Application of Pin-On-Disc Techniques for the Study of Tribological Interferences in the Dry Machining of A92024-T3 (Al–Cu) Alloys

Abstract

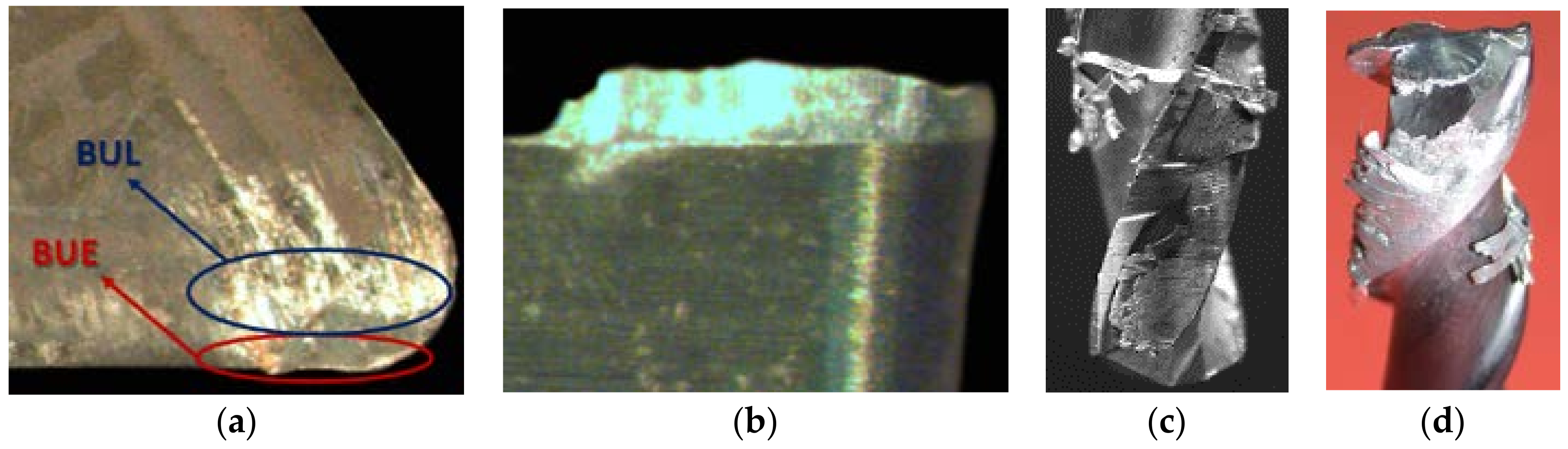

:1. Introduction

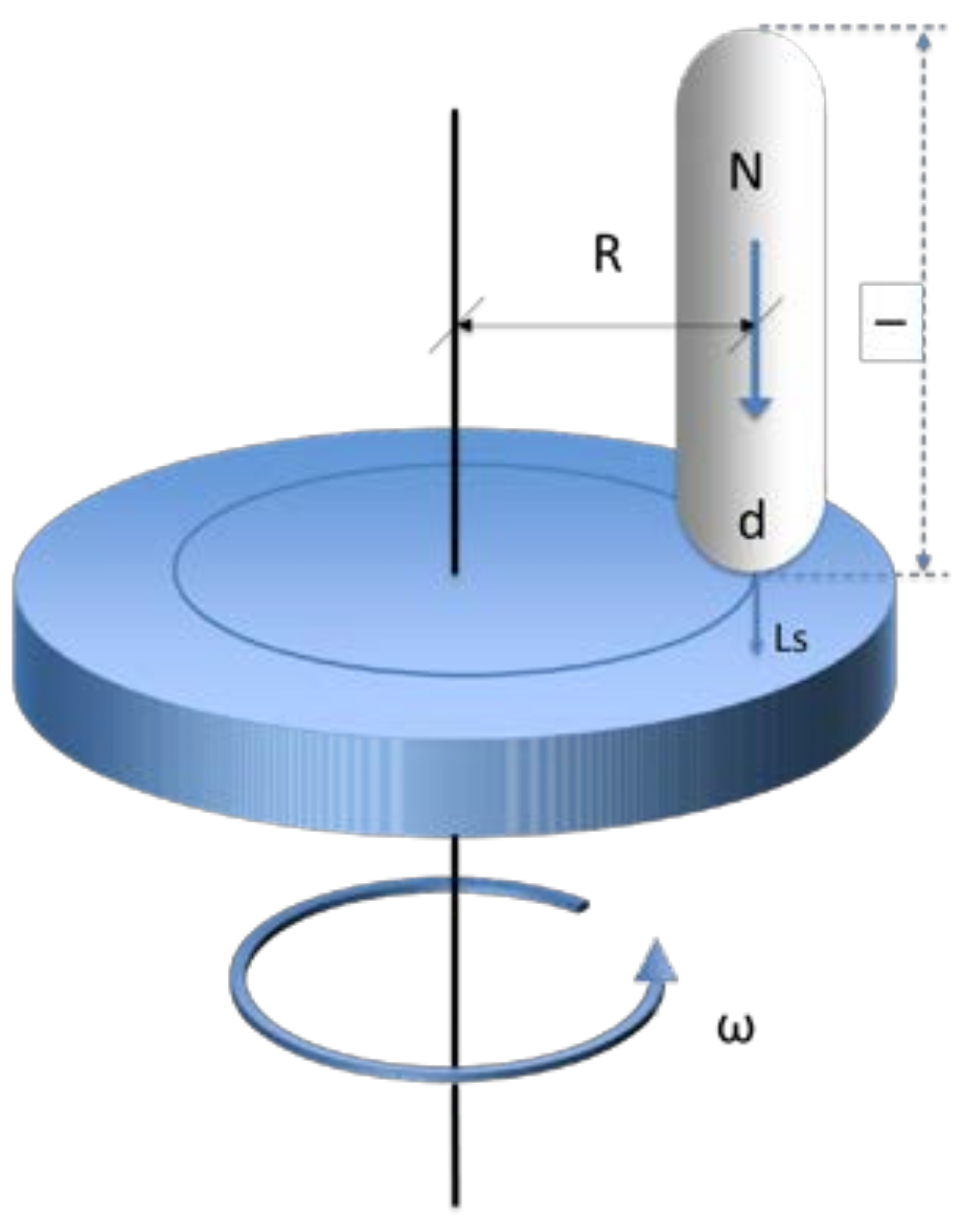

2. Materials and Methods

3. Results and Discussion

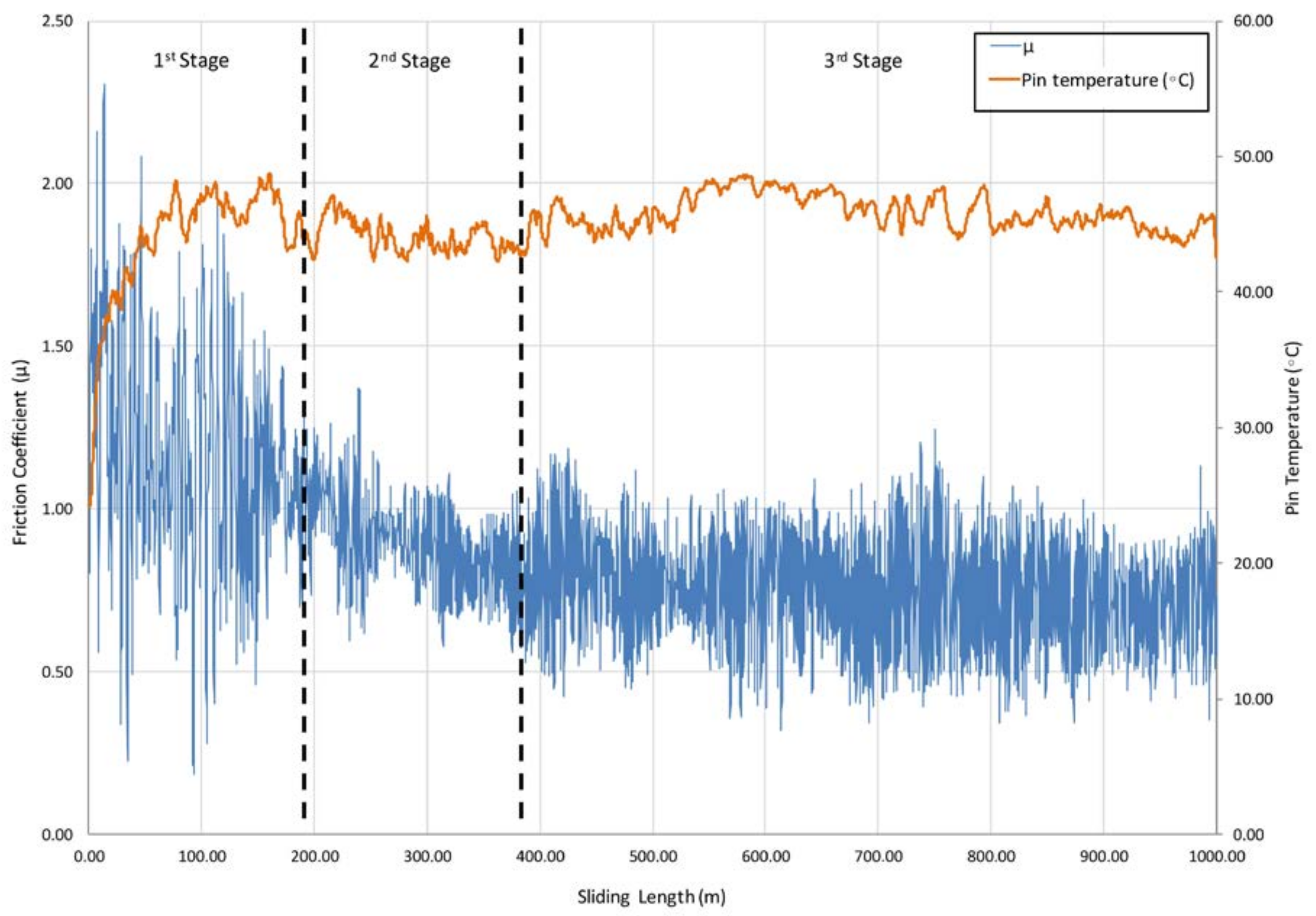

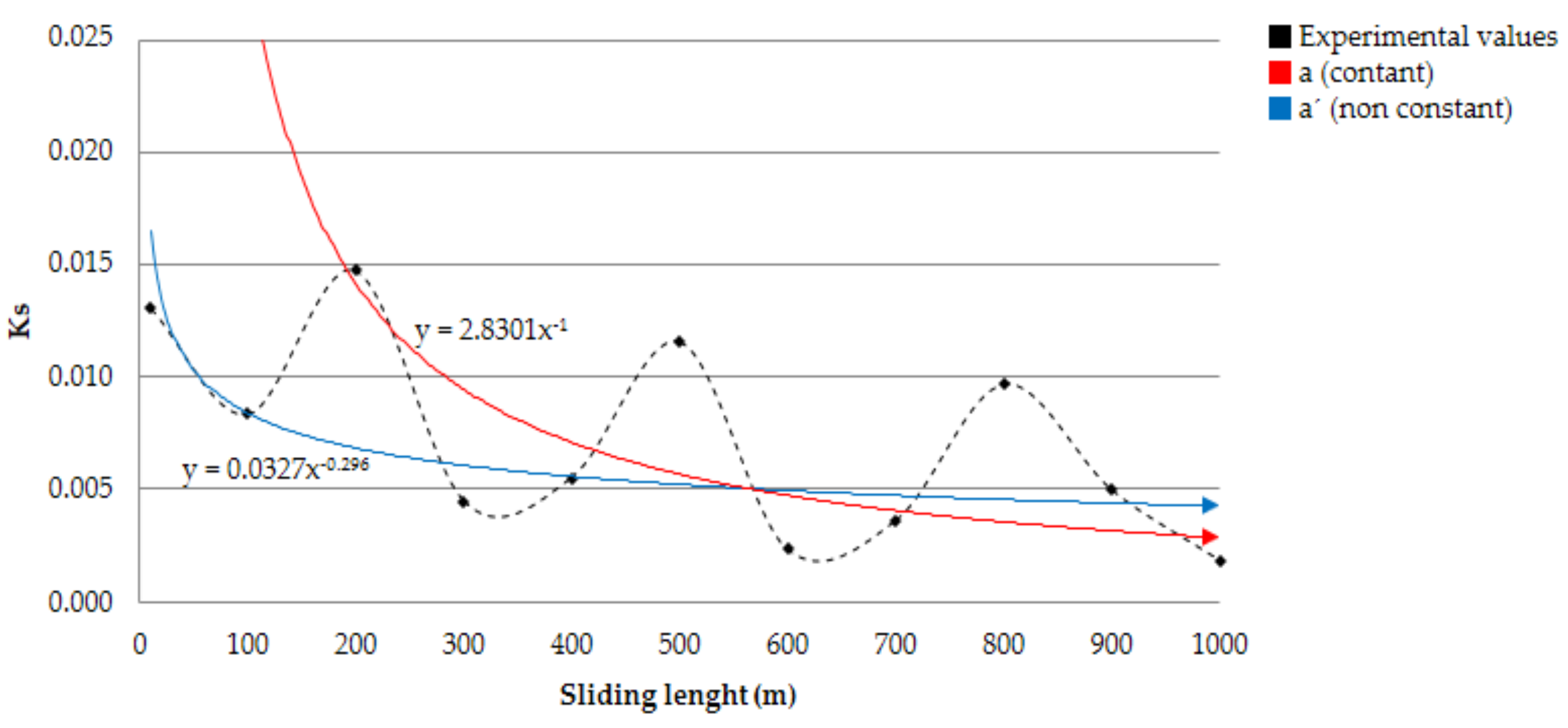

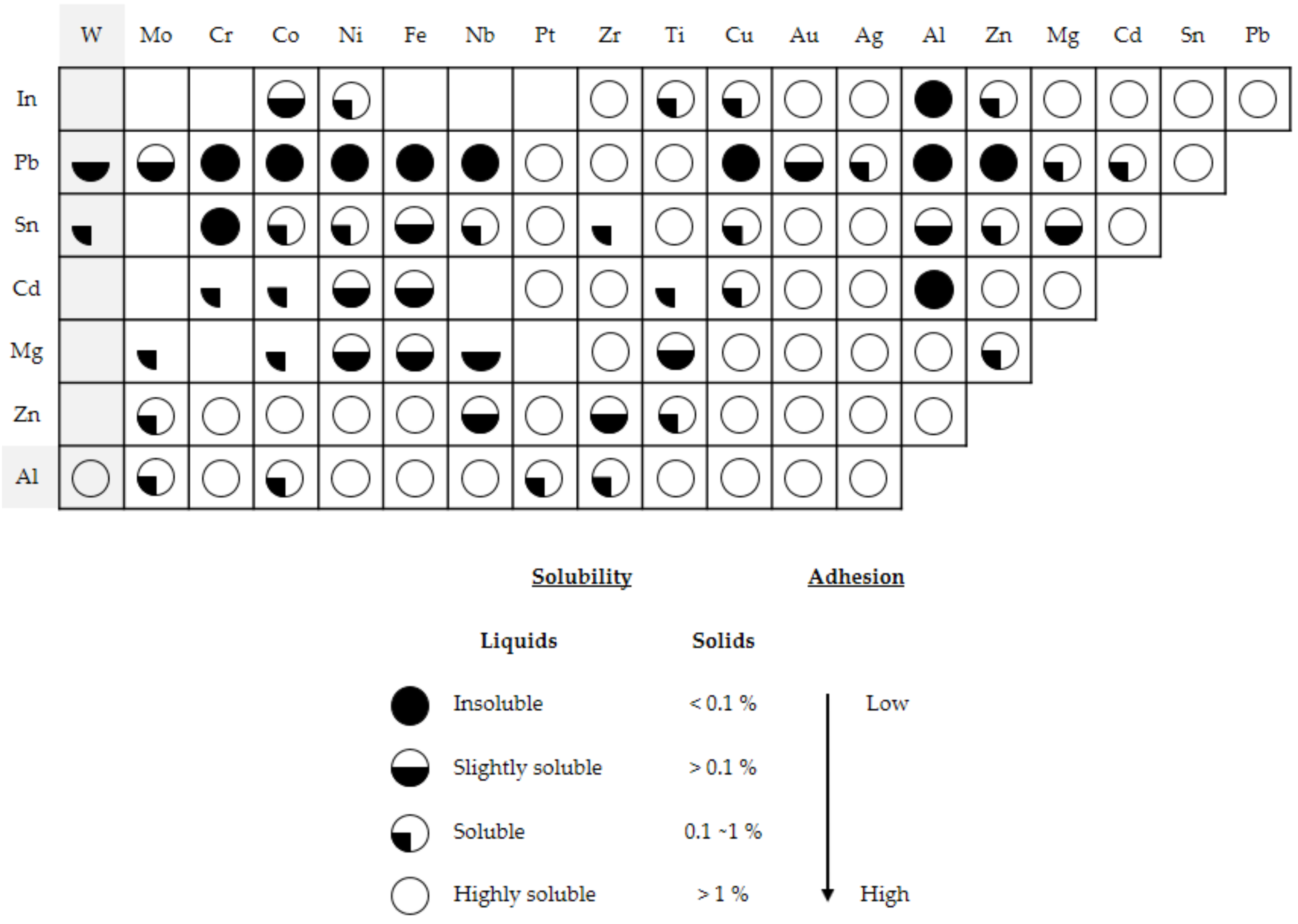

3.1. Friction Coefficient Evaluation

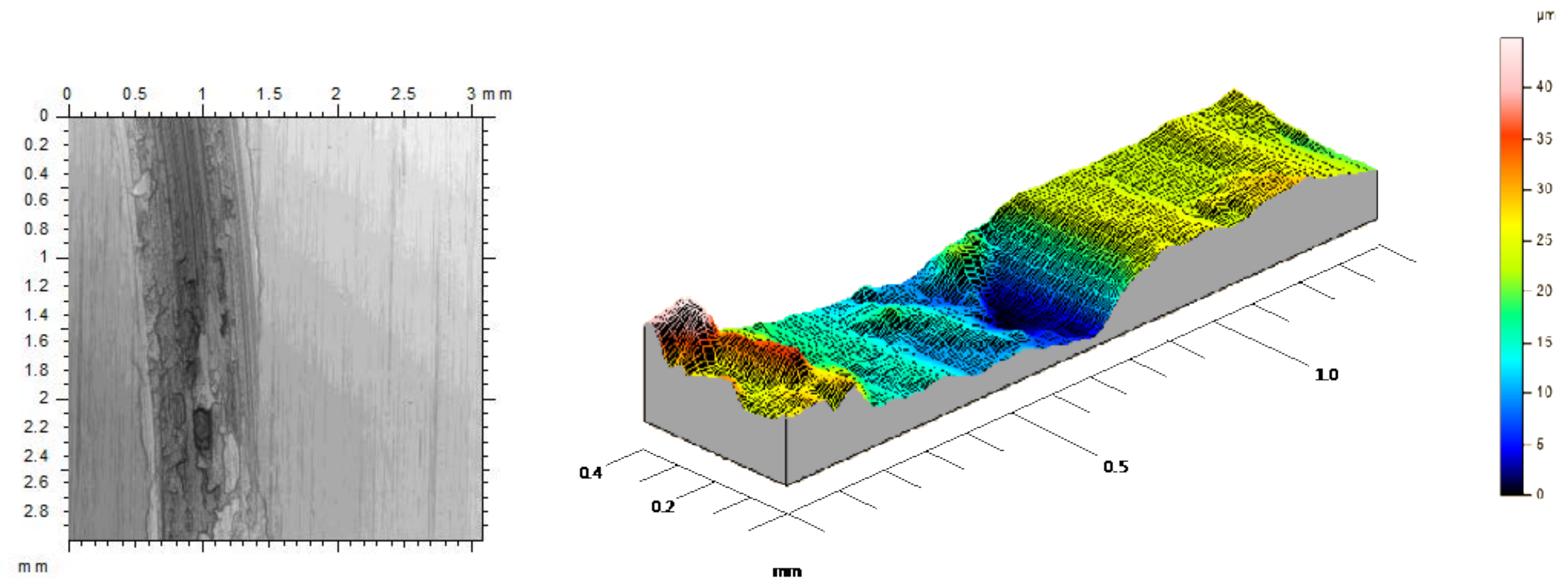

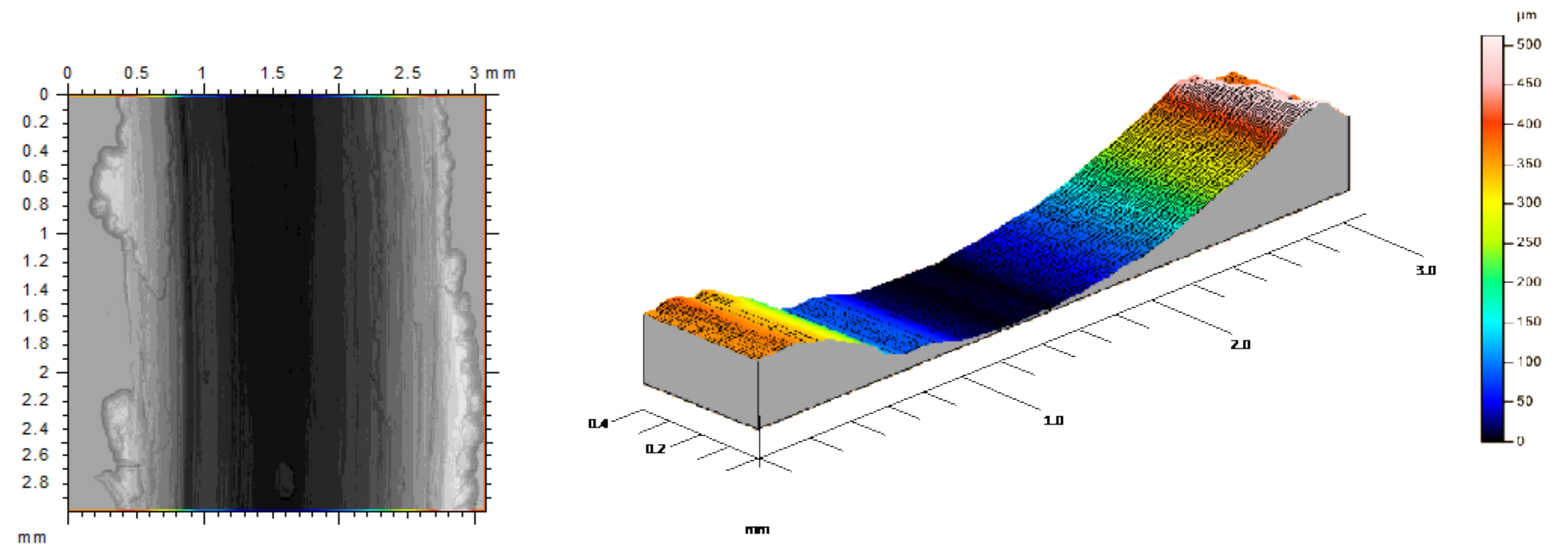

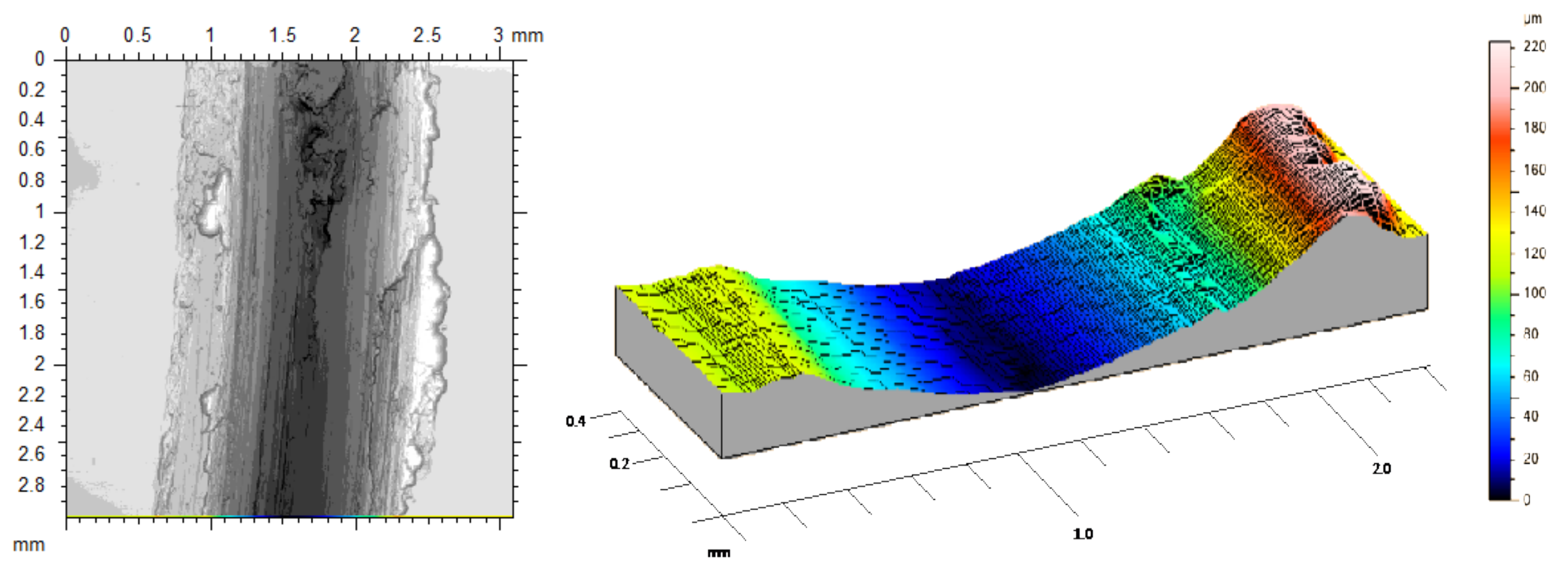

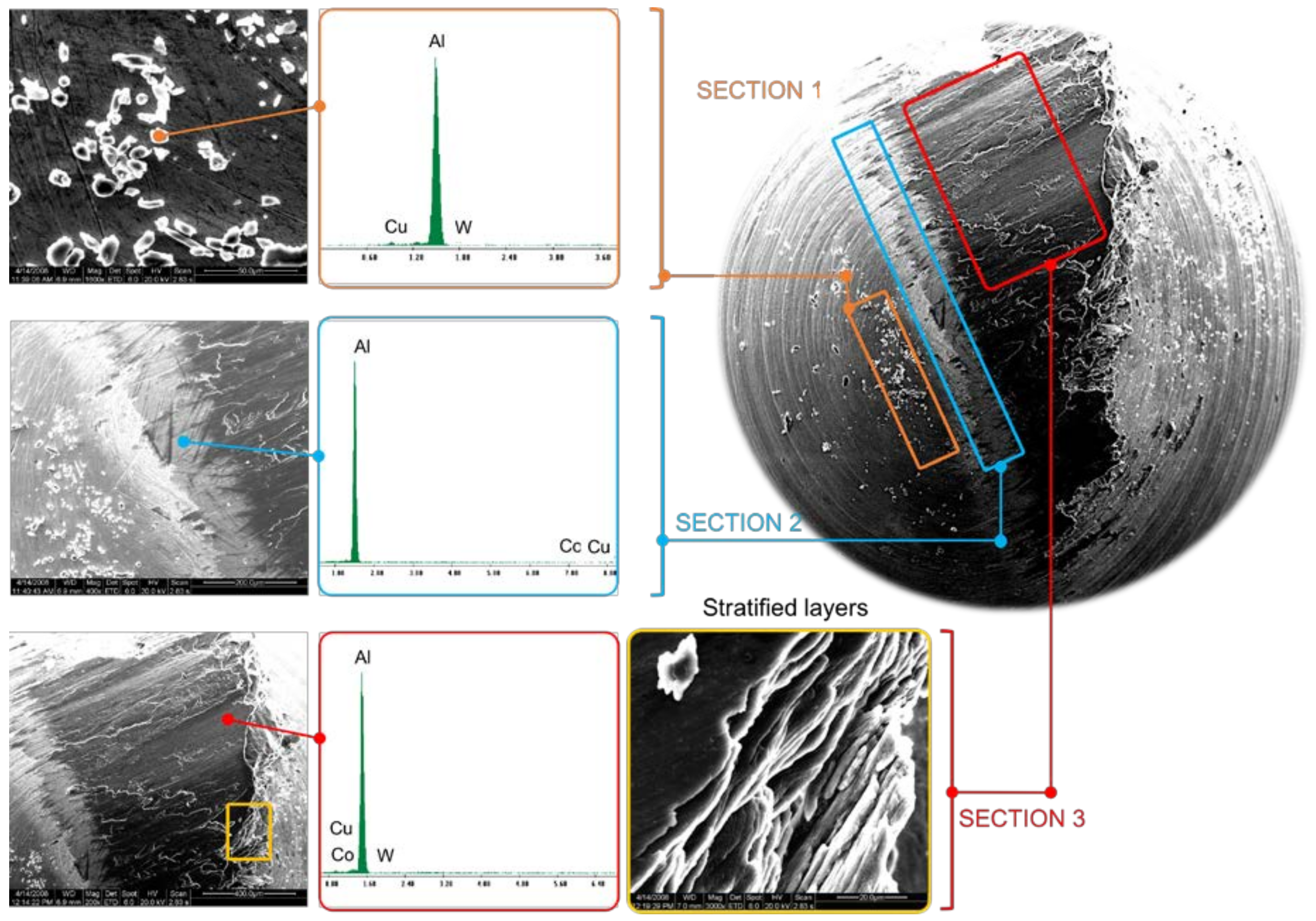

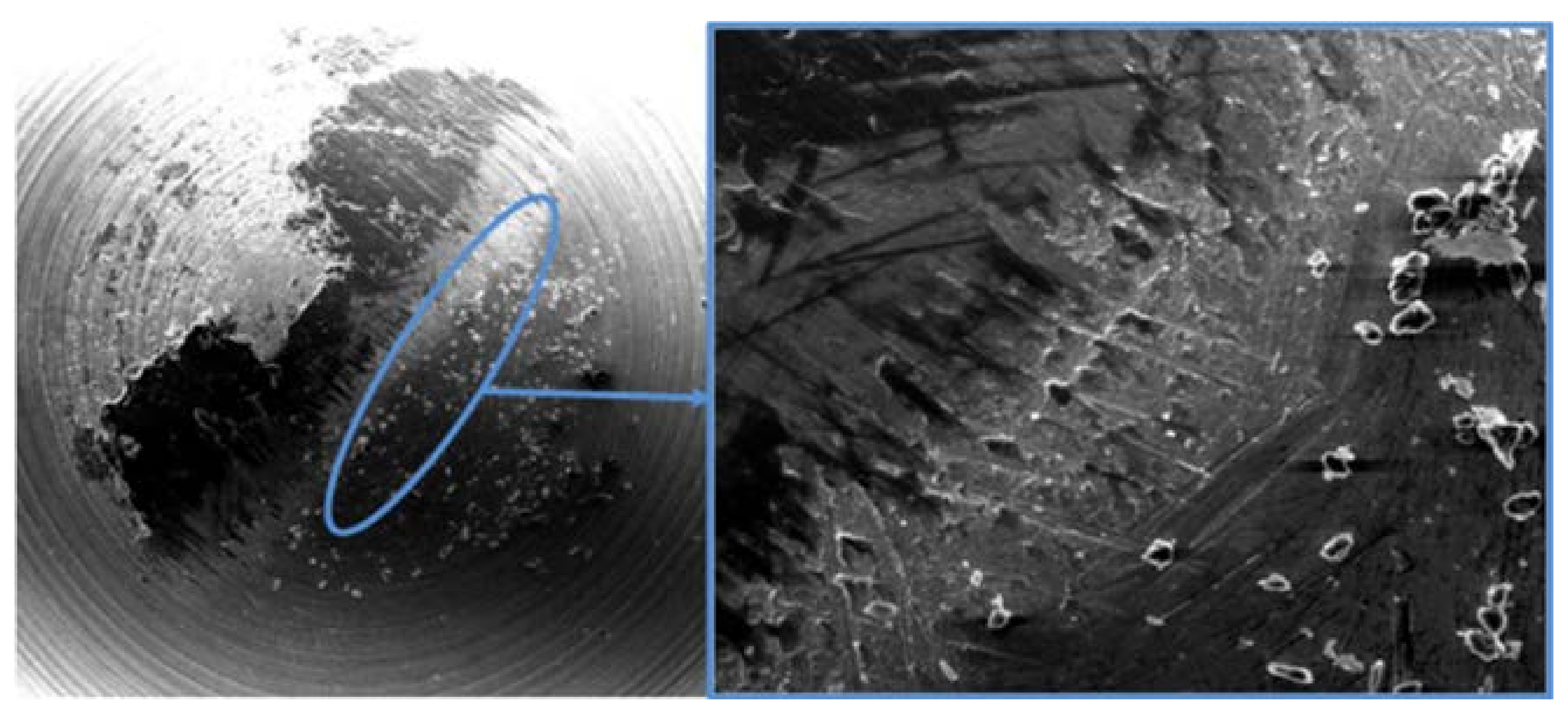

3.2. Wear Effects Evaluation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kishawy, H.A.; Dumitrescu, M.; Ng, E.-G.; Elbestawi, M.A. Effect of Coolant Strategy on Tool Performance, Chip Morphology and Surface Quality during High-Speed Machining of A356 Aluminum Alloy. Int. J. Mach. Tools Manuf. 2005, 45, 219–227. [Google Scholar] [CrossRef]

- Totten, G.E.; Liang, H. Mechanical Tribology. Materials, Characterization and Applications; Marcel Dekker: New York, NY, USA, 2004; ISBN 9780824748739. [Google Scholar]

- Gómez-Parra, A.; Álvarez-Alcón, M.; Salguero, J.; Batista, M.; Marcos, M. Analysis of the evolution of the Built-Up Edge and Built-Up Layer formation mechanisms in the dry turning of aeronautical aluminium alloys. Wear 2013, 302, 1209–1218. [Google Scholar] [CrossRef]

- List, G.; Nouari, M.; Géhin, D.; Gomez, S.; Manaud, J.P.; Le Petitcorps, Y.; Girot, F. Wear behaviour of cemented carbide tools in dry machining of aluminium alloy. Wear 2005, 259, 1177–1189. [Google Scholar] [CrossRef]

- Veldhuis, S.C.; Dosbaeva, G.K.; Yamamoto, K. Tribological compatibility and improvement of machining productivity and surface integrity. Tribol. Int. 2009, 42, 1004–1010. [Google Scholar] [CrossRef]

- Gokkaya, H.; Taskesen, A. The effects of cutting speed and feed rate on BUE-BUL formation, cutting forces and surface roughness when machining Aa6351 (T6) alloy. J. Mech. Eng. 2008, 54, 524–530. [Google Scholar]

- Gharam, A.A.; Lukitsch, M.J.; Balogh, M.P.; Irish, N.; Alpas, A.T. High temperature tribological behavior of W-DLC against aluminum. Surf. Coat. Technol. 2011, 206, 1905–1912. [Google Scholar] [CrossRef]

- Islam, M.A.; Farhat, Z. Wear of A380M Aluminum Alloy under Reciprocating Load. J. Mater. Eng. Perform. 2010, 19, 1208–1213. [Google Scholar] [CrossRef]

- Ismail, O. Abrasive wear behavior of various reinforced AA6061 matrix composites produced with hot pressing process: A comparative study. Materialwiss. Werksttech. 2017, 48, 589–599. [Google Scholar] [CrossRef]

- Strahin, B.L.; Doll, G.L. Tribological coatings for improving cutting tool performance. Surf. Coat. Technol. 2018, 336, 117–122. [Google Scholar] [CrossRef]

- Xie, H.; Cheng, Y.; Li, S.; Cao, J.; Cao, L. Wear and corrosion resistant coatings on surface of cast A356 aluminum alloy by plasma electrolytic oxidation in moderately concentrated aluminate electrolytes. Trans. Nonferrous Met. Soc. China 2017, 27, 336–351. [Google Scholar] [CrossRef]

- Sánchez, J.M.; Rubio, E.; Álvarez, M.; Sebastián, M.A.; Marcos, M. Microstructural characterisation of material adhered over cutting tool in the dry machining of aerospace aluminium alloys. J. Mater. Process. Technol. 2005, 164–165, 911–918. [Google Scholar] [CrossRef]

- Carrilero, M.S.; Bienvenido, R.; Sánchez, J.M.; Álvarez, M.; González, A.; Marcos, M. A SEM and EDS insight into the BUL and BUE differences in the turning processes of AA2024 Al–Cu alloy. Int. J. Mach. Tools Manuf. 2002, 42, 215–220. [Google Scholar] [CrossRef]

- Menezes, P.L.; Kishore; Kailas, S.V. On the effect of surface texture on friction and transfer layer formation—A study using Al and steel pair. Wear 2008, 265, 1655–1669. [Google Scholar] [CrossRef]

- Liu, R.; Li, D. Modification of Archard’s equation by taking account of elastic/pseudoelastic properties of materials. Wear 2001, 251, 956–964. [Google Scholar] [CrossRef]

- UNE-38314 Aluminio y Aleaciones de Aluminio Para Forja, Serie 2000, AlCu-AENOR 2000; AENOR: Madrid, Spain, 2000.

- Rubio, E.M.; Camacho, A.M.; Sánchez-Sola, J.M.; Marcos, M. Surface roughness of AA7050 alloy turned bars: Analysis of the influence of the length of machining. J. Mater. Process. Technol. 2005, 162–163, 682–689. [Google Scholar] [CrossRef]

- Choudhury, I.A.; El-Baradie, M.A. Machinability assessment of inconel 718 by factorial design of experiment coupled with response surface methodology. J. Mater. Process. Technol. 1999, 95, 30–39. [Google Scholar] [CrossRef]

- Chan, K.; Cheung, C.; Ramesh, M.; Lee, W.; To, S. A theoretical and experimental investigation of surface generation in diamond turning of an Al6061/SiCp metal matrix composite. Int. J. Mech. Sci. 2001, 43, 2047–2068. [Google Scholar] [CrossRef]

- Abouelatta, O.B.; Mádl, J. Surface roughness prediction based on cutting parameters and tool vibrations in turning operations. J. Mater. Process. Technol. 2001, 118, 269–277. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Rabinowicz, E. Friction and Wear of Materials; Wiley: Hoboken, NJ, USA, 1995; ISBN 9780471830849. [Google Scholar]

| Load (N) | Sliding Speed (m/s) | Sliding Distance (m) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 1.0 | 10 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Cu | Mg | Mn | Si | Fe | Zn | Ti | Cr | Al |

|---|---|---|---|---|---|---|---|---|

| 4.00 | 1.50 | 0.60 | 0.50 | 0.50 | 0.25 | 0.15 | 0.10 | rest |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salguero, J.; Vazquez-Martinez, J.M.; Sol, I.D.; Batista, M. Application of Pin-On-Disc Techniques for the Study of Tribological Interferences in the Dry Machining of A92024-T3 (Al–Cu) Alloys. Materials 2018, 11, 1236. https://doi.org/10.3390/ma11071236

Salguero J, Vazquez-Martinez JM, Sol ID, Batista M. Application of Pin-On-Disc Techniques for the Study of Tribological Interferences in the Dry Machining of A92024-T3 (Al–Cu) Alloys. Materials. 2018; 11(7):1236. https://doi.org/10.3390/ma11071236

Chicago/Turabian StyleSalguero, Jorge, Juan Manuel Vazquez-Martinez, Irene Del Sol, and Moises Batista. 2018. "Application of Pin-On-Disc Techniques for the Study of Tribological Interferences in the Dry Machining of A92024-T3 (Al–Cu) Alloys" Materials 11, no. 7: 1236. https://doi.org/10.3390/ma11071236

APA StyleSalguero, J., Vazquez-Martinez, J. M., Sol, I. D., & Batista, M. (2018). Application of Pin-On-Disc Techniques for the Study of Tribological Interferences in the Dry Machining of A92024-T3 (Al–Cu) Alloys. Materials, 11(7), 1236. https://doi.org/10.3390/ma11071236