Research on Mechanisms and Controlling Methods of Macro Defects in TC4 Alloy Fabricated by Wire Additive Manufacturing

Abstract

1. Introduction

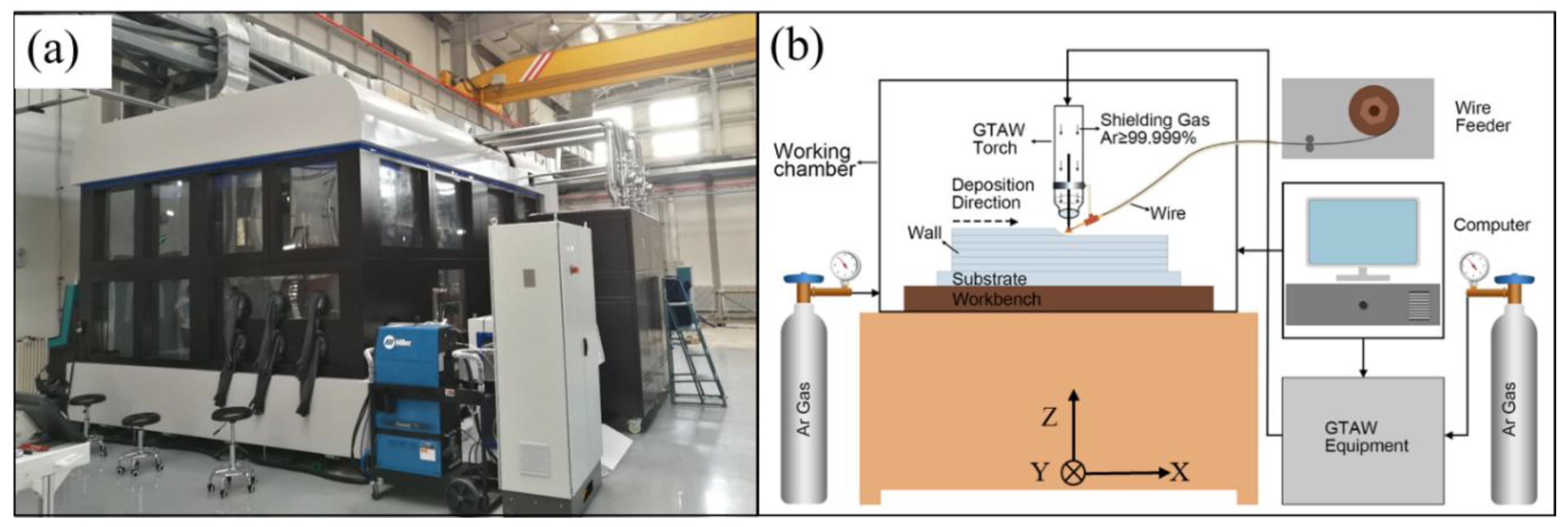

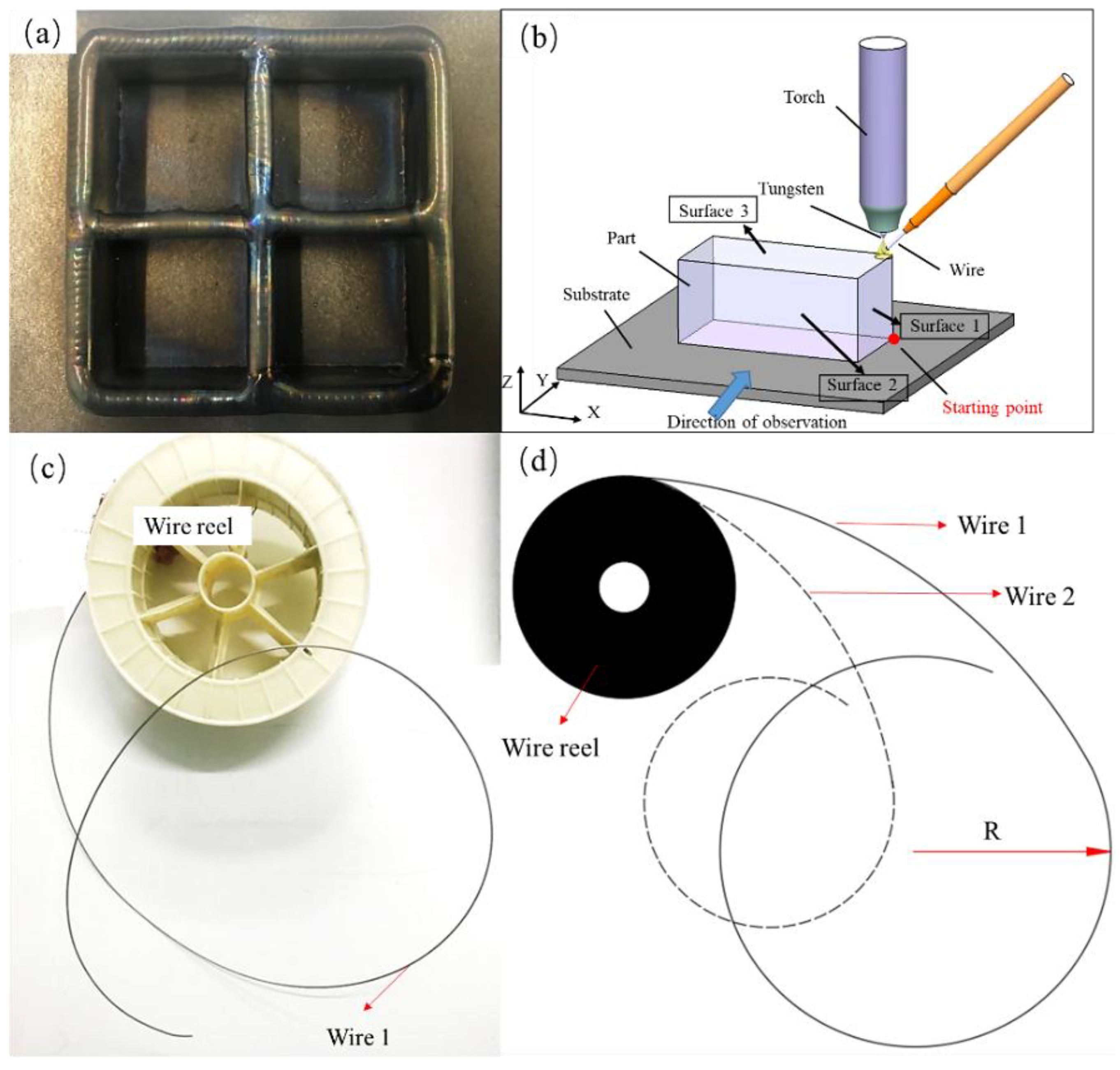

2. Experimental Details

3. Results and Discussions

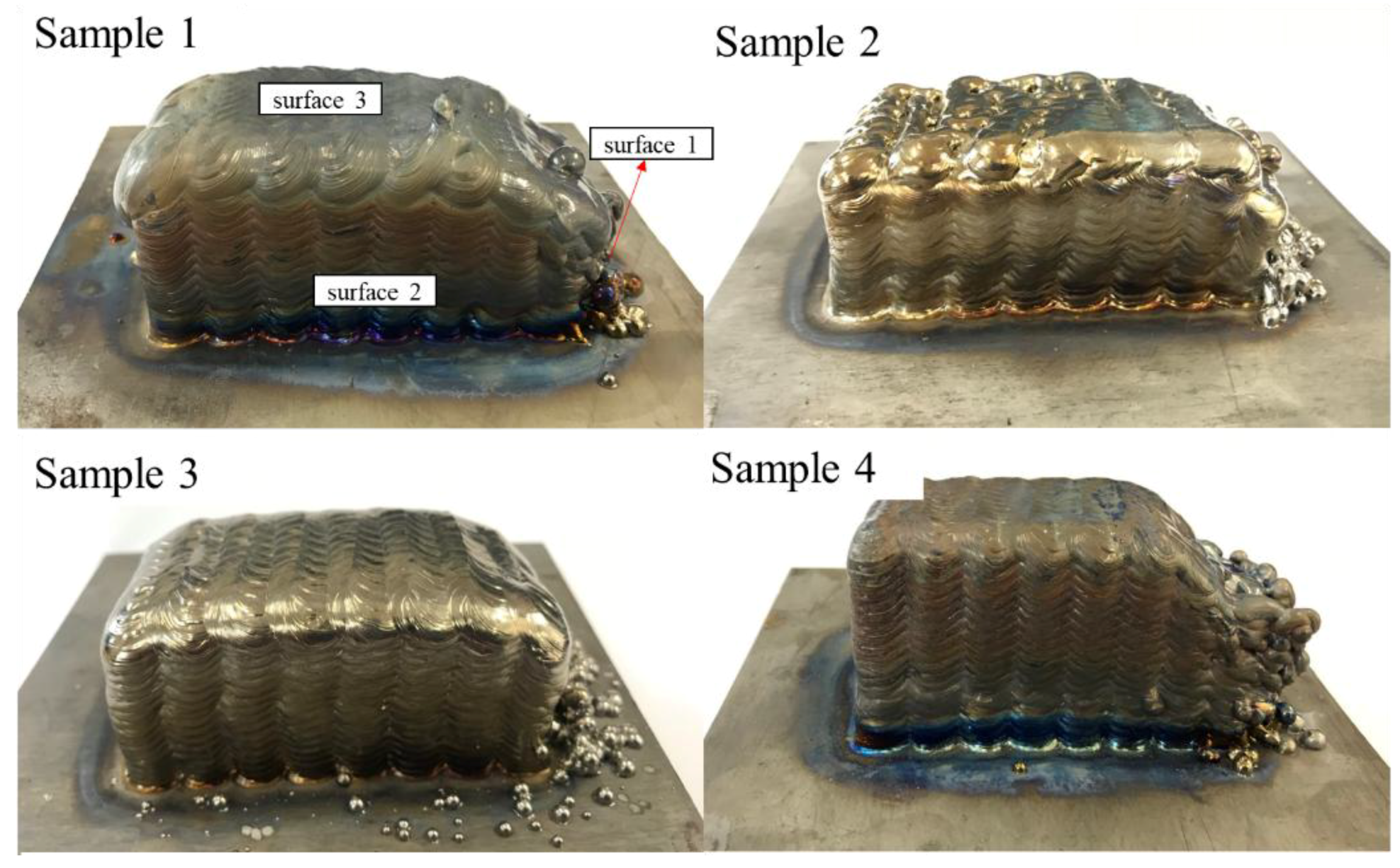

3.1. Effect of Heat Input on Macro Defects

3.1.1. The Form of Defects

3.1.2. Macro Defect Mechanisms with Different Heat Inputs

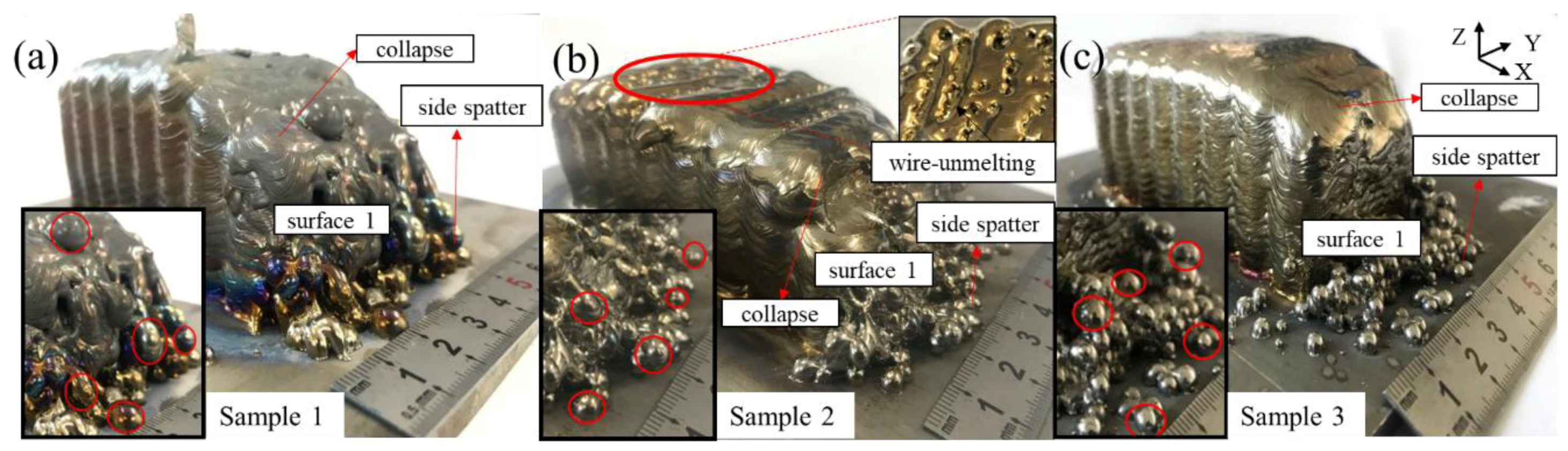

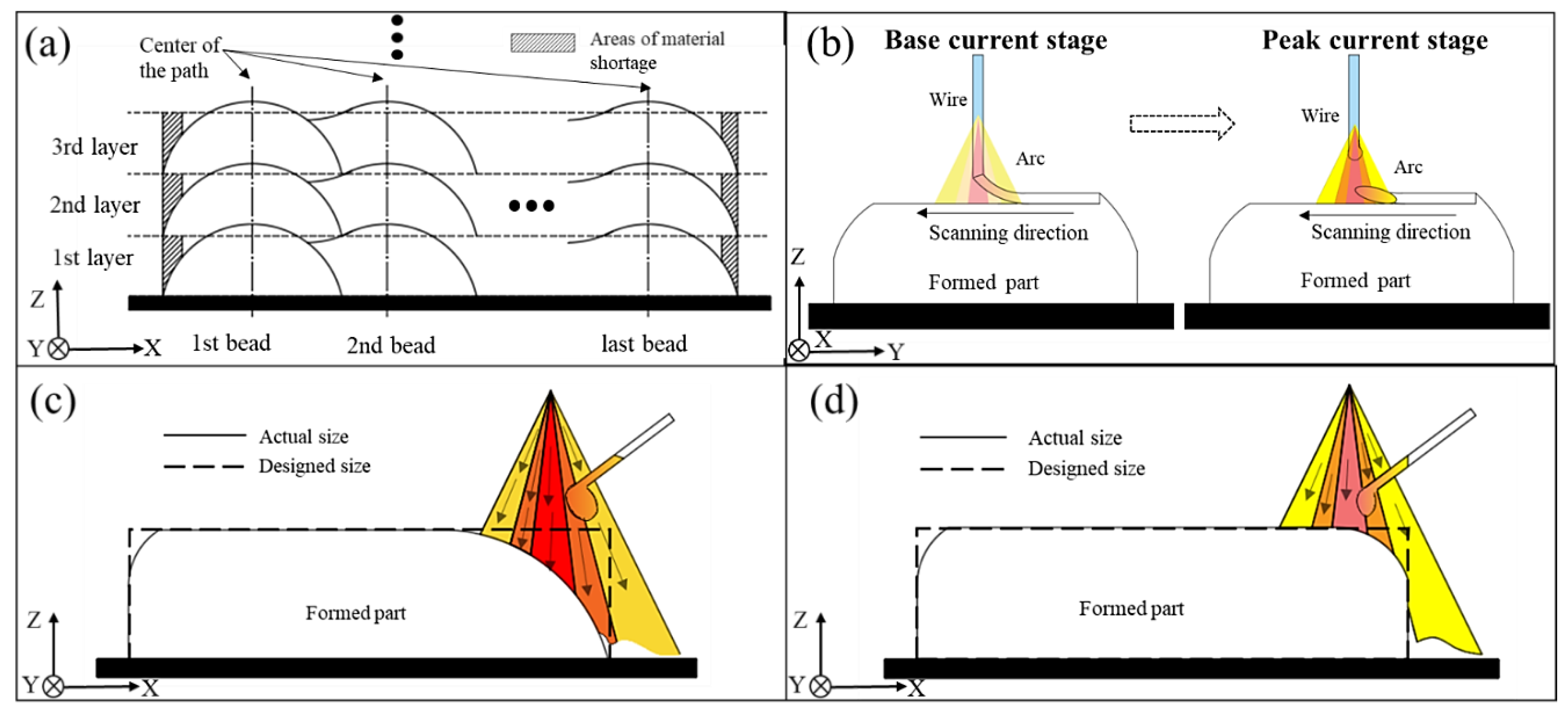

- Side collapse is mainly caused by an overlapping process and excessive heat input. When fabricating the multi-layer, multi-bead blocks, the paths used are coincident in every layer. Therefore, the blocks’ edge is lower than the blocks’ main body. As Figure 6a shows, Li [24] demonstrated that material shortage areas are generated at the edges of the blocks when two layers overlap. With the increase of the number of layers, material shortage areas can accumulate, and finally the blocks begin to collapse. Moreover, excessive heat input can cause serious collapse because of the metal flow along the wall. As Figure 6c,d shows, with decreasing heat input, the degree of collapse can be significantly reduced and the actual size of the part becomes closer to the designed size.

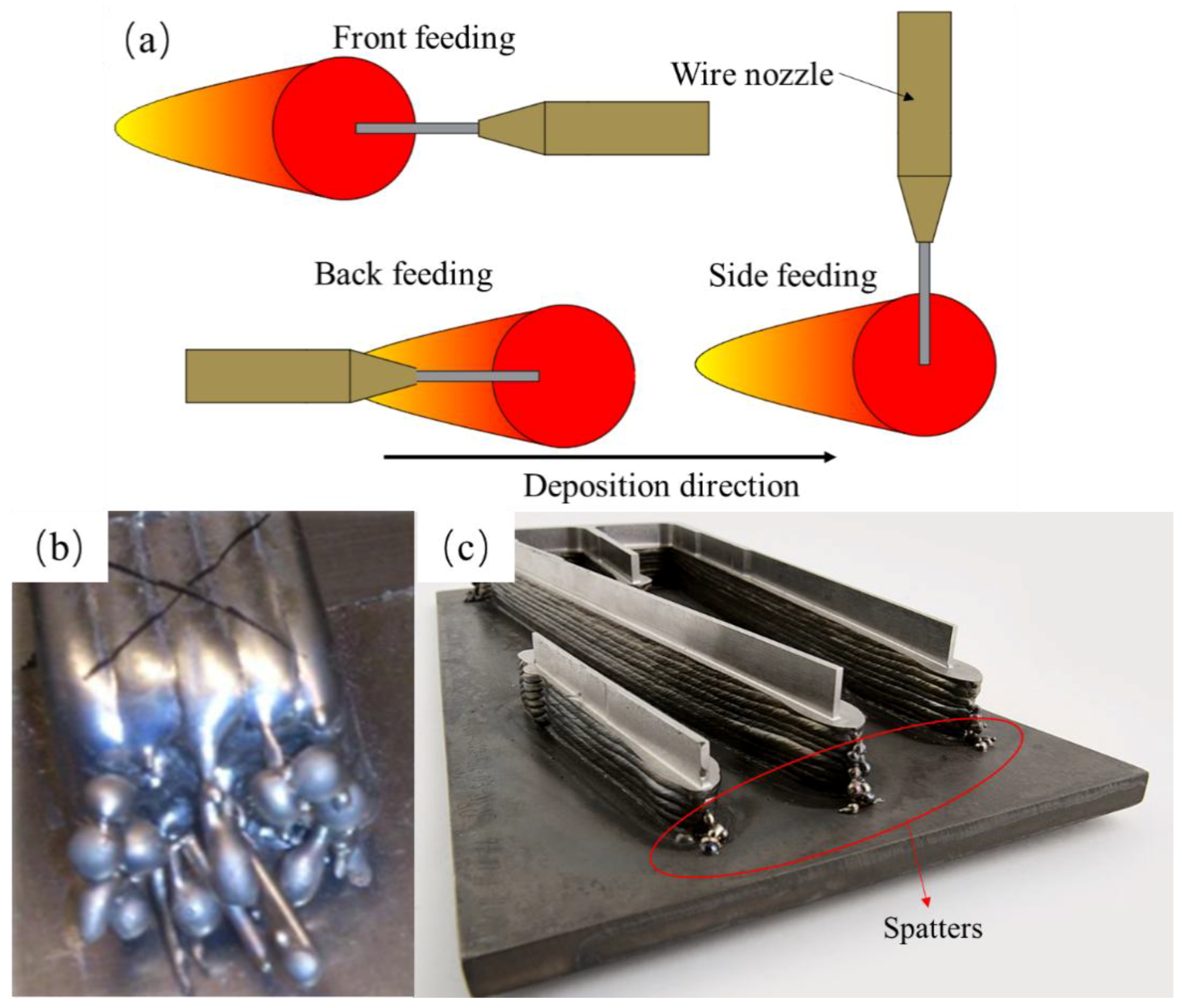

- Side spatters are mainly caused by the lateral wire feeding mode and excessive heat input. The wire is always inserted from one side, which can easily generate side spatters. When the process parameters are not matched with each other, the metal droplets can easily be splashed under the arc force in a fastigiated direction.As Figure 6c shows, when the heat input is 261 J/mm, the wire melts away from the center of the arc. Because the arc temperature is fairly high, the wire can easily be melted and the droplets generated at the front of the wire are larger and larger. Once at the pulsed current stage, the droplet falls under the arc force in a fastigiated direction, causing the droplet to be blown to the outside. The part material is lessened as well, especially at the edge of the block, so the droplets cannot fall into the center of the path with the lower surface. Therefore, the droplets are splashed as side spatters. When the heat input is decreased to 216 and 173 J/mm, the wire is more likely to be sent to the center of the arc and the size of the droplet is diminished, as Figure 6d shows. Once at the pulsed current stage, the droplet can be blown to the path more accurately.As shown in Figure 5, five droplets with a clear appearance are selected for each sample and the average size is calculated. The spatter sizes of samples 1, 2, and 3 in Figure 5 are 6.39, 4.21, and 4.25 mm. That is, even if the heat input is reduced, spatter still exists because of the special side feeding mode, but the size of the spatters and their number can be reduced efficiently.

- The wire cannot be fully melted when the heat input is too small. As Figure 6b shows, a large amount of wire material is not melted at the base current, with the wire traveling against the formed surface. Once at the peak current, the wire is directly fused to the formed surface, causing the wire not to be fully melted and resulting in poor bonding between the contiguous weld beads. When the heat input is insufficient, the parts are not well formed and the wire feeding system becomes unstable during manufacturing and the stability of part forming is reduced, owing to the front of the wire touching the surface.

3.2. Effect of Layer Thickness on Macro Defects

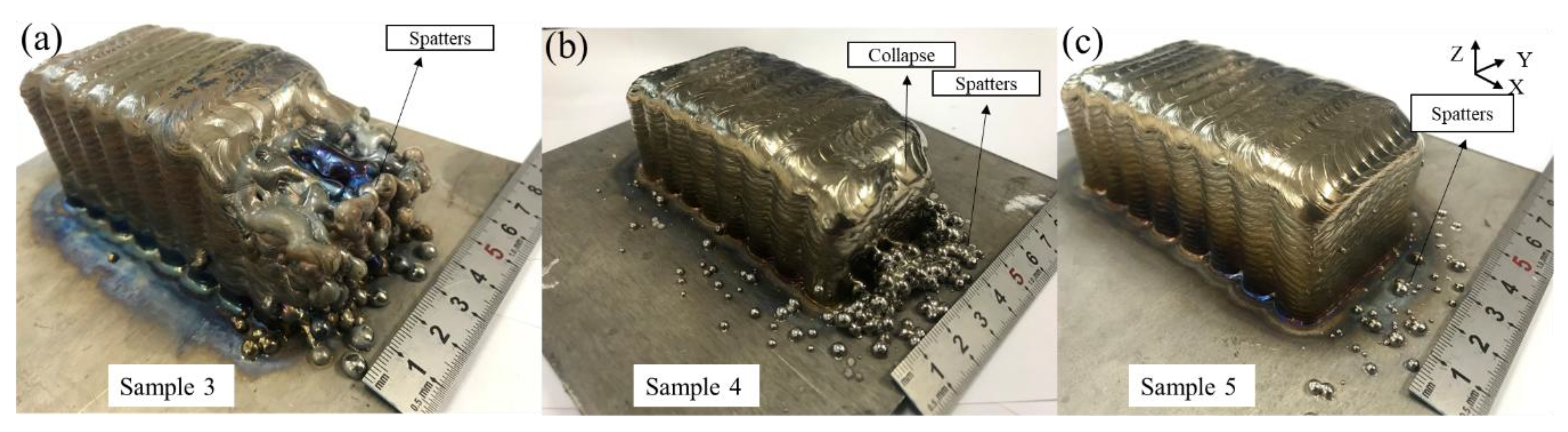

3.2.1. The Form of Defects

3.2.2. Macro Defect Mechanisms with Different Layer Thicknesses

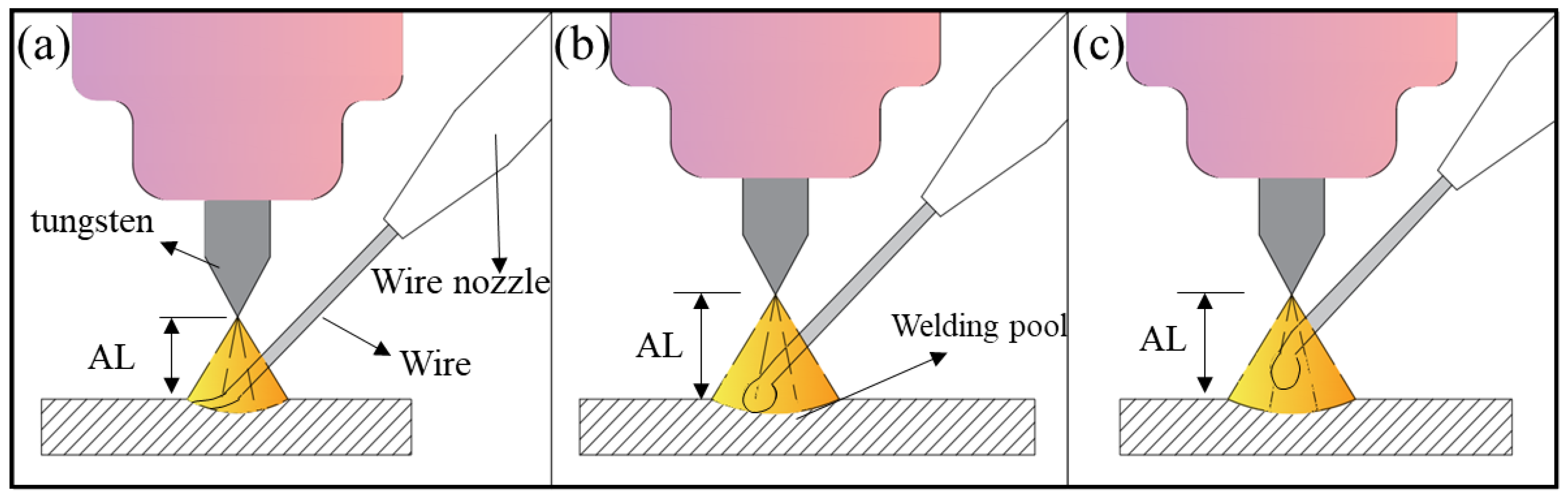

- Figure 8a shows the no-droplet mode with small AL. The wire is fed into the bottom of the molten pool during the fabricating process, which means that the wire is in contact with the bottom of the molten pool during the feeding as in continuous molding. Opderbecke and Guiheux mentioned the existence of a liquid bridge, which contrasts with the no-contact mode. In this mode, the metal in the molten pool is mainly controlled by surface tension and gravity and remains stable, so each weld bead has a relatively flat appearance [26]. Compared with other modes, this mode can lower the height of the weld bead, reflected as collapse when the block part is fabricated.

- As the AL increases, as shown in the Figure 8b, the tangent-droplet mode dominates. Here the wire does not touch the bottom of the molten pool during the feeding process. The front of the wire is melted, then a droplet is formed that adheres to the front of the wire owing to its own surface tension. The droplet becomes larger and larger until it is in contact with the molten pool. Owing to its own gravity and the arc force under the peak current, the droplet falls off the front of the wire and falls onto the formed surface to complete the metal transition from the wire smoothly.

- Figure 8c shows the no-contact mode with large AL. The wire is further away from the bottom of the molten pool. Similarly, a droplet forms at the base current and sticks to the front of the wire. Necking phenomenon occurs as a result of gravity, and the droplet is stretched but cannot be in contact with the molten pool. Such droplets are blown to the formed surface by the arc force until the pulsed current works. In this mode, magnetic bias blowing occurs, and this easily leads to the splash of the droplets. At the same time, droplets in this mode are relatively close to the tungsten, and may pollute the tungsten and reduce the service life and fabricating stability.

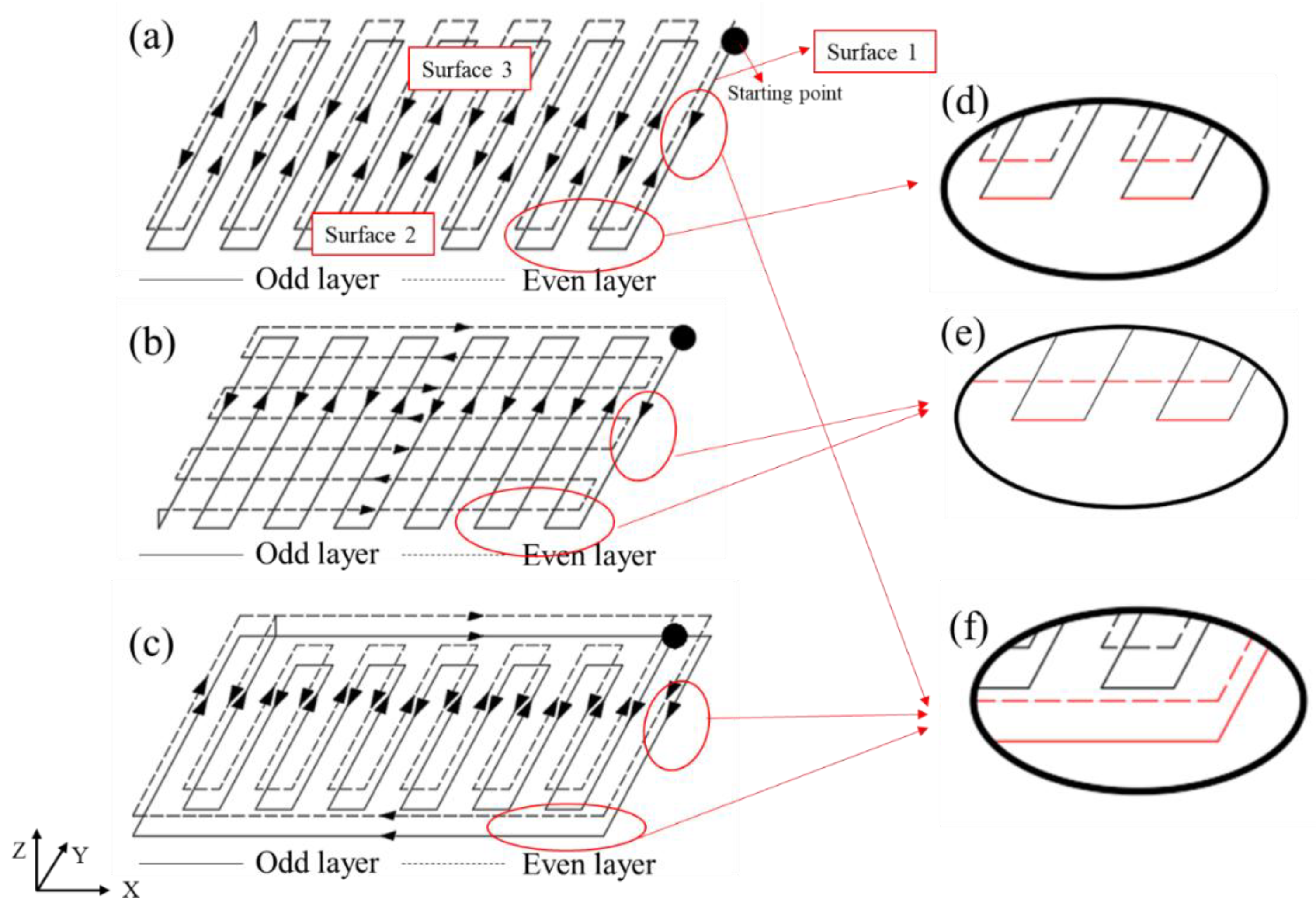

3.3. Effect of Tool Path on Macro Defects

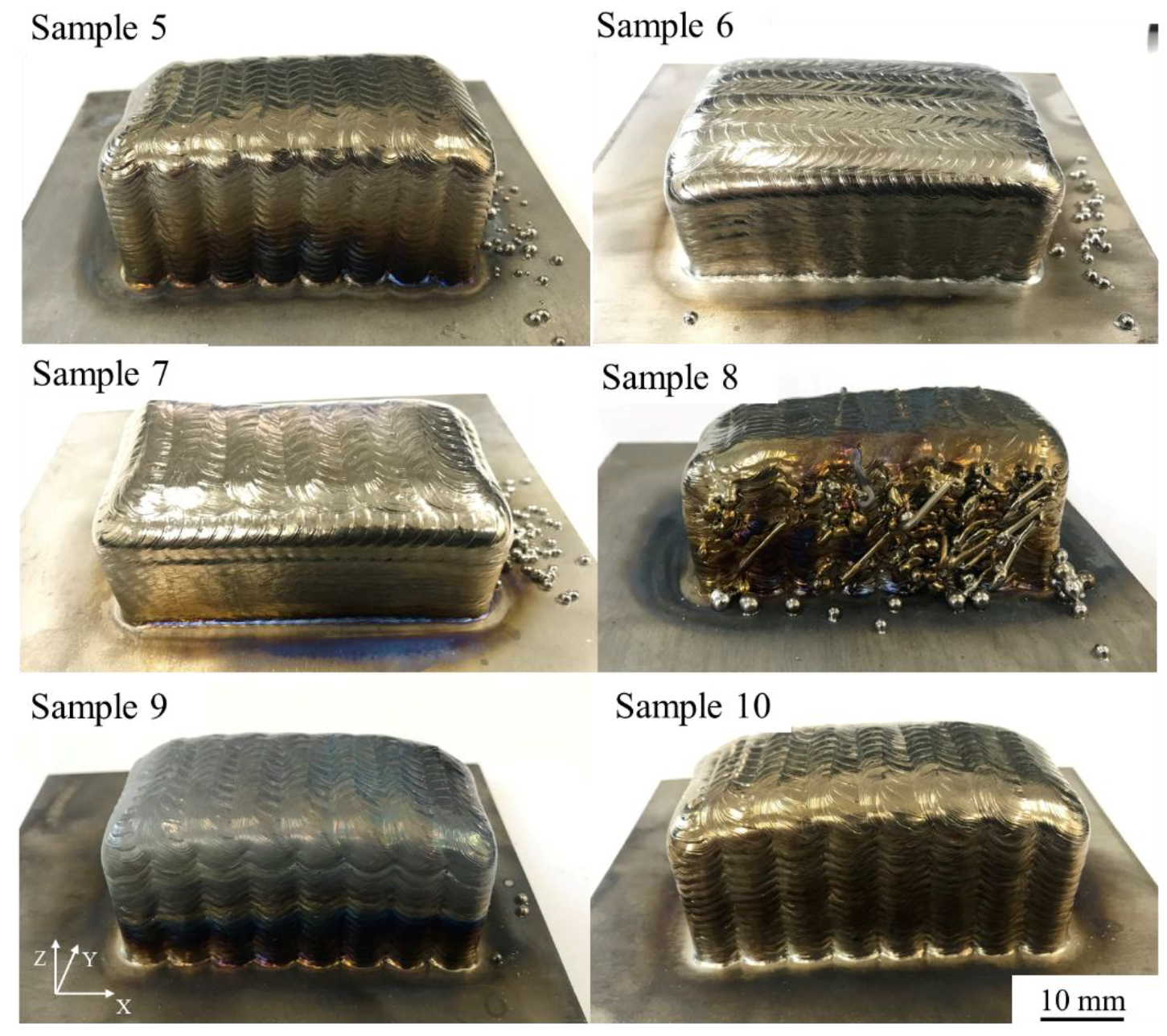

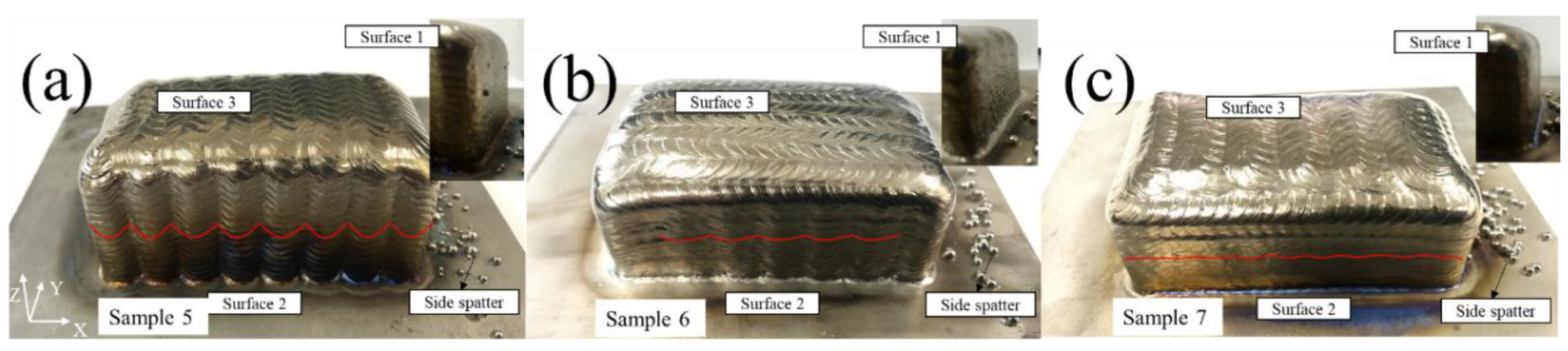

3.3.1. The Form of Defects

3.3.2. Macro Defect Mechanisms with Different Tool Paths

- The first overlapping type is shown in Figure 10d. The surface is composed of the metal that is located on the turning of each weld bead. The movement of the machine tool is continuous, and the weld bead has a certain width. Therefore, the path in the 180° corner of each layer is always in the form of a circle, and because the paths of each layer are repetitive, surface 2 becomes obviously corrugated during the fabricating process.Figure 11 reflects the flatness values of surface 1, surface 2, and surface 3 of the three paths. Surface 2 of sample 5 in Figure 9 is used with this overlapping method with a flatness value of 1.689 mm.The second overlapping type is shown in Figure 10e. The metal of odd layers is at the corners of each weld bead, and the metal of even layers is covered by a straight weld bead directly. In this way, the overlapping gaps produced by the odd layers are supplemented by the metal of even layers, and the even-numbered layers of molten metal complement the voids from the odd-numbered layers, reducing the amount of ripple phenomenon of surface 2.

- The overlap patterns of surface 1 and surface 2 of sample 6 in Figure 9 are the same, but the values are 0.329 and 0.628 mm, a difference of nearly a factor of 2. This difference occurs mainly because the weld bead of surface 1 is much shorter than that of surface 2. The heat input is relatively concentrated, causing the even layer to fill the odd layers with more metal, thus reducing the flatness value. Furthermore, the accumulation of heat input tends to cause collapse on surface 1, which corresponds to the previous result.The third overlapping type is shown in Figure 10f. Each layer is a complete straight weld bead without turning of the path, so the surface can be smoother. There are only small scale patterns in the horizontal direction, which is the effect of overlapping of welding pool, an inherent phenomenon in wire arc additive manufacturing.

- Surface 1 of sample 5 and surfaces 1 and 2 of sample 7 of Figure 9 are of the same overlapping type, according to the above description. Their flatness values are 0.434, 0.405, and 0.354 mm, which are almost the same and confirms the above-mentioned overlap mechanism.

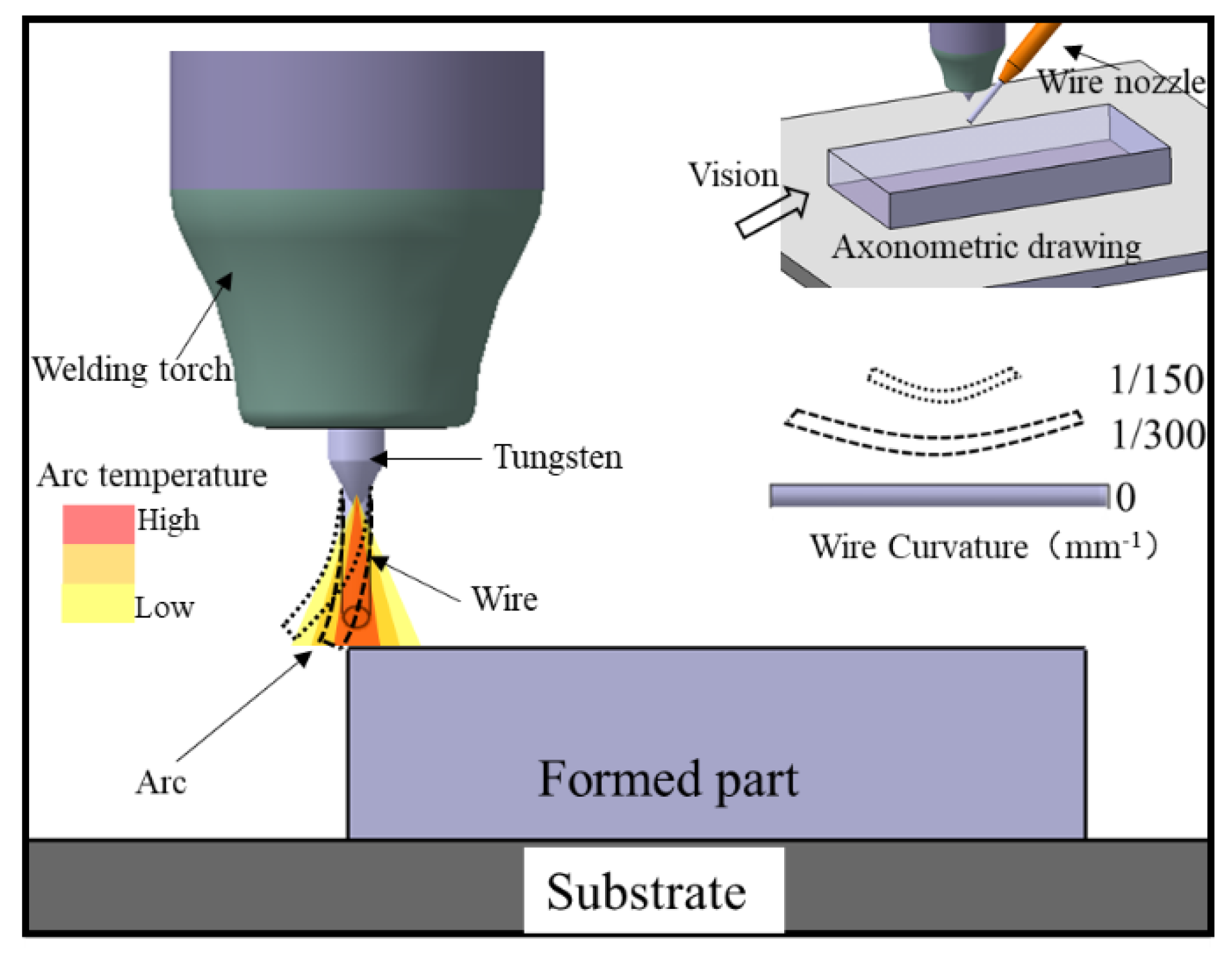

3.4. Effect of Wire Curvature on Macro Defects

3.4.1. The Form of Defects

3.4.2. Macro Defect Mechanisms with Different Wire Curvatures

4. Conclusions

- Improper heat input brings effect of side spatters, collapse, and unmelted wire. When the heat input is decreased from 261 to 173 J/mm, the size and number of spatters are reduced obviously and less degree of collapse is observed as well. However, unmelted wire occurs as the heat input is decreased. Even if decreasing the heat input can reduce defects, the main reason for the side spatters is the lateral wire feeding mode.

- Improper layer thickness brings effects of side spatters and collapse. Different layer thicknesses affect the arc length, which can determine the metal transfer mode: no-droplet mode, tangent-droplet mode, or no-contact mode. Based on lateral wire feeding, the no-contact mode easily results in side spatters and the no-droplet mode easily results in collapse. Choosing a changeable layer thickness can effectively reduce those defects.

- Different tool paths mainly lead to different surface flatness levels. Three overlapping types at the edge of the sample are proposed. It is meaningful to choose the appropriate tool path to fabricate the components in WFAM, which can efficiently reduce post-processing time and improve manufacturing efficiency.

- Different wire curvatures bring side spatters and unmelted wire. In this paper, three kinds of wire with curvatures of 0, 1/300, and 1/150 were investigated. It was found that the more bent the wire, the more frequent are the spatters and the appearance of unmelted wire. Therefore, the development of wire standards or the use of a straightener in the manufacturing process can effectively improve the straightness of the wire and the reliability of manufacturing, which is of significance to the development of WFAM.

Author Contributions

Funding

Conflicts of Interest

References

- Fousova, M.; Vojtech, D.; Doubrava, K.; Daniel, M.; Lin, C.F. Influence of inherent surface and internal defects on mechanical properties of additively manufactured Ti6Al4V alloy: Comparison between selective laser melting and electron beam melting. Materials 2018, 11, 537. [Google Scholar] [CrossRef] [PubMed]

- Brandl, E.; Schoberth, A.; Leyens, C. Morphology, microstructure, and hardness of titanium (Ti-6Al-4V) blocks deposited by wire-feed additive layer manufacturing (ALM). Mater. Sci. Eng. A 2012, 532, 295–307. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Wu, Q.; Lu, J.; Liu, C.; Shi, X.; Ma, Q.; Tang, S.; Fan, H.; Ma, S. Obtaining uniform deposition with variable wire feeding direction during wire-feed additive manufacturing. Mater. Manuf. Process. 2017, 32, 1881–1886. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + arc additive manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Moures, F.; Cicală, E.; Sallamand, P.; Grevey, D.; Vannes, B.; Ignat, S. Optimisation of refractory coatings realised with cored wire addition using a high-power diode laser. Surf. Coat. Technol. 2005, 200, 2283–2292. [Google Scholar] [CrossRef]

- Mok, S.H.; Bi, G.; Folkes, J.; Pashby, I. Deposition of Ti–6Al–4V using a high power diode laser and wire, part I: Investigation on the process characteristics. Surf. Coat. Technol. 2008, 202, 3933–3939. [Google Scholar] [CrossRef]

- Thomsen, P.; Malmstrom, J.; Emanuelsson, L.; Rene, M.; Snis, A. Electron beam-melted, free-form-fabricated titanium alloy implants: Material surface characterization and early bone response in rabbits. J. Biomed. Mater. Res. B Appl. Biomater. 2009, 90, 35–44. [Google Scholar] [CrossRef] [PubMed]

- Hafley, R.; Taminger, K.; Bird, R. Electron beam freeform fabrication in the space environment. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–11 January 2007. [Google Scholar]

- Yilmaz, O.; Ugla, A.A. Microstructure characterization of SS308LSi components manufactured by GTAW-based additive manufacturing: Shaped metal deposition using pulsed current arc. Int. J. Adv. Manuf. Technol. 2016, 89, 13–25. [Google Scholar] [CrossRef]

- Guo, J.; Zhou, Y.; Liu, C.; Wu, Q.; Chen, X.; Lu, J. Wire arc additive manufacturing of AZ31 magnesium alloy: Grain refinement by adjusting pulse frequency. Materials 2016, 9, 823. [Google Scholar] [CrossRef] [PubMed]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Bai, X.; Colegrove, P.; Ding, J.; Zhou, X.; Diao, C.; Bridgeman, P.; Roman Hönnige, J.; Zhang, H.; Williams, S. Numerical analysis of heat transfer and fluid flow in multilayer deposition of PAW-based wire and arc additive manufacturing. Int. J. Heat Mass Transf. 2018, 124, 504–516. [Google Scholar] [CrossRef]

- Brandl, E.; Palm, F.; Michailov, V.; Viehweger, B.; Leyens, C. Mechanical properties of additive manufactured titanium (Ti–6Al–4V) blocks deposited by a solid-state laser and wire. Mater. Des. 2011, 32, 4665–4675. [Google Scholar] [CrossRef]

- Hagqvist, P. Laser Metal Deposition with Wire-Enabling New Manufacturing Solutions through Process Control. Available online: http://www.lortek.es/files/merlin/03-P_Hagqvist-UW&GKN-Aero-Case-study.pdf (accessed on 27 June 2018).

- Boeing 787 Dreamliner Will Be First Commercial Airplane to Fly with Certified Additive-Manufactured Titanium Parts in Structural Applications. Available online: http://www.norsktitanium.com/media/press/norsk-titanium-to-deliver-the-worlds-first-faa-approved-3d-printed-structural-titanium-components-to-boeing (accessed on 27 June 2018).

- Civil Aviation Demand Flying High. Available online: https://www.metalbulletin.com/Article/3552854/3650683/ (accessed on 27 June 2018).

- Li, Y.; Han, Q.; Zhang, G.; Horváth, I. A layers-overlapping strategy for robotic wire and arc additive manufacturing of multi-layer multi-bead components with homogeneous layers. Int. J. Adv. Manuf. Technol. 2018, 96, 3331–3344. [Google Scholar] [CrossRef]

- Kwak, Y.-M.; Doumanidis, C.C. Geometry regulation of material deposition in near-net shape manufacturing by thermally scanned welding. J. Manuf. Process. 2002, 4, 28–41. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Qiu, Z.; Li, Y. Vision-sensing and bead width control of a single-bead multi-layer part: Material and energy savings in gmaw-based rapid manufacturing. J. Clean. Prod. 2013, 41, 82–88. [Google Scholar] [CrossRef]

- Wu, Q.; Ma, Z.; Chen, G.; Liu, C.; Ma, D.; Ma, S. Obtaining fine microstructure and unsupported overhangs by low heat input pulse arc additive manufacturing. J. Manuf. Process. 2017, 27, 198–206. [Google Scholar] [CrossRef]

- Giridharan, P.K.; Murugan, N. Optimization of pulsed GTA welding process parameters for the welding of AISI 304L stainless steel sheets. Int. J. Adv. Manuf. Technol. 2008, 40, 478–489. [Google Scholar] [CrossRef]

- Kishore Babu, N.; Ganesh Sundara Raman, S.; Mythili, R.; Saroja, S. Correlation of microstructure with mechanical properties of TIG weldments of Ti–6Al–4V made with and without current pulsing. Mater. Charact. 2007, 58, 581–587. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot. Comput.-Integr. Manuf. 2015, 31, 101–110. [Google Scholar] [CrossRef]

- Suryakumar, S.; Karunakaran, K.P.; Bernard, A.; Chandrasekhar, U.; Raghavender, N.; Sharma, D. Weld bead modeling and process optimization in hybrid layered manufacturing. Comput.-Aided Des. 2011, 43, 331–344. [Google Scholar] [CrossRef]

- Opderbecke, T.; Guiheux, S. Toptig: Robotic tig welding with integrated wire feeder. Weld. Int. 2009, 23, 523–529. [Google Scholar] [CrossRef]

| Sample | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Experimental group | Group 1 | Group 3 | ||||||||

| Group 2 | Group 4 | |||||||||

| Heat input (J/mm) | 262 | 173 | 217 | 217 | 217 | 217 | 217 | 217 | 217 | 217 |

| Layer thickness (mm) | 1.05 | 1.05 | 1.05 | 1.1 | 1.05/1.1 | 1.05/1.1 | 1.05/1.1 | 1.05/1.1 | 1.05/1.1 | 1.05/1.1 |

| Path | Z | Z | Z | Z | Z | Vertical | Contour filling | Z | Z | Z |

| Wire curvature (mm−1) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1/150 | 1/300 | 0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, L.; Lu, J.; Tang, S.; Wu, Q.; Wang, J.; Ma, S.; Fan, H.; Liu, C. Research on Mechanisms and Controlling Methods of Macro Defects in TC4 Alloy Fabricated by Wire Additive Manufacturing. Materials 2018, 11, 1104. https://doi.org/10.3390/ma11071104

Ji L, Lu J, Tang S, Wu Q, Wang J, Ma S, Fan H, Liu C. Research on Mechanisms and Controlling Methods of Macro Defects in TC4 Alloy Fabricated by Wire Additive Manufacturing. Materials. 2018; 11(7):1104. https://doi.org/10.3390/ma11071104

Chicago/Turabian StyleJi, Lei, Jiping Lu, Shuiyuan Tang, Qianru Wu, Jiachen Wang, Shuyuan Ma, Hongli Fan, and Changmeng Liu. 2018. "Research on Mechanisms and Controlling Methods of Macro Defects in TC4 Alloy Fabricated by Wire Additive Manufacturing" Materials 11, no. 7: 1104. https://doi.org/10.3390/ma11071104

APA StyleJi, L., Lu, J., Tang, S., Wu, Q., Wang, J., Ma, S., Fan, H., & Liu, C. (2018). Research on Mechanisms and Controlling Methods of Macro Defects in TC4 Alloy Fabricated by Wire Additive Manufacturing. Materials, 11(7), 1104. https://doi.org/10.3390/ma11071104