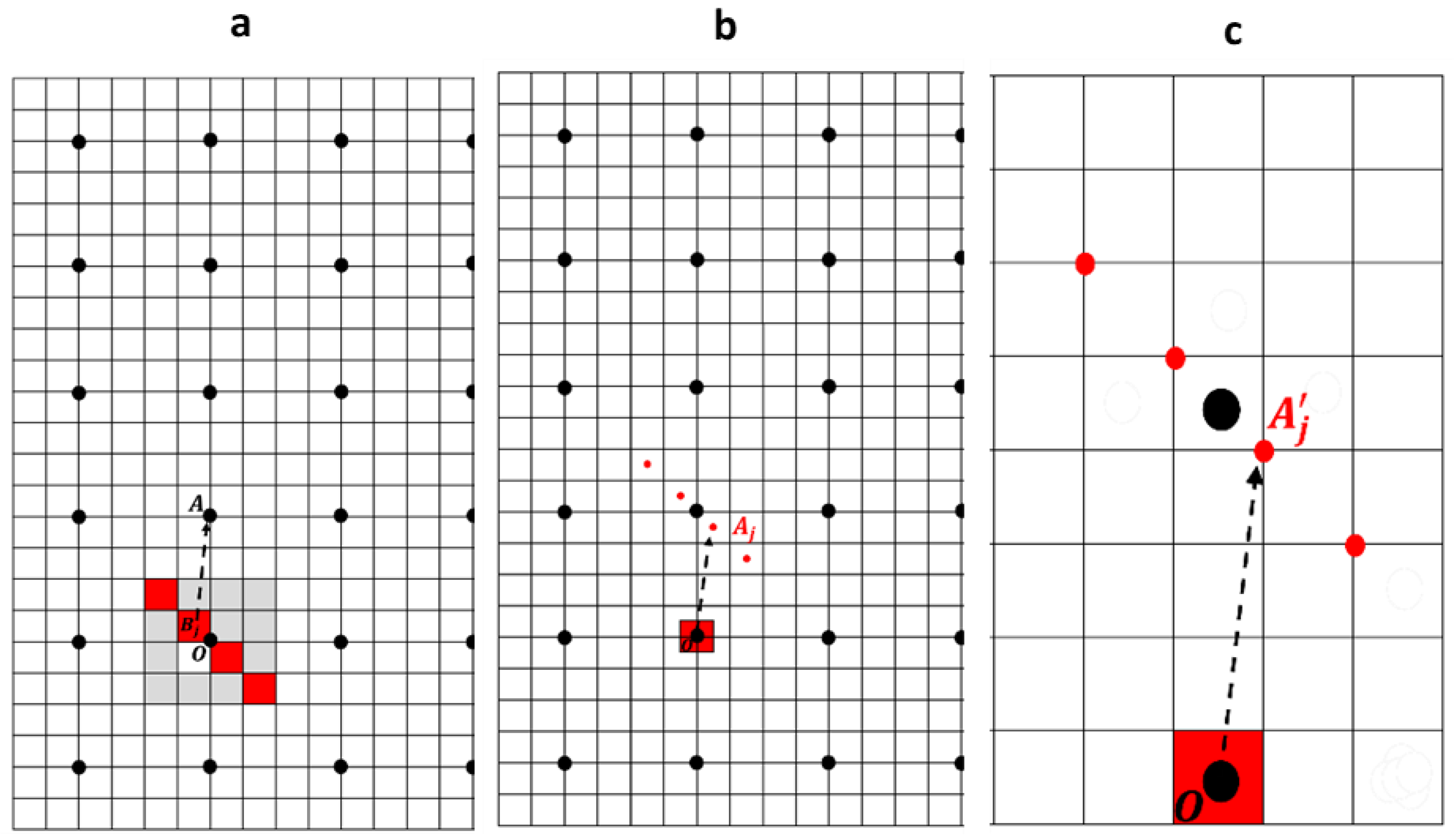

3.1. Sub-Voxelization Method

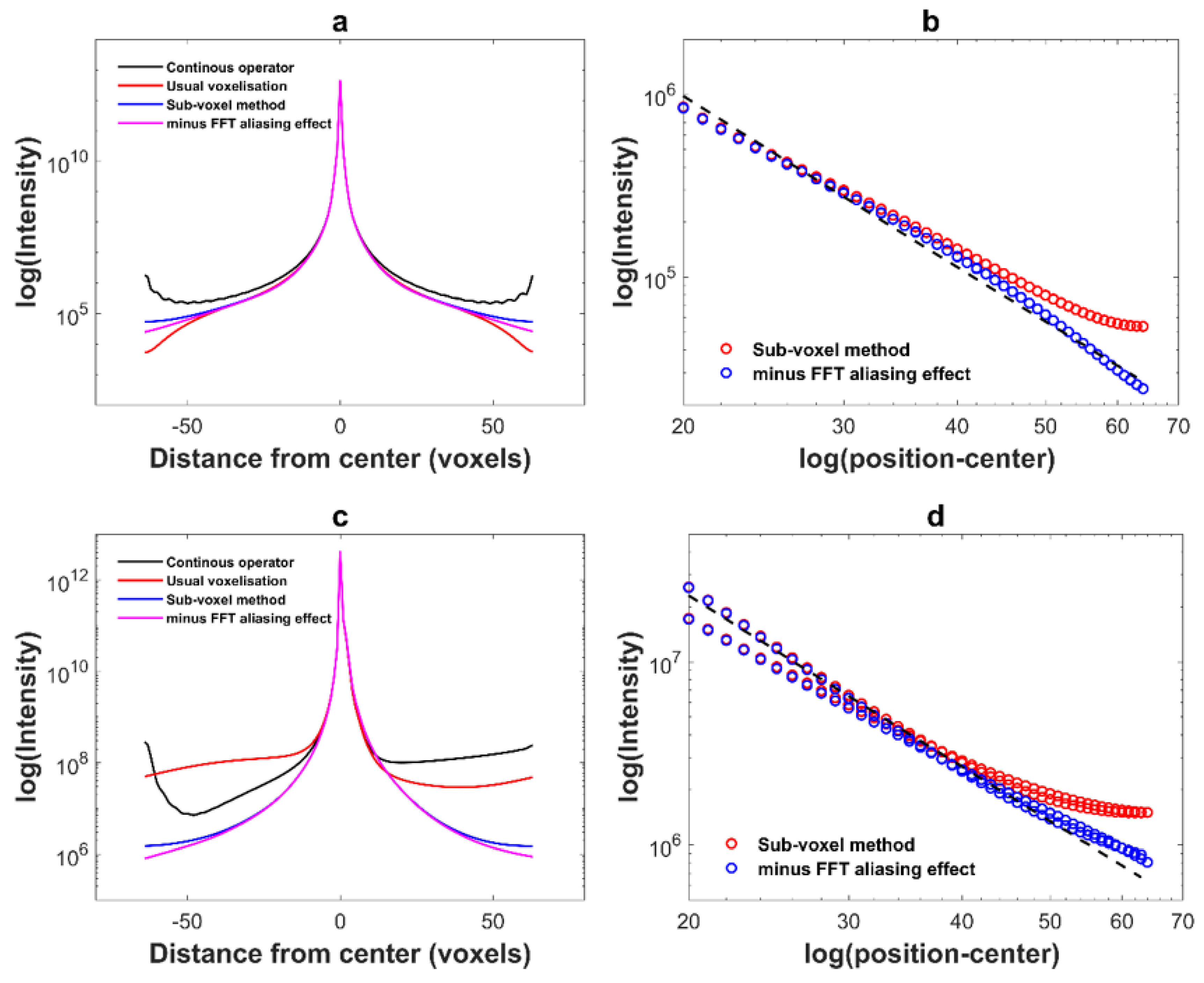

3.2. Results

4. Application on Diffraction Peak Simulation

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Graverend, J.-B.L.; Dirand, L.; Jacques, A.; Cormier, J.; Ferry, O.; Schenk, T.; Gallerneau, F.; Kruch, S.; Mendez, J. In Situ Measurement of the γ/γ′ Lattice Mismatch Evolution of a Nickel-Based Single-Crystal Superalloy during Non-isothermal Very High-Temperature Creep Experiments. Metall. Mater. Trans. A 2012, 43, 3946–3951. [Google Scholar] [CrossRef]

- Robinson, I.; Harder, R. Coherent X-ray diffraction imaging of strain at the nanoscale. Nat. Mater. 2009, 8, 291–298. [Google Scholar] [CrossRef] [PubMed]

- Pfeifer, M.A.; Williams, G.J.; Vartanyants, I.A.; Harder, R.; Robinson, I.K. Three-dimensional mapping of a deformation field inside a nanocrystal. Nature 2006, 442, 63. [Google Scholar] [CrossRef] [PubMed]

- Ungár, T. Strain Broadening Caused by Dislocations. Available online: https://www.scientific.net/MSF.278-281.151 (accessed on 16 June 2018).

- Ungár, T.; Gubicza, J.; Ribárik, G.; Borbély, A. Crystallite size distribution and dislocation structure determined by diffraction profile analysis: Principles and practical application to cubic and hexagonal crystals. J. Appl. Crystallogr. 2001, 34, 298–310. [Google Scholar] [CrossRef]

- Ribárik, G.; Ungár, T.; Gubicza, J. MWP-fit: A program for multiple whole-profile fitting of diffraction peak profiles by ab initio theoretical functions. J. Appl. Crystallogr. 2001, 34, 669–676. [Google Scholar] [CrossRef]

- Ribárik, G.; Gubicza, J.; Ungár, T. Correlation between strength and microstructure of ball-milled Al–Mg alloys determined by X-ray diffraction. Mater. Sci. Eng. A 2004, 387, 343–347. [Google Scholar] [CrossRef]

- Balogh, L.; Ribárik, G.; Ungár, T. Stacking faults and twin boundaries in fcc crystals determined by X-ray diffraction profile analysis. J. Appl. Phys. 2006, 100, 023512. [Google Scholar] [CrossRef]

- Groma, I. X-ray line broadening due to an inhomogeneous dislocation distribution. Phys. Rev. B 1998, 57, 7535. [Google Scholar] [CrossRef]

- Tréhorel, R.; Ribarik, G.; Schenk, T.; Jacques, A. Real time study of transients during high temperature creep of a Ni-based superlloy by far field high energy synchrotron X-rays diffraction. J. Appl. Crystallogr. 2018. under review. [Google Scholar]

- Tréhorel, R. Comportement Mécanique Haute Température Du Superalliage Monocristallin Am1: Etude In-Situ Par Une Nouvelle Technique De Diffraction En Rayonnement Synchrotron; Université de Lorraine: Nancy, France, 2018. [Google Scholar]

- Bernier, J.V.; Park, J.-S.; Pilchak, A.L.; Glavicic, M.G.; Miller, M.P. Measuring Stress Distributions in Ti-6Al-4V Using Synchrotron X-Ray Diffraction. Metall. Mater. Trans. A 2008, 39, 3120–3133. [Google Scholar] [CrossRef]

- Miller, M.P.; Bernier, J.V.; Park, J.-S.; Kazimirov, A. Experimental measurement of lattice strain pole figures using synchrotron X rays. Rev. Sci. Instrum. 2005, 76, 113903. [Google Scholar] [CrossRef]

- Jacques, A. From Modeling of Plasticity in Single-Crystal Superalloys to High-Resolution X-rays Three-Crystal Diffractometer Peaks Simulation. Metall. Mater. Trans. A 2016, 47, 5783–5797. [Google Scholar] [CrossRef]

- Weisbrook, C.M.; Gopalaratnam, V.S.; Krawitz, A.D. Use of finite element modeling to interpret diffraction peak broadening from elastic strain distributions. Mater. Sci. Eng. A 1995, 201, 134–142. [Google Scholar] [CrossRef]

- Miller, M.P.; Dawson, P.R. Understanding local deformation in metallic polycrystals using high energy X-rays and finite elements. Curr. Opin. Solid State Mater. Sci. 2014, 5, 286–299. [Google Scholar] [CrossRef]

- Demir, E.; Park, J.-S.; Miller, M.P.; Dawson, P.R. A computational framework for evaluating residual stress distributions from diffraction-based lattice strain data. Comput. Methods Appl. Mech. Eng. 2013, 265, 120–135. [Google Scholar] [CrossRef]

- Vaxelaire, N.; Proudhon, H.; Labat, S.; Kirchlechner, C.; Keckes, J.; Jacques, V.; Ravy, S.; Forest, S.; Thomas, O. Methodology for studying strain inhomogeneities in polycrystalline thin films during in situ thermal loading using coherent X-ray diffraction. New J. Phys. 2010, 12, 035018. [Google Scholar] [CrossRef]

- Song, X.; Xie, M.; Hofmann, F.; Illston, T.; Connolley, T.; Reinhard, C.; Atwood, R.C.; Connor, L.; Drakopoulos, M.; Frampton, L. Residual stresses and microstructure in powder bed direct laser deposition (PB DLD) samples. Int. J. Mater. Form. 2015, 8, 245–254. [Google Scholar] [CrossRef]

- Hofmann, F.; Song, X.; Jun, T.-S.; Abbey, B.; Peel, M.; Daniels, J.; Honkimäki, V.; Korsunsky, A.M. High energy transmission micro-beam Laue synchrotron X-ray diffraction. Mater. Lett. 2010, 64, 1302–1305. [Google Scholar] [CrossRef]

- Hofmann, F.; Abbey, B.; Liu, W.; Xu, R.; Usher, B.F.; Balaur, E.; Liu, Y. X-ray micro-beam characterization of lattice rotations and distortions due to an individual dislocation. Nat. Commun. 2013, 4, 2774. [Google Scholar] [CrossRef] [PubMed]

- Suter, R.M.; Hennessy, D.; Xiao, C.; Lienert, U. Forward modeling method for microstructure reconstruction using X-ray diffraction microscopy: Single-crystal verification. Rev. Sci. Instrum. 2006, 77, 123905. [Google Scholar] [CrossRef]

- Moulinec, H.; Suquet, P. A numerical method for computing the overall response of nonlinear composites with complex microstructure. Comput. Methods Appl. Mech. Eng. 1998, 157, 69–94. [Google Scholar] [CrossRef]

- Moulinec, H.; Suquet, P. Fast numerical method for computing the linear and nonlinear properties of composites. C. R. Acad. Sci. Ser. II 1994, 318, 1417–1423. [Google Scholar]

- Michel, J.C.; Moulinec, H.; Suquet, P. A computational scheme for linear and non-linear composites with arbitrary phase contrast. Int. J. Numer. Methods Eng. 2001, 52, 139–160. [Google Scholar] [CrossRef]

- Müller, W. Mathematical vs. Experimental Stress Analysis of Inhomogeneities in Solids. J. Phys. IV Colloq. 1996, 6, C1-139–C1-148. [Google Scholar] [CrossRef]

- Vinogradov, V.; Milton, G.W. An accelerated FFT algorithm for thermoelastic and non-linear composites. Int. J. Numer. Methods Eng. 2008, 76, 1678–1695. [Google Scholar] [CrossRef]

- Anglin, B.S.; Lebensohn, R.A.; Rollett, A.D. Validation of a numerical method based on Fast Fourier Transforms for heterogeneous thermoelastic materials by comparison with analytical solutions. Comput. Mater. Sci. 2014, 87, 209–217. [Google Scholar] [CrossRef]

- Graham, J.T.; Rollett, A.D.; LeSar, R. Fast Fourier transform discrete dislocation dynamics. Model. Simul. Mater. Sci. Eng. 2016, 24, 085005. [Google Scholar] [CrossRef]

- Berbenni, S.; Taupin, V.; Djaka, K.S.; Fressengeas, C. A numerical spectral approach for solving elasto-static field dislocation and g-disclination mechanics. Int. J. Solids Struct. 2014, 51, 4157–4175. [Google Scholar] [CrossRef]

- Eyre, D.J.; Milton, G.W. A fast numerical scheme for computing the response of composites using grid refinement. Eur. Phys. J. AP 1999, 6, 41–47. [Google Scholar] [CrossRef]

- Prakash, A.; Lebensohn, R.A. Simulation of micromechanical behavior of polycrystals: Finite elements versus fast Fourier transforms. Model. Simul. Mater. Sci. Eng. 2009, 17, 064010. [Google Scholar] [CrossRef]

- Lebensohn, R.A. N-site modeling of a 3D viscoplastic polycrystal using Fast Fourier Transform. Acta Mater. 2001, 49, 2723–2737. [Google Scholar] [CrossRef]

- Lebensohn, R.A.; Rollett, A.D.; Suquet, P. Fast fourier transform-based modeling for the determination of micromechanical fields in polycrystals. JOM 2011, 63, 13–18. [Google Scholar] [CrossRef]

- Lebensohn, R.A.; Kanjarla, A.K.; Eisenlohr, P. An elasto-viscoplastic formulation based on fast Fourier transforms for the prediction of micromechanical fields in polycrystalline materials. Int. J. Plast. 2012, 32–33, 59–69. [Google Scholar] [CrossRef]

- Suquet, P.; Moulinec, H.; Castelnau, O.; Montagnat, M.; Lahellec, N.; Grennerat, F.; Duval, P.; Brenner, R. Multi-scale modeling of the mechanical behavior of polycrystalline ice under transient creep. Procedia IUTAM 2012, 3, 76–90. [Google Scholar] [CrossRef]

- Eloh, K.S.; Jacques, A.; Berbenni, S. Development of a new consistent discrete Green operator for FFT-based methods to solve heterogeneous problems with eigenstrain. Int. J. Plast. 2018. submitted. [Google Scholar]

- Hirth, J.P.; Lothe, J. Theory of Dislocations; Krieger Publishing Company: Malabar, FL, USA, 1982; ISBN 978-0-89464-617-1. [Google Scholar]

- Mura, T. Micromechanics of Defects in Solids, 2nd ed.; Mechanics of Elastic and Inelastic Solids; Springer: Dordrecht, The Netherlands, 1987; ISBN 978-90-247-3256-2. [Google Scholar]

- Li, Q.; Anderson, P.M. A Compact Solution for the Stress Field from a Cuboidal Region with a Uniform Transformation Strain. J. Elast. 2001, 64, 237–245. [Google Scholar] [CrossRef]

- Anderson, P.M. Crystal-based plasticity. In Fundamentals of Metal Forming; Wagoner, R.H., Chenot, J.-L., Eds.; Wiley: New York, NY, USA, 1997; pp. 263–293. [Google Scholar]

- Takagi, S. A Dynamical Theory of Diffraction for a Distorted Crystal. J. Phys. Soc. Japan 1969, 26, 1239–1253. [Google Scholar] [CrossRef]

- Vartanyants, I.A.; Yefanov, O.M. Coherent X-ray Diffraction Imaging of Nanostructures. arXiv, 2013; arXiv:1304.5335. [Google Scholar]

- Takagi, S. Dynamical theory of diffraction applicable to crystals with any kind of small distortion. Acta Crystallogr. 1962, 15, 1311–1312. [Google Scholar] [CrossRef]

- Ungár, T. Microstructural parameters from X-ray diffraction peak broadening. Scr. Mater. 2004, 51, 777–781. [Google Scholar] [CrossRef]

- Krivoglaz, M.A. Theory of X-Ray and Thermal Neutron Scattering by Real Crystals; Springer: New York, NY, USA, 1969; ISBN 978-1-4899-5584-5. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eloh, K.S.; Jacques, A.; Ribarik, G.; Berbenni, S. The Effect of Crystal Defects on 3D High-Resolution Diffraction Peaks: A FFT-Based Method. Materials 2018, 11, 1669. https://doi.org/10.3390/ma11091669

Eloh KS, Jacques A, Ribarik G, Berbenni S. The Effect of Crystal Defects on 3D High-Resolution Diffraction Peaks: A FFT-Based Method. Materials. 2018; 11(9):1669. https://doi.org/10.3390/ma11091669

Chicago/Turabian StyleEloh, Komlavi Senyo, Alain Jacques, Gabor Ribarik, and Stéphane Berbenni. 2018. "The Effect of Crystal Defects on 3D High-Resolution Diffraction Peaks: A FFT-Based Method" Materials 11, no. 9: 1669. https://doi.org/10.3390/ma11091669

APA StyleEloh, K. S., Jacques, A., Ribarik, G., & Berbenni, S. (2018). The Effect of Crystal Defects on 3D High-Resolution Diffraction Peaks: A FFT-Based Method. Materials, 11(9), 1669. https://doi.org/10.3390/ma11091669