1. Introduction

Due to the difference in the mechanical and physical properties between the metals and polymers, joining a metal and a polymer is often difficult, and the combined behaviors are not yet fully understood. Mechanical fastening and adhesive bonding are commonly applied in joining a metal and a polymer; however, these methods have some drawbacks, such as low joining efficiency and a high environmental impact [

1]. New joining processes have been developed recently involving laser joining, ultrasonic joining, and friction-assisted joining to exploit the possibility of obtaining high-quality joints of metals and polymers [

2,

3,

4]. These methods may play an important role in different applications; however, ultrasonic joining is limited to small components with joining lengths typically not exceeding a few centimeters; and friction-assisted joining requires very stiff clamping system due to high loads involved during the processes. Laser transmission joining has become a joining process for metals and polymers, and is widely used in a variety of industrial areas including automobiles, aircraft, and electronics [

5,

6,

7]. This is because of advantages such as good joining quality, small deformation, high efficiency, easy operation, and non-contact interaction. In the past few years, Mian conducted the joining experiment of polyimide (PI) and titanium-coated glass, and analyzed the joining mechanism [

8]. Song et al. studied the laser transmission joining of polyethylene terephthalate (PET) and 316L stainless steel, and revealed the change rule for joint quality with respect to changes in the process parameters [

9]. Georgiev determined that the reason a strong joint was formed between Teflon

TM (fluorinated ethylene propylene (FEP), Wilmington, DE, USA) and Ti was the formation of Ti–F chemical bonds at the joint [

10]. Wang et al. studied the joint of PET and Ti, and found a formation of Ti–C chemical bonds between PET and Ti [

11,

12].

To improve the joint strength, the metal surface can be anodized or microtextured; e.g., Roesner et al. studied the laser transmission joining of various polymers such as glass fiber- reinforced nylon 66, nylon 66, and polycarbonate with metal, and processed the groove on the metal surface by a laser ablation method. During the joining process, the upper layer of molten polymer flowed into the groove to form a mechanical riveting, thereby increasing the joint strength [

13]. Bergmann et al. studied the joining between nylon and a steel plate, and effectively improved the joint strength by producing a relatively rough surface on the steel plate through manual sandblasting, and then performing the laser transmission joining [

14]. Lambiase et al. conducted laser sculpturing on the aluminum substrate to produce teeth features, and then investigated the laser-assisted joining of aluminum alloy sheets with polyvinyl chloride (PVC) and polyetheretherketone (PEEK) [

5,

15]. Yusof et al. investigated the joining of PET and surface-anodized A5052. From the experiment, the authors found that both PET and anodized A5052 and PET and untreated A5052 clearly formed molten pools, and the joint strength was mainly affected by the heat input, rather than the pulse duration. At the same time, the generation of bubbles and the depth of the molten pool were two aspects that affected the joint strength [

16]. Zhang et al. investigated the joining of aluminum alloy A6061 and carbon fiber-reinforced plastic (CFRP). A phosphate-anodizing pretreatment of A6061 was carried out [

17]. Jung et al. conducted a pre-oxidation process on the surface of the zinc-coated steel using a selected temperature and air atmosphere in a furnace. A thick zinc oxide layer that reacted on the zinc-coated steel increases the possibility of chemical bonding between zinc oxide and carbon (Zn–O–C) [

7]. In summary, the pretreatment methods for improving the strength of the joint are mainly through the microtexturing of the metal or the anodization of the metal surface, while research on the treatment of the polymer surface is relatively less. Arai et al. studied the laser transmission joining of cyclic olefin polymers (COP) and SUS304 through surface UV-ozone treatments, and found that the increase in the surface energy of COP improved the surface interaction between COP and SUS304, and thus improved the joint strength [

18].

Polystyrene (PS) and titanium are widely used in the biomedical applications. PS is one of the important polymers in the numerous applications for the fabrication of everyday life objects, and has been widely used in biomedical material as tissue culture dishes for its aging resistance, high transparency, low toxicity, good rigidity, etc. The transmission joining between PS and a thin titanium plate shows that the joint strength of untreated PS and titanium is very low. PS is a non-polar material. Its molecular chain does not contain polar groups, so the surface energy is very low. Using the plasma treatment can generate oxygen-containing functional groups on the PS surface. In different plasma atmospheres (H

2, Ar, N

2, air, or O

2), PS gains various functional groups. Oxygen plasma-treated PS has a relatively high percentage of oxygen atoms and a high compositional ratio of O/C [

19].

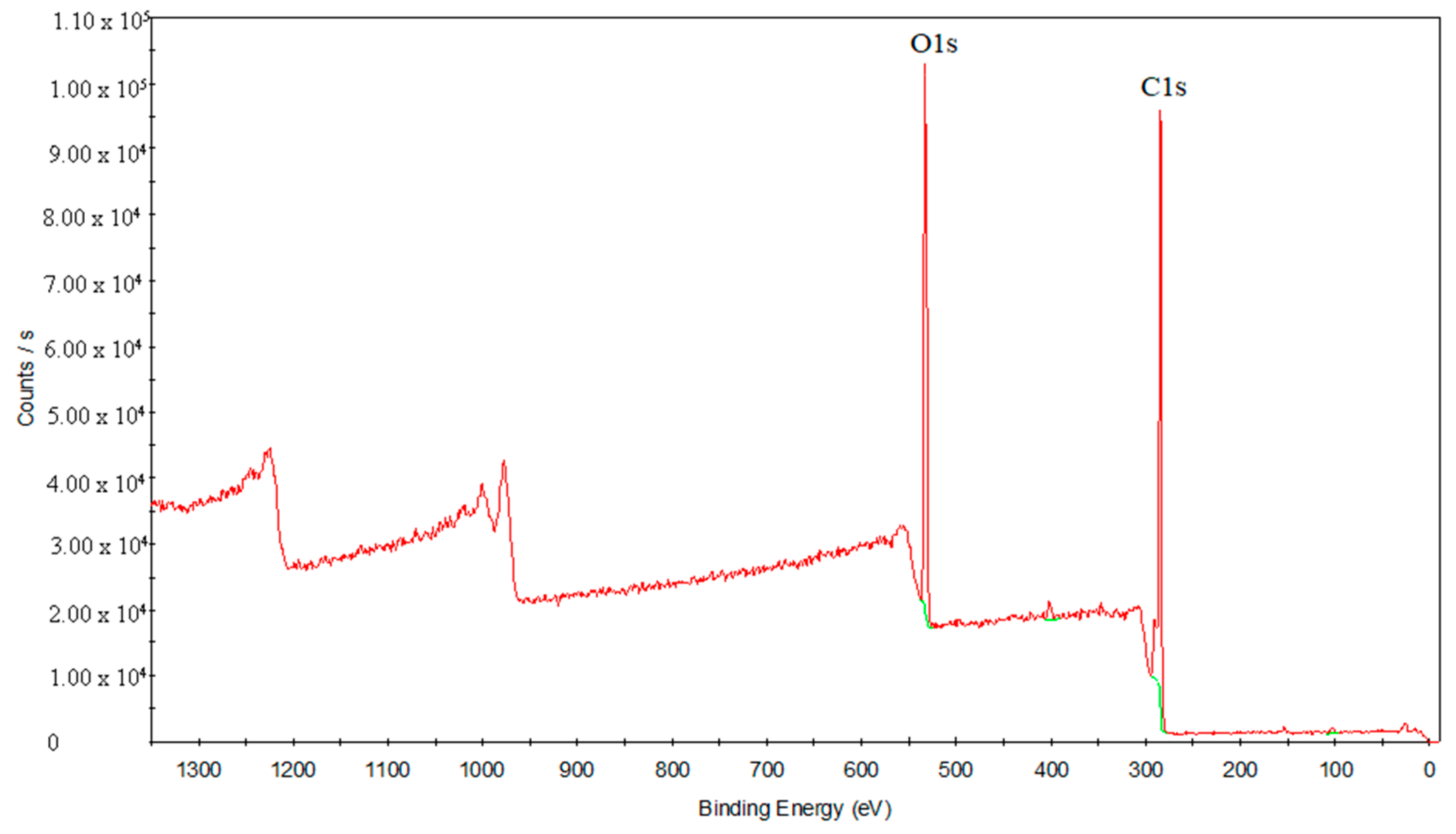

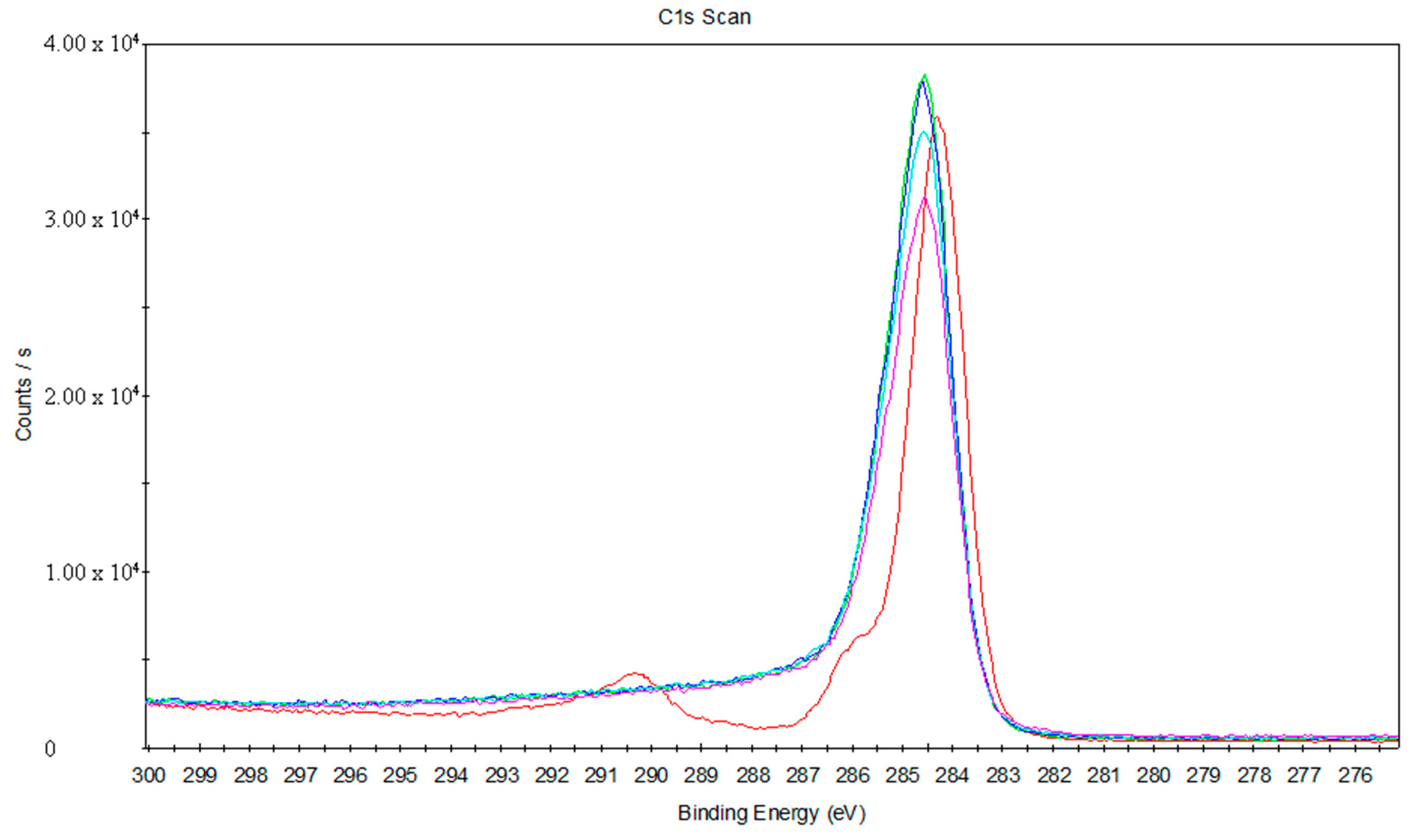

In this paper, based on the above methods for the surface modification of polymers and the surface treatment of metals, it is proposed to first perform an oxygen plasma treatment of PS and a laser surface treatment of titanium, and then perform a laser transmission joining of PS and titanium plates. This paper focuses on the strength of joints obtained by four different treatment methods, and investigated the joining mechanism of PS and titanium by tensile failure mode, joint micromorphology observation, contact angle and surface free energy experiments, and X-ray photoelectron spectroscopy (XPS) analysis.

2. Experimental Procedures

2.1. Experimental Equipment and Sample Preparation

Laser transmission joining and laser surface treatment were conducted with a semiconductor laser (Compact 130/140, DILAS Diodenlaser GmbH, Mainz, Germany) with an output wavelength of 980 ± 10 nm, a minimum spot diameter of 700–800 μm with a circular shape, a maximum output power of 130 W, and a working temperature kept between 15–25 °C.

A universal tensile machine (UTM4104, Shenzhen Suns Technology Co., Ltd., Shenzhen, China) was used for testing the joint strength, with v = 2 mm/min. The lap shearing test finally broke the joints through loading tension at both ends of the joints. In this paper, the joint strength is measured by shear stress, and the shear stress is calculated as Formula (1):

An ultra-depth optical microscopy (VHX-1000, Keyence Corporation, Osaka, Japan) was used to observe the micromorphology of the joint.

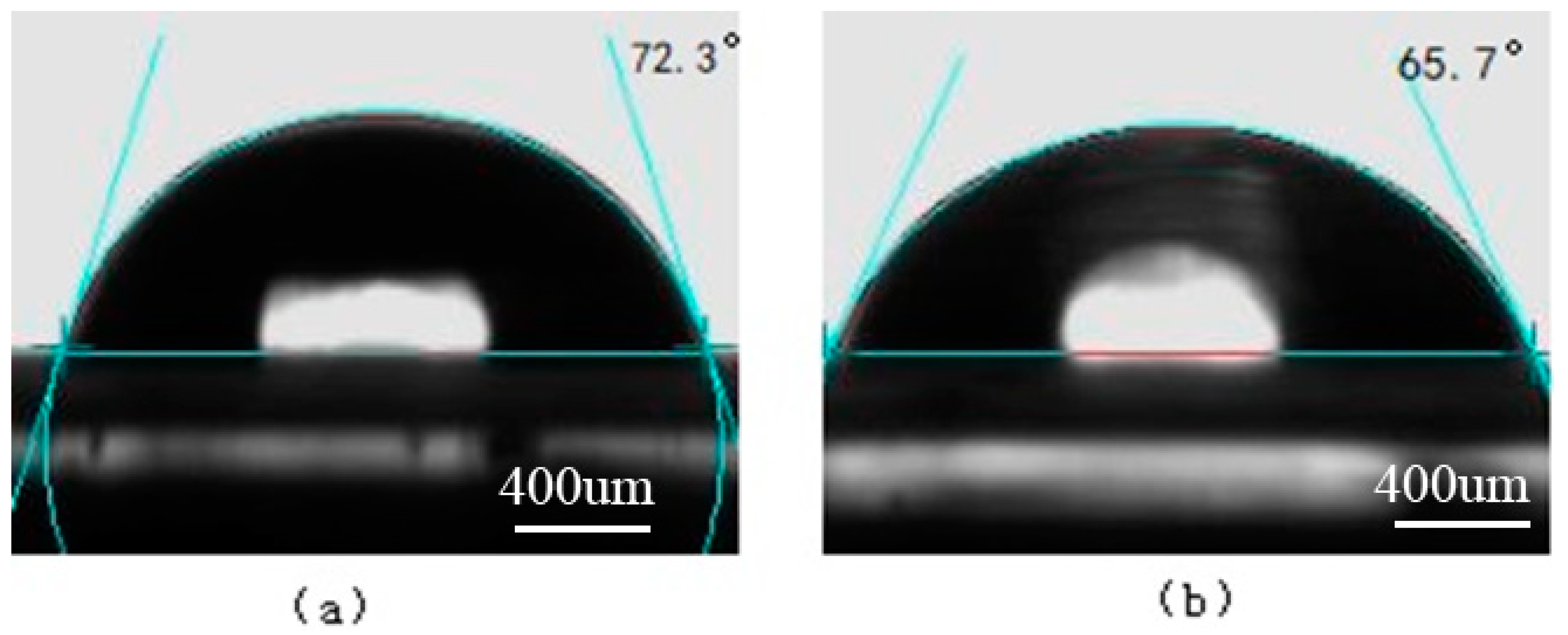

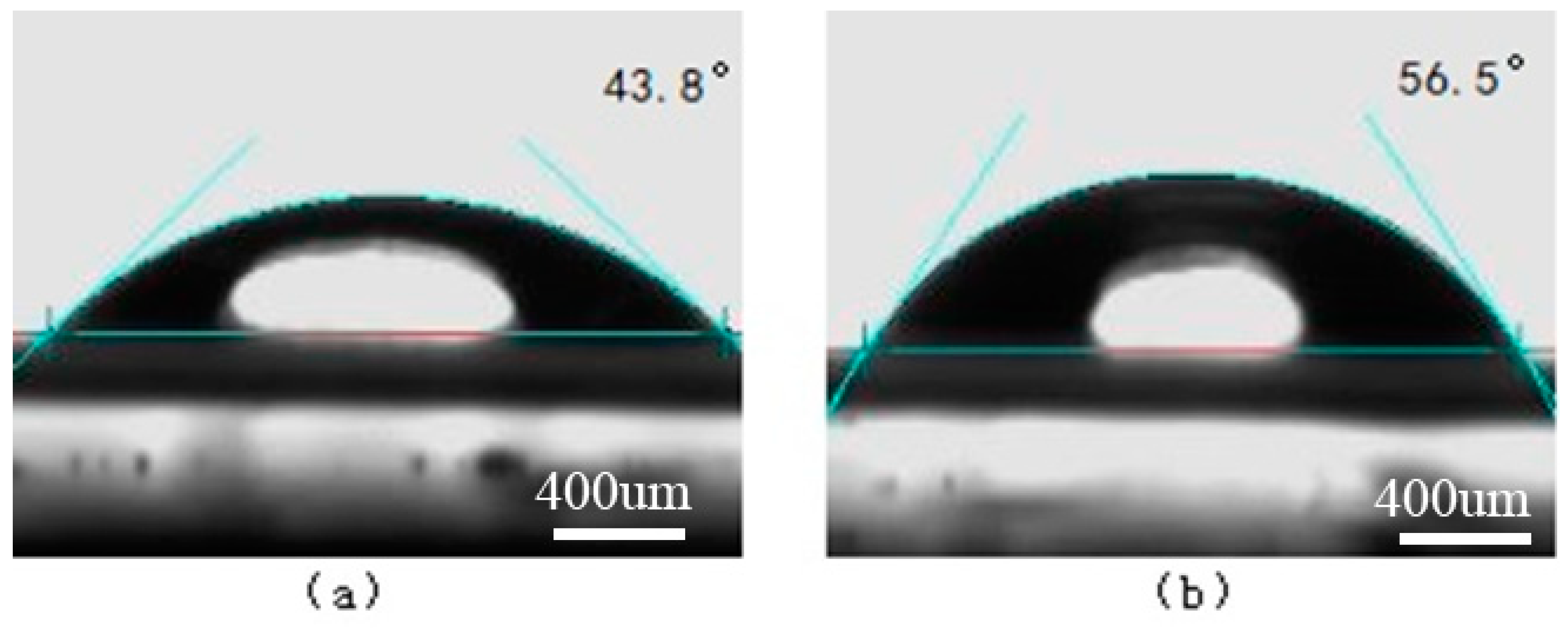

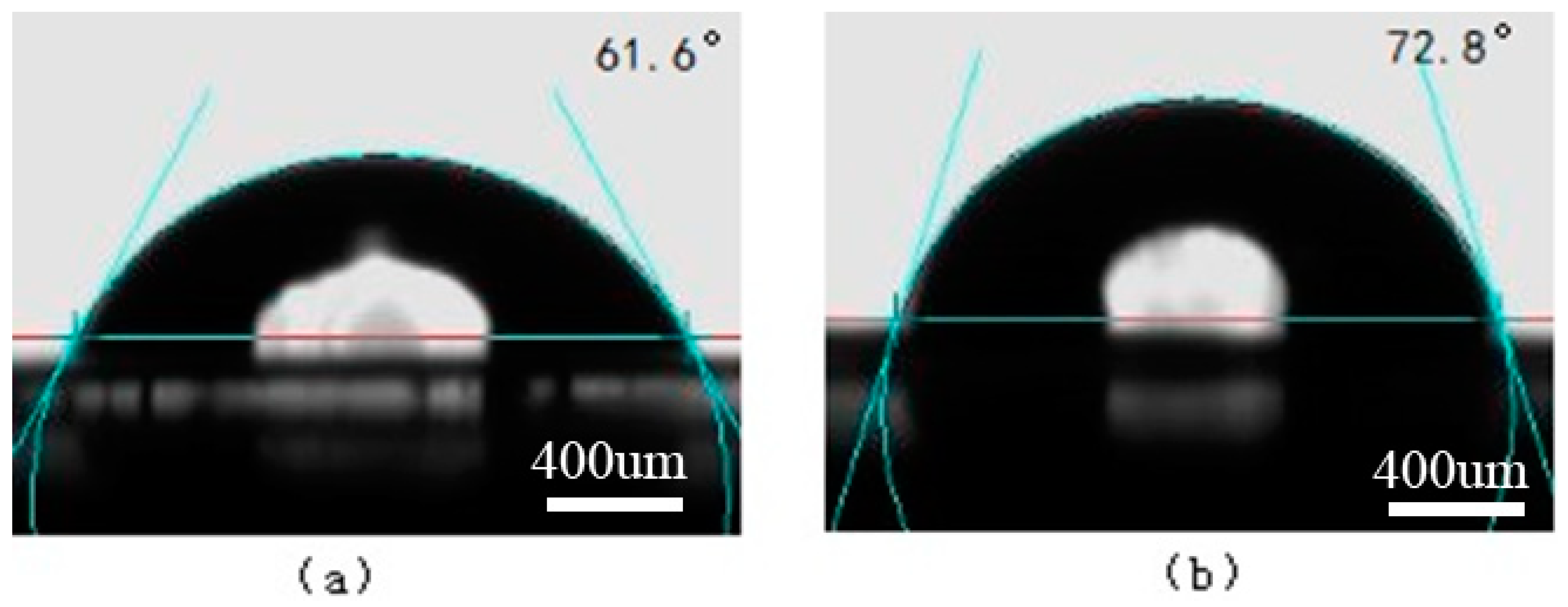

Contact angle measurements (OCA40, Dataphysics Instruments GmbH, Stuttgart, Germany) were performed to study the changes in the contact angles of the surface.

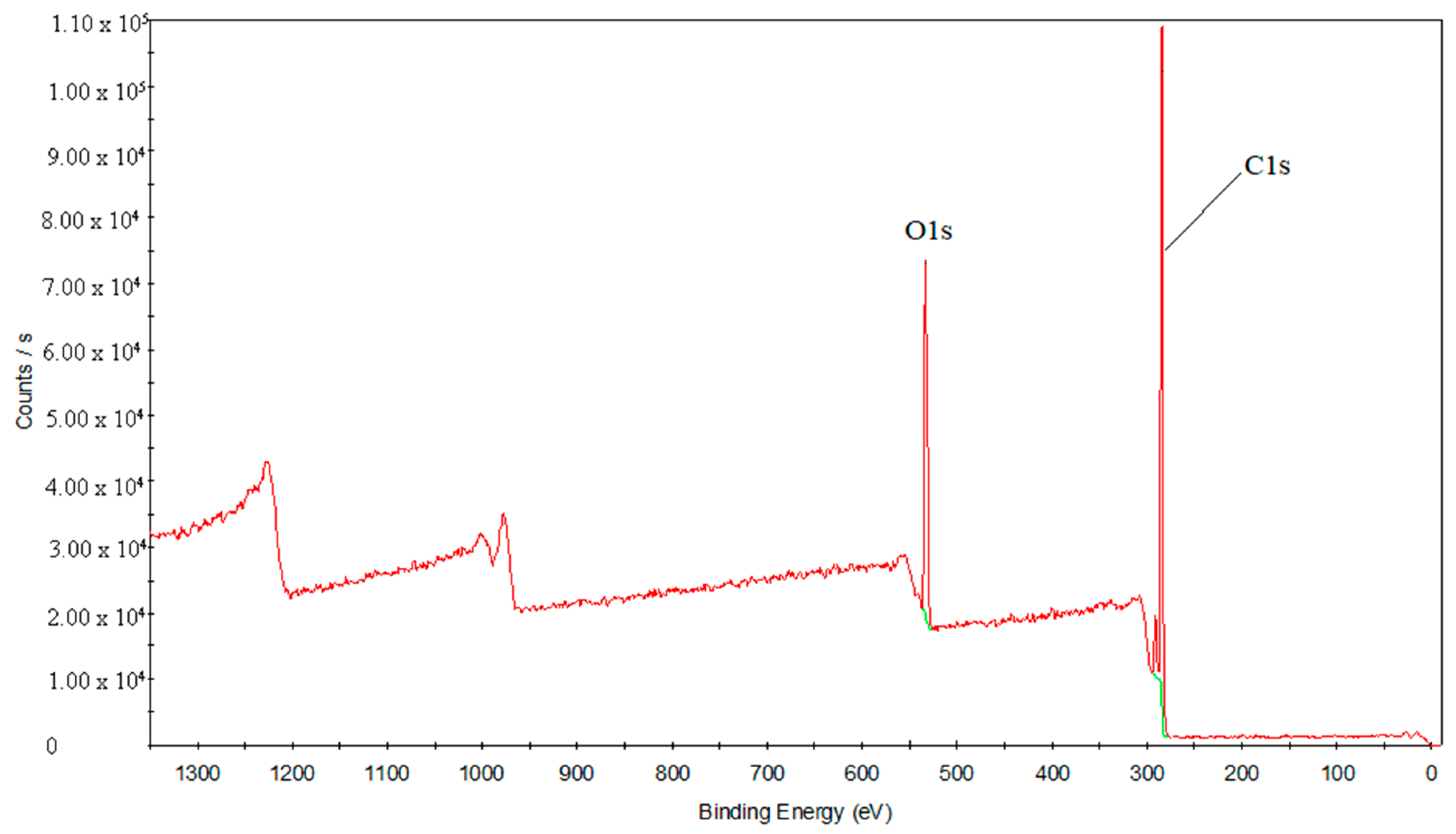

An X-ray photoelectron spectrometer (ESCALAB 250Xi, Thermo Fisher Scientific, Waltham, MA, USA) was used for the interface analysis of the chemical composition and chemical bond state before and after treatments.

The dimensions of all of the samples were 150 mm × 20 mm × 0.1 mm. The main properties of the materials are shown in

Table 1. Before the experiments, the titanium and PS surfaces were cleaned using an ultrasonic cleaning machine with ethanol to remove impurities, and drying in a dry machine for 12 h.

2.2. Experimental Methods

2.2.1. Laser Surface Treatment

The essence of the laser surface treatment includes scanning the titanium metal surface by the laser in the air atmosphere, oxidizing by heating, and forming an oxide layer of a certain thickness on the metal surface [

20].

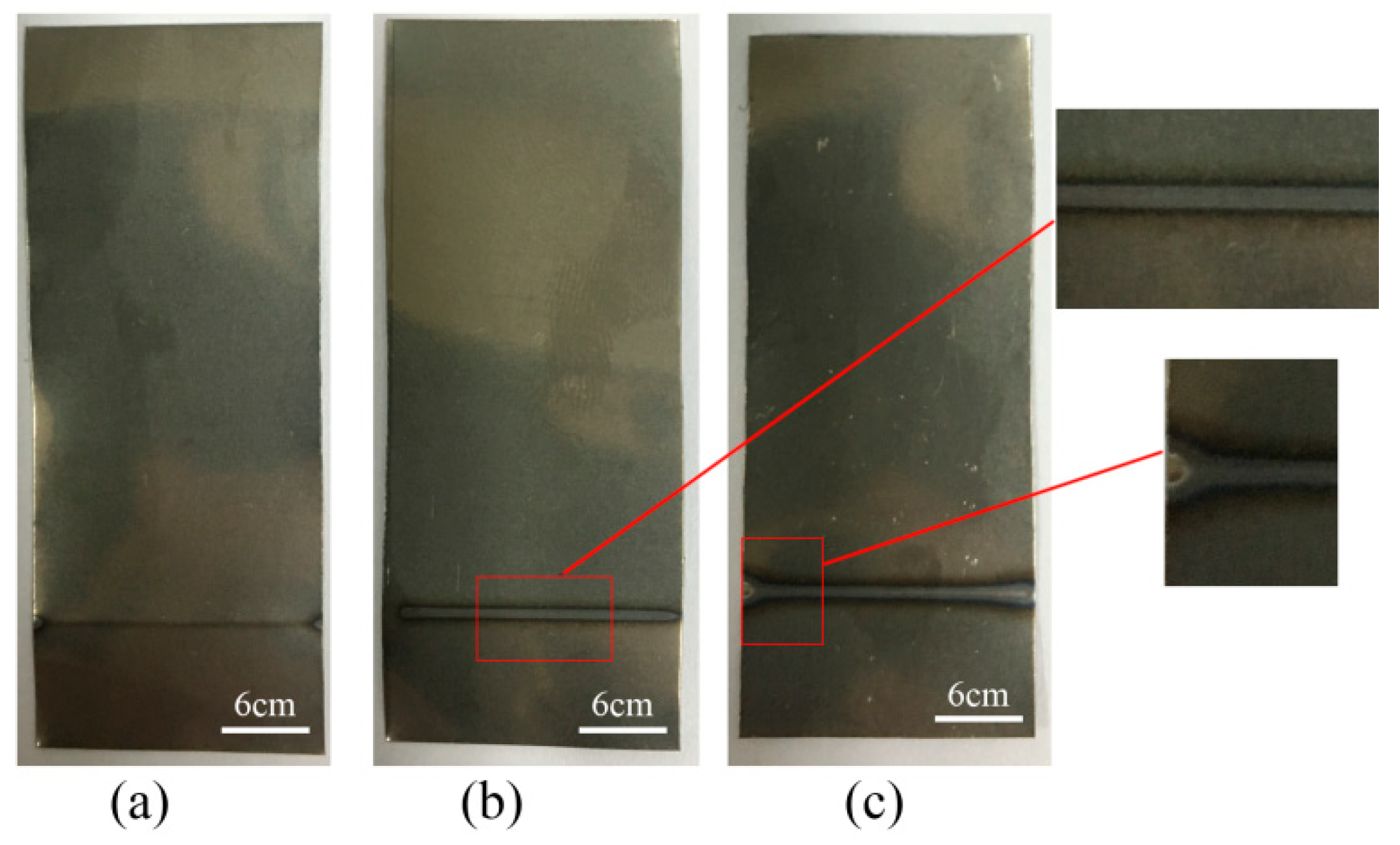

Figure 1 shows the samples of the titanium surface treated by the laser power for surface treatment of 4 W, 5 W, and 6 W. The scanning speed was 2 mm/s, the number of scans was six, and the spot diameter was 2 mm. From

Figure 1, oxidation is not apparent at the laser power of 4 W, because of the low laser power for surface treatment. When the laser power is 5 W, an oxide layer of uniform width is produced along the scan direction of the laser, and the titanium surface oxidization is optimal. When the laser power is 6 W, the surface temperature of the titanium is high, causing the melt of the titanium surface.

The topography of titanium after the laser treatment could be altered, and could promote the joint strength by a mechanical interference effect. In this study, which focuses on what is attributed to the chemical bond between titanium and the polymer, the process parameters for laser surface treatment are fixed and shown in

Table 2.

2.2.2. Oxygen Plasma Treatment

Plasma treatment is an effective method for the surface modification of polymers [

20]. In this study, plasma treatment apparatus (HD-1B, Changzhou Zhongke Changtsi Plasma Processing Apparatus Plasma Technology Co., Ltd., Changzhou, China) was used. The samples to be treated were placed in the instrument’s reaction chamber made of hard and high temperature-resistant glass. For the plasma pretreatment, the output power of 150 W was used with the working gas of oxygen and the pressure of 40 Pa. The pretreatment time was 120 s. The materials after plasma pretreatment were placed for 90 min, and then, the laser transmission welding experiments were carried out.

2.2.3. Laser Transmission Joining

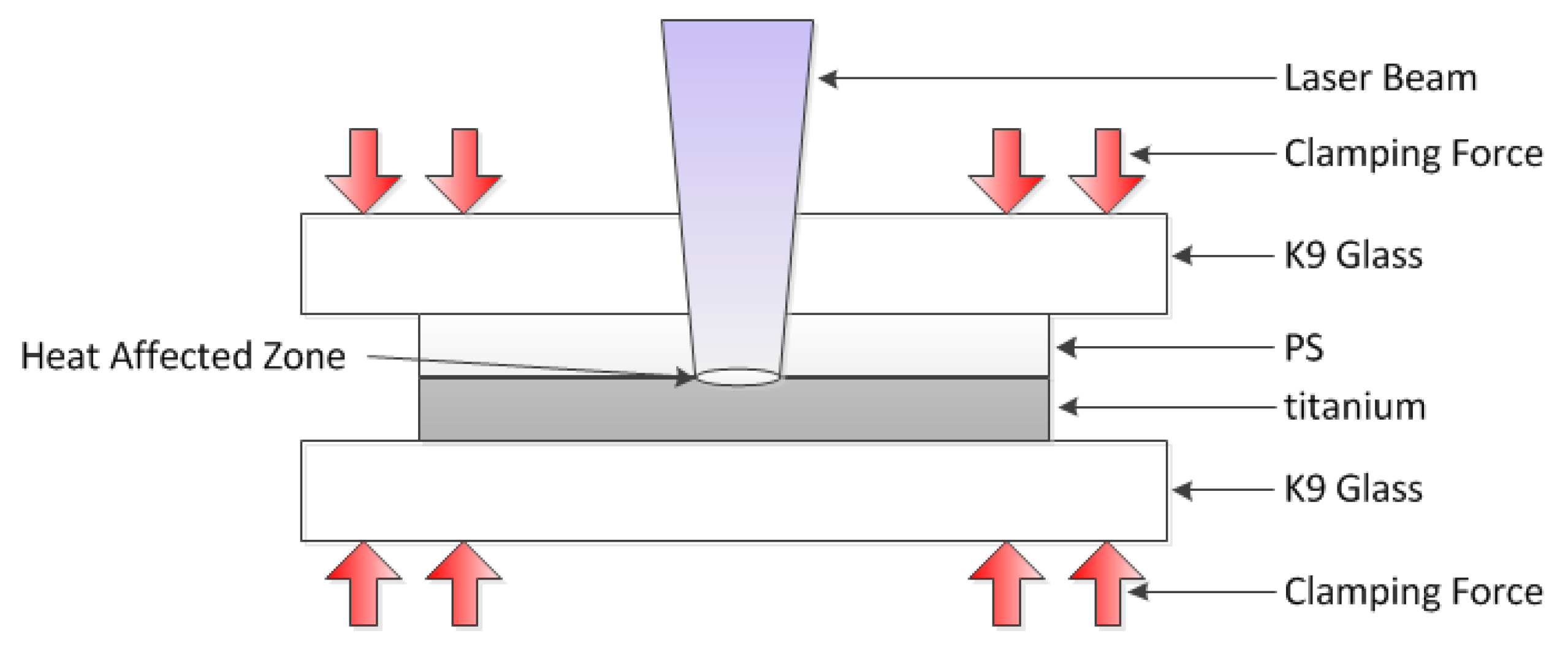

For the laser transmission joining experiment, the PS sample was used as the upper transparent material, and the thin titanium was the lower material. The titanium surface was selected as the laser absorber.

Figure 2 presents a schematic of laser transmission joining between PS and titanium. The experiment was performed in the form of the lap joint, using the K9 glass as the clamping layer, and a certain clamping pressure of 0.5 MPa was applied. The process parameters and limits for laser joining are shown in

Table 3. Three replicates were performed for each test condition.

4. Conclusions

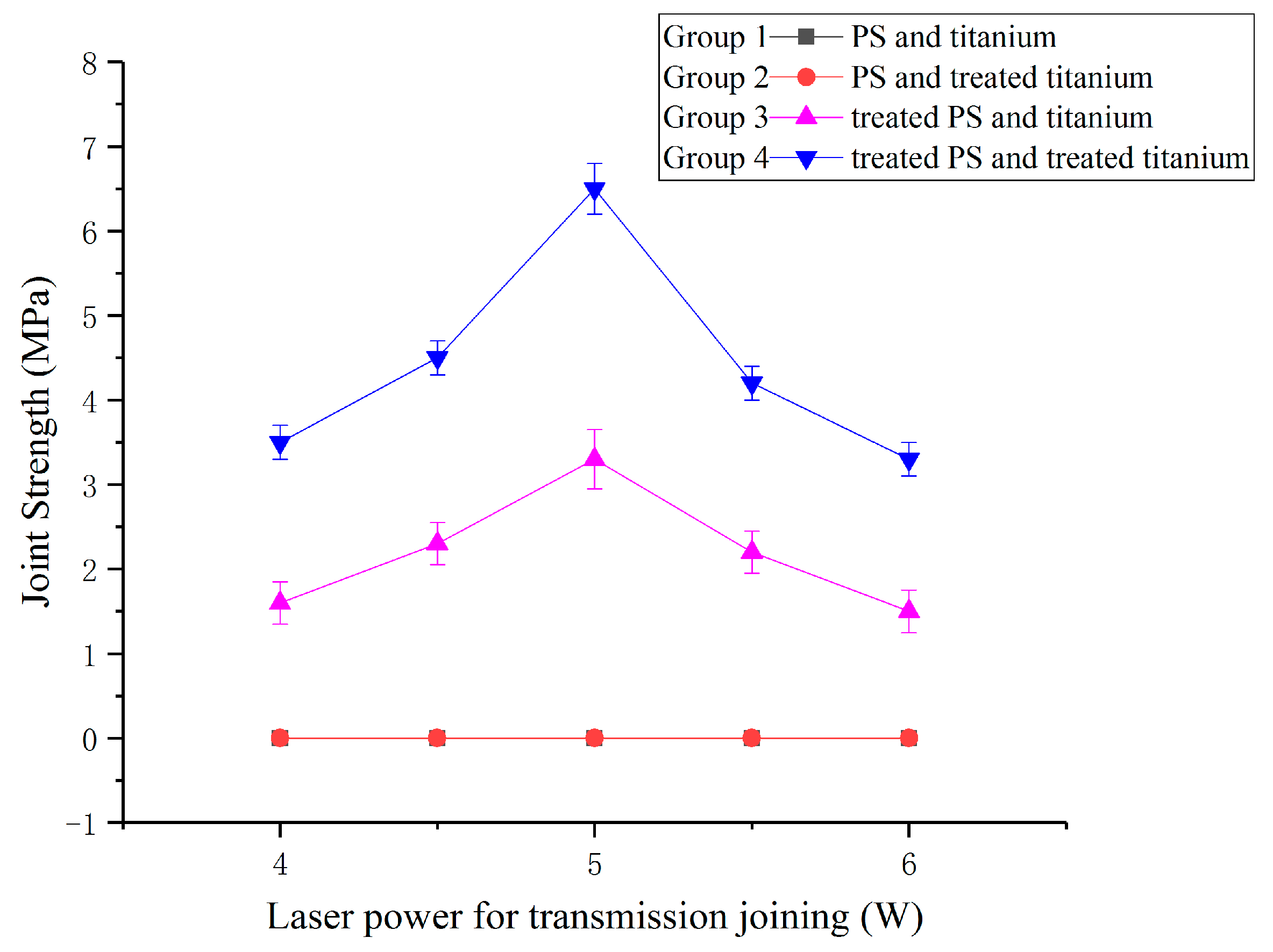

This work presents the laser transmission joining experiments of PS and titanium, the introduction of two pretreatment methods (laser surface treatment and oxygen plasma surface treatment), and a comparison of the joint strength using the different treatment methods. Finally, after an investigation of the joining mechanism by analysis of the fracture mode, contact angle and surface free energy experiments, and XPS analysis, the following conclusions are obtained:

(1) The oxygen plasma-treated PS is a necessary condition to achieve the joining of PS and titanium. The joint strength is the highest when the laser-treated surface of titanium is joined to the oxygen plasma-treated PS.

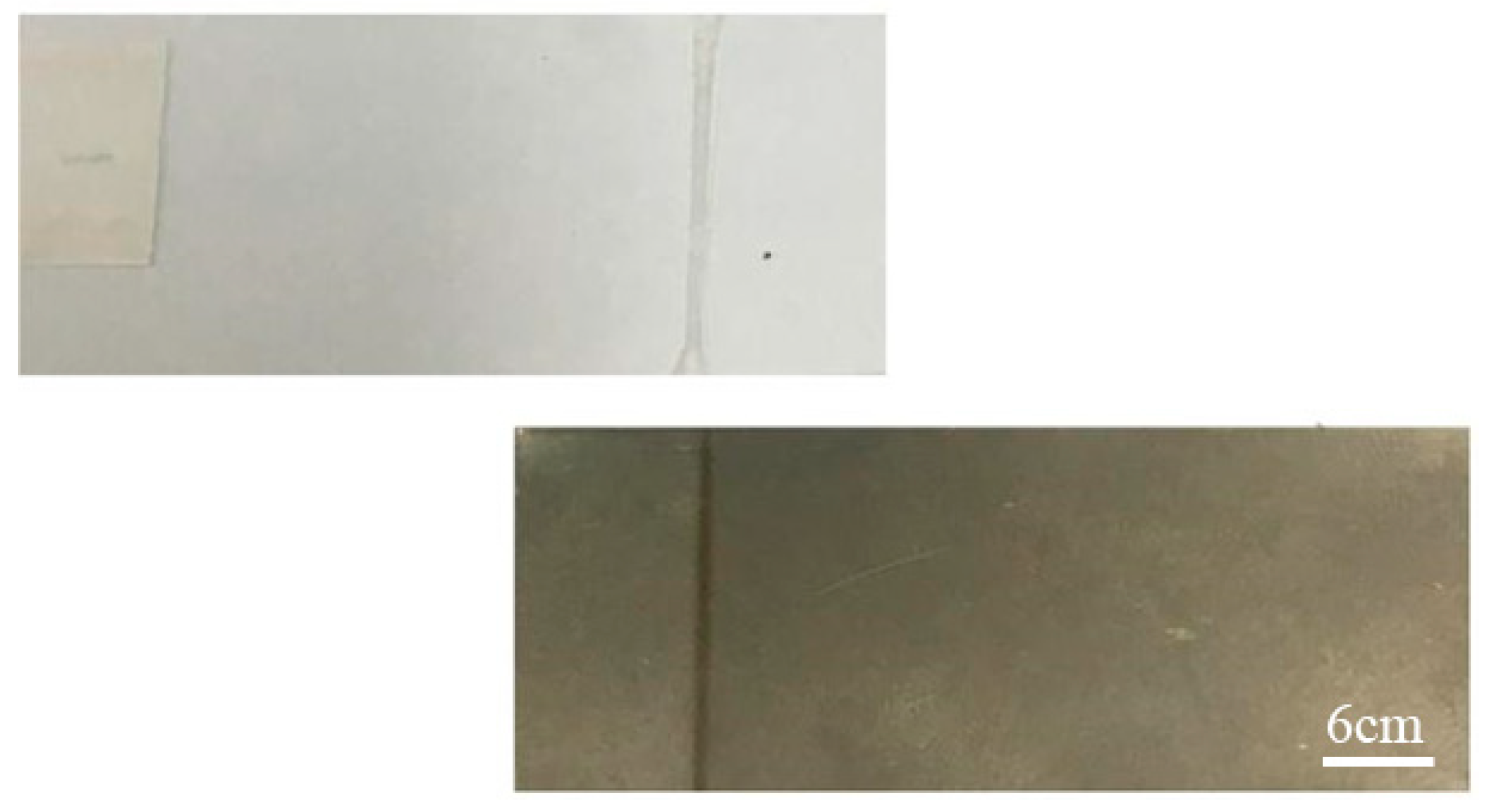

(2) The tensile failure mode of the laser transmission joining of the oxygen plasma-treated PS and oxidization-treated titanium is interfacial failure.

(3) The size and amount of bubbles play an important role in the joining strength, and the joints with fine and uniform bubbles have the highest joint strength.

(4) The oxygen plasma treatment and laser oxidization treatment can increase the surface energies of the joint materials, improve the compatibility between the oxygen plasma-treated PS and the laser-treated titanium, raise the surface chemical activity, generate new chemical bonds, and contribute to the joint strength enhancement.

(5) Ti–C and Ti–O forms exist at the joint between the treated PS and laser-oxidized titanium. The formation of Ti–C and Ti–O chemical bonds is the main reason that the joint strength is the highest for the oxygen plasma-treated PS and laser-oxidized titanium.