Experimental and Numerical Assessment of Temperature Field and Analysis of Microstructure and Mechanical Properties of Low Power Laser Annealed Welded Joints

Abstract

:1. Introduction

2. Experimental Procedure and Material

2.1. Welding Material

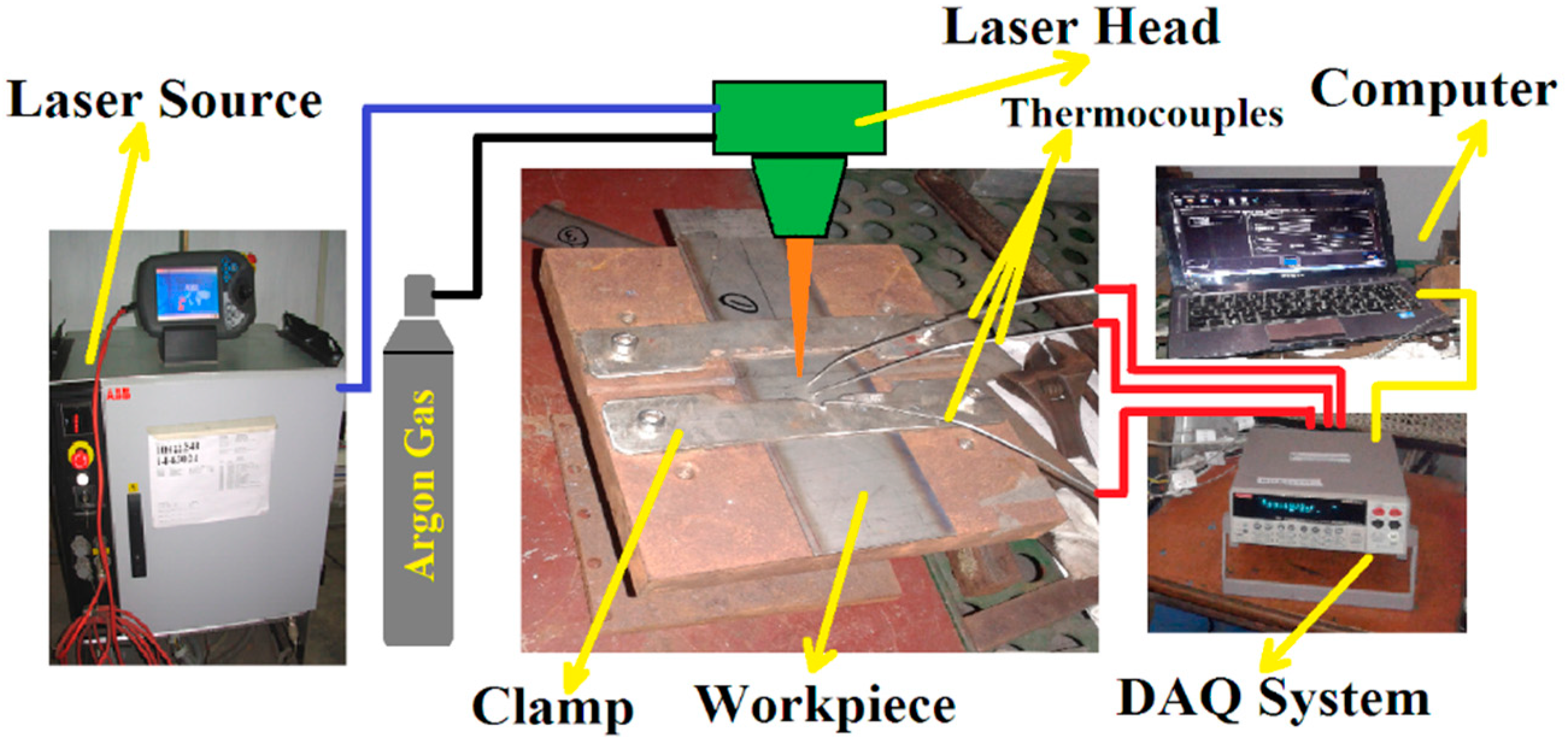

2.2. Experimental Setup and Procedure

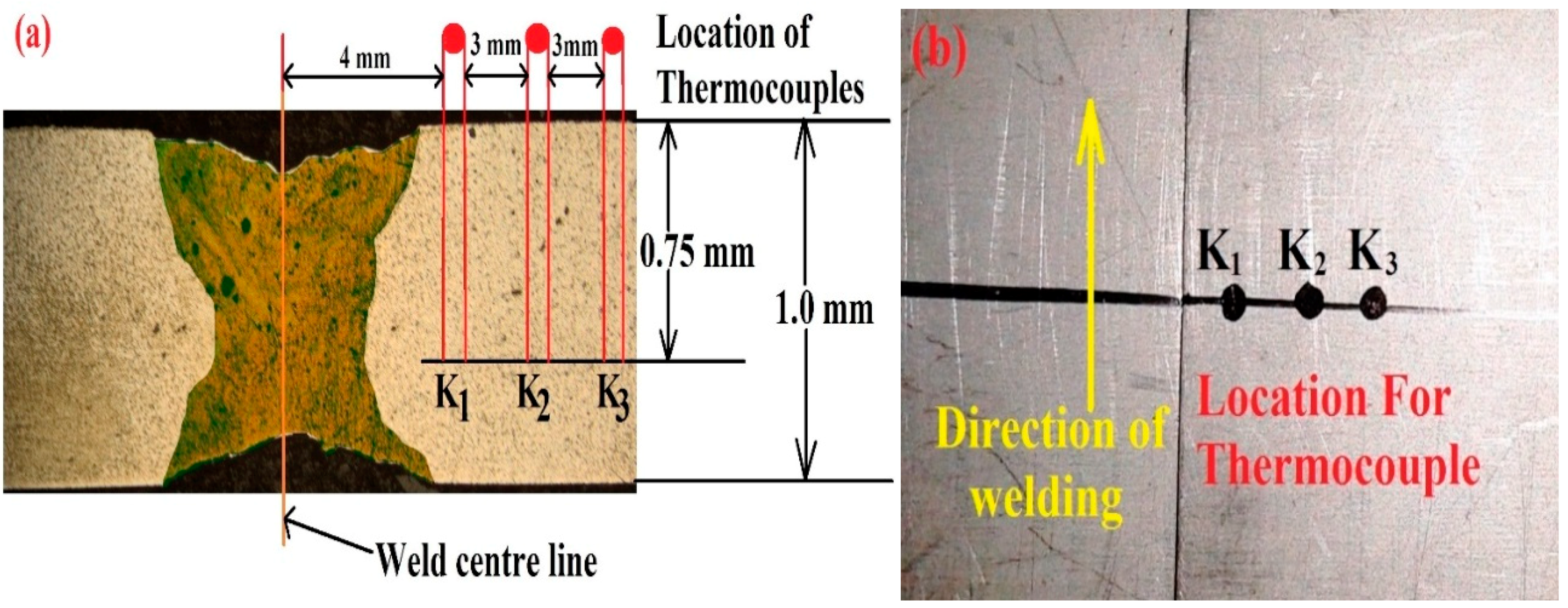

2.3. Thermal Measurement

2.4. Annealing

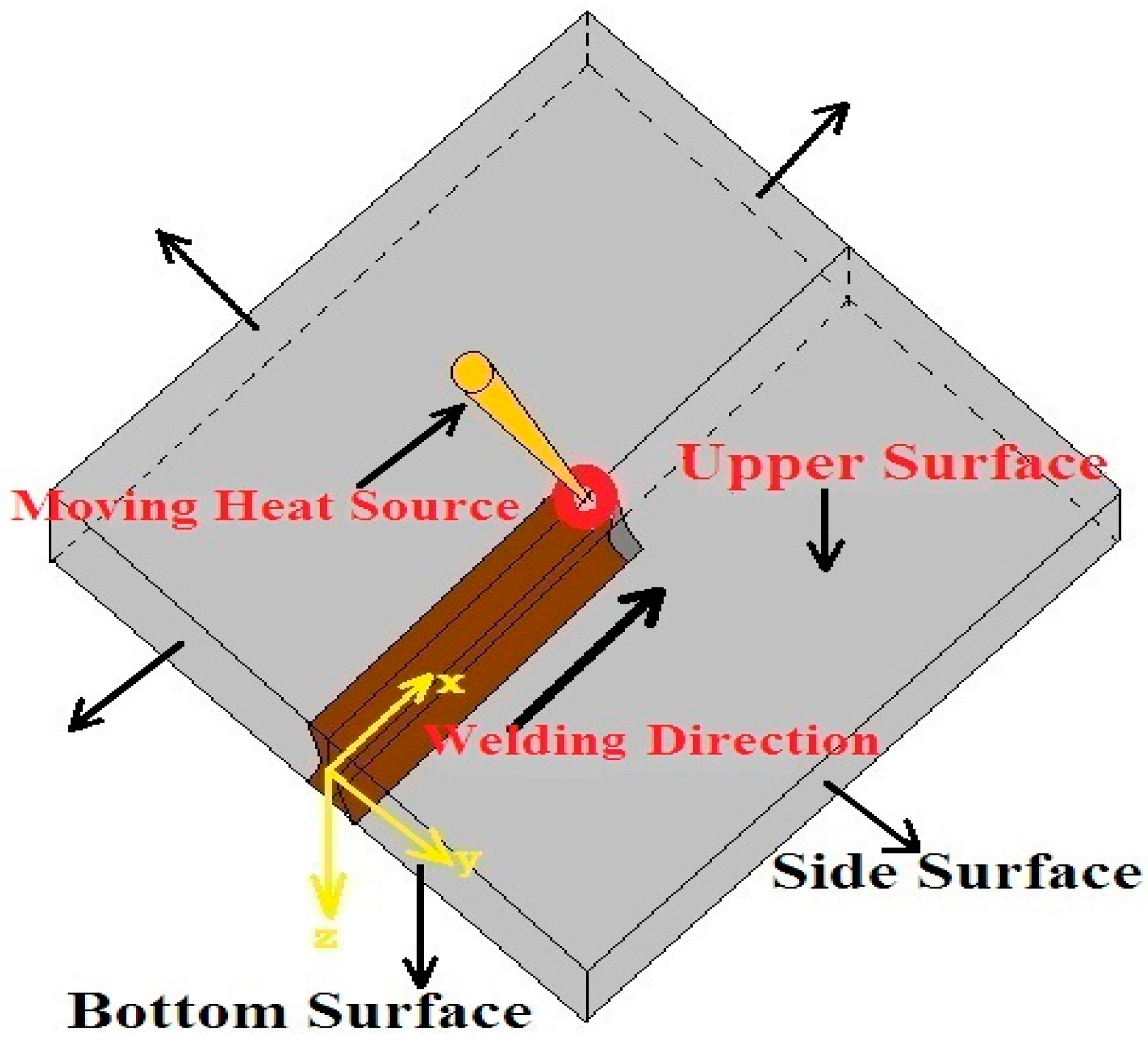

3. Numerical Simulation

3.1. Mathematical Description of the Model

- Workpiece is moving only in one direction, i.e., x-direction.

- Workpiece moving velocity is constant.

- Top surface of the weld pool is considered to be smooth and flat.

- The effect of shielding gas is neglected.

- Half of the geometry is considered to make it less cumbersome.

- Initially the work piece is at a temperature of 300 K (room temperature).

- All the thermophysical properties of the workpiece are considered to be temperature dependent.

- During welding operation, the molten flow is assumed to be incompressible and laminar.

- A 3D time dependent flow is considered for the case.

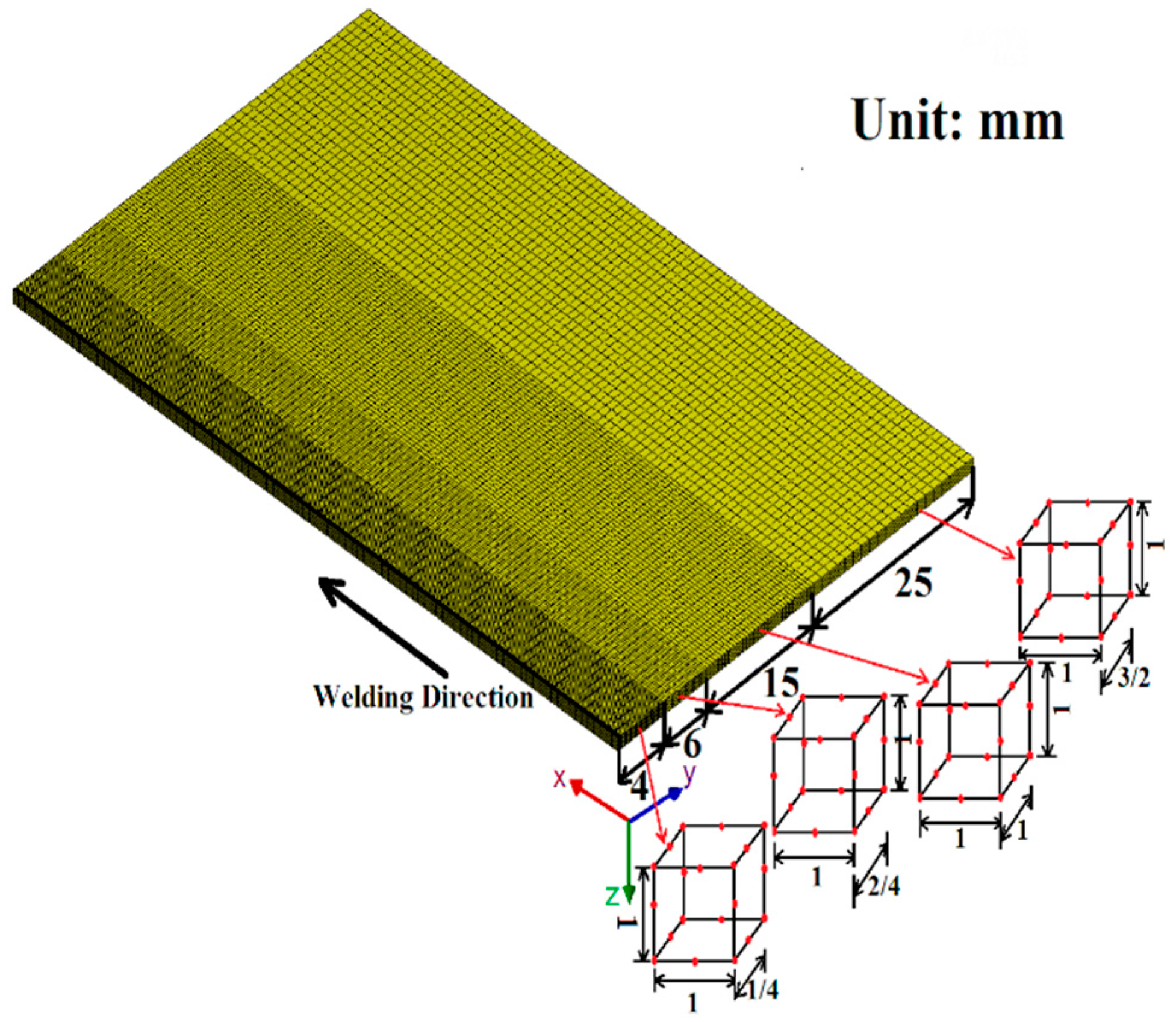

3.2. Finite Element Model

4. Result and Discussion

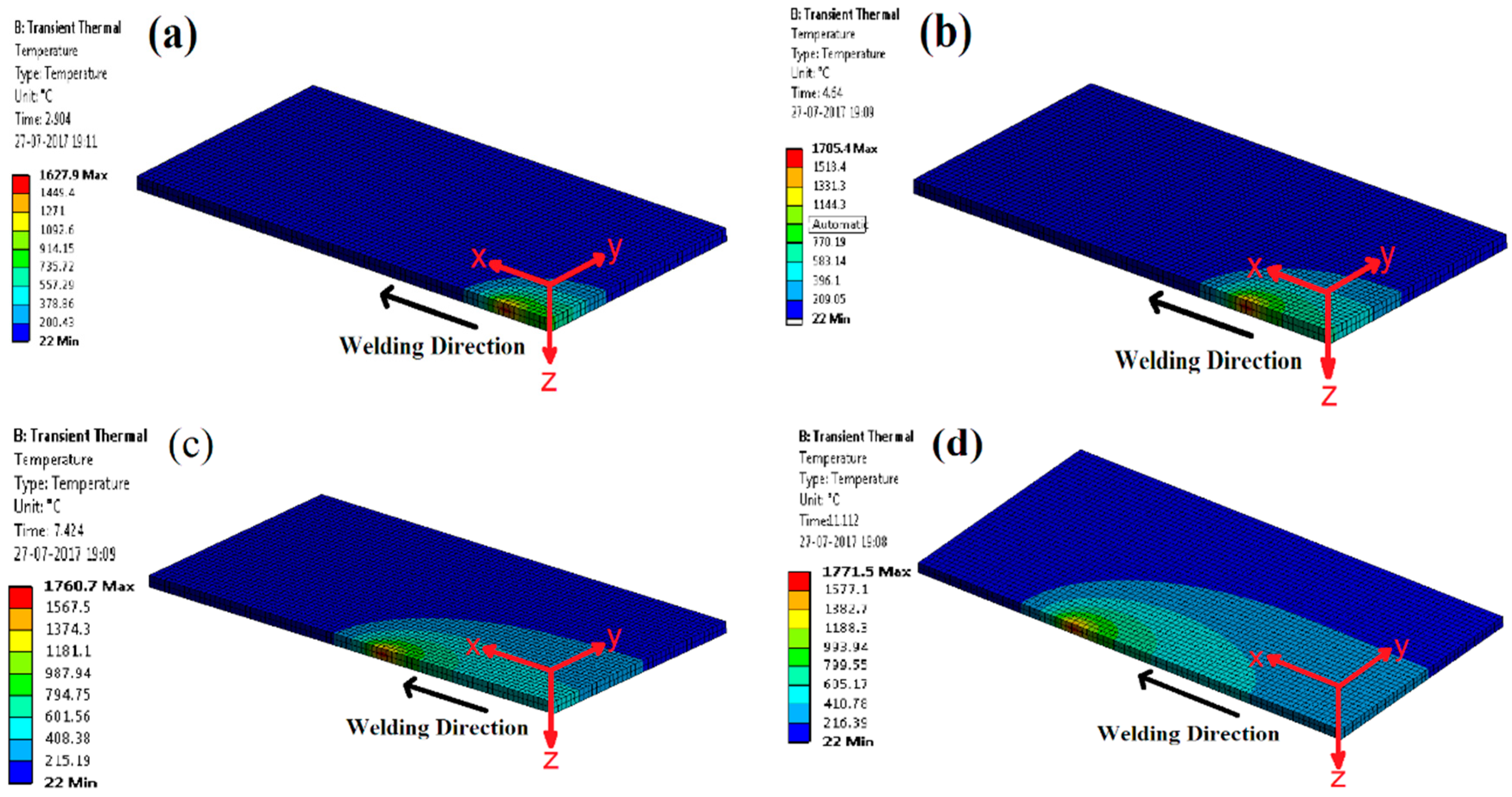

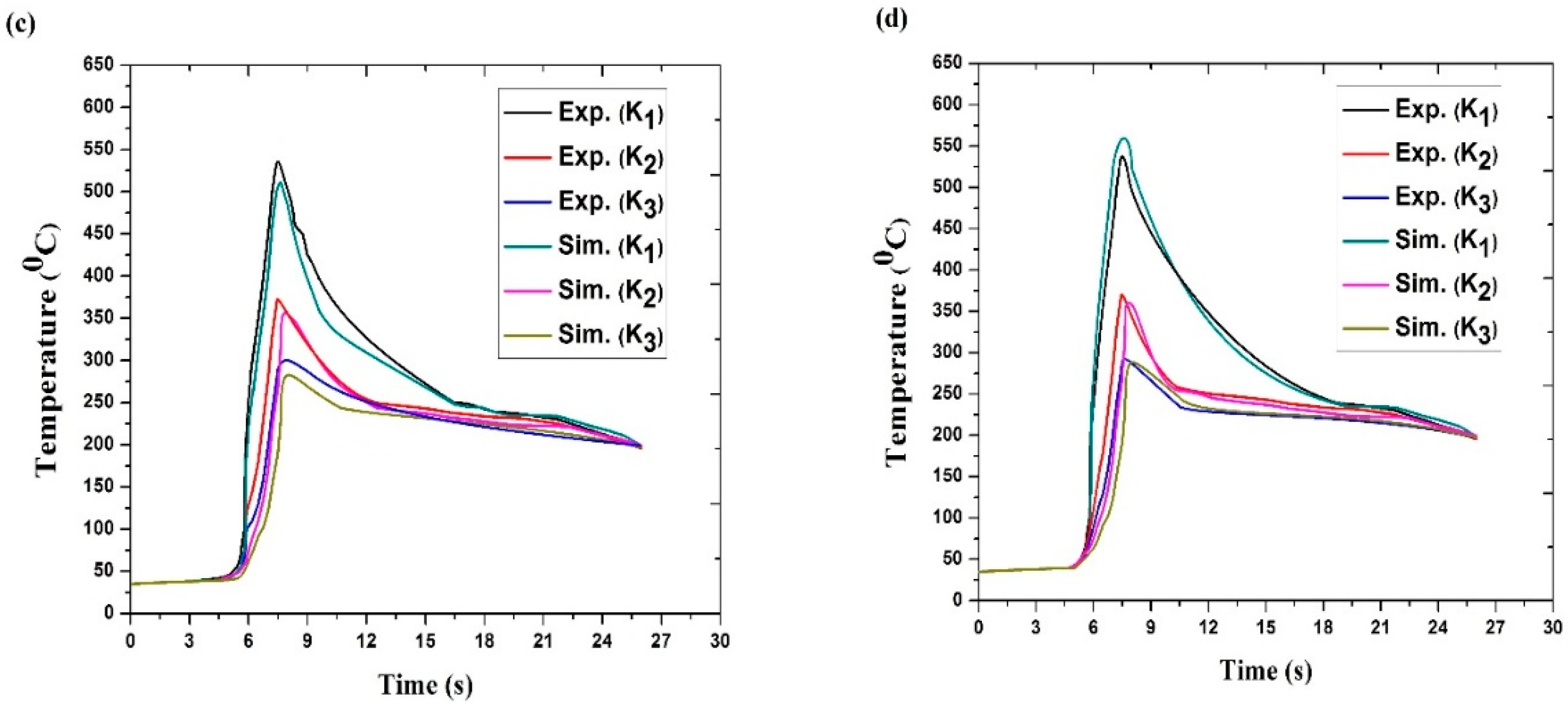

4.1. Thermal Field

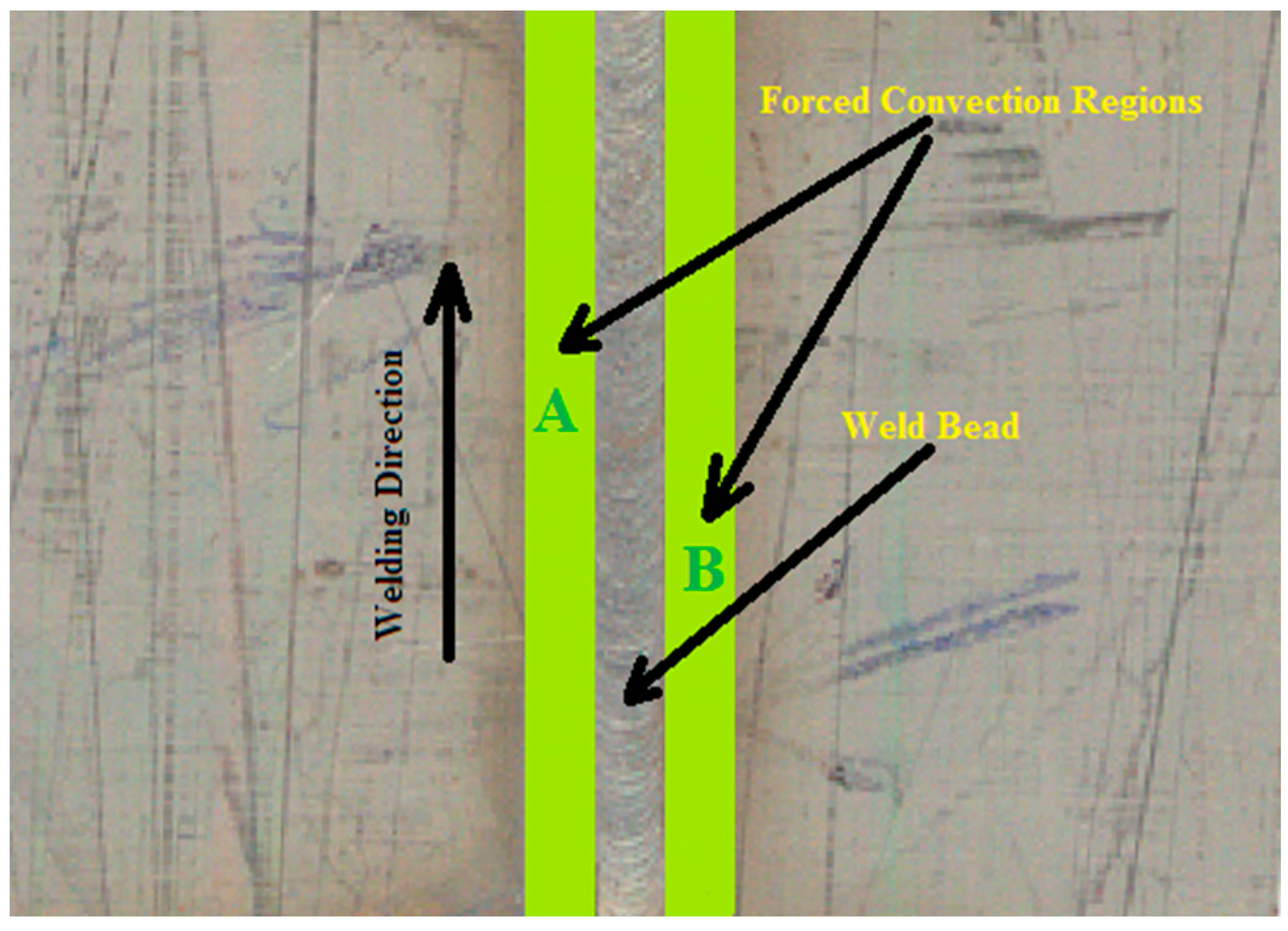

4.2. Weld Bead Analysis

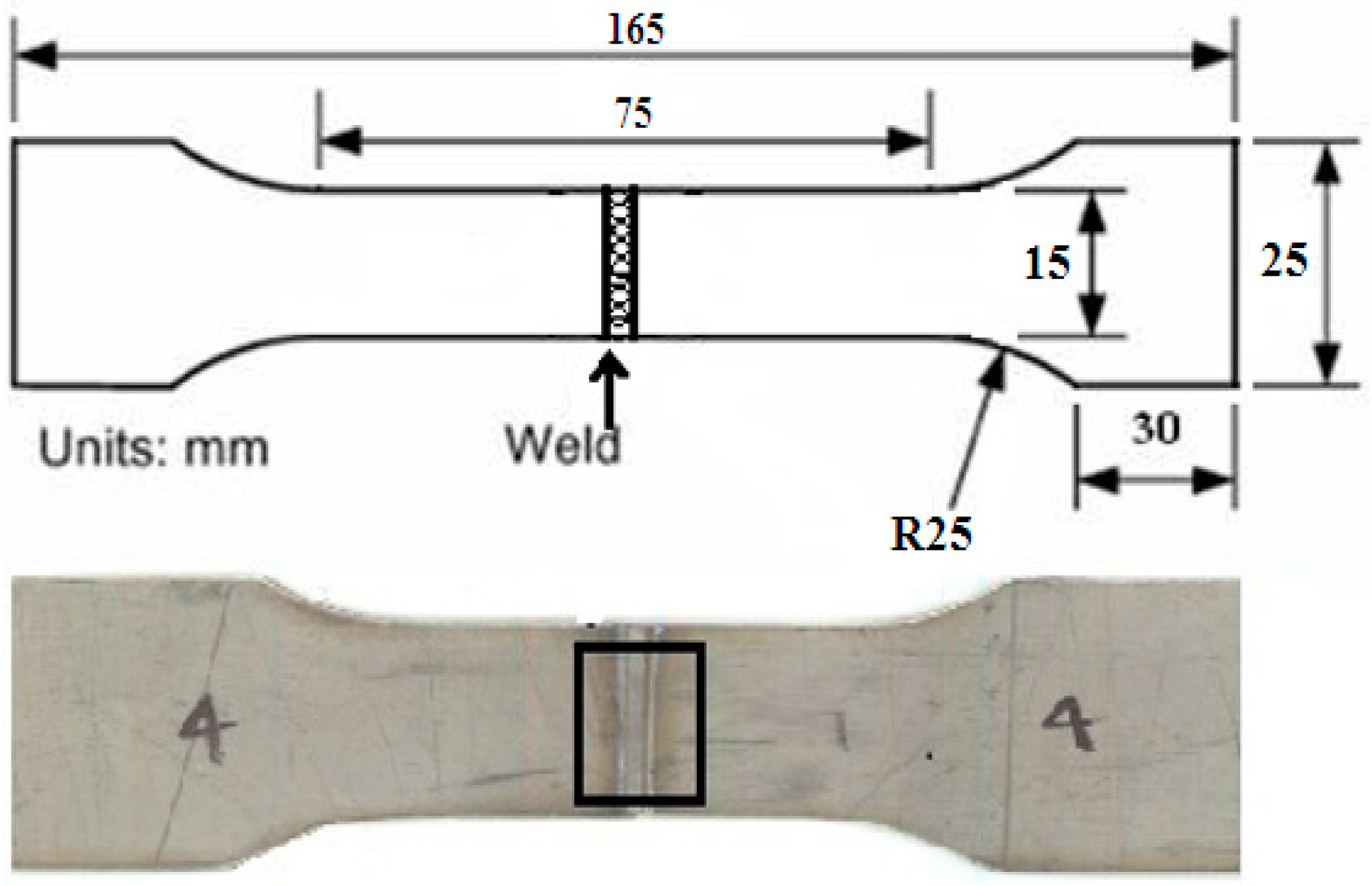

4.3. Tensile Properties Analysis

4.4. Effects of Annealing on Microstructure and Mechanical Properties

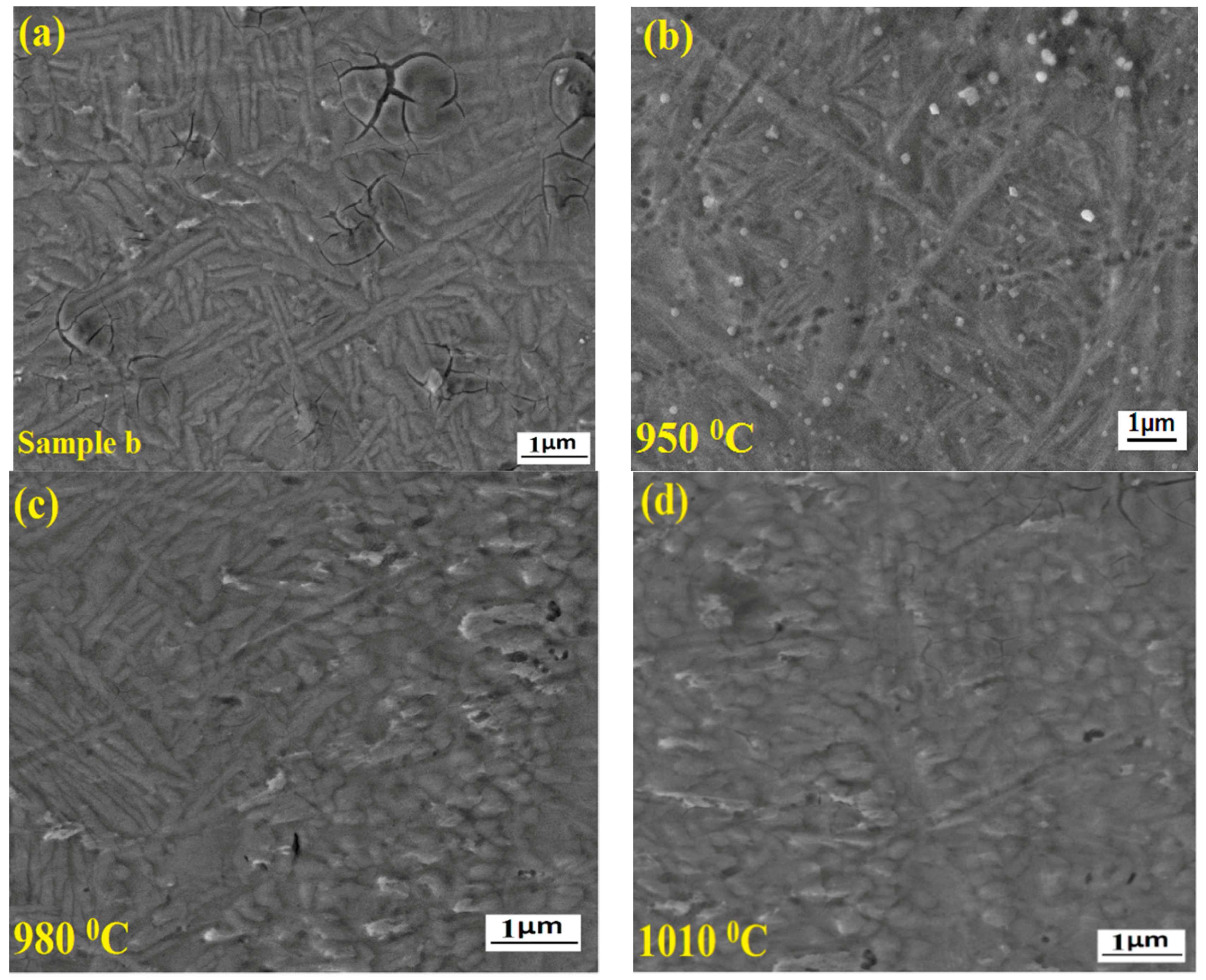

4.4.1. Microstructure

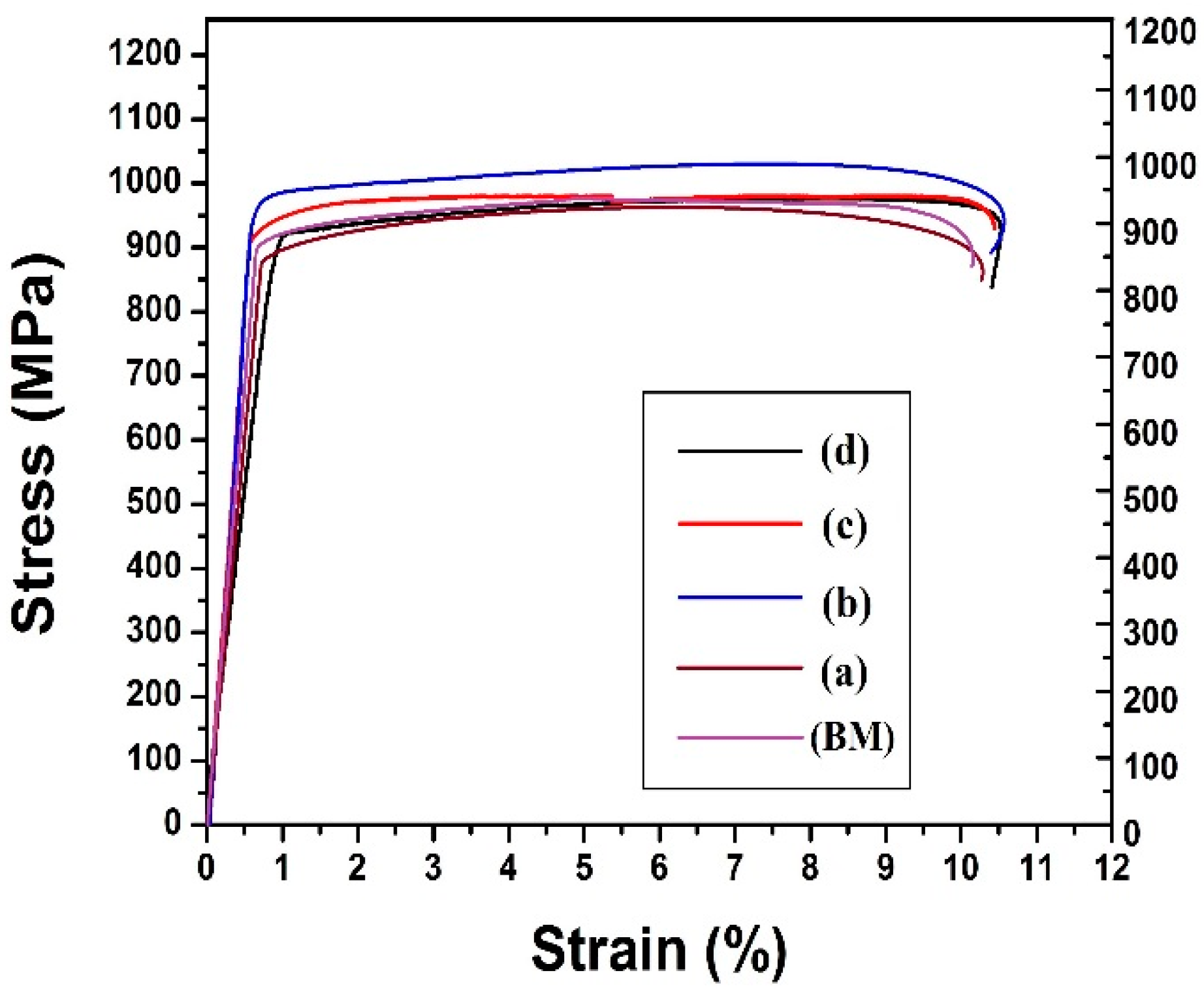

4.4.2. Tensile Properties Analysis

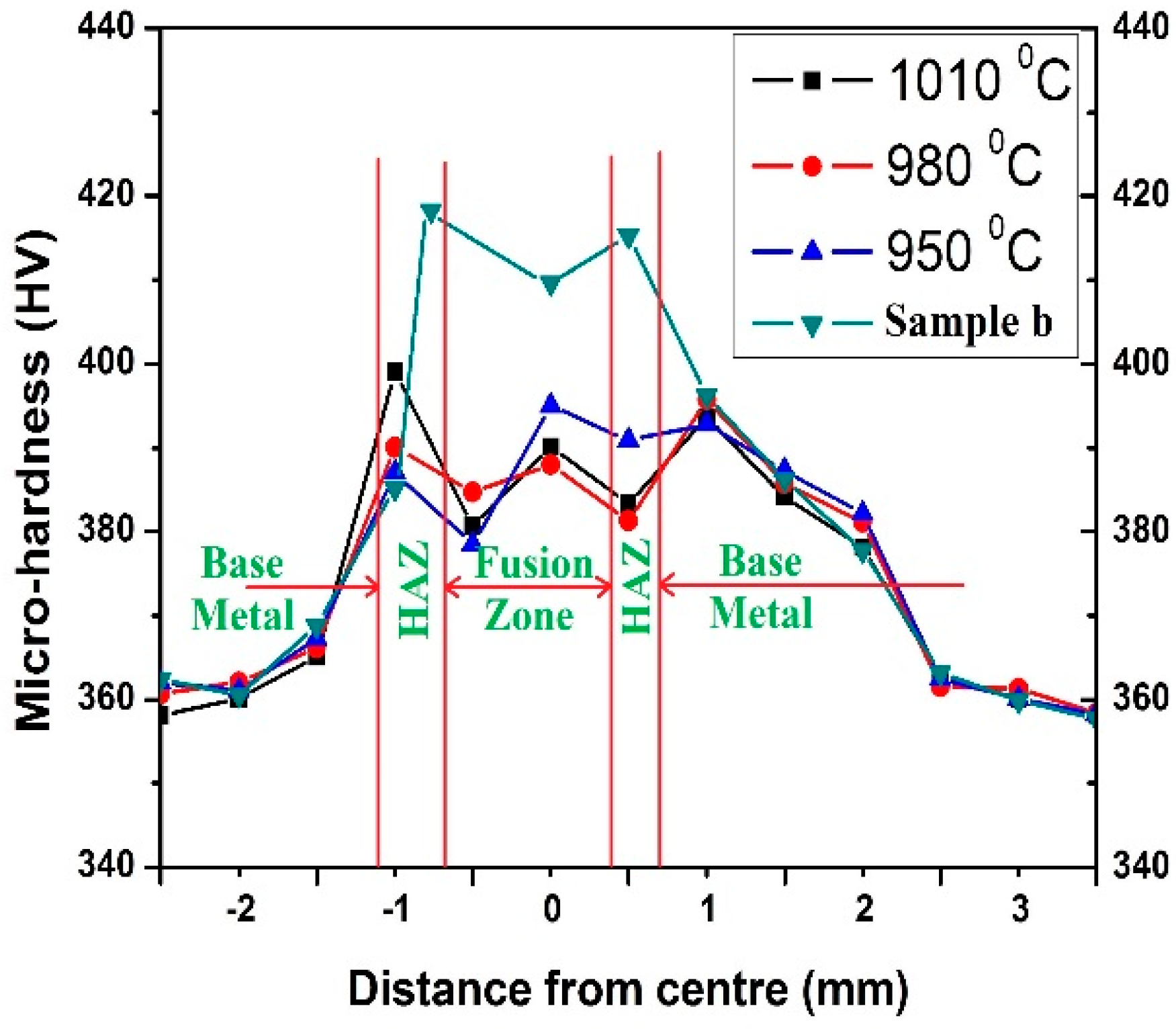

4.4.3. Microhardness

5. Conclusions

- An appreciable agreement was found when the simulated results are compared with the experimental results.

- During comparison, the shape of the thermal histories for some parameters were very similar for both simulated and experimental data.

- The microstructures of the weld zone of annealed samples changed to a great extent after annealing. With an increase in annealing temperature, the number of equiaxed α grains increases, and it was maximum for the sample annealed at 980 °C.

- The annealed samples at 980 °C have shown the best tensile strength among all the heat-treated samples.

- The tensile strength of the annealed sample b at 980 °C was observed to be maximum with a value of 1048 MPa and it is 3% to 4% more than that of a conventional weld sample and 8% to 9% greater than that of the base metal.

Author Contributions

Funding

Conflicts of Interest

References

- Caiazzo, F.; Curcio, F.; Daurelio, G.; Minutolo, F.M.C. Ti6Al4V sheets lap and butt joints carried out by CO2 laser: mechanical and morphological characterization. J. Mater. Process. Technol. 2004, 149, 546–552. [Google Scholar] [CrossRef]

- Casalino, G.; Curcio, F.; Minutolo, F.M.C. Investigation on Ti6Al4V laser welding using statistical and Taguchi approaches. J. Mater. Process. Technol. 2005, 167, 422–428. [Google Scholar] [CrossRef]

- Wang, S.H.; Wei, M.D.; Tsay, L.W. Tensile properties of LBW welds in Ti-6Al-4V alloy at evaluated temperatures below 450 °C. Mater. Lett. 2003, 57, 1815–1823. [Google Scholar] [CrossRef]

- Akman, E.; Demir, A.; Canel, T.; Sınmazcelik, T. Laser welding of Ti6Al4V titanium alloys. J. Mater. Process. Technol. 2009, 209, 3705–3713. [Google Scholar] [CrossRef]

- Gao, X.L.; Zhang, L.J.; Liu, J.; Zhang, J.X. A comparative study of pulsed Nd: YAG laser welding and TIG welding of thin Ti6Al4V titanium alloy plate. Mater. Sci. Eng. A 2013, 559, 14–21. [Google Scholar] [CrossRef]

- Rosenthal, D. The theory of moving source of heat and its application to metal transfer. Transit. ASME 1946, 43, 849–866. [Google Scholar]

- Deng, D.; Murakawa, H. Prediction of welding distortion and residual stress in a thin plate butt-welded joint. Comput. Mater. Sci. 2008, 43, 353–365. [Google Scholar] [CrossRef]

- Deng, D.; Zhou, Y.; Bi, T.; Liu, B. Experimental and numerical investigations of welding distortion induced by CO2 gas arc welding in thin-plate bead-on joints. Mater. Des. 2013, 52, 720–729. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Arif, A.F.M.; Aleem, B.J.A. Laser welding of low carbon steel and thermal stress analysis. Opt. Laser Technol. 2010, 42, 760–768. [Google Scholar] [CrossRef]

- Adamus, K.; Kucharczyk, Z.; Wojsyk, K.; Kudla, K. Numerical analysis of electron beam welding of different grade titanium sheets. Comput. Mater. Sci. 2013, 77, 286–294. [Google Scholar] [CrossRef]

- Du, H.; Hu, L.; Liu, J.; Hu, X. A study on the metal flow in full penetration laser beam welding for titanium alloy. Comput. Mater. Sci. 2009, 29, 419–427. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, Z.; Tang, K.; Mao, C.; Hu, Y.; Chen, G. Analysis of mechanisms of underfill in full penetration laser welding of thick stainless steel with a 10 kW fiber laser. Opt. Laser Technol. 2018, 98, 97–105. [Google Scholar] [CrossRef]

- Zhang, L.J.; Zhang, J.X.; Gumenyuk, A.; Rethmeier, M.; Na, S.J. Numerical simulation of full penetration laser welding of thick steel plate with high power high brightness laser. J. Mater. Process. Technol. 2014, 214, 1710–1720. [Google Scholar] [CrossRef]

- Venkatesh, B.D.; Chen, D.L.; Bhole, S.D. Effect of heat treatment on mechanical properties of Ti-6Al-4V ELI alloy. Mater. Sci. Eng. A 2009, 506, 117–124. [Google Scholar] [CrossRef]

- Zhao, M.S.; Chiew, S.P.; Lee, C.K. Post weld heat treatment for high strength steel welded connections. J. Constr. Steel Res. 2016, 122, 167–177. [Google Scholar] [CrossRef]

- Chen, W.; Chen, Z.Y.; Wu, C.C.; Li, J.W.; Tang, Z.Y.; Wang, Q.J. The effect of annealing on microstructure and tensile properties of Ti-22Ale25Nb electron beam weld joint. Intermetallics 2016, 75, 8–14. [Google Scholar] [CrossRef]

- Vargas, J.A.; Torres, J.E.; Pacheco, J.A.; Hernandez, R.J. Analysis of heat input effect on the mechanical properties of Al-6061-T6 alloy weld joints. Mater. Des. 2013, 52, 556–564. [Google Scholar] [CrossRef]

- Incropera, F.; Dewitt, D.; Bergman, T.; Lavine, A. Fundamentals of Heat and Mass Transfer; John Wiley & Sons Inc.: London, UK, 2007; pp. 71–72, 571–583, 449–451. [Google Scholar]

- Bajpei, T.; Chelladurai, H.; Ansari, M.Z. Mitigation of residual stresses and distortions in thin aluminium alloy GMAW plates using different heat sink models. J. Manuf. Process. 2016, 22, 199–210. [Google Scholar] [CrossRef]

- Coppa, P.; Consorti, A. Normal emissivity of sample surrounded by surfaces at diverse temperatures. Measurement 2005, 38, 124–131. [Google Scholar] [CrossRef]

- Akbari, M.; Saedodin, S.; Toghraie, D.; Razavi, R.S.; Kowsari, F. Experimental and numerical investigation of temperature distribution and melt pool geometry during pulsed laser welding of Ti6Al4V alloy. Opt. Laser Technol. 2014, 59, 52–59. [Google Scholar] [CrossRef]

- Ferro, P.; Zambon, A.; Bonollo, F. Investigation of electron-beam welding in wrought Inconel 706—Experimental and numerical analysis. Mater. Sci. Eng. A 2005, 392, 94–105. [Google Scholar] [CrossRef]

- Mastanaiah, P.; Sharma, A.; Reddy, G.M. Process parameters-weld bead geometry interactions and their influence on mechanical properties: A case of dissimilar aluminium alloy electron beam welds. Def. Technol. 2018, 14, 137–150. [Google Scholar] [CrossRef]

- Kumar, P.; Saw, K.; Kumar, U.; Kumar, R.; Chattopadhyaya, S.; Hloch, S. Effect of laser power and welding speed on microstructure and mechanical properties of fibre laser-welded Inconel 617 thin sheet. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 4579–4588. [Google Scholar] [CrossRef]

- Gao, X.; Zeng, W.; Wang, Y.; Long, Y.; Zhang, S.; Wang, Q. Evolution of equiaxed alpha phase during heat treatment in a near alpha titanium alloy. J. Alloys Compd. 2017, 725, 536–543. [Google Scholar] [CrossRef]

| C | Al | V | O | Ti |

|---|---|---|---|---|

| 3.78 | 7.08 | 3.38 | 0.25 | 85.51 |

| Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|

| 964 ± 12 | 891 ± 19 | 14 | 356 |

| Wavelength | 1.06 μm |

| Pulse energy | 20 J |

| Peak pulse power | 1000 W |

| Pulse duration | 20 ms |

| Pulse frequency | 20 Hz |

| Spot diameter | 0.45 mm |

| Sample | Average Power (Watt) | Welding Speed (mm/s) |

|---|---|---|

| a | 192 | 4 |

| b | 192 | 6 |

| c | 202 | 4 |

| d | 202 | 6 |

| Tensile Properties | Sample b | At 950 °C | At 980 °C | At 1010 °C |

|---|---|---|---|---|

| UTS (MPa) | 1014 | 1016 | 1048 | 1021 |

| Elongation (%) | 10.5 | 9.9 | 9.7 | 9.3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, U.; Gope, D.K.; Srivastava, J.P.; Chattopadhyaya, S.; Das, A.K.; Krolczyk, G. Experimental and Numerical Assessment of Temperature Field and Analysis of Microstructure and Mechanical Properties of Low Power Laser Annealed Welded Joints. Materials 2018, 11, 1514. https://doi.org/10.3390/ma11091514

Kumar U, Gope DK, Srivastava JP, Chattopadhyaya S, Das AK, Krolczyk G. Experimental and Numerical Assessment of Temperature Field and Analysis of Microstructure and Mechanical Properties of Low Power Laser Annealed Welded Joints. Materials. 2018; 11(9):1514. https://doi.org/10.3390/ma11091514

Chicago/Turabian StyleKumar, Uday, D. K. Gope, J. P. Srivastava, Somnath Chattopadhyaya, A. K. Das, and Grzegorz Krolczyk. 2018. "Experimental and Numerical Assessment of Temperature Field and Analysis of Microstructure and Mechanical Properties of Low Power Laser Annealed Welded Joints" Materials 11, no. 9: 1514. https://doi.org/10.3390/ma11091514

APA StyleKumar, U., Gope, D. K., Srivastava, J. P., Chattopadhyaya, S., Das, A. K., & Krolczyk, G. (2018). Experimental and Numerical Assessment of Temperature Field and Analysis of Microstructure and Mechanical Properties of Low Power Laser Annealed Welded Joints. Materials, 11(9), 1514. https://doi.org/10.3390/ma11091514