Effect of Rejuvenator Containing Dodecyl Benzene Sulfonic Acid (DBSA) on Physical Properties, Chemical Components, Colloidal Structure and Micro-Morphology of Aged Bitumen

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Aged Bitumen

2.3. Preparation of Regenerated Bitumen

2.4. Physical Properties Testing

2.5. Chemical Components Testing

2.6. Colloidal Structure Characterization

2.7. Micro-Morphology Characterization

3. Results and Discussions

3.1. Characterization of TA and PA

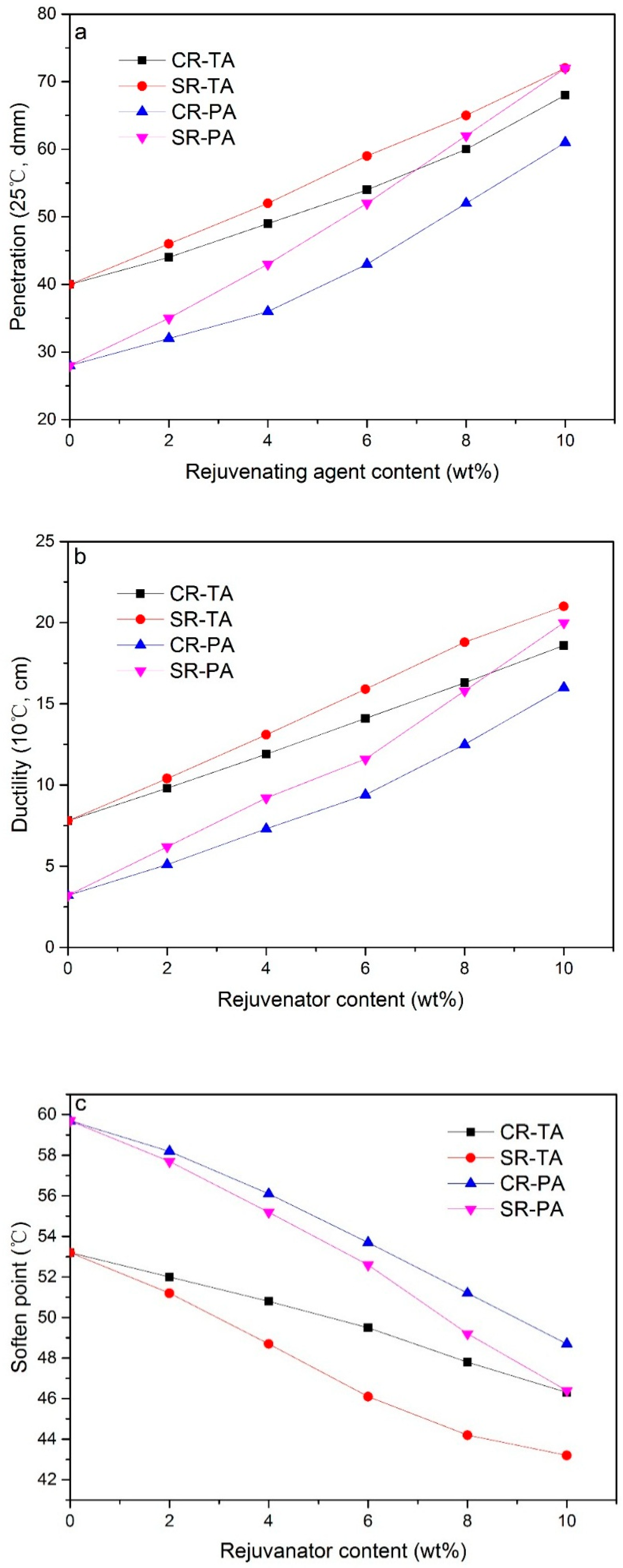

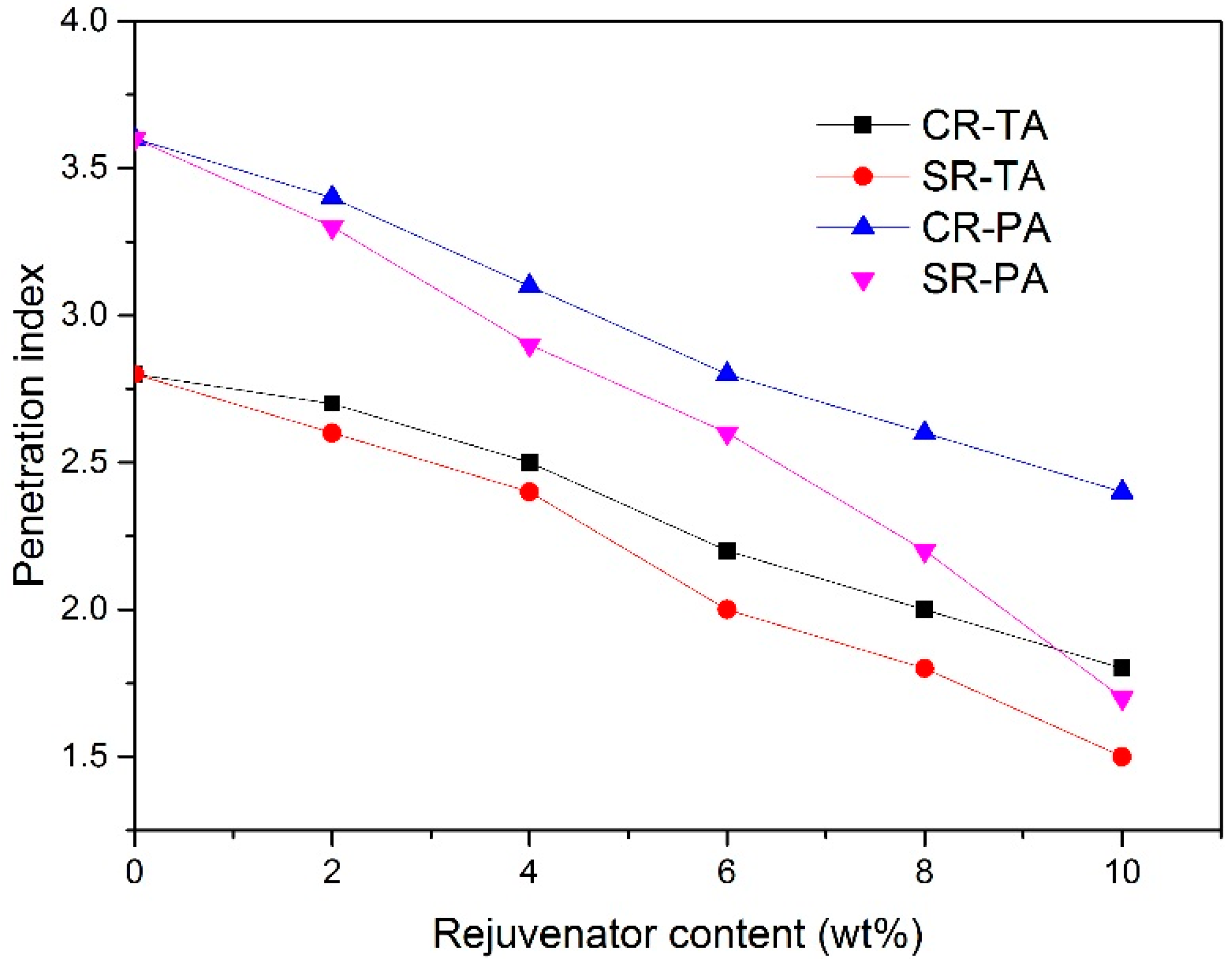

3.2. Physical Properties of Regenerated Bitumen

3.3. Chemical Components of Regenerated Bitumen

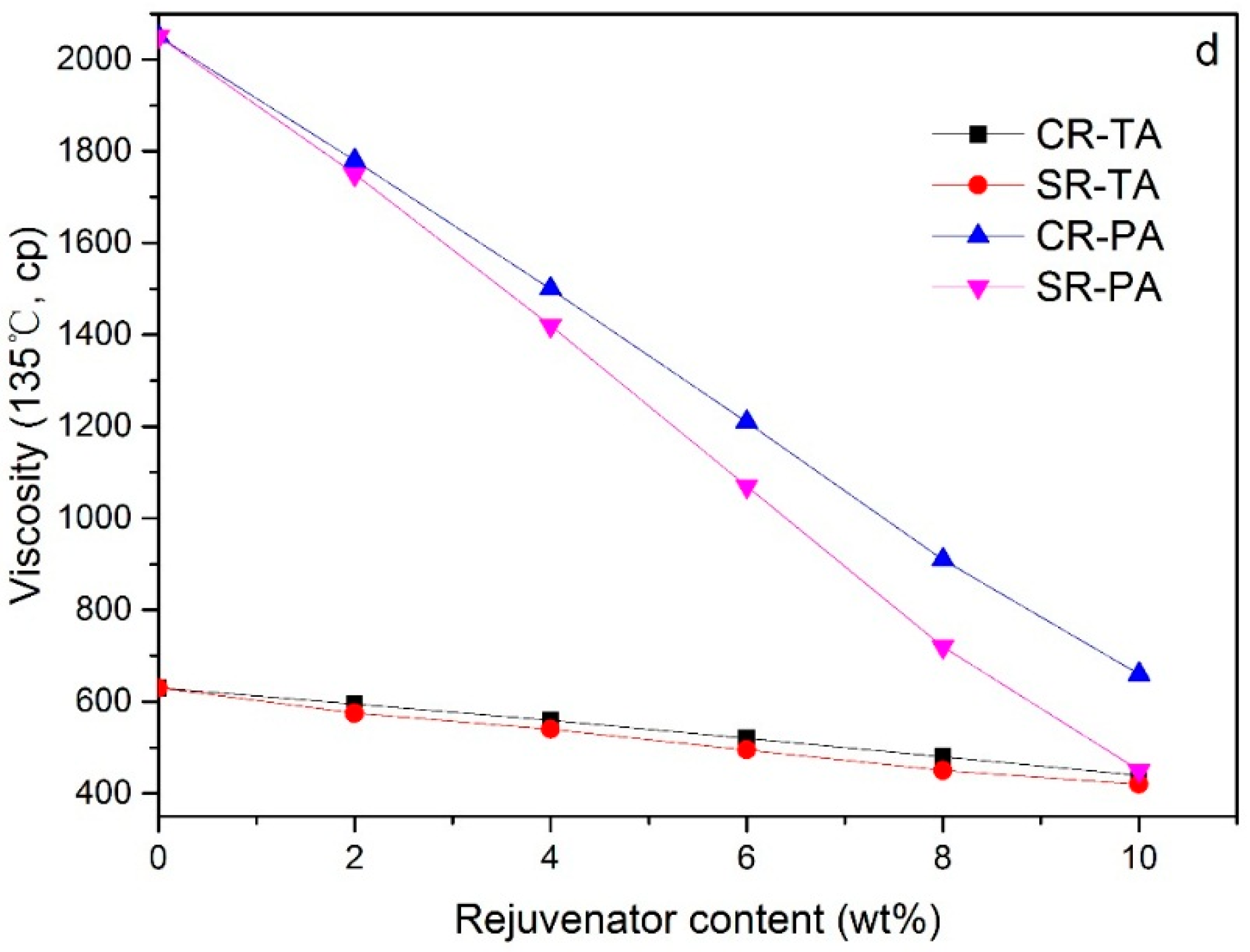

3.4. Colloidal Structure Stability of Regenerated Bitumen

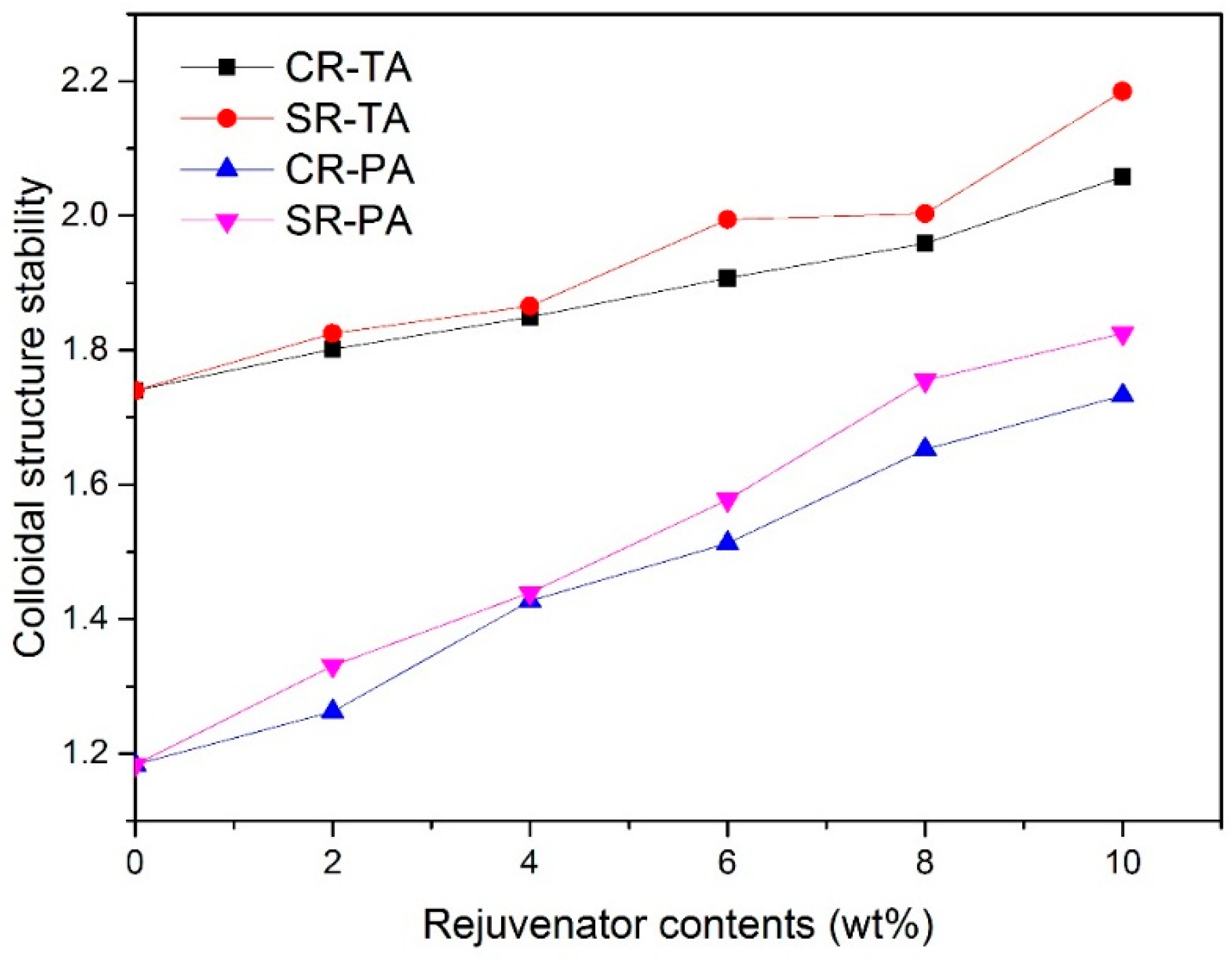

3.5. Colloidal Structure Type of Regenerated Bitumen

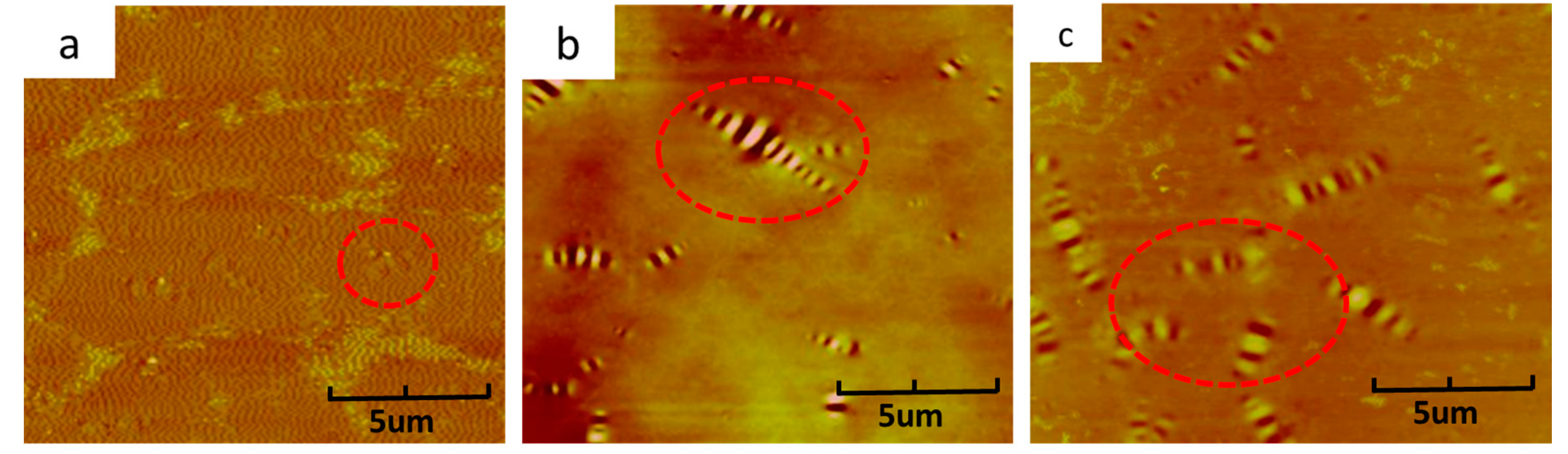

3.6. AFM Characterization

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Elkashef, M.; Williams, R.; Cochran, E. Physical and chemical characterization of rejuvenated reclaimed asphalt pavement (RAP) binders using rheology testing and pyrolysis gas chromatography-mass spectrometry. Mater. Struct. 2018, 51, 11–19. [Google Scholar] [CrossRef]

- Zhang, K.; Muhunthan, B. Effects of production stages on blending and mechanical properties of asphalt mixtures with reclaimed asphalt pavement. Constr. Build. Mater. 2017, 149, 679–689. [Google Scholar] [CrossRef]

- Gao, L.; Li, H.; Xie, J.; Yu, Z. Evaluation of pavement performance for reclaimed asphalt materials in different layers. Constr. Build. Mater. 2018, 159, 561–566. [Google Scholar] [CrossRef]

- Vegazamanillo, A.; Calzadaperez, M.; Lastragonzalez, P.; Indacoecheavega, I.; Fernandezortega, J.A. Analysis of the use of cupola furnace slags, green sand and reclaimed asphalt pavement in asphalt concrete mixtures for low intensity traffic. Revista de la Construccion 2017, 16, 229–237. [Google Scholar] [CrossRef]

- Chen, M.; Leng, B.; Wu, S.; Sang, Y. Physical, chemical and rheological properties of waste edible vegetable oil rejuvenated asphalt binders. Constr. Build. Mater. 2014, 66, 286–298. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B.; Vukosavljevic, D. Laboratory evaluation of fatigue characteristics of recycled asphalt mixture. Constr. Build. Mater. 2008, 7, 1323–1330. [Google Scholar] [CrossRef]

- Sivilevicius, H.; Braziunas, J.; Prentkovskis, O. Technologies and principles of hot recycling and investigation of preheated reclaimed asphalt pavement batching process in an asphalt mixing plant. Appl. Sci. 2017, 7, 1104. [Google Scholar] [CrossRef]

- Vislavicius, K.; Sivilevicius, H. Effect of reclaimed asphalt pavement gradation variation on the homogeneity of recycled hot-mix asphalt. Arch. Civ. Mech. Eng. 2013, 13, 345–363. [Google Scholar] [CrossRef]

- Xu, J.; Hao, P.; Zhang, D.; Yuan, G. Investigation of reclaimed asphalt pavement blending efficiency based on micro-mechanical properties of layered asphalt binders. Constr. Build. Mater. 2018, 163, 390–401. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, C.; Wan, M.; Zhou, X.; Wang, Y.; Wu, S. Study of the diffusion of rejuvenators and its effect on aged bitumen binder. Appl. Sci. 2017, 7, 397. [Google Scholar] [CrossRef]

- Arshad, M.; Ahmed, M. Potential use of reclaimed asphalt pavement and recycled concrete aggregate in base/subbase layers of flexible pavements. Constr. Build. Mater. 2017, 151, 83–97. [Google Scholar] [CrossRef]

- Yang, S.; Lee, L. Characterizing the chemical and rheological properties of severely aged reclaimed asphalt pavement materials with high recycling rate. Constr. Build. Mater. 2016, 111, 139–146. [Google Scholar] [CrossRef]

- Kuang, D.; Feng, Z.; Yu, J. A new approach for evaluating rejuvenator diffusing into aged bitumen. J. Wuhan Univ. Technol. 2011, 26, 43–46. [Google Scholar] [CrossRef]

- Cavalli, M.; Zaumanis, M.; Mazza, E.; Partl, M.; Poulikakos, L. Effect of ageing on the mechanical and chemical properties of binder from RAP treated with bio-based rejuvenators. Compos. Part B 2018, 141, 174–181. [Google Scholar] [CrossRef]

- Gamarra, A.; Ossa, E. Thermo-oxidative aging of bitumen. Int. J. Pavement Eng. 2018, 19, 641–650. [Google Scholar] [CrossRef]

- Mangiafico, S.; Benedetto, H.; Sauzeat, C.; Olard, F.; Pouget, S.; Planque, L. Effect of colloidal structure of bituminous binder blends on linear viscoelastic behaviour of mixtures containing reclaimed asphalt pavement. Mater. Des. 2016, 111, 126–139. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, H.; Yu, J. Effect of aging on morphology of organo-montmorillonite modified bitumen by atomic force microscopy. J. Microsc. 2011, 242, 37–45. [Google Scholar] [CrossRef] [PubMed]

- Jahromi, S.; Khodaii, A. Effects of nanoclay on rheological properties of bitumen binder. Constr. Build. Mater. 2009, 23, 2894–2904. [Google Scholar] [CrossRef]

- Loeber, L.; Sutton, O.; Morel, J.; Valleton, J.; Muller, G. New direct observations of asphalts and asphalt binder by scanning electron microscopy and atomic force microscopy. J. Microsc. 2010, 182, 32–39. [Google Scholar] [CrossRef]

- Baumgardner, G.; Masson, J.; Hardee, J.; Menapace, A.; Williams, A. Polyphosphoric acid modified asphalt: Proposed mechanisms. J. Assoc. Asph. Paving Technol. 2006, 74, 283–305. [Google Scholar]

- Kuang, D.; Yu, J.; Cai, Z. Effect of rejuvenator on rejuvenation properties of aged bitumen of different aging degree. Highway 2011, 5, 153–157. [Google Scholar]

- Lee, S.; Amirkhanian, S.; Park, N.; Kim, K. Characterization of warm mix asphalt binder containing artifically long-term aged binders. Constr. Build. Mater. 2007, 23, 2371–2379. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.; Miller, J. Effects of rejuvenating agents on superpave mixtures containing reclaimed asphalt pavement. J. Mater. Civ. Eng. 2007, 19, 376–384. [Google Scholar] [CrossRef]

- Kuang, D. Preparation of diffusible rejuvenator and its influence on performances of recycled bitumen and recycled asphalt mixture. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 28 June 2012. [Google Scholar]

- Zargar, G.; Gheysari, R.; Takassi, M.; Rostami, A.; Zadehnazari, A. Evaluation of a sulfanilic acid based surfactant in crude oil demulsification: An experimental study. Oil Gas Sci. Technol. 2018, 73, 176–182. [Google Scholar] [CrossRef]

- ASTM D 5. Standard Test Method for Penetration of Bituminous Materials; American Society for Testing Materials: West Conshohocken, PA, USA, 2005. [Google Scholar]

- ASTM D 1754. Standard Test Method for Effects of Heat and Air on Asphaltic Materials; American Society for Testing Materials: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM D 6521. Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel Lpar; American Society for Testing Materials: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM D 36. Standard Test Method for Softening Point of Bitumen; American Society for Testing Materials: West Conshohocken, PA, USA, 2006. [Google Scholar]

- ASTM D 113. Standard Test Method for Ductility of Bituminous Materials; American Society for Testing Materials: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM D 113. Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer; American Society for Testing Materials: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM D 4124. Standard Test Method for Separation of Asphalt into Four Fractions; American Society for Testing Materials: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Yu, X.; Burnham, N.; Tao, M. Surface microstructure of bitumen characterized by atomic force microscopy. Adv. Colloid Interface Sci. 2015, 218, 17–33. [Google Scholar] [CrossRef] [PubMed]

| Items | Value | |

|---|---|---|

| Physical properties | Softening point (°C) | 45.2 |

| Penetration (25 °C, dmm) | 74 | |

| Ductility (10 °C, cm) | 22 | |

| Viscosity (135 °C, cp) | 420 | |

| Colloidal structure | Penetration index a | 1.2 |

| Chemical components | Saturates (%) | 15.3 |

| Aromatics (%) | 44.6 | |

| Resins (%) | 28.8 | |

| Asphaltenes (%) | 11.3 | |

| Items | SR | CR | |

|---|---|---|---|

| Physical properties | Flash point (°C) | >220 | >220 |

| Viscosity (60 °C, Pa·s) | 0.95 | 1.52 | |

| Viscosity ratio after TFOT | 1.7 | 2.1 | |

| Weight loss after TFOT (%) | −1.5 | −2.2 | |

| Chemical components | Saturates (%) | 13.3 | 12.5 |

| Aromatics (%) | 62.7 | 64.2 | |

| Resins (%) | 17.3 | 15.4 | |

| Asphaltenes (%) | 6.7 | 7.9 | |

| Items | TA | PA | |

|---|---|---|---|

| Physical properties | Softening point (°C) | 53.2 | 59.7 |

| Penetration (25 °C, dmm) | 40 | 28 | |

| Ductility (10 °C, cm) | 7.8 | 3.2 | |

| Viscosity (135 °C, cp) | 630 | 2050 | |

| Colloidal structure | Penetration index | 1.7 | 3.5 |

| Chemical components | Saturates (%) | 14.5 | 12.4 |

| Aromatics (%) | 37.3 | 29.6 | |

| Resins (%) | 26.2 | 24.6 | |

| Asphaltenes (%) | 22.0 | 33.4 | |

| Samples | Rejuvenator Content (wt %) | Weight of Chemical Components (wt %) | |||

|---|---|---|---|---|---|

| Sa | Ar | Re | As | ||

| CR-TA | 0 | 14.5 | 37.3 | 26.2 | 22 |

| 2 | 14.2 | 38.5 | 25.8 | 21.5 | |

| 4 | 14.4 | 38.9 | 26 | 20.7 | |

| 6 | 14.6 | 39.7 | 25.9 | 19.8 | |

| 8 | 15.4 | 40.7 | 25.5 | 18.4 | |

| 10 | 15.2 | 41.7 | 25.6 | 17.5 | |

| SR-TA | 0 | 14.5 | 37.3 | 26.2 | 22 |

| 2 | 14.1 | 38.1 | 26.5 | 21.3 | |

| 4 | 14.5 | 40.4 | 24.7 | 20.4 | |

| 6 | 14.2 | 41.9 | 24.7 | 19.2 | |

| 8 | 14.4 | 42.3 | 24.4 | 18.9 | |

| 10 | 14.1 | 43.5 | 25.1 | 17.3 | |

| Samples | Rejuvenator Content (wt %) | Weight of Chemical Components (wt %) | |||

|---|---|---|---|---|---|

| Sa | Ar | Re | As | ||

| CR-PA | 0 | 12.4 | 29.6 | 24.6 | 33.4 |

| 2 | 11.8 | 31.3 | 24.5 | 32.4 | |

| 4 | 12.6 | 34.6 | 24.2 | 28.6 | |

| 6 | 12.5 | 36.4 | 23.8 | 27.3 | |

| 8 | 12.5 | 38.2 | 24.1 | 25.2 | |

| 10 | 13.1 | 40 | 23.4 | 23.5 | |

| SR-PA | 0 | 12.4 | 29.6 | 24.6 | 33.4 |

| 2 | 11.7 | 31.3 | 25.8 | 31.2 | |

| 4 | 11.4 | 33.7 | 25.3 | 29.6 | |

| 6 | 12.5 | 37.9 | 23.3 | 26.3 | |

| 8 | 12.2 | 39.8 | 23.9 | 24.1 | |

| 10 | 12.9 | 41 | 23.6 | 22.5 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuang, D.; Ye, Z.; Yang, L.; Liu, N.; Lu, Z.; Chen, H. Effect of Rejuvenator Containing Dodecyl Benzene Sulfonic Acid (DBSA) on Physical Properties, Chemical Components, Colloidal Structure and Micro-Morphology of Aged Bitumen. Materials 2018, 11, 1476. https://doi.org/10.3390/ma11081476

Kuang D, Ye Z, Yang L, Liu N, Lu Z, Chen H. Effect of Rejuvenator Containing Dodecyl Benzene Sulfonic Acid (DBSA) on Physical Properties, Chemical Components, Colloidal Structure and Micro-Morphology of Aged Bitumen. Materials. 2018; 11(8):1476. https://doi.org/10.3390/ma11081476

Chicago/Turabian StyleKuang, Dongliang, Zhou Ye, Lifeng Yang, Ning Liu, Zaihong Lu, and Huaxin Chen. 2018. "Effect of Rejuvenator Containing Dodecyl Benzene Sulfonic Acid (DBSA) on Physical Properties, Chemical Components, Colloidal Structure and Micro-Morphology of Aged Bitumen" Materials 11, no. 8: 1476. https://doi.org/10.3390/ma11081476

APA StyleKuang, D., Ye, Z., Yang, L., Liu, N., Lu, Z., & Chen, H. (2018). Effect of Rejuvenator Containing Dodecyl Benzene Sulfonic Acid (DBSA) on Physical Properties, Chemical Components, Colloidal Structure and Micro-Morphology of Aged Bitumen. Materials, 11(8), 1476. https://doi.org/10.3390/ma11081476