Fluorinated Graphene Prepared by Direct Fluorination of N, O-Doped Graphene Aerogel at Different Temperatures for Lithium Primary Batteries

Abstract

1. Introduction

2. Experimental

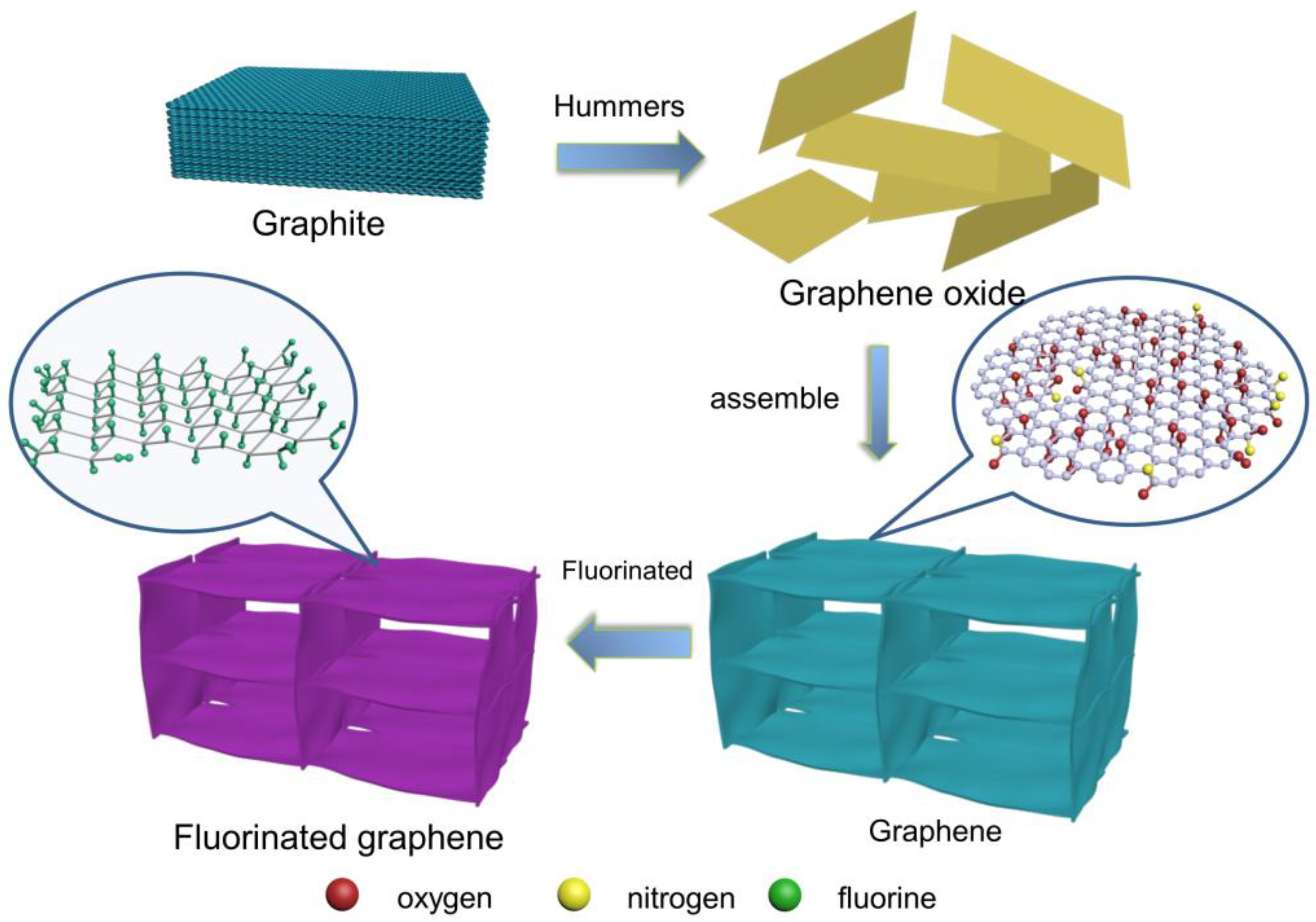

2.1. Preparation of Fluorinated Graphene

2.2. Materials Characterizations

2.3. Electrochemical Tests in Lithium Primary Battery

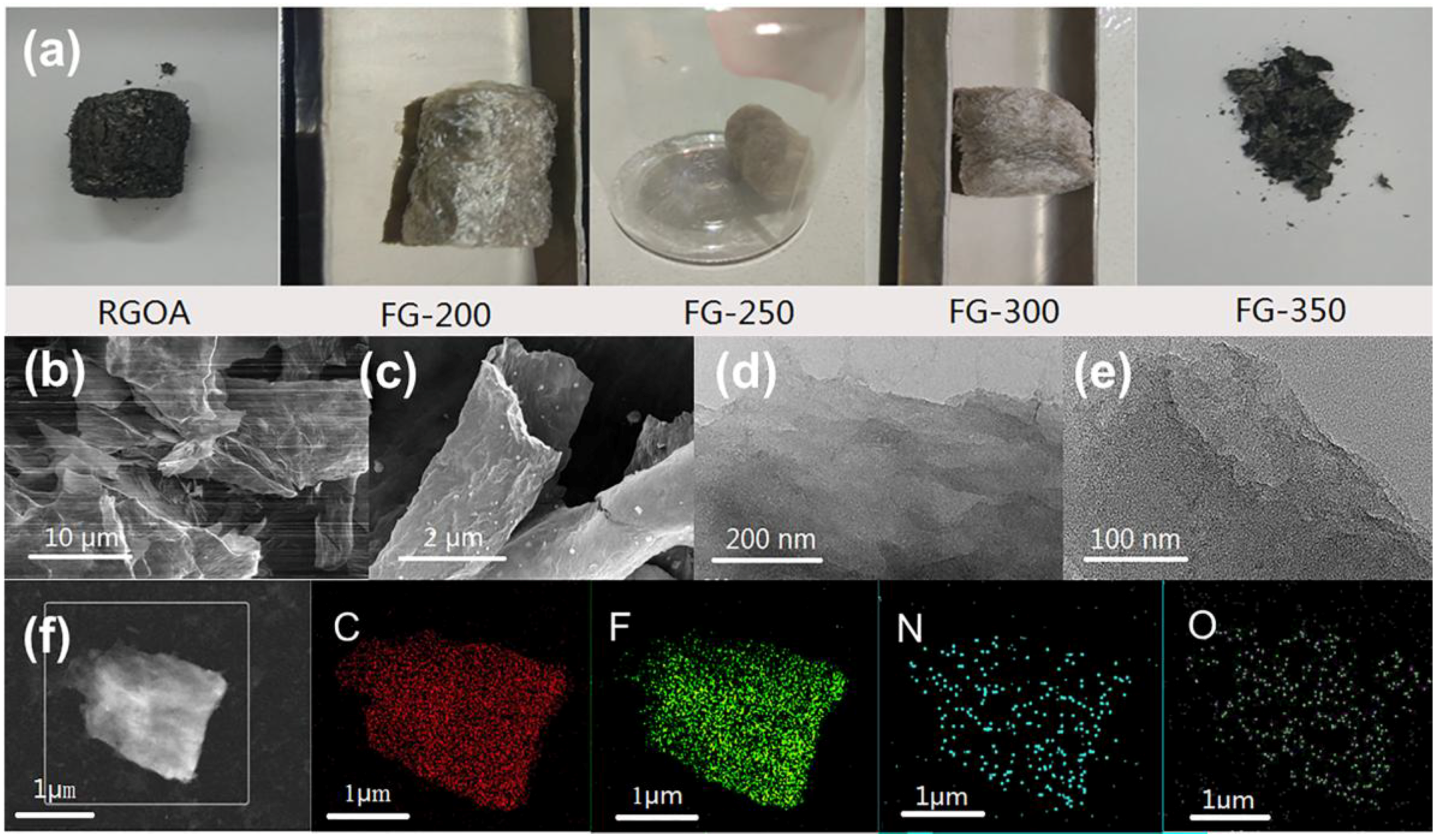

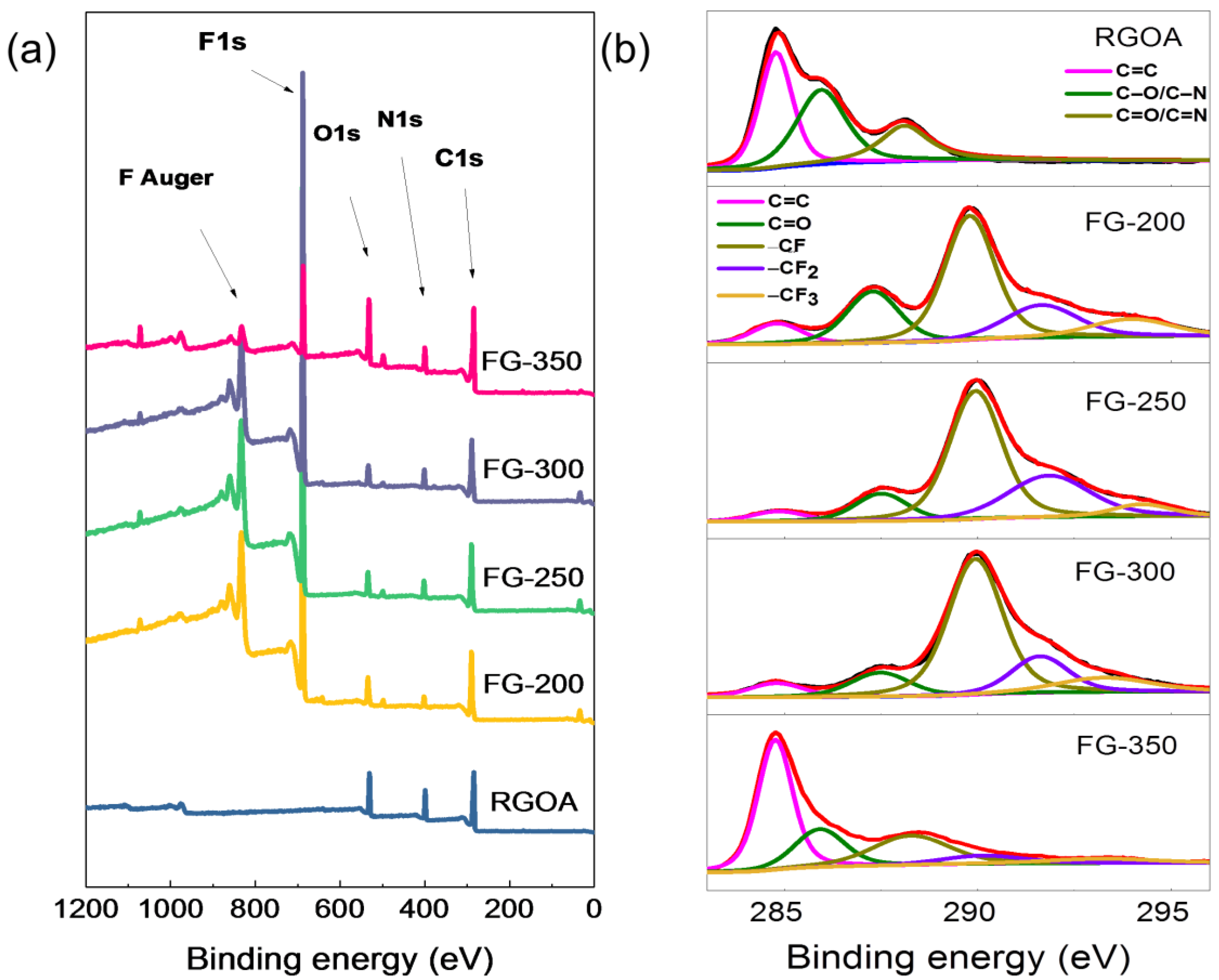

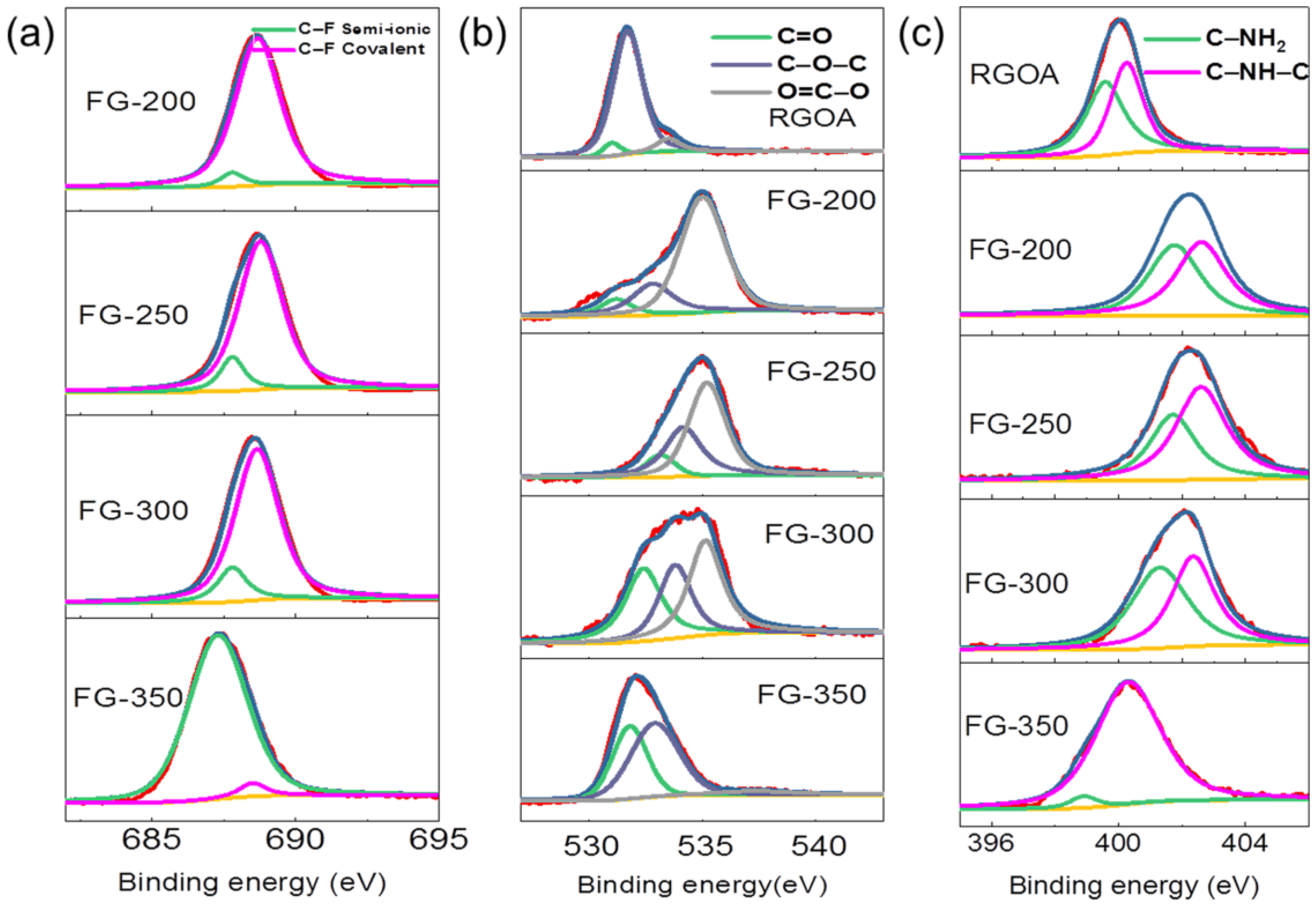

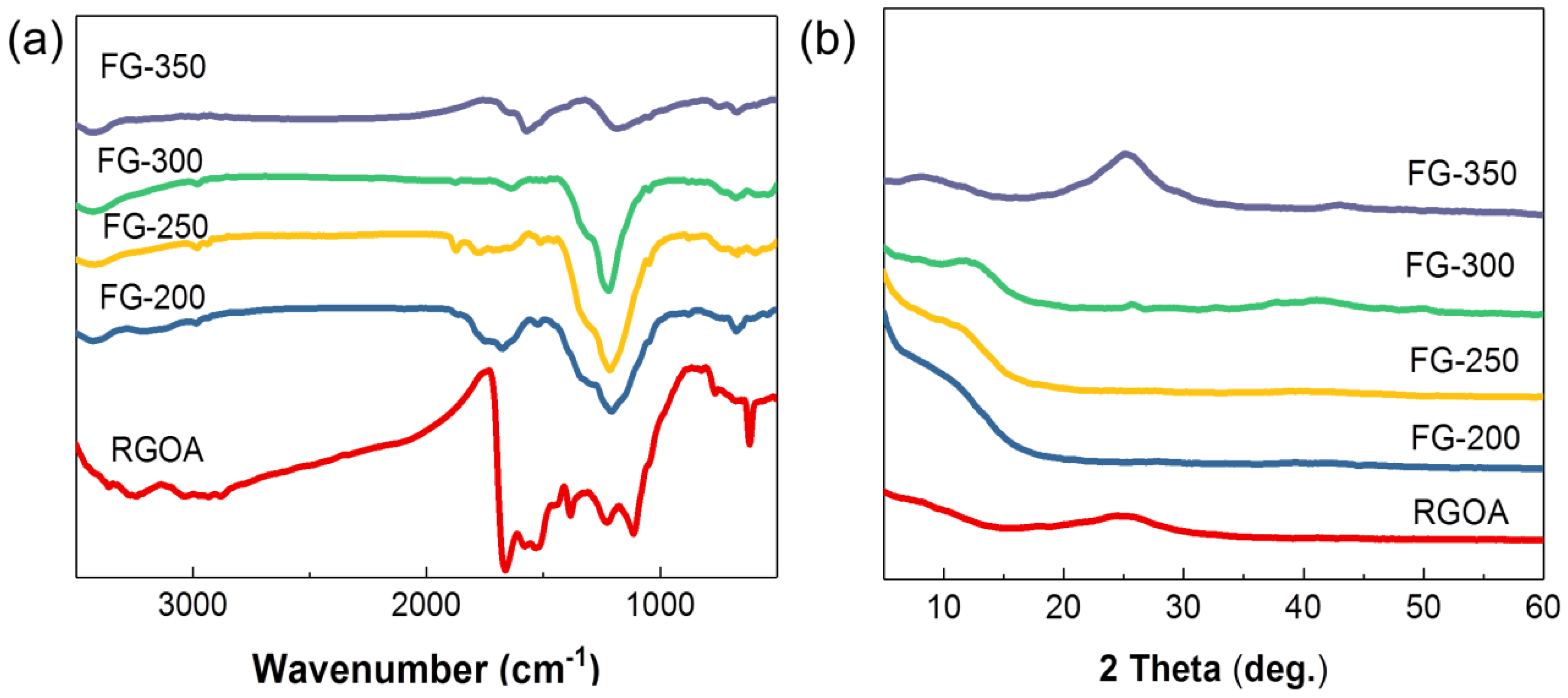

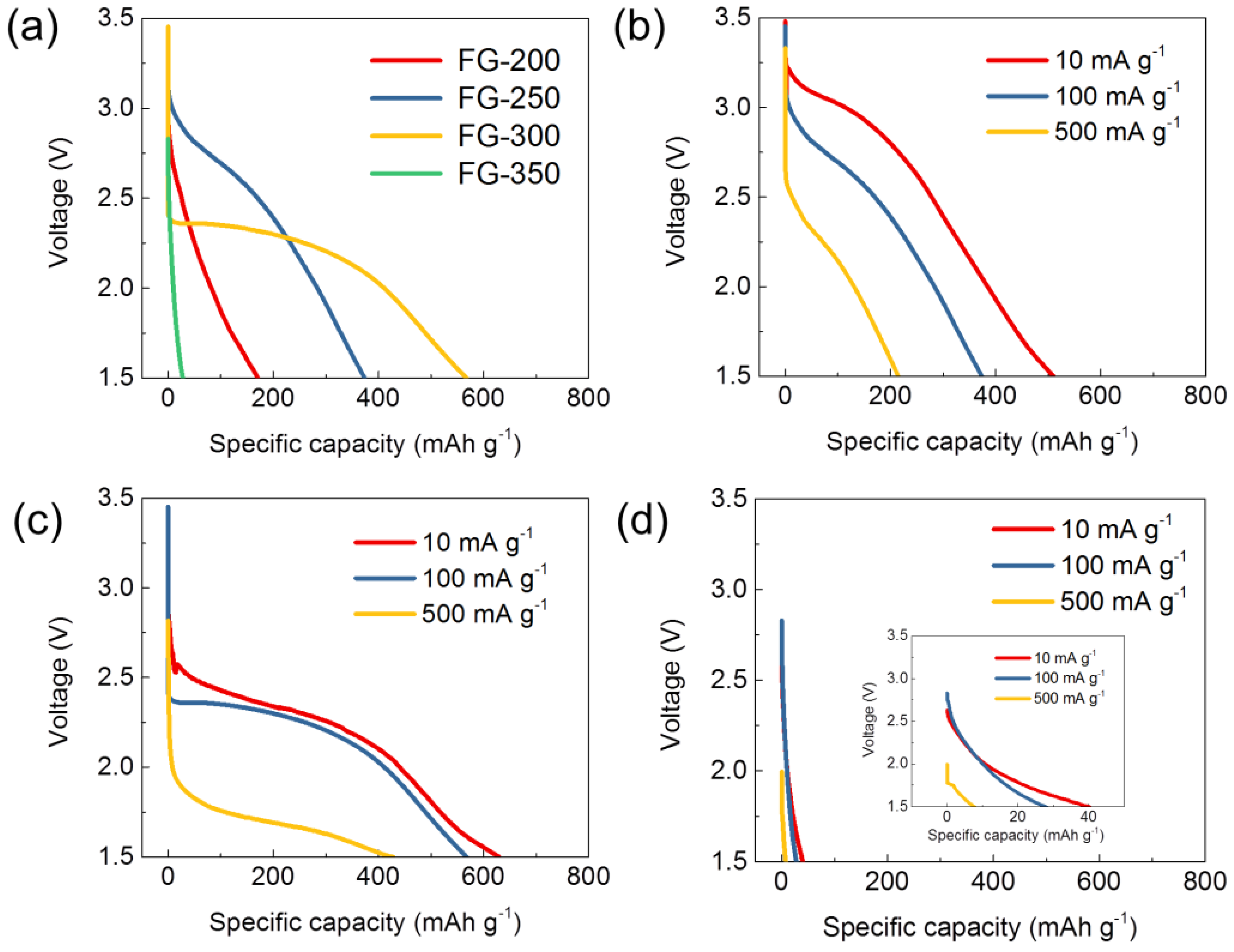

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Roche, S. Nanoelectronics: Graphene gets a better gap. Nat. Nanotechnol. 2011, 6, 8. [Google Scholar] [CrossRef] [PubMed]

- Huo, P.; Zhao, P.; Wang, Y.; Liu, B.; Yin, G.; Dong, M. A roadmap for achieving sustainable energy conversion and storage: Graphene-based composites used both as an electrocatalyst for oxygen reduction reactions and an electrode material for a supercapacitor. Energies 2018, 11, 167. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, J.; Zhou, J.; Zhao, Y.; Tang, X.; Zhuo, S. Interfacial engineering of metal oxide/graphene nanoscrolls with remarkable performance for lithium ion batteries. Energy Storage Mater. 2017, 8, 35–41. [Google Scholar] [CrossRef]

- Zhao, D.; Yu, L.; Liu, D. Ultralight graphene/carbon nanotubes aerogels with compressibility and oil absorption properties. Materials 2018, 11, 641. [Google Scholar] [CrossRef] [PubMed]

- Joshi, R.; Carbone, P.; Wang, F.-C.; Kravets, V.G.; Su, Y.; Grigorieva, I.V.; Wu, H.; Geim, A.K.; Nair, R.R. Precise and ultrafast molecular sieving through graphene oxide membranes. Science 2014, 343, 752–754. [Google Scholar] [CrossRef] [PubMed]

- Lou, C.; Wang, S.; Liang, T.; Pang, C.; Huang, L.; Run, M.; Liu, X. A graphene-based flexible pressure sensor with applications to plantar pressure measurement and gait analysis. Materials 2017, 10, 1068. [Google Scholar] [CrossRef] [PubMed]

- Ruff, O.; Bretschneider, O. Die reaktionsprodukte der verschiedenen kohlenstoffformen mit fluor ii (kohlenstoff-monofluorid). Z. Anorg. Allg. Chem. 1934, 217, 1–18. [Google Scholar] [CrossRef]

- Inagaki, M.; Kang, F. Graphene derivatives: Graphane, fluorographene, graphene oxide, graphyne and graphdiyne. J. Mater. Chem. A 2014, 2, 13193–13206. [Google Scholar] [CrossRef]

- Jeon, K.-J.; Lee, Z.; Pollak, E.; Moreschini, L.; Bostwick, A.; Park, C.-M.; Mendelsberg, R.; Radmilovic, V.; Kostecki, R.; Richardson, T.J.; et al. Fluorographene: A wide bandgap semiconductor with ultraviolet luminescence. ACS Nano 2011, 5, 1042–1046. [Google Scholar] [CrossRef] [PubMed]

- Feng, W.; Long, P.; Feng, Y.; Li, Y. Two-dimensional fluorinated graphene: Synthesis, structures, properties and applications. Adv. Sci. 2016, 3. [Google Scholar] [CrossRef] [PubMed]

- Robinson, J.T.; Burgess, J.S.; Junkermeier, C.E.; Badescu, S.C.; Reinecke, T.L.; Perkins, F.K.; Zalalutdniov, M.K.; Baldwin, J.W.; Culbertson, J.C.; Sheehan, P.E.; et al. Properties of fluorinated graphene films. Nano Lett. 2010, 10, 3001–3005. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Feng, Y.; Li, Y.; Qin, C.; Zhang, Q.; Feng, W. Solvothermally exfoliated fluorographene for high-performance lithium primary batteries. Nanoscale 2014, 6, 2634–2641. [Google Scholar] [CrossRef] [PubMed]

- Damien, D.; Sudeep, P.; Narayanan, T.; Anantharaman, M.; Ajayan, P.; Shaijumon, M. Fluorinated graphene based electrodes for high performance primary lithium batteries. RSC Adv. 2013, 3, 25702–25706. [Google Scholar] [CrossRef]

- Xu, Y.; Zhan, L.; Wang, Y.; Wang, Y.-L.; Shi, Y.-H. Fluorinated grapheneasa cathode material for high performance primary lithium ion batteries. New Carbon Mater. 2015, 30, 79–85. [Google Scholar] [CrossRef]

- Ahmad, Y.; Dubois, M.; Guérin, K.; Hamwi, A.; Zhang, W. Pushing the theoretical limit of Li–CFx batteries using fluorinated nanostructured carbon nanodiscs. Carbon 2015, 94, 1061–1070. [Google Scholar] [CrossRef]

- Lam, P.; Yazami, R. Physical characteristics and rate performance of (CFx) n (0.33 < x < 0.66) in lithium batteries. J. Power Sources 2006, 153, 354–359. [Google Scholar]

- Read, J.; Collins, E.; Piekarski, B.; Zhang, S. Lif formation and cathode swelling in the Li/CFx battery. J. Electrochem. Soc. 2011, 158, A504–A510. [Google Scholar] [CrossRef]

- Rangasamy, E.; Li, J.; Sahu, G.; Dudney, N.; Liang, C. Pushing the theoretical limit of Li-CFx batteries: A tale of bifunctional electrolyte. J. Am. Chem. Soc. 2014, 136, 6874–6877. [Google Scholar] [CrossRef] [PubMed]

- Gong, P.; Wang, Z.; Wang, J.; Wang, H.; Li, Z.; Fan, Z.; Xu, Y.; Han, X.; Yang, S. One-pot sonochemical preparation of fluorographene and selective tuning of its fluorine coverage. J. Mater. Chem. 2012, 22, 16950–16956. [Google Scholar] [CrossRef]

- Nair, R.R.; Ren, W.; Jalil, R.; Riaz, I.; Kravets, V.G.; Britnell, L.; Blake, P.; Schedin, F.; Mayorov, A.S.; Yuan, S. Fluorographene: A two-dimensional counterpart of teflon. Small 2010, 6, 2877–2884. [Google Scholar] [CrossRef] [PubMed]

- Mazanek, V.; Jankovsky, O.; Luxa, J.; Sedmidubsky, D.; Janousek, Z.; Sembera, F.; Mikulics, M.; Sofer, Z. Tuning of fluorine content in graphene: Towards large-scale production of stoichiometric fluorographene. Nanoscale 2015, 7, 13646–13655. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Pei, S.; Ren, W.; Gao, L.; Cheng, H.-M. Efficient preparation of large-area graphene oxide sheets for transparent conductive films. ACS Nano 2010, 4, 5245–5252. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Zhao, Z.; Wan, W.; Gogotsi, Y.; Qiu, J. Ultralight and highly compressible graphene aerogels. Adv. Mater. 2013, 25, 2219–2223. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Shen, Y.; Sun, L.; Li, J.; Liu, C.; Ren, W.; Li, F.; Gao, L.; Chen, J.; Liu, F. Elemental superdoping of graphene and carbon nanotubes. Nat. Commun. 2016, 7, 10921. [Google Scholar] [CrossRef] [PubMed]

- Dubecký, M.S.; Otyepková, E.; Lazar, P.; Karlický, F.E.; Petr, M.; Cépe, K.R.; Banáš, P.; Zbořil, R.; Otyepka, M. Reactivity of fluorographene: A facile way toward graphene derivatives. J. Phys. Chem. Lett. 2015, 6, 1430–1434. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Wang, X.; Liu, Y.; Li, B.; Cheng, Z.; Wang, Z.; Lai, W.; Liu, X. Effects of the oxygenic groups on the mechanism of fluorination of graphene oxide and its structure. Phys. Chem. Chem. Phys. 2017, 19, 5504–5512. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, J.; Li, Z.; Gong, P.; Liu, X.; Zhang, L.; Ren, J.; Wang, H.; Yang, S. Synthesis of fluorinated graphene with tunable degree of fluorination. Carbon 2012, 50, 5403–5410. [Google Scholar] [CrossRef]

- Qiu, Z.; Wang, Y.; Bi, X.; Zhou, T.; Zhou, J.; Zhao, J.; Miao, Z.; Yi, W.; Fu, P.; Zhuo, S. Biochar-based carbons with hierarchical micro-meso-macro porosity for high rate and long cycle life supercapacitors. J. Power Sources 2018, 376, 82–90. [Google Scholar] [CrossRef]

- Si, W.; Zhou, J.; Zhang, S.; Li, S.; Xing, W.; Zhuo, S. Tunable n-doped or dual n, s-doped activated hydrothermal carbons derived from human hair and glucose for supercapacitor applications. Electrochim. Acta 2013, 107, 397–405. [Google Scholar] [CrossRef]

- Clark, D.T.; Feast, W.J.; Tweedale, P.J.; Thomas, H.R. ESCA applied to polymers. XXVI. Investigation of a series of aliphatic, aromatic, and fluorine-containing polycarbonates. J. Polym. Sci. Polym. Chem. Ed. 1980, 18, 1651–1664. [Google Scholar] [CrossRef]

- Wang, X.; Dai, Y.; Gao, J.; Huang, J.; Li, B.; Fan, C.; Yang, J.; Liu, X. High-yield production of highly fluorinated graphene by direct heating fluorination of graphene-oxide. ACS Appl. Mater. Interfaces 2013, 5, 8294–8299. [Google Scholar] [CrossRef] [PubMed]

- Guérin, K.; Dubois, M.; Hamwi, A. Electrochemical discharge mechanism of fluorinated graphite used as electrode in primary lithium batteries. J. Phys. Chem. Solids 2006, 67, 1173–1177. [Google Scholar] [CrossRef]

- Yoo, E.; Kim, J.; Hosono, E.; Zhou, H.-S.; Kudo, T.; Honma, I. Large reverible Li storge of graphene nanosheet families for use in rechargeable lithium ion batteries. Nano Lett. 2008, 8, 2277–2282. [Google Scholar] [CrossRef] [PubMed]

| Sample | C | F | O | N | C1s (%) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| C=C | C–O (N) | C=O (N) | –CF | –CF2 | –CF3 | |||||

| RGOA | 67.5 | 16.1 | 16.4 | 39.3 | 39.3 | 21.4 | ||||

| FG-200 | 62.3 | 26.5 | 6.1 | 5.2 | 5.8 | 10.9 | 57.1 | 15.8 | 10.3 | |

| FG-250 | 59.5 | 30.35 | 5.12 | 5.0 | 4.2 | 8.2 | 55.6 | 21.5 | 9.4 | |

| FG-300 | 54.8 | 35.6 | 4.7 | 4.9 | 7.5 | 7.9 | 56.1 | 17 | 11.2 | |

| FG-350 | 62.8 | 12.7 | 15.3 | 9.3 | 46.0 | 19.5 | 23.1 | 6.7 | 4.6 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, X.; Li, Y.; Qiu, Z.; Liu, C.; Zhou, T.; Zhuo, S.; Zhou, J. Fluorinated Graphene Prepared by Direct Fluorination of N, O-Doped Graphene Aerogel at Different Temperatures for Lithium Primary Batteries. Materials 2018, 11, 1072. https://doi.org/10.3390/ma11071072

Bi X, Li Y, Qiu Z, Liu C, Zhou T, Zhuo S, Zhou J. Fluorinated Graphene Prepared by Direct Fluorination of N, O-Doped Graphene Aerogel at Different Temperatures for Lithium Primary Batteries. Materials. 2018; 11(7):1072. https://doi.org/10.3390/ma11071072

Chicago/Turabian StyleBi, Xu, Yanyan Li, Zhipeng Qiu, Chao Liu, Tong Zhou, Shuping Zhuo, and Jin Zhou. 2018. "Fluorinated Graphene Prepared by Direct Fluorination of N, O-Doped Graphene Aerogel at Different Temperatures for Lithium Primary Batteries" Materials 11, no. 7: 1072. https://doi.org/10.3390/ma11071072

APA StyleBi, X., Li, Y., Qiu, Z., Liu, C., Zhou, T., Zhuo, S., & Zhou, J. (2018). Fluorinated Graphene Prepared by Direct Fluorination of N, O-Doped Graphene Aerogel at Different Temperatures for Lithium Primary Batteries. Materials, 11(7), 1072. https://doi.org/10.3390/ma11071072