Mechanical and Dielectric Properties of Two Types of Si3N4 Fibers Annealed at Elevated Temperatures

Abstract

1. Introduction

2. Experimentation

2.1. Materials and Heat Treatments

2.2. Microstructure Characterization

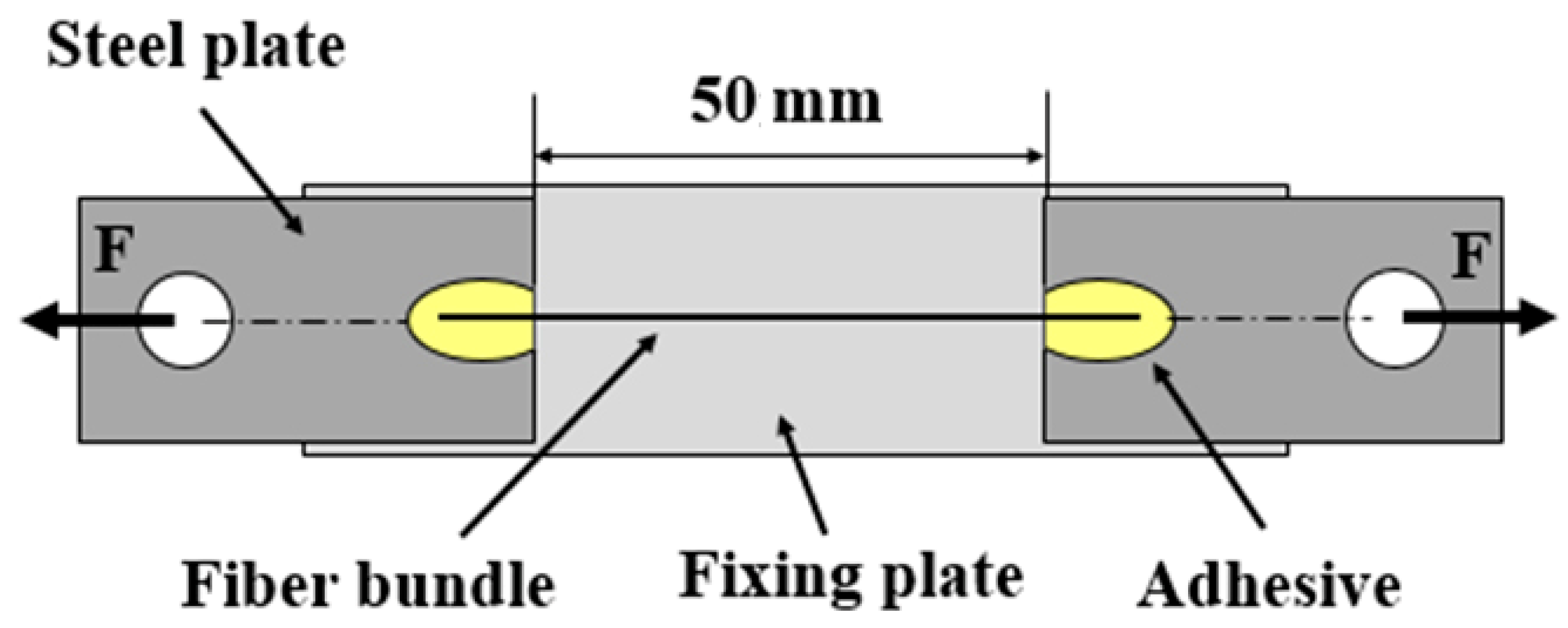

2.3. Property Characterization

3. Results and Discussion

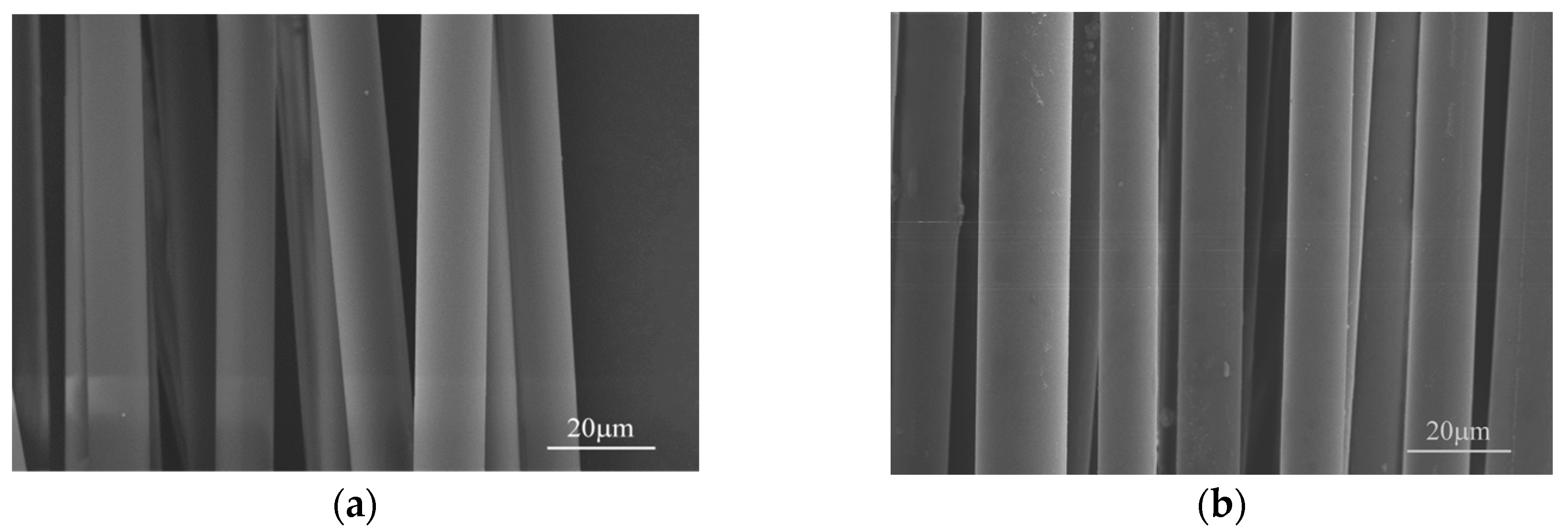

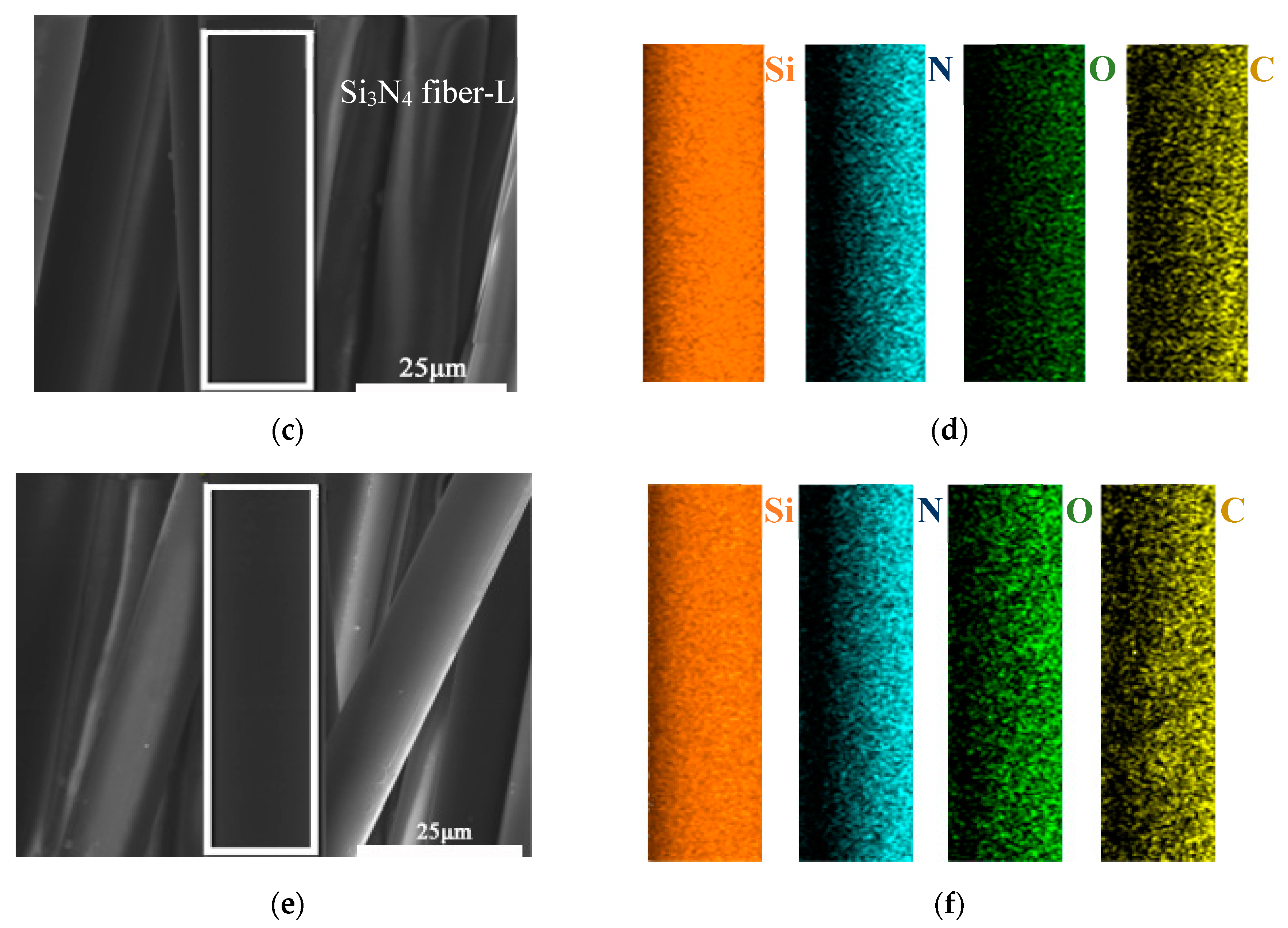

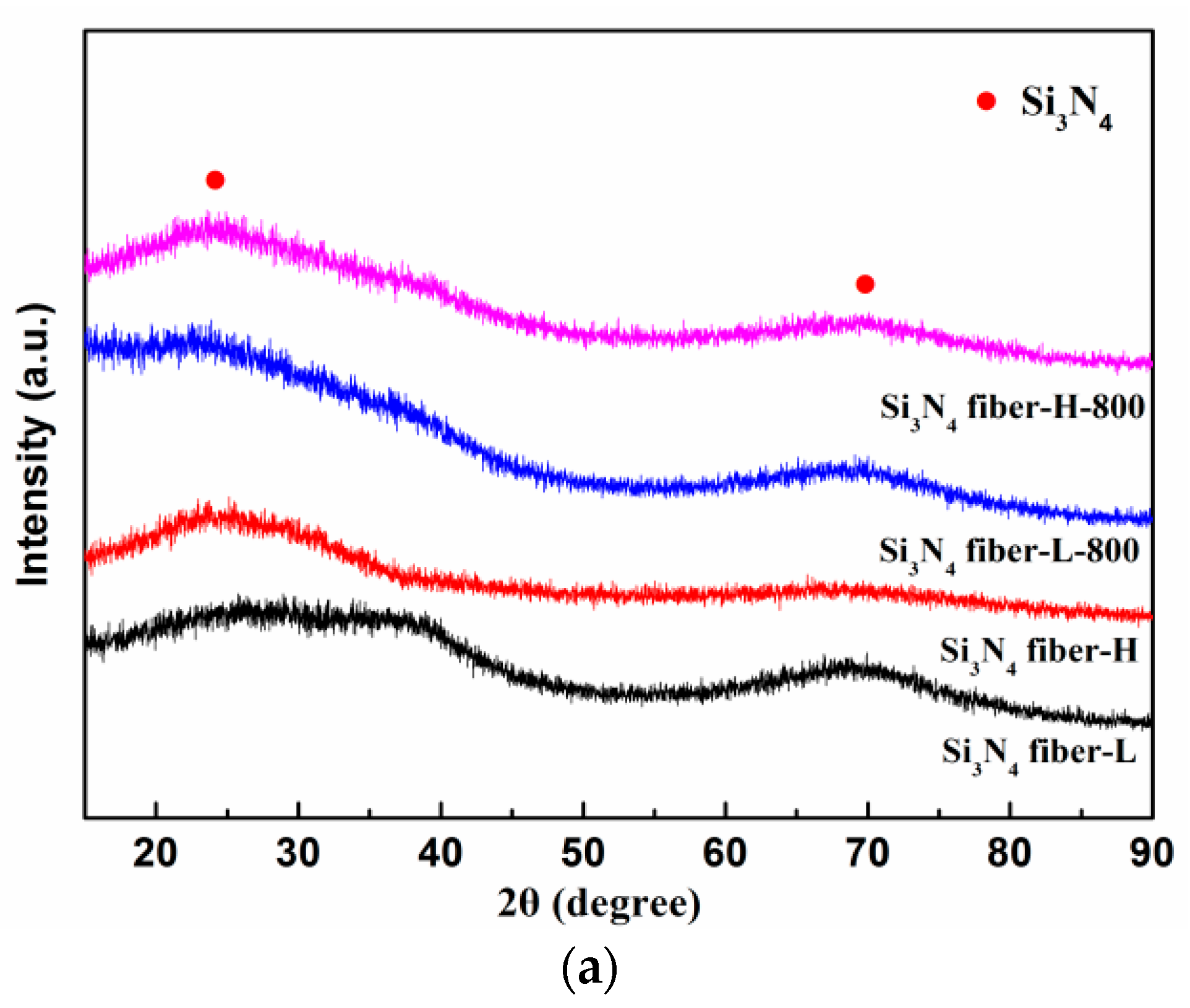

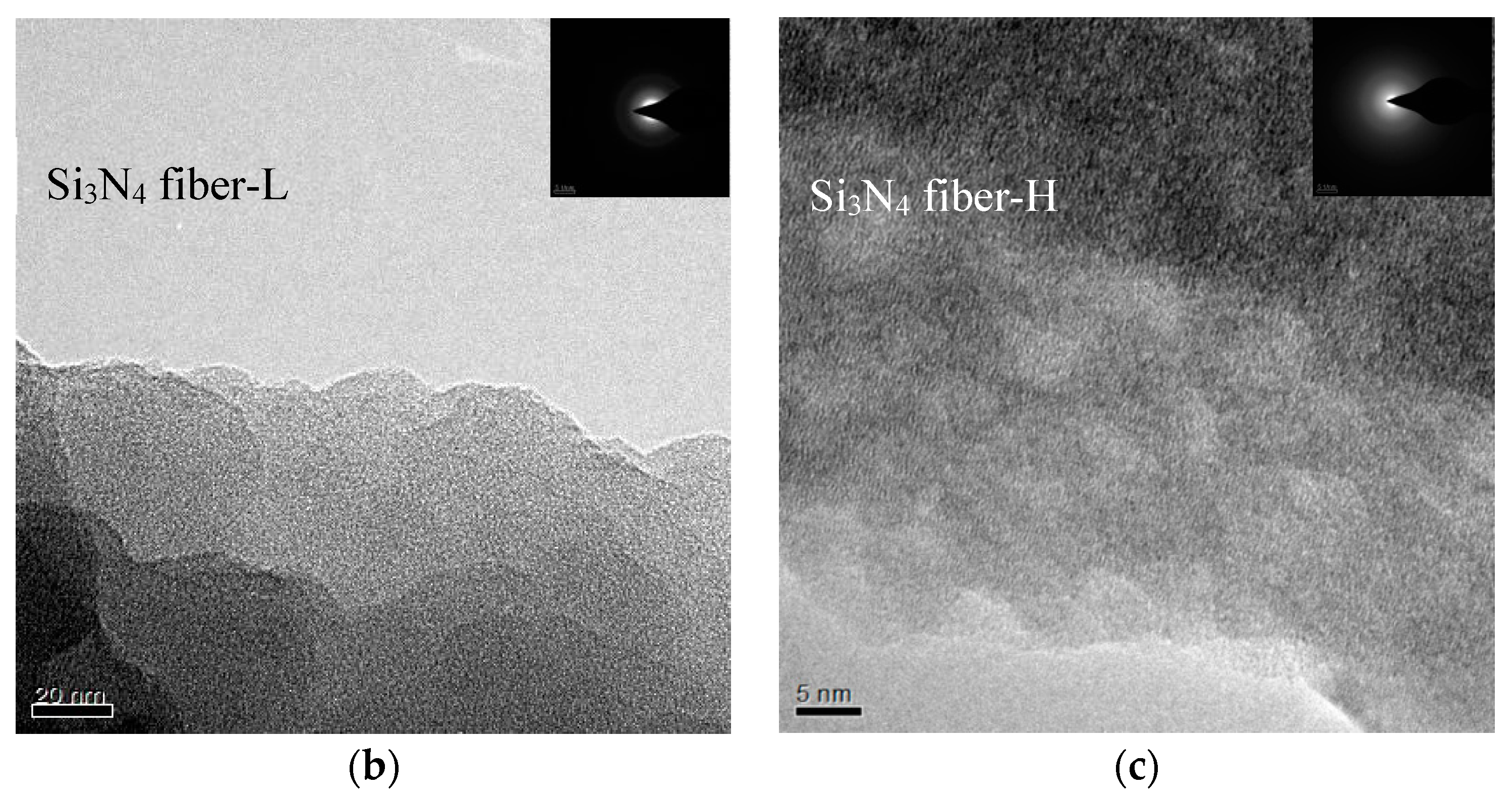

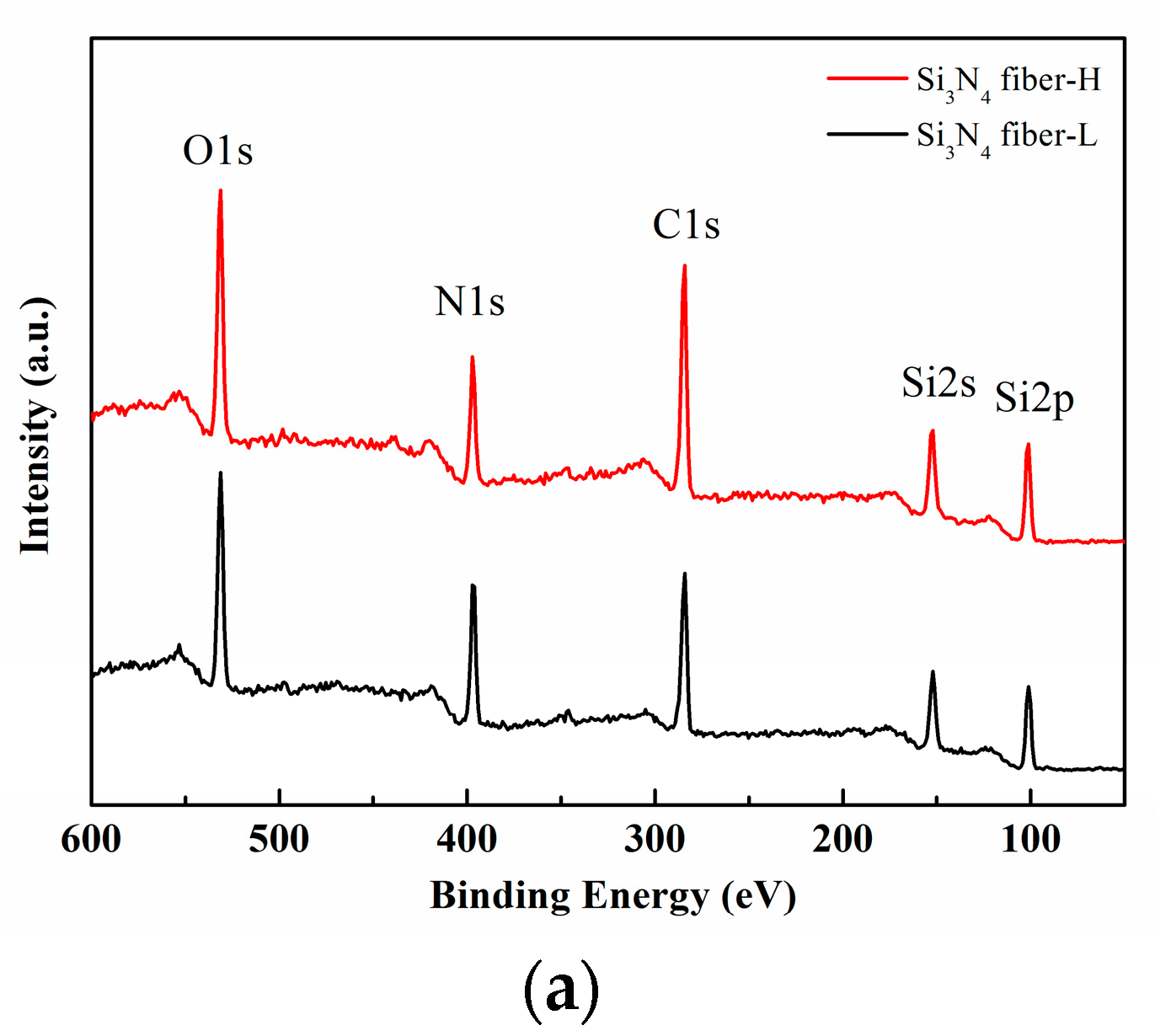

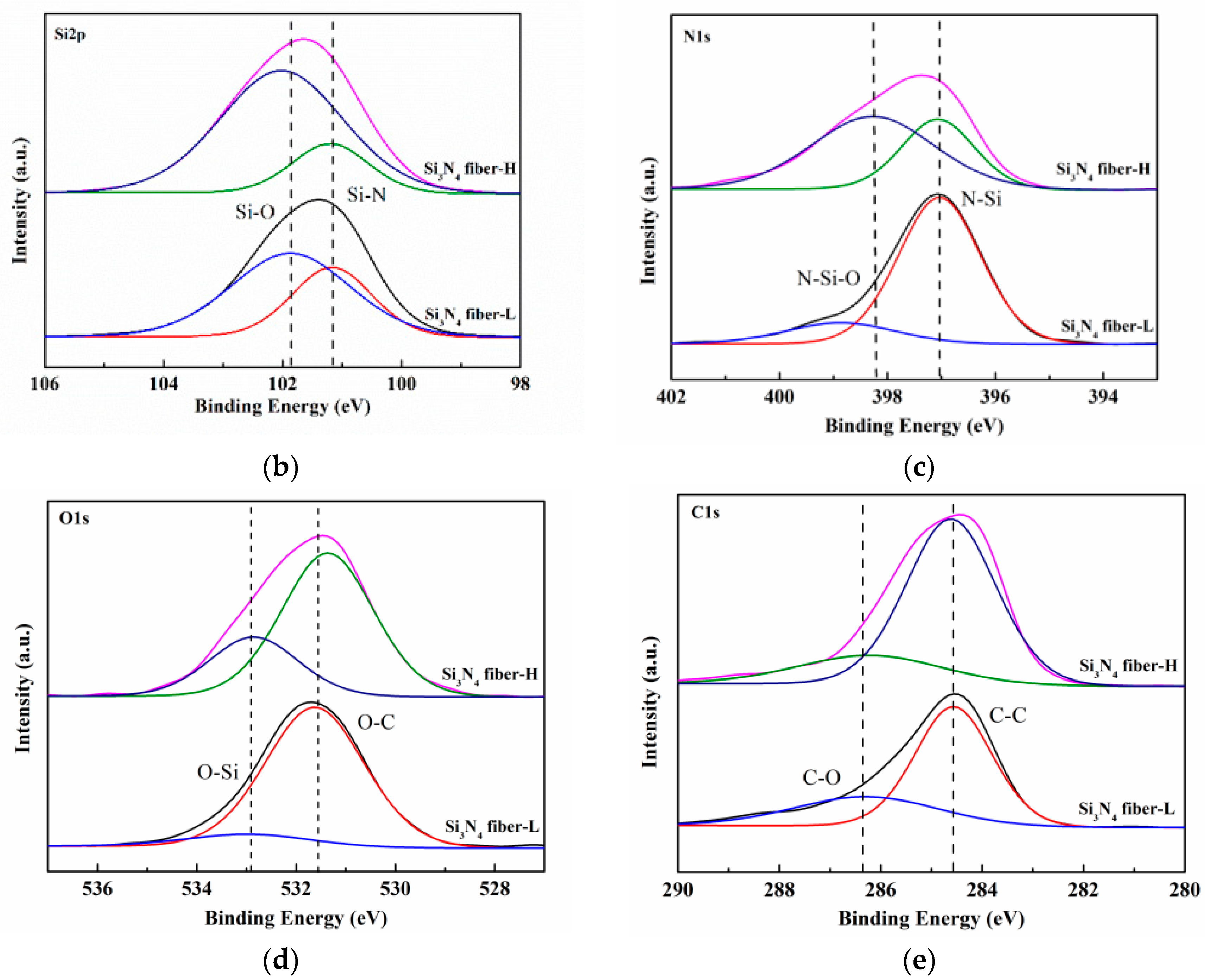

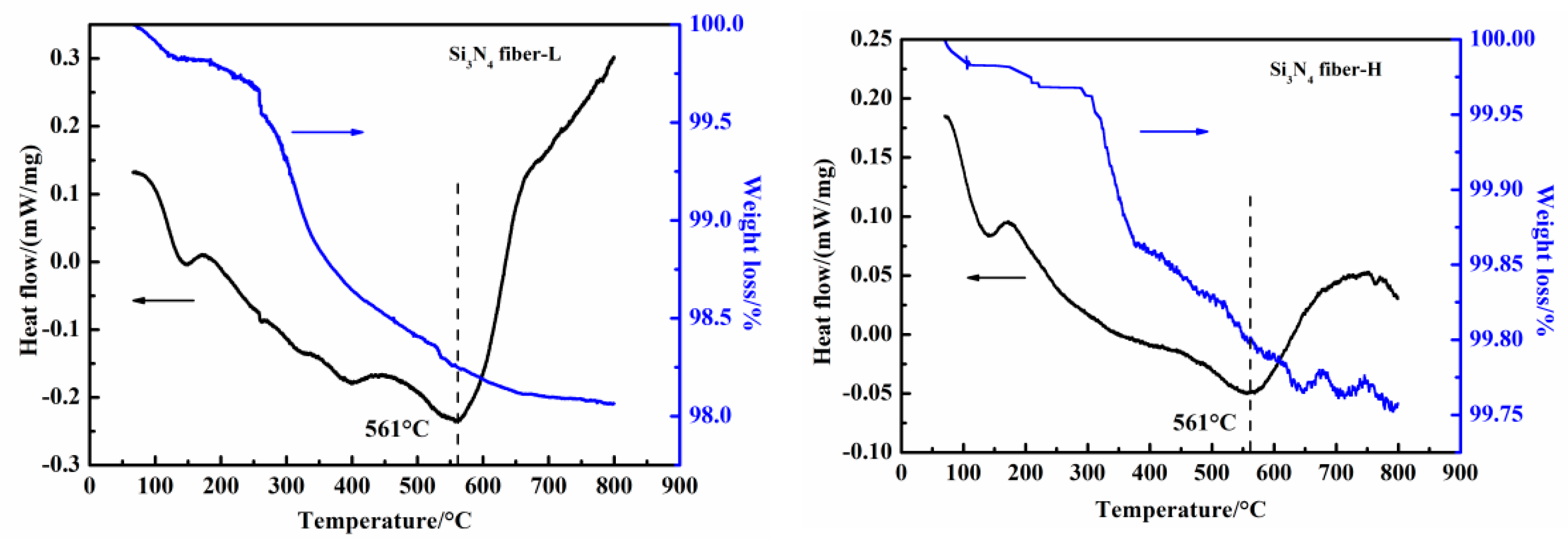

3.1. Microstructure and Composition of As-Received Fibers

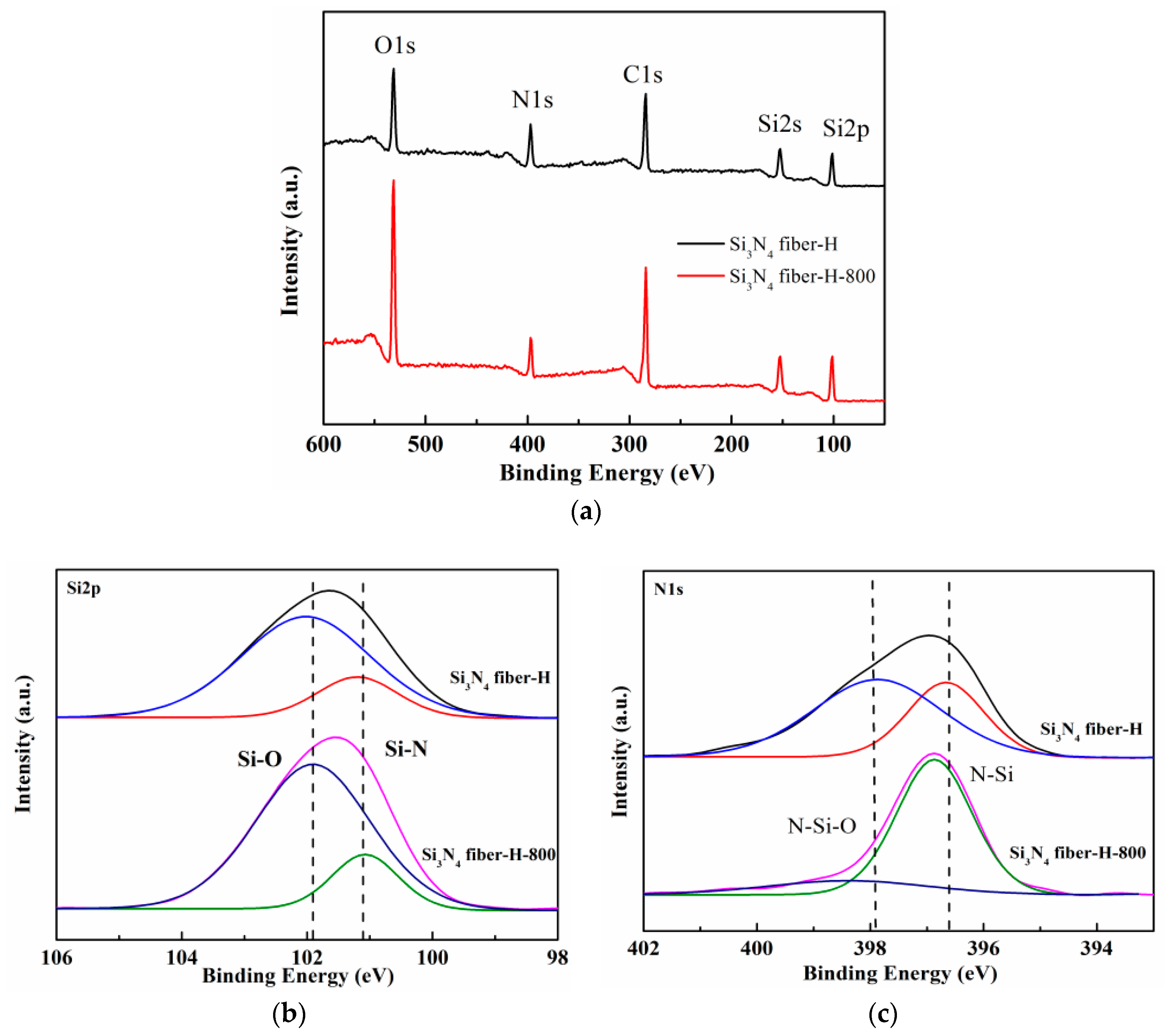

3.2. Effects of Heat Treatment on Microstructure and Composition

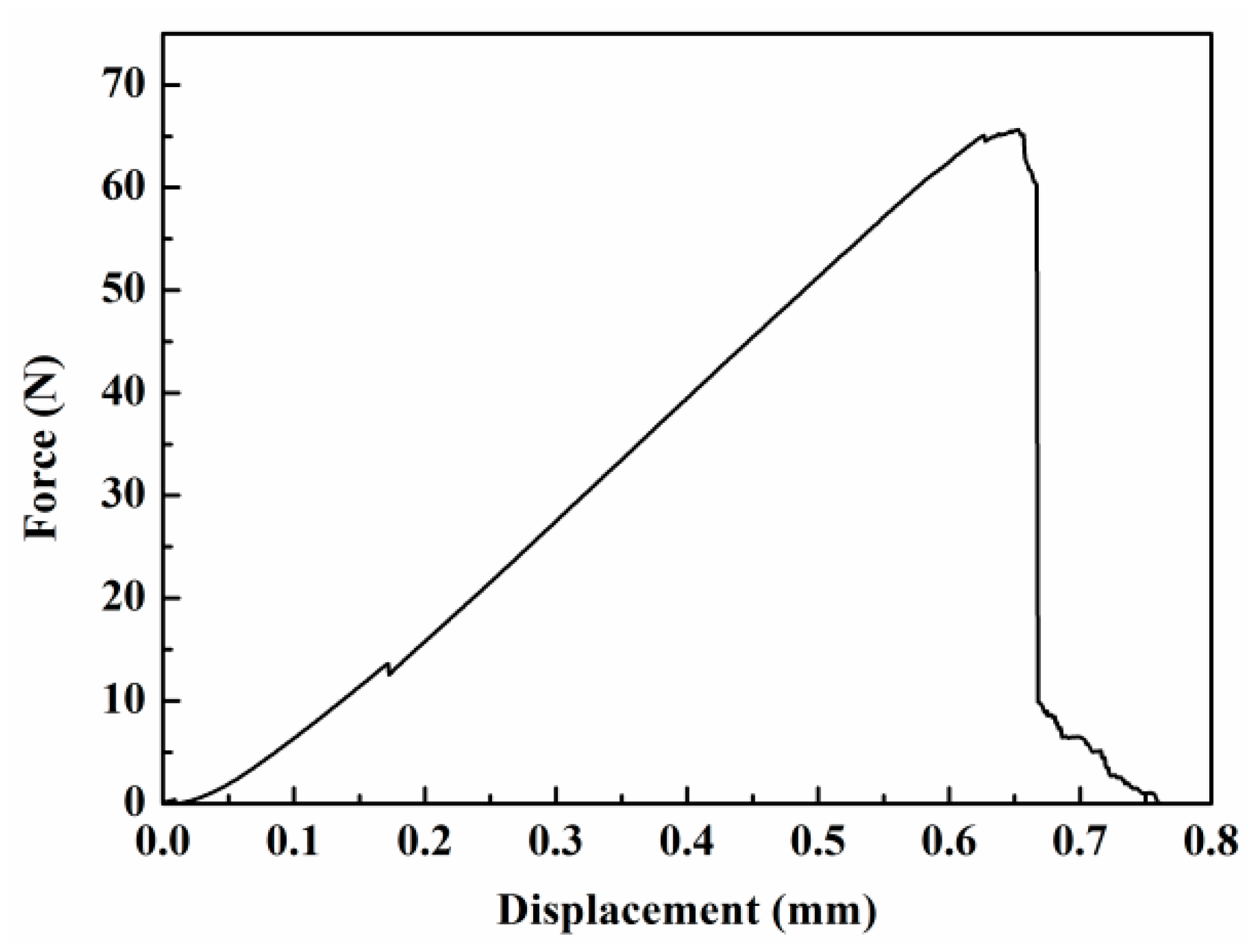

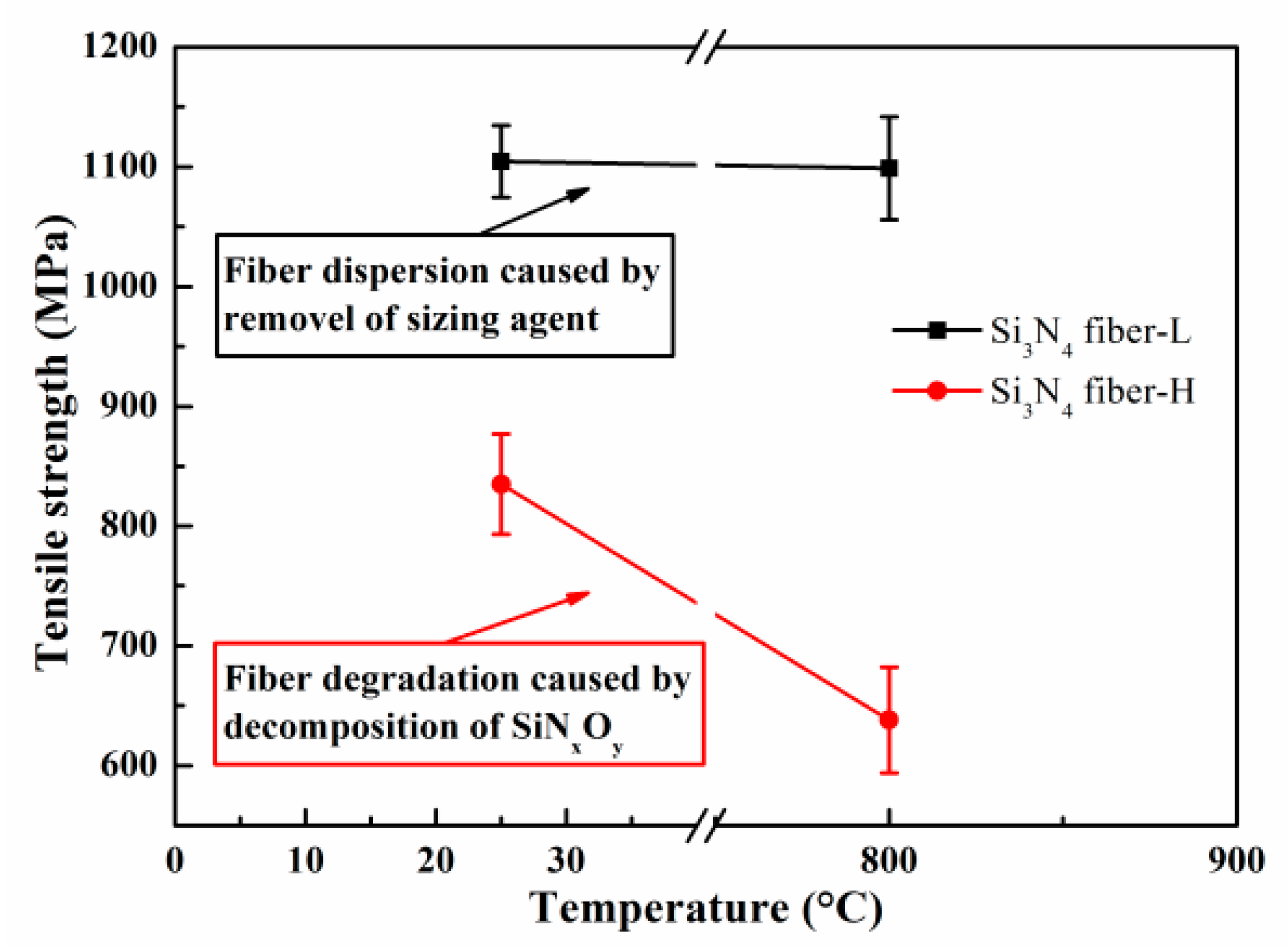

3.3. Effect of Heat Treatment on Room-Temperature Tensile Strength

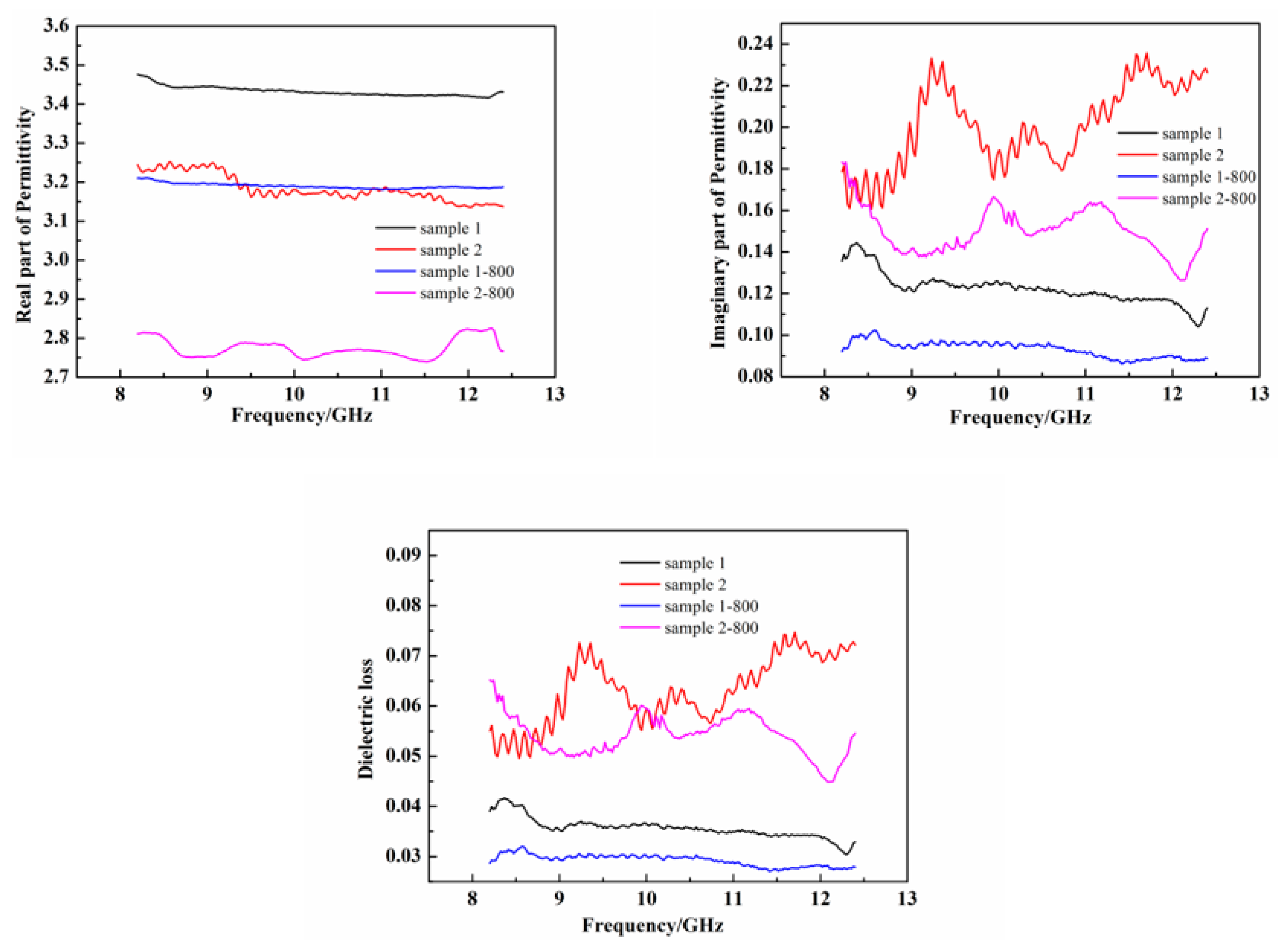

3.4. Effect of Heat Treatment on Room-Temperature Dielectric Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mani, G.S. Radome materials. In Microwave Materials; Murthy, V.R.K., Sundaram, S., Viswanathan, B., Eds.; Springer: Berlin/Heidelberg, Germany, 1994; pp. 200–239. [Google Scholar]

- Gilbert, D.E.; Lee, J.R.; Kramer, T.J. Multilayer Radome. U.S. Patent 4,180,605, 25 December 1979. [Google Scholar]

- Barta, J.; Manela, M.; Fischer, R. Si3N4 and Si2N2O for high performance radomes. Mater. Sci. Eng. 1985, 71, 265–272. [Google Scholar] [CrossRef]

- Suzdal’tsev, E.I.; Kharitonov, D.V.; Anashkina, A.A. Analysis of existing radioparent refractory materials, composites and technology for creating high-speed rocket radomes. Part 2. Comparative analysis of the main properties of materials used for creating rocket radomes. Refract. Ind. Ceram. 2010, 51, 283–288. [Google Scholar] [CrossRef]

- Kim, P.C.; Lee, D.G.; Seo, I.S.; Kim, G.H. Low-observable radomes composed of composite sandwich constructions and frequency selective surfaces. Compos. Sci. Technol. 2008, 68, 2163–2170. [Google Scholar] [CrossRef]

- Place, T.M. Low Loss Radar Window for Reentry Vehicle. U.S. Patent 4,786,548, 22 November 1988. [Google Scholar]

- Penas, O.; Zenati, R.; Dubois, J.; Fantozzi, G. Processing, microstructure, mechanical properties of Si3N4 obtained by slip casting and pressureless sintering. Ceram. Int. 2001, 27, 591–596. [Google Scholar] [CrossRef]

- Ziegler, A.; Idrobo, J.C.; Cinibulk, M.K.; Kisielowski, C.; Browning, N.D.; Ritchie, R.O. Interface structure and atomic bonding characteristics in silicon nitride ceramics. Science 2004, 306, 1768–1770. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Li, J.; Chen, Y.; Yang, L. Effect of the residual phases in β-si3n4 seed on the mechanical properties of self-reinforced si3n4 ceramics. J. Eur. Ceram. Soc. 2003, 23, 1543–1547. [Google Scholar] [CrossRef]

- Verzemnieks, J.; Simpson, F.H. Silicon Nitride Articles with Controlled Multi-Density Regions. U.S. Patent 5,103,239, 7 April 1992. [Google Scholar]

- Chen, F.; Shen, Q.; Zhang, L. Electromagnetic optimal design and preparation of broadband ceramic radome material with graded porous structure. Prog. Electromagn. Res. 2010, 105, 445–461. [Google Scholar] [CrossRef]

- Krstic, Z.; Krstic, V.D. Silicon nitride: The engineering material of the future. J. Mater. Sci. 2012, 47, 535–552. [Google Scholar] [CrossRef]

- Riley, F.L. Silicon nitride and related materials. J. Am. Ceram. Soc. 2010, 83, 245–265. [Google Scholar] [CrossRef]

- Klemm, H. Silicon nitride for high-temperature applications. J. Am. Ceram. Soc. 2010, 93, 1501–1522. [Google Scholar] [CrossRef]

- Miyazaki, H.; Yoshizawa, Y.-I.; Hirao, K. Fabrication of high thermal-conductive silicon nitride ceramics with low dielectric loss. Mater. Sci. Eng. B 2009, 161, 198–201. [Google Scholar] [CrossRef]

- Li, J.Q.; Luo, F.; Zhu, D.M.; Zhou, W.C. Influence of phase formation on dielectric properties of Si3N4 ceramics. J. Am. Ceram. Soc. 2007, 90, 1950–1952. [Google Scholar] [CrossRef]

- Żyła, G.; Vallejo, J.P.; Lugo, L. Isobaric heat capacity and density of ethylene glycol based nanofluids containing various nitride nanoparticle types: An experimental study. J. Mol. Liquids 2018, 261, 530–539. [Google Scholar] [CrossRef]

- Żyła, G.; Fal, J.; Bikić, S.; Wanic, M. Ethylene glycol based silicon nitride nanofluids: An experimental study on their thermophysical, electrical and optical properties. Phys. E Low-Dimens. Syst. Nanostruct. 2018, 104, 82–90. [Google Scholar] [CrossRef]

- Chollon, G.; Pailler, R.; Naslain, R.; Laanani, F.; Monthioux, M.; Olry, P. Thermal stability of a pcs-derived sic fibre with a low oxygen content (hi-nicalon). J. Mater. Sci. 1997, 32, 327–347. [Google Scholar] [CrossRef]

- Okamura, K.; Sato, M.; Hasegawa, Y. Silicon nitride fibers and silicon oxynitride fibers obtained by the nitridation of polycarbosilane. Ceram. Int. 1987, 13, 55–61. [Google Scholar] [CrossRef]

- Kamimura, S.; Seguchi, T.; Okamura, K. Development of silicon nitride fiber from si-containing polymer by radiation curing and its application. Radiat. Phys. Chem. 1999, 54, 575–581. [Google Scholar] [CrossRef]

- Pavarajarn, V.; Precharyutasin, R.; Praserthdam, P. Synthesis of silicon nitride fibers by the carbothermal reduction and nitridation of rice husk ash. J. Am. Ceram. Soc. 2010, 93, 973–979. [Google Scholar] [CrossRef]

- Li, X.; Yin, X.; Zhang, L.; Cheng, L.; Qi, Y. Mechanical and dielectric properties of porous Si3N4–SiO2 composite ceramics. Mater. Sci. Eng. A 2009, 500, 63–69. [Google Scholar] [CrossRef]

- Kingery, W.D.; Bowen, H.K.; Uhlmann, D.R. Introduction to Ceramics, 2nd ed.; Springer: Tokyo, Japan, 1976. [Google Scholar]

- Ye, F.; Zhang, L.; Yin, X.; Liu, Y.; Cheng, L. Dielectric and electromagnetic wave absorbing properties of two types of sic fibres with different compositions. J. Mater. Sci. Technol. 2013, 29, 55–58. [Google Scholar] [CrossRef]

- Chu, Z.; Feng, C.; Song, Y. Effect of oxygen content on tensile strength of polymer-derived sic fibers. Trans. Nonferrous Met. Soc. China 2002, 12, 894–898. [Google Scholar]

- Liu, Y.; Cheng, L.; Zhang, L.; Hua, Y.; Yang, W. Microstructure and properties of particle reinforced silicon carbide and silicon nitride ceramic matrix composites prepared by chemical vapor infiltration. Mater. Sci. Eng. A 2008, 475, 217–223. [Google Scholar] [CrossRef]

- Lin, L.; Xia, W.L.; Chen, J.M.; Ling, L.; Ding, S.N.; Liu, A.H. Preparation of silicon nitride fibers by pyrolysis nitridation of polycarbosilance. J. Funct. Mater. 2013, 44, 2981–2984. [Google Scholar]

- Sun, X.; Liu, H.T.; Cheng, H.F. Oxidation behavior of silicon nitride fibers obtained from polycarbosilane fibers via electron beam irradiation curing. RSC Adv. 2017, 7, 47833–47839. [Google Scholar] [CrossRef]

- Chollon, G.; Vogt, U.; Berroth, K. Processing and characterization of an amorphous Si–N–(O) fibre. J. Mater. Sci. 1998, 33, 1529–1540. [Google Scholar] [CrossRef]

- Singhal, S.C. Thermodynamic analysis of the high-temperature stability of silicon nitride and silicon carbide. Ceramur. Int. 1976, 2, 123–130. [Google Scholar] [CrossRef]

- Taylor, S.T.; Zhu, Y.T.; Blumenthal, W.R.; Stout, M.G.; Butt, D.P.; Lowe, T.C. Characterization of nicalon fibres with varying diameters: Part i strength and fracture studies. J. Mater. Sci. 1998, 33, 1465–1473. [Google Scholar] [CrossRef]

- Dassios, K.G.; Steen, M.; Filiou, C. Mechanical properties of alumina nextel™ 720 fibres at room and elevated temperatures: Tensile bundle testing. Mater. Sci. Eng. A 2003, 349, 63–72. [Google Scholar] [CrossRef]

- Wolfenden, A.; van der Zwaag, S. The concept of filament strength and the weibull modulus. J. Test. Eval. 1989, 17, 292–298. [Google Scholar] [CrossRef]

- Riccardi, C.C.; Vallo, C.I. Estimation of weibull parameters for the flexural strength of pmma-based bone cements. Polym. Eng. Sci. 2002, 42, 1260–1273. [Google Scholar] [CrossRef]

- Wang, G.; Chen, X.; Duan, Y.; Liu, S. Electromagnetic properties of carbon black and barium titanate composite materials. J. Alloys Compd. 2008, 454, 340–346. [Google Scholar] [CrossRef]

- Yin, X.; Xue, Y.; Zhang, L.; Cheng, L. Dielectric, electromagnetic absorption and interference shielding properties of porous yttria-stabilized zirconia/silicon carbide composites. Ceram. Int. 2012, 38, 2421–2427. [Google Scholar] [CrossRef]

- Wen, B.; Cao, M.S.; Hou, Z.L.; Song, W.L.; Zhang, L.; Lu, M.M.; Jin, H.B.; Fang, X.Y.; Wang, W.Z.; Yuan, J. Temperature dependent microwave attenuation behavior for carbon-nanotube/silica composites. Carbon 2013, 65, 124–139. [Google Scholar] [CrossRef]

- Jia, D.; Shao, Y.; Liu, B.; Yu, Z. Characterization of porous silicon nitride/silicon oxynitride composite ceramics produced by sol infiltration. Mater. Chem. Phys. 2010, 124, 97–101. [Google Scholar] [CrossRef]

| Materials | Element/wt % | Diameter/μm | |||

|---|---|---|---|---|---|

| Si | N | O | C | ||

| Si3N4 fiber-L | 59.79 | 36.0 | 3.56 | 0.65 | 12.2 |

| Si3N4 fiber-H | 52.39 | 33.14 | 13.56 | 0.91 | 13 |

| Materials | Element/wt % | |||

|---|---|---|---|---|

| Si | N | O | C | |

| Si3N4 fiber-L | 66.97 | 27.23 | 5.12 | 0.68 |

| Si3N4 fiber-H | 64.26 | 25.68 | 9.24 | 0.82 |

| Materials | Temperature/°C | Weibull Modulus | Scale Parameter/MPa | Tensile Strength/MPa |

|---|---|---|---|---|

| Si3N4 fiber-L | as-received | 17.80 | 1137.9 | 1104.4 |

| 800 | 13.31 | 1142.2 | 1098.7 | |

| Si3N4 fiber-H | as-received | 13.92 | 866.8 | 835.0 |

| 800 | 13.45 | 663.1 | 638.0 |

| As-Received | Following Annealing | |||

|---|---|---|---|---|

| Materials | μ/Ώ m | σ/S m−1 | μ/Ώ m | σ/S m−1 |

| Si3N4 fiber-L | 18.94 | 0.0528 | 24.29 | 0.0412 |

| Si3N4 fiber-H | 31.17 | 0.0321 | 33.39 | 0.0299 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Ye, F.; Cui, X.; Cheng, L.; Li, J.; Liu, Y.; Zhang, L. Mechanical and Dielectric Properties of Two Types of Si3N4 Fibers Annealed at Elevated Temperatures. Materials 2018, 11, 1498. https://doi.org/10.3390/ma11091498

Zhou J, Ye F, Cui X, Cheng L, Li J, Liu Y, Zhang L. Mechanical and Dielectric Properties of Two Types of Si3N4 Fibers Annealed at Elevated Temperatures. Materials. 2018; 11(9):1498. https://doi.org/10.3390/ma11091498

Chicago/Turabian StyleZhou, Jie, Fang Ye, Xuefeng Cui, Laifei Cheng, Jianping Li, Yongsheng Liu, and Litong Zhang. 2018. "Mechanical and Dielectric Properties of Two Types of Si3N4 Fibers Annealed at Elevated Temperatures" Materials 11, no. 9: 1498. https://doi.org/10.3390/ma11091498

APA StyleZhou, J., Ye, F., Cui, X., Cheng, L., Li, J., Liu, Y., & Zhang, L. (2018). Mechanical and Dielectric Properties of Two Types of Si3N4 Fibers Annealed at Elevated Temperatures. Materials, 11(9), 1498. https://doi.org/10.3390/ma11091498