3.1. Orthogonal Experimental Analysis

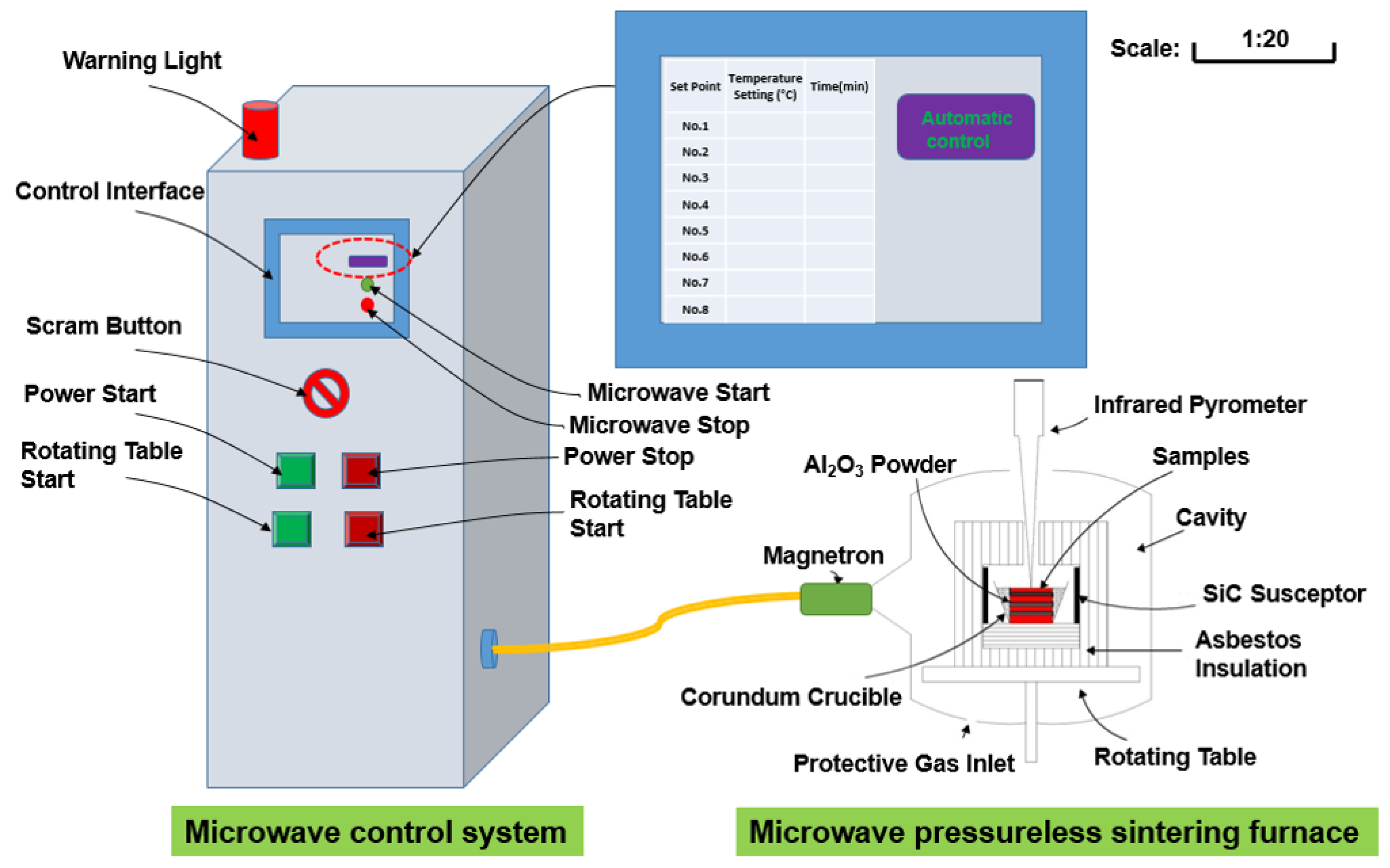

It is well known that the orthogonal design is a commonly used experimental design method. In this work, an orthogonal design was used to arrange experiments to study the effect of different MPS conditions on the sintering effect (

Table 2). The experimental results are showed in

Table 3 and

Table 4 and

Figure 2a,

Figure 3a,

Figure 4a and

Figure 5a. The rightmost three columns of

Table 2 are the value of the evaluation index, i.e., relative density, hardness, and flexural strength of the sintered samples. Through the range analysis of

Table 2 data,

Table 3 was obtained.

Table 3 was the range analysis of three evaluation indexes. In

Table 4,

Xet,

Yet, and

Zet is the sum of the relative density, hardness, and flexural strength of all orthogonal experimental results.

Xet/3,

Yet/3, and

Zet/3 are the average value of the

Xet,

Yet, and

Zet, with the meaning of the evaluation indexes value for level

i under factor

e (

e = A, B, C;

t = 1, 2, 3). When the factor is certain, the difference in these average values of

Xet,

Yet, and

Zet is indicated influence degree of the levels for factor

e (

e = A, B, C;

t = 1, 2, 3) on the relative density, hardness, and flexural strength of all orthogonal experimental results. Through range analysis of Equations (4)–(6), the range value

RX,

RY, and

RZ of

Xet,

Yet, and

Zet are obtained, as follows [

20]:

The effects of the three factors, namely,

A,

B,

C on the relative density, hardness, and flexural strength based on the range analysis are shown in

Figure 2,

Figure 3 and

Figure 4.

It can be seen from

Table 3 that the sintering temperature, the cold pressure, and holding time have the same influence trends on the density, hardness, and flexural strength of the sintered samples. In addition, the sintering temperature has a most obvious effect on the density, hardness, and flexural strength of the sintered sample and cold pressure is second, holding time has the minimal effect. Therefore, the sintering temperature is considered to be important factor affecting the performance of the sintered samples. Detailed analysis of the influence between mechanism performance and three sintering parameters are as follows.

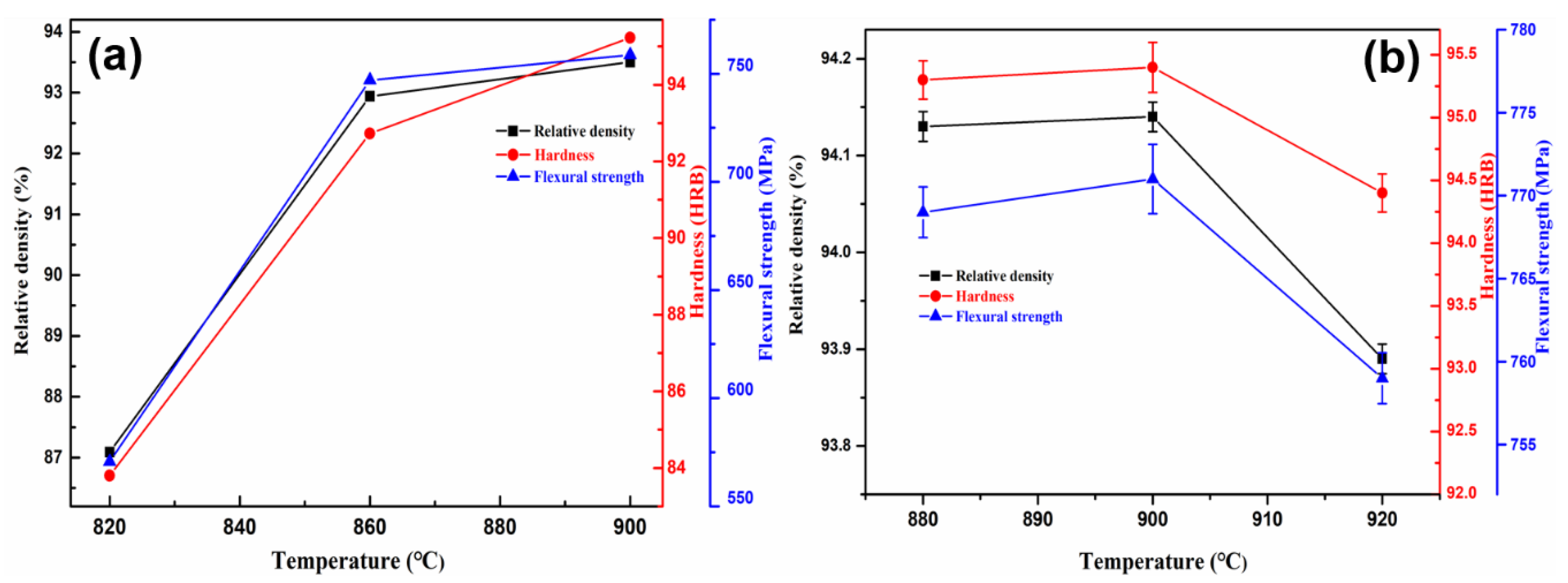

Firstly, the sintering temperature mainly enhances the mechanical properties of sintered samples by promoting the formation of liquid phases and internal alloying reactions in the sintered samples. It can be clearly seen in

Figure 2a and

Table 3 that the relative density, hardness, and flexural strength of the sintered Cu-based samples increase with the increase of sintering temperature. There may be two reasons account for this phenomena. On the one hand, low-melting Sn is a liquid phase element, melts into the gap between other particles under the action of the capillary force to form a bonding medium [

4]. On the other hand, it is an alloying reaction between elements, such as Cu and Sn, diffuses into each other to form an alloy [

18]. As the temperature increases, the amount of liquid phase gradually increases, and the pores in the matrix are continuously filled so that the porosity gradually decreases, and the mutual diffusion of copper and tin intensifies. Therefore, the mechanical properties of sintered samples are also gradually improved. It is further observed that the increasing tendency of mechanical properties is obvious in the sintering temperature range from 820 °C to 860 °C, namely the relative density, hardness, and flexural strength increased by 6.7%, 10.7%, and 23.6%, respectively. At the same time, a noteworthy phenomenon displays that the mechanical properties only increased by 0.6%, 2.7%, and 1.5%, respectively, once the temperature increased from 860 to 900 °C. The following reasons can be responsible for this changing trend. In the low sintering temperatures stage, only a little liquid phase and the low activity of the metallic powder particles are inadequate to trigger sufficient alloying reaction, resulting in an undesirable relative density and hardness of the sintered samples. Due to low flexural strength when the samples were sintered at low temperature, it may ascribe to the incomplete grain development because of slow grain growth and movement rate, in turn, the crack easily spreads along grain boundary in the measurement of fracture [

21]. As such, when the sintering temperature is moderately raised after the low-temperature stage, it can significantly increase the amount of liquid phase, enhance the alloying reaction, accelerate the migration rate of metallic elements, and finally improve the mechanical properties of sintered samples. However, excessive high sintering temperature leads to grain coarsening and a high grain boundary movement rate. When the motion rate of the grain boundary is faster than the rate of gaseous emission, it means that some pores will be surrounded by adjacent grains and resulting in a decline of hardness, relative density, and flexural strength. In addition, excessive sintering temperatures, especially exceeding 900 °C, will also give rise to the graphitization transformation of diamond phase. Therefore, it is critical to choose a suitable sintering temperature since both sintering efficiency and energy saving should be taken into consideration. Based on the above analysis, it may be reasonable to choose the temperature range of 860–900 °C for microwave sintering.

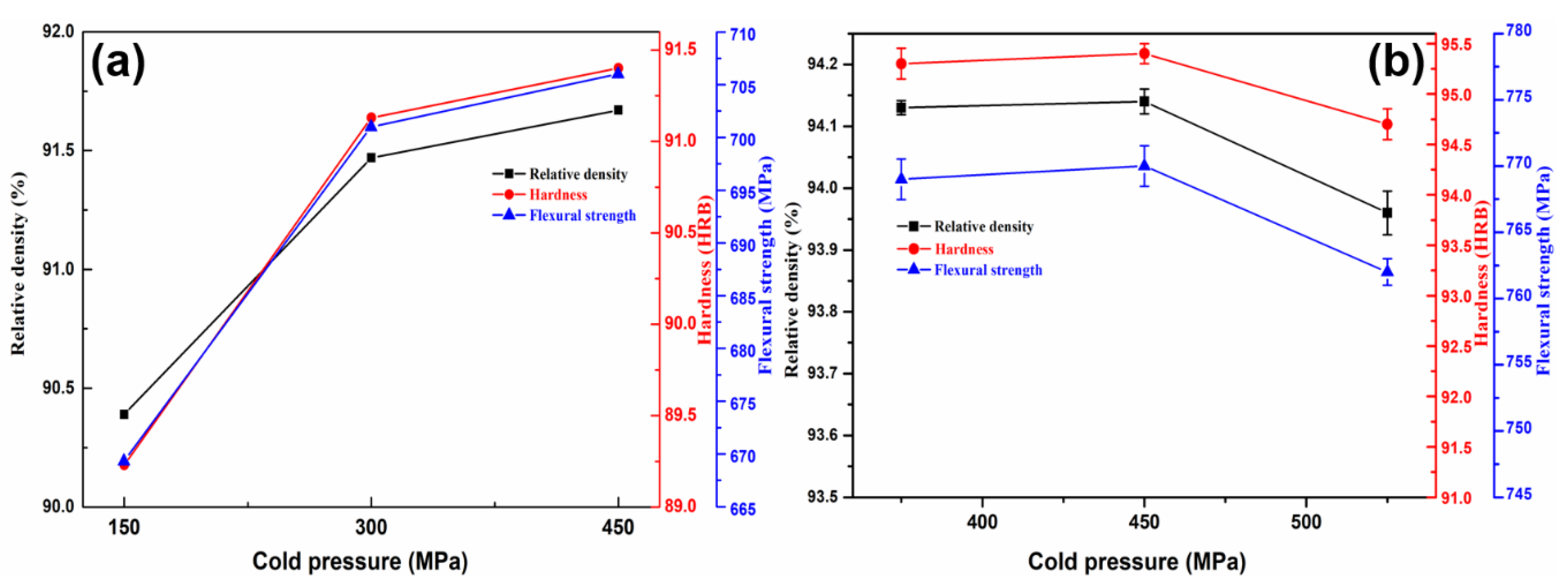

Secondly, similar to the effect of sintering temperature, the evaluation of relative density, hardness, and flexural strength with the change of cold pressure is performed and the experiment results are shown in

Figure 3a and

Table 3. It is observed that the value of relative density, hardness, and flexural strength increases by 1.2%, 2.1%, and 4.5%, respectively, with the increase of cold pressure from 150 to 300 MPa, whereas the corresponding indicators increase only 0.2%, 0.3%, and 0.7%, respectively, with the range of cold press from 300 to 450 MPa. It is deduced that the incompact green compacts with large pores are obtained by using small cold pressure, which results in the generated liquid phase is difficult to fill the big pores and finally degenerates the mechanical properties of the sintered samples. Then, as the pressure increases, the decrease of pores in green compact gradually and the increase of diffusion interface facilitate grain-to-grain diffusion and more complete alloying reaction due to the grain boundary moves sufficiently [

21,

22]. Therefore, the relative density, hardness, and flexural strength are significantly increased. However, the excessive cold pressure causes the decrease in porosity in the compact, which will hinder the penetrability of microwave radiation and decrease sintering efficiency [

23]. According to the above analysis, the desired cold pressure should be in the range of 300–450 MPa.

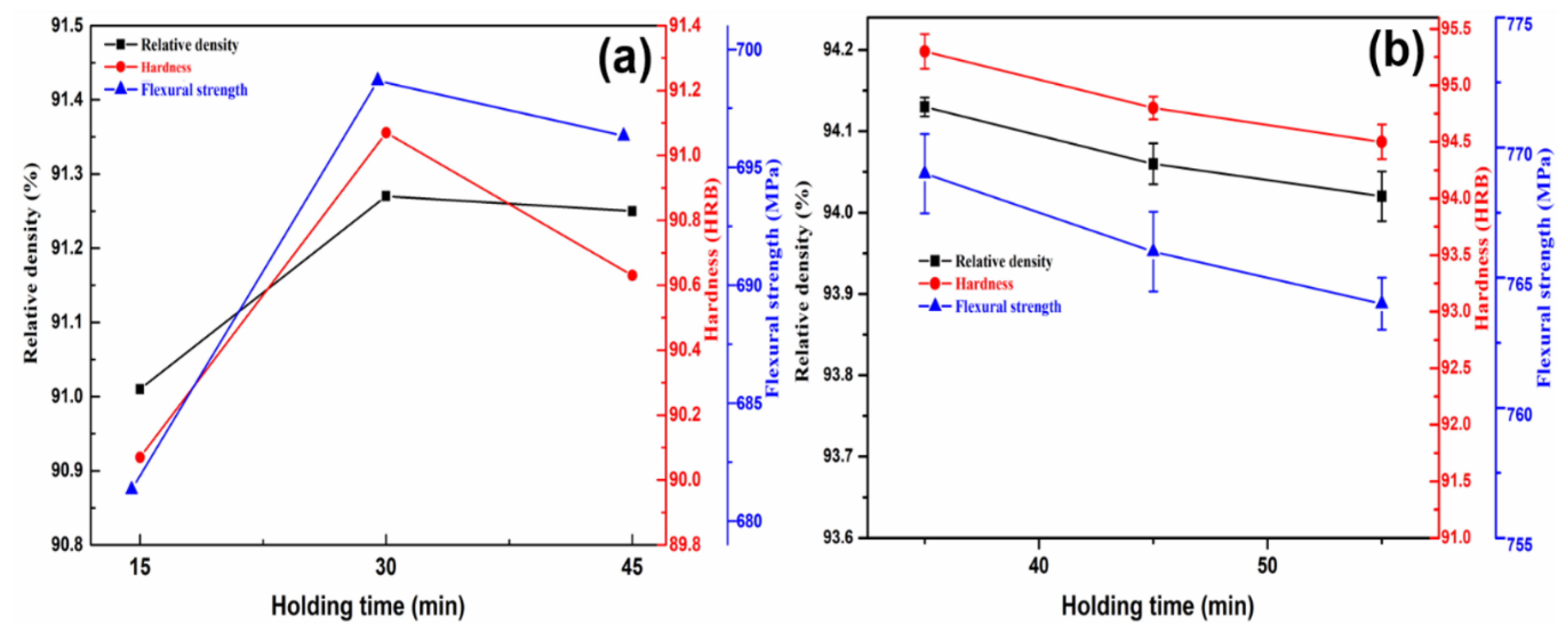

Thirdly, the holding time has less effect on the relative density, hardness, and flexural strength of the sintered samples. This may ascribe to the unique advantage of microwave heating in the sintering process, that is, the alloying reaction can be completed in a short sintering time and obtain good mechanical properties. This interpretation is verified in

Figure 4a and

Table 3, and it can be seen that the relative density, hardness, and bending strength are not significantly increased with the increase of the holding time from 15 min to 30 min. However, the continuous increase in holding time will decrease the relative density, hardness, and flexural strength of the samples. The main reason is that the extension of holding time may cause the crystal grains to grow abnormally. At the same time, the elements with a low fusion point will volatilize to generate holes, resulting in the deterioration of relative density, hardness, and flexural strength. Therefore, the desired holding time should be in the range of 30–45 min.

According to the above comprehensive consideration, the suitable sintering process parameters, such as sintering temperature, cold pressure, and holding time is identified as 860–900 °C, 300–450 MPa, and 30–45 min, respectively. Further, in order to deter mine the appropriate sintering conditions, conditional experiments were carried out on the basis of orthogonal experiments. The results are shown in

Figure 2b,

Figure 3b and

Figure 4b. Looking into the sintering temperature effect (35 min, 375 MPa, 880 to 920 °C), the relative density, hardness, and flexural strength of the sintered samples slightly decrease with temperature increase than decline (

Figure 2b). This is as mentioned above, i.e., excessive high sintering temperature lead to grain coarsening and high grain boundary movement rate. When the motion rate of the grain boundary is faster than the rate of gaseous emission, it means that some pores will be surrounded by adjacent grains and resulting in a decline of hardness, relative density, and flexural strength. In addition, we suspect that there is a balance between gas discharge and grain boundary movement. The grain boundary moving rate increases as the sintering temperature increases, but it also increases the probability that the grain boundary prevents gas from being discharged. However, this does not mean that the relative density, hardness, and flexural strength of the samples are reduced, and only when the gas gas discharges is severely hindered. Therefore, the relative density, hardness, and flexural strength of the samples from 880–900 °C are increased. The effect of the cold pressure (35 min, 880 °C) clearly indicates that the relative density, hardness, and flexural strength of the sintered samples slightly decrease with cold pressure increase than decline (

Figure 3b). The experimental results are shown in

Figure 3b are consistent with those that are analyzed above for

Figure 3a. However, when the cold pressure exceeds 450 MPa, the relative density, hardness, and flexural strength of the samples are declined. This may be due to the excessive cold pressure causes the decrease of porosity in the compact, which will hinder the penetrability of microwave radiation and decrease sintering efficiency. The effect of the holding time (375 MPa, 880 °C) reveals that the relative density, hardness, and flexural strength of the samples are in decline with an increase in holding time (

Figure 4b). The experimental results are consistent with

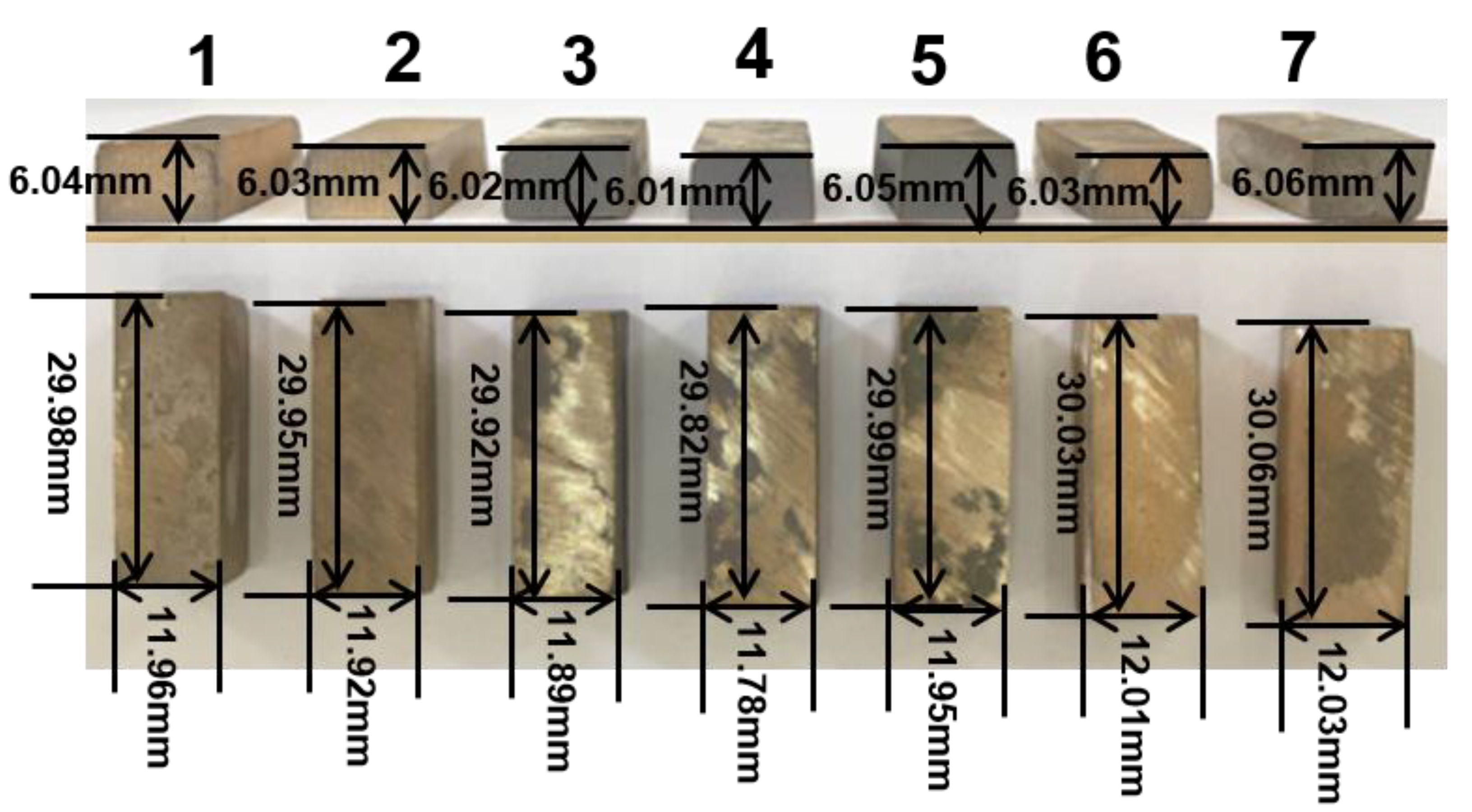

Figure 4a. In addition, the samples size after sintering was measured as shown in

Figure 5.

Figure 5 shows that the regular samples can be obtained under the set microwave pressureless sintering conditions. The green compact shrinks to near standard size (30 mm × 12 mm × 6 mm) after microwave pressureless sintering. However, the sintered samples have slightly different sizes under different sintering conditions. It should be noted that the shrinkage process and the densification process of the sample are consistent. Intuitively, denser samples may have better mechanical properties, and the results that are shown in

Figure 5 coincide with the results shown in

Figure 2b,

Figure 3b and

Figure 4b.

In summary, when the sintering temperature and cold pressure were increased from 880 to 900 °C, 375 to 450 MPa, the relative density, hardness, and flexural strength of the samples are slightly increased. The relative density, hardness, and flexural strength of the samples are increased when the holding time exceeds 35 min. Based on energy saving considerations, we believe that the MPS conditions chosen should be 880 °C, 375 MPa, 35 min.

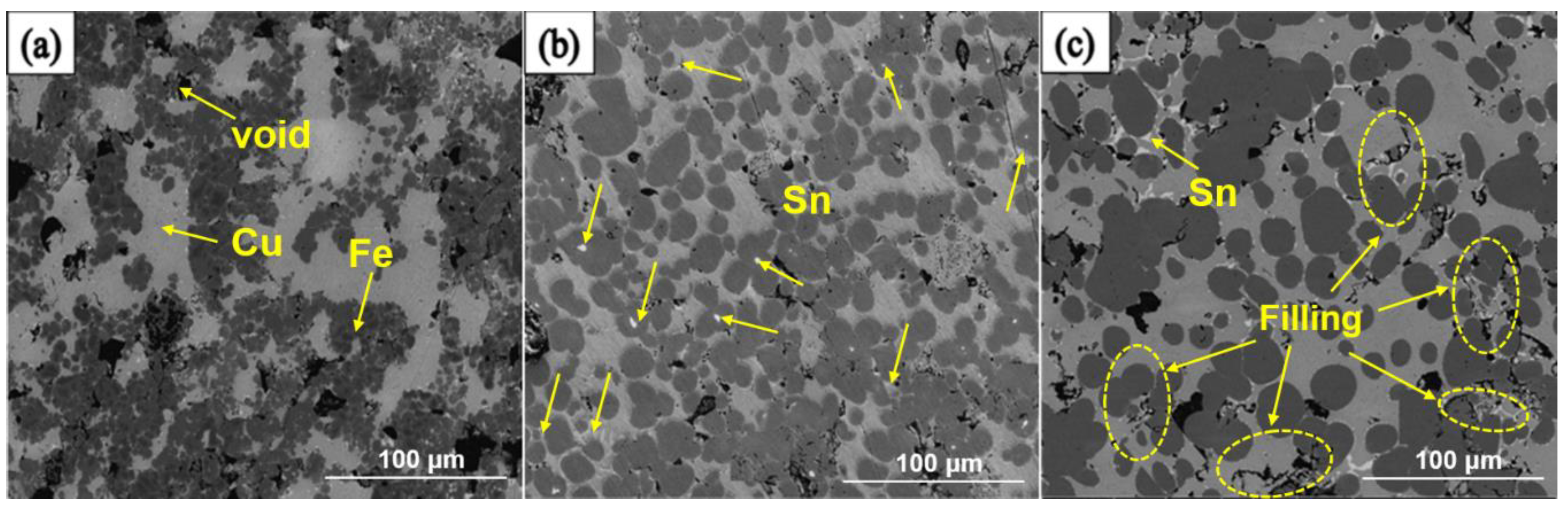

Based on the above analysis, it can be noticed that the sintering temperature in the MPS method is an uppermost factor to affect the quality of the sintered samples. In order to further reveal the effect of sintering temperature on mechanical properties, the microstructure of samples are tested and the results are shown in

Figure 6 and

Figure 7. SEM was adopted to confirm the microtopography of sintered Cu-based matrix samples at different sintering temperature and the results were shown in

Figure 6. According to our previous work [

4], it is confirmed that the region of gray, dark gray, and white in

Figure 6 represent Cu-rich phase, Fe-rich phase, and Sn-rich phase, respectively, and the area of dark black stands for the pore.

Figure 6a displays the inhomogeneous distribution of the particles when the samples sintered at 820 °C. Many large-sized holes exist and the aggregated behavior of Fe-rich and Cu-rich phase can be observed. With the increase of sintering temperature up to 860 °C, as shown in

Figure 6b, the amount of voids is reduced and the Fe-rich phase in the alloy matrix diffuses into the Cu-rich phase to achieve an overall uniform distribution. This may be derived from a fact that the excellent migration efficiency of metallic elements and liquid phase rearrangement behavior in the matrix with the increase of sintering temperature. As the sintering temperature increases up to 900 °C, as manifested in

Figure 6c, it is observed that the evident growth of pores and grains. This is mainly because the formation of adequate amounts of the liquid phase at high temperature facilitates the continuous dissolution of metallic powder particles, which leads to recrystallization and abnormal grain growth. Furthermore, the emergence of holes results from the loss of the low melting point element at high temperature. It is worth mentioning that the evolution regularity of microstructure with the change of sintering temperature can account for the results of mechanism performance in

Table 4 and

Figure 2.

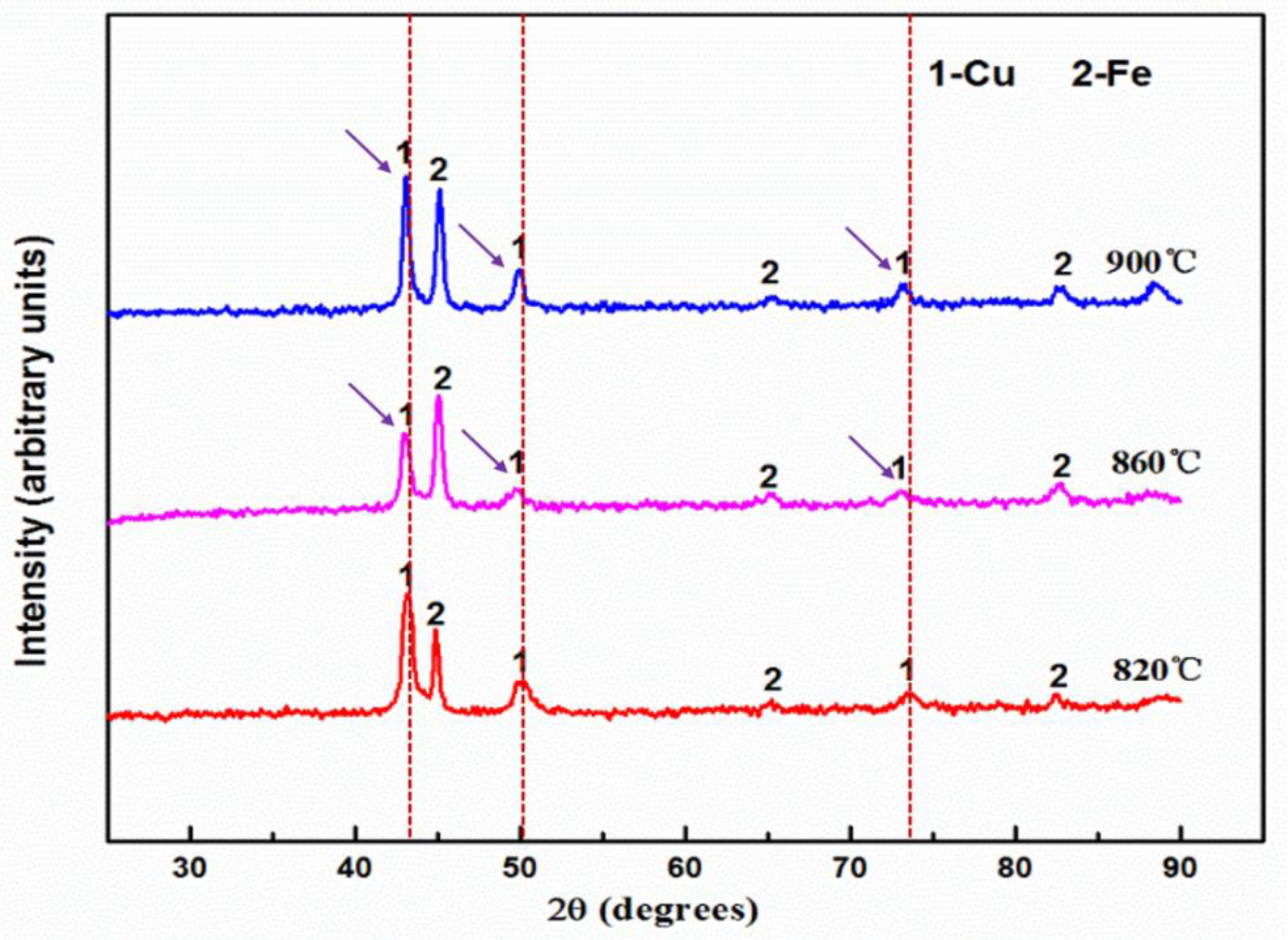

In order to investigate the migration behavior of main metallic elements with the sintering temperature, XRD test of sample sintered at different temperatures was performed and the results were shown in

Figure 7. It is observed that the slightly blue shift for the characteristic diffraction peak of Cu with the increase of sintering temperature, meanwhile the intensity of the Cu characteristic peak rises after an initial decline. The strong intensity of the diffraction peak at 820 °C may attribute to the accumulation of copper and the incorporation of other elements in the copper lattice at low sintering temperatures [

24,

25]. With the increase of sintering temperature up to 860 °C, the appearances of blue shift and intensity reduction of the Cu diffraction peak should be ascribed to liquid phase Sn elements enter Cu lattice and then cause lattice distortion. As to the rising tendency of Cu diffraction peak intensity at 900 °C, it is indicating that the copper component diffuses and accumulates at high temperatures, which is also related to the evolution of microstructure in

Figure 6.

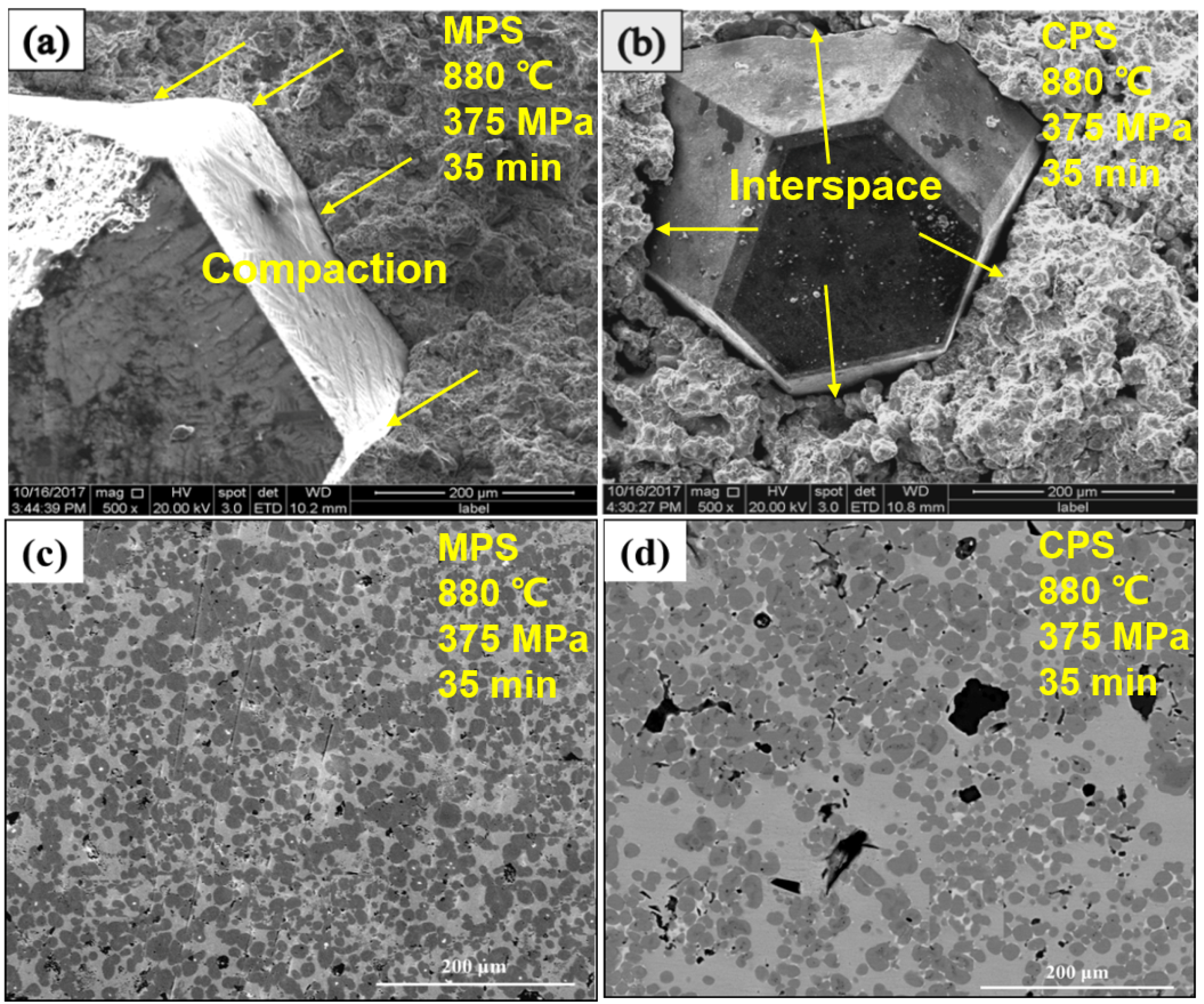

3.2. Comparison of Microwave and Conventional Sintering

To further contrast the discrepancy of sintering method by microwave and conventional heating, the same process condition, i.e., the optimum MPS process parameter 880 °C/375 MPa/35 min, is selected for MPS and CPS, respectively. In addition, an attempt to prepare the diamond-containing (mass percentage, 3%) Cu-based metal matrix by MPS and CPS is also performed under the above sintering process condition, and the experimental results are shown in

Table 4 and

Figure 8,

Figure 9 and

Figure 10. From

Table 4, the average relative density of microwave sintered samples is 94.12%, which is 1.23% higher than that of conventional sintering. It shows a better densification degree of microwave sintered samples under the same process conditions. At the same time, compared to conventional sintering, the hardness, flexural strength-N (no addition of diamond abrasive), flexural strength-C (containing diamond abrasive) and holding force coefficient of microwave sintered samples also increased by 3.72%, 5.91%, 9.99%, and 4.35%, respectively.

Figure 8a,b are the fracture morphology of the sample after MPS and CPS. It can be clearly seen that the sample has fewer fracture pores by MPS, and the sample after CPS has more holes. At the same time, it can be found that the diamond abrasives tightly bound to the metal matrix by the MPS method, whereas there is a large gap between the diamond and matrix by the CPS method, which means that the holding force coefficient of samples by microwave sintering is obviously more excellent than that of conventional sintering. From

Figure 8c,d, the samples that are sintered by MPS have more uniform microstructure, smaller porosity, and fine crystal grain size. In summary, the mechanical properties of sintered samples that were prepared by the MPS method are significantly better than the CPS method. For this reason, we attempt to explain these phenomena from element diffusion and alloying reactions and EPMA spectra results of samples sintered by MPS are shown in

Figure 9 and

Figure 10. As manifested in

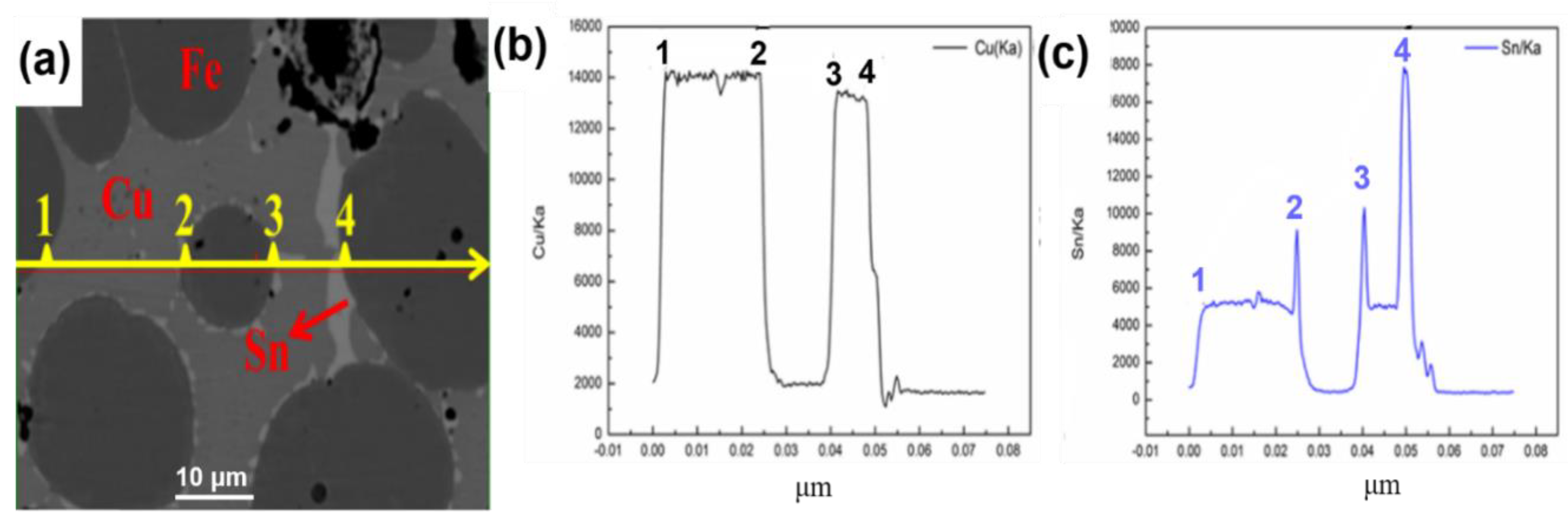

Figure 9a, the light gray area represents Cu-rich phase, the dark gray represents Fe-rich phase, the red arrow indicates Sn-rich phase, and the yellow arrow indicates the direction of line scanning.

Figure 9b,c are the changes of the Cu and Sn elements in the substrate along the sweep direction, respectively. It can be observed that the content of Cu and Sn increases rapidly in the scan region from point 1 to point 2. The signal of Cu and Sn disappear when the scan region from point 2 to point 3. It is worth mentioning that strong the signal intensity of Sn emerged in point 2, 3, and 4, which means that the Sn element accumulates around the Fe-rich phase as a liquid filling phase in the process of sintering. As a consequence, in the area of Cu-rich phase, there is a similar change trend for Cu and Sn elements, which indicates the sufficient alloying reaction of Cu and Sn to produce the Cu-Sn alloy or solid solution phase. In addition, Sn phase is enriched at the binding boundary between Fe-rich phase and Cu-rich phase to act as a binder to improve the mechanical properties of the metallic matrix. To further investigate the situation of metallic element distribution, EPMA mapping analysis is adopted and the results are shown in

Figure 10. As figuratively displayed in

Figure 10b,c, the distribution of Cu and Sn elements in the matrix is obtained, and the color depth in the graph indicates the concentration of corresponding elemental distribution. It is found that the Sn elements aggregate in the interface of Cu-Fe, while it uniformly distributes in the Cu-rich phase. The main reason is that Cu and Sn generate a part of a Cu-Sn liquid phase in the sintered body, and the Cu-Sn liquid phase first wets the surface of Fe skeleton at a sintering temperature of 880 °C [

18,

26]. In addition, the inefficient diffusion rate of Cu-Sn liquid phase in the iron skeleton and high diffusion rate of Sn to Fe-rich phase, which results in the diffusion of Sn liquid phase into the sintering necks between Fe and Cu grains. Therefore, abundant Sn phase distributes around the neck. It is precisely due to the diffusion of Cu-Sn liquid phase that the pores are continuously filled, meanwhile, the mechanical properties of the sintered sample are improved due to the reinforcing effect of Cu-Sn alloy between the different particles.

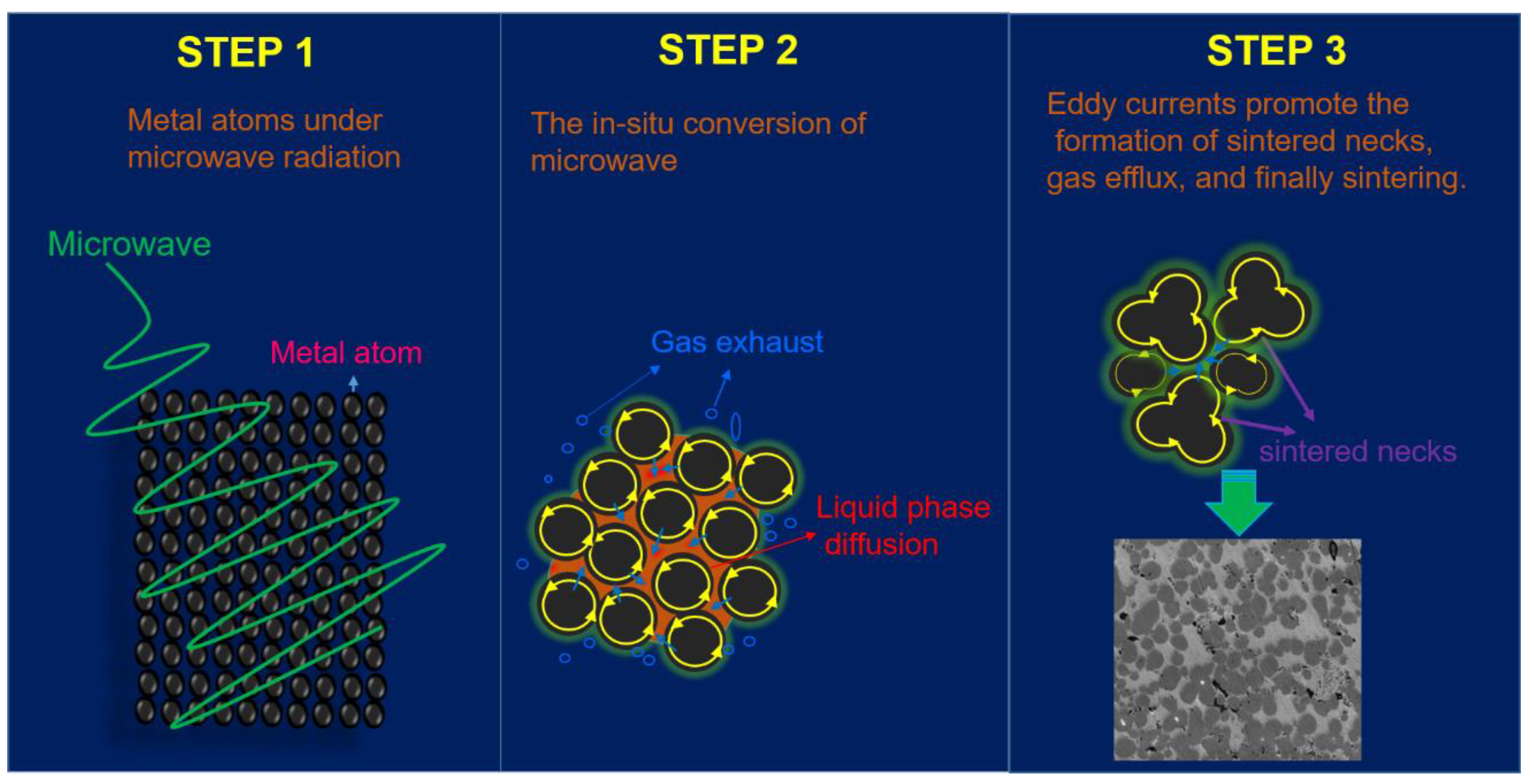

3.3. The Possible Mechanism of Microwave Pressureless Sintering

According to the above discussion, the Cu-based metal matrix was successfully prepared by MPS and the quality of samples that were sintered by MPS and CPS methods were comparatively evaluated. It was found that the mechanical properties of samples sintered by the MPS method were significantly better than those of the CPS method. The diversity of mechanical properties may stem from the different heating principles of microwave and conventional sintering. In the absence of pressure, for conventional sintering processes, the metal block absorbs thermal energy through the convection and conduction modes of the heat source, usually some high resistance heating elements [

9]. Densification of sintered samples is accomplished by the diffusion of liquid phase elements and alloying reactions. However, the temperature gradient from the outside to the inside that is generated by the conventional heating method may hinder the discharge of gas inside the sintered body [

13,

17]. Obviously, this is very detrimental to the diffusion of elements, and thus affects the quality of sintered samples. Unlike conventional heating, the microwaves start heating from the inside of the material, and the resulting temperature gradient is consistent with the direction of gas discharge, which facilitates the densification of the sintered sample and the formation of a uniform microstructure. In addition, metal atoms may directly absorb microwave energy and be converted to activate sintering, which facilitates alloying reactions. This is consistent with the analysis of

Figure 5,

Figure 6,

Figure 7,

Figure 8 and

Figure 9. Therefore, we proposed the possible MPS mechanism that is shown in

Figure 11. It is generally believed that the microwave heating of metals can be simply divided into two processes, the formation of the sintering neck before and after [

27,

28,

29]. During the early stage of MPS, the green compactors have a certain void that can receive microwave radiation and be heated. The microwave energy is absorbed by metal powders and the behavior of in situ energy conversion will increase the activity of metal atoms, in turn, facilitate the diffusion of elements and alloying reactions [

24,

30]. In addition, the magnetic permeability loss mechanism of metal particles may also have a similar effect [

9]. The appearance of sintering neck is accompanied by the formation of a liquid phase, and the liquid phase element diffuses to fill the internal pores. For diamond-containing sintered samples, the liquid phase elements also bond tightly with the diamond to enhance the diamond holding ability in the matrix. As the previous analysis, the temperature is the main factor in the process of sintering and high temperatures can promote the formation of liquid phase elements. Demirskyi et al. found that the liquid phase appeared around tungsten carbide sintering neck at the sintering temperature of 950 °C in the microwave field in spite of the temperature were far lower than the melting temperature of WC [

27]. It means that microwave sintering can form a local liquid phase at low temperature, and then the diffusion and migration of liquid phase elements will promote the holding force of diamond abrasives in metallic matrix due to the filling effect. This may be one reason to account for the results of

Figure 8. In addition, SiC assisted heating is required to provide thermal energy with the gradual densification of green compacts because of the weak penetrability of microwave radiation in quasi-bulk metal.

Through the above analysis and our previous work, we have reason to believe that the unique heating mode of microwaves is conducive to the rapid shrinkage of microstructures and the reduction of porous defects to enhance the mechanical properties of the sintered samples.