Experimental Study on the Effects of Coolants on Surface Quality and Mechanical Properties of Micromilled Thin-Walled Elgiloy

Abstract

1. Introduction

2. Materials and Methods

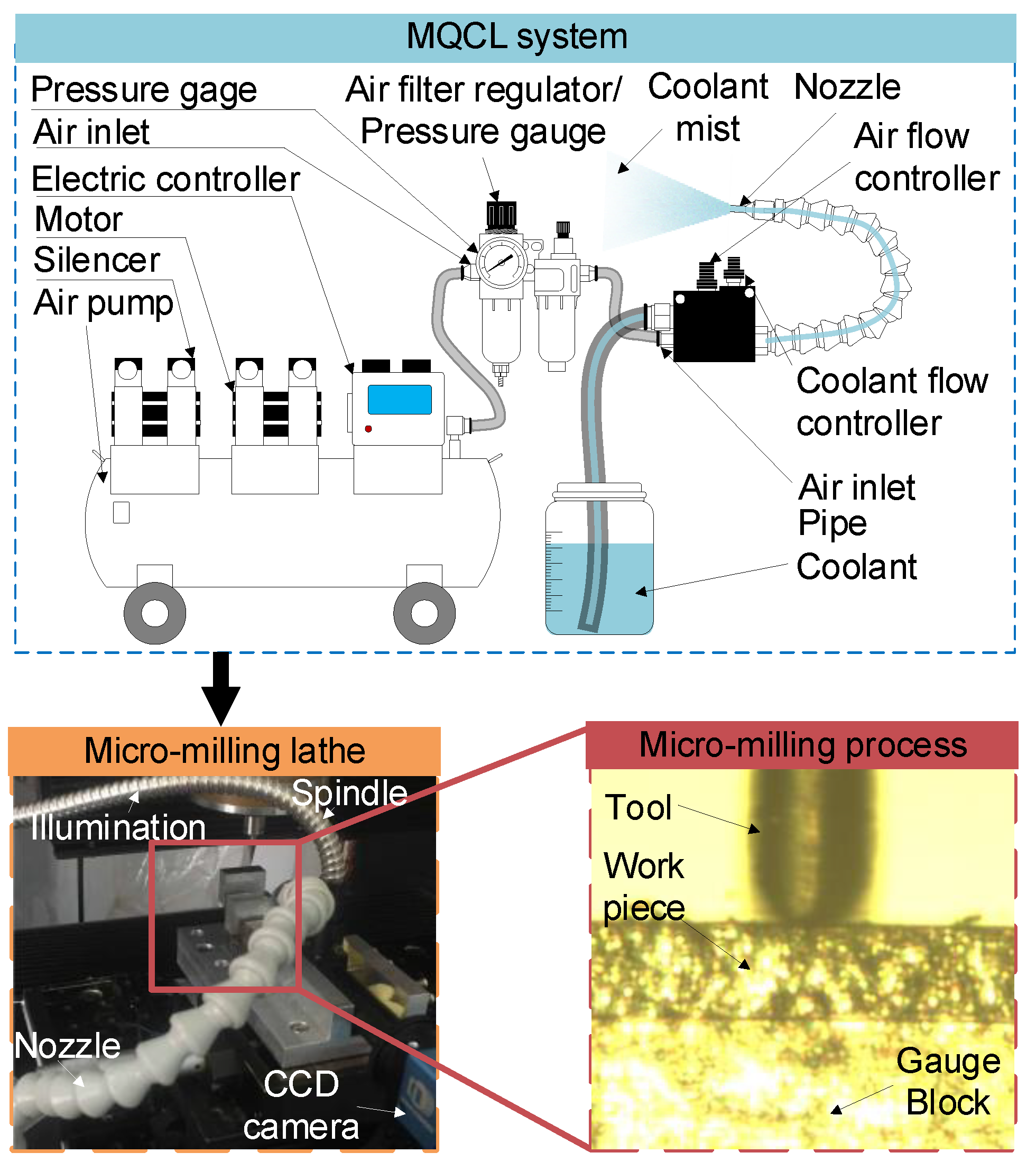

2.1. Hardware System and Milling Tool for Micromilling

2.2. Materials

2.3. Experimental Method and Coolant Selection

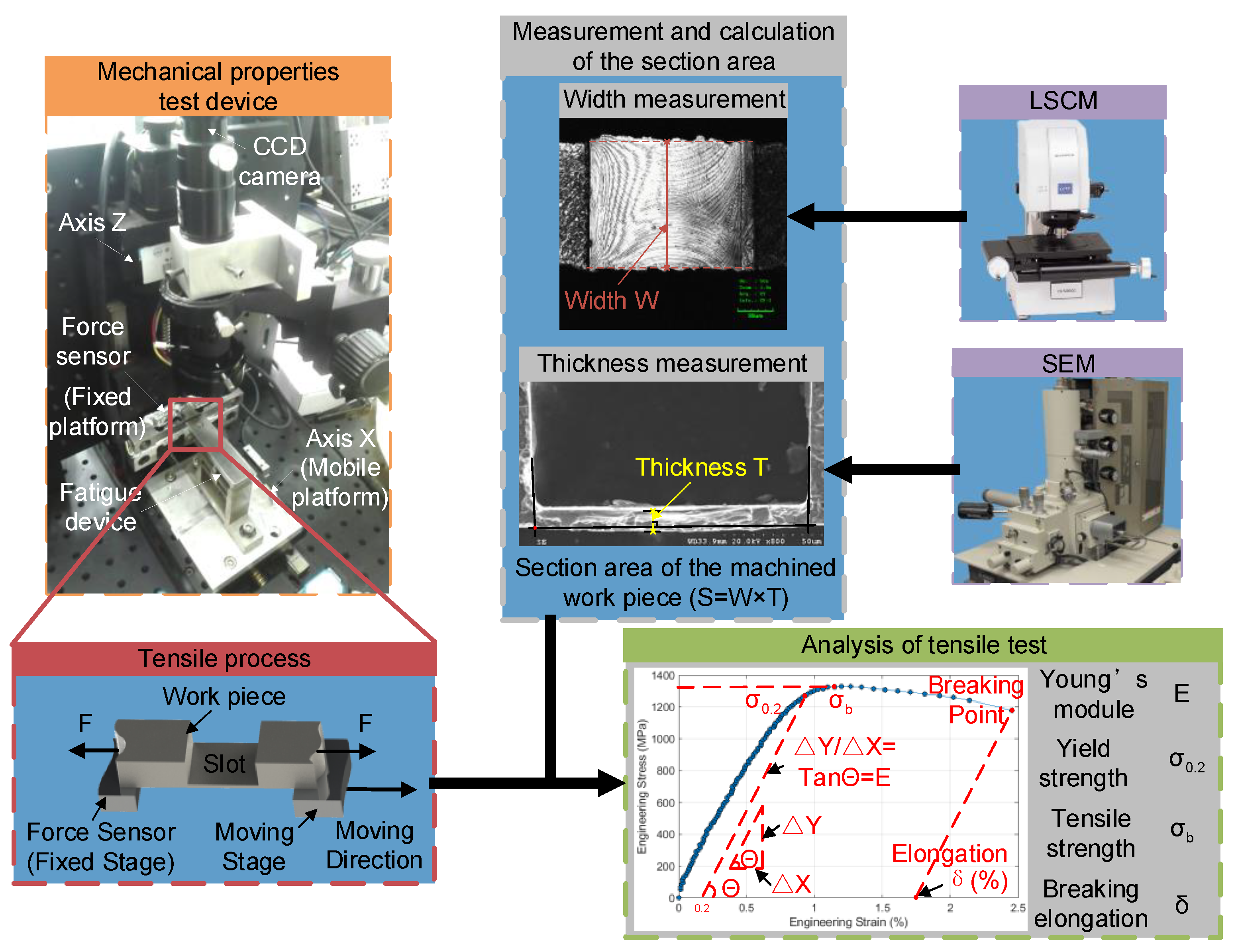

2.4. Hardware System for Testing Mechanical Properties

3. Results and Discussion

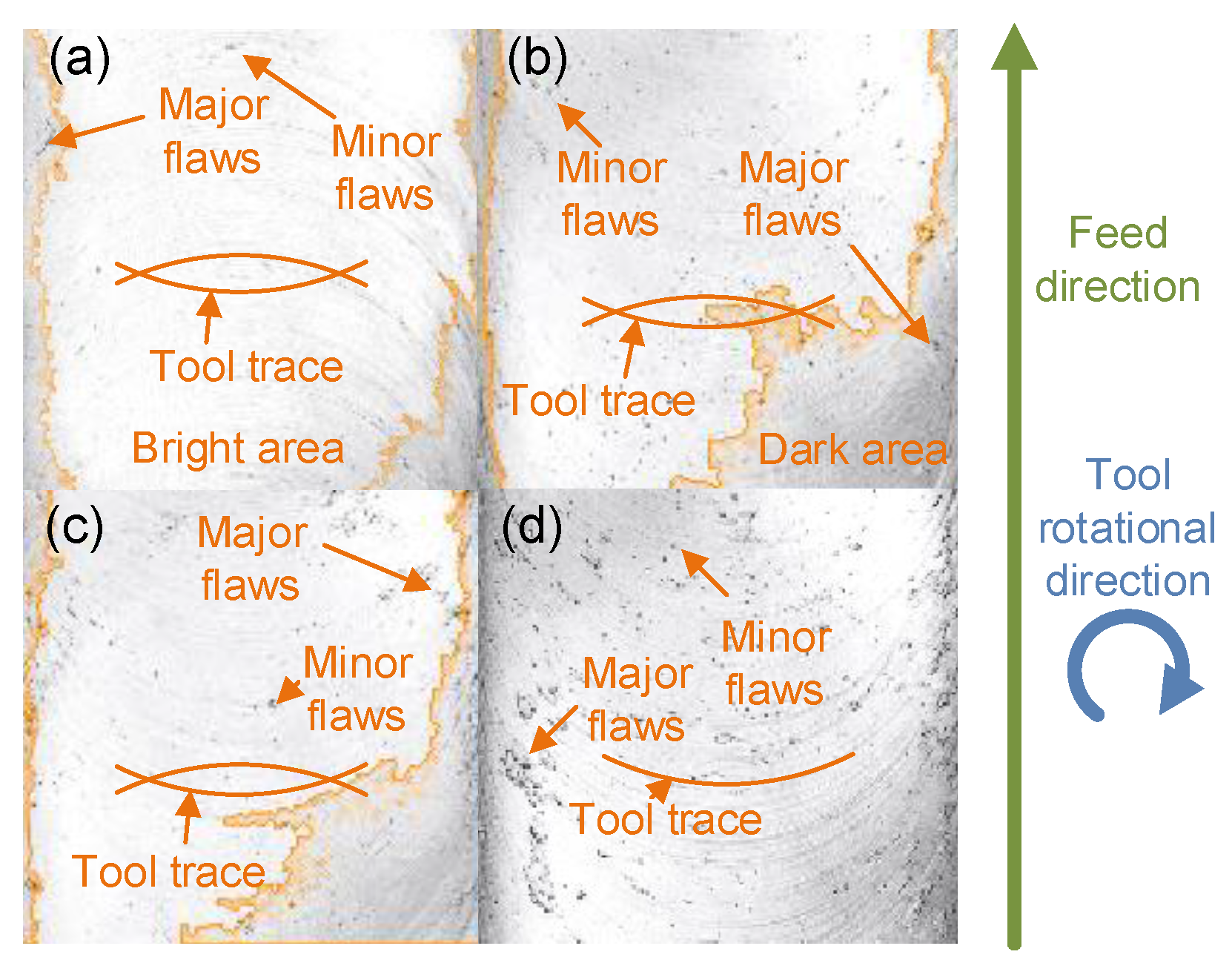

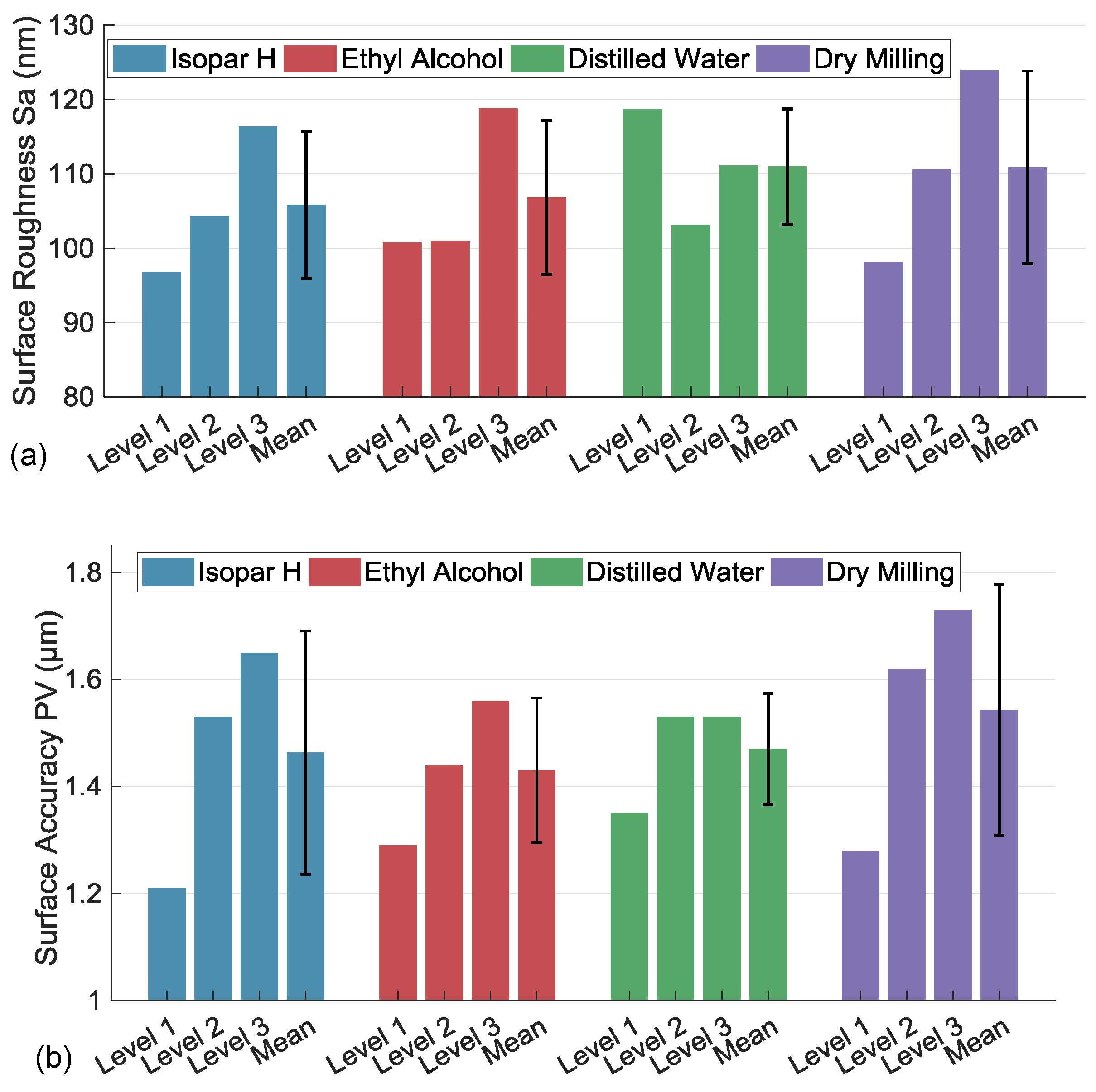

3.1. Effect on Surface Quality

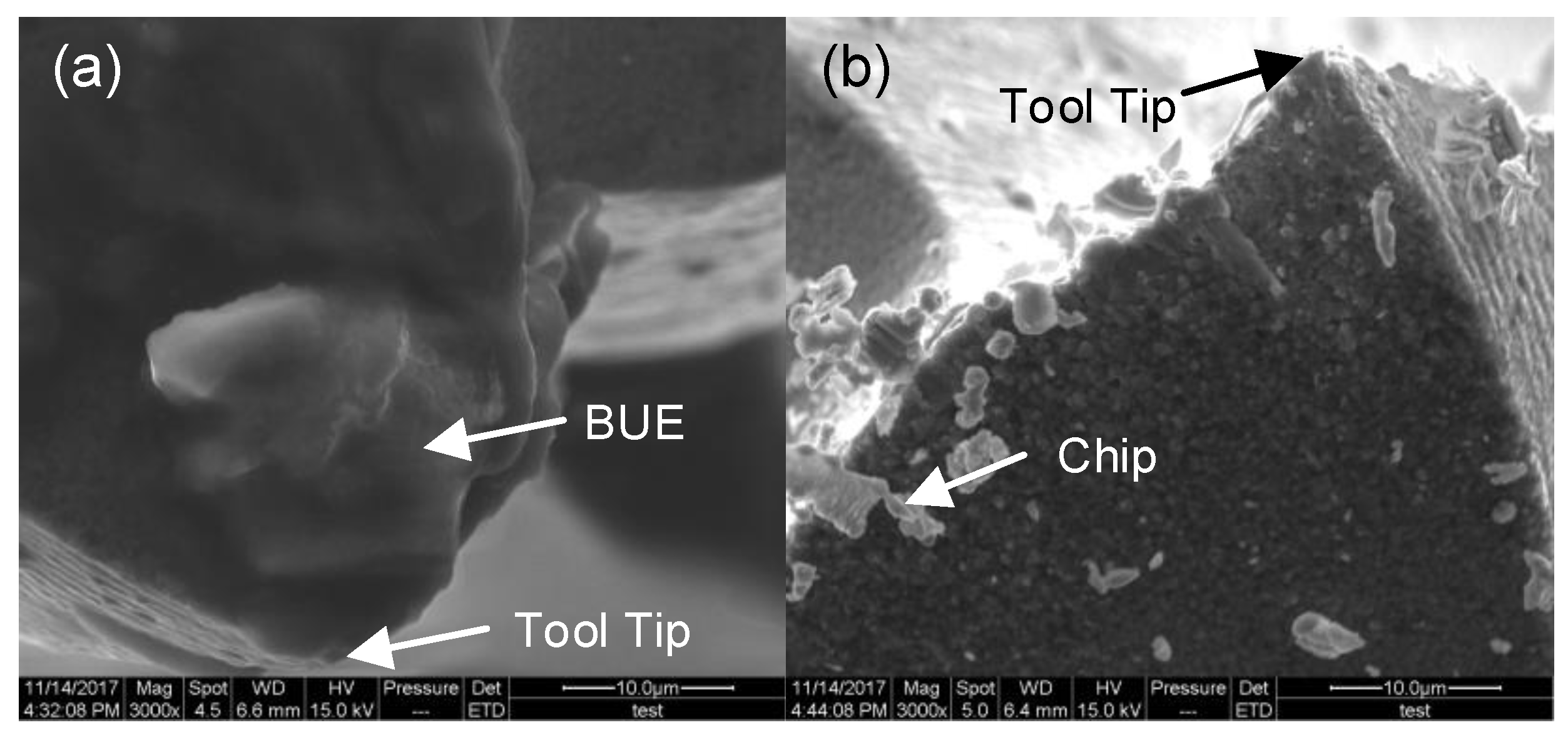

3.2. Observation of Tool Edge

3.3. The Effect of the Coolants on the Mechanical Properties

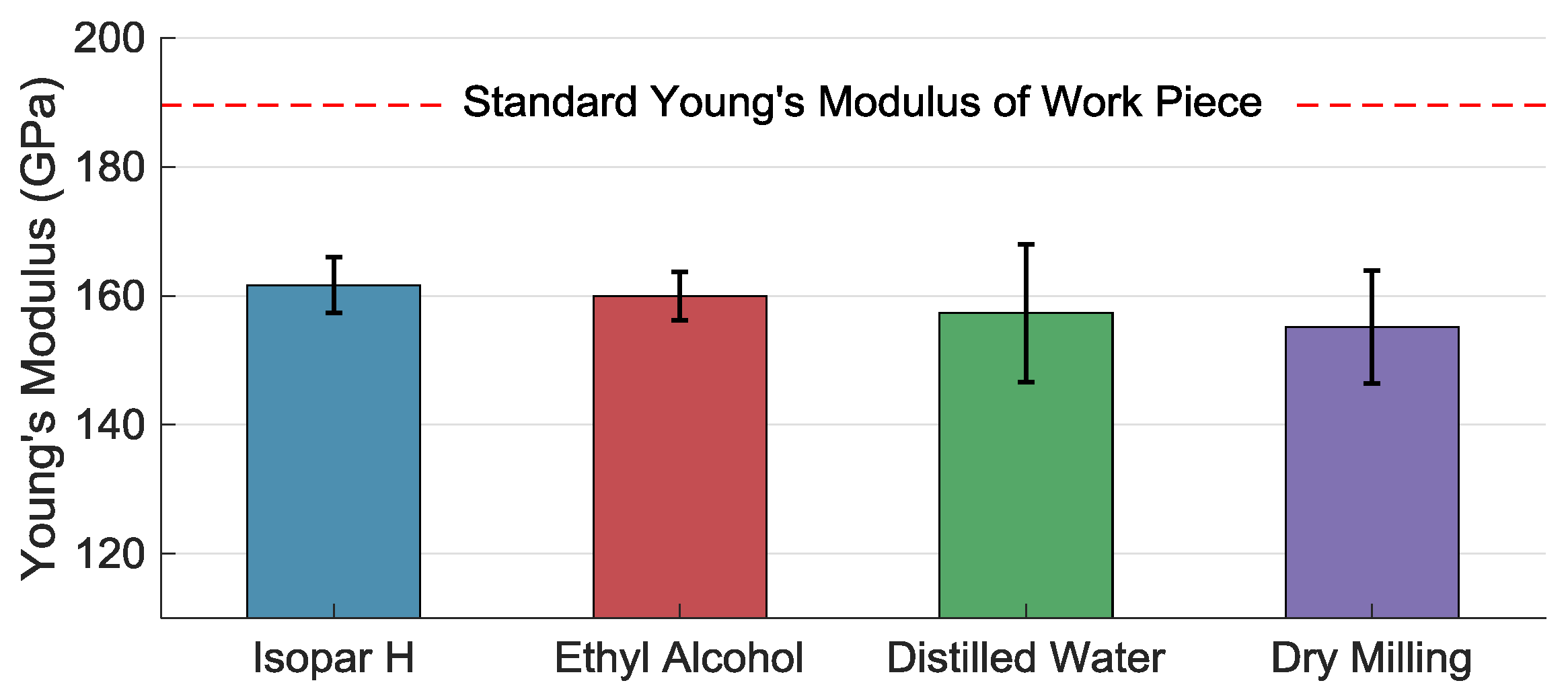

3.3.1. The Effect of the Coolants on Young’s Module

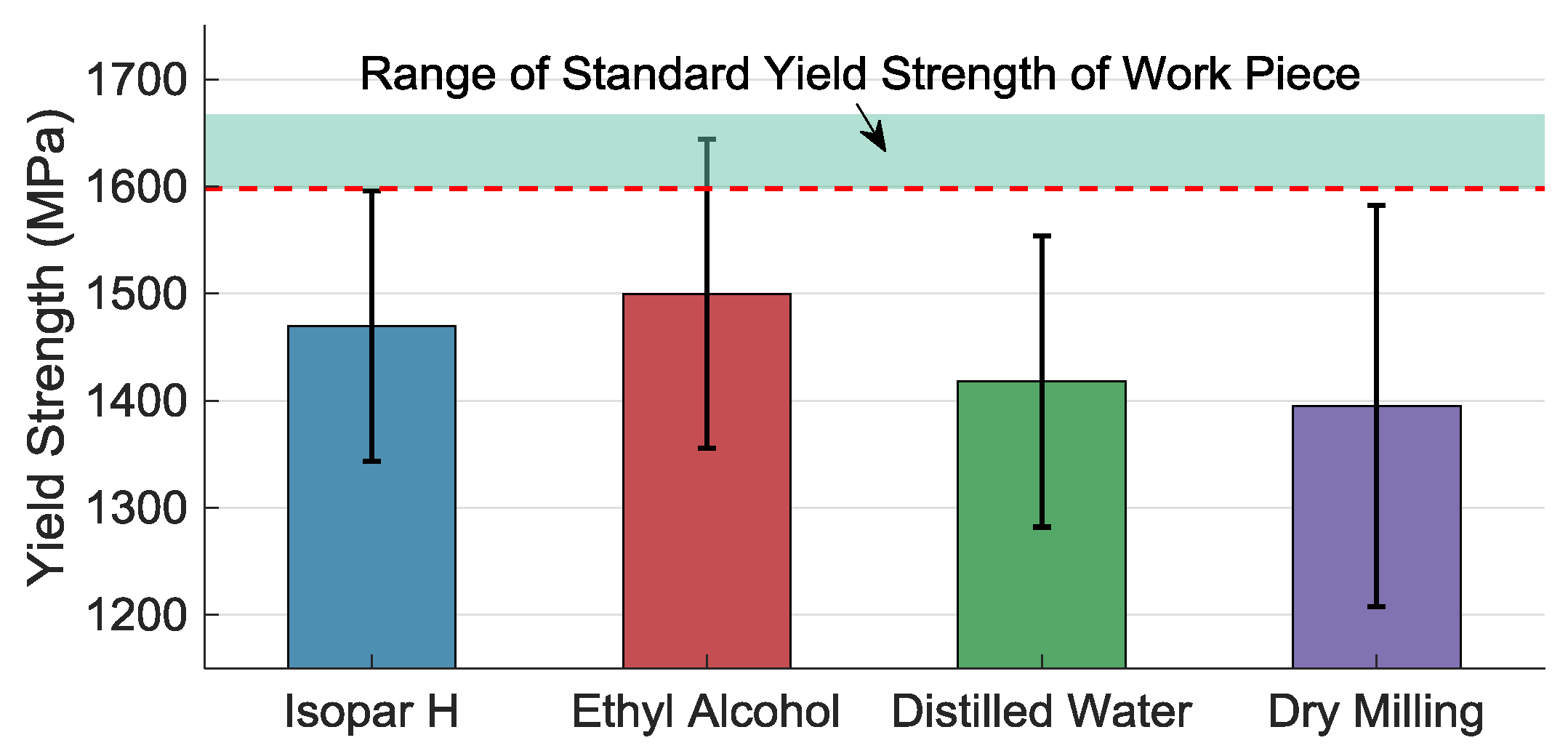

3.3.2. The Effect of the Coolants on Yield Strength

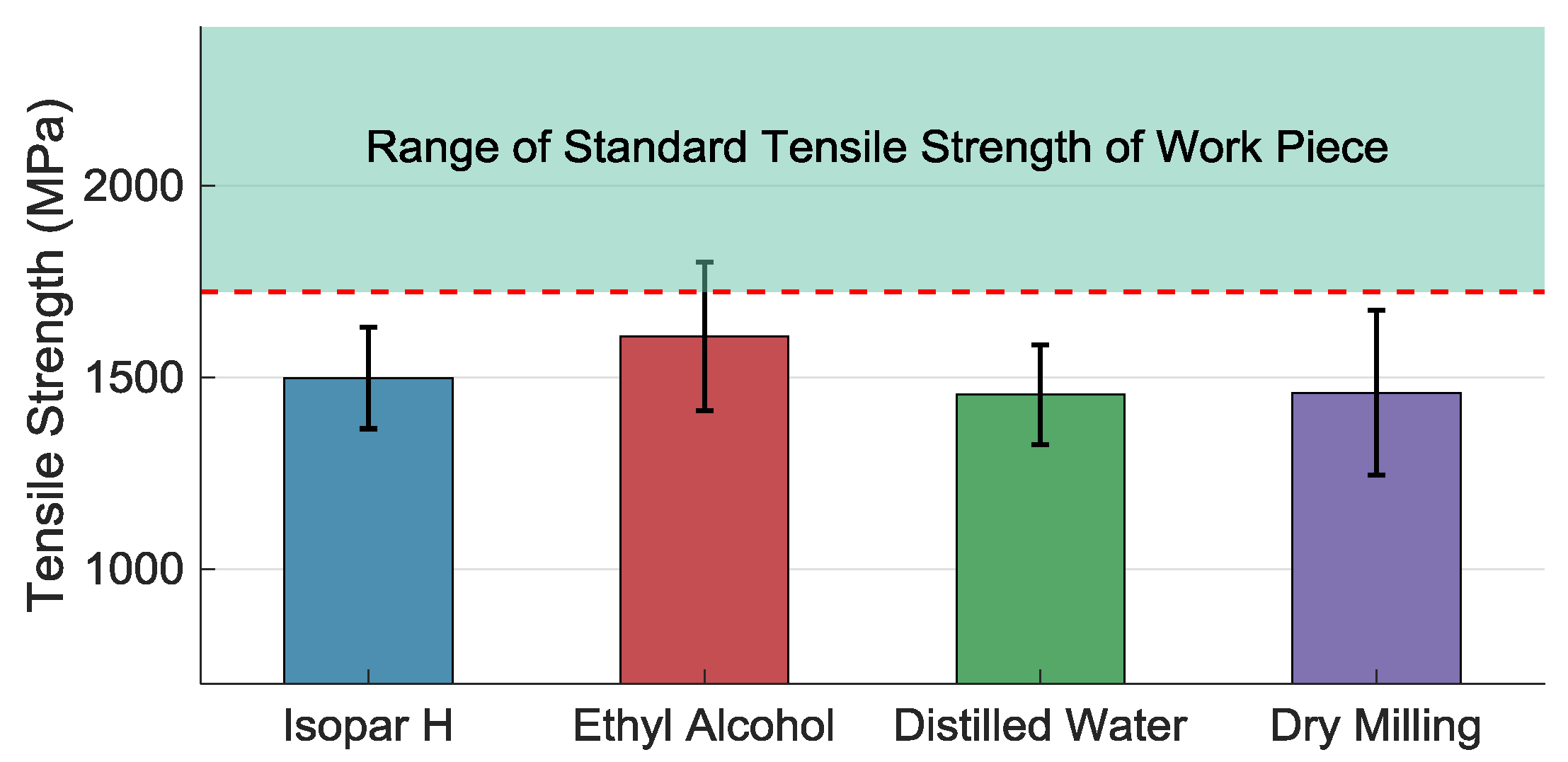

3.3.3. The Effect of the Coolants on Tensile Strength

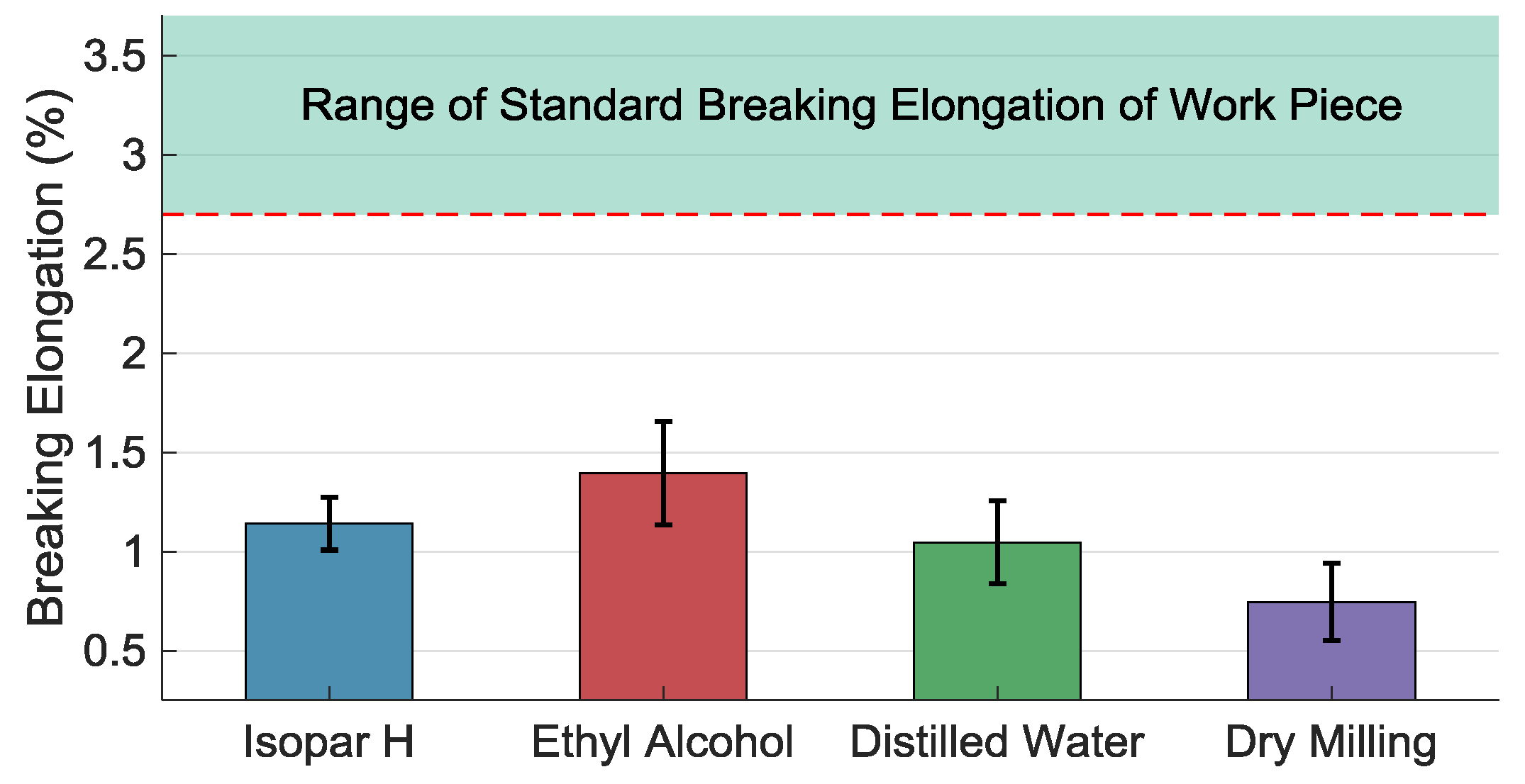

3.3.4. The Effect of the Coolants on Breaking Elongation

3.3.5. Analysis on the Performance of the Coolants

4. Conclusions

- (1)

- In the dry-machining case, minor and major flaws on the surface are much more than those in MQCL cases. Even though MQCL has good performance on decreasing probability of BUE formation and improving surface quality, it cannot totally eliminate tool traces on the machined surface.

- (2)

- Surface roughness in MQCL cases is decreased by a maximum of 10.4%, compared with that in dry-machining cases. The best surface roughness is generated in the Isopar H case, but the best surface accuracy appears in the ethyl alcohol case.

- (3)

- The mechanical properties of the work piece after being micromilled are all smaller than the standard mechanical properties. The yield strength has positive correlation with the tensile strength of the machined work piece; however, the changing law of Young’s module is not obvious.

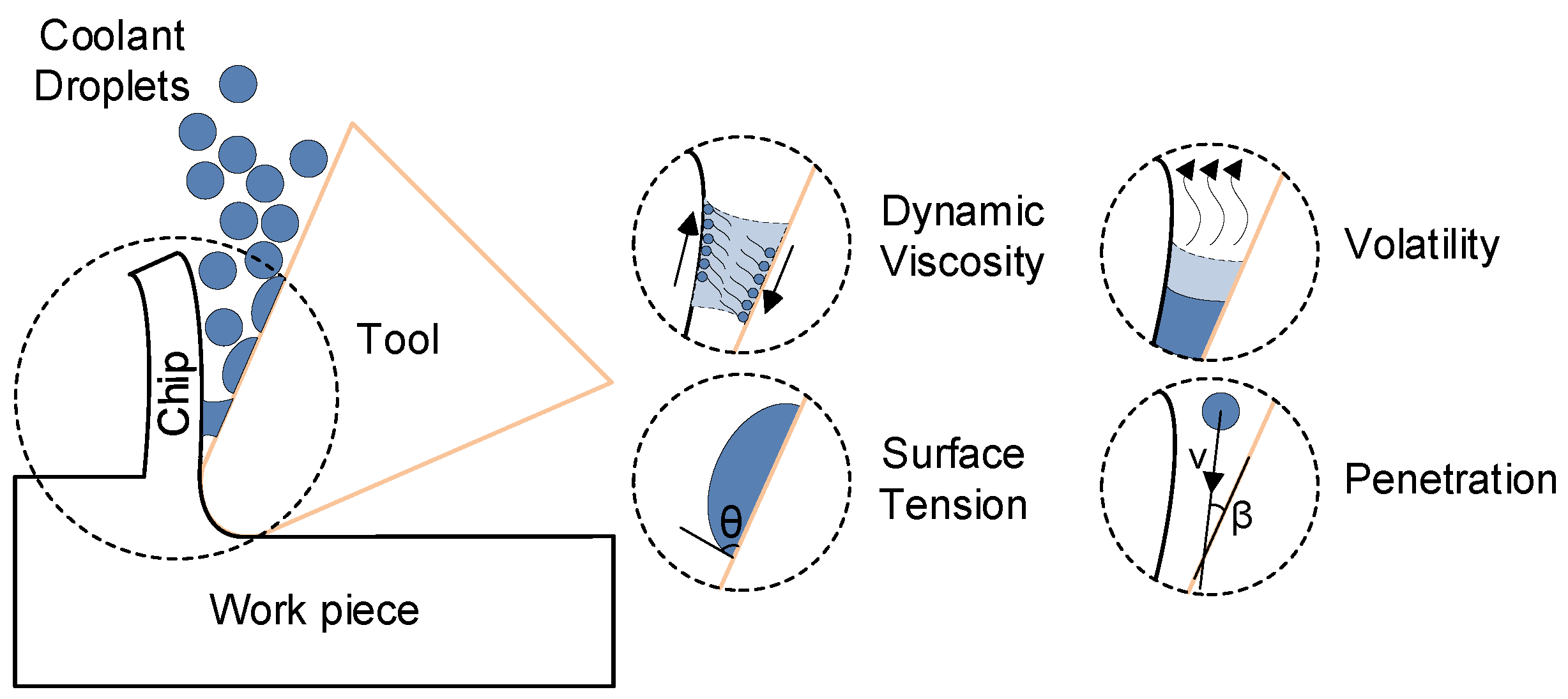

- (4)

- Penetration of the coolants is important and is mainly affected by the physical characteristics of the coolant droplets. Combining the lubrication, penetration, and cooling effects of these coolants, in the selected coolants, ethyl alcohol is the most suitable one for micromilling thin-walled Elgiloy. Hence, to obtain good mechanical properties of a machined thin-walled work piece, cooling effect and penetration are more important, especially for machining materials with low thermal conductivity and high ductility.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Effects of minimum quantity lubrication (mql) in machining processes using conventional and nanofluid based cutting fluids: A comprehensive review. J. Clean. Prod. 2016, 127, 1–18. [Google Scholar] [CrossRef]

- Astakhov, V.; Basak, A.; Dixit, U.S.; Grzesik, W.; Habrat, W.F.; Hakami, F.; Laskowski, P.; Markopoulos, A.; Pramanik, A.; Rosa, P. Metal Cutting Technologies: Progress and Current Trends; Walter de Gruyter GmbH and Co KG: Berlin, Germany, 2016. [Google Scholar]

- Biermann, D.; Abrahams, H.; Metzger, M. Experimental investigation of tool wear and chip formation in cryogenic machining of titanium alloys. Adv. Manuf. 2015, 3, 292–299. [Google Scholar] [CrossRef]

- Sun, Y.; Huang, B.; Puleo, D.A.; Jawahir, I.S. Enhanced machinability of Ti-5553 alloy from cryogenic machining: Comparison with mql and flood-cooled machining and modeling. Proc. CIRP 2015, 31, 477–482. [Google Scholar] [CrossRef]

- Klocke, F.; Settineri, L.; Lung, D.; Claudio Priarone, P.; Arft, M. High performance cutting of gamma titanium aluminides: Influence of lubricoolant strategy on tool wear and surface integrity. Wear 2013, 302, 1136–1144. [Google Scholar] [CrossRef]

- Kakinuma, Y.; Yasuda, N.; Aoyama, T. Micromachining of soft polymer material applying cryogenic cooling. J. Adv. Mech. Des. Syst. 2008, 2, 560–569. [Google Scholar] [CrossRef]

- Park, K.H.; Yang, G.D.; Lee, D.Y. Tool wear analysis on coated and uncoated carbide tools in inconel machining. Int. J. Precis. Eng. Man. 2015, 16, 1639–1645. [Google Scholar] [CrossRef]

- Mohsan, A.U.I.H.; Liu, Z.; Padhy, G.K. A review on the progress towards improvement in surface integrity of inconel 718 under high pressure and flood cooling conditions. Int. J. Adv. Manuf. Technol. 2016, 91, 107–125. [Google Scholar] [CrossRef]

- Pusavec, F.; Deshpande, A.; Yang, S.; M’Saoubi, R.; Kopac, J.; Dillon, O.W.; Jawahir, I.S. Sustainable machining of high temperature nickel alloy–Inconel 718: Part 1–Predictive performance models. J. Clean. Prod. 2014, 81, 255–269. [Google Scholar] [CrossRef]

- De Paula Oliveira, G.; Cindra Fonseca, M.; Araujo, A.C. Analysis of residual stress and cutting force in end milling of inconel 718 using conventional flood cooling and minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2017, 92, 3265–3272. [Google Scholar] [CrossRef]

- Liao, Y.S.; Lin, H.M. Mechanism of minimum quantity lubrication in high-speed milling of hardened steel. Int. J. Mach. Tool. Manuf. 2007, 47, 1660–1666. [Google Scholar] [CrossRef]

- Chirita, B.; Mustea, G.; Brabie, G. A statistical analysis applied for optimal cooling system selection and for a superior surface quality of machined magnesium alloy parts. Proc. Inst. Mech. Eng. B-J. Eng. Manuf. 2014, 229, 392–408. [Google Scholar] [CrossRef]

- Wojciechowski, S. Machined surface roughness including cutter displacements in milling of hardened teel. Metrol. Meas. Syst. 2011, 18, 429–440. [Google Scholar] [CrossRef]

- Pereira, O.; Martín-Alfonso, J.E.; Rodríguez, A.; Calleja, A.; Fernández-Valdivielso, A.; López de Lacalle, L.N. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Weinert, K.; Petzoldt, V. Machining niti micro-parts by micromilling. Mater. Sci. Eng. A 2008, 481–482, 672–675. [Google Scholar] [CrossRef]

- Maruda, R.W.; Legutko, S.; Krolczyk, G.M.; Hloch, S.; Michalski, M. An influence of active additives on the formation of selected indicators of the condition of the x10crni18-8 stainless steel surface layer in mqcl conditions. Int. J. Surf. Sci. Eng. 2015, 9, 452–465. [Google Scholar] [CrossRef]

- Li, K.M.; Chou, S.Y. Experimental evaluation of minimum quantity lubrication in near micromilling. J. Mater. Process. Technol. 2010, 210, 2163–2170. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Feldshtein, E.; Pusavec, F.; Szydlowski, M.; Legutko, S.; Sobczak-Kupiec, A. A study on droplets sizes, their distribution and heat exchange for minimum quantity cooling lubrication (MQCL). Int. J. Mach. Tools Manuf. 2016, 100, 81–92. [Google Scholar] [CrossRef]

- Pervaiz, S.; Deiab, I.; Rashid, A.; Nicolescu, M. Minimal quantity cooling lubrication in turning of ti6al4v: Influence on surface roughness, cutting force and tool wear. Proc. Inst. Mech. Eng. B-J. Eng. Manuf. 2015, 231, 1542–1558. [Google Scholar] [CrossRef]

- Chetan; Behera, B.C.; Ghosh, S.; Rao, P.V. Wear behavior of pvd tin coated carbide inserts during machining of nimonic 90 and ti6al4v superalloys under dry and mql conditions. Ceram. Int. 2016, 42, 14873–14885. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, B.; Liang, Y.; Jackson, M.J. Experimental study on the surface roughness of micromilled elgiloytm. Proc. Inst. Mech. Eng. B-J. Eng. Manuf. 2011, 225, 2138–2143. [Google Scholar] [CrossRef]

- Li, K.M.; Chou, S.Y. Effect of minimum quantity lubrication on tool wear and surface roughness in micro-milling. In Proceedings of the ASME 2009 International Manufacturing Science and Engineering Conference, West Lafayette, IN, USA, 4–7 October 2009; American Society of Mechanical Engineers: New York, NY, USA, 2009; pp. 393–399. [Google Scholar]

- Kajaria, S.; Chittipolu, S.; Adera, S.; Hung, W.N. Micromilling in minimum quantity lubrication. Mach. Sci. Technol. 2012, 16, 524–546. [Google Scholar] [CrossRef]

- Qu, D.; Wang, B.; Peng, Z. The influence of processing parameters on surface characteristics in micro-milling thin-walled slot on elgiloy. Int. J. Adv. Manuf. Technol. 2017, 92, 2843–2852. [Google Scholar] [CrossRef]

- Itoigawa, F.; Childs, T.H.C.; Nakamura, T.; Belluco, W. Effects and mechanisms in minimal quantity lubrication machining of an aluminum alloy. Wear 2006, 260, 339–344. [Google Scholar] [CrossRef]

- Cai, X.J.; Liu, Z.Q.; Chen, M.; An, Q.L. An experimental investigation on effects of minimum quantity lubrication oil supply rate in high-speed end milling of Ti6Al4V. Proc. Inst. Mech. Eng. B-J. Eng. Manuf. 2012, 226, 1784–1792. [Google Scholar] [CrossRef]

- Guo, Y.B.; Li, W.; Jawahir, I.S. Surface integrity characterization and prediction in machining of hardened and difficult-to-machine alloys: A state-of-art research review and analysis. Mach. Sci. Technol. 2009, 13, 437–470. [Google Scholar] [CrossRef]

- Zhang, X.; Ehmann, K.F.; Yu, T.; Wang, W. Cutting forces in micro-end-milling processes. Int. J. Mach. Tools. Manuf. 2016, 107, 21–40. [Google Scholar] [CrossRef]

- Ucun, İ.; Aslantaş, K.; Gökçe, B.; Bedir, F. Effect of tool coating materials on surface roughness in micromachining of inconel 718 super alloy. Proc. Inst. Mech. Eng. B-J. Eng. Manuf. 2014, 228, 1550–1562. [Google Scholar] [CrossRef]

- Ji, X.; Zhang, X.; Li, B.; Liang, S.Y. Modeling the effects of minimum quantity lubrication on machining force, temperature, and residual stress. Mach. Sci. Technol. 2014, 18, 547–564. [Google Scholar] [CrossRef]

- NikPa, N.M.; Sarhan, A.A.D.; Abdelnaeim Hassan, M.; Hamdi Abd Shukor, M. Novel uses of SiO2 nanolubrication in end milling of medium carbon steel for higher compressive residual stress measured by high-energy X-ray diffraction data. Proc. Inst. Mech. Eng. B-J. Eng. Manuf. 2015, 230, 697–708. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, Z.; Xu, C. Influence of size effect on burr formation in micro cutting. Int. J. Adv. Manuf. Technol. 2013, 68, 1911–1917. [Google Scholar] [CrossRef]

- Sreejith, P.S. Machining of 6061 aluminium alloy with MQL, dry and flooded lubricant conditions. Mater. Lett. 2008, 62, 276–278. [Google Scholar] [CrossRef]

- Park, K.H.; Suhaimi, M.A.; Yang, G.D.; Lee, D.Y.; Lee, S.W.; Kwon, P. Milling of titanium alloy with cryogenic cooling and minimum quantity lubrication (MQL). Int. J. Precis. Eng. Man. 2017, 18, 5–14. [Google Scholar] [CrossRef]

- Pusavec, F.; Hamdi, H.; Kopac, J.; Jawahir, I.S. Surface integrity in cryogenic machining of nickel based alloy-inconel 718. J. Mater. Process. Technol. 2011, 211, 773–783. [Google Scholar] [CrossRef]

- Maledi, N.B.; Oladijo, O.P.; Botef, I.; Ntsoane, T.P.; Madiseng, A.; Moloisane, L. Influence of cold spray parameters on the microstructures and residual stress of zn coatings sprayed on mild steel. Surf. Coat. Technol. 2017, 318, 106–113. [Google Scholar] [CrossRef]

- Salimon, S.R.; Salimon, A.I.; Korsunsky, A.M. The evolution of electrochemical, microstructural, and mechanical properties of aluminium alloy 2024-t4 (d16at) during fatigue cycling. Proc. Inst. Mech. Eng. G-J. Aerosp. Eng. 2009, 224, 339–353. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Michalski, M.; Nieslony, P.; Wojciechowski, S. Structural and microhardness changes after turning of the aisi 1045 steel for minimum quantity cooling lubrication. J. Mater. Eng. Perform. 2016, 26, 431–438. [Google Scholar] [CrossRef]

- Hassanpour, H.; Sadeghi, M.H.; Rasti, A.; Shajari, S. Investigation of surface roughness, microhardness and white layer thickness in hard milling of aisi 4340 using minimum quantity lubrication. J. Clean. Prod. 2016, 120, 124–134. [Google Scholar] [CrossRef]

- Toozandehjani, M.; Matori, K.A.; Ostovan, F.; Abdul Aziz, S.; Mamat, M.S. Effect of milling time on the microstructure, physical and mechanical properties of Al-Al2O3 nanocomposite synthesized by ball milling and powder metallurgy. Materials 2017, 10, 1232. [Google Scholar] [CrossRef] [PubMed]

- Arunachalam, R.M.; Mannan, M.A.; Spowage, A.C. Surface integrity when machining age hardened inconel 718 with coated carbide cutting tools. Int. J. Mach. Tools Manuf. 2004, 44, 1481–1491. [Google Scholar] [CrossRef]

- Outeiro, J.C.; Pina, J.C.; M’Saoubi, R.; Pusavec, F.; Jawahir, I.S. Analysis of residual stresses induced by dry turning of difficult-to-machine materials. CIRP Ann. 2008, 57, 77–80. [Google Scholar] [CrossRef]

- Ji, X.; Li, B.; Zhang, X.; Liang, S.Y. The effects of minimum quantity lubrication (MQL) on machining force, temperature, and residual stress. Int. J. Precis. Eng. Man. 2014, 15, 2443–2451. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Mrozek, K. Mechanical and technological aspects of micro ball end milling with various tool inclinations. Int. J. Mech. Sci. 2017, 134, 424–435. [Google Scholar] [CrossRef]

- Griffiths, B. Manufacturing Surface Technology: Surface Integrity and Functional Performance; Elsevier: London, UK, 2001. [Google Scholar]

- Sharman, A.R.C.; Hughes, J.I.; Ridgway, K. An analysis of the residual stresses generated in inconel 718™ when turning. J. Mater. Process. Technol. 2006, 173, 359–367. [Google Scholar] [CrossRef]

| Dia. (μm) | Length of Cut (mm) | Neck Taper Angle (°) | Edge Radius (μm) | Material |

|---|---|---|---|---|

| ≈150 | 0.2 | 9 | ≈2.5 | WC |

| Beryllium | Carbon | Chromium | Cobalt | Molybdenum | Iron | Manganese | Nickel |

|---|---|---|---|---|---|---|---|

| 0.1 max | 0.15 max | 19–21 | 39–41 | 6–8 | 11.3–20.5 | 1.5–2.5 | 14–16 |

| Elasticity Module | Yield Strength | Tensile Strength | Breaking Elongation |

|---|---|---|---|

| (GPa) | (MPa) | (MPa) | (%) |

| 189.6 | 1598–1667 | 1724–2413 | 2.7–3.7 |

| Spindle Speed (rpm) | Feed Rate (mm/s) | Milling Depth (μm × times) |

|---|---|---|

| 40,000 | 1.67 | 10 × 5 + 5 × 2 + 1 × 5 |

| Work Piece Surface at Tool Total Cutting Length for | ||||

|---|---|---|---|---|

| Level | Isopar H (μm) | Ethyl Alcohol (μm) | Distilled Water (μm) | Dry (μm) |

| 1 | 1320–1440 | 2760–2880 | 4200–4320 | 1320–1440 |

| 2 | 8520–8640 | 5640–5760 | 7080–7200 | 7080–7200 |

| 3 | 11,400–11,520 | 12,840–12,960 | 9960–10,080 | 12,840–12,960 |

| Young’s Module | Yield Strength | Tensile Strength | Breaking Elongation |

|---|---|---|---|

| (GPa) | (MPa) | (MPa) | (%) |

| 189.59 | 1617.93 | 2065.21 | 3.39 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, D.; Zhang, P.; Xue, J.; Fan, Y.; Chen, Z.; Wang, B. Experimental Study on the Effects of Coolants on Surface Quality and Mechanical Properties of Micromilled Thin-Walled Elgiloy. Materials 2018, 11, 1497. https://doi.org/10.3390/ma11091497

Qu D, Zhang P, Xue J, Fan Y, Chen Z, Wang B. Experimental Study on the Effects of Coolants on Surface Quality and Mechanical Properties of Micromilled Thin-Walled Elgiloy. Materials. 2018; 11(9):1497. https://doi.org/10.3390/ma11091497

Chicago/Turabian StyleQu, Da, Peng Zhang, Jiadai Xue, Yun Fan, Zuhui Chen, and Bo Wang. 2018. "Experimental Study on the Effects of Coolants on Surface Quality and Mechanical Properties of Micromilled Thin-Walled Elgiloy" Materials 11, no. 9: 1497. https://doi.org/10.3390/ma11091497

APA StyleQu, D., Zhang, P., Xue, J., Fan, Y., Chen, Z., & Wang, B. (2018). Experimental Study on the Effects of Coolants on Surface Quality and Mechanical Properties of Micromilled Thin-Walled Elgiloy. Materials, 11(9), 1497. https://doi.org/10.3390/ma11091497