The Particle Shape of WC Governing the Fracture Mechanism of Particle Reinforced Iron Matrix Composites

Abstract

1. Introduction

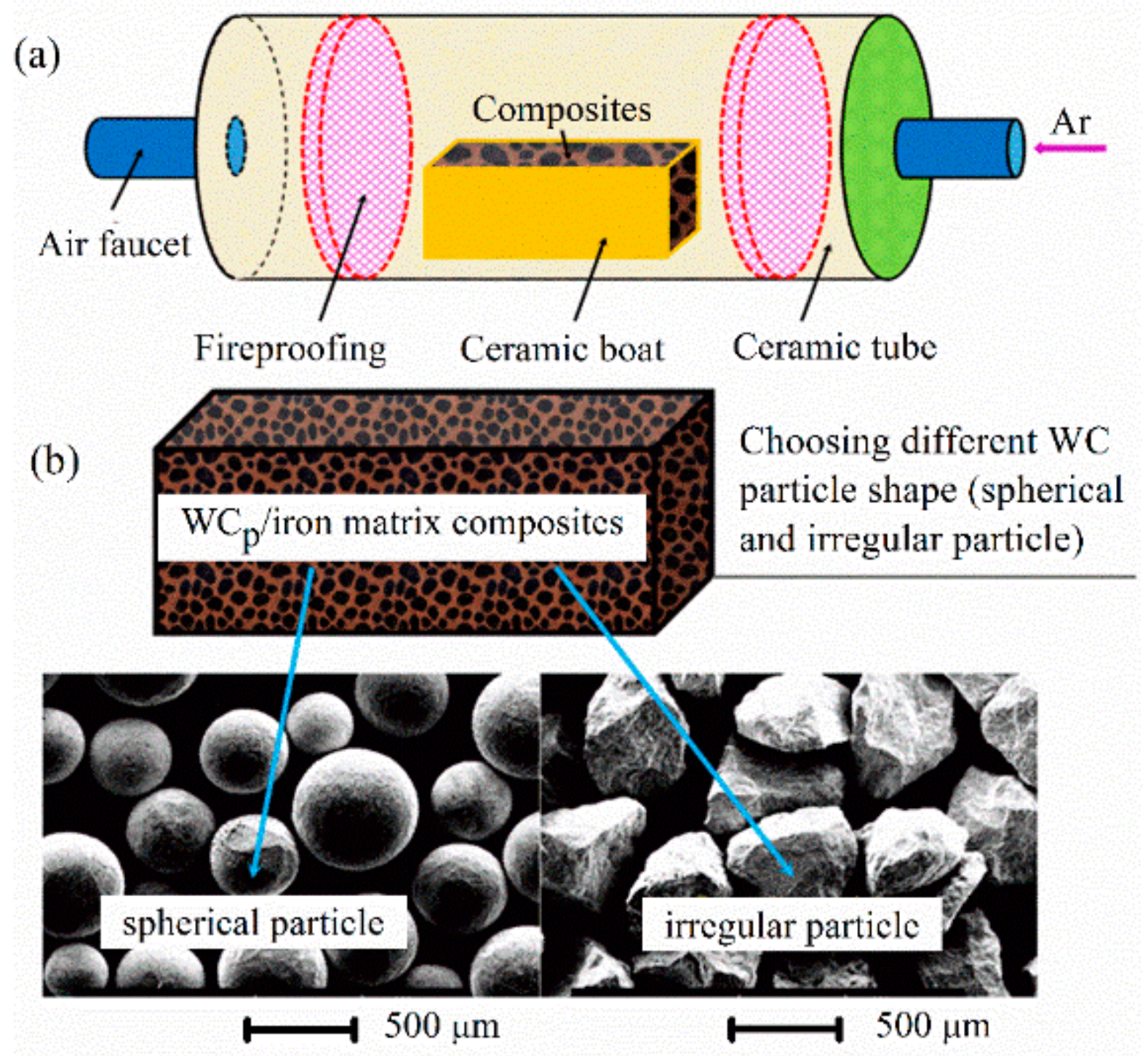

2. Materials and Methods

2.1. Preparation of Composites

2.2. Characterization

3. Results

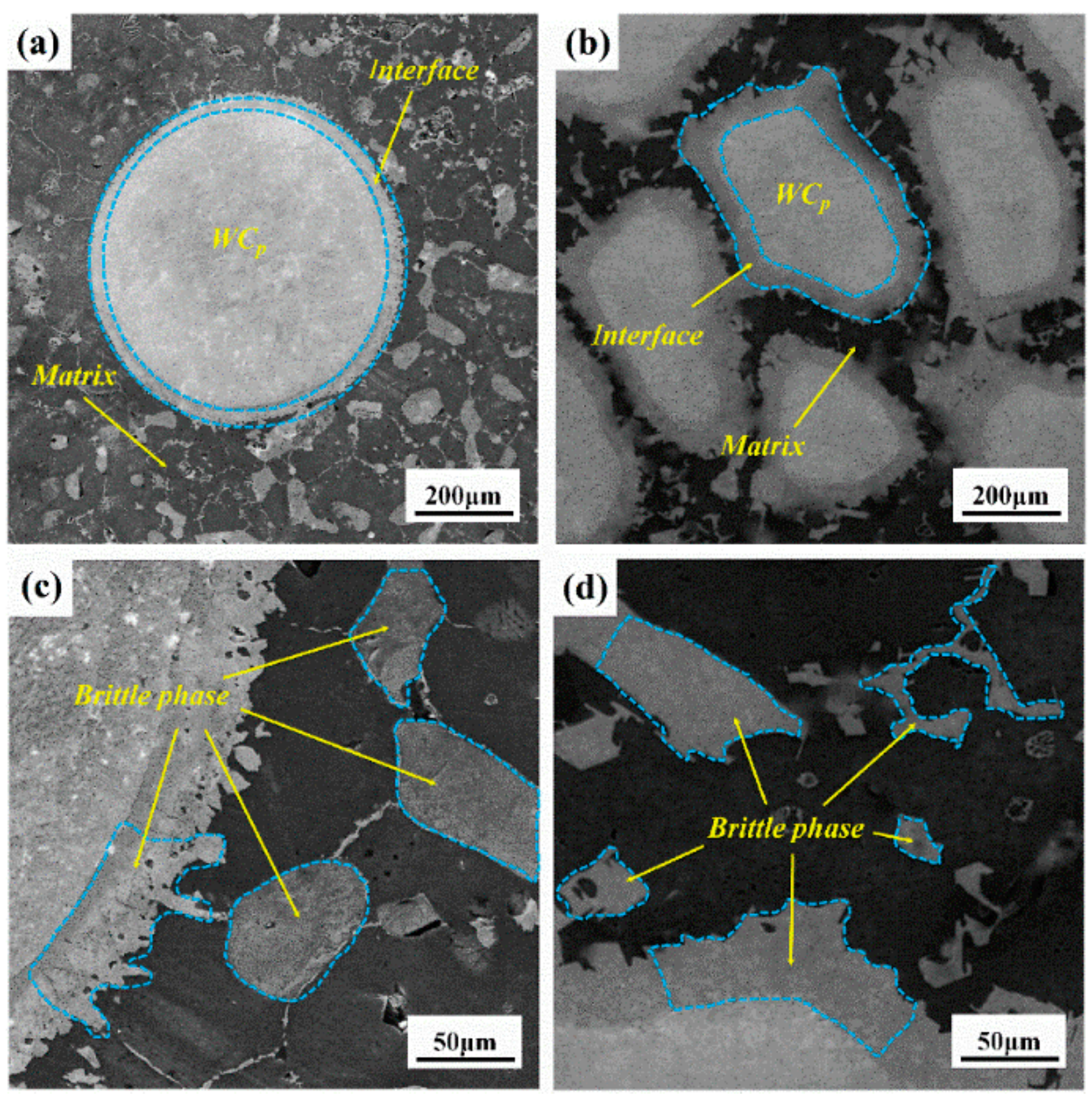

3.1. Microstructure

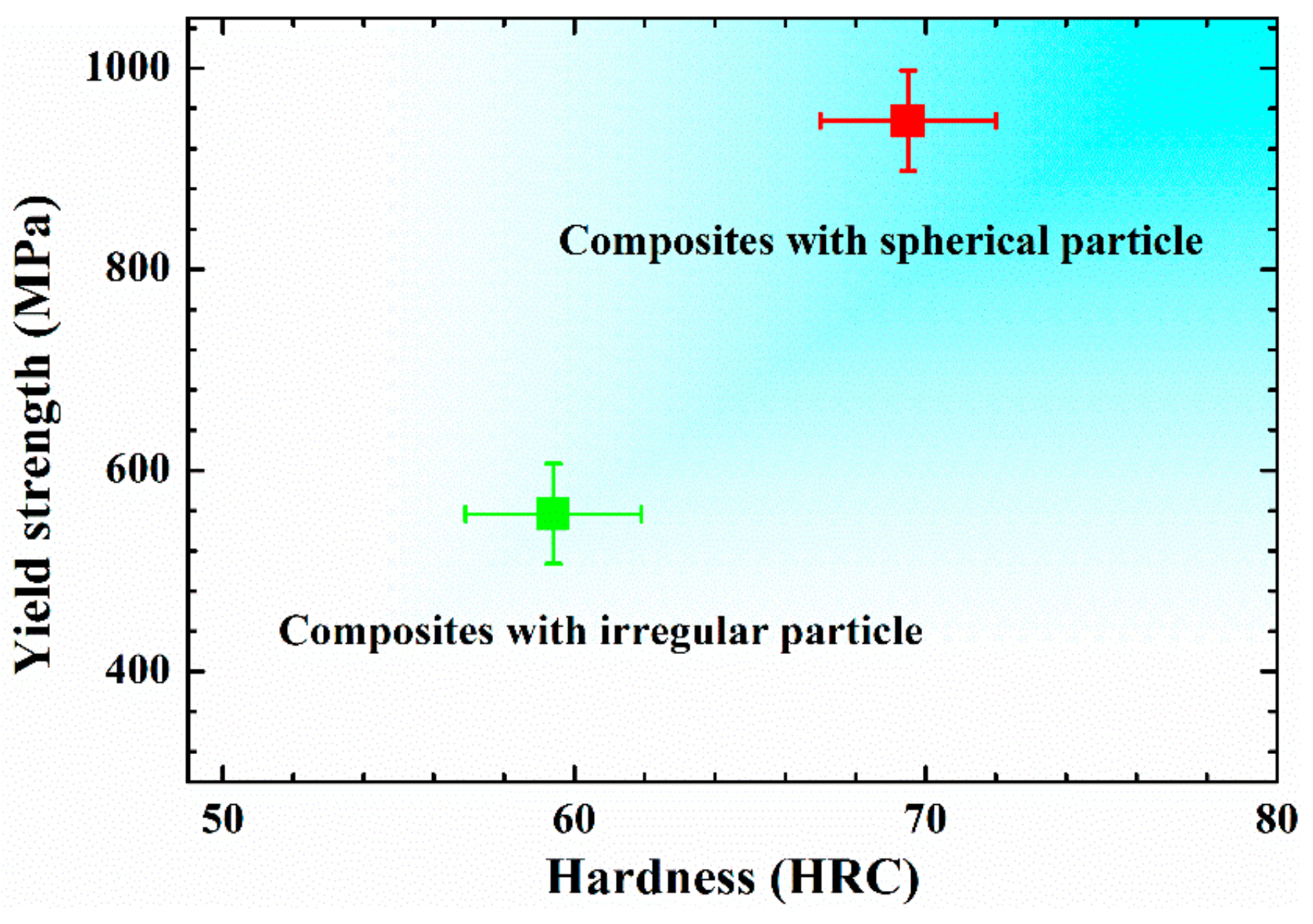

3.2. Mechanical Properties

4. Discussion

5. Conclusions

- (1)

- In the interfacial reaction zone, WC particle and iron matrix could react into a brittle Fe3W3C phase.

- (2)

- The spherical WCp/iron matrix composites had higher compression yield strength and hardness compared with the irregular ones.

- (3)

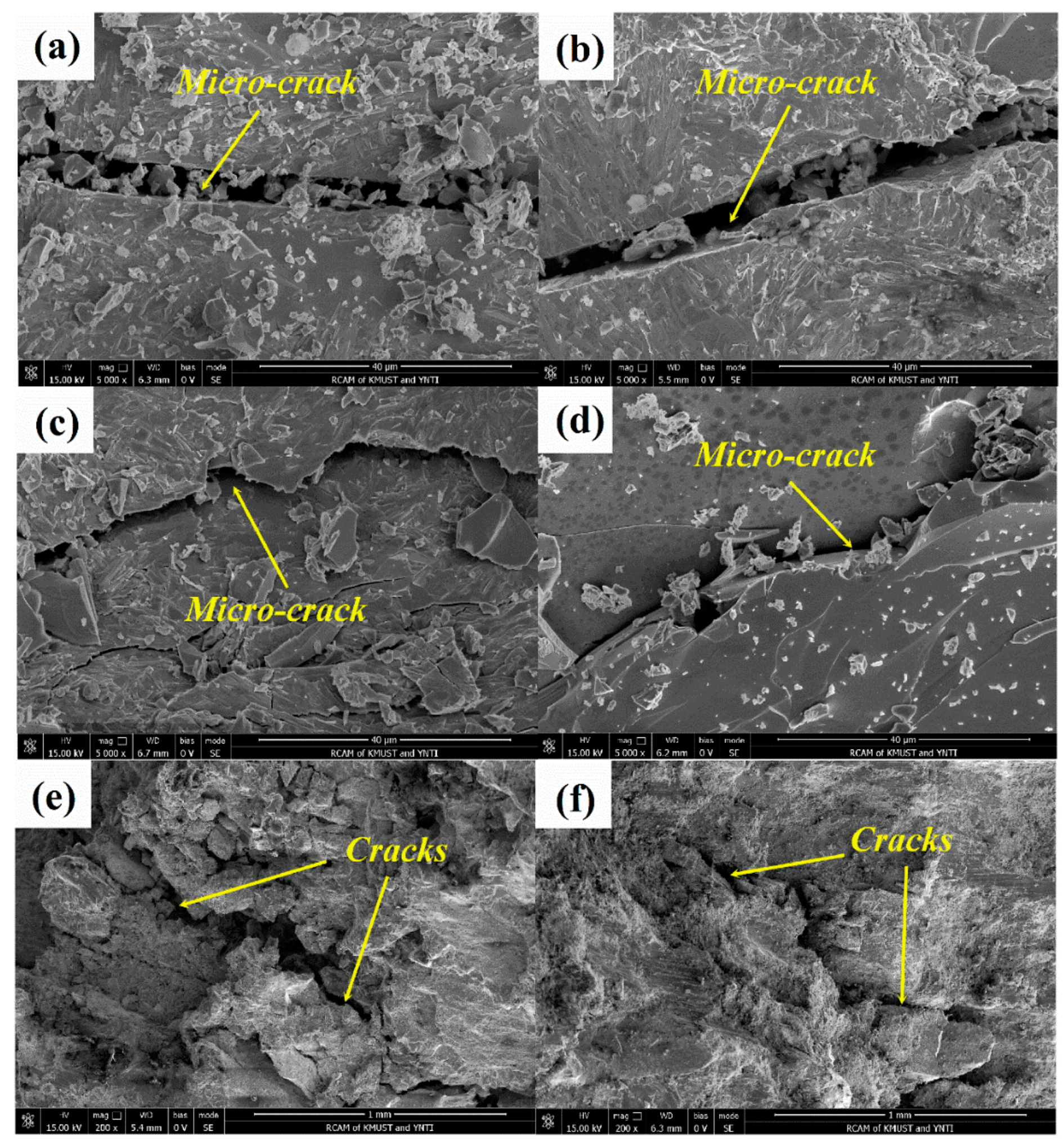

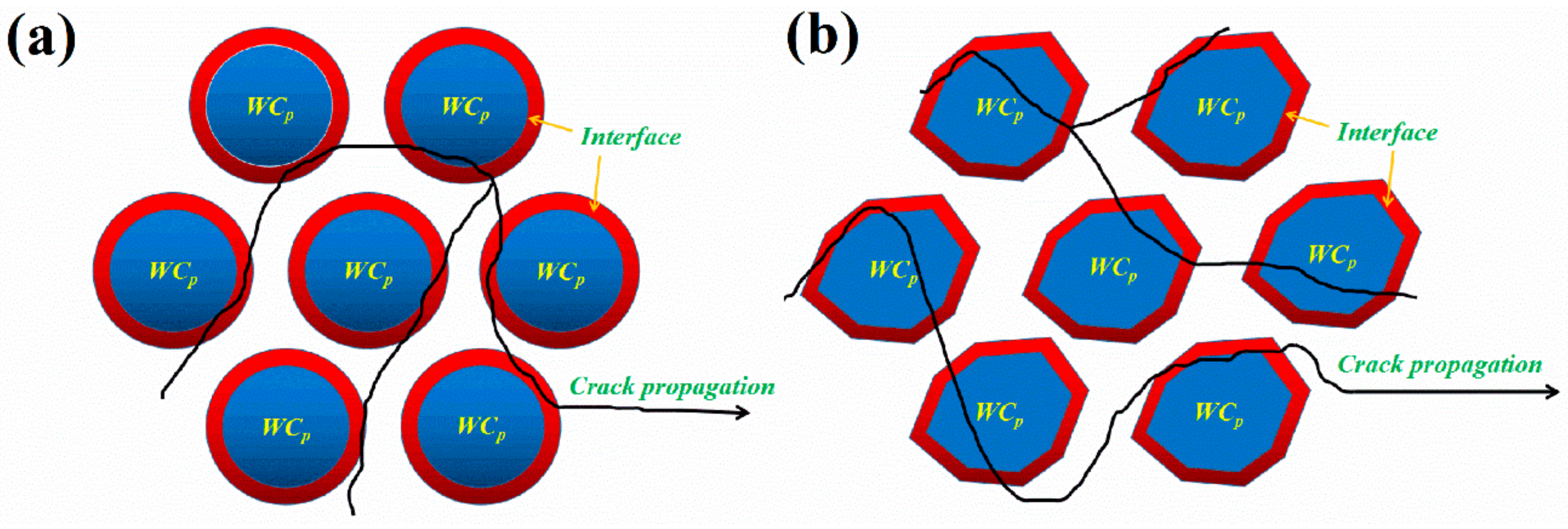

- The micro-cracks source of composites were generated at the interface. The irregular WCp within composites tended to produce a higher stress concentration compared with spherical WCp, which were prone to cause brittle fracture.

- (4)

- Bigger specific surface area resulting from more bulges on irregular WCp could lead to a more brittle Fe3W3C phase in the interfacial reaction zones. Therefore, the irregular WCp/iron matrix composites had lower yield strength and hardness.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| PRMMSC | particle reinforced metal matrix surface composites |

| WCp | tungsten carbide particles |

| a. u. | arbitrary units |

| XRD | X-ray diffractometer |

| SEM | scanning electron microscopy |

| EDS | Energy Dispersive Spectrometer |

| HRC | Rockwell C hardness |

| FE-SEM | field emission scanning electron microscopy |

References

- Pramanik, A. Developments in the non-traditional machining of particle reinforced metal matrix composites. Int. J. Mach. Tools Manuf. 2014, 86, 44–61. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, Y.; Zhou, R.; Chen, Z.; Shan, Q.; Tan, J. Effect of Cr addition on the microstructure and abrasive wear resistance of WC-reinforced iron matrix surface composites. J. Mater. Res. 2014, 29, 778–785. [Google Scholar] [CrossRef]

- An, L.; Qu, J.; Luo, J.; Fan, Y.; Zhang, L.; Liu, J.; Xu, C.; Blau, P.J. Aluminum nanocomposites having wear resistance better than stainless steel. J. Mater. Res. 2011, 26, 2479–2483. [Google Scholar] [CrossRef]

- Akbari, M.K.; Baharvandi, H.; Mirzaee, O. Nano-sized aluminum oxide reinforced commercial casting A356 alloy matrix: Evaluation of hardness, wear resistance and compressive strength focusing on particle distribution in aluminum matrix. Compos. Part B Eng. 2013, 52, 262–268. [Google Scholar] [CrossRef]

- Do Nascimento, A.; Ocelík, V.; Ierardi, M.; De Hosson, J.T.M. Wear resistance of WCp/duplex stainless steel metal matrix composite layers prepared by laser melt injection. Surf. Coat. Technol. 2008, 202, 4758–4765. [Google Scholar] [CrossRef]

- Gassmann, R. Laser cladding with (WC + W2C)/Co–Cr–C and (WC + W2C)/Ni–B–Si composites for enhanced abrasive wear resistance. Mater. Sci. Technol. 1996, 12, 691–696. [Google Scholar] [CrossRef]

- Zhang, G.-S.; Xing, J.-D.; Gao, Y.-M. Impact wear resistance of WC/Hadfield steel composite and its interfacial characteristics. Wear 2006, 260, 728–734. [Google Scholar] [CrossRef]

- Bateni, M.R.; Szpunar, J.; Wang, X.; Li, D. Wear and corrosion wear of medium carbon steel and 304 stainless steel. Wear 2006, 260, 116–122. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Odoni, B.U. Mechanical properties, wear and corrosion behavior of copper matrix composites reinforced with steel machining chips. Eng. Sci. Tech. 2016, 19, 1593–1599. [Google Scholar] [CrossRef]

- Wang, W.; Wang, D.; Yamaguchi, T.; Nishio, K.; Yan, M.; Li, Y. Comparative study of wear performance of ceramic/iron composite coatings under two different wear modes. Surf. Coat. Technol. 2017, 309, 136–148. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, Y.; Zhou, R.; Gao, F.; Shan, Q.; Tan, J. Thermal fatigue mechanism of WC particles reinforced steel substrate surface composite at different thermal shock temperatures. J. Alloys Compd. 2014, 596, 48–54. [Google Scholar] [CrossRef]

- Li, Z.; Wei, H.; Shan, Q.; Jiang, Y.; Zhou, R.; Feng, J. Formation mechanism and stability of the phase in the interface of tungsten carbide particles reinforced iron matrix composites: First principles calculations and experiments. J. Mater. Res. 2016, 31, 2376–2383. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Saha, P. Crack and wear behavior of SiC particulate reinforced aluminium based metal matrix composite fabricated by direct metal laser sintering process. Mater. Des. 2011, 32, 139–145. [Google Scholar] [CrossRef]

- Lin, C.-M. Functional composite metal for WC-dispersed 304L stainless steel matrix composite with alloying by direct laser: Microstructure, hardness and fracture toughness. Vacuum 2015, 121, 96–104. [Google Scholar] [CrossRef]

- Fernández, M.; García, A.; Cuetos, J.; González, R.; Noriega, A.; Cadenas, M. Effect of actual WC content on the reciprocating wear of a laser cladding NiCrBSi alloy reinforced with WC. Wear 2015, 324, 80–89. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Tao, W. Crack initiation and propagation behavior of WC particles reinforced Fe-based metal matrix composite produced by laser melting deposition. Opt. Laser Technol. 2016, 82, 170–182. [Google Scholar] [CrossRef]

- You, X.; Zhang, C.; Liu, N.; Huang, M.; Ma, J. Laser surface melting of electro-metallurgic WC/steel composites. J. Mater. Sci. 2008, 43, 2929–2934. [Google Scholar] [CrossRef]

- Pu, J.; He, D.; Wang, L. Effects of WC phase contents on the microstructure, mechanical properties and tribological behaviors of WC/a-C superlattice coatings. Appl. Surf. Sci. 2015, 357, 2039–2047. [Google Scholar] [CrossRef]

- Shan, Q.; Li, Z.; Jiang, Y.; Zhou, R.; Sui, Y. Effect of Ni Addition on Microstructure of Matrix in Casting Tungsten Carbide Particle Reinforced Composite. J. Mater. Sci. Technol. 2013, 29, 720–724. [Google Scholar] [CrossRef]

- Mandel, K.; Radajewski, M.; Krüger, L. Strain-rate dependence of the compressive strength of WC–Co hard metals. Mater. Sci. Eng. A 2014, 612, 115–122. [Google Scholar] [CrossRef]

- Mandel, K.; Krüger, L.; Krause, R.; Radajewski, M. The influence of stress state on the compressive strength of WC–Co with different Co contents. Int. J. Refract. Met. Hard Mater. 2014, 47, 124–130. [Google Scholar] [CrossRef]

- Timakul, P.; Rattanaprasit, W.; Aungkavattana, P. Improving compressive strength of fly ash-based geopolymer composites by basalt fibers addition. Ceram. Int. 2016, 42, 6288–6295. [Google Scholar] [CrossRef]

- Wei, H.; Li, Z.; Shan, Q.; Jiang, Y.; Zhou, R. Effects of WC volume fraction on microstructures and compression performances of WCp/Fe composites. Acta Mater. Compos. Sin. 2016, 33, 2560–2568. [Google Scholar]

- Böhm, H.J.; Rasool, A. Effects of particle shape on the thermoelastoplastic behavior of particle reinforced composites. Int. J. Solids Struct. 2016, 87, 90–101. [Google Scholar] [CrossRef]

- Rasool, A.; Böhm, H.J. Effects of particle shape on the macroscopic and microscopic linear behaviors of particle reinforced composites. Int. J. Eng. Sci. 2012, 58, 21–34. [Google Scholar] [CrossRef]

- Trofimov, A.; Drach, B.; Sevostianov, I. Effective elastic properties of composites with particles of polyhedral shapes. Int. J. Solids Struct. 2017, 120, 157–170. [Google Scholar] [CrossRef]

- Wang, L.; Shen, J.; Zhang, Y.; Fu, H. Microstructure, fracture toughness and compressive property of as-cast and directionally solidified NiAl-based eutectic composite. Mater. Sci. Eng. A 2016, 664, 188–194. [Google Scholar] [CrossRef]

- Madge, S.; Louzguine-Luzgin, D.; Kawashima, A.; Greer, A.; Inoue, A. Compressive plasticity of a La-based glass-crystal composite at cryogenic temperatures. Mater. Des. 2016, 101, 146–151. [Google Scholar] [CrossRef]

- Wang, M.-L.; Yang, B. Fracture mechanism of tungsten fiber reinforced ZrTiCuNiBeNb metallic glass composites. T. Mater. Heat Treat. 2012, 33, 7–11. [Google Scholar]

| Particle Shape | WCp Volume Fraction/% | Particles Size/μm | Holding Temperature/°C | Holding Time/min. |

|---|---|---|---|---|

| Spherical particle | 40% | 300–550 | 1500 | 60 |

| Irregular particle | 40% | 300–550 | 1500 | 60 |

| Point | Fe | W | C |

|---|---|---|---|

| 1 | 85 | 5 | 10 |

| 2 | 87 | 4 | 9 |

| 3 | 43 | 40 | 17 |

| 4 | 43 | 39 | 18 |

| 5 | 43 | 39 | 18 |

| 6 | 43 | 40 | 17 |

| 7 | 2 | 63 | 35 |

| 8 | 3 | 62 | 35 |

| 9 | 43 | 40 | 17 |

| 10 | 43 | 40 | 17 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Wang, P.; Shan, Q.; Jiang, Y.; Wei, H.; Tan, J. The Particle Shape of WC Governing the Fracture Mechanism of Particle Reinforced Iron Matrix Composites. Materials 2018, 11, 984. https://doi.org/10.3390/ma11060984

Li Z, Wang P, Shan Q, Jiang Y, Wei H, Tan J. The Particle Shape of WC Governing the Fracture Mechanism of Particle Reinforced Iron Matrix Composites. Materials. 2018; 11(6):984. https://doi.org/10.3390/ma11060984

Chicago/Turabian StyleLi, Zulai, Pengfei Wang, Quan Shan, Yehua Jiang, He Wei, and Jun Tan. 2018. "The Particle Shape of WC Governing the Fracture Mechanism of Particle Reinforced Iron Matrix Composites" Materials 11, no. 6: 984. https://doi.org/10.3390/ma11060984

APA StyleLi, Z., Wang, P., Shan, Q., Jiang, Y., Wei, H., & Tan, J. (2018). The Particle Shape of WC Governing the Fracture Mechanism of Particle Reinforced Iron Matrix Composites. Materials, 11(6), 984. https://doi.org/10.3390/ma11060984