Fiber Laser Welding of Fuel Cladding and End Plug Made of La2O3 Dispersion-Strengthened Molybdenum Alloy

Abstract

:1. Introduction

2. Materials and Methods

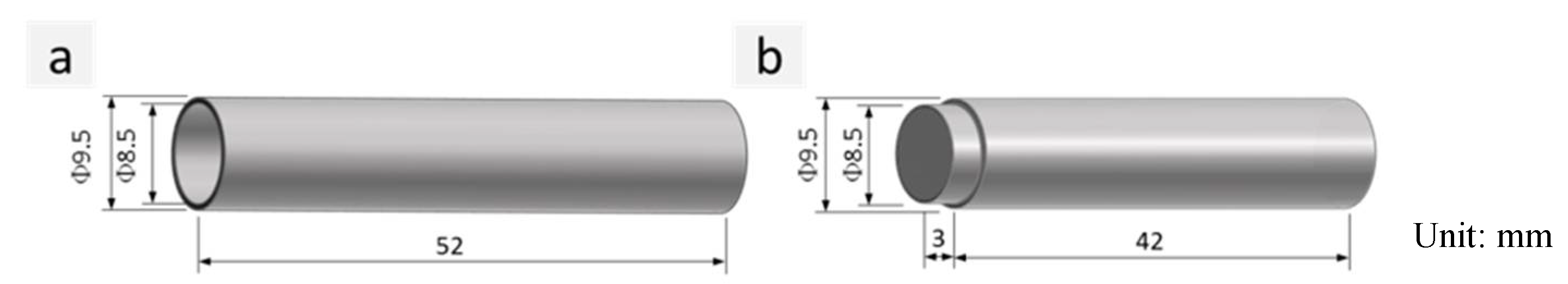

2.1. Experimental Materials

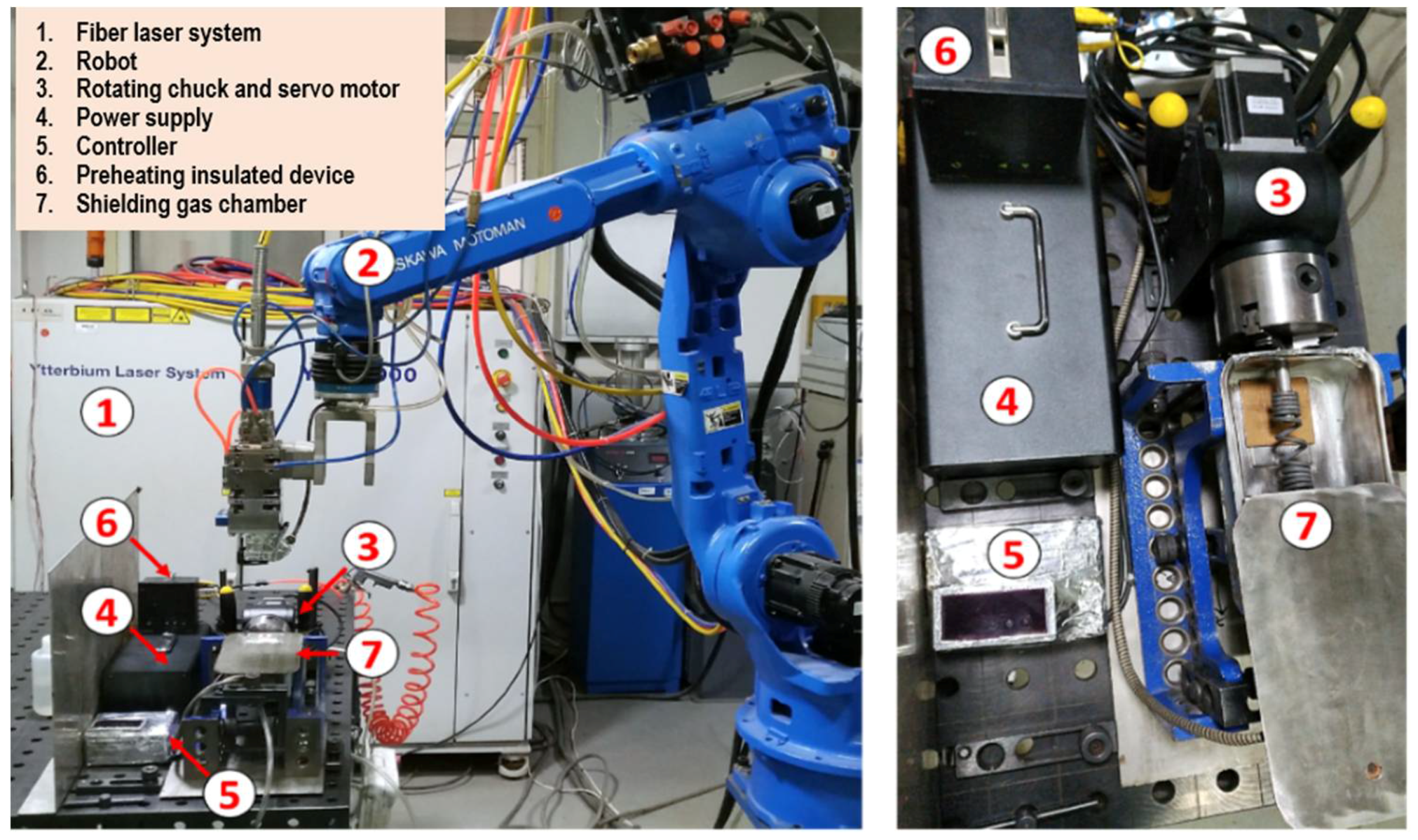

2.2. Experimental Equipment and Method

3. Experimental Results and Discussion

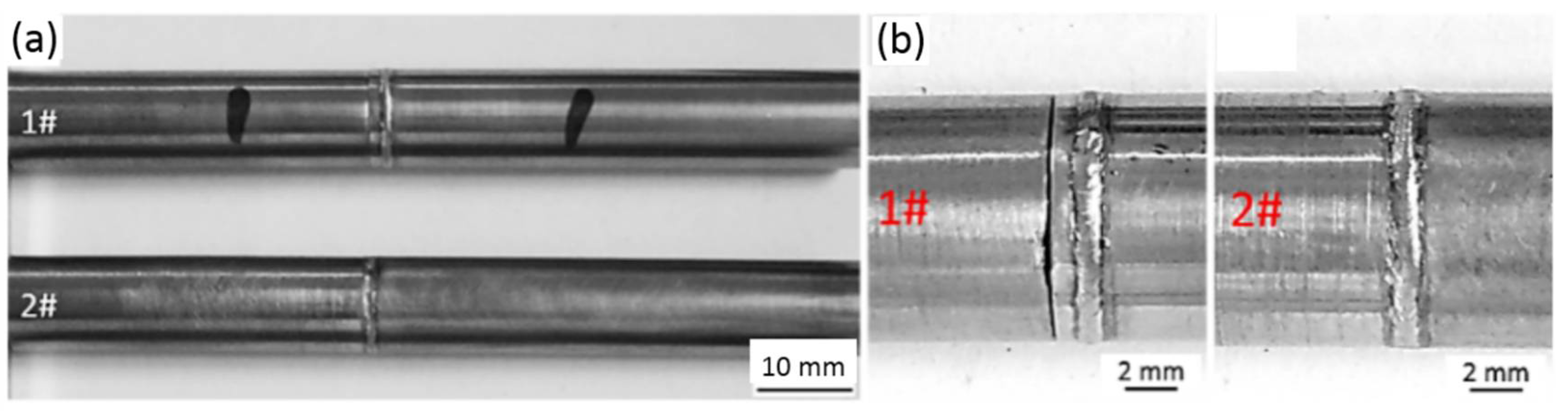

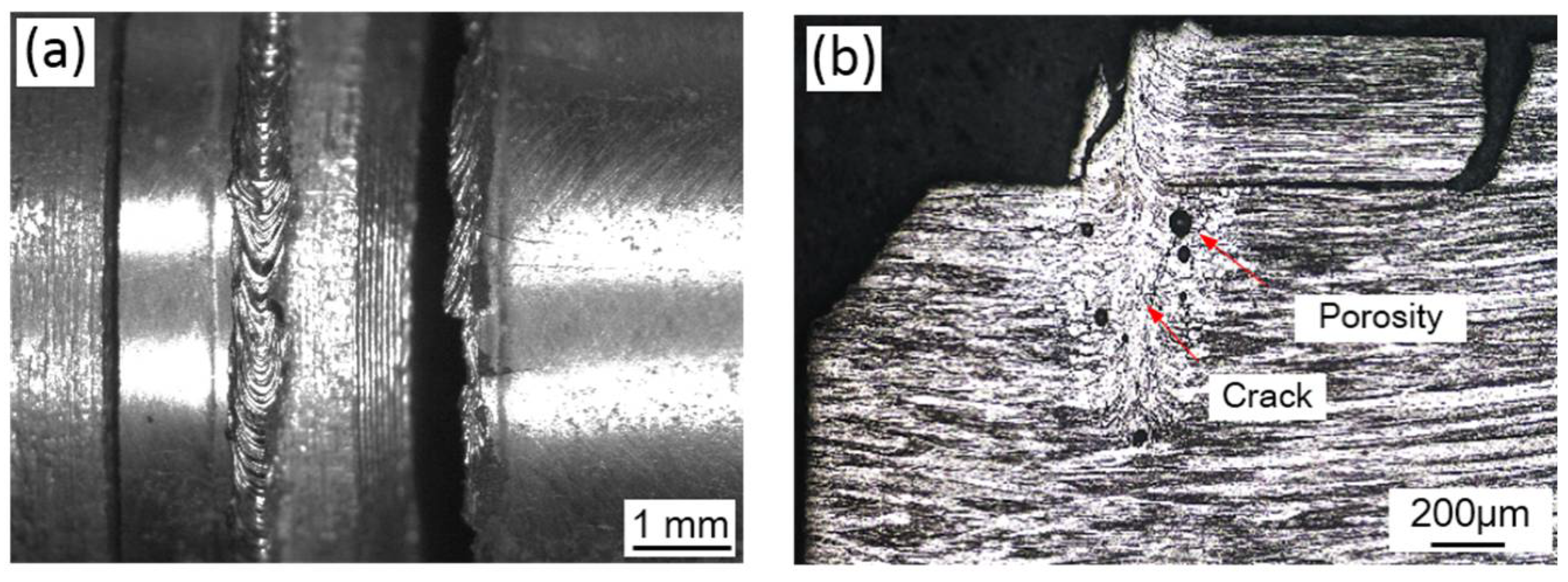

3.1. Effects of Weld Position and Preheating

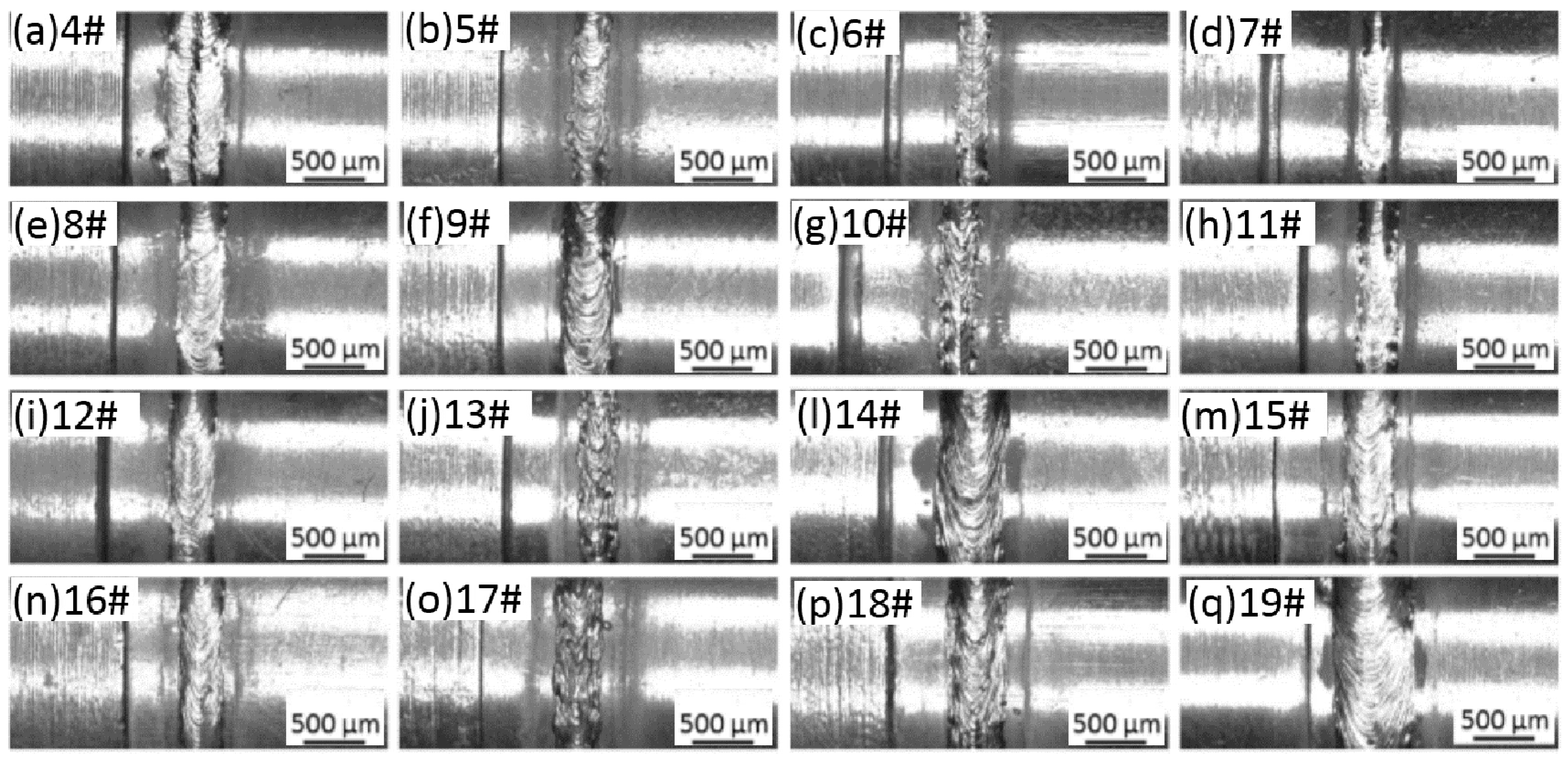

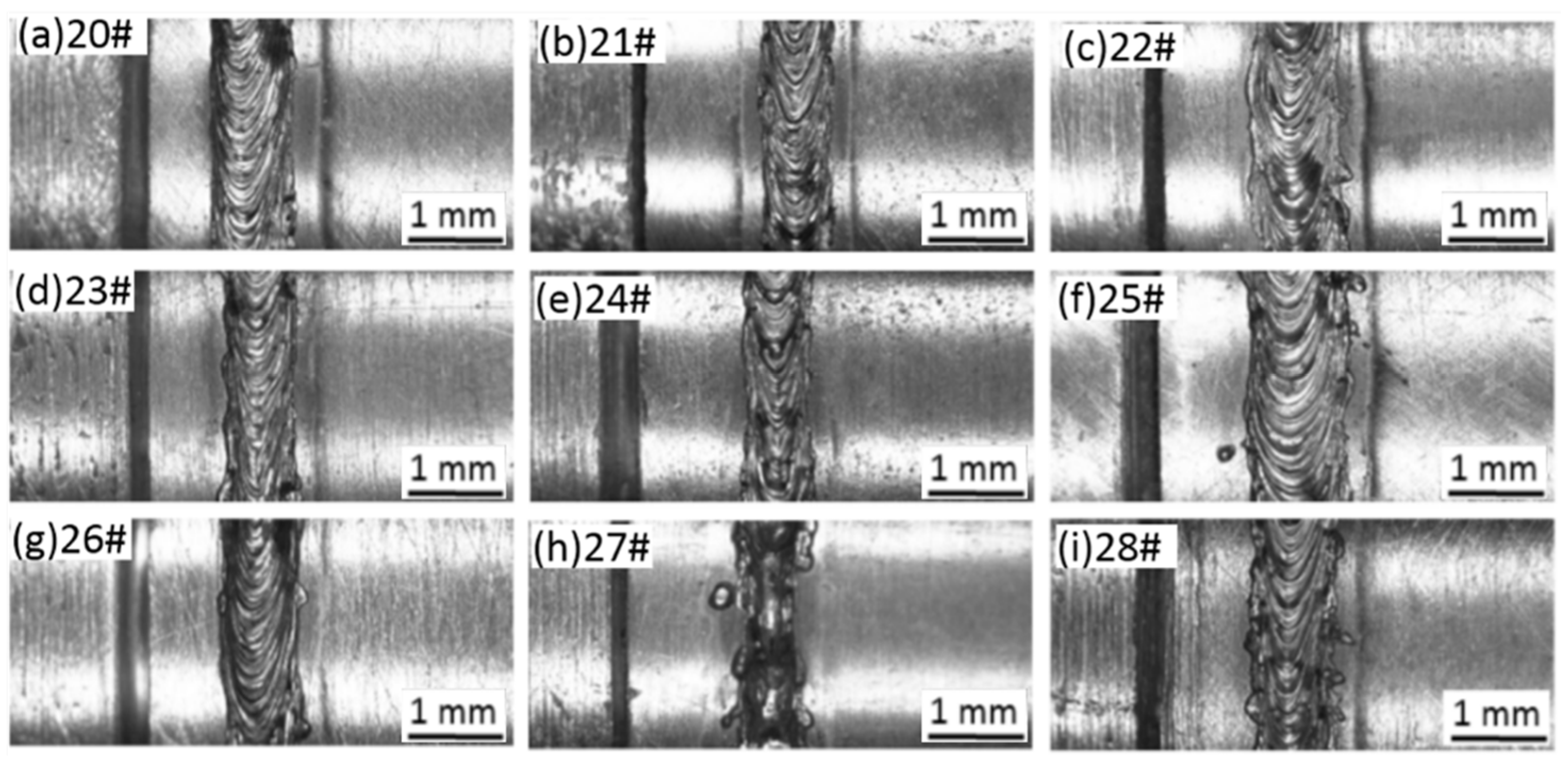

3.2. Optimization of Welding Parameters

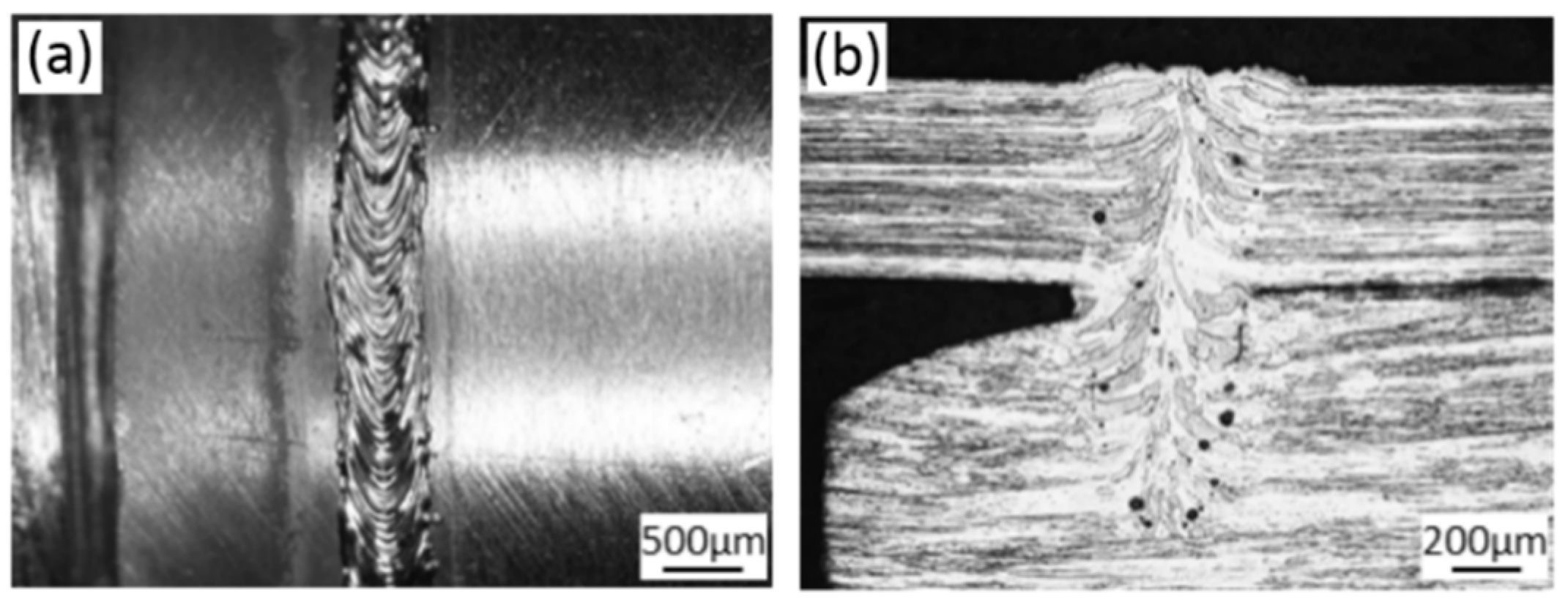

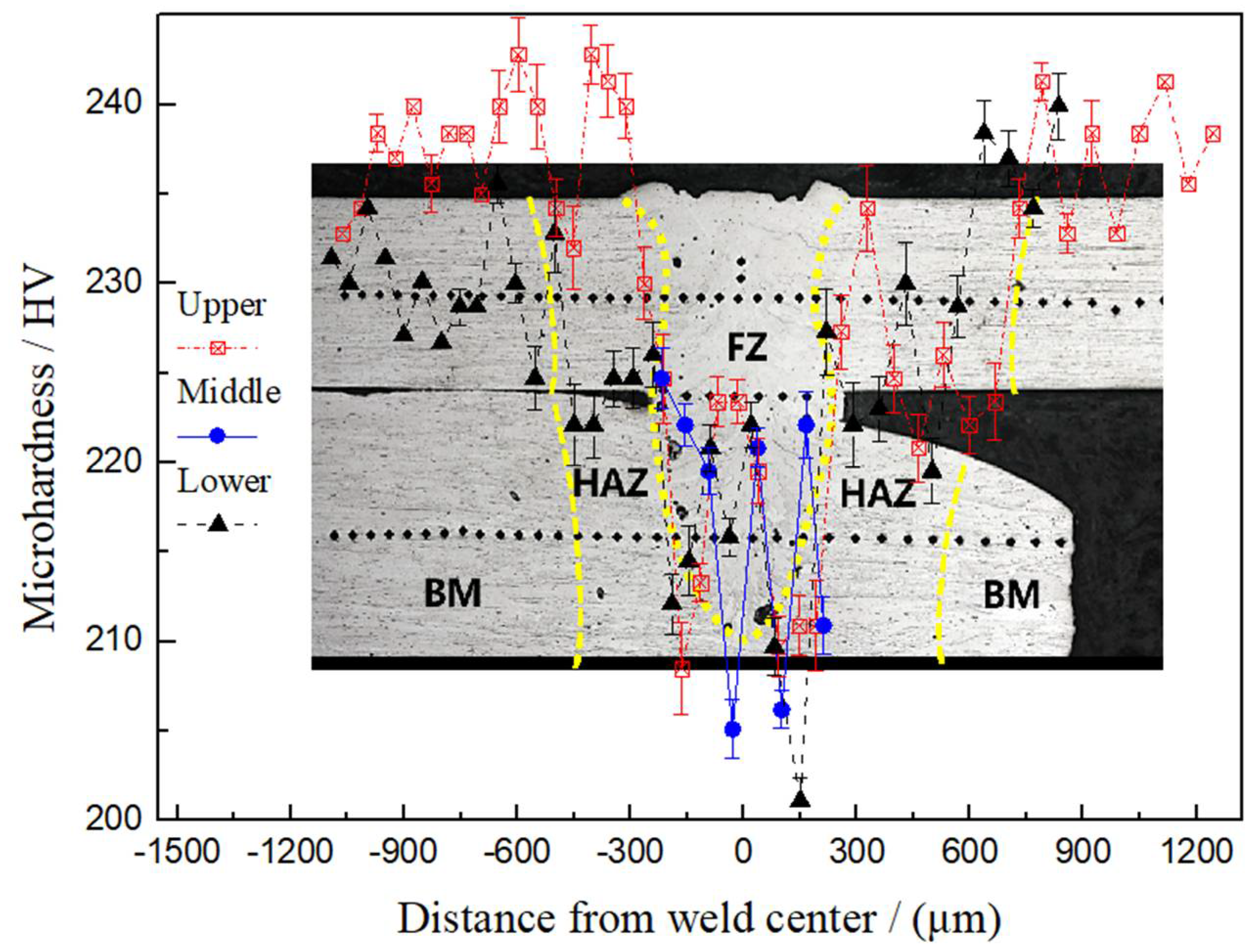

3.3. Microstructure and Mechanical Properties

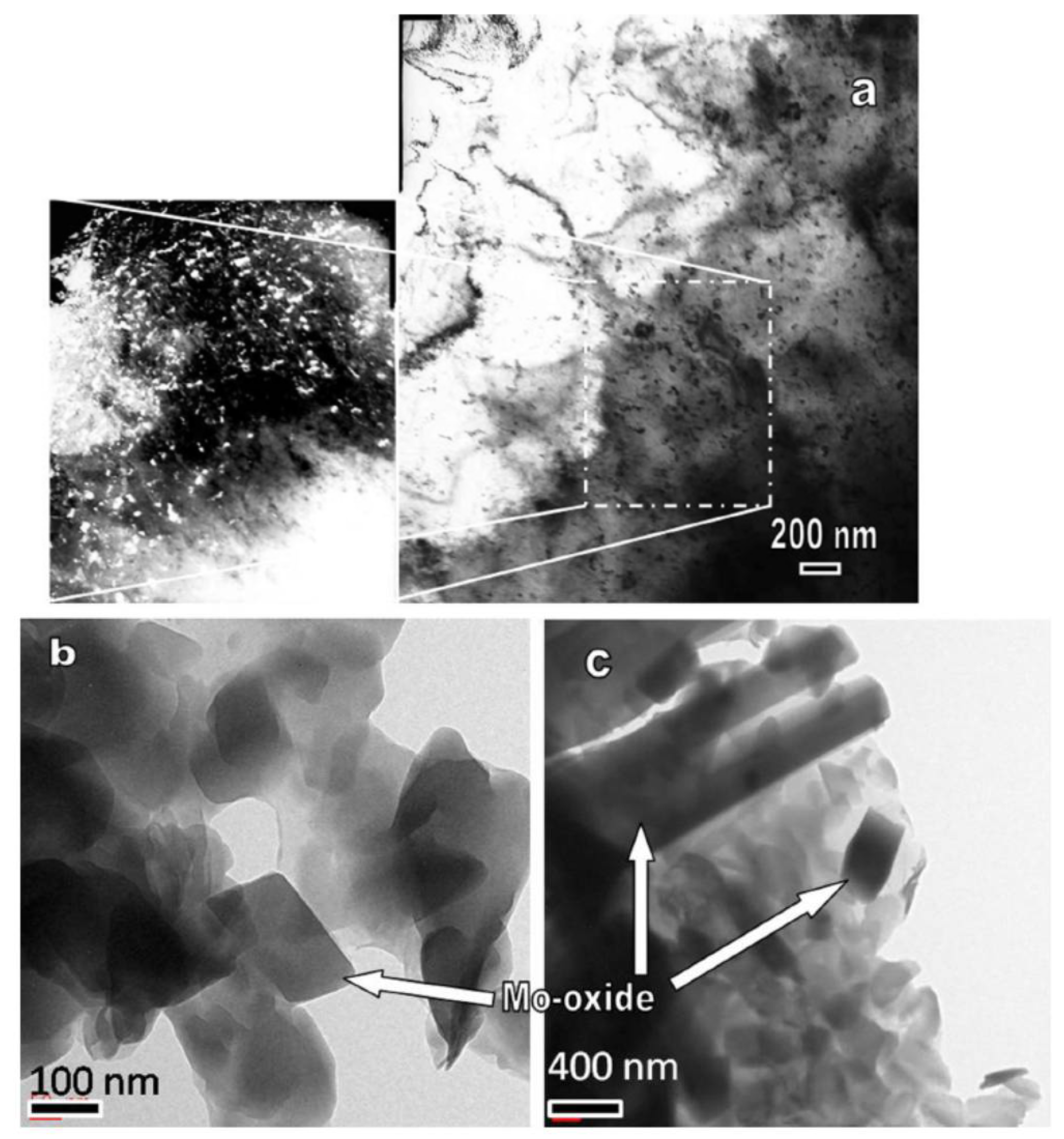

3.4. Grain Boundary Segregation

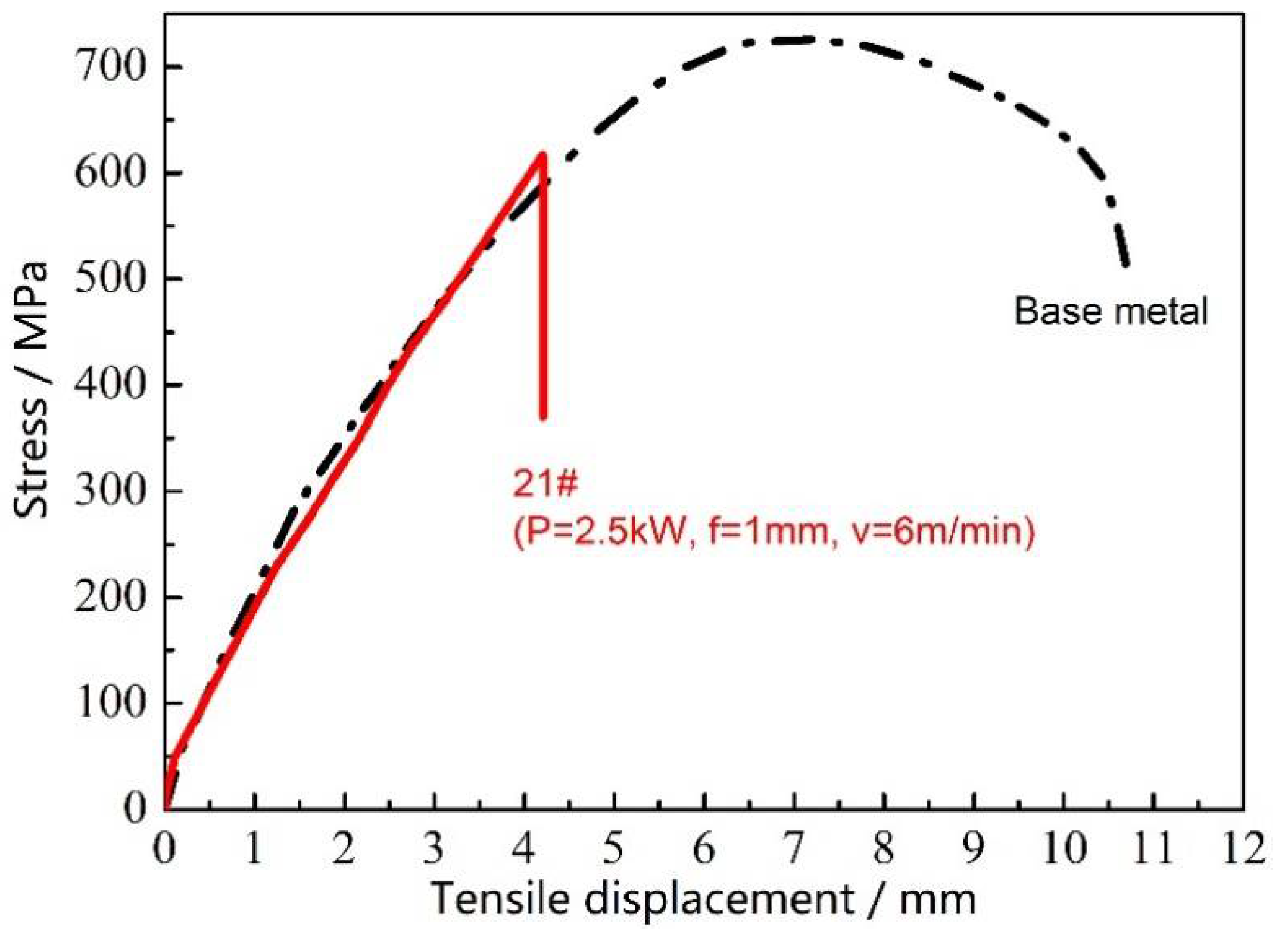

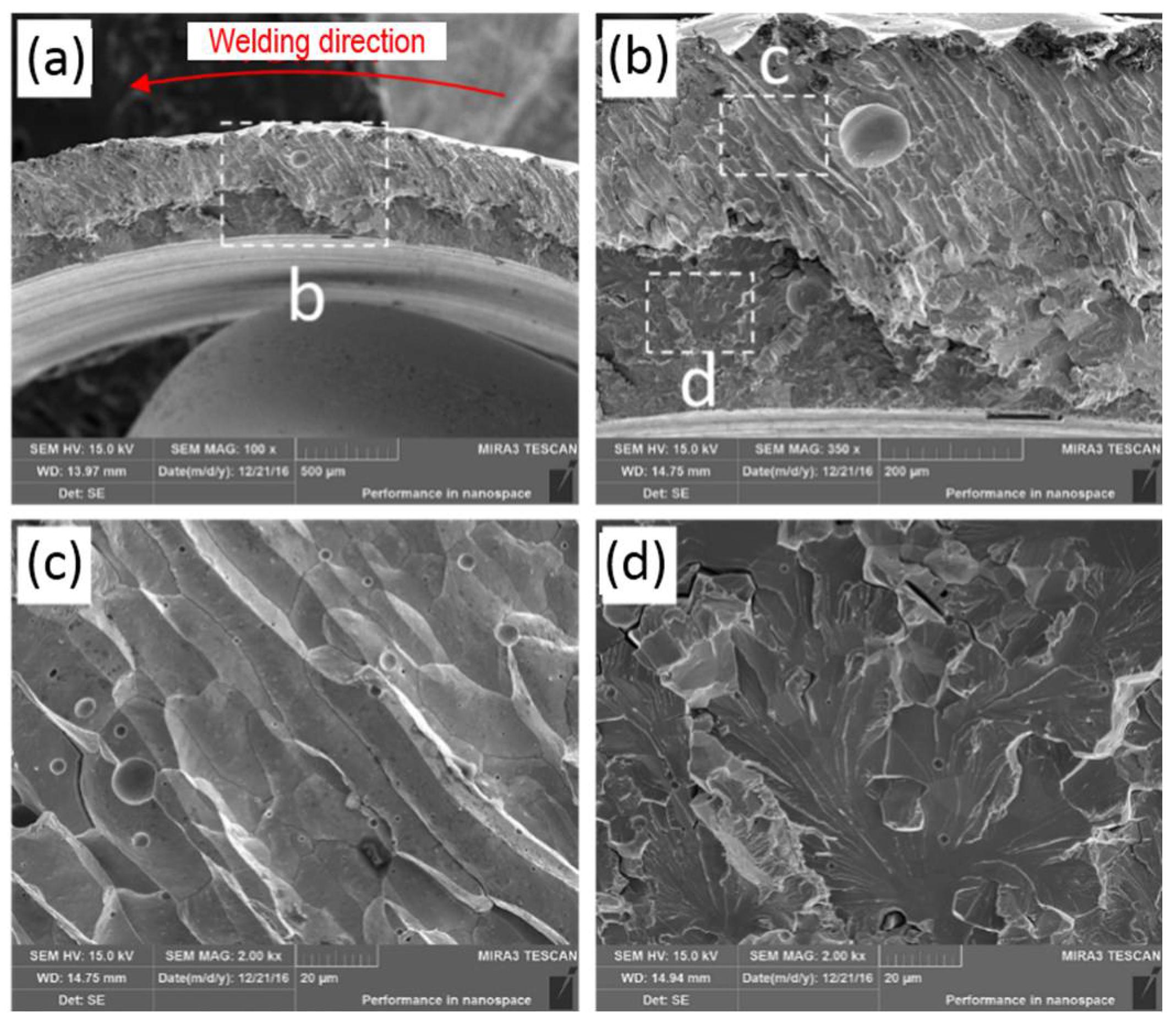

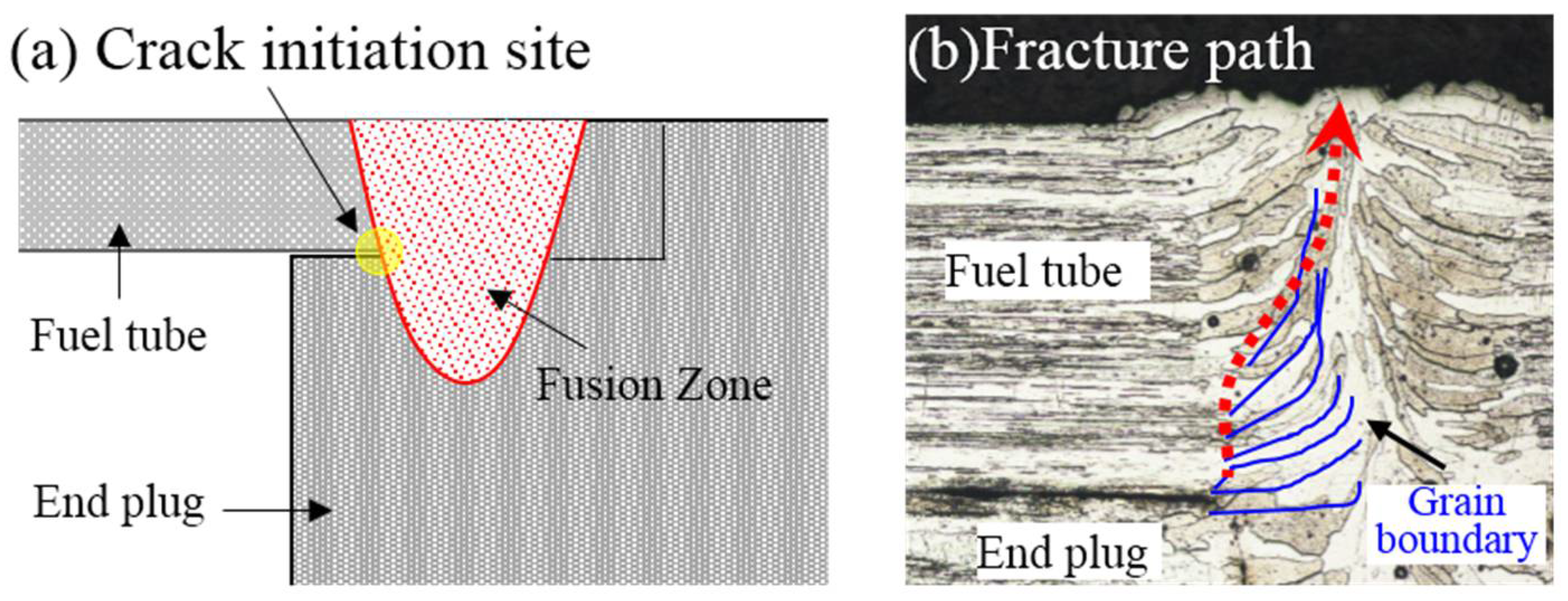

3.5. Fracture Observation

4. Conclusions

- (1)

- Changing the seam position from the joint of fuel cladding and end plug to the Mo tube can significantly improve the tensile strength of the joint. Preheating before welding can also greatly enhance the tensile strength of the lap joint.

- (2)

- The longitudinal cross sections of the base metals of the fuel cladding and the end plug made of Mo alloy were typical rolling structure while the HAZ appeared as the recrystallized structure. The weld zone was full of coarse columnar structures. Moreover, the weld and HAZ significantly softened after the welding.

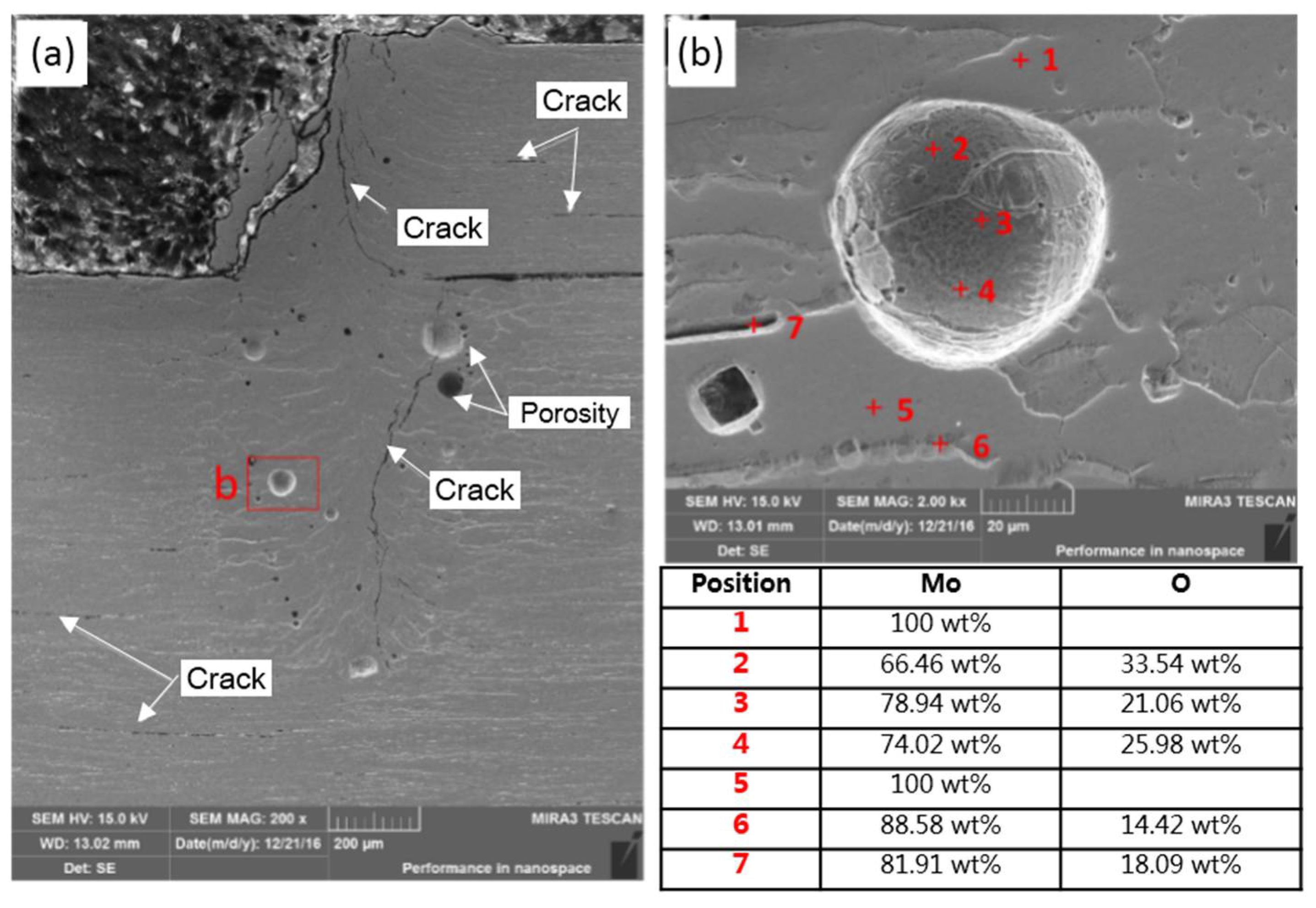

- (3)

- The inner of the columnar crystals in the weld zone was filled with 100 wt % Mo while 14–18 wt % of O content was found at the grain boundary in the weld zone. The O content on the internal walls of pores reached up to 33 wt %.

- (4)

- The tensile strength and elongation rate of fuel cladding made of Mo alloy were 750 MPa and 36.7% while the tensile strength of the welded joint was 617 MPa, which was about 82.3% of the base metal. The welded joint was basically not subjected to the plastic deformation during the whole tensile process but showed brittle fracture.

- (5)

- There were numerous slender columnar crystals on the cross section of the joint entering the weld zone of fuel cladding from that of end plug where the crystals were nucleated and grew upwards. The presence of these slender columnar crystals crossing the interface of fuel cladding and end plug was favorable for enhancing the capacity of the joint for bearing the shear loads.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Braun, J.; Guéneau, C.; Alpettaz, T.; Sauder, C.; Brackx, E.; Domenger, R.; Gossé, S.; Balbaud-Célérier, F. Chemical compatibility between UO2 fuel and SiC cladding for LWRs. Application to ATF (accident-tolerant fuels). J. Nucl. Mater. 2017, 487, 380–395. [Google Scholar] [CrossRef]

- Zhou, X.; Huang, Y.; Hao, K.; Chen, Y. Cracking in dissimilar laser welding of tantalum to molybdenum. Opt. Laser Technol. 2018, 102, 54–59. [Google Scholar] [CrossRef]

- Dong, L.; Chen, W.; Hou, L.; Wang, J.; Song, J. Metallurgical and mechanical examinations of molybdenum/graphite joints by vacuum arc pressure brazing using Ti-Zr filler materials. J. Mater. Process. Technol. 2017, 249, 39–45. [Google Scholar] [CrossRef]

- Stütz, M.; Oliveira, D.; Rüttinger, M.; Reheis, N.; Kestler, H.; Enzinger, N.; Stütz, M.; Oliveira, D.; Rüttinger, M.; Reheis, N. Electron beam welding of TZM sheets. Mater. Sci. Forum 2017, 879, 1865–1869. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, T.; Zhang, B.; Wang, Y.; Feng, J. Microstructure evolution and embrittlement of electron beam welded TZM alloy joint. Mater. Sci. Eng. A 2017, 700, 512–518. [Google Scholar] [CrossRef]

- Chatterjee, A.; Kumar, S.; Tewari, R.; Dey, G.K. Welding of mo-based alloy using electron beam and laser-gtaw hybrid welding techniques. Metall. Mater. Trans. A 2015, 47, 1–10. [Google Scholar] [CrossRef]

- Jiang, Q.; Li, Y.; Puchkov, U.A.; Wang, J.; Xia, C. Microstructure characteristics in TIG welded joint of Mo–Cu composite and 18-8 stainless steel. Int. J. Refract. Met. Hard Mater. 2010, 28, 429–433. [Google Scholar]

- Kolarikova, M.; Kolarik, L.; Vondrous, P. Welding of thin molybdenum sheets by EBW and GTAW. Ann. DAAAM Proc. 2012, 23, 1005. [Google Scholar]

- Xu, J.; Jiang, X.; Zeng, Q.; Zhai, T.; Leonhardt, T.; Farrell, J.; Umstead, W.; Effgen, M.P. Optimization of resistance spot welding on the assembly of refractory alloy 50Mo–50Re thin sheet. J. Nucl. Mater. 2007, 366, 417–425. [Google Scholar] [CrossRef]

- Xia, C.; Wu, L.; Xu, X.; Zou, J. Phase constitution and fracture analysis of vacuum brazed joint of 50Mo-50Re refractory alloys. Vacuum 2017, 136, 97–100. [Google Scholar] [CrossRef]

- Song, X.G.; Tian, X.; Zhao, H.Y.; Si, X.Q.; Han, G.H.; Feng, J.C. Interfacial microstructure and joining properties of titanium–zirconium–molybdenum alloy joints brazed using Ti–28Ni eutectic brazing alloy. Mater. Sci. Eng. A 2016, 653, 115–121. [Google Scholar] [CrossRef]

- Fujii, H.; Sun, Y.; Kato, H.; Nakata, K. Investigation of welding parameter dependent microstructure and mechanical properties in friction stir welded pure Ti joints. Mater. Sci. Eng. A 2010, 527, 3386–3391. [Google Scholar] [CrossRef]

- Ambroziak, A. Friction welding of molybdenum to molybdenum and to other metals. Int. J. Refract. Met. Hard Mater. 2011, 29, 462–469. [Google Scholar] [CrossRef]

- Morito, F. Tensile properties and microstructures of electron beam welded molybdenum and TZM. J. Less Common Met. 1989, 146, 337–346. [Google Scholar] [CrossRef]

- Morito, F. Characteristics of EB-weldable molybdenum and Mo-Re alloys. JOM 1993, 45, 54–58. [Google Scholar] [CrossRef]

- Morito, F. Weldability and fracture of molybdenum-rhenium welds. Met. Powder Rep. 1998, 53, 46. [Google Scholar] [CrossRef]

- Krajnikov, A.V.; Morito, F.; Slyunyaev, V.N. Impurity-induced embrittlement of heat-affected zone in welded Mo-based alloys. Int. J. Refract. Met. Hard Mater. 1997, 15, 325–339. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, M.; Li, S.; Zhou, Y. Direct observation of keyhole characteristics in deep penetration laser welding with a 10 kw fiber laser. Opt. Express 2013, 21, 19997–20004. [Google Scholar]

- Zhang, L.J.; Bai, Q.L.; Ning, J.; Wang, A.; Yang, J.N.; Yin, X.Q.; Zhang, J.X. A comparative study on the microstructure and properties of copper joint between MIG welding and laser-MIG hybrid welding. Mater. Des. 2016, 110, 35–50. [Google Scholar] [CrossRef]

- Zhou, L.; Li, Z.Y.; Song, X.G.; Tan, C.W.; He, Z.Z.; Huang, Y.X.; Feng, J.C. Influence of laser offset on laser welding-brazing of Al/brass dissimilar alloys. J. Alloys Compd. 2017, 717, 78–92. [Google Scholar] [CrossRef]

- Wei, H.L.; Elmer, J.W.; Debroy, T. Three-dimensional modeling of grain structure evolution during welding of an aluminum alloy. Acta Mater. 2017, 126, 413–425. [Google Scholar] [CrossRef]

- Pang, S.; Chen, X.; Shao, X.; Gong, S.; Xiao, J. Dynamics of vapor plume in transient keyhole during laser welding of stainless steel: Local evaporation, plume swing and gas entrapment into porosity. Opt. Lasers Eng. 2016, 82, 28–40. [Google Scholar] [CrossRef]

- Pang, S.; Chen, X.; Li, W.; Shao, X.; Gong, S. Efficient multiple time scale method for modeling compressible vapor plume dynamics inside transient keyhole during fiber laser welding. Opt. Laser Technol. 2016, 77, 203–214. [Google Scholar] [CrossRef]

- Guo, W.; Crowther, D.; Francis, J.A.; Thompson, A.; Liu, Z.; Li, L. Microstructure and mechanical properties of laser welded S960 high strength steel. Mater. Des. 2015, 85, 534–548. [Google Scholar] [CrossRef]

- Gao, X.L.; Zhang, L.J.; Liu, J.; Zhang, J.X. Effects of weld cross-section profiles and microstructure on properties of pulsed Nd:YAG laser welding of Ti6Al4V sheet. Int. J. Adv. Manuf. Technol. 2014, 72, 895–903. [Google Scholar] [CrossRef]

- Gao, X.L.; Zhang, L.J.; Liu, J.; Zhang, J.X. A comparative study of pulsed Nd:YAG laser welding and TIG welding of thin Ti6Al4V titanium alloy plate. Mater. Sci. Eng. A 2013, 559, 14–21. [Google Scholar] [CrossRef]

- Liu, P.; Feng, K.Y.; Zhang, G.M. A novel study on laser lap welding of refractory alloy 50Mo-50Re of small-scale thin sheet. Vacuum 2017, 136, 10–13. [Google Scholar] [CrossRef]

- Lin, Y.; Jiang, G. Pulsed Nd:YAG laser fine spot welding for attachment of refractory mini-pins. Proc. SPIE 2013, 8608, 885–905. [Google Scholar]

- Kramer, D.P.; Mcdougal, J.R.; Booher, B.A.; Ruhkamp, J.D. Electron beam and Nd-YAG laser welding of niobium-1% zirconium and molybdenum-44.5% rhenium thin select material. In Proceedings of the 35th Intersociety Energy Conversion Engineering Conference and Exhibit, Las Vegas, NV, USA, 24–28 July 2000; Volume 952, pp. 956–961. [Google Scholar]

- Liu, G.; Zhang, G.J.; Jiang, F.; Ding, X.D.; Sun, Y.J.; Sun, J.; Ma, E. Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility. Nat. Mater. 2013, 12, 344–350. [Google Scholar] [CrossRef] [PubMed]

- Wahba, M.; Mizutani, M.; Kawahito, Y.; Katayama, S. Laser welding of die-cast AZ91D magnesium alloy. Mater. Des. 2011, 33, 569–576. [Google Scholar] [CrossRef]

| Number | Weld Position | Laser Power (W) | Defocusing Amount (mm) | Welding Speed (m/min) | Preheating Temperature (°C) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| 1 | Tube | 2000 | 2 | 2 | 450 | 280.1 |

| 2 | Shoulder of end plug | 2000 | 2 | 2 | 450 | 126.8 |

| 3 | Tube | 2000 | 2 | 2 | - | 66.3 |

| Number | Laser Power P (W) | Defocusing Amount f (mm) | Welding Speed v (m/min) | Cracks | Weld Position | Preheating Temperature (°C) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|---|

| 4 | 1500 | −2 | 2 | Yes | Tube | 450 | 0 |

| 5 | 1500 | 0 | 3 | No | Tube | 450 | 252.12 |

| 6 | 1500 | 2 | 4 | Yes | Tube | 450 | 99.19 |

| 7 | 1500 | 4 | 5 | No | Tube | 450 | 52.79 |

| 8 | 2000 | −2 | 3 | No | Tube | 450 | 229.87 |

| 9 | 2000 | 0 | 2 | No | Tube | 450 | 213.00 |

| 10 | 2000 | 2 | 5 | No | Tube | 450 | 219.00 |

| 11 | 2000 | 4 | 4 | Yes | Tube | 450 | 29.00 |

| 12 | 2500 | −2 | 4 | Yes | Tube | 450 | 98.00 |

| 13 | 2500 | 0 | 5 | No | Tube | 450 | 426.58 |

| 14 | 2500 | 2 | 2 | No | Tube | 450 | 436.00 |

| 15 | 2500 | 4 | 3 | Yes | Tube | 450 | 163.70 |

| 16 | 3000 | −2 | 5 | No | Tube | 450 | 517.81 |

| 17 | 3000 | 0 | 4 | No | Tube | 450 | 209.98 |

| 18 | 3000 | 2 | 3 | No | Tube | 450 | 141.14 |

| 19 | 3000 | 4 | 2 | No | Tube | 450 | 165.00 |

| Number | Laser Power P (W) | Defocusing Amount f (mm) | Welding Speed v (m/min) | Tensile Strength (MPa) |

|---|---|---|---|---|

| 20 | 2500 | 0 | 4 | 285.08 |

| 21 | 2500 | 1 | 6 | 617.18 |

| 22 | 2500 | 2 | 5 | 373.98 |

| 23 | 2800 | 0 | 6 | 505.17 |

| 24 | 2800 | 1 | 5 | 253.82 |

| 25 | 2800 | 2 | 4 | 365.26 |

| 26 | 3000 | 0 | 5 | 376.10 |

| 27 | 3000 | 1 | 4 | 369.62 |

| 28 | 3000 | 2 | 6 | 388.02 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, G.; Sun, J.; Sun, Y.; Cao, W.; Zhu, Q.; Bai, Q.; Zhang, L. Fiber Laser Welding of Fuel Cladding and End Plug Made of La2O3 Dispersion-Strengthened Molybdenum Alloy. Materials 2018, 11, 1071. https://doi.org/10.3390/ma11071071

An G, Sun J, Sun Y, Cao W, Zhu Q, Bai Q, Zhang L. Fiber Laser Welding of Fuel Cladding and End Plug Made of La2O3 Dispersion-Strengthened Molybdenum Alloy. Materials. 2018; 11(7):1071. https://doi.org/10.3390/ma11071071

Chicago/Turabian StyleAn, Geng, Jun Sun, Yuanjun Sun, Weicheng Cao, Qi Zhu, Qinglin Bai, and Linjie Zhang. 2018. "Fiber Laser Welding of Fuel Cladding and End Plug Made of La2O3 Dispersion-Strengthened Molybdenum Alloy" Materials 11, no. 7: 1071. https://doi.org/10.3390/ma11071071

APA StyleAn, G., Sun, J., Sun, Y., Cao, W., Zhu, Q., Bai, Q., & Zhang, L. (2018). Fiber Laser Welding of Fuel Cladding and End Plug Made of La2O3 Dispersion-Strengthened Molybdenum Alloy. Materials, 11(7), 1071. https://doi.org/10.3390/ma11071071