Evaluation of Residual Compressive Strength and Behavior of Corrosion-Damaged Carbon Steel Tubular Members

Abstract

:1. Introduction

2. Compressive Test Conditions

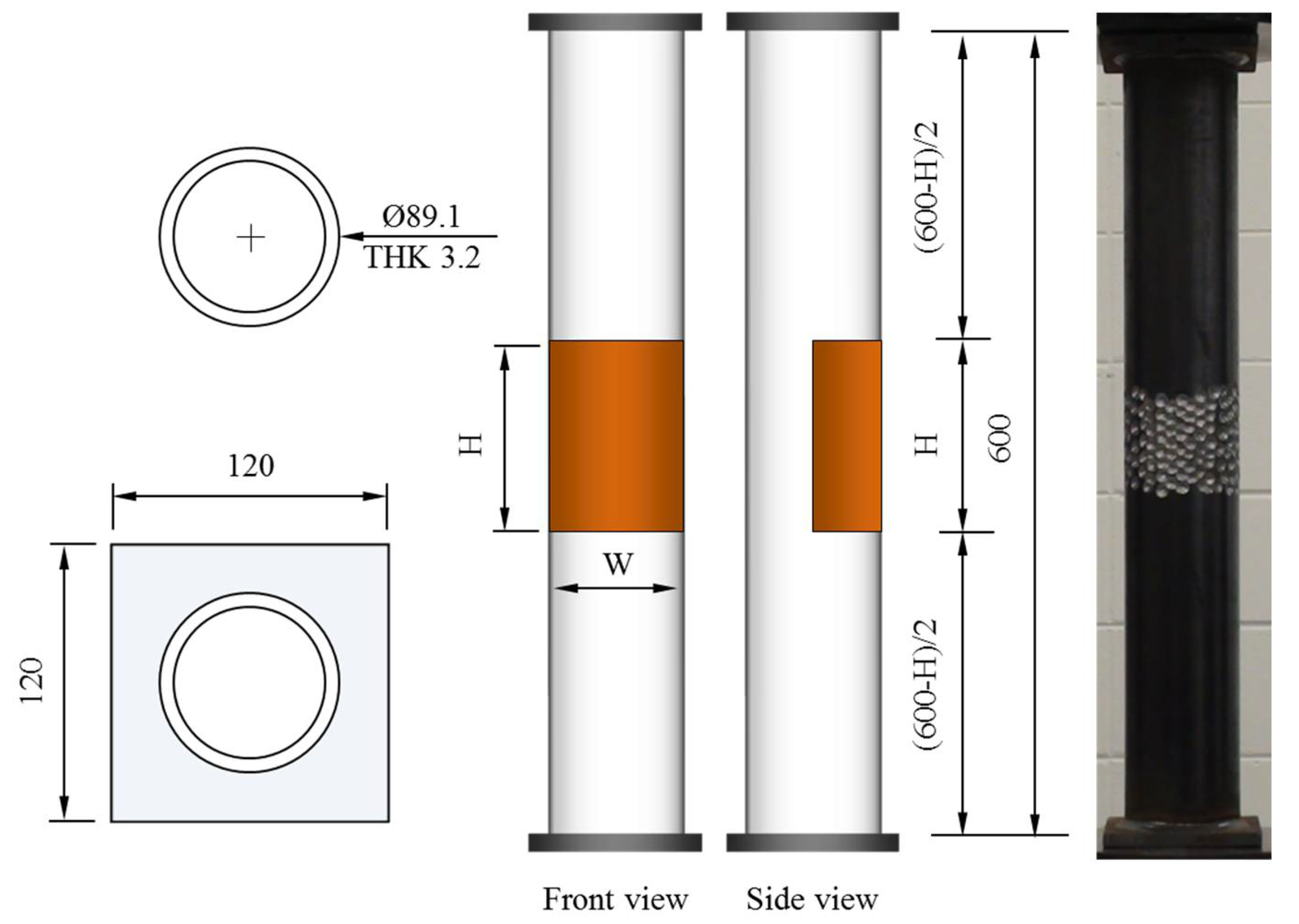

2.1. Localized Cross–Sectional Damaged Tubular Specimens

2.2. Loading Test Conditions

3. Test Result Evaluation

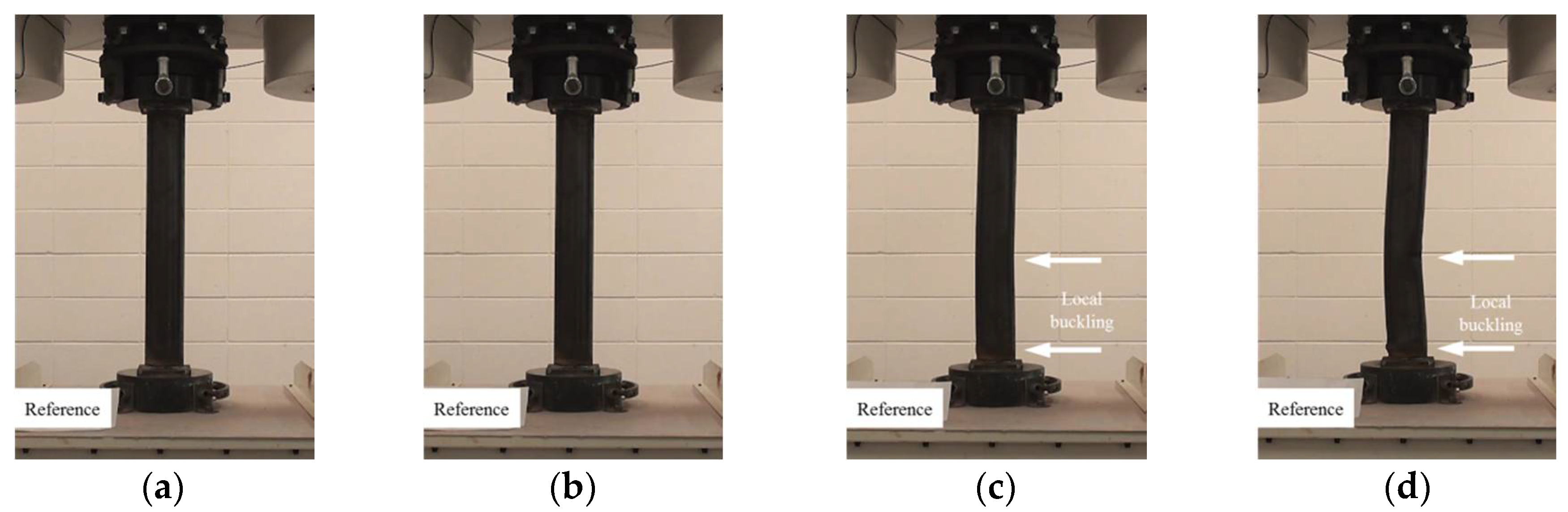

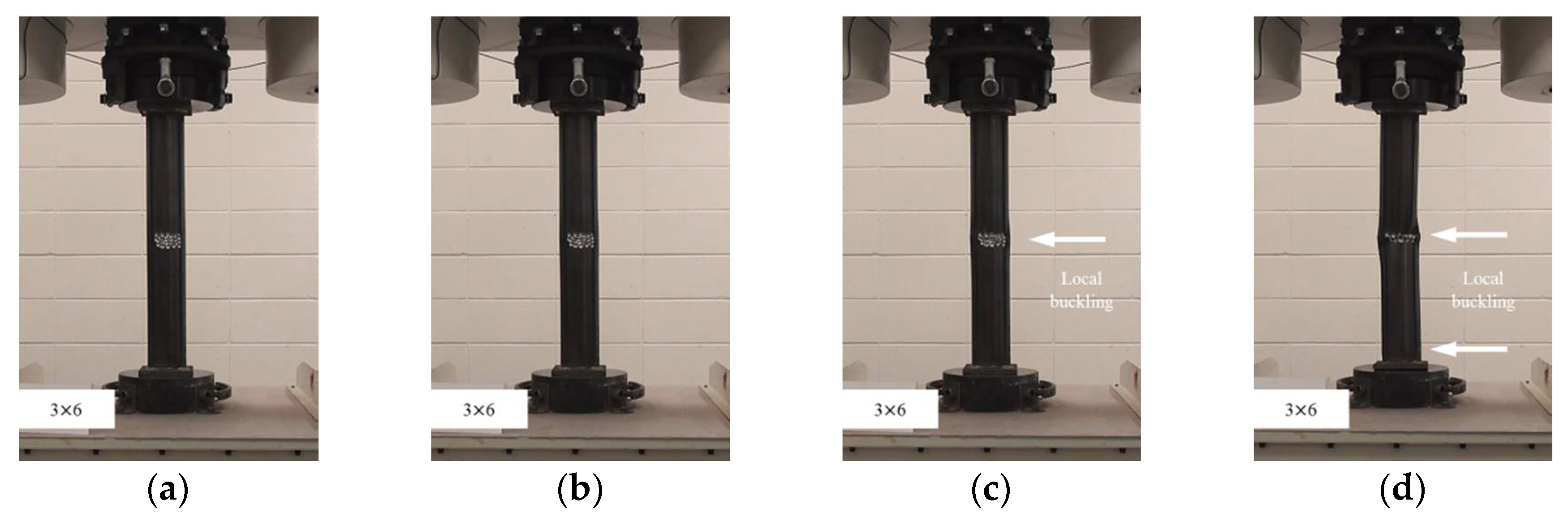

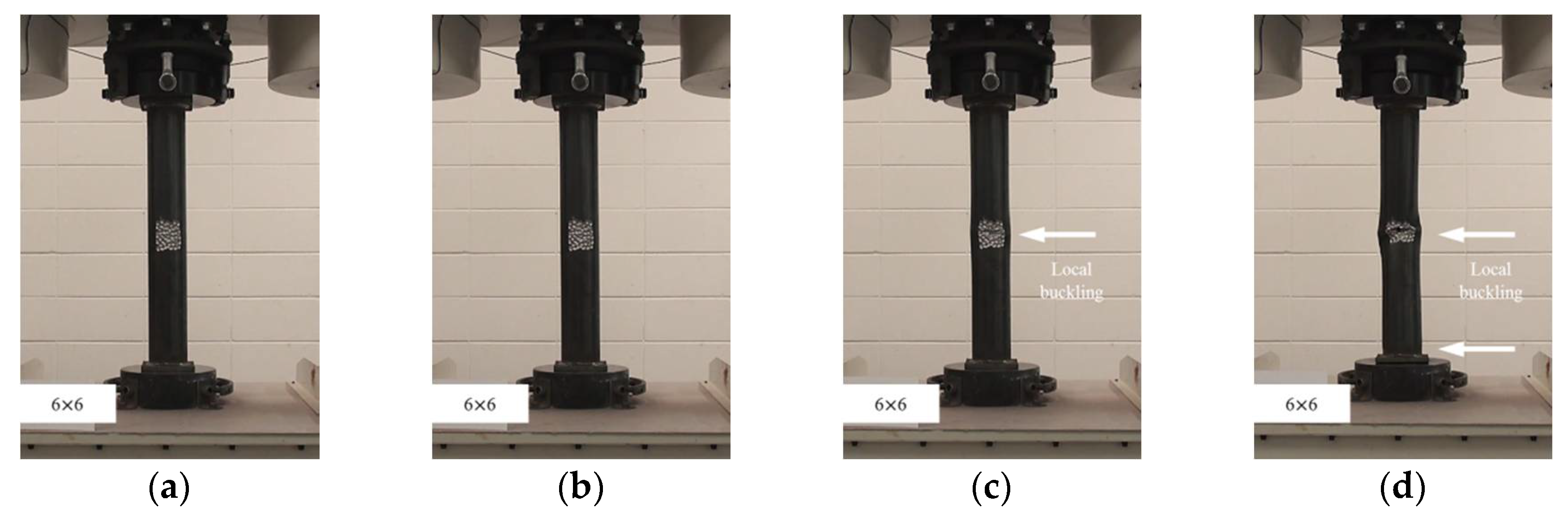

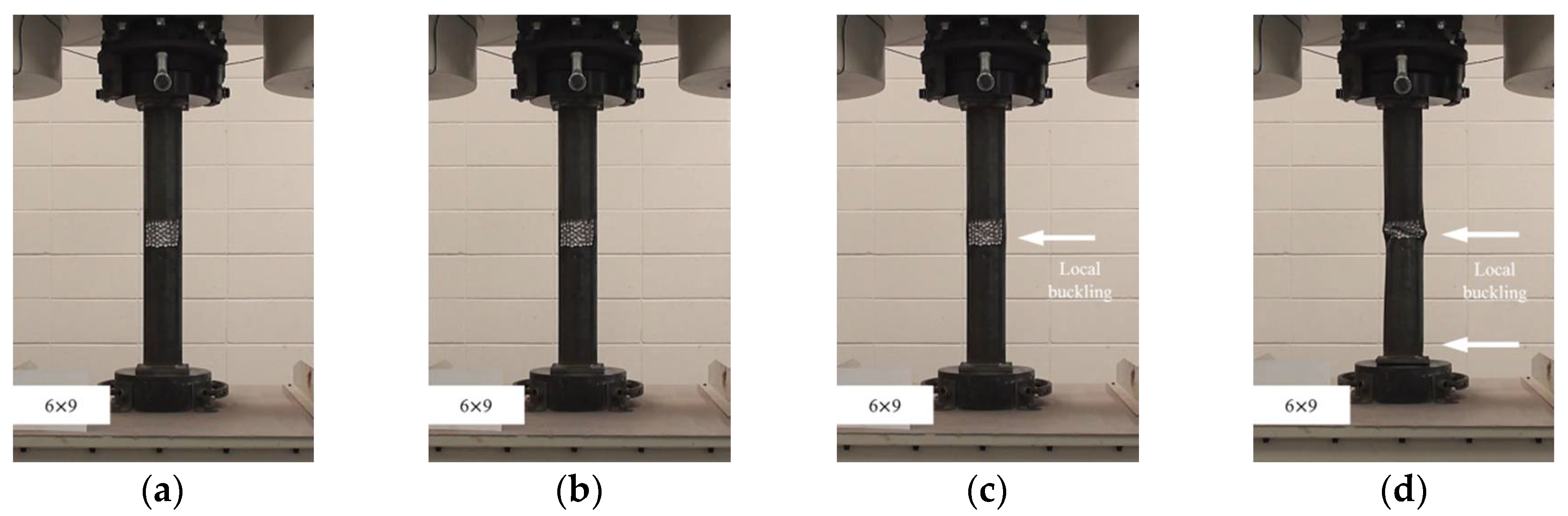

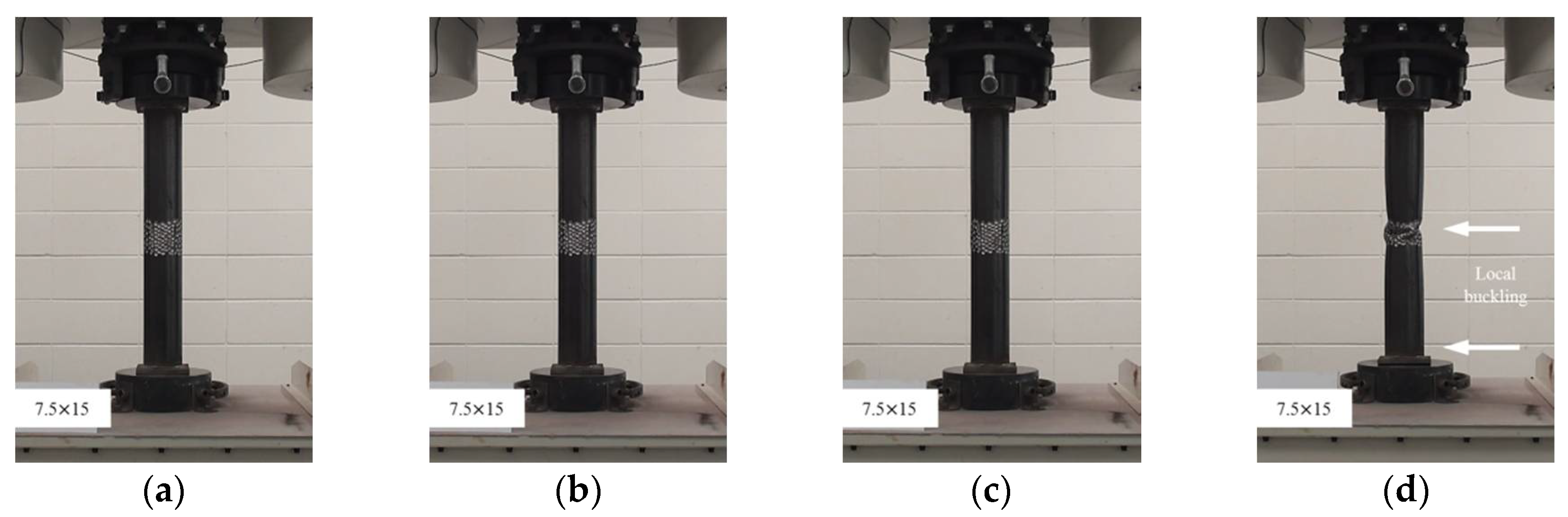

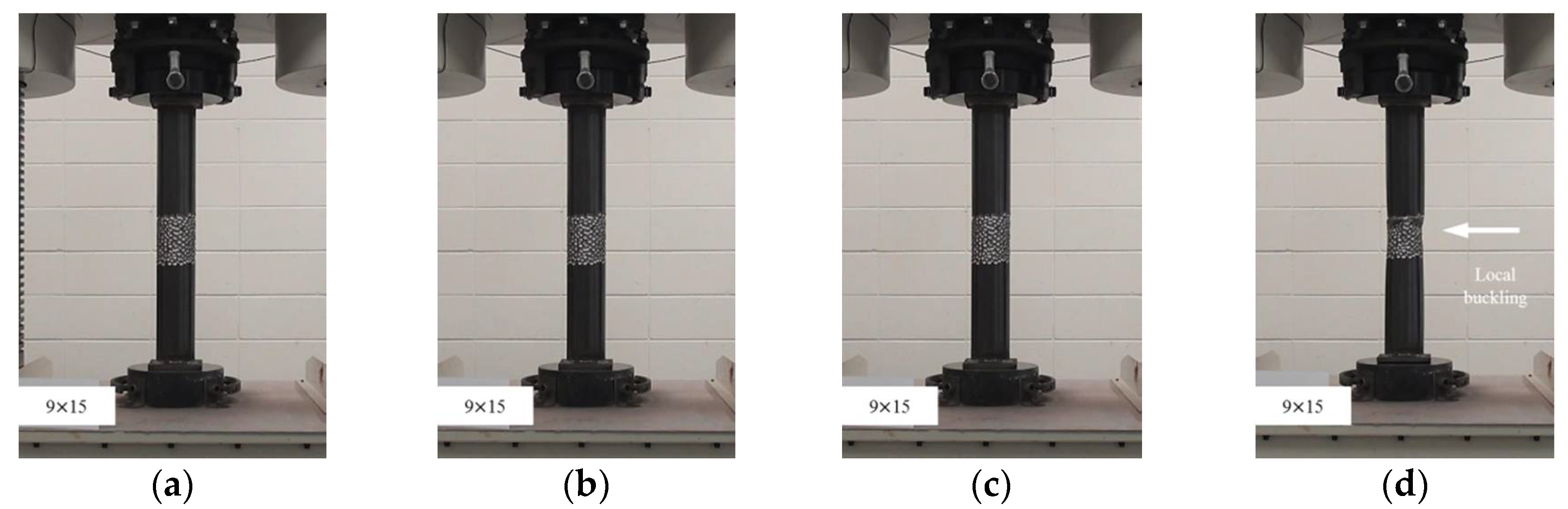

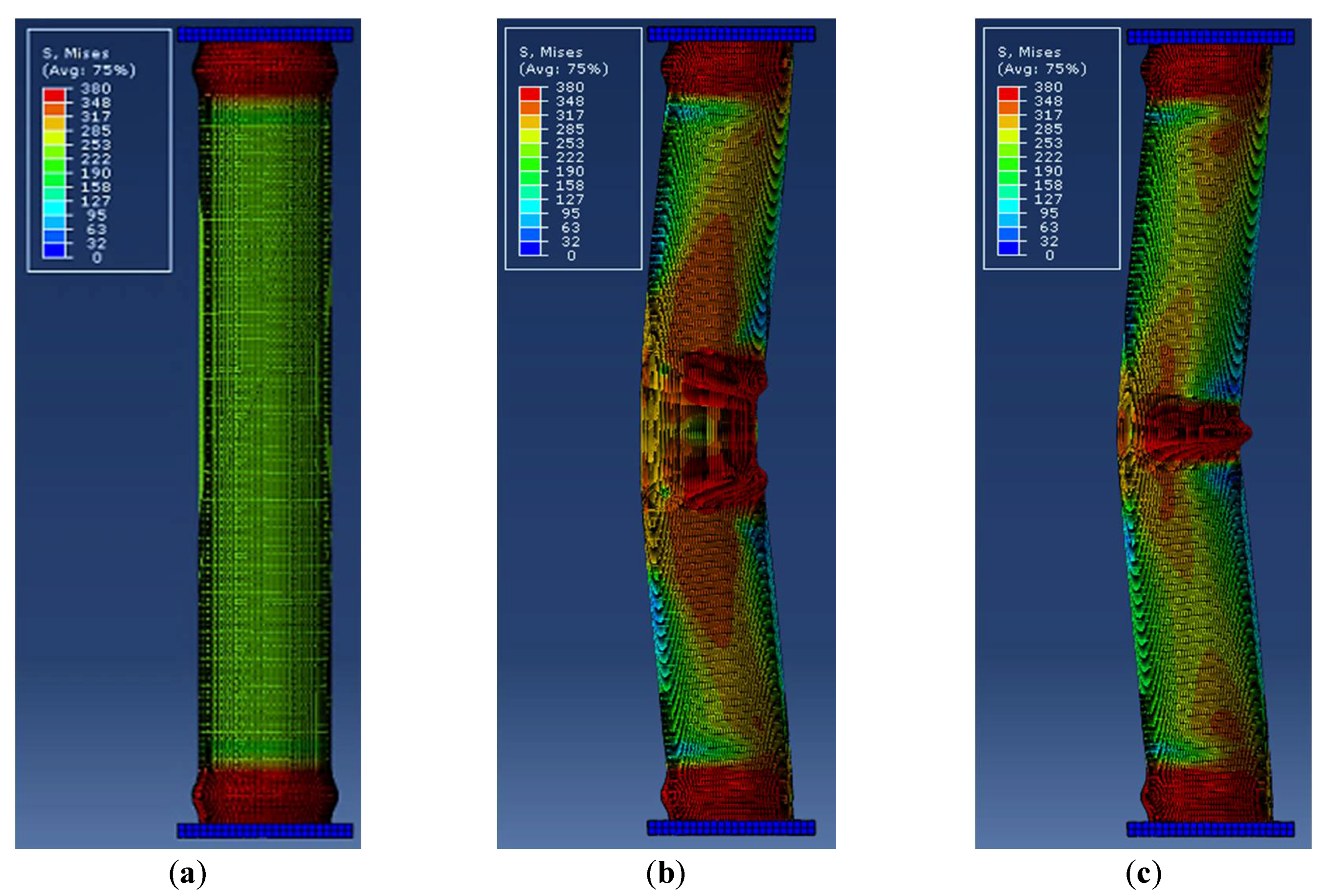

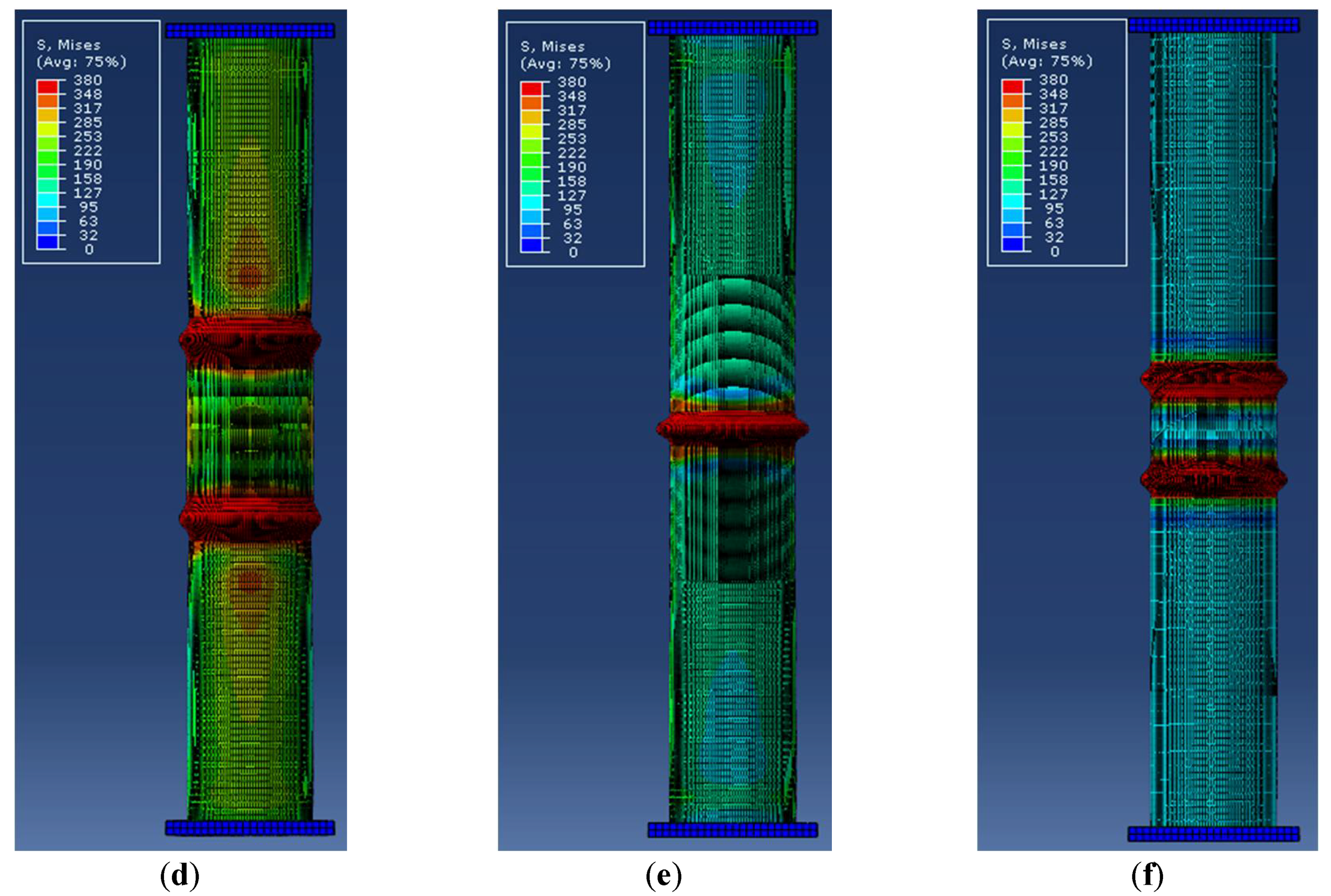

3.1. Failure Modes

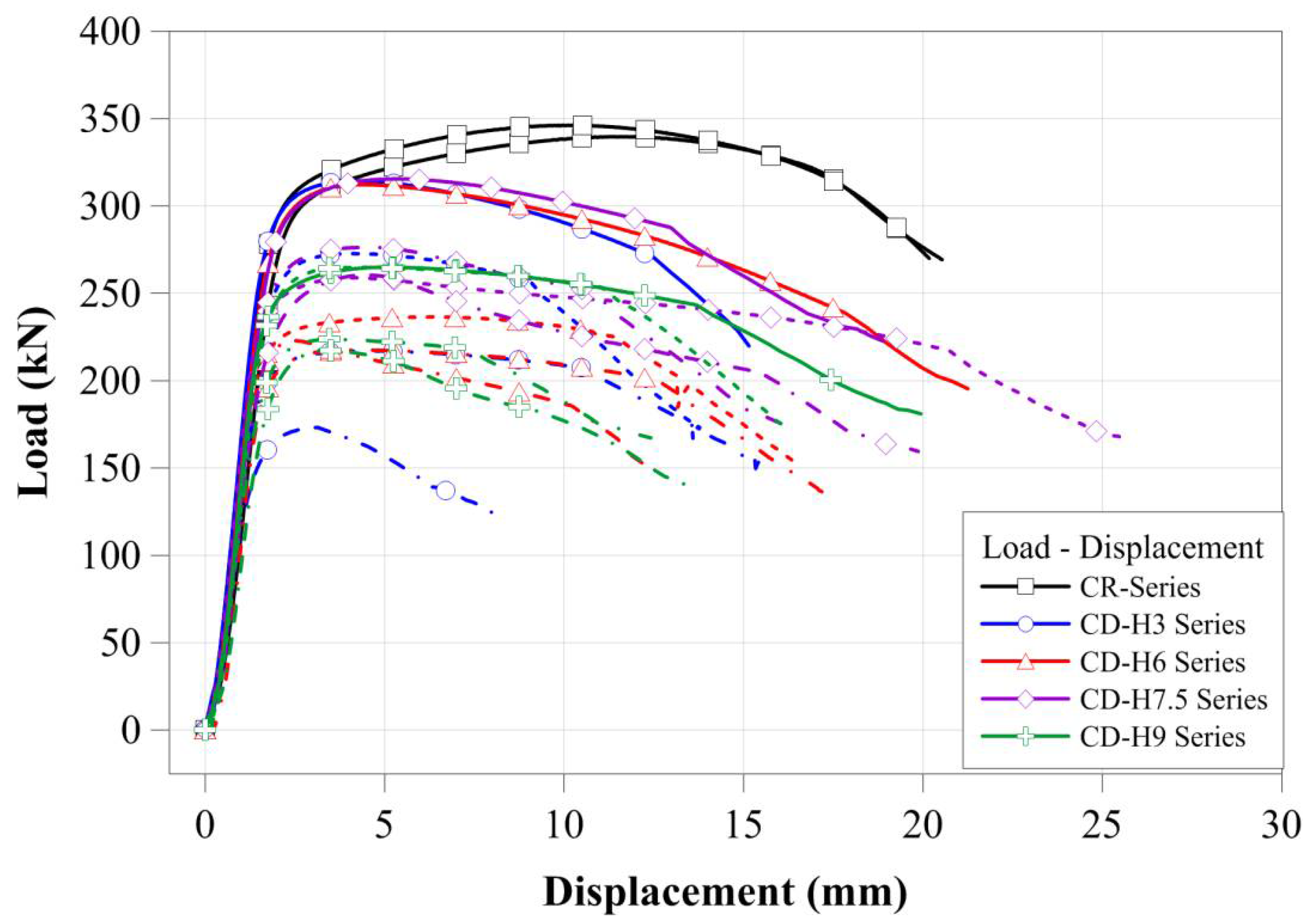

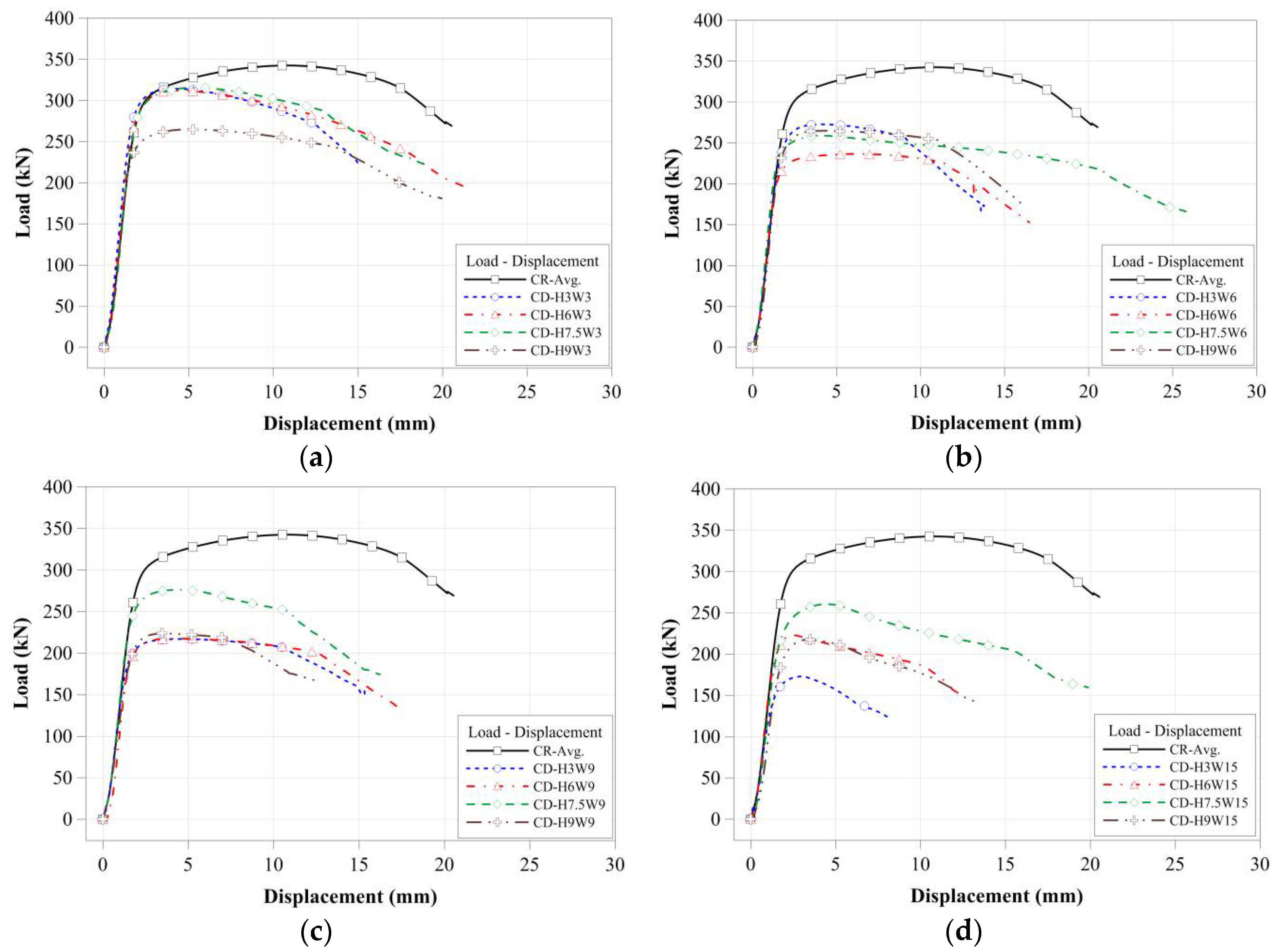

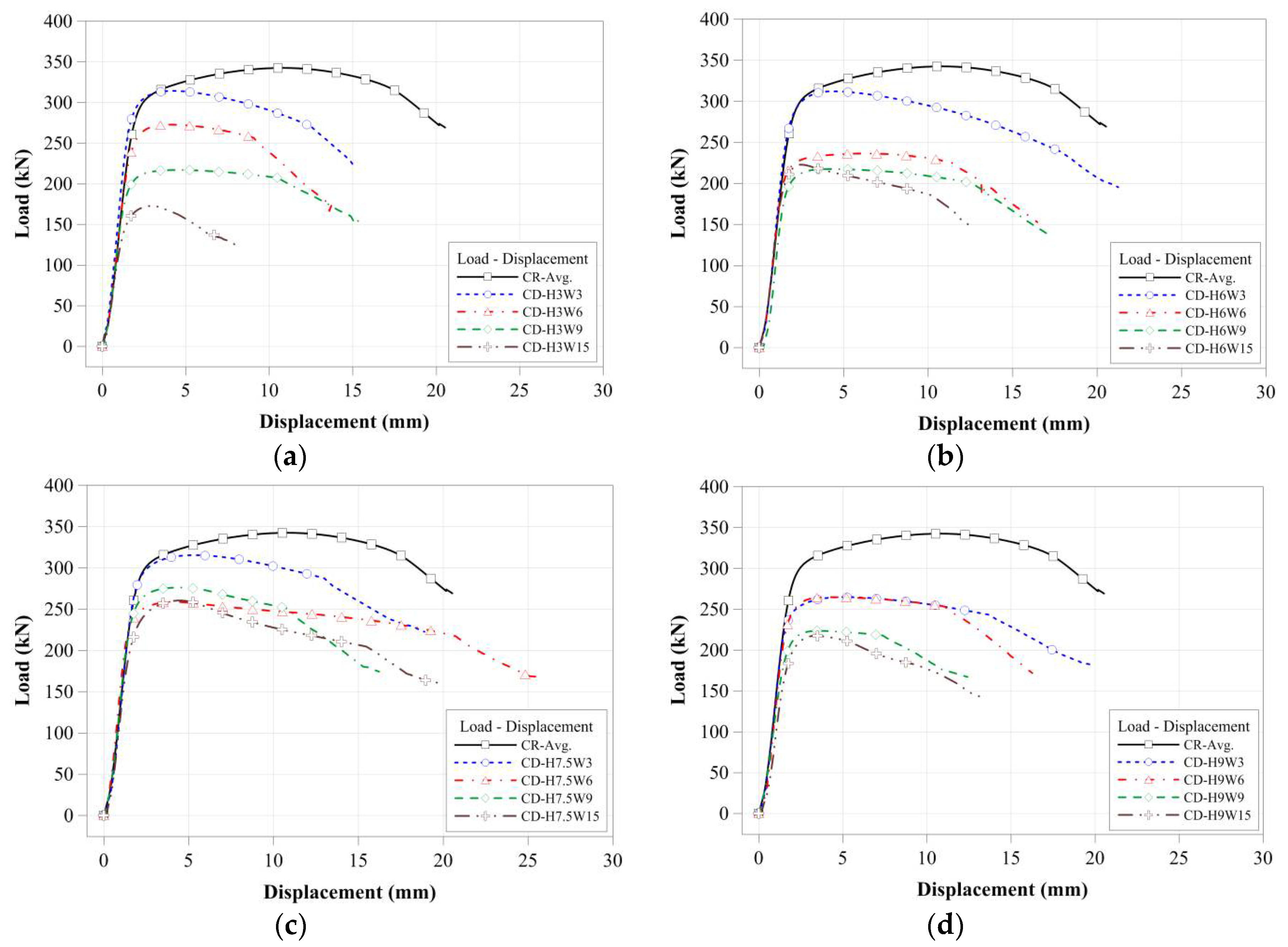

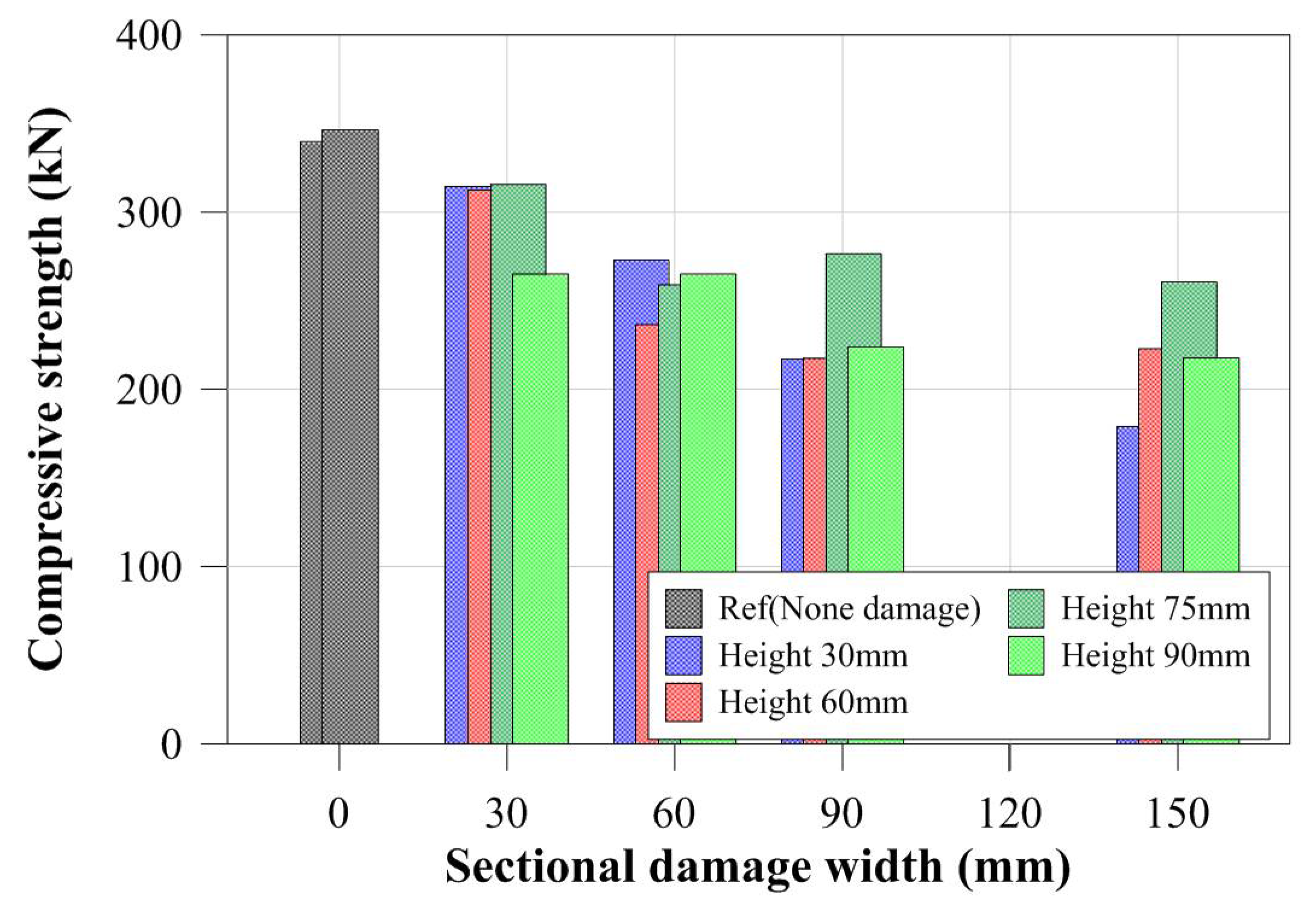

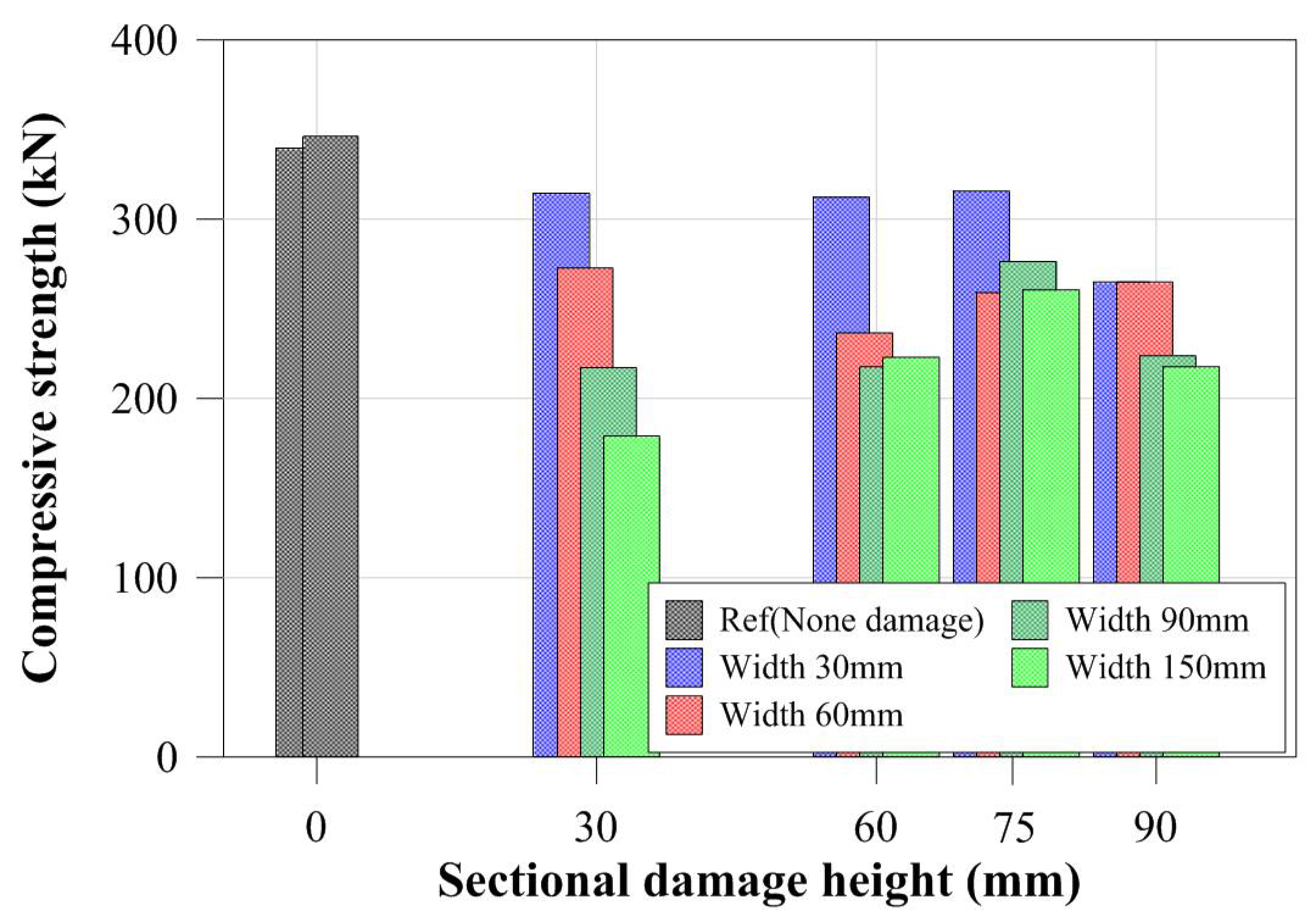

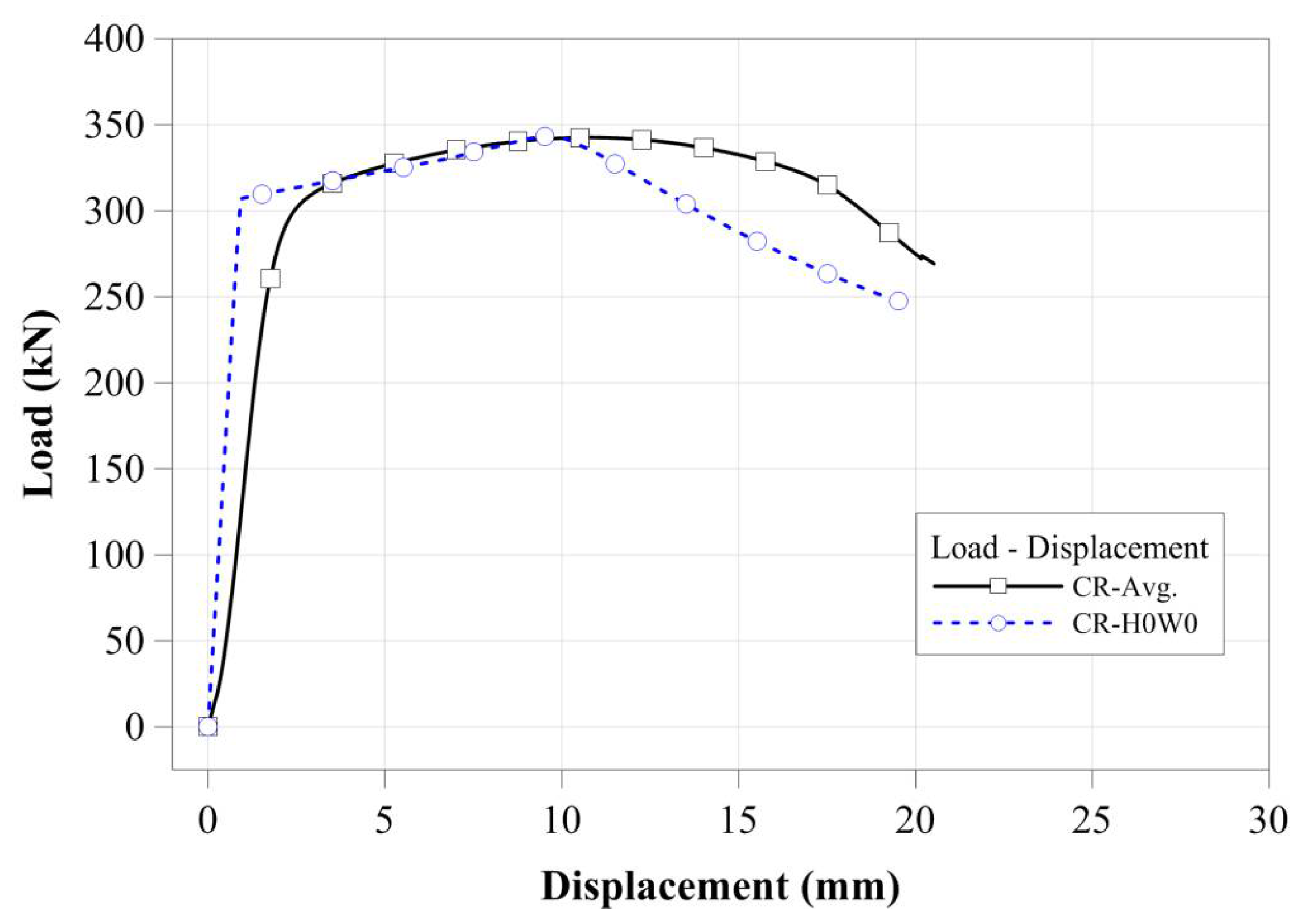

3.2. Compressive Loading Results

3.2.1. Summary of Compressive Loading Tests

3.2.2. Effect of the Cross-Sectional Damaged Condition on Compressive Strength

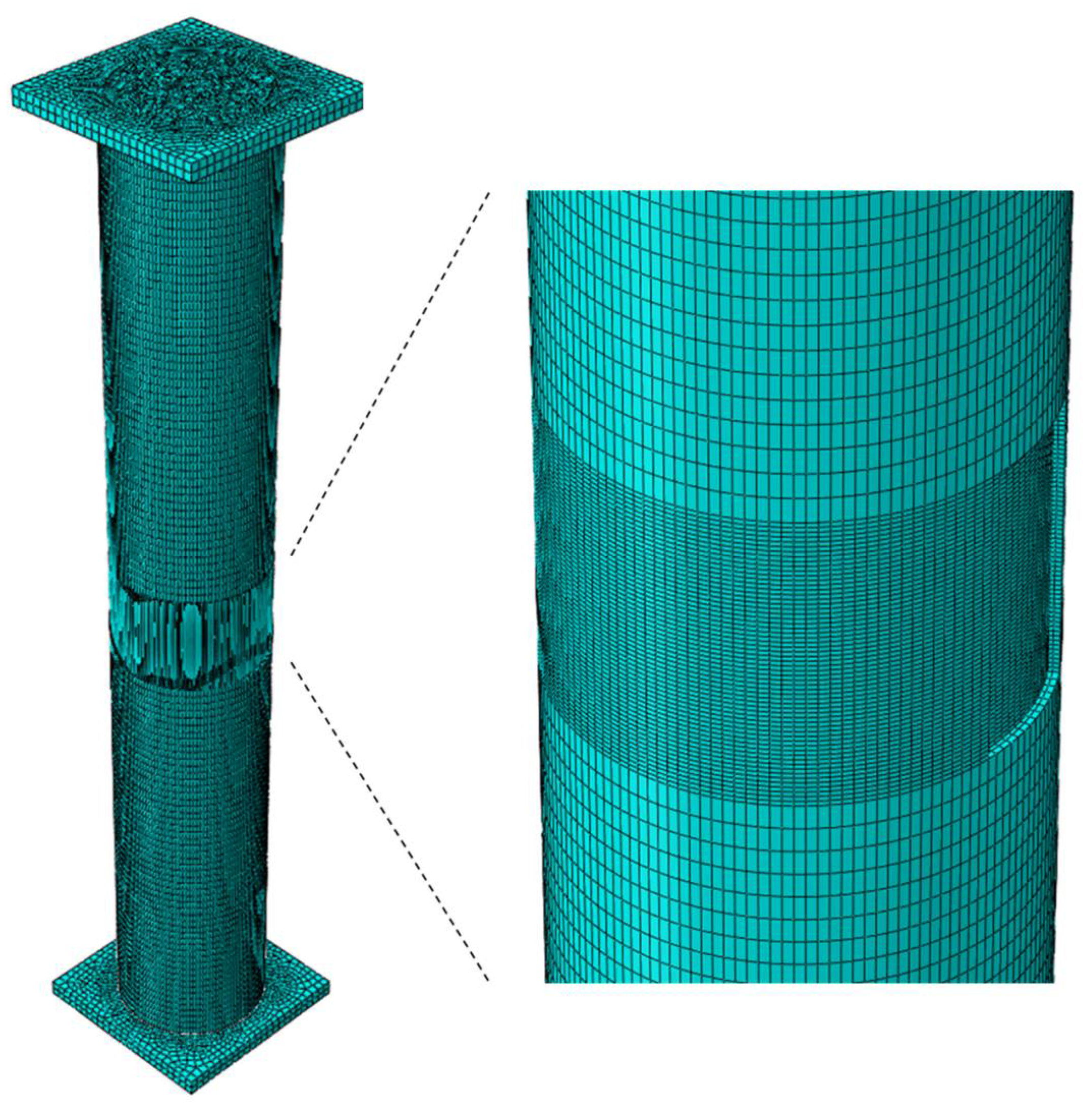

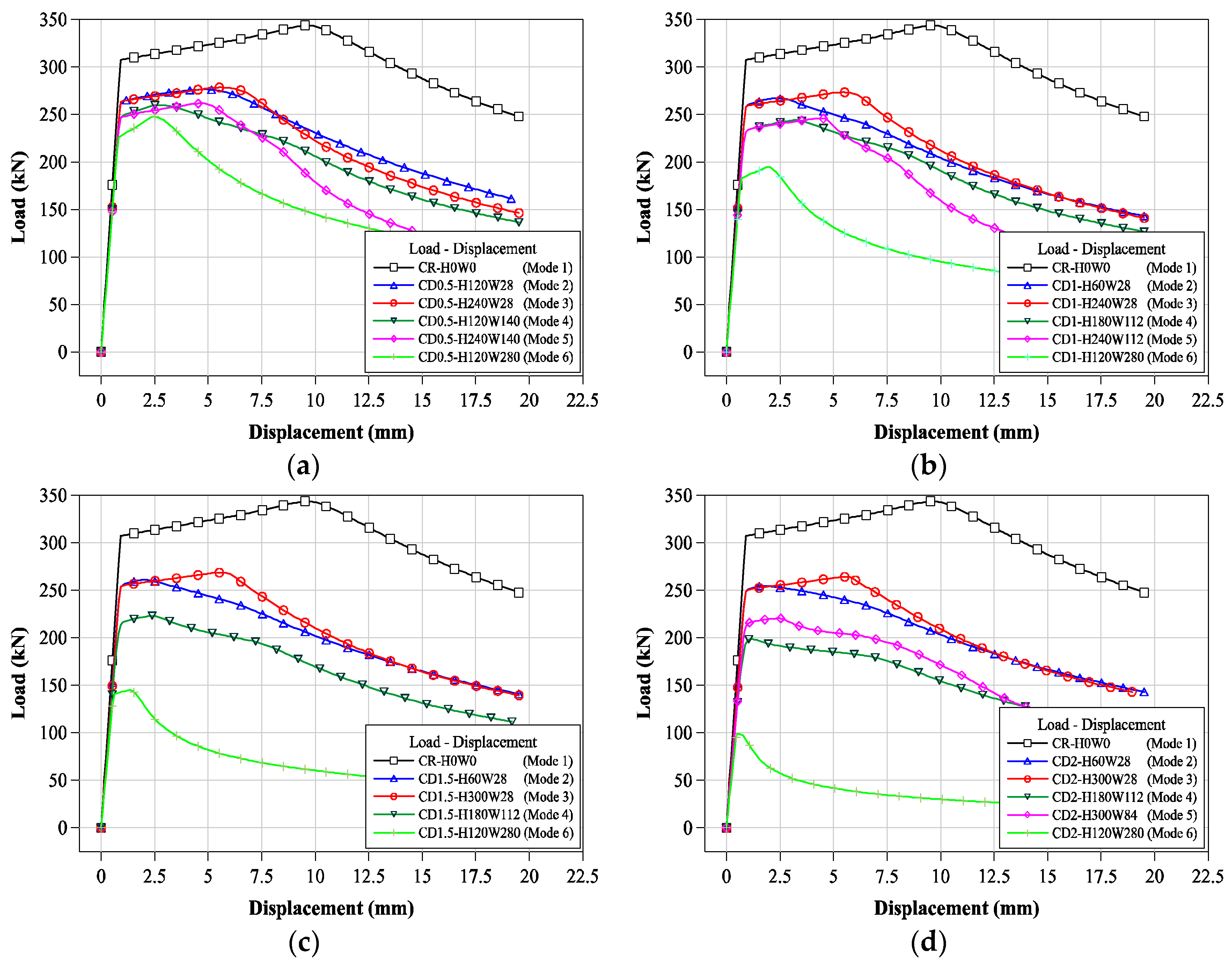

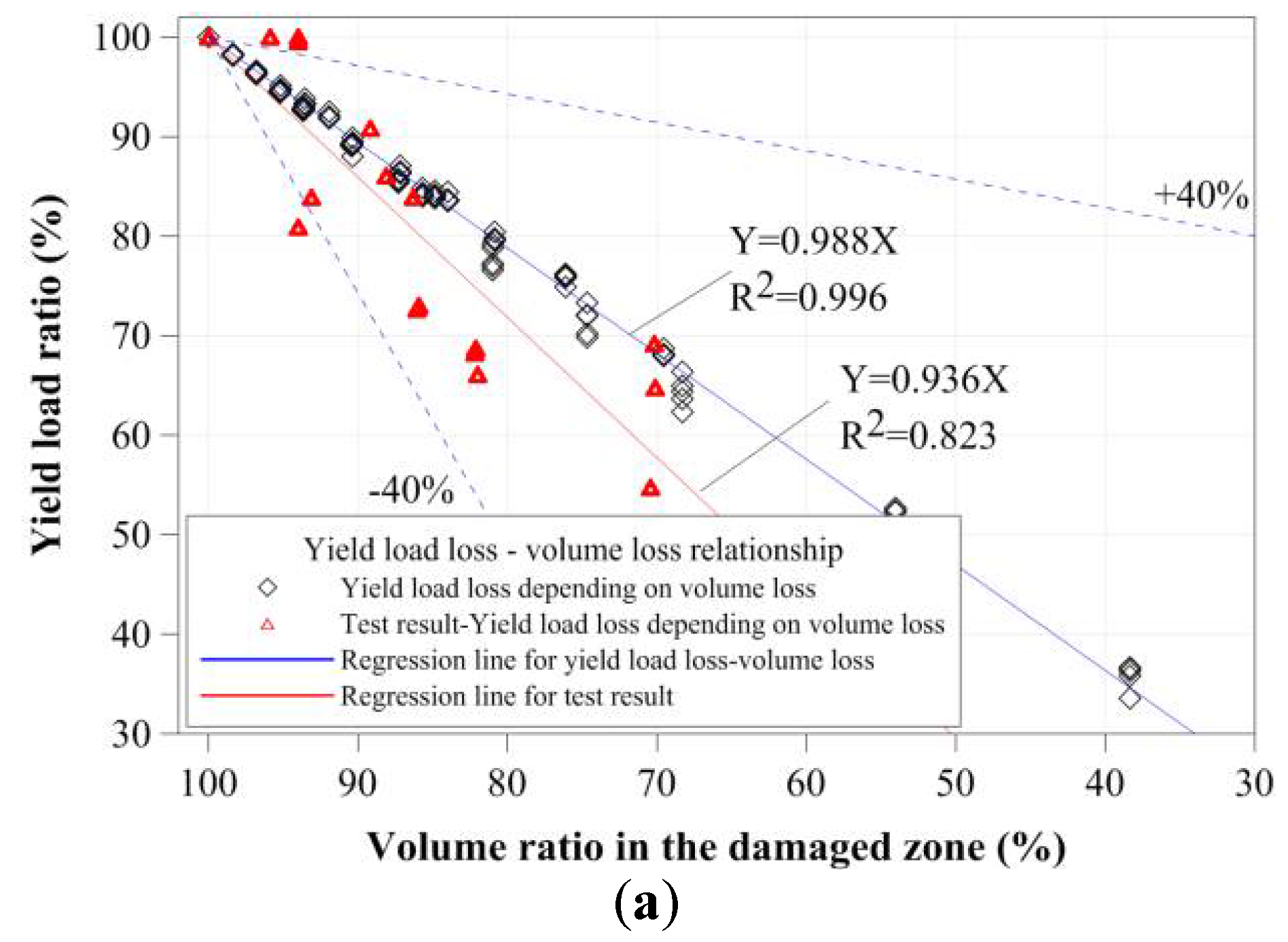

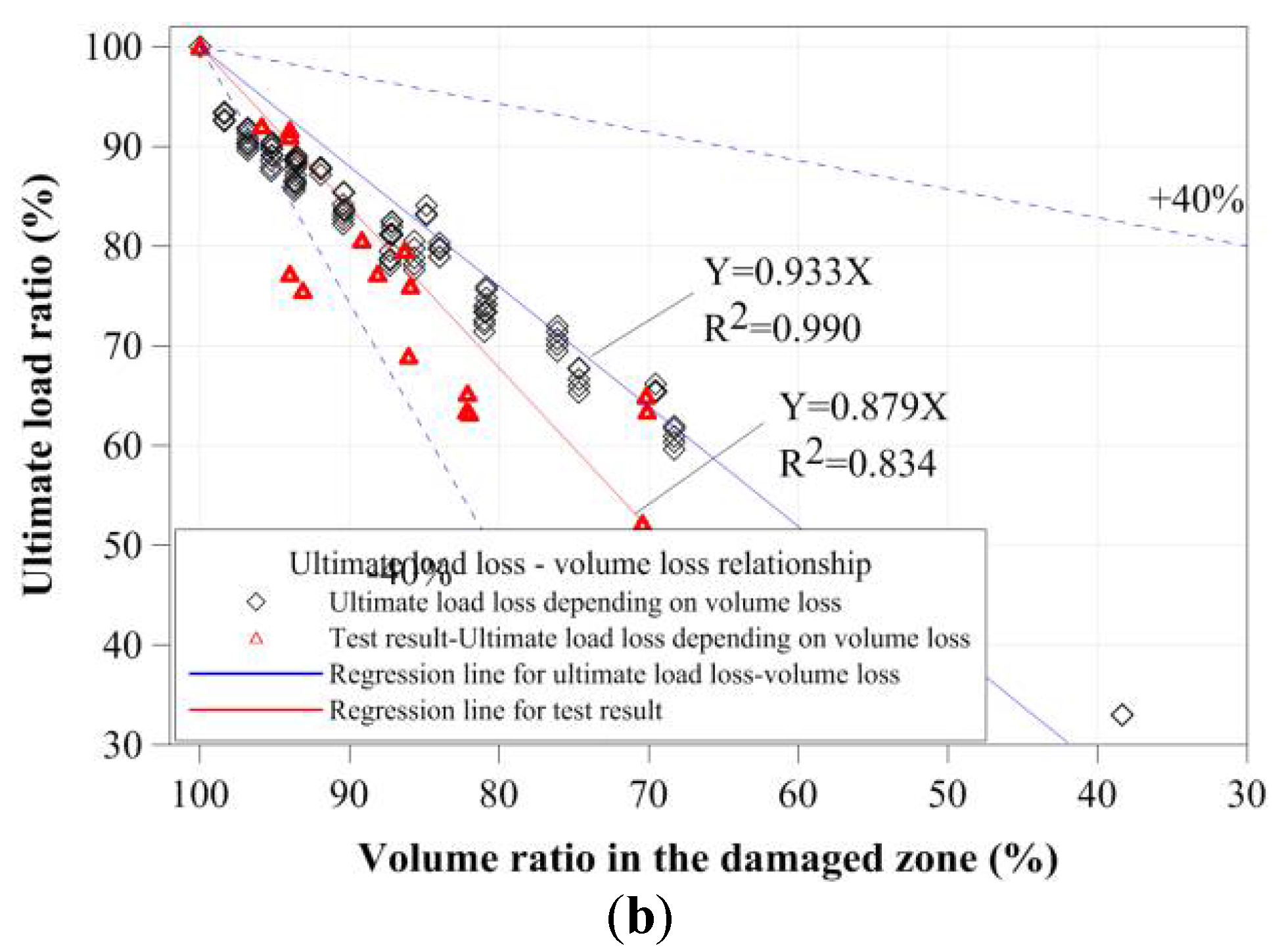

3.3. FEA of Compressive Loading Cases

3.3.1. FEA Model and Parameters

3.3.2. FEA Model and Parameters

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Airoldi, A.; Janszen, G. A design solution for a crashworthy landing gear with a new triggering mechanism for the plastic collapse of metallic tubes. Aerosp. Sci. Technol. 2005, 9, 445–455. [Google Scholar] [CrossRef]

- Guo, L.; Yang, S.; Jiao, H. Behavior of thin-walled circular hollow section tubes subjected to bending. Thin Wall. Struct. 2013, 73, 281–289. [Google Scholar] [CrossRef]

- Martinez, E.; Tyrell, D.; Perlman, B. Development of crash energy management designs for existing passenger rail vehicles. In Proceedings of the ASME 2004 International Mechanical Engineering Congress, Anaheim, CA, USA, 13–19 November 2004; pp. 107–115. [Google Scholar]

- Stavridou, N.; Efthymiou, E.; Gerasimidis, S.; Baniotopoulos, C.C. Investigation of stiffening scheme effectiveness towards buckling stability enhancement in tubular steel wind turbine towers. Steel Compos. Struct. 2015, 19, 1115–1144. [Google Scholar] [CrossRef]

- Chaves, L.A.; Melchers, R.E. Pitting corrosion in pipeline steel weld zones. Corros. Sci. 2011, 53, 4026–4032. [Google Scholar] [CrossRef]

- Nasirpouri, F.; Mostafaei, A.; Fathyunes, L.; Jafari, R. Assessment of localized corrosion in carbon steel tube-grade AISI 1045 used in output oil–gas separator vessel of desalination unit in oil refinery industry. Eng. Failure Anal. 2014, 40, 75–88. [Google Scholar] [CrossRef]

- Wang, X.; Melchers, R.E. Long-term under-deposit pitting corrosion of carbon steel pipes. Ocean Eng. 2017, 133, 231–243. [Google Scholar] [CrossRef]

- Eliyan, F.F.; Alfantazi, A. Mechanisms of Corrosion and Electrochemical Significance of Metallurgy and Environment with Corrosion of Iron and Steel in Bicarbonate and Carbonate Solutions—A Review. Corrs. Sci. 2017, 70, 880–898. [Google Scholar] [CrossRef]

- Liu, T.; Cheng, Y.F.; Sharma, M.; Voordouw, G. Effect of fluid flow on biofilm formation and microbiologically influenced corrosion of pipelines in oilfield produced water. J. Pet. Sci. Eng. 2017, 156, 451–459. [Google Scholar] [CrossRef]

- Eliyan, F.F.; Mohammadi, F.; Alfantazi, A. An electrochemical investigation on the effect of the chloride content on CO2 corrosion of API-X100 steel. Corrs. Sci. 2012, 64, 37–43. [Google Scholar] [CrossRef]

- Nazari, M.; Khedmati, M.R.; Khalaj, A.F. A numerical investigation into ultimate strength and buckling behavior of locally corroded steel tubular members. Lat. Am. J. Solids Struct. 2014, 11, 1063–1076. [Google Scholar] [CrossRef]

- Lutes, L.D.; Kohutek, T.L.; Ellison, B.K.; Konen, K.F. Assessing the compressive strength of corroded tubular members. Appl. Ocean Res. 2001, 23, 263–268. [Google Scholar] [CrossRef]

- Nishimura, N.; Murakami, S.; Takeshita, K.; Jikuya, K.; Yoshihito, Y. Ultimate strength of cylindrical tubular columns with corrosive damage. J. Jpn. Soc. Steel Constr. 1999, 6, 55–66. (In Japanese) [Google Scholar]

- Hassani, N.; Kolbadi, S.; Shiravand, M.R.; Golafshani, J.H. Impact of geometric pattern corrosion on limit failure pressure of buried gas pipelines. Struct. Eng. Mech. 2016, 61, 795–802. [Google Scholar] [CrossRef]

- Hebor, M.F.; Ricles, J.M. Local buckling strength of patch corrosion damaged steel tubular bracing. Int. J. Steel Struct. 2002, 2, 59–70. [Google Scholar]

- Yamane, M.; Tanaka, K.; Matsuda, B.; Fujikubo, M.; Yanagihara, D.; Iwao, N. Evaluation of the residual strength of corroded steel tubular members in marine environments. J. Jpn. Soc. Nav. Archit. Ocean Eng. 2006, 3, 243–251. (In Japanese) [Google Scholar] [CrossRef]

- Chen, M.; Das, S. Experimental study on repair of corroded steel beam using CFRP. Steel Compos. Struct. 2009, 9, 103–118. [Google Scholar] [CrossRef]

- Khaled, S.; Sherwood, T. Bond behavior of corroded steel reinforcement in concrete wrapped with carbon fiber reinforced polymer sheets. J. Mater. Civ. Eng. 2003, 15, 358–370. [Google Scholar]

- Ahn, J.H.; Nam, D.K.; Lee, W.H.; Huh, J.W.; Kim, I.T. Compressive strengths of circular steel members according to corrosion cross-sectional damage and damage shape. J. Korean Soc. Steel Constr. 2016, 28, 213–222. (In Korean) [Google Scholar] [CrossRef]

- Ahn, J.H.; Choi, W.R.; Jeon, S.H.; Kim, S.H.; Kim, I.T. Residual compressive strength of inclined steel tubular members with local corrosion. Appl. Ocean Res. 2016, 59, 498–509. [Google Scholar] [CrossRef]

| Specimens | Damaged Height (H)/Width (W) (mm) | Weight Loss after Artificial Cross-Sectional Damage (g) | Equivalent Cross-Sectional Area (mm2)/(%) | Artificial Cross-Sectional Damaged Volume (mm3) |

|---|---|---|---|---|

| CR-H0W0-1 | - | 0 | 990.2/100 | 0 |

| CR-H0W0-2 | - | 0 | 990.2/100 | 0 |

| CR-H0W0-3 | - | 0 | 990.2/100 | 0 |

| CR-H0W0_mean | - | 0 | 990.2/100 | 0 |

| CD-H3W3 | 30/30 | 14 | 930.7/93.99 | 1783.4 |

| CD-H3W6 | 30/60 | 32 | 854.3/86.28 | 4076.4 |

| CD-H3W9 | 30/90 | 42 | 811.8/81.99 | 5350.3 |

| CD-H3W15 | 30/150 | 69 | 697.2/70.41 | 8789.8 |

| CD-H6W3 | 60/30 | 28 | 930.7/93.99 | 3566.9 |

| CD-H6W6 | 60/60 | 65 | 852.2/86.07 | 8280.3 |

| CD-H6W9 | 60/90 | 83 | 813.9/82.2 | 10,573.2 |

| CD-H6W15 | 60/150 | 139 | 695/70.19 | 17,707.0 |

| CD-H7.5W3 | 75/30 | 24 | 949.4/95.88 | 3057.3 |

| CD-H7.5W6 | 75/60 | 40 | 922.2/93.14 | 5095.5 |

| CD-H7.5W9 | 75/90 | 63 | 883.2/89.2 | 8025.5 |

| CD-H7.5W15 | 75/150 | 82 | 850.9/85.94 | 10,445.9 |

| CD-H9W3 | 90/30 | 42 | 930.7/93.99 | 5350.3 |

| CD-H9W6 | 90/60 | 83 | 872.7/88.14 | 10,573.2 |

| CD-H9W9 | 90/90 | 125 | 813.2/82.13 | 15,923.6 |

| CD-H9W15 | 90/150 | 209 | 694.3/70.12 | 26,624.2 |

| Specimens | Damaged Height (H)/Width (W) (mm) | Damaged Volume (mm3) | Converted Cross-Sectional Area (mm2) | Compressive Strength (kN) | Displacement (mm) |

|---|---|---|---|---|---|

| CR-H0W0-1 | - | 0 | 990.2/100 | 0 | 12.0 |

| CR-H0W0-2 | - | 0 | 990.2/100 | 0 | 10.0 |

| CR-H0W0-3 | - | 0 | 990.2/100 | 0 | 10.9 |

| CR-H0W0_mean | 0 | 990.2/100 | 0 | 4.2 | |

| CD-H3W3 | 30/30 | 1783.4 | 930.7/93.99 | 1783.4 | 4.0 |

| CD-H3W6 | 30/60 | 4076.4 | 854.3/86.28 | 4076.4 | 4.7 |

| CD-H3W9 | 30/90 | 5350.3 | 811.8/81.99 | 5350.3 | 3.4 |

| CD-H3W15 | 30/150 | 8789.8 | 697.2/70.41 | 8789.8 | 4.5 |

| CD-H6W3 | 60/30 | 3566.9 | 930.7/93.99 | 3566.9 | 6.3 |

| CD-H6W6 | 60/60 | 8280.3 | 852.2/86.07 | 8280.3 | 4.3 |

| CD-H6W9 | 60/90 | 10,573.2 | 813.9/82.2 | 10,573.2 | 2.5 |

| CD-H6W15 | 60/150 | 17,707.0 | 695/70.19 | 17,707.0 | 5.3 |

| CD-H7.5W3 | 75/30 | 3057.3 | 949.4/95.88 | 3057.3 | 3.9 |

| CD-H7.5W6 | 75/60 | 5095.5 | 922.2/93.14 | 5095.5 | 4.3 |

| CD-H7.5W9 | 75/90 | 8025.5 | 883.2/89.2 | 8025.5 | 4.5 |

| CD-H7.5W15 | 75/150 | 10,445.9 | 850.9/85.94 | 10,445.9 | 5.4 |

| CD-H9W3 | 90/30 | 5350.3 | 930.7/93.99 | 5350.3 | 4.3 |

| CD-H9W6 | 90/60 | 10,573.2 | 872.7/88.14 | 10,573.2 | 3.6 |

| CD-H9W9 | 90/90 | 15,923.6 | 813.2/82.13 | 15,923.6 | 3.6 |

| CD-H9W15 | 90/150 | 26,624.2 | 694.3/70.12 | 26,624.2 | 12.0 |

| Parameter of Analysis Model | |

|---|---|

| Corroded depth | 0.5, 1, 1.5, 2 mm |

| Corroded height | 60, 120, 180, 240, 300 mm |

| Corroded width | 28, 56, 84, 112, 140, 280 mm |

| Specimens | Equivalent Cross-Sectional Area (mm2)/(%) | Volume Ratio in the Damaged Zone (%) | Yield Load (kN)/(%) | Ultimate Load (kN)/(%) | Failure Mode |

|---|---|---|---|---|---|

| CR-H0W0 | 863.6/100 | 100 | 267.7/100 | 297.7/100 | 1 |

| CD0.5-H60W28 | 849.6/98.39 | 98.39 | 263.1/95.01 | 275.4/92.51 | 3 |

| CD0.5-H120W28 | 849.6/98.39 | 98.39 | 263.3/95.01 | 275.9/92.68 | 2 |

| CD0.5-H180W28 | 849.6/98.39 | 98.39 | 262.8/95.01 | 277.5/93.23 | 2 |

| CD0.5-H240W28 | 849.6/98.39 | 98.39 | 262.8/95.01 | 278.1/93.4 | 3 |

| CD0.5-H300W28 | 849.6/98.39 | 98.39 | 262.8/95.01 | 278.1/93.43 | 3 |

| CD0.5-H60W56 | 835.7/96.78 | 96.78 | 258.7/90.39 | 268.7/90.27 | 2 |

| CD0.5-H120W56 | 835.7/96.78 | 96.78 | 258.1/90.39 | 269.1/90.39 | 2 |

| CD0.5-H180W56 | 835.7/96.78 | 96.78 | 258/90.39 | 271.7/91.26 | 2 |

| CD0.5-H240W56 | 835.7/96.78 | 96.78 | 258/90.39 | 273.3/91.8 | 3 |

| CD0.5-H300W56 | 835.7/96.78 | 96.78 | 258.1/90.39 | 273.5/91.87 | 3 |

| CD0.5-H60W84 | 821.8/95.17 | 95.17 | 254.7/86.49 | 265.4/89.16 | 2 |

| CD0.5-H120W84 | 821.8/95.17 | 95.17 | 253.8/86.49 | 265/89.03 | 2 |

| CD0.5-H180W84 | 821.8/95.17 | 95.17 | 253.5/86.49 | 267.2/89.76 | 2 |

| CD0.5-H240W84 | 821.8/95.17 | 95.17 | 253.5/86.49 | 268.7/90.27 | 3 |

| CD0.5-H300W84 | 821.8/95.17 | 95.17 | 253.7/86.49 | 269.2/90.43 | 3 |

| CD0.5-H60W112 | 807.9/93.55 | 93.55 | 251.1/83.55 | 263.1/88.36 | 2 |

| CD0.5-H120W112 | 807.9/93.55 | 93.55 | 249.9/83.55 | 262/88 | 2 |

| CD0.5-H180W112 | 807.9/93.55 | 93.55 | 249.6/83.55 | 263.8/88.61 | 2 |

| CD0.5-H240W112 | 807.9/93.55 | 93.55 | 249.5/83.55 | 264.5/88.85 | 3 |

| CD0.5-H300W112 | 807.9/93.55 | 93.55 | 249.6/83.55 | 265.1/89.06 | 3 |

| CD0.5-H60W140 | 794/91.94 | 91.94 | 247.7/81.62 | 261.1/87.71 | 2 |

| CD0.5-H120W140 | 794/91.94 | 91.94 | 246.3/81.62 | 259.6/87.2 | 4 |

| CD0.5-H180W140 | 794/91.94 | 91.94 | 245.9/81.62 | 261.1/87.69 | 4 |

| CD0.5-H240W140 | 794/91.94 | 91.94 | 245.8/81.62 | 261.3/87.78 | 5 |

| CD0.5-H300W140 | 794/91.94 | 91.94 | 245.8/81.62 | 261.6/87.89 | 5 |

| CD0.5-H60W280 | 724.4/83.88 | 84.87 | 226.4/83.88 | 250.4/84.1 | 5 |

| CD0.5-H120W280 | 724.4/83.88 | 84.87 | 225.2/83.88 | 247.6/83.19 | 6 |

| CD0.5-H180W280 | 724.4/83.88 | 84.87 | 224.8/83.88 | 247.6/83.18 | 6 |

| CD0.5-H240W280 | 724.4/83.88 | 84.87 | 224.3/83.88 | 247.7/83.21 | 6 |

| CD0.5-H300W280 | 724.4/83.88 | 84.87 | 225.2/83.88 | 247.6/83.19 | 6 |

| CD1-H60W28 | 835.9/96.79 | 96.79 | 258.1/90.13 | 266.7/89.6 | 2 |

| CD1-H120W28 | 835.9/96.79 | 96.79 | 257.8/90.13 | 267.8/89.94 | 2 |

| CD1-H180W28 | 835.9/96.79 | 96.79 | 257.7/90.13 | 270.2/90.77 | 2 |

| CD1-H240W28 | 835.9/96.79 | 96.79 | 257.8/90.13 | 272.9/91.69 | 3 |

| CD1-H300W28 | 835.9/96.79 | 96.79 | 258/90.13 | 273.1/91.74 | 3 |

| CD1-H60W56 | 808.2/93.59 | 93.59 | 248.9/81.12 | 256.6/86.19 | 2 |

| CD1-H120W56 | 808.2/93.59 | 93.59 | 248.2/81.12 | 257.5/86.48 | 2 |

| CD1-H180W56 | 808.2/93.59 | 93.59 | 248/81.12 | 259.3/87.11 | 2 |

| CD1-H240W56 | 808.2/93.59 | 93.59 | 248.2/81.12 | 263.5/88.5 | 2 |

| CD1-H300W56 | 808.2/93.59 | 93.59 | 248.5/81.12 | 263.8/88.63 | 3 |

| CD1-H60W84 | 780.5/90.38 | 90.38 | 240.5/73.76 | 248.5/83.47 | 2 |

| CD1-H120W84 | 780.5/90.38 | 90.38 | 239.4/73.76 | 249.1/83.69 | 2 |

| CD1-H180W84 | 780.5/90.38 | 90.38 | 239.4/73.76 | 249.1/83.69 | 2 |

| CD1-H240W84 | 780.5/90.38 | 90.38 | 239.3/73.76 | 254.1/85.34 | 3 |

| CD1-H300W84 | 780.5/90.38 | 90.38 | 235.5/73.76 | 254.2/85.37 | 3 |

| CD1-H60W112 | 752.9/87.18 | 87.18 | 233/68.41 | 241.3/81.06 | 4 |

| CD1-H120W112 | 752.9/87.18 | 87.18 | 231.5/68.41 | 241.8/81.22 | 4 |

| CD1-H180W112 | 752.9/87.18 | 87.18 | 231.2/68.41 | 243.8/81.89 | 4 |

| CD1-H240W112 | 752.9/87.18 | 87.18 | 231.2/68.41 | 245.6/82.49 | 5 |

| CD1-H300W112 | 752.9/87.18 | 87.18 | 231.4/68.41 | 245.2/82.37 | 5 |

| CD1-H60W140 | 725.2/83.97 | 83.97 | 226/65 | 234.9/78.9 | 4 |

| CD1-H120W140 | 725.2/83.97 | 83.97 | 224.2/65 | 235.1/78.96 | 4 |

| CD1-H180W140 | 725.2/83.97 | 83.97 | 223.7/65 | 237.1/79.64 | 4 |

| CD1-H240W140 | 725.2/83.97 | 83.97 | 223.6/65 | 239.2/80.34 | 4 |

| CD1-H300W140 | 725.2/83.97 | 83.97 | 223.7/65 | 237.9/79.91 | 5 |

| CD1-H60W280 | 586.8/67.95 | 69.55 | 183.9/67.95 | 196.9/66.14 | 6 |

| CD1-H120W280 | 586.8/67.95 | 69.55 | 182.5/67.95 | 194.4/65.32 | 6 |

| CD1-H180W280 | 586.8/67.95 | 69.55 | 182/67.95 | 194.8/65.44 | 6 |

| CD1-H240W280 | 586.8/67.95 | 69.55 | 182.5/67.95 | 194.9/65.47 | 6 |

| CD1-H300W280 | 586.8/67.95 | 69.55 | 182.2/67.95 | 194.9/65.48 | 6 |

| CD1.5-H60W28 | 822.3/95.22 | 95.22 | 253.1/85.38 | 260.6/87.55 | 2 |

| CD1.5-H120W28 | 822.3/95.22 | 95.22 | 252.8/85.38 | 261.6/87.87 | 2 |

| CD1.5-H180W28 | 822.3/95.22 | 95.22 | 252.8/85.38 | 263.6/88.55 | 2 |

| CD1.5-H240W28 | 822.3/95.22 | 95.22 | 253/85.38 | 267.4/89.81 | 2 |

| CD1.5-H300W28 | 822.3/95.22 | 95.22 | 253.2/85.38 | 268.4/90.14 | 3 |

| CD1.5-H60W56 | 781/90.44 | 90.44 | 238.9/72.28 | 244.7/82.19 | 2 |

| CD1.5-H120W56 | 781/90.44 | 90.44 | 238.2/72.28 | 246/82.64 | 2 |

| CD1.5-H180W56 | 781/90.44 | 90.44 | 238.2/72.28 | 247.5/83.13 | 2 |

| CD1.5-H240W56 | 781/90.44 | 90.44 | 238.6/72.28 | 250.5/84.16 | 2 |

| CD1.5-H300W56 | 781/90.44 | 90.44 | 239.1/72.28 | 254.1/85.35 | 3 |

| CD1.5-H60W84 | 739.7/85.66 | 85.66 | 227.1/61.96 | 231/77.58 | 2 |

| CD1.5-H120W84 | 739.7/85.66 | 85.66 | 225.1/61.96 | 232.9/78.22 | 2 |

| CD1.5-H180W84 | 739.7/85.66 | 85.66 | 224.9/61.96 | 234.6/78.81 | 2 |

| CD1.5-H240W84 | 739.7/85.66 | 85.66 | 225.3/61.96 | 237.5/79.79 | 2 |

| CD1.5-H300W84 | 739.7/85.66 | 85.66 | 225.9/61.96 | 239.6/80.48 | 2 |

| CD1.5-H60W112 | 698.4/80.88 | 80.88 | 215.2/54.79 | 218.6/73.42 | 4 |

| CD1.5-H120W112 | 698.4/80.88 | 80.88 | 213.1/54.79 | 220.6/74.11 | 4 |

| CD1.5-H180W112 | 698.4/80.88 | 80.88 | 212.9/54.79 | 222.7/74.81 | 4 |

| CD1.5-H240W112 | 698.4/80.88 | 80.88 | 213.1/54.79 | 225.2/75.64 | 4 |

| CD1.5-H300W112 | 698.4/80.88 | 80.88 | 213.5/54.79 | 226.1/75.95 | 2 |

| CD1.5-H60W140 | 657.2/76.1 | 76.10 | 203.9/50.34 | 206.7/69.44 | 4 |

| CD1.5-H120W140 | 657.2/76.1 | 76.10 | 200.4/50.34 | 208.7/70.09 | 4 |

| CD1.5-H180W140 | 657.2/76.1 | 76.10 | 202.9/50.34 | 210.5/70.7 | 4 |

| CD1.5-H240W140 | 657.2/76.1 | 76.10 | 203.3/50.34 | 212.8/71.47 | 4 |

| CD1.5-H300W140 | 657.2/76.1 | 76.10 | 203.6/50.34 | 214.2/71.95 | 4 |

| CD1.5-H60W280 | 450.8/52.2 | 54.05 | 140/52.2 | 144.2/48.42 | 6 |

| CD1.5-H120W280 | 450.8/52.2 | 54.05 | 140.2/52.2 | 144.5/48.53 | 6 |

| CD1.5-H180W280 | 450.8/52.2 | 54.05 | 139.9/52.2 | 144.7/48.59 | 6 |

| CD1.5-H240W280 | 450.8/52.2 | 54.05 | 141/52.2 | 144.5/48.55 | 6 |

| CD1.5-H300W280 | 450.8/52.2 | 54.05 | 139.9/52.2 | 144.8/48.63 | 6 |

| CD2-H60W28 | 808.8/93.66 | 93.66 | 248.2/80.77 | 254.7/85.55 | 2 |

| CD2-H120W28 | 808.8/93.66 | 93.66 | 247.8/80.77 | 255.7/85.91 | 2 |

| CD2-H180W28 | 808.8/93.66 | 93.66 | 247.9/80.77 | 257.5/86.48 | 2 |

| CD2-H240W28 | 808.8/93.66 | 93.66 | 248.1/80.77 | 261.1/87.7 | 2 |

| CD2-H300W28 | 808.8/93.66 | 93.66 | 248.5/80.77 | 264/88.68 | 3 |

| CD2-H60W56 | 754.1/87.33 | 87.33 | 228.6/63.93 | 232.4/78.06 | 2 |

| CD2-H120W56 | 754.1/87.33 | 87.33 | 228.6/63.93 | 233.9/78.55 | 2 |

| CD2-H180W56 | 754.1/87.33 | 87.33 | 228.6/63.93 | 234.4/78.75 | 2 |

| CD2-H240W56 | 754.1/87.33 | 87.33 | 229.5/63.93 | 236.7/79.5 | 2 |

| CD2-H300W56 | 754.1/87.33 | 87.33 | 229.1/63.93 | 241.7/81.18 | 2 |

| CD2-H60W84 | 699.4/80.99 | 80.99 | 204.9/51.22 | 212.8/71.48 | 4 |

| CD2-H120W84 | 699.4/80.99 | 80.99 | 211.9/51.22 | 215/72.22 | 2 |

| CD2-H180W84 | 699.4/80.99 | 80.99 | 210.9/51.22 | 215.9/72.52 | 2 |

| CD2-H240W84 | 699.4/80.99 | 80.99 | 206.1/51.22 | 218.5/73.41 | 2 |

| CD2-H300W84 | 699.4/80.99 | 80.99 | 206.8/51.22 | 220.3/73.99 | 5 |

| CD2-H60W112 | 644.7/74.65 | 74.65 | 188/42.83 | 194.5/65.33 | 4 |

| CD2-H120W112 | 644.7/74.65 | 74.65 | 193/42.83 | 196.5/66.02 | 4 |

| CD2-H180W112 | 644.7/74.65 | 74.65 | 192.7/42.83 | 198.4/66.64 | 4 |

| CD2-H240W112 | 644.7/74.65 | 74.65 | 187/42.83 | 201.5/67.68 | 4 |

| CD2-H300W112 | 644.7/74.65 | 74.65 | 196.2/42.83 | 201.8/67.79 | 4 |

| CD2-H60W140 | 589.9/68.31 | 68.31 | 173.9/37.75 | 177.5/59.63 | 4 |

| CD2-H120W140 | 589.9/68.31 | 68.31 | 170.4/37.75 | 179.6/60.34 | 4 |

| CD2-H180W140 | 589.9/68.31 | 68.31 | 166.8/37.75 | 181.4/60.95 | 4 |

| CD2-H240W140 | 589.9/68.31 | 68.31 | 172.5/37.75 | 184.4/61.93 | 4 |

| CD2-H300W140 | 589.9/68.31 | 68.31 | 177.6/37.75 | 183.7/61.72 | 5 |

| CD2-H60W280 | 316.3/36.63 | 38.37 | 97.8/36.63 | 98.3/33.03 | 6 |

| CD2-H120W280 | 316.3/36.63 | 38.37 | 89.9/36.63 | 98.3/33.02 | 6 |

| CD2-H180W280 | 316.3/36.63 | 38.37 | 97.2/36.63 | 98.3/33.03 | 6 |

| CD2-H240W280 | 316.3/36.63 | 38.37 | 98.1/36.63 | 98.3/33.03 | 6 |

| CD2-H300W280 | 316.3/36.63 | 38.37 | 95.9/36.63 | 98.3/33.03 | 6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, J.-H.; Jeon, S.-H.; Jeong, Y.-S.; Cho, K.-I.; Huh, J. Evaluation of Residual Compressive Strength and Behavior of Corrosion-Damaged Carbon Steel Tubular Members. Materials 2018, 11, 1254. https://doi.org/10.3390/ma11071254

Ahn J-H, Jeon S-H, Jeong Y-S, Cho K-I, Huh J. Evaluation of Residual Compressive Strength and Behavior of Corrosion-Damaged Carbon Steel Tubular Members. Materials. 2018; 11(7):1254. https://doi.org/10.3390/ma11071254

Chicago/Turabian StyleAhn, Jin-Hee, Seok-Hyeon Jeon, Young-Soo Jeong, Kwang-Il Cho, and Jungwon Huh. 2018. "Evaluation of Residual Compressive Strength and Behavior of Corrosion-Damaged Carbon Steel Tubular Members" Materials 11, no. 7: 1254. https://doi.org/10.3390/ma11071254

APA StyleAhn, J.-H., Jeon, S.-H., Jeong, Y.-S., Cho, K.-I., & Huh, J. (2018). Evaluation of Residual Compressive Strength and Behavior of Corrosion-Damaged Carbon Steel Tubular Members. Materials, 11(7), 1254. https://doi.org/10.3390/ma11071254