1. Introduction

Laser Material Processing is an alternative to many traditional manufacturing processes, such as arc welding, electrochemical machining, hand polishing, electron beam welding, etc. Laser Material Processing’s main characteristic is the use of a high-power laser as a heat source, which results in a very high concentration of the energy density that reduces the Heat Affected Zone (HAZ) and thermally induced distortions [

1].

One of the laser-based processes that is experiencing a continuous growth is the Laser Metal Deposition (LMD). This additive manufacturing (AM) technique consists on generating a melt pool on the surface of the substrate, while wire or powder shaped filler material is added simultaneously [

2]. Besides, LMD enables to obtain near-net-shape parts, which reduces the amount of wasted material [

3,

4]. Regarding environmental impact considerations, if material reductions as high as 50% with respect to the initial part are required during the manufacturing process, AM becomes environmentally friendlier compared with machining and forging [

5]. In the same way, the aeronautical industry uses the buy-to-fly ratio as an efficiency factor, since it relates the weight of the part that really flights with the weight of the initial part stock. Laser Material Deposition can reduce the buy-to-fly ratio below 1.5:1, comparable to laser welding processes [

6]. However, LMD manufactured parts do not meet the final surface roughness and dimensional requirements, and a finishing operation is always required [

7]. Usually, conventional machining is applied for the finishing of the parts.

Another laser-based process that has found a niche in the market is the Laser Beam Machining (LBM), where the laser beam is directly applied for melting and vaporizing unwanted material from the substrate surface [

8]. As the LBM is a laser-based process, no cutting tools are required, and materials can be machined regardless their hardness [

9]. In addition, LBM process applies a laser beam (usually smaller than 75 μm beam diameter) directly for removing surface material. Hence, this process is especially suitable for the machining of small details on hard materials [

10]. Moreover, high aspect-ratio grooves and holes can also be achieved [

11] and almost no HAZ is generated when nano or femto pulse-duration lasers are used [

12]. Nevertheless, as Dubey et al. stated, LBM process is not fully developed, and it is still waiting to its industrial use [

8].

LBM does not always provide the desired surface quality and a finishing operation is therefore required. To this end, highly skilled operators using abrasive tools have traditionally performed finishing operations manually. For instance, Peng et al., proposed the Abrasive Flow Machining for removing the falling effect and the powder adhesion generated during AM [

13].

An alternative to reduce the surface roughness of previously manufactured parts, which has caught the interest of many researchers, is the laser polishing (LP) [

14,

15,

16]. In LP, peaks of the surface roughness are melted, and the material is redistributed in the valleys due to the surface tension and the gravity [

17]. Therefore, when laser-polishing material is not removed, nor the final shape of the part is modified, but material is relocated while melted. To improve the understanding of the effect of LP on additively manufactured parts, Marimuthu et al., studied the influence of the melt pool dynamics on the resulting surface topology and roughness [

18].

Other authors have studied experimentally the improvement of the surface quality when AM and LP are combined. For example, Zhihao et al., studied the surface roughness reduction of additively built-up parts using LP [

19]. They concluded that LP improves the surface roughness of Inconel 718 Selective Laser Melting manufactured parts. On the other hand, Ma et al., also studied the improvement of the surface roughness of additively manufactured Ti alloys [

17]. Nevertheless, the reference surface on which authors applied LP was a W-EDM cut surface and not the wavy surface characteristic of AM.

Up to now, the roughness and excess material resulting from the AM process is eliminated mechanically via milling or other abrasive processes, such as grinding. In this direction, the current trend of modern industry is to combine additive and subtractive technologies within the same machine [

20]. However, laser-based processes are not always easily combined with other manufacturing techniques. For instance, the combination of LMD with milling or turning may result problematic, especially when cutting fluids are used. The problems arisen can be classified in two groups. On the one hand, the handling and filtering of the moisture generated when the powder particles and the cutting fluid are mixed results problematic. On the other hand, pore phenomena do appear if the surface is not properly cleaned before the LMD process [

21].

Consequently, if LMD, LBM and LP processes are combined, the machining operation could be eliminated from the production chain, which leads to a much cleaner and environmentally friendlier manufacture. Moreover, the use of coolants, tooling, etc. is eliminated, which simplifies the management of the generated residues during the manufacturing process.

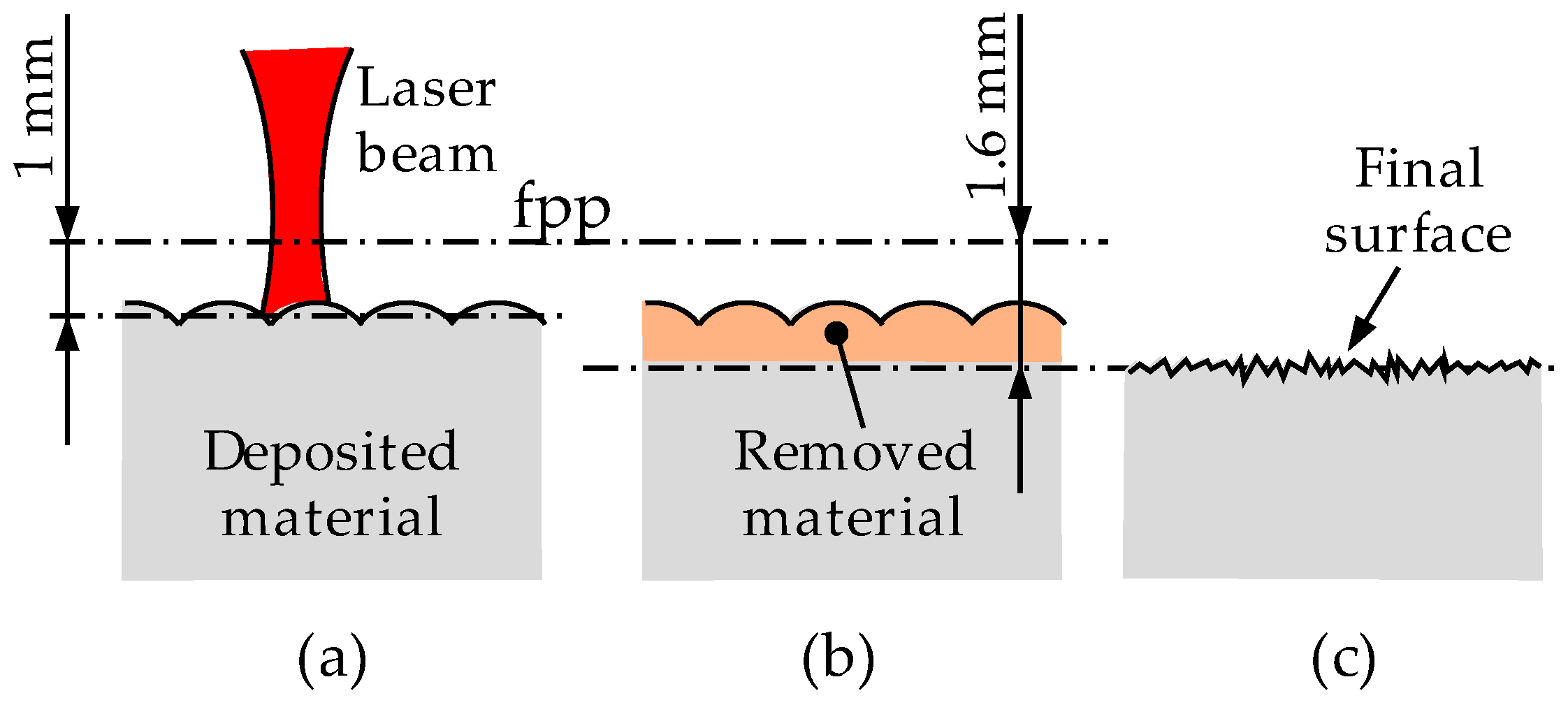

To demonstrate the validity of this statement, a novel manufacturing procedure, fully based on laser, which combines LMD, LBM and LP technologies is developed, where Laser Beam Machining is employed for removing the overstock and waviness generated by Laser Material Deposition. Finally, LP is used for reducing the roughness resulting from the LBM process. Topographies of the attained surfaces are obtained for each operation and roughness values as well as the microstructure are analyzed to evaluate the surface quality.

2. Materials and Methods

The proposed process involves very different laser operations. On the one hand, LMD is usually carried out with Continuous Wave lasers, while LBM and LP are usually performed with pulsed lasers. On the other hand, laser beam diameters for LMD are usually between 100 μm and 1 mm, while LBM and LP processes used to be carried out with much smaller laser beams (usually below 75 μm). Therefore, two different machines have been used to perform the proposed procedure. Firstly, the Kondia Aktinos 500 laser center (Kondia, Elgoibar, Spain) coupled with a 1 kW Rofin FL010 fiber laser (ROFIN-SINAR Laser GmbH, Bergkirchen, Germany) has been employed for the LMD tests. The LMD head includes a 200 mm focal length lens that concentrates the laser beam in a 0.75 mm diameter spot, values provided by the laser supplier. Powder material is supplied using a Sulzer Metco Twin 10 C powder feeder (Oerlikon Metco, Pfäffikon, Switzerland) and focused by an in house designed coaxial nozzle, denominated as EHUCoax-2015 (UPV/EHU, Bilbao, Spain) [

22]. Argon has been used as protective and carrier gas. Then, a Trumpf TruMark Station 5000 (Trumpf, Ditzingen, Germany) is used for the LBM and LP operations [

23]. This marking station has a fiber laser with a Q-switch pulse technology that concentrates a 50 W laser power in 7–500 ns duration pulses. A 2D galvanometric scanner (Trumpf, Ditzingen, Germany) controls the laser beam position and focuses it at a 212 mm focal distance and a 45 μm diameter; these values are supplied by Trumpf (Ditzingen, Germany).

The material used for the tests is Inconel 718 superalloy, which is supplied by Oerlikon Metco (Pfäffikon, Switzerland) under the name MetcoClad 718. The chemical composition of the powder material is shown in

Table 1 and, as it can be observed, it is similar to that of Inconel 718. Powder is supplied with a particle size between 44 and 90 microns in diameter and the spherical shape of the particles is ensured as they are manufactured via Argon-gas atomization.

Before manufacturing a final test part, three types of tests are performed:

- (1)

First, a preliminary test (Test Part 1) for evaluating the capability of LBM for machining LMD manufactured Inconel 718 parts is performed. For this purpose, a 3 mm thickness layer is deposited by means of LMD. Afterwards, the surface of the deposited material is grinded to ensure a flat reference surface. On this surface, different LBM parameters are tested, and, in each case, the reached depth and the resulting surface quality are evaluated. Based on the obtained results, the maximum effective depth at which the laser could remove material is defined.

- (2)

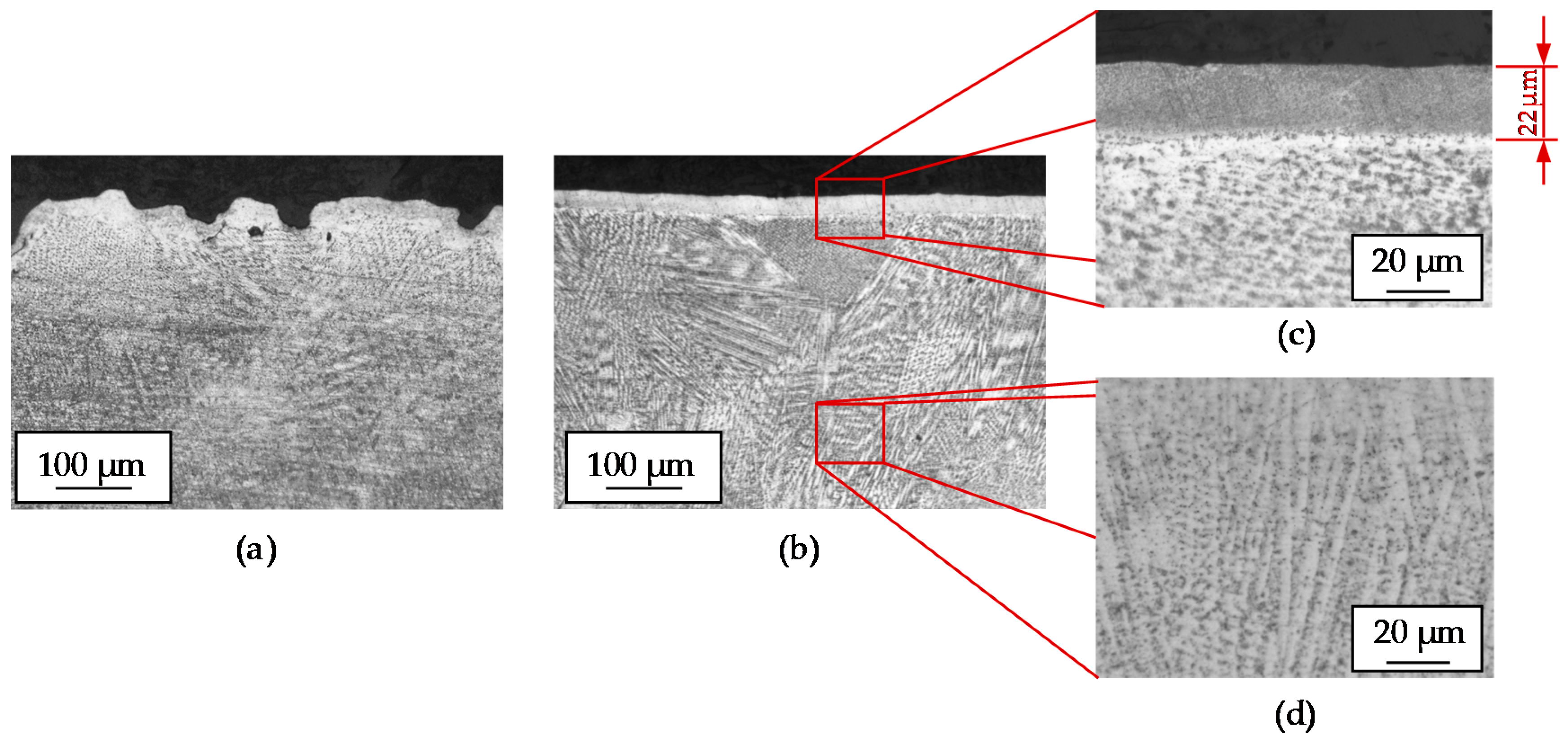

Secondly, following the same procedure and based on the results obtained in Test 1, the capability of LP for improving the roughness resulting from LBM is evaluated. Based on these results, the optimum LP parameters are defined. Besides, the recast layer generated by LP is measured.

- (3)

Finally, the capability of LBM for eliminating the surface waviness resulting from LMD is evaluated. In this case, no intermediate grinding operation is performed.

Process parameters for LMD of MetcoClad 718 were obtained in a previous work [

21] and they are detailed in

Table 2. In

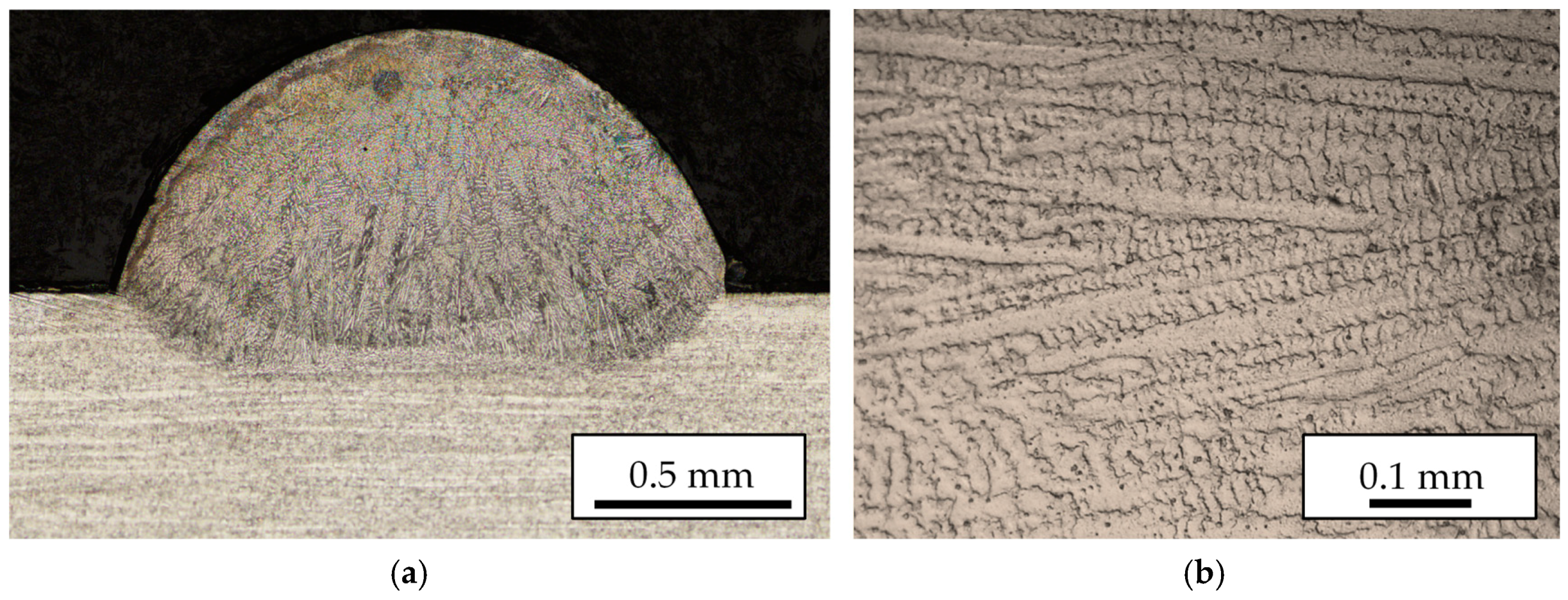

Figure 1 a cross section of a single clad is shown, where the dimensions and dilution can be observed. The sample is etched using Kalling’s 2 reagent to reveal the microstructure originated during the cooling stage. Generated clads have 2 mm width and a constant 0.8 mm height is obtained with each layer.

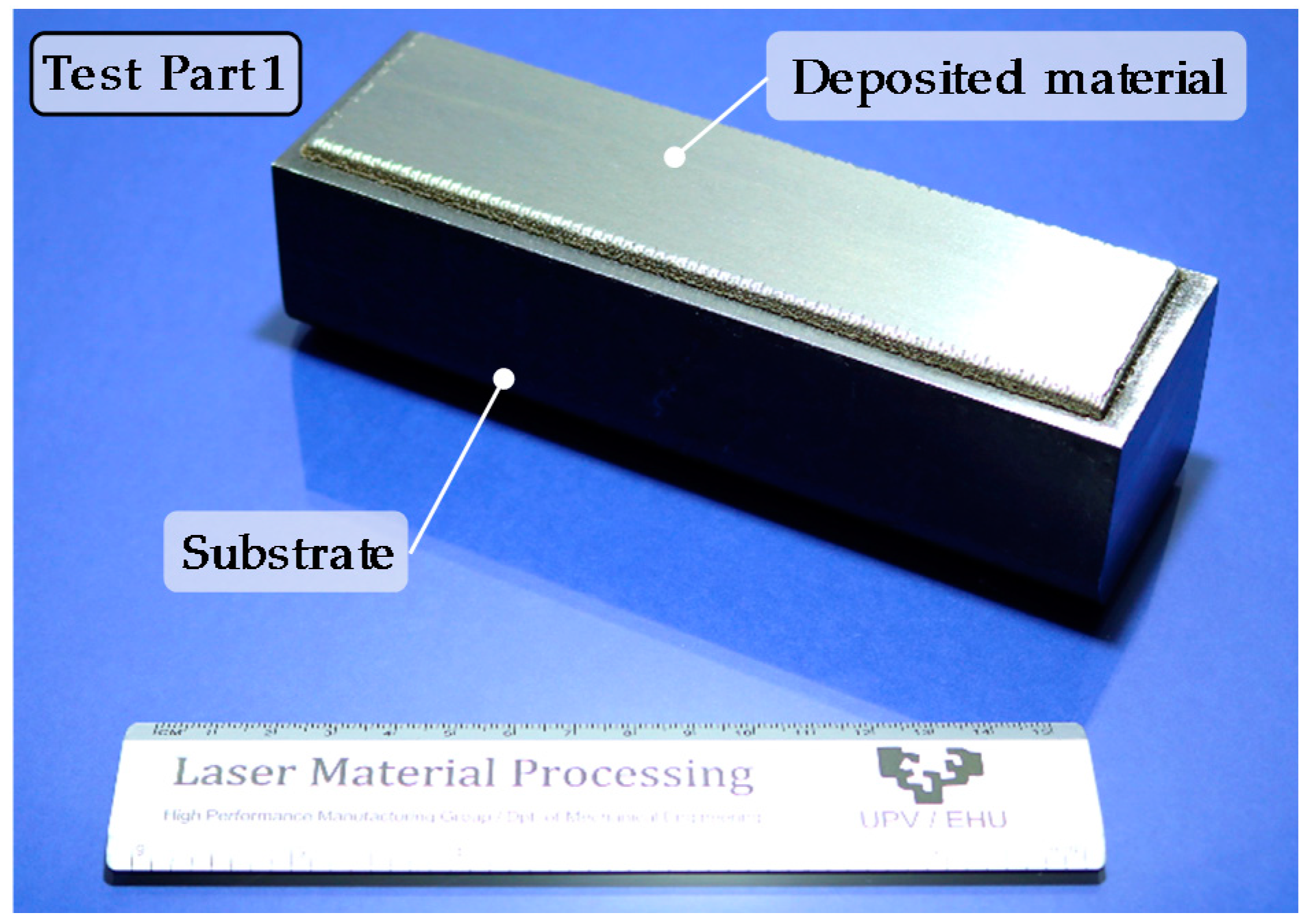

For the first test, material is deposited over an AISI 1045 substrate. This substrate has no influence on the subsequent LBM operations since they are performed only in the LMD zone. Nevertheless, for the final tests, Inconel 718 substrate is used.

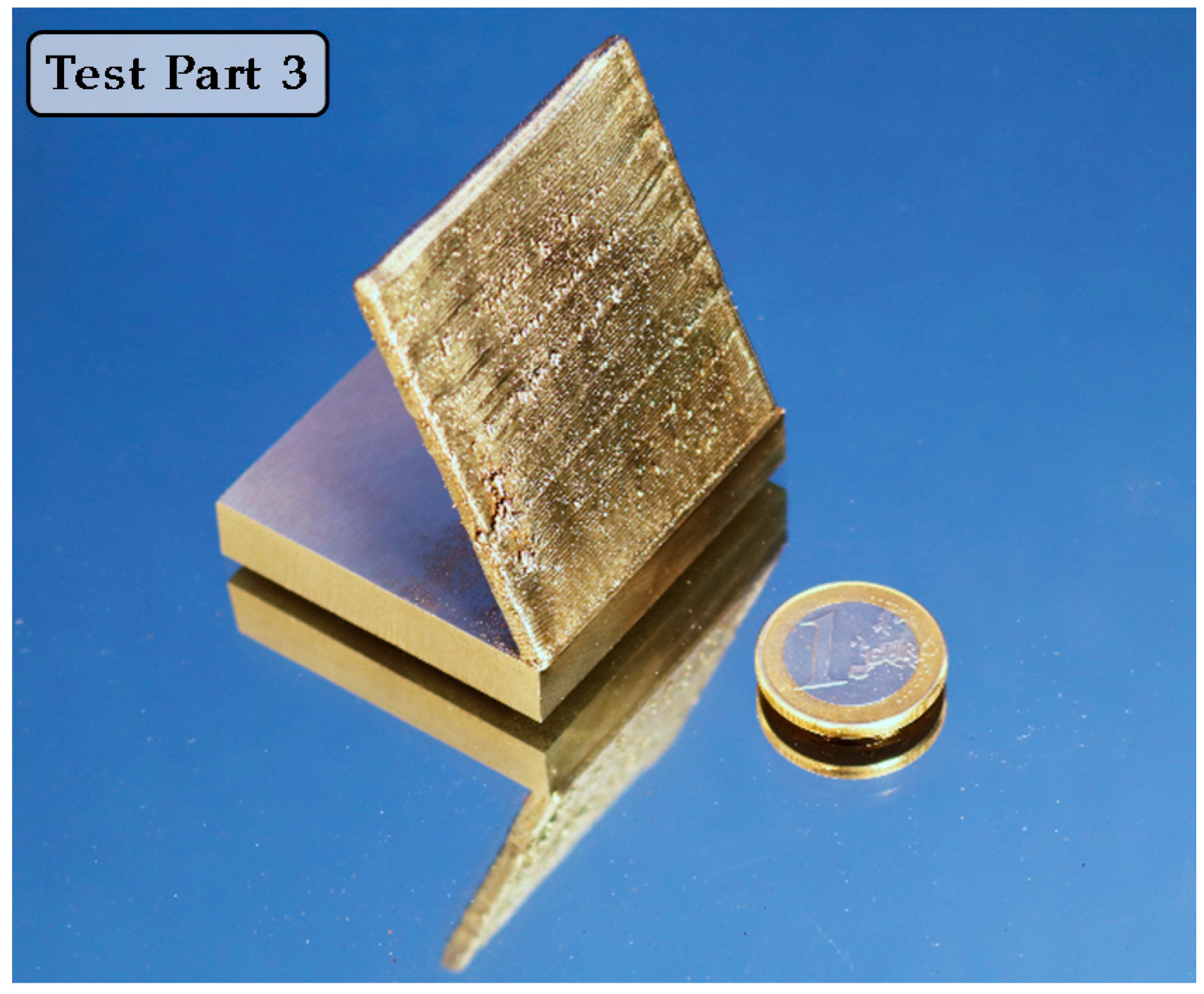

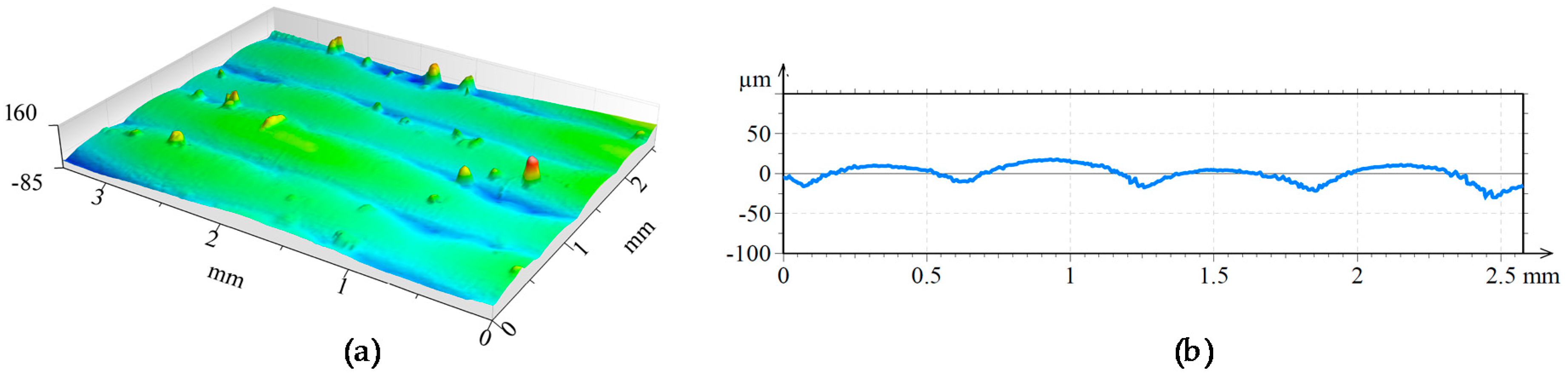

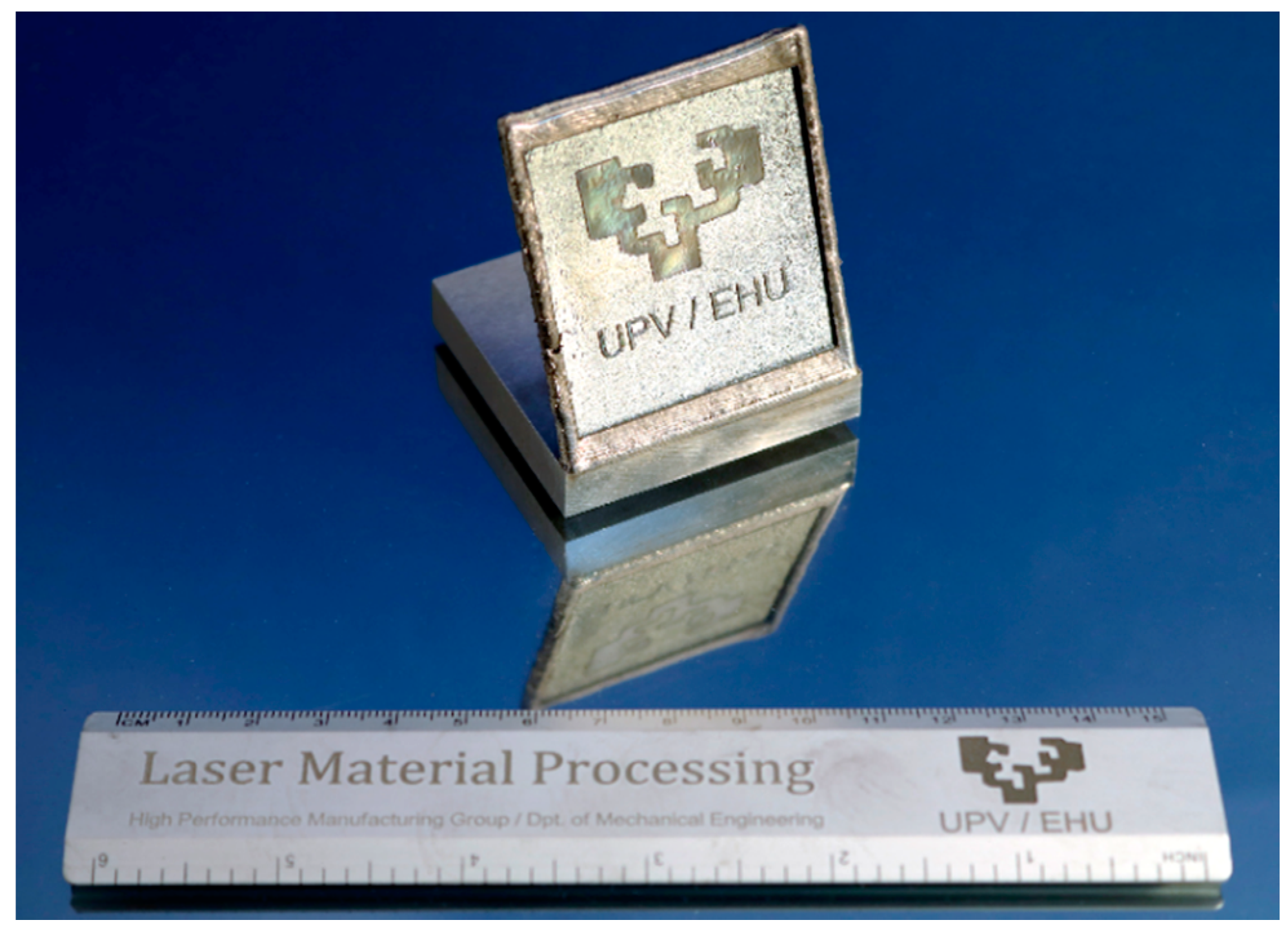

Figure 2 shows the substrate with the deposited area after the grinding operation.

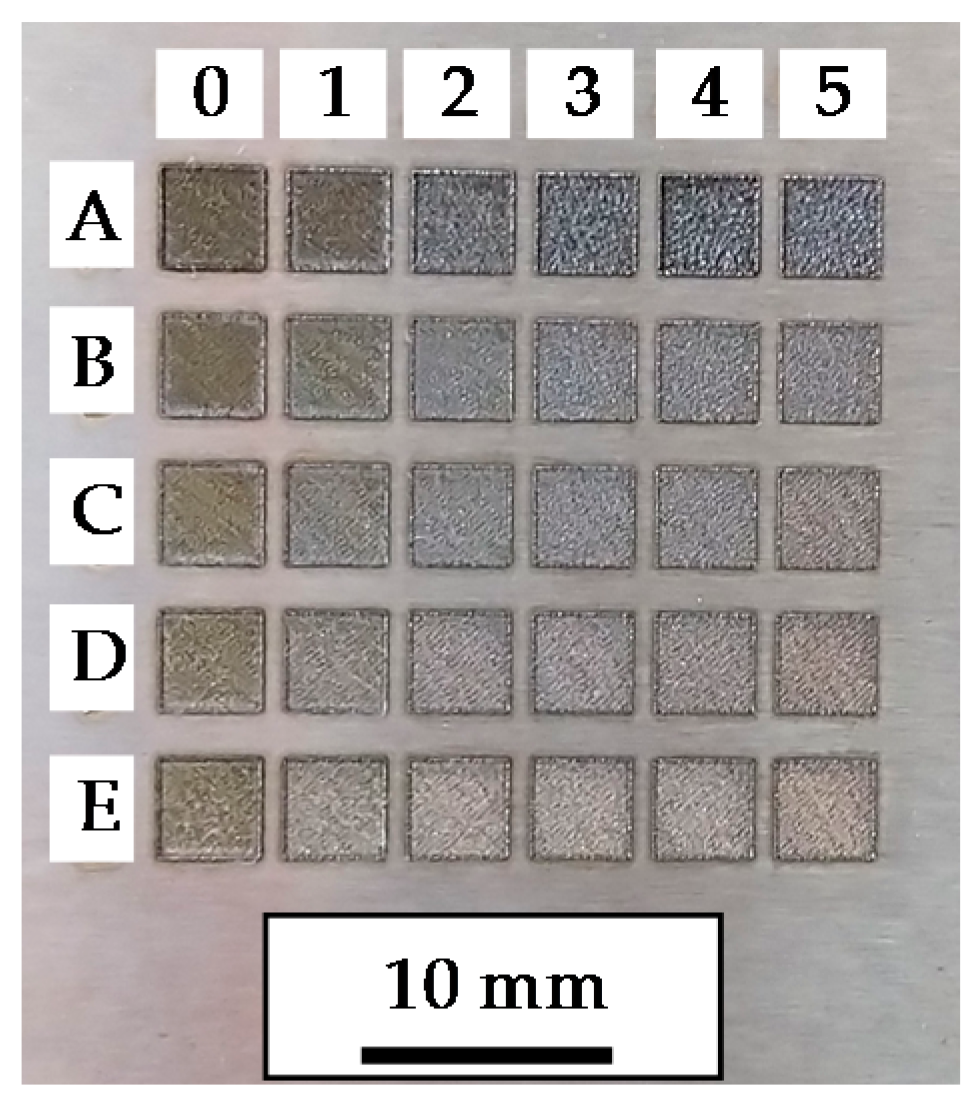

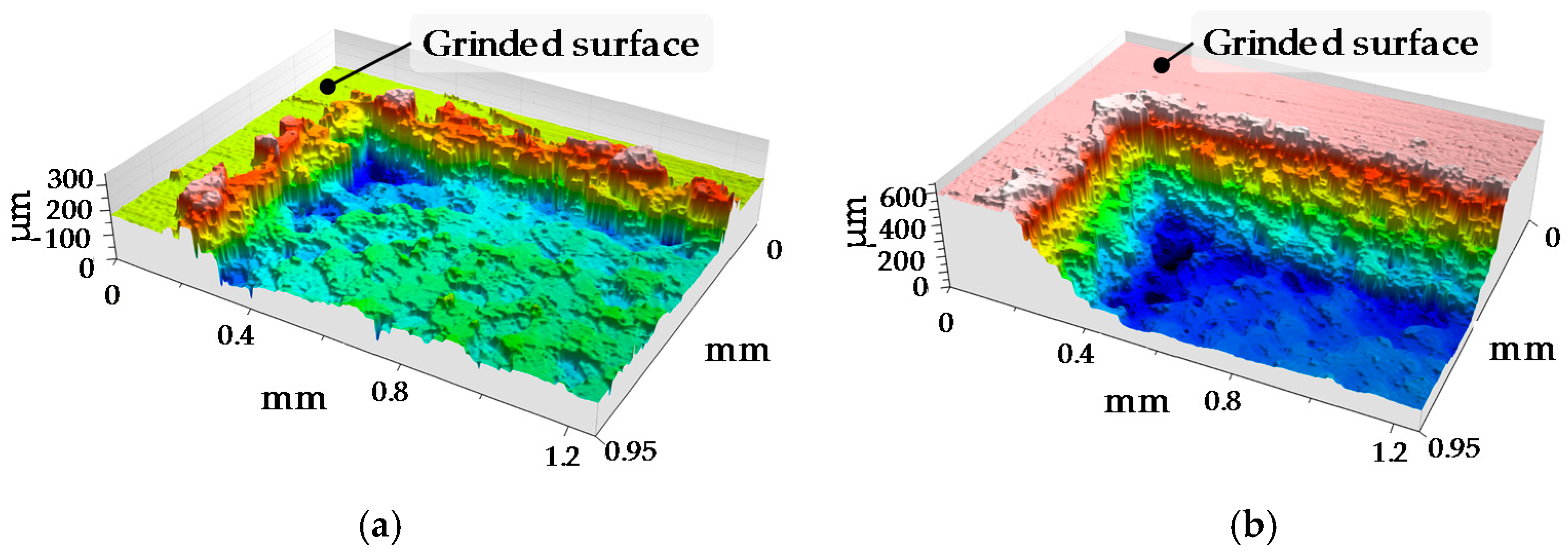

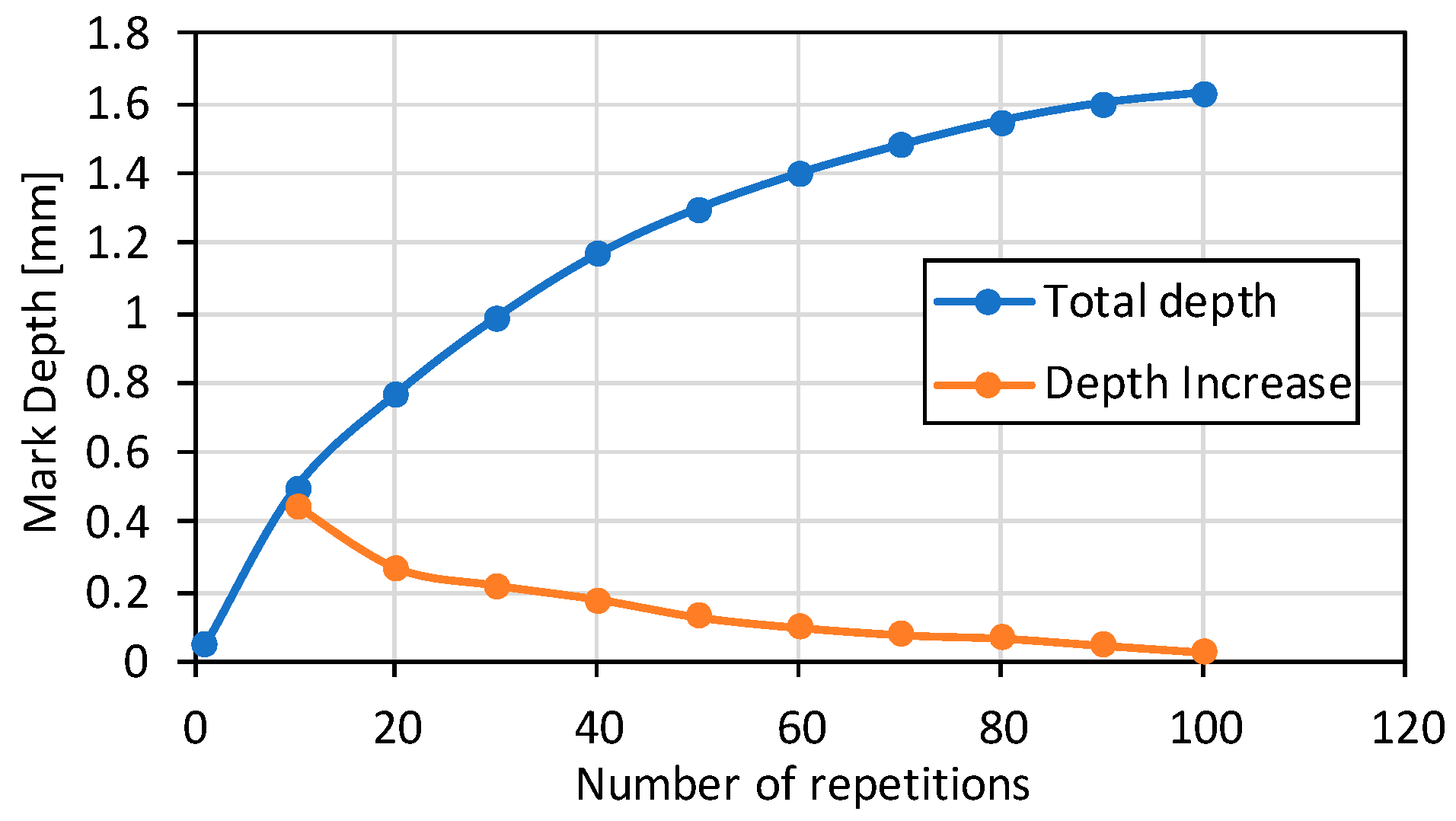

To determine the best conditions for LBM, a parameter scanning is performed over the grinded flat surface in Test Part 1. Obtained results are shown in

Figure 3, whereas the employed parameters in these tests are shown in

Table A1 (see

Appendix A).

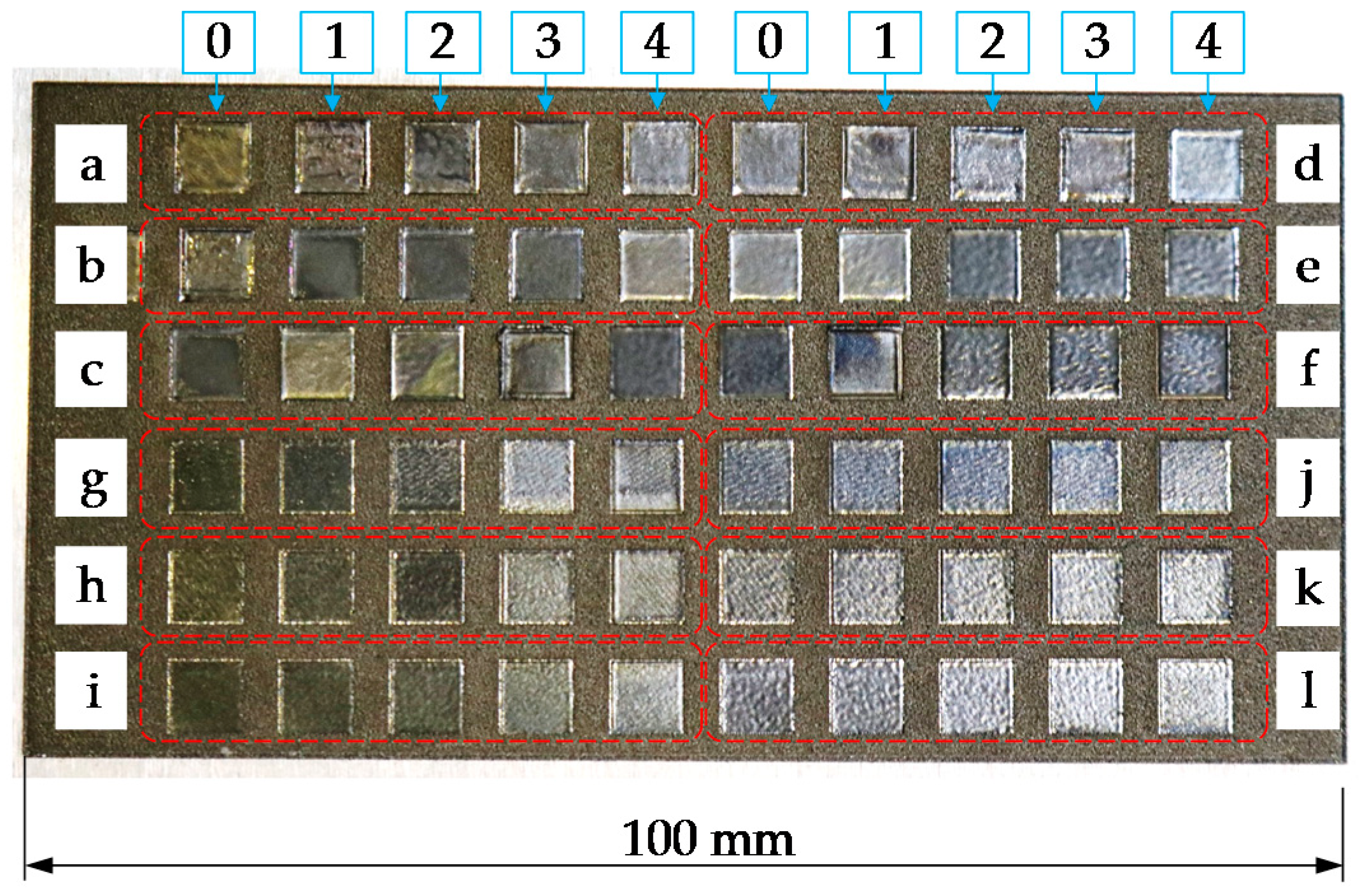

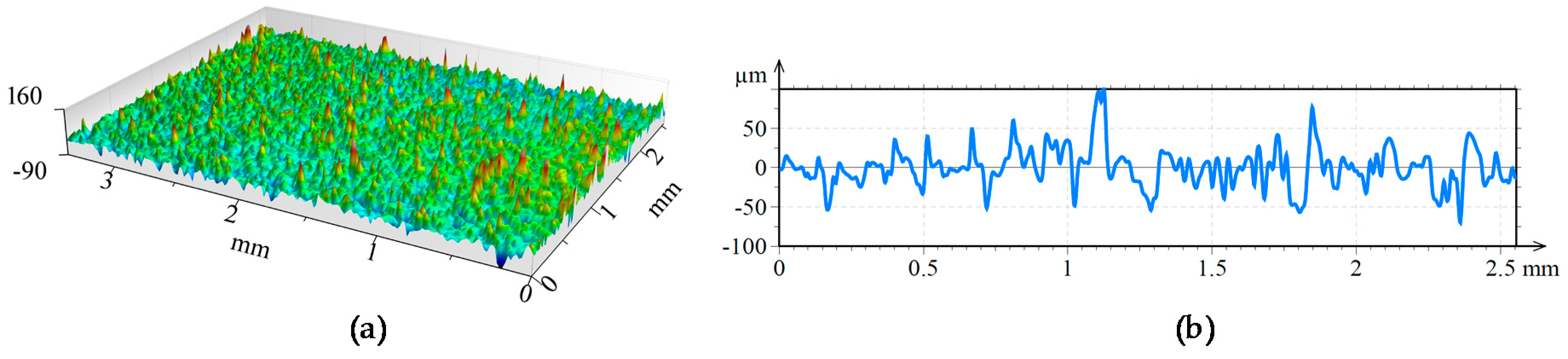

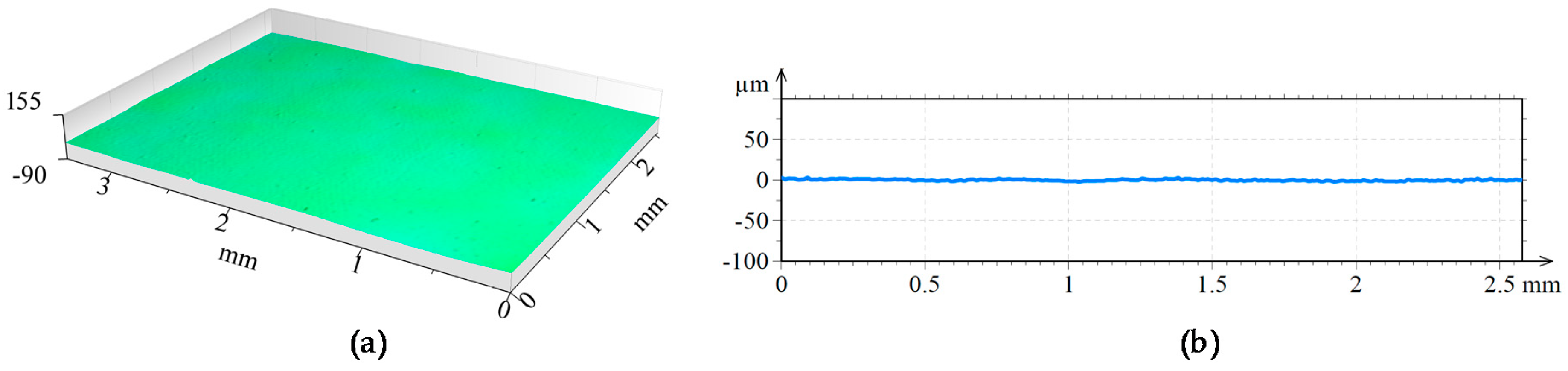

Likewise, with a view to determining the best LP conditions, a parameter scanning has been performed over the LBM surface resulted from applying the optimum process conditions determined previously, see

Figure 4. Test codes for the LP tests are named with lower case letters to avoid misunderstandings with the LBM test naming. The parameters of these tests are showed in

Table A2 (see

Appendix B).

Once Tests 1 and 2 are carried out and the optimum parameters for LBM and LP are defined for an LMD manufactured Inconel 718 part, Test 3 is performed. Test Part 3, which is also used for the manufacture of the Final Test Part, is manufactured layer-by-layer via LMD and the result is a 50 mm high wall with a 4 mm thickness and 60° inclination, see

Figure 5. Please note that in this test, no grinding operation is executed and surface waviness resulting from the LMD process is eliminated exclusively via LBM.