Comparison of Tensile and Compressive Properties of Carbon/Glass Interlayer and Intralayer Hybrid Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

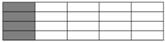

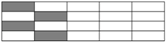

2.2. Layer Structures Schemes of Interlayer Hybrid Structures

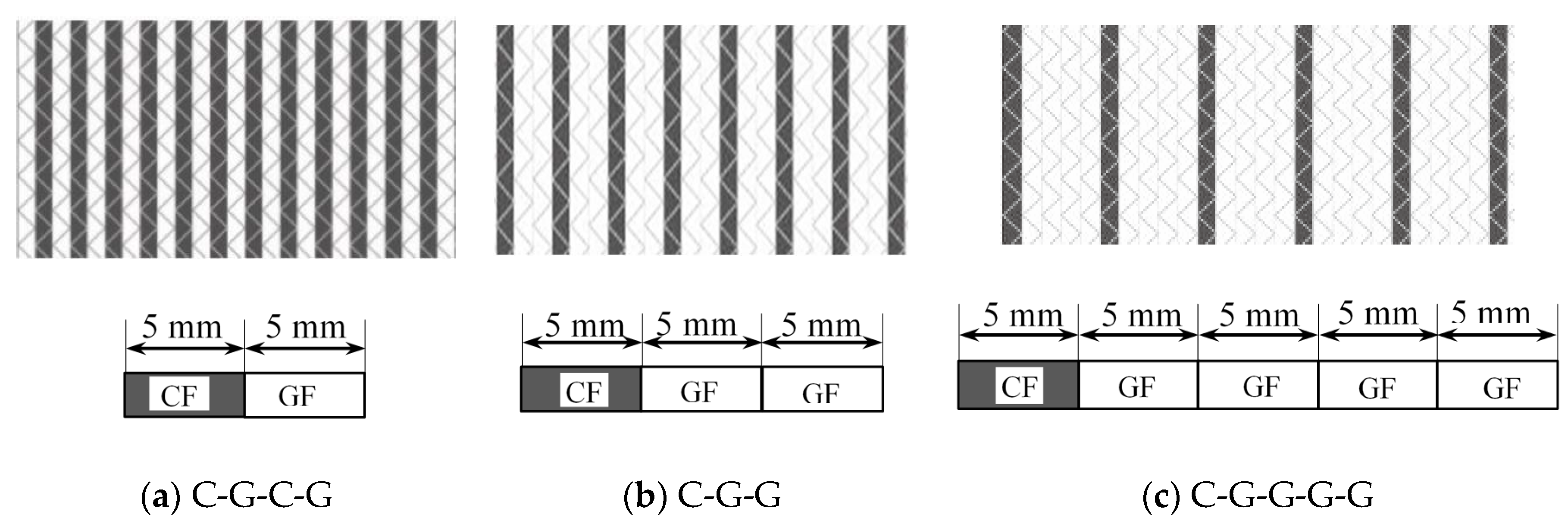

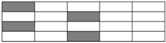

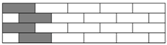

2.3. Schemes Design of Intralayer Hybrid Structures

2.4. Experiments

3. Results and Discussions

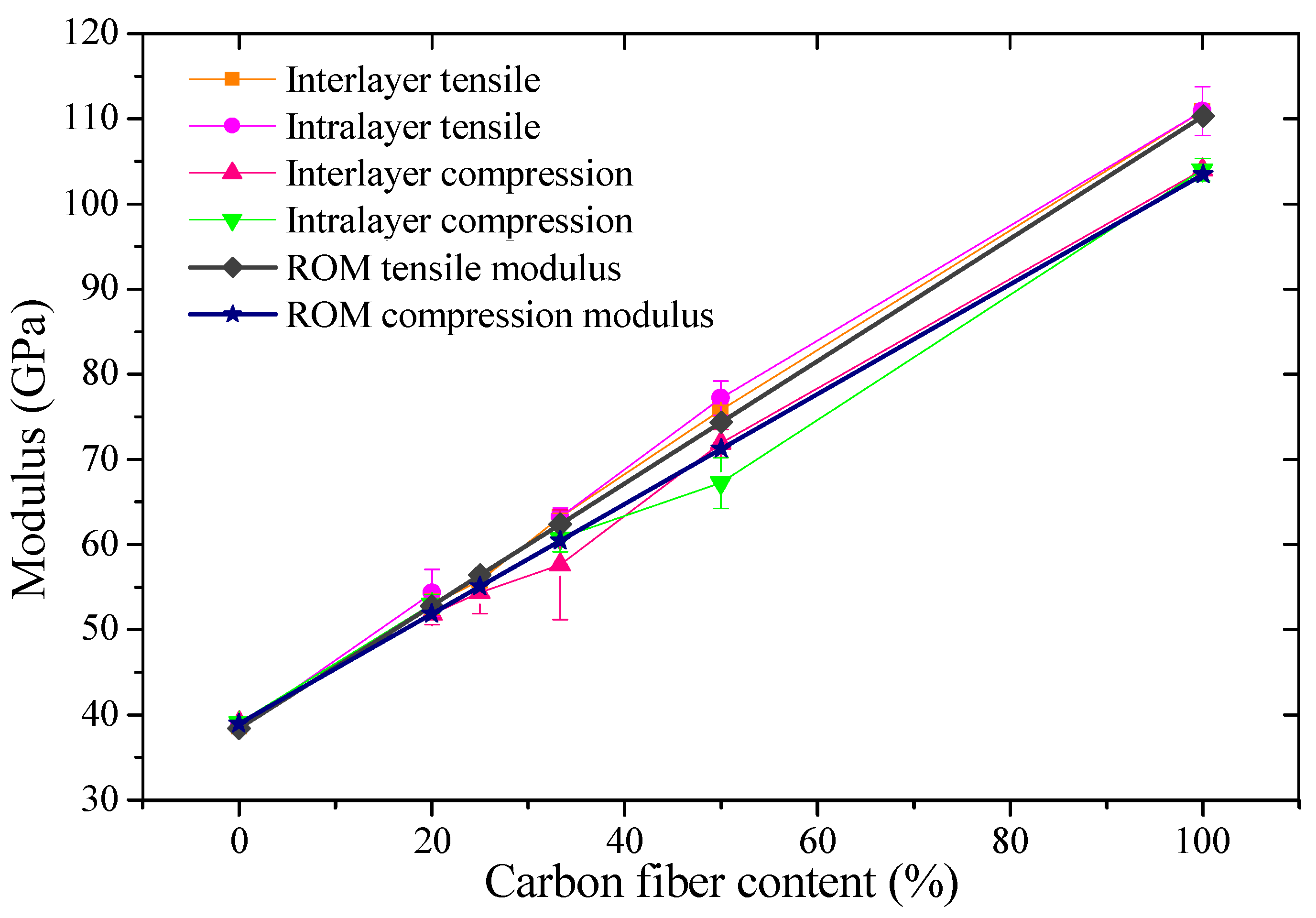

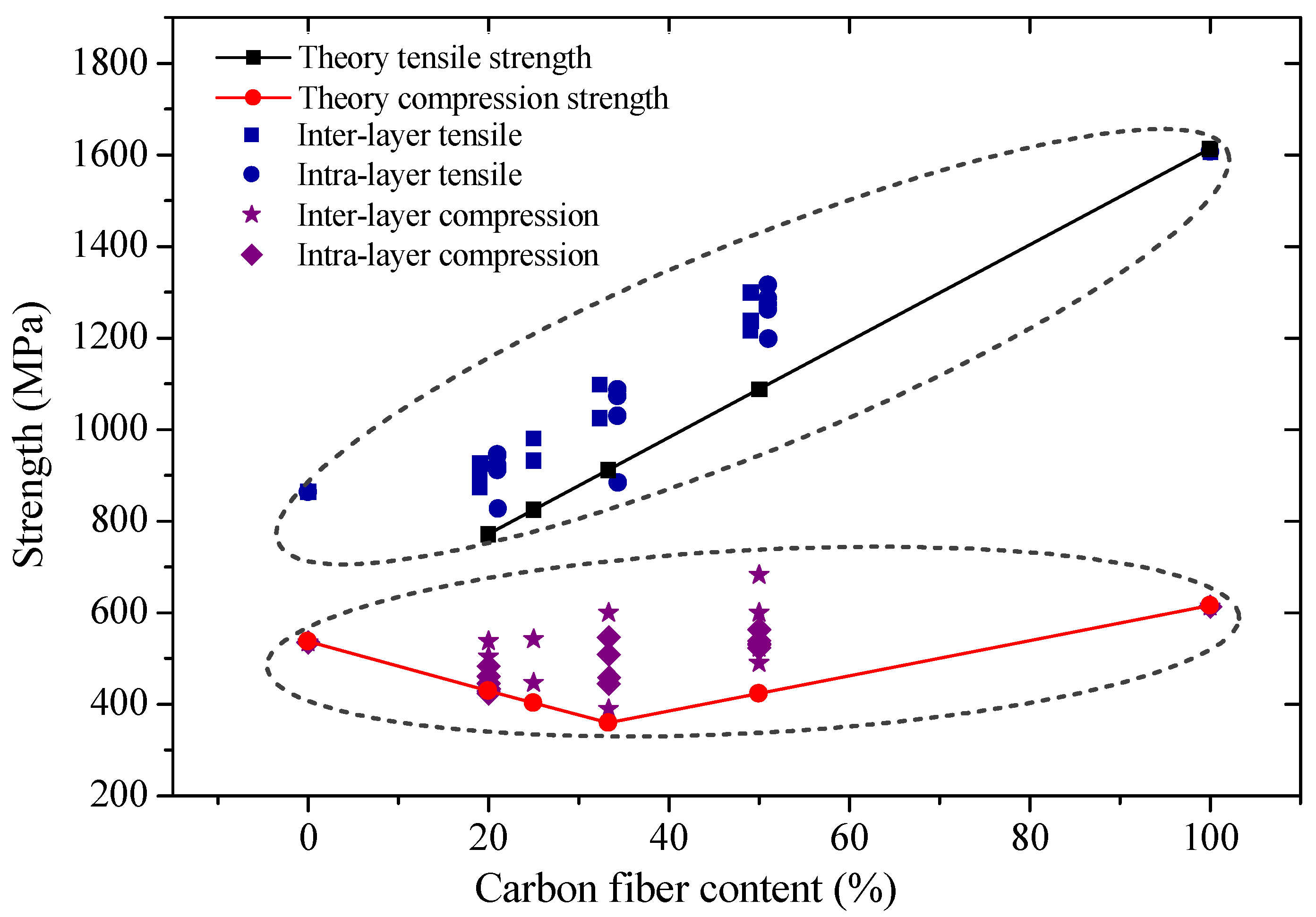

3.1. Tensile and Compressive Properties of Interlayer Hybrid Composites

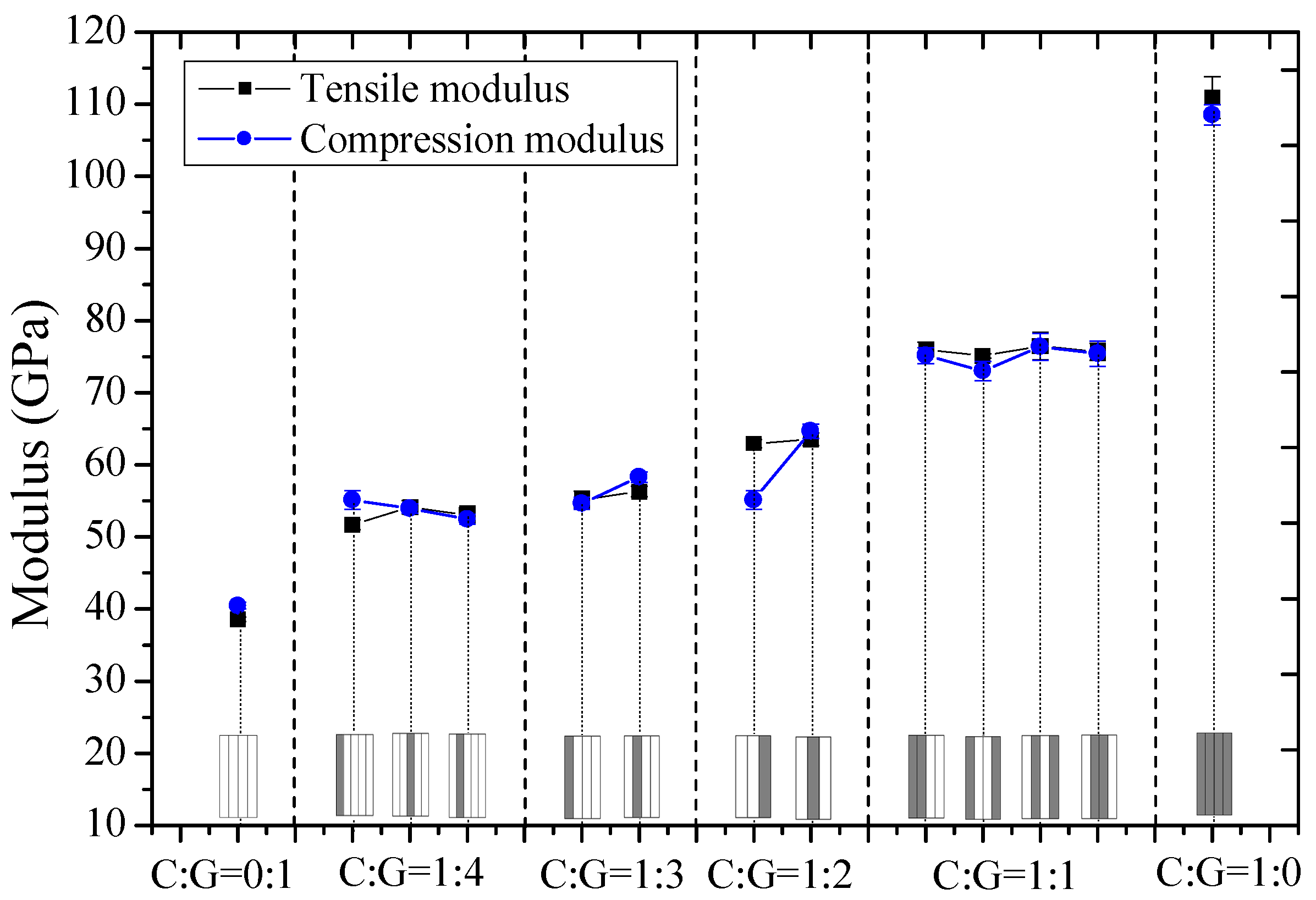

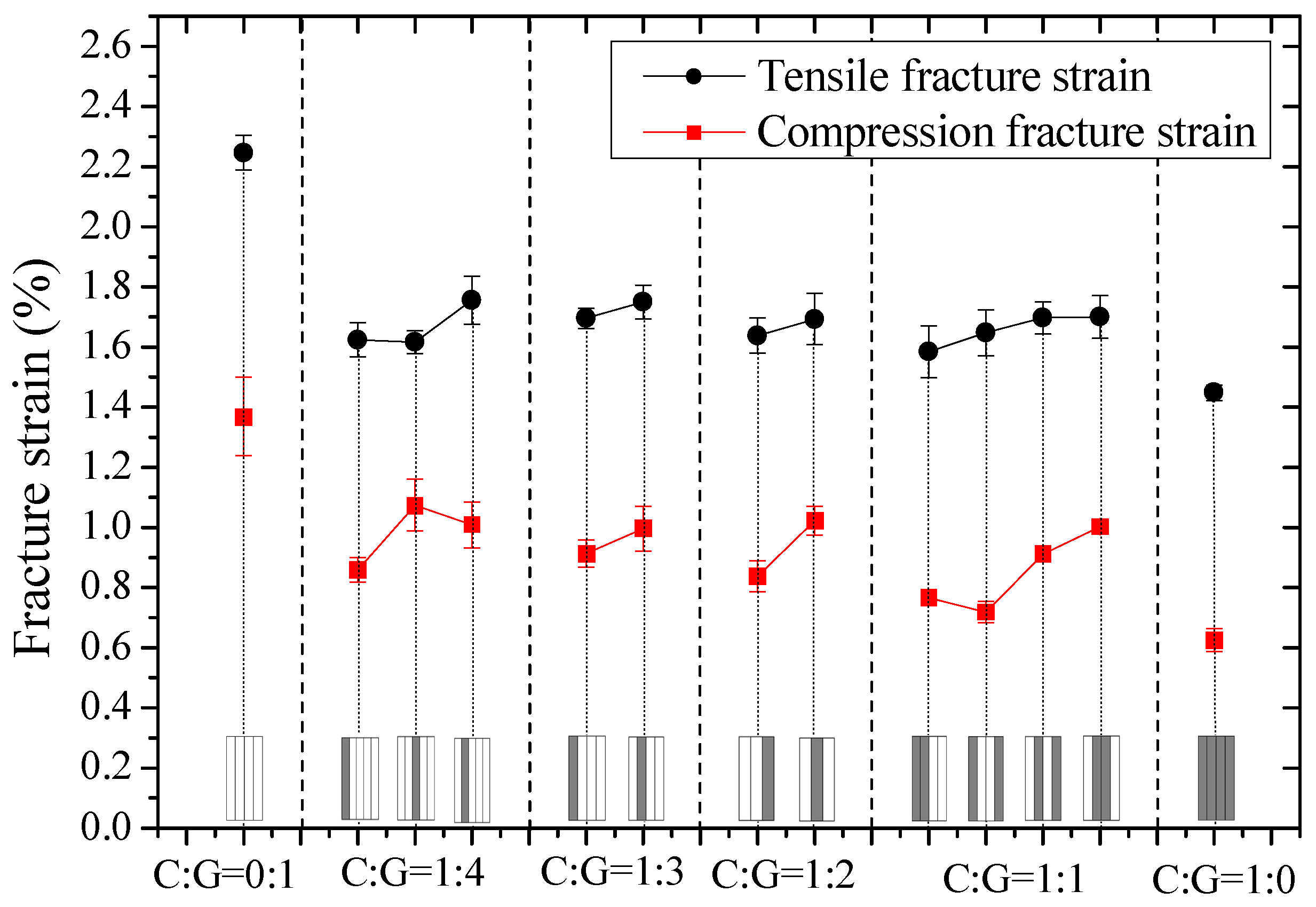

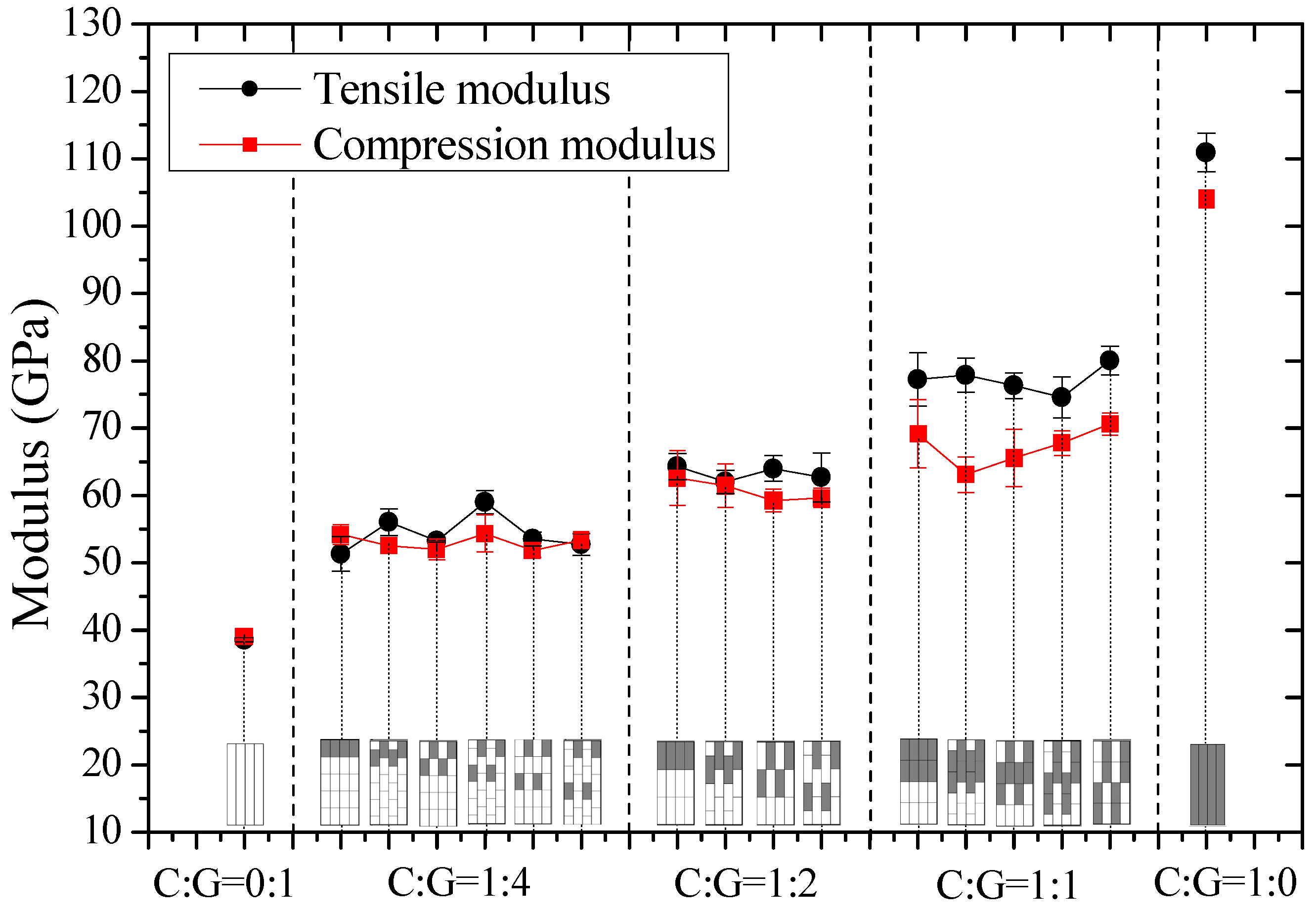

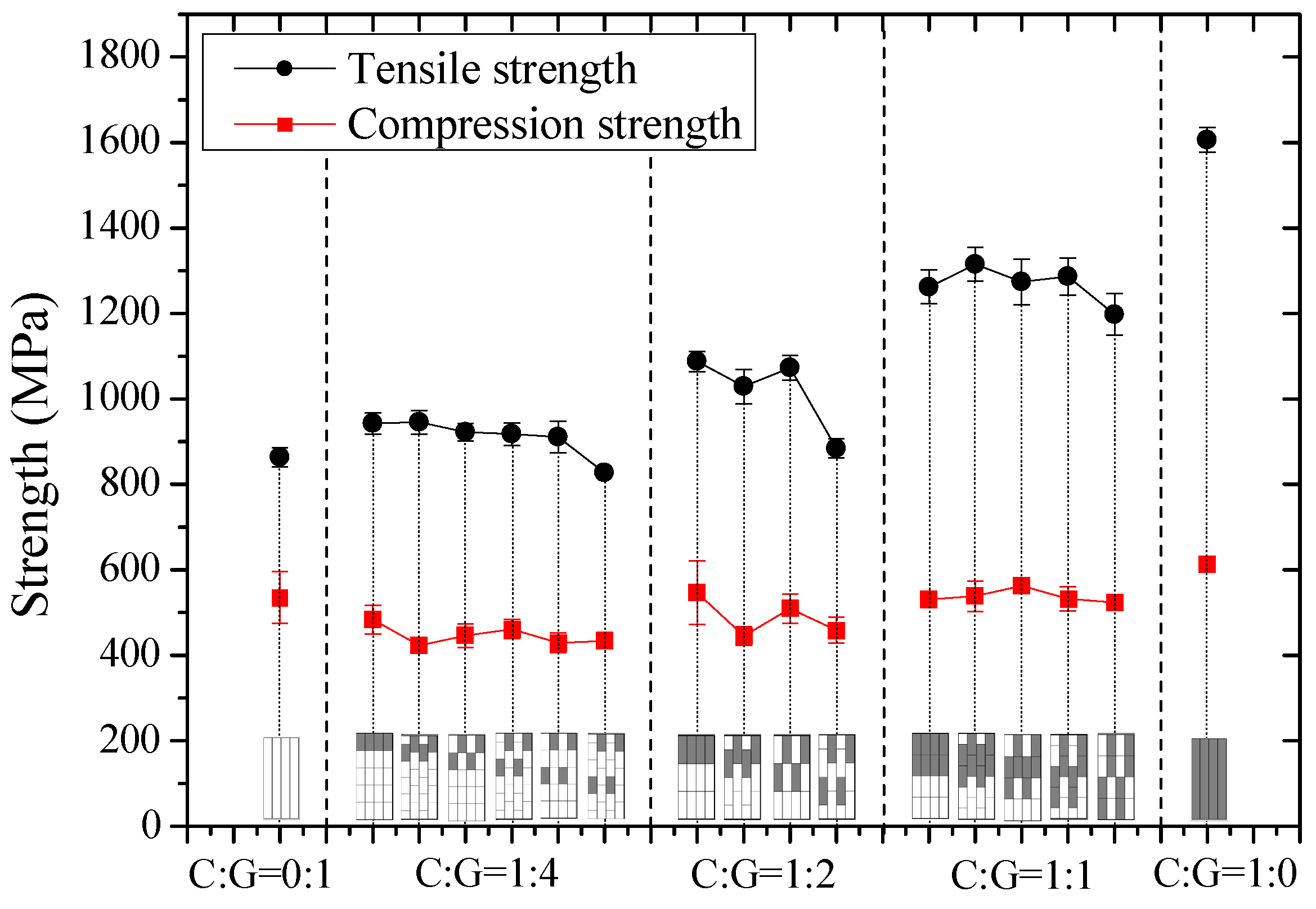

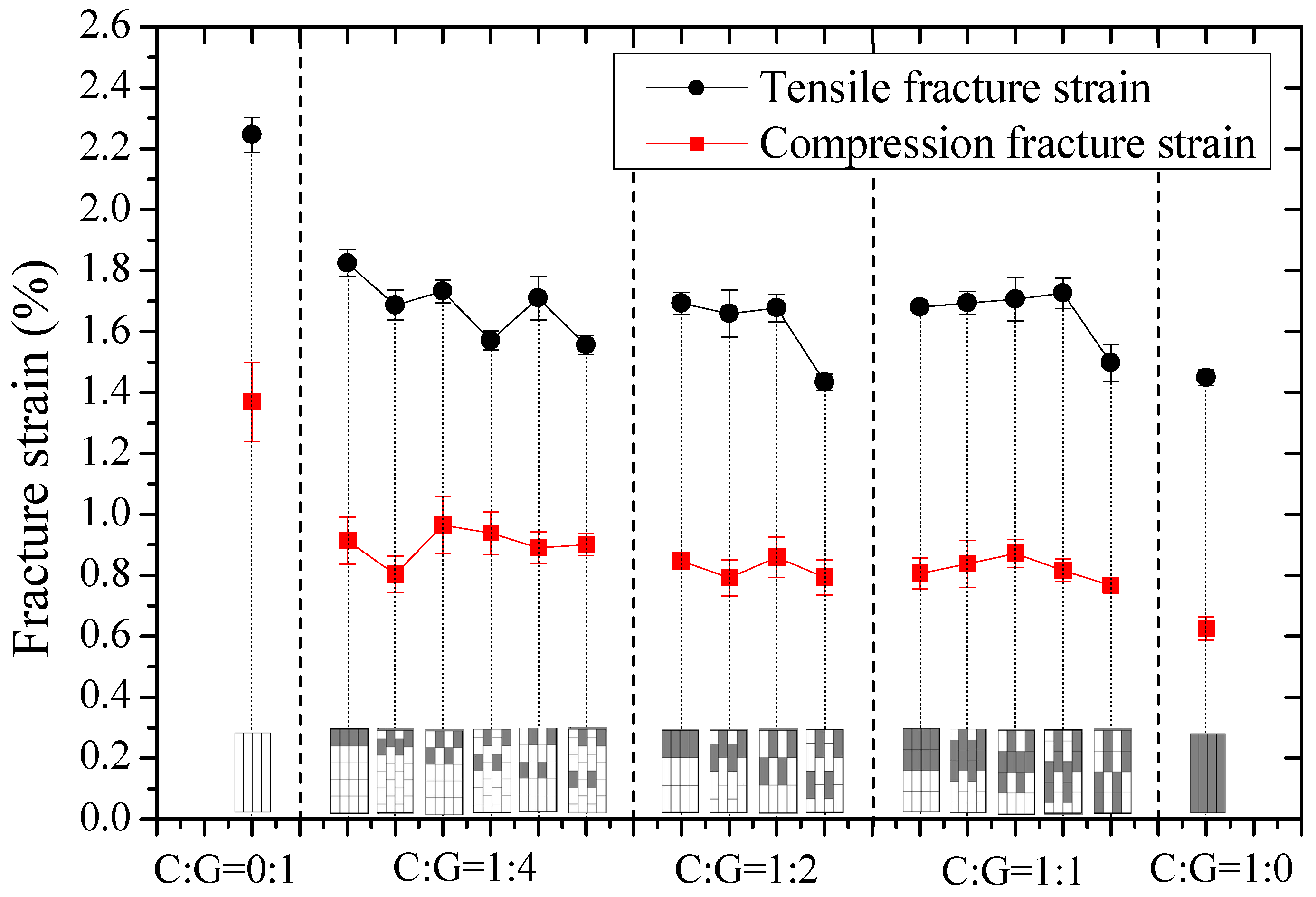

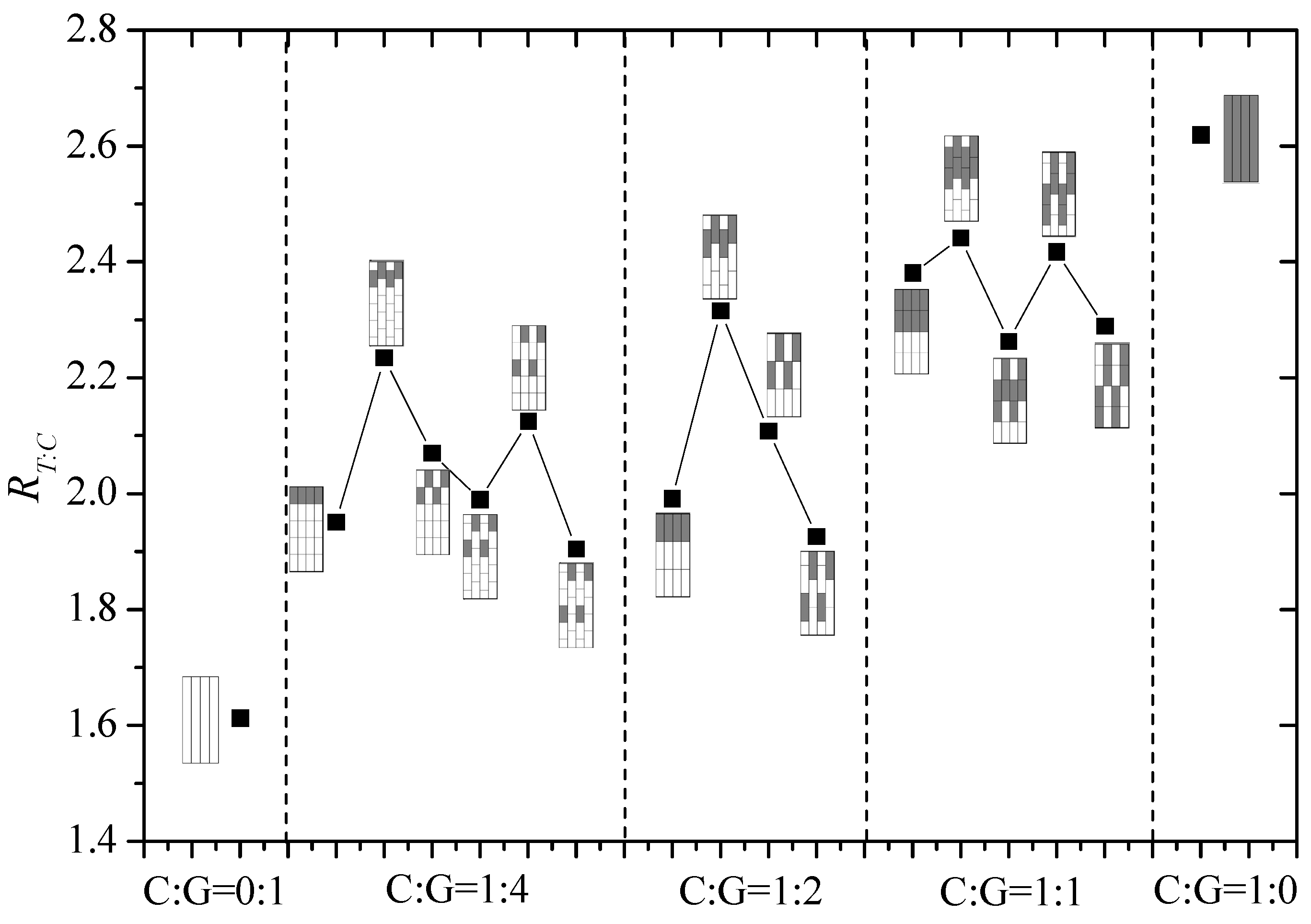

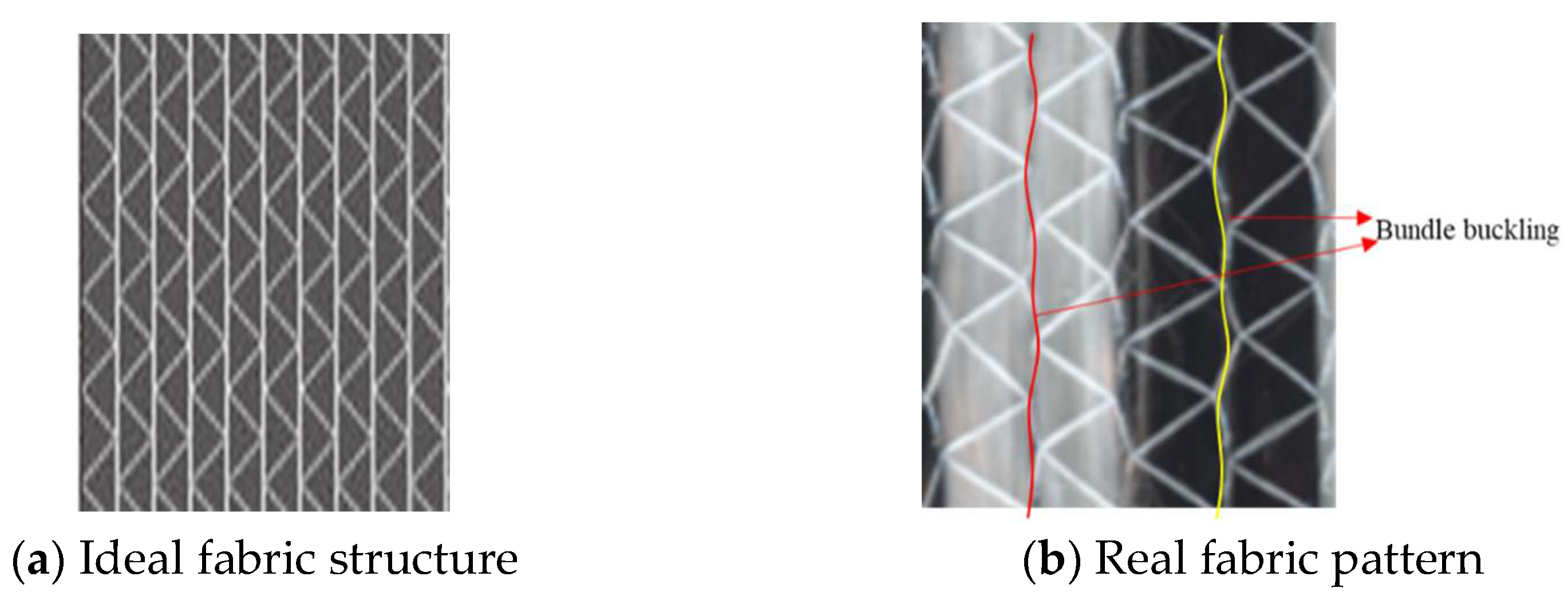

3.2. Tensile and Compressive Properties of Intralayer Hybrid Composites

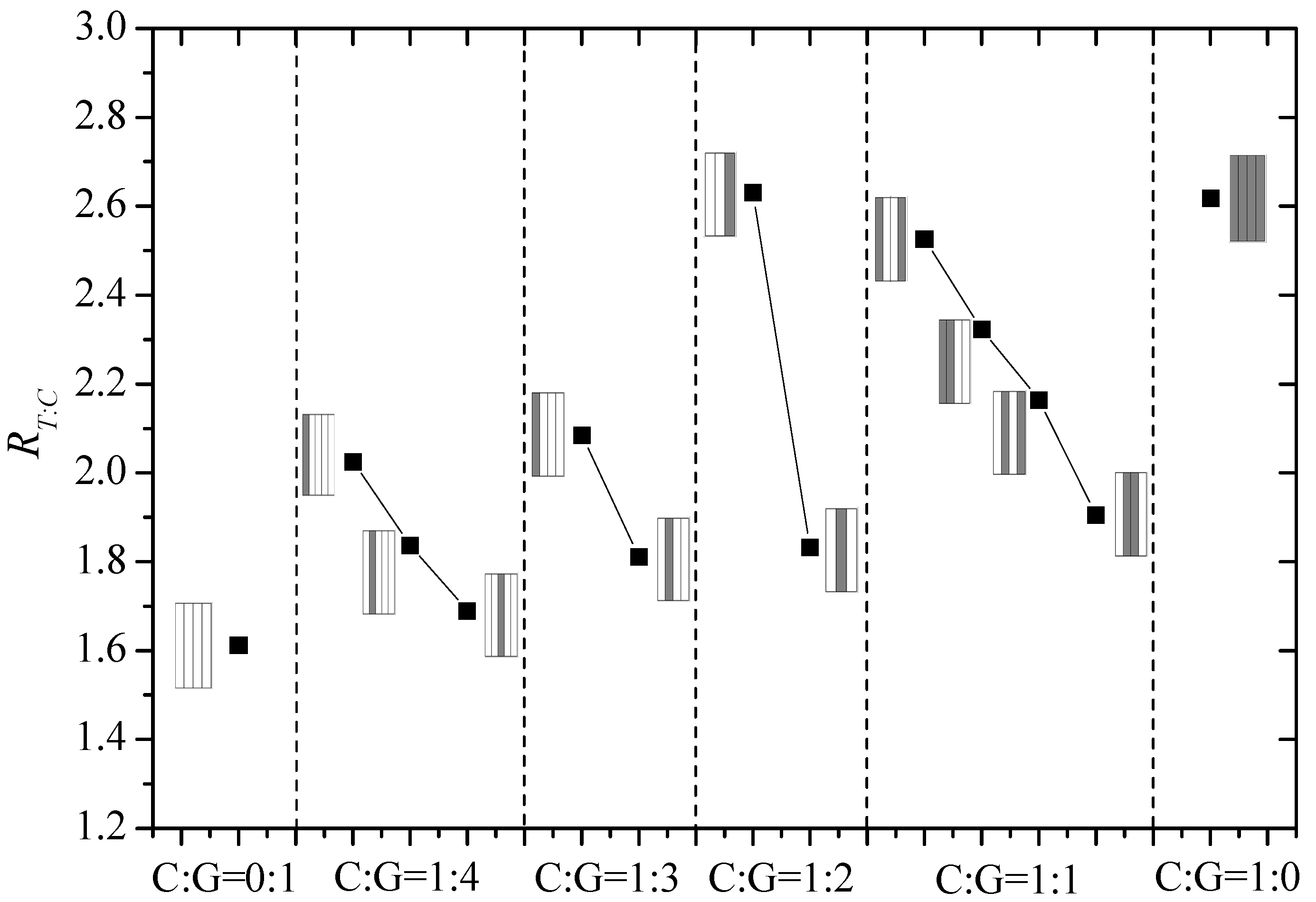

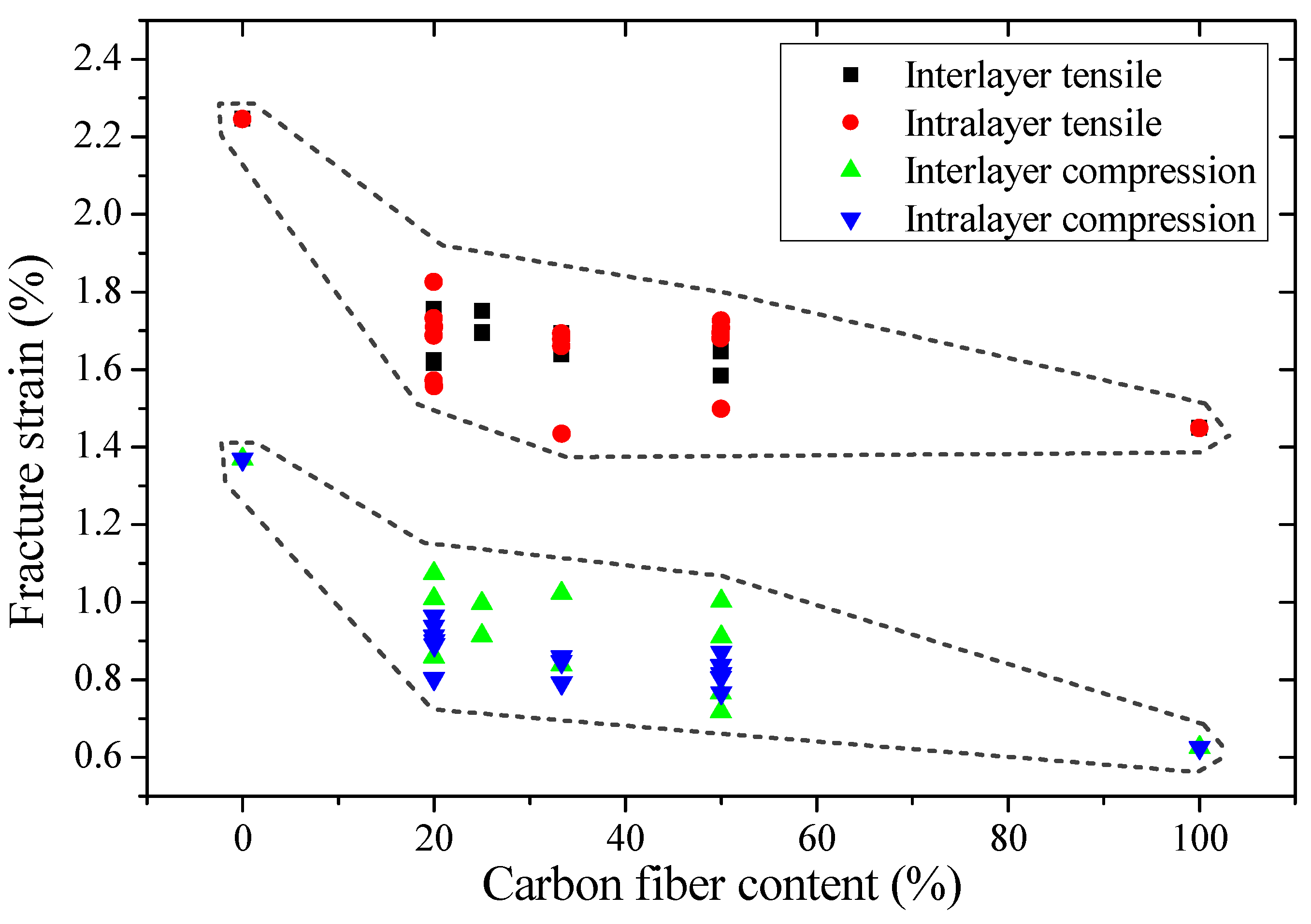

3.3. Comparison of Tensile and Compressive Properties of Interlayer and Intralayer Hybrid Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kretsis, G. A review of the tensile, compressive, flexural and shear properties of hybrid fiber-reinforced Plastics. Composites 1987, 18, 13–23. [Google Scholar] [CrossRef]

- Yan, L.; Kou, K. New fibre material used in advanced composite material. Mater. Rev. 2004, 3, 61–63. [Google Scholar]

- Haery, H.A.; Zahari, R.; Kuntjoro, W.; Taib, Y.M. Tensile strength of notched woven fabric hybrid glass, carbon/epoxy composite laminates. J. Ind. Text. 2014, 43, 383–395. [Google Scholar] [CrossRef]

- Taketa, I.; Ustarroz, J.; Gorbatikh, L.; Lomov, S.V.; Verpoest, I. Interply hybrid composites with carbon fiber reinforced polypropylene and self-reinforced polypropylene. Compos. Part A 2010, 41, 927–932. [Google Scholar] [CrossRef]

- Atiqah, A.; Maleque, M.; Jawaid, M.; Iqbal, M. Development of kenaf-glass reinforced unsaturated polyester hybrid composite for structural applications. Compos. Part B 2014, 56, 68–73. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.; Wypych, F. Biodegradable composites based on lignocellulosic fibers—An overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Dong, C.; Davies, I.J. Optimal design for the flexural behaviour of glass and carbon fibre reinforced polymer hybrid composites. Mater. Des. 2012, 37, 450–457. [Google Scholar] [CrossRef]

- Dong, C.; Ranaweera-Jayawardena, H.A.; Davies, I.J. Flexural properties of hybrid composites reinforced by S-2 glass and T700S carbon fibres. Compos. Part B 2012, 43, 573–581. [Google Scholar] [CrossRef]

- Marom, G.; Fischer, S.; Tuler, F.; Wagner, H. Hybrid effects in composites: Conditions for positive or negative effects versus rule-of-mixtures behaviour. J. Mater. Sci. 1978, 13, 1419–1426. [Google Scholar] [CrossRef]

- Miwa, M.; Horiba, N. Effects of fibre length on tensile strength of carbon/glass fibre hybrid composites. J. Mater. Sci. 1994, 29, 973–977. [Google Scholar] [CrossRef]

- Zweben, C. Tensile strength of hybrid composites. J. Mater. Sci. 1977, 12, 1325–1337. [Google Scholar] [CrossRef]

- Manders, P.W.; Bader, M. The strength of hybrid glass/carbon fibre composites. J. Mater. Sci. 1981, 16, 2233–2245. [Google Scholar] [CrossRef]

- Oya, N.; Hamada, H. Effects of reinforcing fibre properties on various mechanical behaviors of unidirectional carbon/epoxy laminates. Sci. Eng. Compos. Mater. 1996, 5, 105–130. [Google Scholar] [CrossRef]

- Phillips, L. The hybrid effect—Does it exist? Composites 1976, 7, 7–8. [Google Scholar] [CrossRef]

- Dong, C.; Davies, I.J. Flexural and tensile strengths of unidirectional hybrid epoxy composites reinforced by S-2 glass and T700S carbon fibres. Mater. Des. 2014, 54, 955–966. [Google Scholar] [CrossRef]

- Dong, C.; Davies, I.J. Flexural and tensile moduli of unidirectional hybrid epoxy composites reinforced by S-2 glass and T700S carbon fibres. Mater. Des. 2014, 54, 893–899. [Google Scholar] [CrossRef]

- Li, Y.; Xian, X.; Choy, C.; Guo, M.; Zhang, Z. Compressive and flexural behavior of ultra-high-modulus polyethylene fiber and carbon fiber hybrid composites. Compos. Sci. Technol. 1999, 59, 13–18. [Google Scholar] [CrossRef]

- Greenwood, J.H.; Rose, P.G. Compressive behaviour of Kevlar 49 fibres and composites. J. Mater. Sci. 1974, 9, 1809–1814. [Google Scholar] [CrossRef]

- Oya, N.; Johnson, D.J.; Hamada, H. Longitudinal compressive behaviour and microstructure of PAN-based carbon fibres. Carbon 2001, 39, 635–645. [Google Scholar] [CrossRef]

- Bos, H.L.; Oever, M.J.A.V.D.; Peters, O.C.J.J. Tensile and compressive properties of flax fibres for natural fibre reinforced composites. J. Mater. Sci. 2002, 37, 1683–1692. [Google Scholar] [CrossRef]

- Meng, M.; Le, H.R.; Rizvi, M.J.; Grove, S.M. The effects of unequal compressive/tensile moduli of composites. Compos. Struct. 2015, 126, 207–215. [Google Scholar] [CrossRef]

- Zobeiry, N.; Forghani, A.; Mcgregor, C.; Vaziri, R.; Poursartip, A. progressive damage modeling of composite materials under both tensile and compressive loading regimes. Mech. Resp. Compos. 2008, 10, 179–195. [Google Scholar]

- Vuure, A.W.V.; Baets, J.; Wouters, K.; Hendrickx, K. Compressive properties of natural fibre composites. Mater. Lett. 2015, 149, 138–140. [Google Scholar] [CrossRef]

- Pinho, S.T.; Robinson, P.; Iannucci, L. Fracture toughness of the tensile and compressive fibre failure modes in laminated composites. Compos. Sci. Technol. 2006, 66, 2069–2079. [Google Scholar] [CrossRef]

- Mujika, F.; Carbajal, N.; Arrese, A.; Mondragon, I. Determination of tensile and compressive moduli by flexural tests. Polym. Test. 2006, 25, 766–771. [Google Scholar] [CrossRef]

- Liu, S.; Yan, C.; Zhang, J.; Zhang, H.; Wang, Z. Experimental study of ratio between splitting tensile strength and compressive strength pva fiber cementitious composites. J. Civ. Archit. Environ. Eng. 2013, S1, 134–138. [Google Scholar]

- Choi, J.I.; Bang, Y.L.; Ranade, R.; Li, V.C.; Yun, L. Ultra-high-ductile behavior of a polyethylene fiber-reinforced alkali-activated slag-based composite. Cem. Concr. Compos. 2016, 70, 153–158. [Google Scholar] [CrossRef]

- Hartl, A.M.; Jerabek, M.; Freudenthaler, P.; Lang, R.W. Orientation-dependent compression/tension asymmetry of short glass fiber reinforced polypropylene: Deformation damage and failure. Compos. Part A 2015, 79, 14–22. [Google Scholar] [CrossRef]

- Dai, S.; Cunningham, P.R.; Marshall, S.; Silva, C. Influence of fibre architecture on the tensile, compressive and flexural behaviour of 3D woven composites. Compos. Part A 2015, 69, 195–207. [Google Scholar] [CrossRef]

- Prabhakaran, D.; Andersen, T.L.; Markussen, C.; Madsen, B.; Lilholt, H. Tensile and compression properties of hybrid composites—A comparative study. In Proceedings of the 19th International Conference on Composite Material, ICCM19, Montreal, QC, Canada, 28 July–2 August 2013. [Google Scholar]

- Wu, W.; Wang, Q.; Ichenihi, A.; Shen, Y.; Li, W. The Effects of Hybridization on the Flexural Performances of Carbon/Glass Interlayer and Intralayer Composites. Polymers 2018, 10, 549. [Google Scholar] [CrossRef]

- ASTM Committee D-30 on Composite Materials. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Standard, A. Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture; ASTM: West Conshohocken, PA, USA, 2009. [Google Scholar]

| Material | Tensile Strength (MPa) | Tensile Modulus (GPa) |

|---|---|---|

| CPIC ECT469L-2400 glass fiber | 2366 | 78.7 |

| TORAY T620SC-24K-50C carbon fiber | 4175 | 234 |

| SWANCOR 2511-1A/BS epoxy resin | 73.5 | 3.1 |

| Fabric Type | Areal Density (g/m2) | Ratio of C/G | |

|---|---|---|---|

| Carbon Fiber | Glass Fiber | ||

| carbon | 728.3 | 0 | 1:0 |

| glass | 0 | 944.9 | 0:1 |

| C-G-C-G | 364.2 | 472.4 | 1:1 |

| C-G-G | 242.8 | 629.9 | 1:2 |

| C-G-G-G-G | 145.7 | 755.9 | 1:4 |

| Hybrid Ratio | Stacking Sequences | |||

|---|---|---|---|---|

| C:G = 1:1 |  |  |  |  |

| [G/G/C/C] | [G/C/C/G] | [C/G/G/C] | [G/C/G/C] | |

| C:G = 1:2 |  |  | ||

| [G/G/C] | [G/C/G] | |||

| C:G = 1:3 |  |  | ||

| [G/G/G/C] | [G/G/C/G] | |||

| C:G = 1:4 |  |  |  | |

| [G/G/G/G/C] | [G/G/G/C/G] | [G/G/C/G/G] | ||

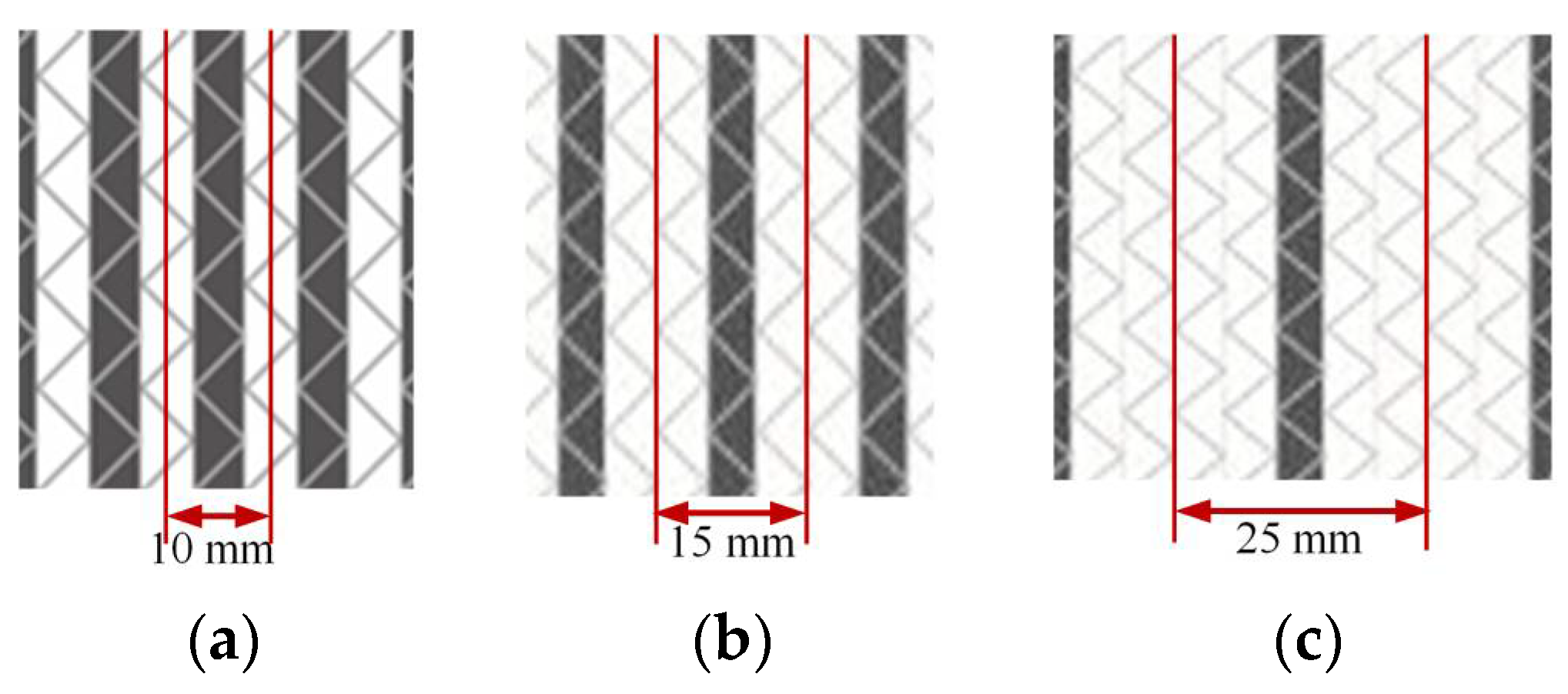

| Hybrid Fabric | Stacking Sequences | |||

|---|---|---|---|---|

| C-C-G-G |  |  |  | |

| [C-C-G-G]-0 | [C-C-G-G]-1 | [C-C-G-G]-2 | ||

|  | |||

| [C-C-G-G]-0.5 | [C-C-G-G]-1.5 | |||

| C-G-G |  |  |  |  |

| [C-G-G]-0 | [C-G-G]-1 | [C-G-G-0].5 | [C-G-G]-1.5 | |

| C-G-G-G-G |  |  |  | |

| [C-G-G-G-G]-0 | [C-G-G-G-G]-1 | [C-G-G-G-G]-2 | ||

|  |  | ||

| [C-G-G-G-G]-0.5 | [C-G-G-G-G]-1.5 | [C-G-G-G-G]-2.5 | ||

| Laminate Structures | C/G Hybrid Ratios | Layers | Laminate Thickness/mm | Width/mm | Span/mm |

|---|---|---|---|---|---|

| pure carbon fabric | 1:0 | 4 | 3.2 | 13 | 64 |

| pure glass fabric | 0:1 | 4 | 3.2 | 13 | 64 |

| interlayer laminate | 1:1 | 4 | 3.2 | 13 | 64 |

| 1:2 | 3 | 2.4 | 13 | 48 | |

| 1:3 | 4 | 3.2 | 13 | 64 | |

| 1:4 | 5 | 4 | 13 | 80 | |

| intralayer laminate | 1:1 | 4 | 3.2 | 20 | 64 |

| 1:2 | 4 | 3.2 | 15 | 64 | |

| 1:4 | 4 | 3.2 | 25 | 64 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, W.; Wang, Q.; Li, W. Comparison of Tensile and Compressive Properties of Carbon/Glass Interlayer and Intralayer Hybrid Composites. Materials 2018, 11, 1105. https://doi.org/10.3390/ma11071105

Wu W, Wang Q, Li W. Comparison of Tensile and Compressive Properties of Carbon/Glass Interlayer and Intralayer Hybrid Composites. Materials. 2018; 11(7):1105. https://doi.org/10.3390/ma11071105

Chicago/Turabian StyleWu, Weili, Qingtao Wang, and Wei Li. 2018. "Comparison of Tensile and Compressive Properties of Carbon/Glass Interlayer and Intralayer Hybrid Composites" Materials 11, no. 7: 1105. https://doi.org/10.3390/ma11071105

APA StyleWu, W., Wang, Q., & Li, W. (2018). Comparison of Tensile and Compressive Properties of Carbon/Glass Interlayer and Intralayer Hybrid Composites. Materials, 11(7), 1105. https://doi.org/10.3390/ma11071105