Enhanced Dielectric and Mechanical Properties of Ternary Composites via Plasticizer-Induced Dense Interfaces

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

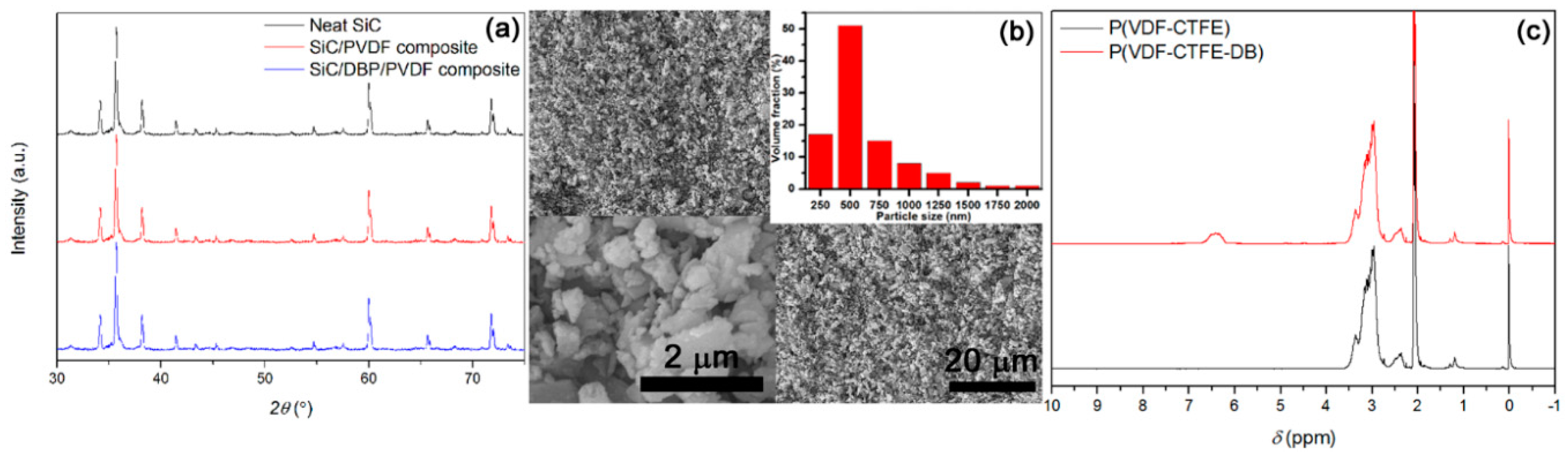

3.1. Characterization of SiC NPs and Polymers

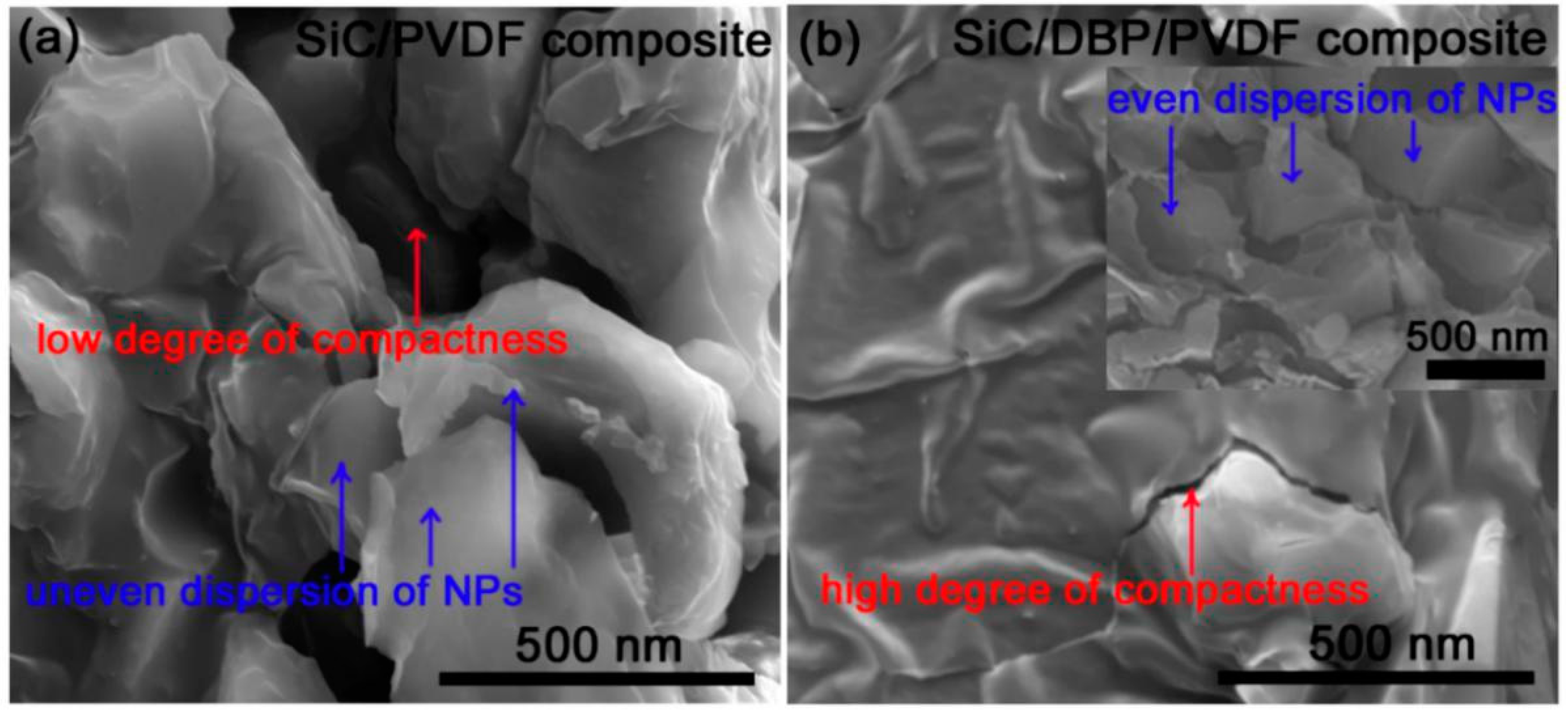

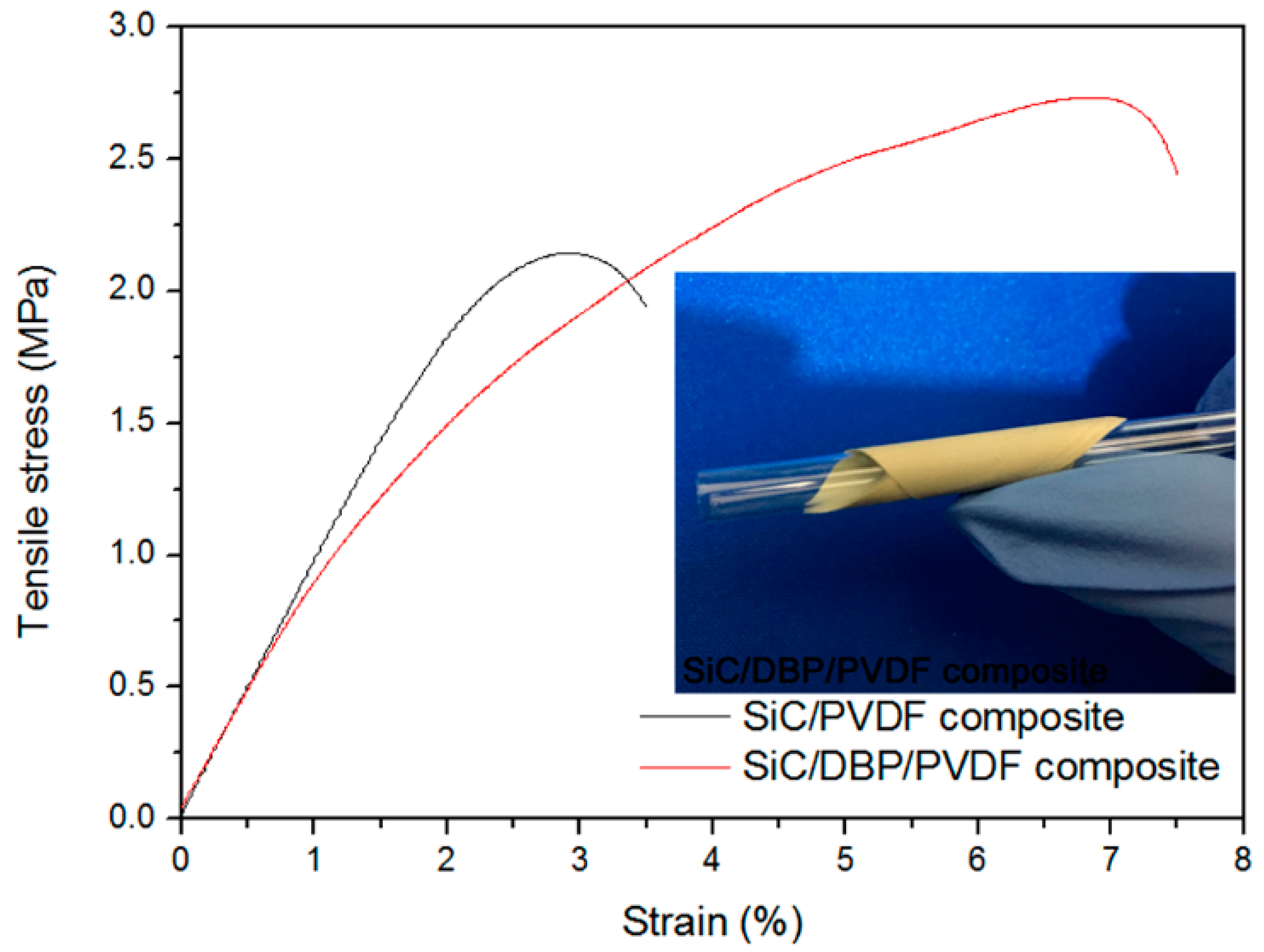

3.2. Degree of Interface Compactness and Its Influence on Mechanical Properties

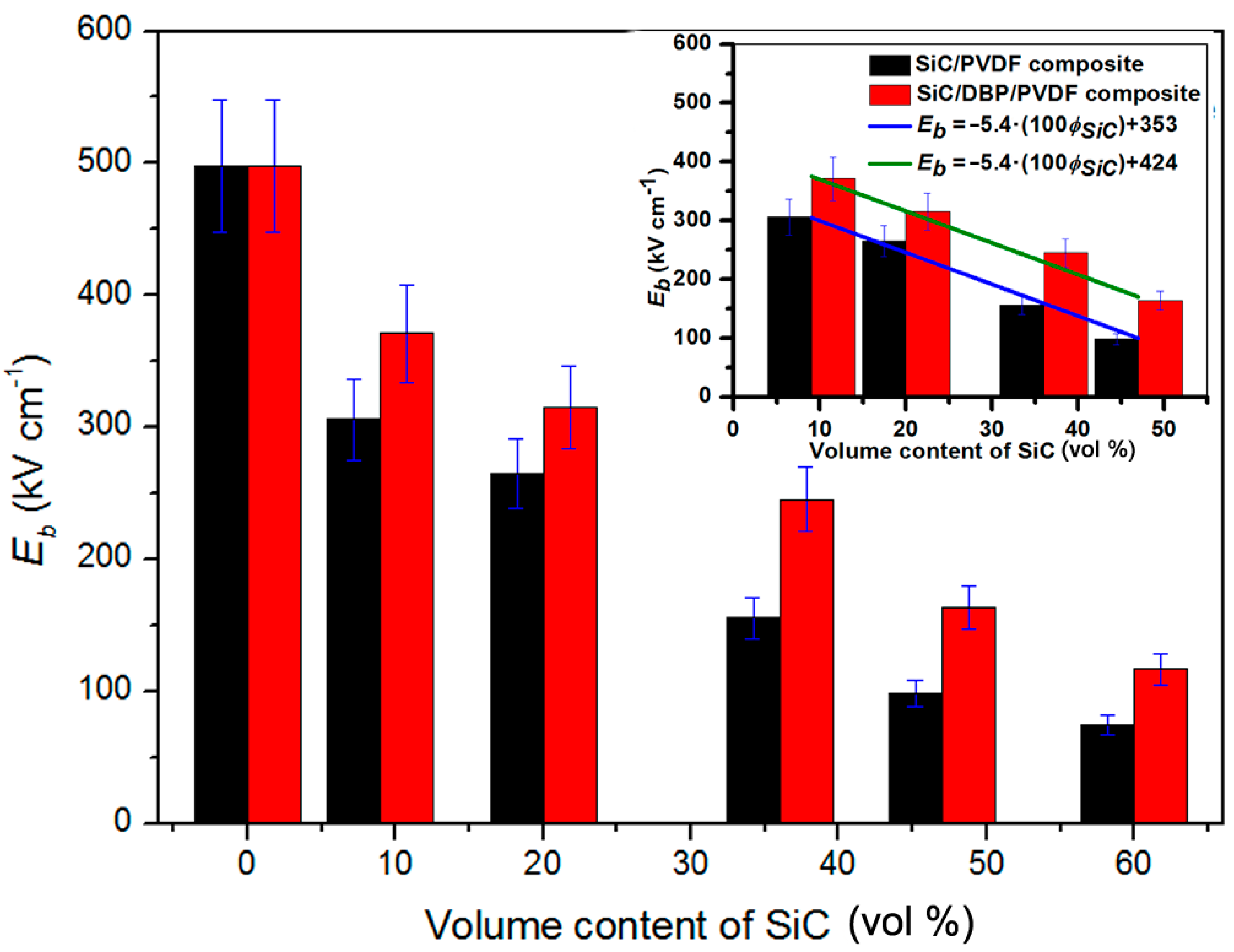

3.3. Electric Breakdown Strength of Nanocomposites

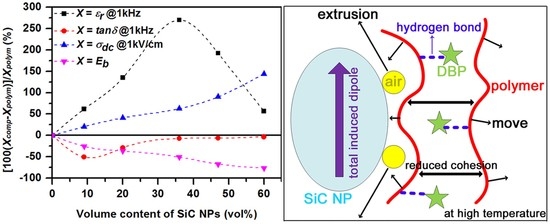

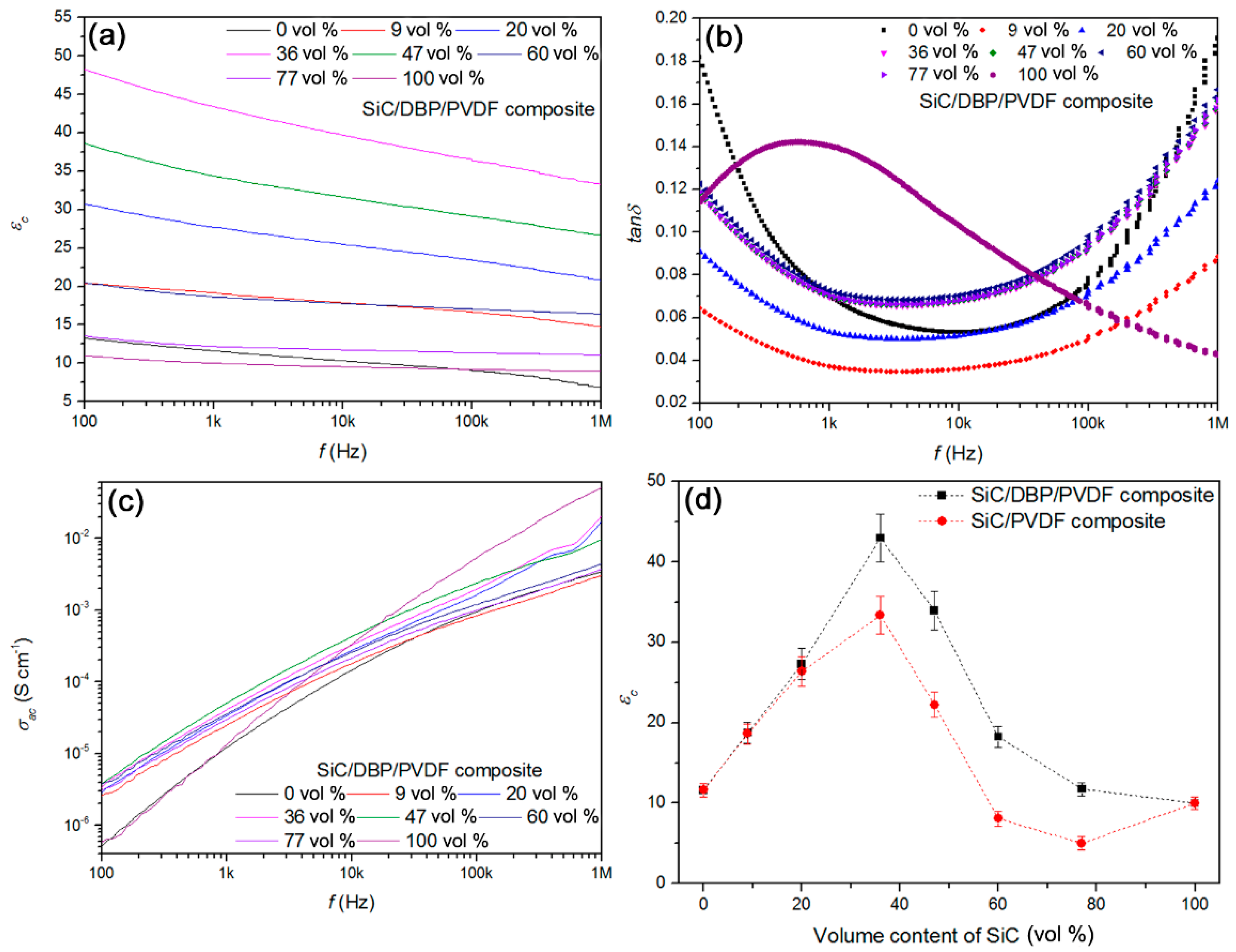

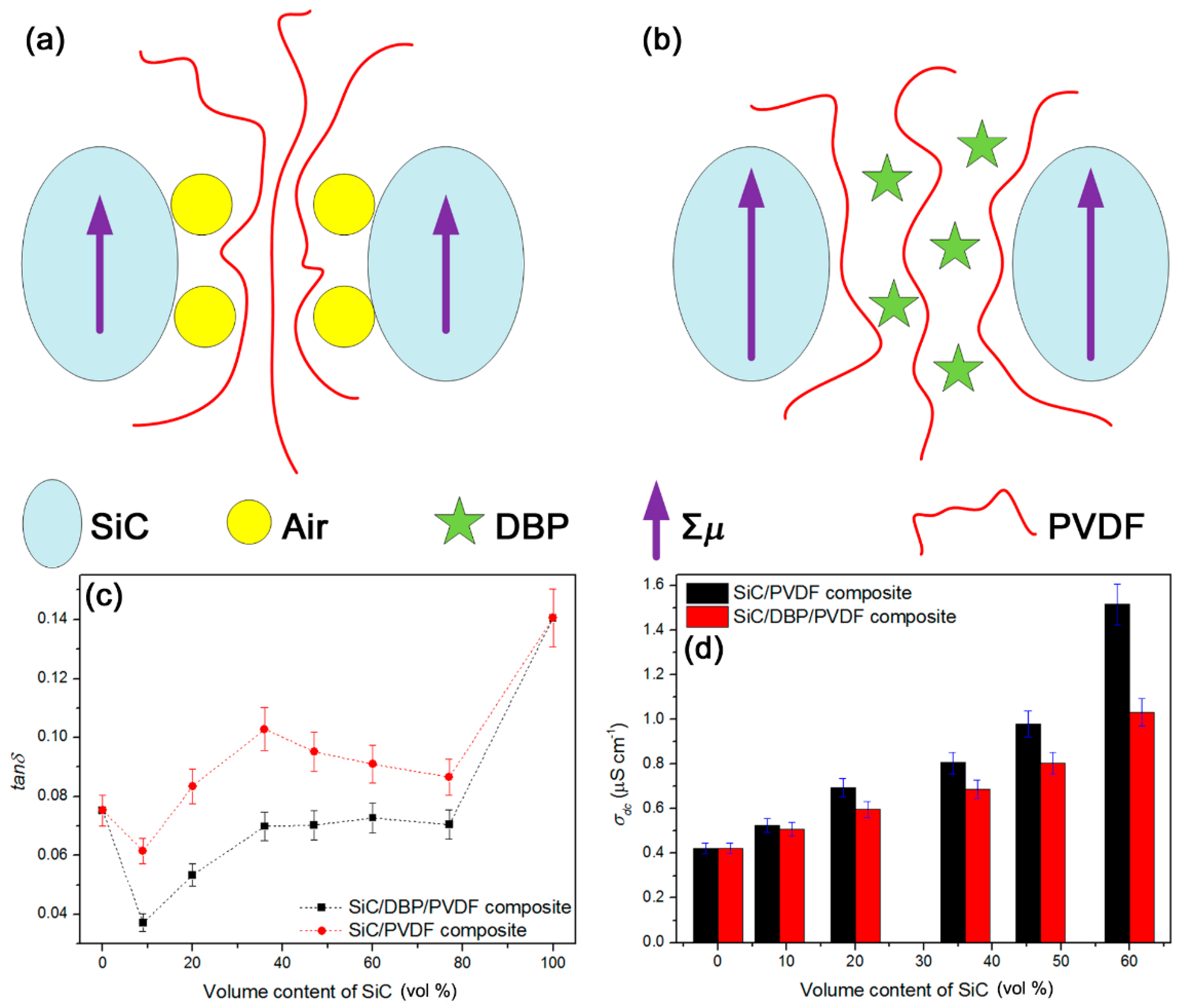

3.4. Dielectric and Conductive Traits of Ternary Nanocomposites

4. Conclusions

- Instead of introducing a surface modification to the filler, an organic plasticizer was added to soften the polymer matrix for fabricating polymer-based nanocomposites.

- After incorporating the plasticizer, SiC/DBP/PVDF composites had a stronger dispersion of SiC, fewer air voids, and a higher compactness degree than SiC/PVDF composites.

- Adding the plasticizer led to an increase in the dielectric constant, breakdown strength, tensile properties, and flexibility, as well as a reduction of loss and conductivity.

- High dielectric and mechanical properties were balanced for the composites via combining high temperature with organic plasticizer.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, Y.; Huang, X.; Li, T.; Wang, Z.; Li, L.; Guo, X.; Jiang, P. Novel crosslinkable high-k copolymer dielectrics for high-energy-density capacitors and organic field-effect transistor applications. J. Mater. Chem. A 2017, 5, 20737–20746. [Google Scholar] [CrossRef]

- Shin, E.Y.; Cho, H.J.; Jung, S.; Yang, C.; Noh, Y.Y. A high-k fluorinated P(VDF-TrFE)-g-PMMA gate dielectric for high-performance flexible field-effect transistors. Adv. Funct. Mater. 2017, 28, 1704780. [Google Scholar] [CrossRef]

- Namitha, L.K.; Sebastian, M.T. High permittivity ceramics loaded silicone elastomer composites for flexible electronics applications. Ceram. Int. 2017, 43, 2994–3003. [Google Scholar] [CrossRef]

- Thakur, V.K.; Gupta, R.K. Recent progress on ferroelectric polymer-based nanocomposites for high energy density capacitors: Synthesis, dielectric properties, and future aspects. Chem. Rev. 2016, 116, 4260–4317. [Google Scholar] [CrossRef]

- Zheng, L.; Yuan, L.; Guan, Q.; Liang, G.; Gu, A. High-k 3D-barium titanate foam/phenolphthalein poly(ether sulfone)/cyanate ester composites with frequency-stable dielectric properties and extremely low dielectric loss under reduced concentration of ceramics. Appl. Surf. Sci. 2017, 427, 1046–1054. [Google Scholar] [CrossRef]

- Zheng, L.; Liang, G.; Gu, A.; Yuan, L.; Guan, Q. Unique pure barium titanate foams with three-dimensional interconnecting pore channels and their high-k cyanate ester resin composites at very low barium titanate loading. J. Mater. Chem. C 2016, 4, 10654–10663. [Google Scholar] [CrossRef]

- Phatharapeetranun, N.; Ksapabutr, B.; Marani, D.; Bowen, J.R.; Esposito, V. 3D-printed barium titanate/poly-(vinylidene fluoride) nano-hybrids with anisotropic dielectric properties. J. Mater. Chem. C 2017, 5, 12430–12440. [Google Scholar] [CrossRef]

- Hu, X.; Zhou, Y.; Liu, J.; Chu, B. Improved flexoelectricity in PVDF/barium strontium titanate (BST) nanocomposites. J. Appl. Phys. 2018, 123, 154101. [Google Scholar] [CrossRef]

- Puli, V.S.; Ejaz, M.; Elupula, R.; Kothakonda, M.; Adireddy, S.; Katiyar, R.S.; Grayson, S.M.; Chrisey, D.B. Core-shell like structured barium zirconium titanate-barium calcium titanate–poly(methyl methacrylate) nanocomposites for dielectric energy storage capacitors. Polymer 2016, 105, 35–42. [Google Scholar] [CrossRef]

- Han, W.; Yoo, B.; Kwon, K.H.; Cho, H.H.; Park, H.H. Fluorine ligand exchange effect in poly (vinylidenefluoride-co-hexafluoropropylene) with embedded fluorinated barium titanate nanoparticles. Thin Solid Films 2016, 619, 17–24. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, J.; Wang, L.; Yuan, Q.; Niu, Y.; Chen, J.; Wang, Q.; Wang, H. Compositional tailoring effect on electric field distribution for significantly enhanced breakdown strength and restrained conductive loss in sandwich-structured ceramic/polymer nanocomposites. J. Mater. Chem. A 2017, 5, 4710–4718. [Google Scholar] [CrossRef]

- Piana, F.; Pfleger, J.; Jambor, R.; Řičica, T.; Macak, J. High-k dielectric composites of poly(2-cyanoethyl vinyl ether) and barium titanate for flexible electronics. J. Appl. Polym. Sci. 2017, 134, 45236. [Google Scholar] [CrossRef]

- Adhlakha, N.; Yadav, K.L.; Truccato, M.; Varshney, M. Reduced leakage current and improved multiferroic properties of 0.5((1 − x)BLPFO-xPZT)-0.5PVDF composite films. Ceram. Int. 2016, 42, 18238–18246. [Google Scholar] [CrossRef]

- Chen, G.; Wang, X.; Lin, J.; Yang, W.; Li, H.; Wen, Y. Interfacial polarity modulation of KTa0.5Nb0.5O3 nanoparticles and its effect on dielectric loss and breakdown strength of polyvinylidene fluoride nanocomposites with high permittivity. J. Phys. Chem. C 2016, 120, 28423–28431. [Google Scholar] [CrossRef]

- Liu, X.; Hou, Z.; Zhang, B.; Zhan, K.; He, P.; Zhang, K.; Song, W. A general model of dielectric constant for porous materials. Appl. Phys. Lett. 2016, 108, 102902. [Google Scholar] [CrossRef]

- Meng, N.; Mao, R.; Tu, W.; Odolczyk, K.; Zhang, Q.; Bilotti, E.; Reece, M.J. Crystallization kinetics and enhanced dielectric properties of free standing lead-free PVDF based composite films. Polymer 2017, 121, 88–96. [Google Scholar] [CrossRef]

- Alluri, N.R.; Selvarajan, S.; Chandrasekhar, A.; Saravanakumar, B.; Lee, G.M.; Ji, H.J.; Kim, S.J. Worm structure piezoelectric energy harvester using ionotropic gelation of barium titanate-calcium alginate composite. Energy 2017, 118, 1146–1155. [Google Scholar] [CrossRef]

- Pu, Z.; Zheng, X.; Tian, Y.; Hu, L.; Zhong, J. Flexible ultrahigh-temperature polymer-based dielectrics with high permittivity for film capacitor applications. Polymers 2017, 9, 596. [Google Scholar] [CrossRef]

- Yuan, Y.; Xu, M.; Pan, H.; Ren, D.; Li, K.; Liu, X. Secondary dispersion of BaTiO3 for the enhanced mechanical properties of the poly(arylene ether nitrile)-based composite laminates. Polym. Test. 2018, 66, 164–171. [Google Scholar] [CrossRef]

- Su, J.; Zhang, J. Effect of treated mica on rheological, cure, mechanical, and dielectric properties of ethylene propylene diene monomer (EPDM)/barium titanate (BaTiO3)/mica. J. Appl. Polym. Sci. 2017, 134, 44833. [Google Scholar] [CrossRef]

- Xu, W.; Ding, Y.; Jiang, S.; Ye, W.; Liao, X.; Hou, H. High permittivity nanocomposites fabricated from electrospun polyimide/BaTiO3 hybrid nanofibers. Polym. Compos. 2016, 37, 794–801. [Google Scholar] [CrossRef]

- Wu, W.; Huang, X.; Li, S.; Jiang, P.; Toshikatsu, T. Novel three-dimensional zinc oxide superstructures for high dielectric constant polymer composites capable of withstanding high electric field. J. Phys. Chem. C 2016, 116, 24887–24895. [Google Scholar] [CrossRef]

- Yuan, J.; Yao, S.; Li, W.; Sylvestre, A.; Bai, J. Anisotropic percolation of SiC–carbon nanotube hybrids: A new route towards thermally conductive high-k polymer composites. J. Phys. Chem. C 2017, 121, 12063–12070. [Google Scholar] [CrossRef]

- Dang, Z.M.; Zheng, M.S.; Zha, J.W. 1D/2D carbon nanomaterial-polymer dielectric composites with high permittivity for power energy storage applications. Small 2016, 12, 1688–1701. [Google Scholar] [CrossRef] [PubMed]

- Lounev, I.V.; Musin, D.R.; Dimiev, A.M. New details to relaxation dynamics of dielectric composite materials comprising longitudinally opened carbon nanotubes. J. Phys. Chem. C 2017, 121, 22995–23001. [Google Scholar] [CrossRef]

- Abraham, T.; Afacan, A.; Dhandharia, P.; Thundat, T. Conduction and dielectric relaxation mechanisms in athabasca oil sands with application to electrical heating. Energy Fuels 2016, 30, 5630–5642. [Google Scholar] [CrossRef]

- Lin, X.; Shen, X.; Sun, X.; Liu, X.; Wu, Y.; Wang, Z.; Kim, J.K. Graphene oxide papers simultaneously doped with Mg2+ and Cl− for exceptional mechanical, electrical and dielectric properties. ACS Appl. Mater. Interfaces 2016, 8, 2360–2371. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Thakur, P.; Hoque, N.A.; Bagchi, B.; Sepay, N.; Khatun, F.; Kool, A.; Das, S. Electroactive and high dielectric folic acid/PVDF composite film rooted simplistic organic photovoltaic self-charging energy storage cell with superior energy density and storage capability. ACS Appl. Mater. Interfaces 2017, 9, 24198–24209. [Google Scholar] [CrossRef] [PubMed]

- Xia, X.; Wang, Y.; Zhong, Z.; Weng, G.J. A frequency-dependent theory of electrical conductivity and dielectric permittivity for graphene-polymer nanocomposites. Carbon 2017, 111, 221–230. [Google Scholar] [CrossRef]

- Xia, X.; Wang, Y.; Zhong, Z.; Weng, G.J. A theory of electrical conductivity, dielectric constant, and electromagnetic interference shielding for lightweight graphene composite foams. J. Appl. Phys. 2016, 120, 3342–3441. [Google Scholar] [CrossRef]

- García-Sánchez, P.; Ramos, A. Electrorotation and electroorientation of semiconductor nanowires. Langmuir 2017, 33, 8553–8561. [Google Scholar] [CrossRef] [PubMed]

- Hashemi, R.; Weng, G.J. A theoretical treatment of graphene nanocomposites with percolation threshold, tunneling-assisted conductivity and microcapacitor effect in ac and dc electrical settings. Carbon 2016, 96, 474–490. [Google Scholar] [CrossRef]

- Shi, Y.D.; Lei, M.; Chen, Y.F.; Zhang, K.; Zeng, J.B.; Wang, M. Ultralow percolation threshold in poly(L-lactide)/poly(ε-caprolactone)/multi-wall carbon nanotubes composites with a segregated electrically conductive network. J. Phys. Chem. C 2017, 121, 3087–3098. [Google Scholar] [CrossRef]

- Li, W.; Song, Z.; Qian, J.; Chu, H.; Wu, X.; Tan, Z.; Nie, W. Surface modification-based three-phase nanocomposites with low percolation threshold for optimized dielectric constant and loss. Ceram. Int. 2017, 44, 4835–4844. [Google Scholar] [CrossRef]

- Barbero, D.R.; Boulanger, N. Ultra-low percolation threshold in nano-confined domains. ACS Nano 2017, 11, 9906–9913. [Google Scholar] [CrossRef] [PubMed]

- Das, G.T.; Maurin, I.; Rowe, A.C.; Gacoin, T. Ultrafine tuning of the metal volume fraction in silver/silicate nanocomposites near the percolation threshold. Nanoscale 2017, 9, 3504–3511. [Google Scholar] [CrossRef]

- Chen, T.; Qiu, J.; Zhu, K.; Li, J. Electro-mechanical performance of polyurethane dielectric elastomer flexible micro-actuator composite modified with titanium dioxide-graphene hybrid fillers. Mater. Des. 2016, 90, 1069–1076. [Google Scholar] [CrossRef]

- Jan, R.; Habib, A.; Gul, I.H. Stiff, strong, yet tough free-standing dielectric films of graphene nanosheets-polyurethane nanocomposites with very high dielectric constant and loss. Electron. Mater. Lett. 2016, 12, 91–99. [Google Scholar] [CrossRef]

- Marashdeh, W.; Iroh, J.O. Electrical properties of flexible graphene reinforced polyimide composites. J. Appl. Polym. Sci. 2017, 134, 45372. [Google Scholar] [CrossRef]

- Chen, T.; Liu, B. A combination of silicone dielectric elastomer and graphene nanosheets for the preparation of bending flexible transducers. Mater. Lett. 2017, 211, 69–73. [Google Scholar] [CrossRef]

- Maity, N.; Mandal, A.; Nandi, A.K. Hierarchical nanostructured polyaniline functionalized graphene/poly(vinylidene fluoride) composites for improved dielectric performances. Polymer 2016, 103, 83–97. [Google Scholar] [CrossRef]

- Al-Saygh, A.; Ponnamma, D.; Almaadeed, M.; Poornima, V.P.; Karim, A.; Hassan, M. Flexible pressure sensor based on PVDF nanocomposites containing reduced graphene oxide-titania hybrid nanolayers. Polymers 2017, 9, 33. [Google Scholar] [CrossRef]

- Zhang, X.; Yuan, L.; Guan, Q.; Liang, G.; Gu, A. Greatly improving energy storage density and reducing dielectric loss of carbon nanotube/cyanate ester composites through building a unique tri-layered structure with mica paper. J. Mater. Chem. A 2017, 5, 21909–21918. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Guo, W.; Sun, X.; Feng, Y.; Sun, D.; Liu, Y.; Yan, K.; Wu, Z.; Su, B. Dielectric and mechanical properties of polyimide composite films reinforced with graphene nanoribbon. Surf. Coat. Technol. 2016, 320, 497–502. [Google Scholar] [CrossRef]

- Zhang, Z.; Gu, Y.; Wang, S.; Li, Q.; Li, M.; Zhang, Z. Enhanced dielectric and mechanical properties in chlorine-doped continuous CNT sheet reinforced sandwich polyvinylidene fluoride film. Carbon 2016, 107, 405–414. [Google Scholar] [CrossRef]

- Kumar, G.S.; Vishnupriya, D.; Chary, K.S.; Patro, T.U. High dielectric permittivity and improved mechanical and thermal properties of poly(vinylidene fluoride) composites with low carbon nanotube content: Effect of composite processing on phase behavior and dielectric properties. Nanotechnology 2016, 27, 385702. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Miao, B.; Gong, H.; Xie, Y.; Wei, X.; Zhang, Z. High dielectric and mechanical properties achieved in cross-linked PVDF/α-SiC nanocomposites with elevated compatibility and induced polarization at the interface. ACS Appl. Mater. Interfaces 2016, 8, 19054–19065. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Yue, Z.; Zhang, Y. Structure characterization and magnetic properties of barium hexaferrite films deposited on 6H-SiC with random in-plane orientation. Ceram. Int. 2017, 43, 8611–8615. [Google Scholar] [CrossRef]

- Xie, Y.; Yu, Y.; Feng, Y.; Jiang, W.; Zhang, Z. Fabrication of stretchable nanocomposites with high energy density and low loss from cross-linked PVDF filled with poly(dopamine) encapsulated BaTiO3. ACS Appl. Mater. Interfaces 2017, 9, 2995–3005. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Li, Y.; Wang, F.; Peng, C.; Xu, Z.; Hu, J. Strong composition dependence of adhesive properties of ultraviolet curing adhesives with modified acrylates. Mater. Res. Express 2018, 5, 056409. [Google Scholar] [CrossRef]

- Dong, B.; Zhang, L.; Wu, Y. Highly conductive natural rubber-graphene hybrid films prepared by solution casting and in situ reduction for solvent-sensing application. J. Mater. Sci. 2016, 51, 10561–10573. [Google Scholar] [CrossRef]

- Xie, W.; Gao, P.Z.; Li, D.Y.; Lv, H.N.; Huang, S.T.; Xiao, H.N. Detailed electrical and mechanical retention characteristics of MoSi2-RSiC composites exhibiting three-dimensional (3D) interpenetrated network structure during long-term high-temperature oxidation process. Ceram. Int. 2016, 42, 5873–5884. [Google Scholar] [CrossRef]

- Feng, Y.; Gong, H.; Xie, Y.; Wei, X.; Yang, L.; Zhang, Z. Strong induced polarity between poly(vinylidene fluoride-co-chlorotrifluoroethylene) and α-SiC and its influence on dielectric permittivity and loss of their composites. J. Appl. Phys. 2015, 117, 094104. [Google Scholar] [CrossRef]

- Pan, M.; Shi, X.; Lyu, F.; Levywendt, B.L.; Zheng, X.; Tang, S. Encapsulation of single nanoparticle in fast-evaporating micro-droplets prevents particle agglomeration in nanocomposites. ACS Appl. Mater. Interfaces 2017, 9, 26602–26609. [Google Scholar] [CrossRef] [PubMed]

- Jia, P.; Meng, Z.; Hu, L.; Zhou, Y. A novel biobased polyester plasticizer prepared from palm oil and its plasticizing effect on poly(vinyl chloride). Pol. J. Chem. Technol. 2016, 18, 9–14. [Google Scholar] [CrossRef]

- Song, X.Y.; Wang, M.; Weng, Y.X.; Huang, Z.G. Effect of bamboo flour grafted lactide on the interfacial compatibility of polylactic acid/bamboo flour composites. Polymers 2017, 9, 323. [Google Scholar] [CrossRef]

- Bhasney, S.M.; Patwa, R.; Kumar, A.; Katiyar, V. Plasticizing effect of coconut oil on morphological, mechanical, thermal, rheological, barrier, and optical properties of poly(lactic acid): A promising candidate for food packaging. J. Appl. Polym. Sci. 2017, 134, 45390. [Google Scholar] [CrossRef]

- Tian, R.; Xu, Q.; Lu, C.; Duan, X.; Xiong, R.G. Spontaneous polarization switching and piezoelectric enhancement of PVDF through strong hydrogen bonds induced by layered double hydroxides. Chem. Commun. 2017, 53, 7933–7936. [Google Scholar] [CrossRef] [PubMed]

- Silva, A.J.D.J.; Nascimento, C.R.; Costa, M.F.D. Thermomechanical properties and long-term behavior evaluation of poly(vinylidene fluoride) (PVDF) exposed to bioethanol fuel under heating. J. Mater. Sci. 2016, 51, 9074–9094. [Google Scholar] [CrossRef]

- Maiza, M.; Benaniba, M.T.; Massardiernageotte, V. Plasticizing effects of citrate esters on properties of poly(lactic acid). J. Polym. Eng. 2016, 36, 371–380. [Google Scholar] [CrossRef]

- Maillard, D.; Kumar, S.K.; Fragneaud, B.; Kysar, J.W.; Rungta, A.; Benicewicz, B.C.; Deng, H.; Brinson, L.C.; Douglas, J.F. Mechanical properties of thin glassy polymer films filled with spherical polymer-grafted nanoparticles. Nano Lett. 2016, 12, 3909–3914. [Google Scholar] [CrossRef] [PubMed]

- Luo, S.; Shen, Y.; Yu, S.; Wan, Y.; Liao, W.H.; Sun, R.; Wong, C.P. Construction of a 3D-BaTiO3 network leading to significantly enhanced dielectric permittivity and energy storage density of polymer composites. Energy Environ. Sci. 2016, 10, 137–144. [Google Scholar] [CrossRef]

- Delixiati, A.; Chung, D.D.L. Bentonite-derived materials preferably with nanocarbon incorporation exhibiting exceptionally high dielectric loss at relatively low electrical conductivity. J. Mater. Sci. 2016, 51, 969–978. [Google Scholar] [CrossRef]

- Feng, Y.; Wu, Y.; Xie, Y.; Wei, X.; Zhang, Z. Tunable permittivity in polymer composites filled with Si-based semiconductors by regulating induced polarization. Mater. Sci. Semicon. Process. 2017, 61, 63–70. [Google Scholar] [CrossRef]

- Feng, Y.; Xu, Z.; Hu, J.; Huang, H.; Peng, C. Significantly reduced dielectric loss and conductivity in polymer-based nano-composites from a suppressed interface coulomb force. Mater. Res. Express 2017, 4, 095001. [Google Scholar] [CrossRef]

| Original Names | Abbreviations | Original Names | Abbreviations |

|---|---|---|---|

| poly(vinylidene fluoride-chlorotrifluoroethylene) with inner double bonds | P(VDF-CTFE-DB); PVDF | nanoparticles | NPs |

| dibutyl phthalate | DBP | high-dielectric-constant | High-k |

| poly(vinylidene fluoride-chlorotrifluoroethylene) | P(VDF-CTFE) | 1-methyl-2-pyrrolidinone | NMP |

| triethylamine | TEA | X-ray diffraction | XRD |

| field-emission scanning electron microscopy | FE-SEM | proton nuclear magnetic resonance | 1H NMR |

| alternative current | AC | direct current | DC |

| weight of cup filled with water | W1 | total mass of SiC, PVDF and DBP introduced | W2 |

| weighed mass of entire sample | W3 | weight of cup, sample and water | W4 |

| average density of sample | ρsample | mass of all air inside sample | Wair |

| density of water | ρwater | total volume of air inside sample | Vair |

| density of air | ρair | overall volume of sample | Vsample |

| volume content of air voids in entire sample | φair | degree of compactness | 1/φair |

| diffraction angle | 2θ | breakdown strength | Eb |

| dielectric constant | εc | dielectric loss | tanδ |

| ac conductivity | σac | testing frequency | f |

| overall induced dipole moment | Σμ | direct current conductivity | σdc |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Peng, C.; Li, Y.; Hu, J. Enhanced Dielectric and Mechanical Properties of Ternary Composites via Plasticizer-Induced Dense Interfaces. Materials 2018, 11, 1111. https://doi.org/10.3390/ma11071111

Feng Y, Peng C, Li Y, Hu J. Enhanced Dielectric and Mechanical Properties of Ternary Composites via Plasticizer-Induced Dense Interfaces. Materials. 2018; 11(7):1111. https://doi.org/10.3390/ma11071111

Chicago/Turabian StyleFeng, Yefeng, Cheng Peng, Yandong Li, and Jianbing Hu. 2018. "Enhanced Dielectric and Mechanical Properties of Ternary Composites via Plasticizer-Induced Dense Interfaces" Materials 11, no. 7: 1111. https://doi.org/10.3390/ma11071111

APA StyleFeng, Y., Peng, C., Li, Y., & Hu, J. (2018). Enhanced Dielectric and Mechanical Properties of Ternary Composites via Plasticizer-Induced Dense Interfaces. Materials, 11(7), 1111. https://doi.org/10.3390/ma11071111