Effects of Deformation Parameters on Microstructural Evolution of 2219 Aluminum Alloy during Intermediate Thermo-Mechanical Treatment Process

Abstract

:1. Introduction

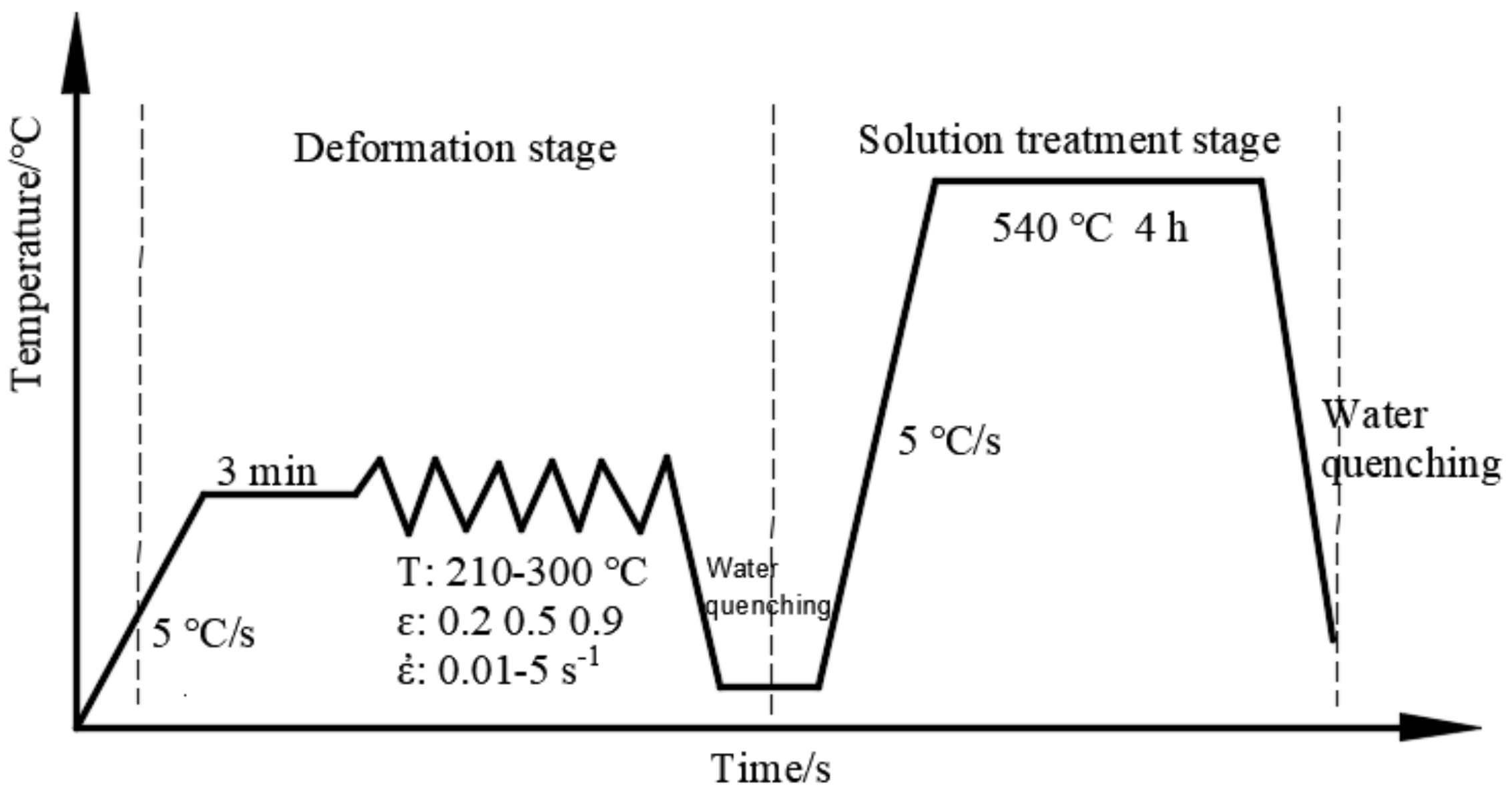

2. Materials and Methods

3. Results and Discussion

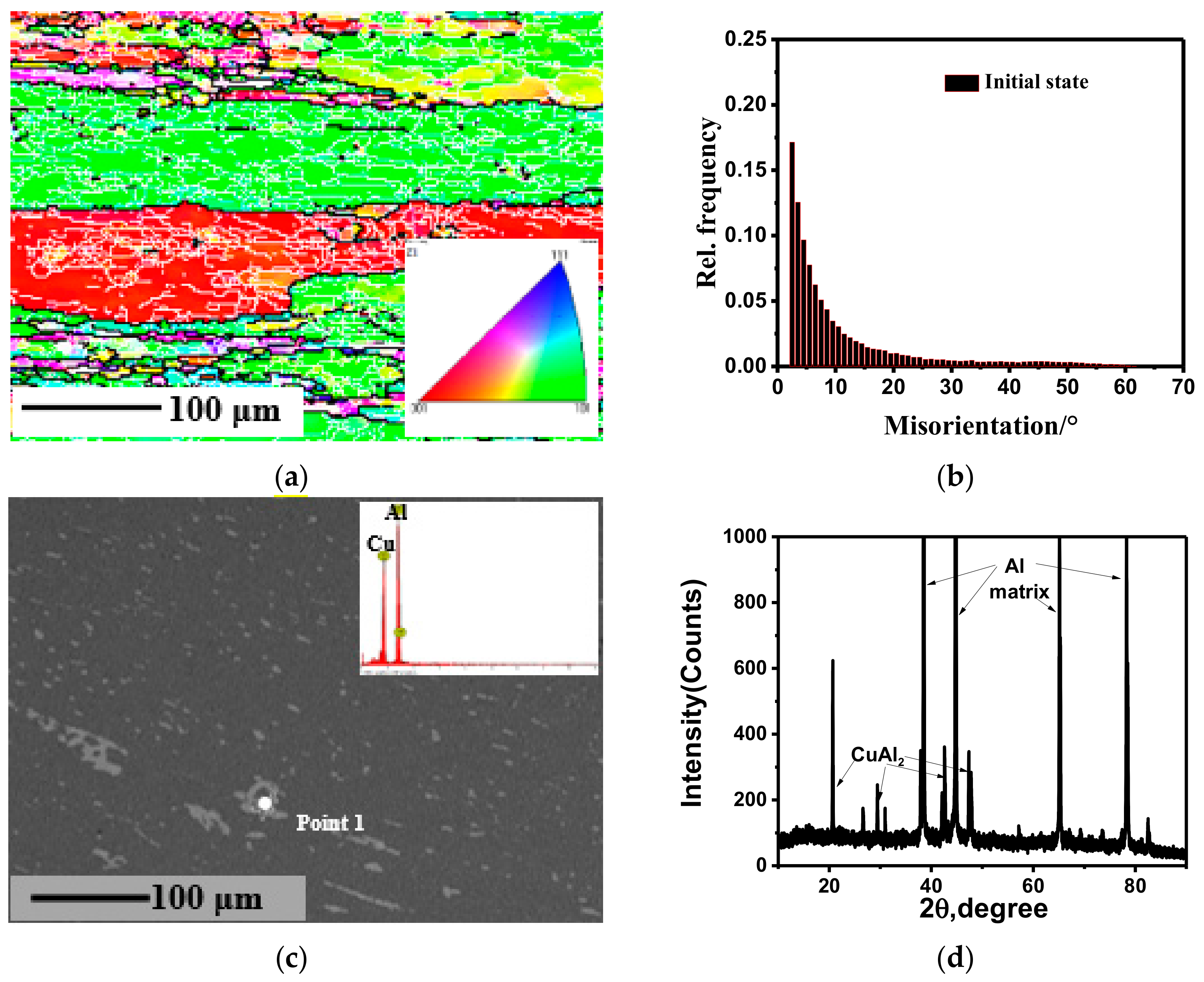

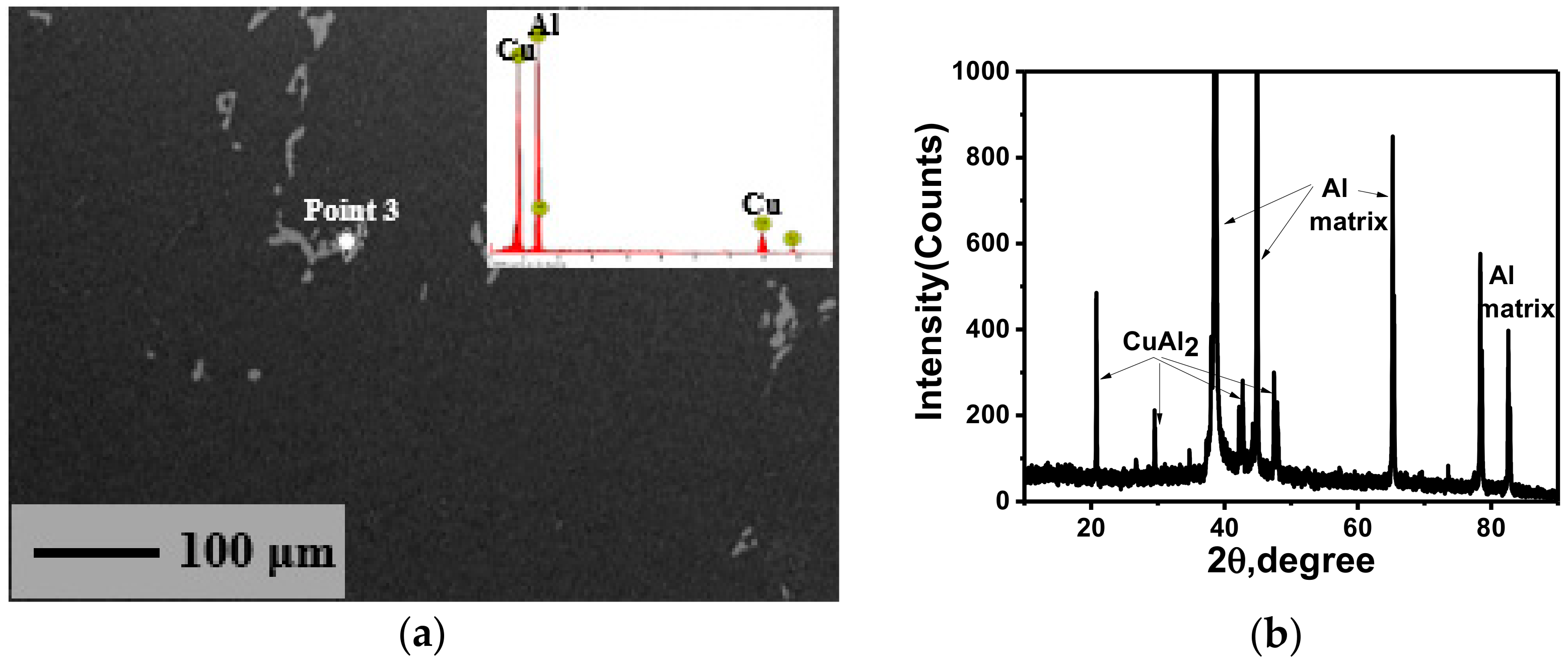

3.1. Initial Micrographs Analysis of the Undeformed Sample

3.2. Effects of Deformation Parameters on the Deformed Microstructure during WD Process

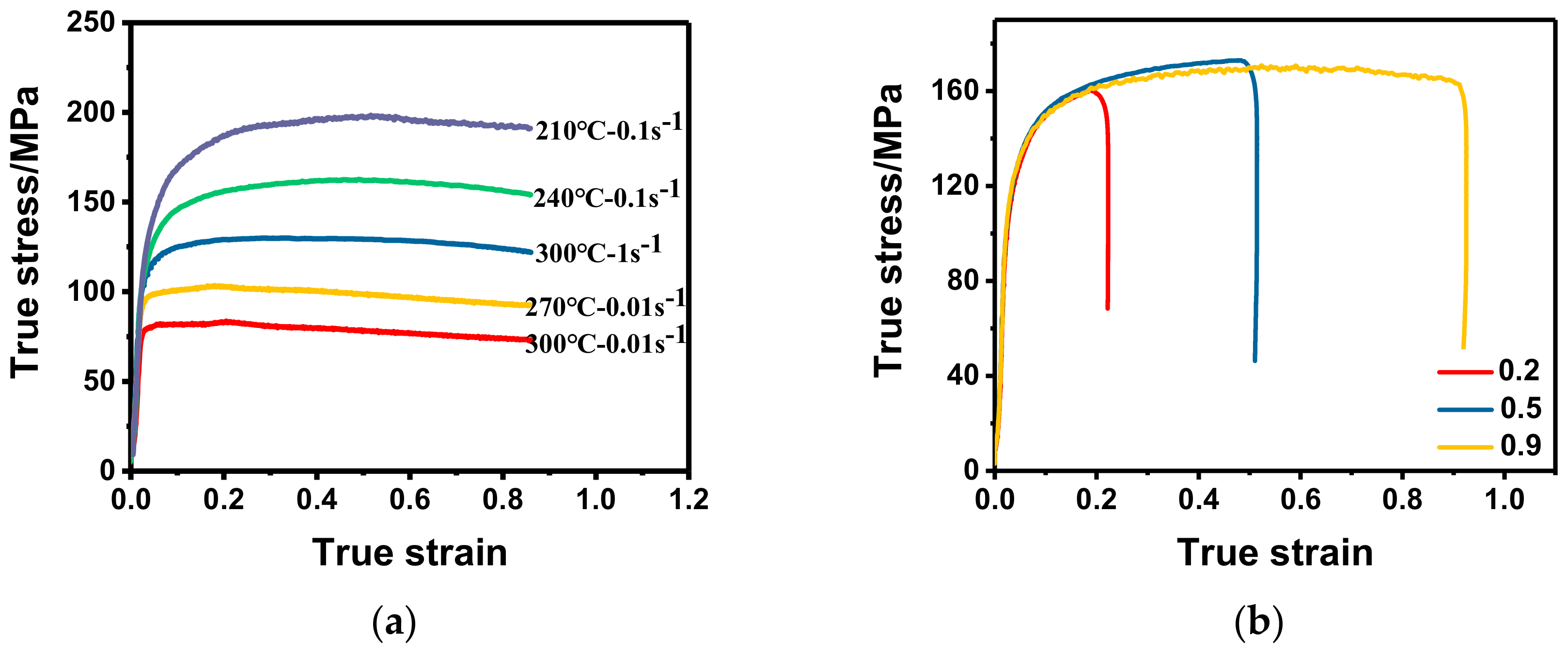

3.2.1. Effects on Flow Behavior

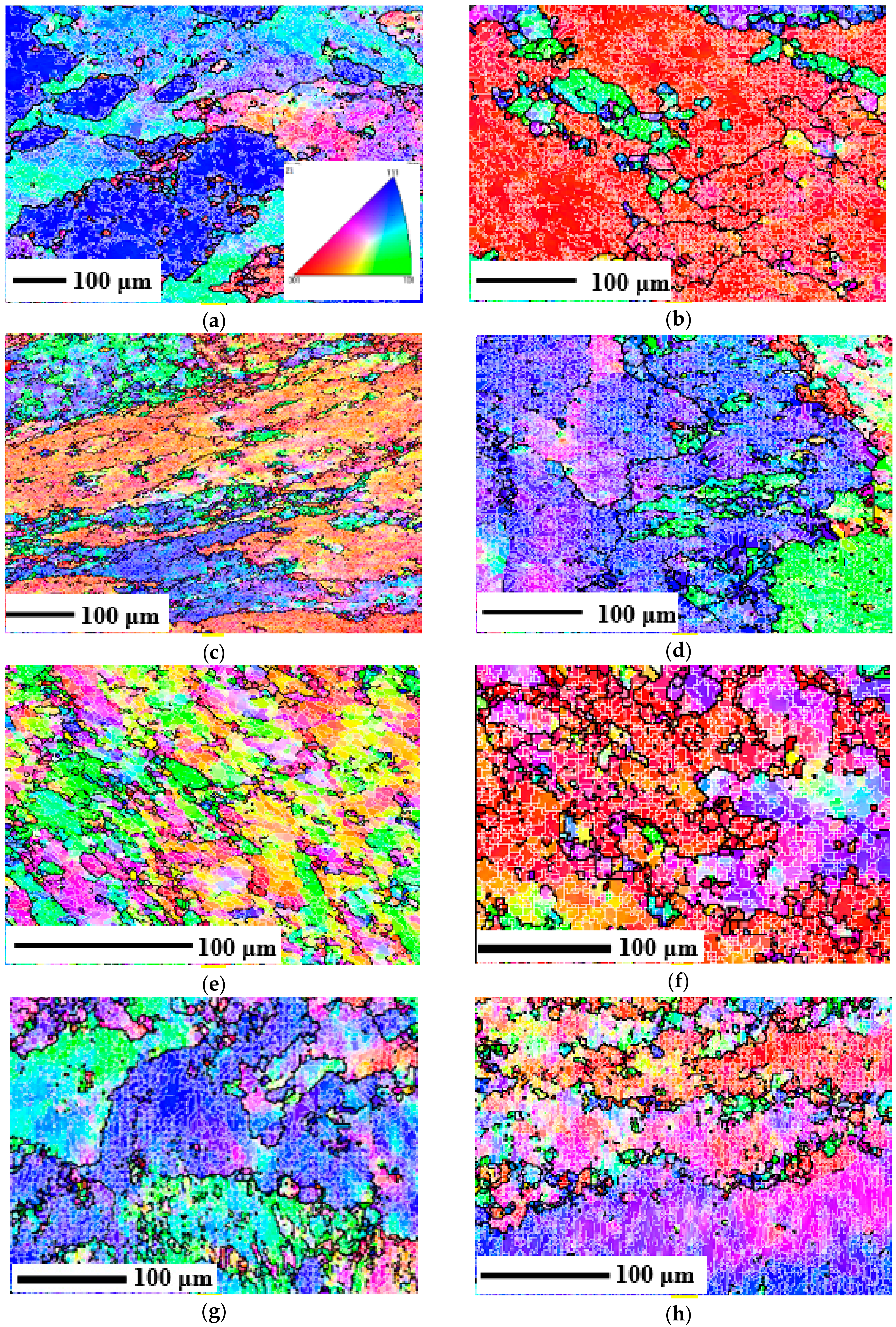

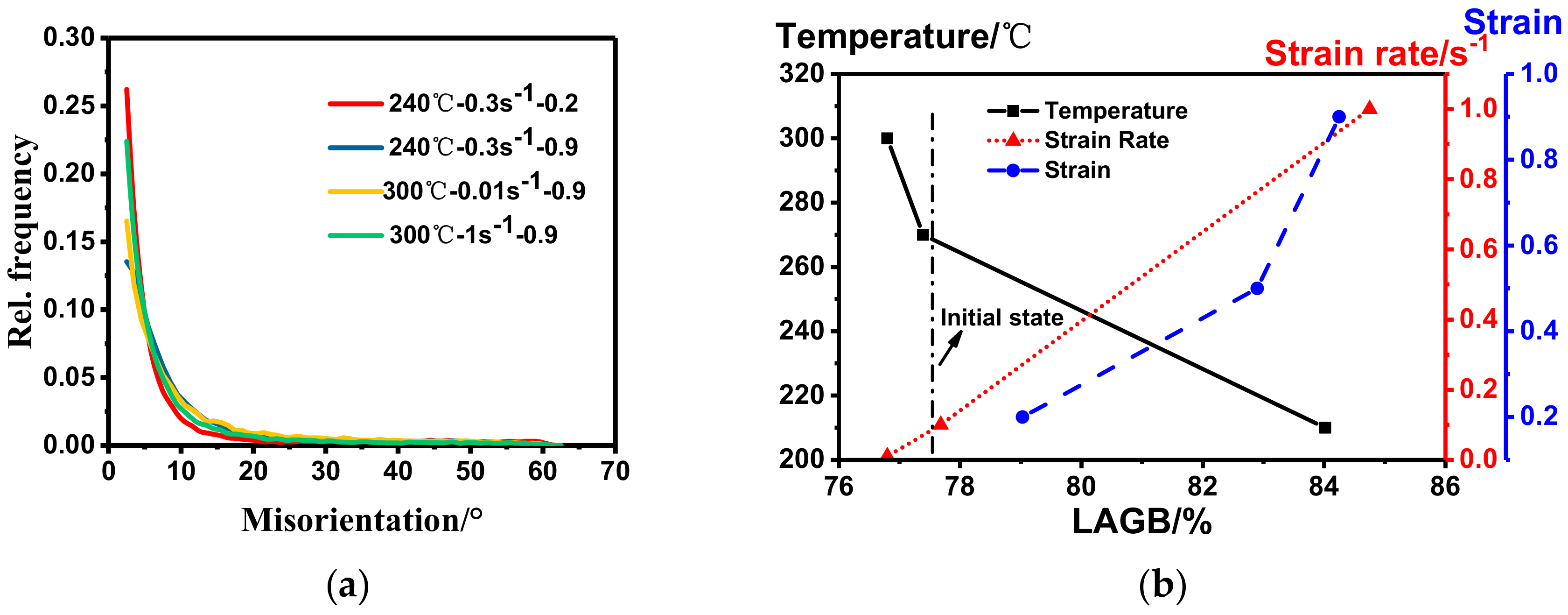

3.2.2. Effects on Subgrain Evolution

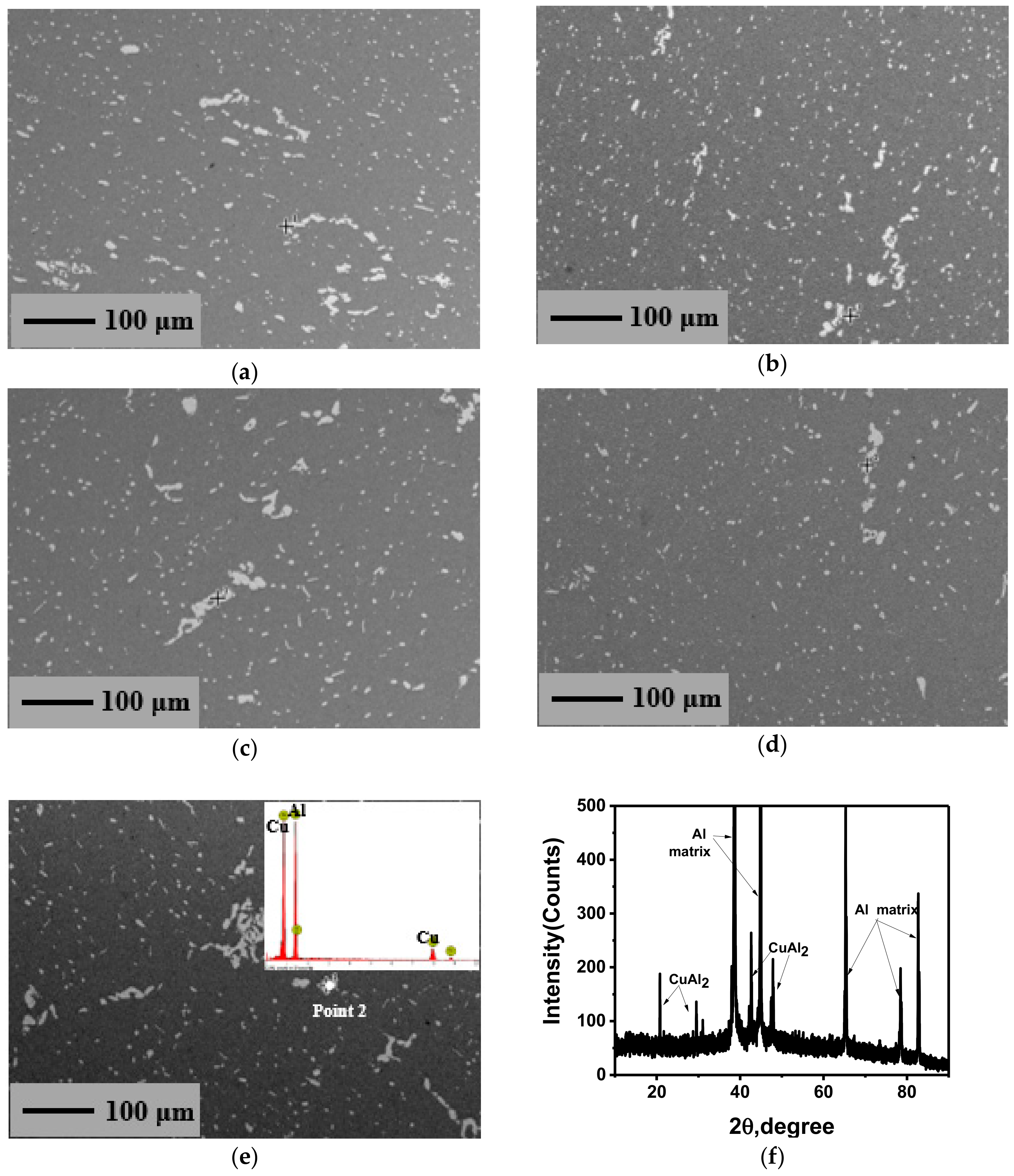

3.2.3. Effects on the Distribution of Precipitated Phase

3.3. Effects of Deformation Parameters on the Microstructures during SST Process

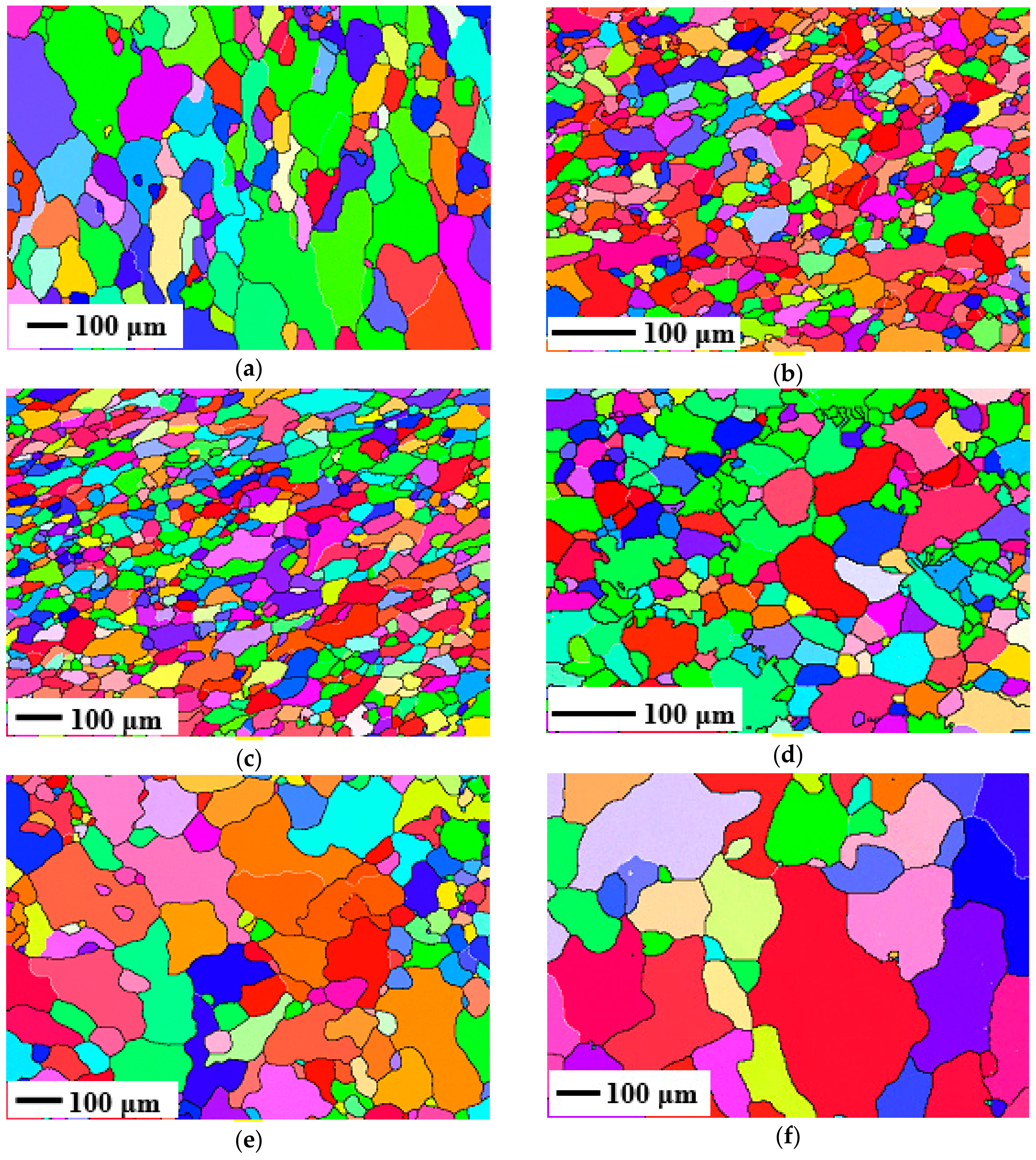

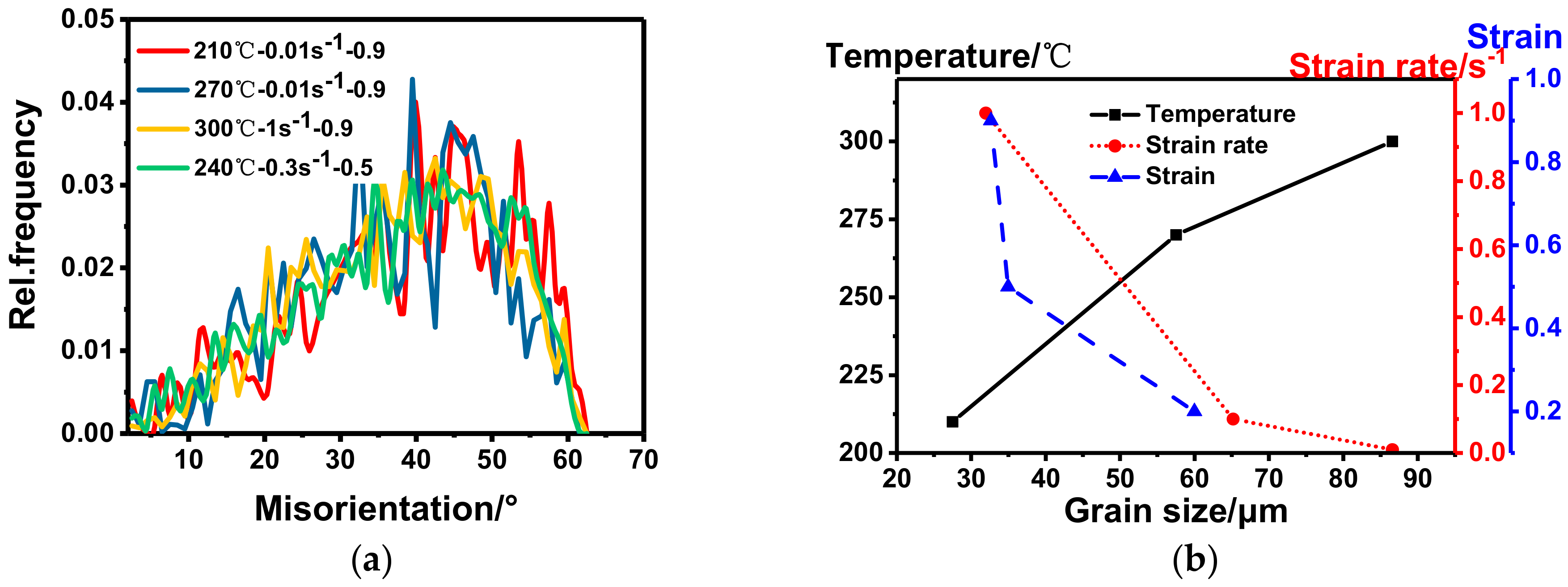

3.3.1. Effects on Grain Refinement

3.3.2. Effects on Precipitated Phase

4. Conclusions

- During the warm deformation process of 2219 aluminum alloy, the flow stress is very sensitive to temperature, strain rate, and strain. The storage energy is found to be proportional to the square of the flow stress, and it decreases with the increase in temperature and/or the decrease in strain rate, and it rises first and then keeps a relatively stable state with the increase in strain. In addition, the main softening mechanism is determined to be dynamic recovery. Under relatively high temperature (270 °C, 300 °C) and lower strain rate (0.01 s−1), incomplete continuous dynamic recrystallization can also occur.

- During the warm deformation process, the grain morphology changes and the substructure content increases. Moreover, the proportion of the low angle grain boundaries increases with the decrease in deforming temperature, the increase in strain rate, and/or the increase in strain. In addition, the distribution of CuAl2 phase is more dispersed with the increase in deforming temperature, the decrease in strain rate, and/or the increase in strain. However, some CuAl2 phase particles are still polymerized.

- During the solid solution treatment process of 2219 aluminum alloy, complete static recrystallization occurred and substructure almost disappeared. The average grain size obtained decreased with the decrease in deforming temperature, the increase in strain rate, and/or the increase in strain. The grain refinement mechanism is related to the amount of storage energy and the distribution of precipitated particles in the whole process of intermediate thermal-mechanical treatment. The previously existing dispersed fine precipitates are all redissolved into the matrix, however, the precipitates remaining exist mainly by the form of polymerization.

- According to the experimental results, the optimum deformation parameters for industrial processing of 2219 aluminum alloy are as follows: T < 240 °C, ε > 0.5, and > 1 s−1, which can get better grain-refining effects at the same time.

Author Contributions

Funding

Conflicts of Interest

References

- An, L.H.; Cai, Y.; Liu, W.; Yuan, S.J.; Zhu, S.Q. Effect of pre-deformation on microstructure and mechanical properties of 2219 aluminum alloy sheet by thermomechanical treatment. Trans. Nonferr. Met. Soc. China 2012, 22, s370–s375. [Google Scholar] [CrossRef]

- Venkatesh, B.D.; Chen, D.L.; Bhole, S.D. Effect of heat treatment on mechanical properties of Ti-6Al-4V ELI alloy. Mater. Sci. Eng. A 2009, 506, 117–124. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, B.; Zhang, B. Effect of initial microstructure on the hot compression deformation behavior of a 2219 aluminum alloy. Mater. Des. 2012, 34, 15–21. [Google Scholar] [CrossRef]

- Qu, W.Q.; Song, M.Y.; Yao, J.S.; Zhao, H.Y. Effect of Temperature and Heat Treatment Status on the Ductile Fracture Toughness of 2219 Aluminum Alloy. Mater. Sci. Forum 2011, 689, 302–307. [Google Scholar] [CrossRef]

- Xia, C.; Zhang, W.; Kang, Z.; Jia, Y.; Wu, Y. High strength and high electrical conductivity Cu-Cr system alloys manufactured by hot rolling–quenching process and thermomechanical treatments. Mater. Sci. Eng. A 2012, 538, 295–301. [Google Scholar] [CrossRef]

- Song, R.; Ponge, D.; Raabe, D.; Speer, J.G.; Matlock, D.K. Overview of processing, microstructure and mechanical properties of ultrafine grained bcc steels. Mater. Sci. Eng. A 2006, 441, 1–17. [Google Scholar] [CrossRef]

- Liu, S.; Zhong, Q.; Zhang, Y.; Liu, W.; Zhang, X. Investigation of quench sensitivity of high strength Al-Zn-Mg-Cu alloys by time-temperature-properties diagrams. Mater. Des. 2010, 31, 3116–3120. [Google Scholar] [CrossRef]

- Petch, N.J. The Cleavage Strength of Polycrystals. J. Iron. Steel. Inst. 1953, 174, 25–28. [Google Scholar]

- Moallemi, M.; Kermanpur, A.; Najafizadeh, A.; Rezaee, A.; Baghbadorani, H.S. Formation of nano/ultrafine grain structure in a 201 stainless steel through the repetitive martensite thermomechanical treatment. Mater. Lett. 2012, 89, 22–24. [Google Scholar] [CrossRef]

- Waldman, J.; Sulinski, H.; Markus, H. The effect of ingot processing treatments on the grain size and properties of Al alloy 7075. Metall. Trans. 1974, 5, 573–584. [Google Scholar] [CrossRef]

- Popov, N.N.; Prokoshkin, S.D.; Sidorkin, M.Y.; Sysoeva, T.I.; Borovkov, D.V. Effect of thermomechanical treatment on the structure and functional properties of a 45Ti-45Ni-10Nb alloy. Russ. Metall. 2007, 2007, 59–64. [Google Scholar] [CrossRef]

- Elmay, W.; Prima, F.; Gloriant, T.; Bolle, B.; Zhong, Y. Effects of thermomechanical process on the microstructure and mechanical properties of a fully martensitic titanium-based biomedical alloy. J. Mech. Behav. Biomed. 2013, 18, 47–56. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.Y.; Ohmatsu, Y.; Kim, J.I.; Hosoda, H.; Miyazaki, S. Mechanical Properties and Shape Memory Behavior of Ti-Mo-Ga Alloys. Mater. Sci. Eng. A 2006, 438–440, 839–843. [Google Scholar] [CrossRef]

- Russo, E.D.; Conserva, M.; Gatto, F.; Markus, H. Thermo-mechanical treatments on high strength Al-Zn-Mg(-Cu) alloys. Metall. Trans. 1973, 4, 1133–1144. [Google Scholar] [CrossRef]

- Russo, E.D.; Conserva, M.; Buratti, M.; Gatto, F. A new thermo-mechanical procedure for improving the ductility and toughness of Al-Zn-Mg-Cu alloys in the transverse directions. Mater. Sci. Eng. 1974, 14, 23–36. [Google Scholar] [CrossRef]

- Lademo, O.G.; Pedersen, K.O.; Berstad, T.; Furu, T.; Hopperstad, O.S. An experimental and numerical study on the formability of textured AlZnMg alloys. Eur. J. Mech. A-Solid 2008, 27, 116–140. [Google Scholar] [CrossRef]

- Tajally, M.; Emadoddin, E. Mechanical and anisotropic behaviors of 7075 aluminum alloy sheets. Mater. Des. 2011, 32, 1594–1599. [Google Scholar] [CrossRef]

- Waldman, J.; Sulinski, H.V.; Markus, H. Processes for the Fabrication of 7000 Series Aluminum Alloys. U.S. Patent 3,847,681, 12 November 1974. [Google Scholar]

- Ward, B.R.; Agrawal, S.P.; Ashton, R.F. Method of Producing Superplastic Aluminum Sheet. U.S. Patent 4,486,244, 4 December 1984. [Google Scholar]

- Wert, J.A.; Paton, N.E.; Hamilton, C.H.; Mahoney, M.W. Grain refinement in 7075 aluminum by thermomechanical processing. Metall. Trans. A 1981, 12, 1267–1276. [Google Scholar] [CrossRef]

- Vandermeer, R.A. Microstructural descriptors and the effects of nuclei clustering on recrystallization path kinetics. Acta. Mater. 2005, 53, 1449–1457. [Google Scholar] [CrossRef]

- Poole, W.J.; Militzer, M.; Wells, M.A. Modelling recovery and recrystallization during annealing of AA 5754 aluminum alloy. Met. Sci. J. 2003, 19, 1361–1368. [Google Scholar]

- Primig, S.; Leitner, H.; Knabl, W.; Lorich, A.; Clemens, H. Influence of the heating rate on the recrystallization behavior of molybdenum. Mater. Sci. Eng. A 2012, 535, 316–324. [Google Scholar] [CrossRef]

- Yoshida, H. Effect of pre-heat treatment on the superplasticity of a 7475 alloy sheet. J. Jpn. Inst. Light. Met. 1991, 41, 446–452. [Google Scholar] [CrossRef]

- Kaibyshev, R.; Sakai, T.; Musin, F.; Nikulin, I.; Miura, H. Superplastic behavior of a 7055 aluminum alloy. Scripta Mater. 2001, 45, 1373–1380. [Google Scholar] [CrossRef]

- Binlung, O.U.; Yang, J.; Yang, C. Effects of Step-Quench and Aging on Mechanical Properties and Resistance to Stress Corrosion Cracking of 7050 Aluminum Alloy. Mater. T. Jim. 2007, 41, 783–789. [Google Scholar]

- Tsai, T.C.; Chuang, T.H. Role of grain size on the stress corrosion cracking of 7475 aluminum alloys. Mater. Sci. Eng. A 1997, 225, 135–144. [Google Scholar] [CrossRef]

- Zuo, J.; Hou, L.; Shi, J.; Cui, H.; Zhuang, L. The mechanism of grain refinement and plasticity enhancement by an improved thermomechanical treatment of 7055 Al alloy. Mater. Sci. Eng. A 2017, 702, 42–52. [Google Scholar] [CrossRef]

- Ye, L.Y.; Zhang, X.M.; Liu, Y.W.; Tang, J.G.; Zheng, D.W. Effect of two-step aging on recrystallized grain size of Al-Mg-Li alloy. Mater. Sci. Technol. 2014, 27, 125–131. [Google Scholar] [CrossRef]

- Troeger, L.P.; Jr, E.A.S. Microstructural and mechanical characterization of a super-plastic 6xxx aluminum alloy. Mater. Sci. Eng. A 2000, 277, 102–113. [Google Scholar] [CrossRef]

- Esmaeili, S.; Lloyd, D.J.; Jin, H. A thermomechanical process for grain refinement in precipitation hardening AA6xxx aluminum alloys. Mater. Lett. 2011, 65, 1028–1030. [Google Scholar] [CrossRef]

- Aboutalebi, M.R.; Karimzadeh, M.; Salehi, M.T.; Abbaasi, S.M.; Morakabati, M. Influences of Aging and Thermomechanical Treatments on the Martensitic Transformation and Superelasticity of Highly Ni-rich Ti-51.5 at.% Ni Shape Memory Alloy. Thermochim. Acta 2015, 616, 14–19. [Google Scholar] [CrossRef]

- Ozan, S.; Lin, J.; Li, Y.; Zhang, Y.; Munir, K. Deformation mechanism and mechanical properties of a thermomechanically processed β Ti-28Nb-35.4Zr alloy. J. Mech. Behav. Biomed. 2018, 78, 224–234. [Google Scholar] [CrossRef] [PubMed]

- Saastamoinen, A.; Kaijalainen, A.; Porter, D.; Suikkanen, P. The effect of thermomechanical treatment and tempering on the subsurface microstructure and bendability of direct-quenched low-carbon strip steel. Mater. Charact. 2017, 134, 172–181. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Kumar, B.R.; Somani, M.; Karjalainen, P. Deformation processes during tensile straining of ultrafine/nanograined structures formed by reversion in metastable austenitic steels. Scripta Mater. 2008, 59, 79–82. [Google Scholar] [CrossRef]

- Eskandari, M.; Kermanpur, A.; Najafizadeh, A. Formation of Nanocrystalline Structure in 301 Stainless Steel Produced by Martensite Treatment. Metall. Mater. Trans. A 2009, 40, 2241–2249. [Google Scholar] [CrossRef]

- Forouzan, F.; Najafizadeh, A.; Kermanpur, A. Production of nano/submicron grained AISI 304L stainless steel through the martensite reversion process. Mater. Sci. Eng. A 2010, 527, 7334–7339. [Google Scholar] [CrossRef]

- Chen, F.; Cui, Z.; Chen, S. Recrystallization of 30Cr2Ni4MoV Ultra-super-critical Rotor Steel during Dot Deformation Part 3 Metadynamic Recrystallization. Mater. Sci. Eng. A 2011, 528, 5073–5080. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Microstructural evolution in 42CrMo steel during compression at elevated temperatures. Mater. Lett. 2008, 62, 2132–2135. [Google Scholar] [CrossRef]

- Momeni, A.; Dehghani, K. Prediction of dynamic recrystallization kinetics and grain size for 410 martensitic stainless steel during hot deformation. Met. Mater. Int. 2010, 16, 843–849. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M.; Wen, D.X.; Chen, M.S. A physically-based constitutive model for a typical nickel-based superalloy. Comp. Mater. Sci. 2014, 83, 282–289. [Google Scholar]

- Khelfaoui, F.; Guénin, G. Influence of the recovery and recrystallization processes on the martensitic transformation of cold worked equiatomic Ti–Ni alloy. Mater. Sci. Eng. A 2003, 355, 292–298. [Google Scholar] [CrossRef]

- Honeycombe, R.W.K.; Bhadeshia, H. Pobert William Kerr. Steels: Microstructure and Properties; Edward Arnold: London, UK, 1981. [Google Scholar]

- Peng, X.N.; Guo, H.Z.; Shi, Z.F.; Qin, C.; Zhao, Z.L. Microstructure characterization and mechanical properties of TC4-DT titanium alloy after thermomechanical treatment. T. Nonferr. Metal. Soc. 2014, 24, 682–689. [Google Scholar] [CrossRef]

- Wert, J.A.; Austin, L.K. Modeling of thermo-mechanical processing of heat-treatable aluminum alloys. Metall. Trans. A 1988, 19, 617–625. [Google Scholar] [CrossRef]

- Nie, W.; Shang, C. Microstructure and toughness of the simulated welding heat affected zone in XIOO pipeline steel with high deformation resistance. Acta. Metall. Sin. 2012, 48, 797–806. [Google Scholar] [CrossRef]

- Sha, G.; Wang, Y.B.; Liao, X.Z.; Duan, Z.C.; Ringer, S.P. Influence of equal-channel angular pressing on precipitation in an Al-Zn-Mg-Cu alloy. Acta. Mater. 2009, 57, 3123–3132. [Google Scholar] [CrossRef]

- Deschamps, A.; Fribourg, G.; Brechet, Y.; Chemin, J.L.; Hutchinson, C.R. In situ evaluation of dynamic precipitation during plastic straining of an Al-Zn-Mg-Cu alloy. Acta. Mater. 2012, 60, 1905–1916. [Google Scholar] [CrossRef]

- Lang, Y.; Zhou, G.; Hou, L.; Zhang, J.; Zhuang, L. Significantly enhanced the ductility of the fine-grained Al-Zn-Mg-Cu alloy by strain-induced precipitation. Mater. Des. 2015, 88, 625–631. [Google Scholar] [CrossRef]

- Kita, K.; Kobayashi, K.; Monzen, R. Dispersions of Particles and Heat Resistance in a Cu-Fe-P Alloy (Special Issue on Composite Materials). J. Soc. Mater. Sci. 2000, 49, 482–487. [Google Scholar] [CrossRef]

- Huo, W.; Hou, L.; Lang, Y.; Cui, H.; Zhuang, L. Improved thermo-mechanical processing for effective grain refinement of high-strength AA 7050 Al alloy. Mater. Sci. Eng. A 2015, 626, 86–93. [Google Scholar] [CrossRef]

- Zuo, J.; Hou, L.; Shi, J.; Cui, H.; Zhuang, L. Precipitates and the evolution of grain structures during double-step rolling of high-strength aluminum alloy and related properties. Acta. Metall. Sin. 2016, 52, 1105–1114. [Google Scholar]

- Yang, H.S.; Mukherjee, A.K.; Roberts, W.T. Effect of cooling rate in over-ageing and other thermomechanical process parameters on grain refinement in an AA7475 aluminum alloy. J. Mater. Sci. 1992, 27, 2515–2524. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: II Characteristics of the Lüders Deformation. Proc. Phys. Soc. 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Wert, J.A. Strength of Metals and Alloys; Pergamon Press: Oxford, UK, 1980. [Google Scholar]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta. Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Yang, Y.; Yu, K.; Li, Y.; Zhao, D.; Liu, X. Evolution of nickel-rich phases in Al-Si-Cu-Ni-Mg piston alloys with different Cu additions. Mater. Des. 2012, 33, 220–225. [Google Scholar] [CrossRef]

- Gourdet, S.; Montheillet, F. An experimental study of the recrystallization mechanism during hot deformation of aluminum. Mater. Sci. Eng. A 2000, 283, 274–288. [Google Scholar] [CrossRef]

- Sitdikov, O.; Sakai, T.; Miura, H.; Hama, C. Temperature effect on fine-grained structure formation in high-strength Al alloy 7475 during hot severe deformation. Mater. Sci. Eng. A 2009, 516, 180–188. [Google Scholar] [CrossRef]

| Cu | Mn | Si | Zr | Fe | Mg | Zn | V | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 5.8–6.8 | 0.2–0.4 | ≤0.2 | 0.1~0.25 | ≤0.3 | ≤0.02 | 0.10 | 0.05~0.15 | 0.02~0.1 | Bal |

| Deformation Parameters | Variables | LAGBs | HAGBs | |

|---|---|---|---|---|

| Initial State | - | 77.6% | 22.4% | |

| 240 °C-0.3 s−1 | strain | 0.2 | 79.0% | 21.0% |

| 0.5 | 82.9% | 17.10% | ||

| 0.9 | 84.3% | 15.7% | ||

| 0.01 s−1-0.9 | temperature/°C | 210 | 84.0% | 16.0% |

| 270 | 77.4% | 22.6% | ||

| 300 | 76.8% | 23.2% | ||

| 300 °C-0.9 | strain rate/s−1 | 0.01 | 76.8% | 23.2% |

| 0.1 | 77.7% | 22.3% | ||

| 1 | 84.8% | 15.2% | ||

| Deformation Parameters | Variables | Average Value of Grain Size, Expectation/μm | Coefficient of Variation(s/EX) | Misorientation Fraction(>15°) |

|---|---|---|---|---|

| 240 °C-0.3 s−1 | 0.2 | 60 | 0.72 | 92.9% |

| 0.5 | 35 | 0.57 | 94.9% | |

| 0.9 | 33 | 0.55 | 93.4% | |

| 0.01 s−1-0.9 | 210 °C | 27 | 0.58 | 93% |

| 270 °C | 58 | 0.91 | 95.5% | |

| 300 °C | 87 | 0.92 | 93.0% | |

| 300 °C-0.9 | 0.01 s−1 | 87 | 0.92 | 93.0% |

| 0.1 s−1 | 65 | 0.78 | 96.3% | |

| 1 s−1 | 32 | 0.73 | 93.5% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Wu, Y.; Gong, H. Effects of Deformation Parameters on Microstructural Evolution of 2219 Aluminum Alloy during Intermediate Thermo-Mechanical Treatment Process. Materials 2018, 11, 1496. https://doi.org/10.3390/ma11091496

Liu L, Wu Y, Gong H. Effects of Deformation Parameters on Microstructural Evolution of 2219 Aluminum Alloy during Intermediate Thermo-Mechanical Treatment Process. Materials. 2018; 11(9):1496. https://doi.org/10.3390/ma11091496

Chicago/Turabian StyleLiu, Lei, Yunxin Wu, and Hai Gong. 2018. "Effects of Deformation Parameters on Microstructural Evolution of 2219 Aluminum Alloy during Intermediate Thermo-Mechanical Treatment Process" Materials 11, no. 9: 1496. https://doi.org/10.3390/ma11091496

APA StyleLiu, L., Wu, Y., & Gong, H. (2018). Effects of Deformation Parameters on Microstructural Evolution of 2219 Aluminum Alloy during Intermediate Thermo-Mechanical Treatment Process. Materials, 11(9), 1496. https://doi.org/10.3390/ma11091496