The Effect of Post-Processes on the Microstructure and Creep Properties of Alloy718 Built Up by Selective Laser Melting

Abstract

:1. Introduction

2. Materials and Experimental Procedure

Design of Post-Processes

3. Results

3.1. Microstructure Changes

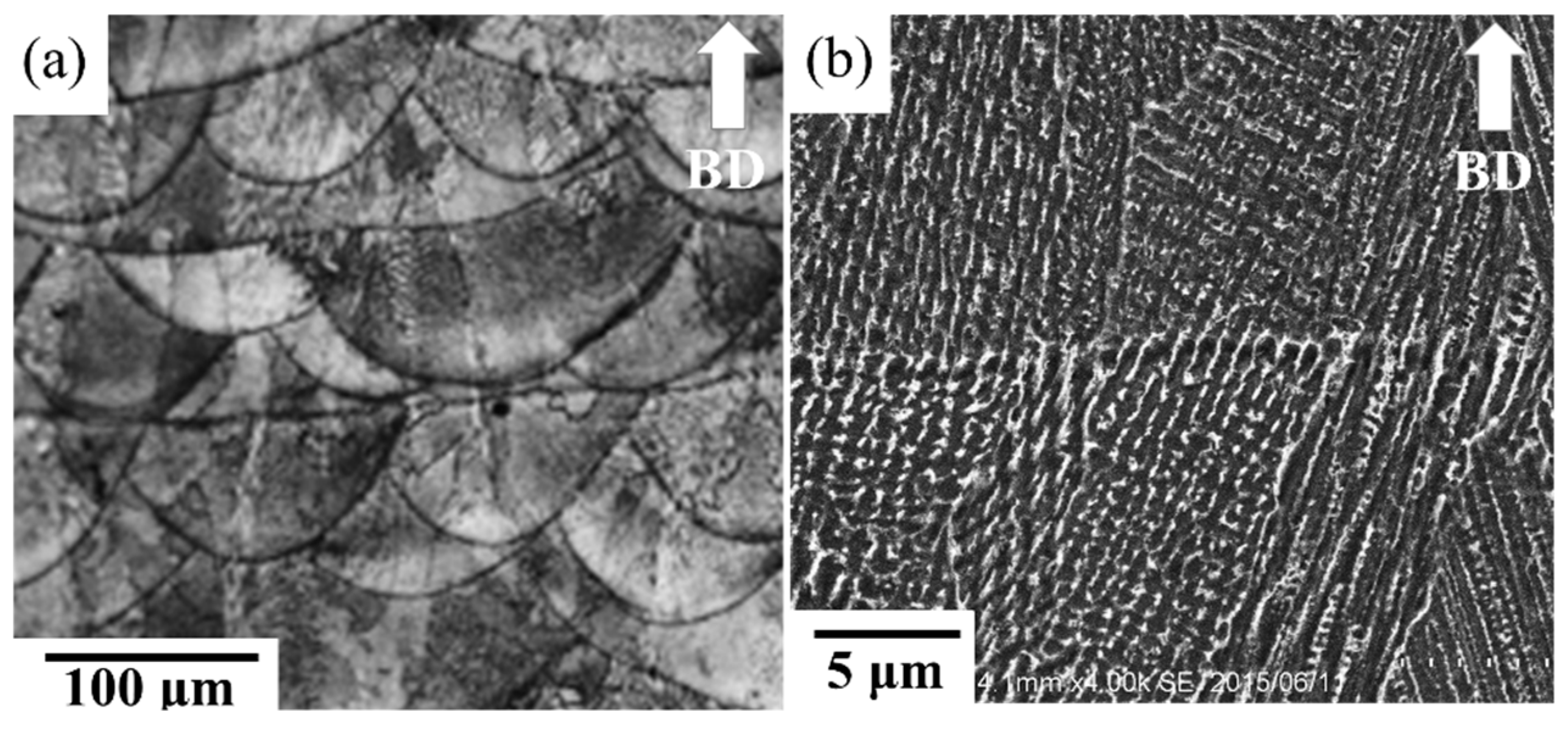

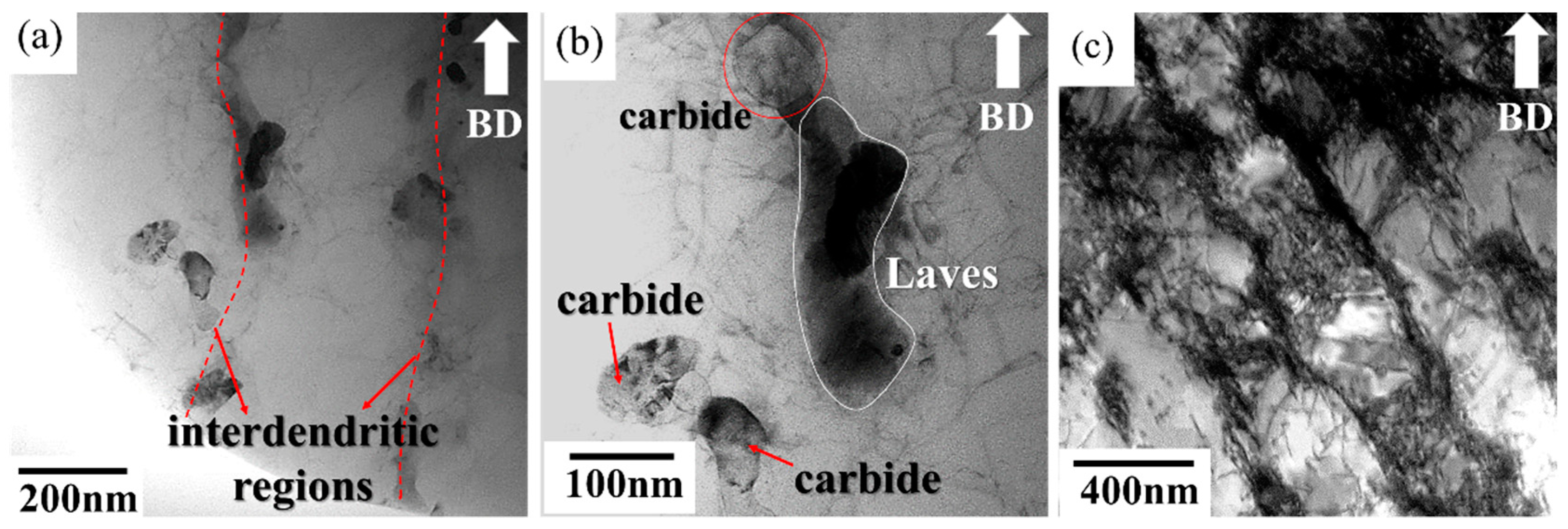

3.1.1. The As-Built Microstructure

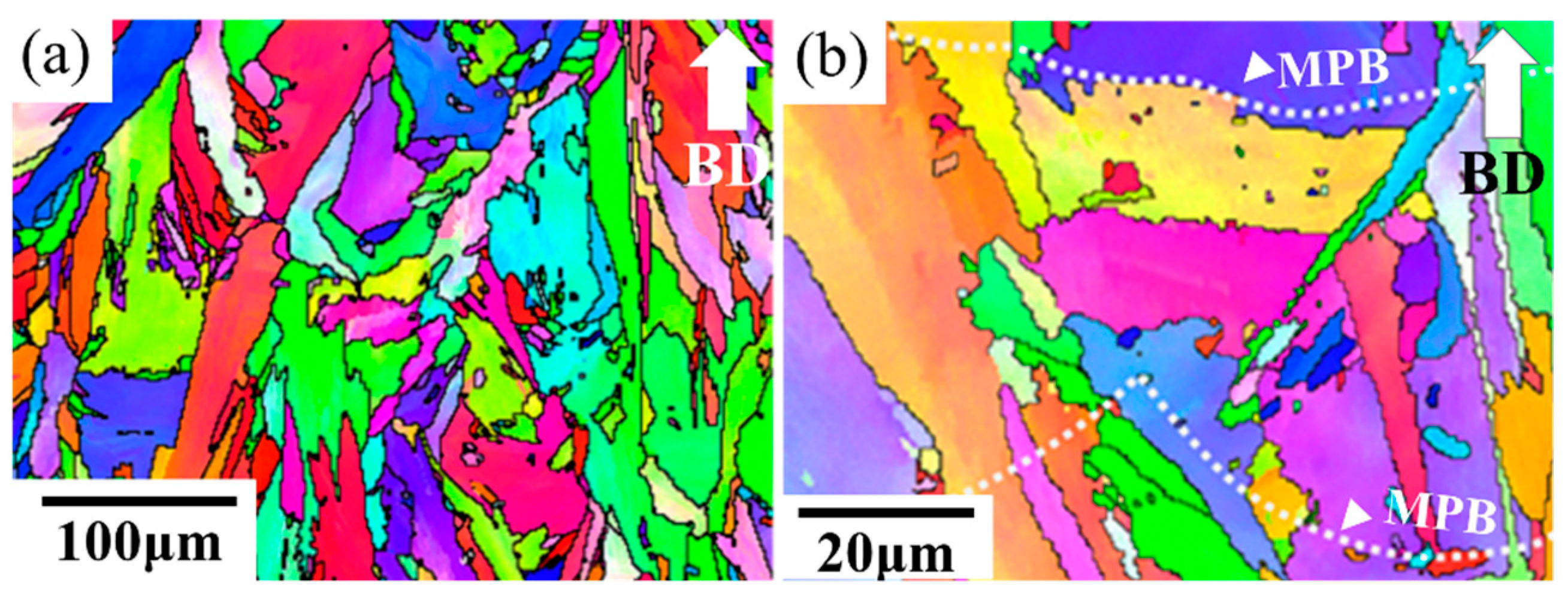

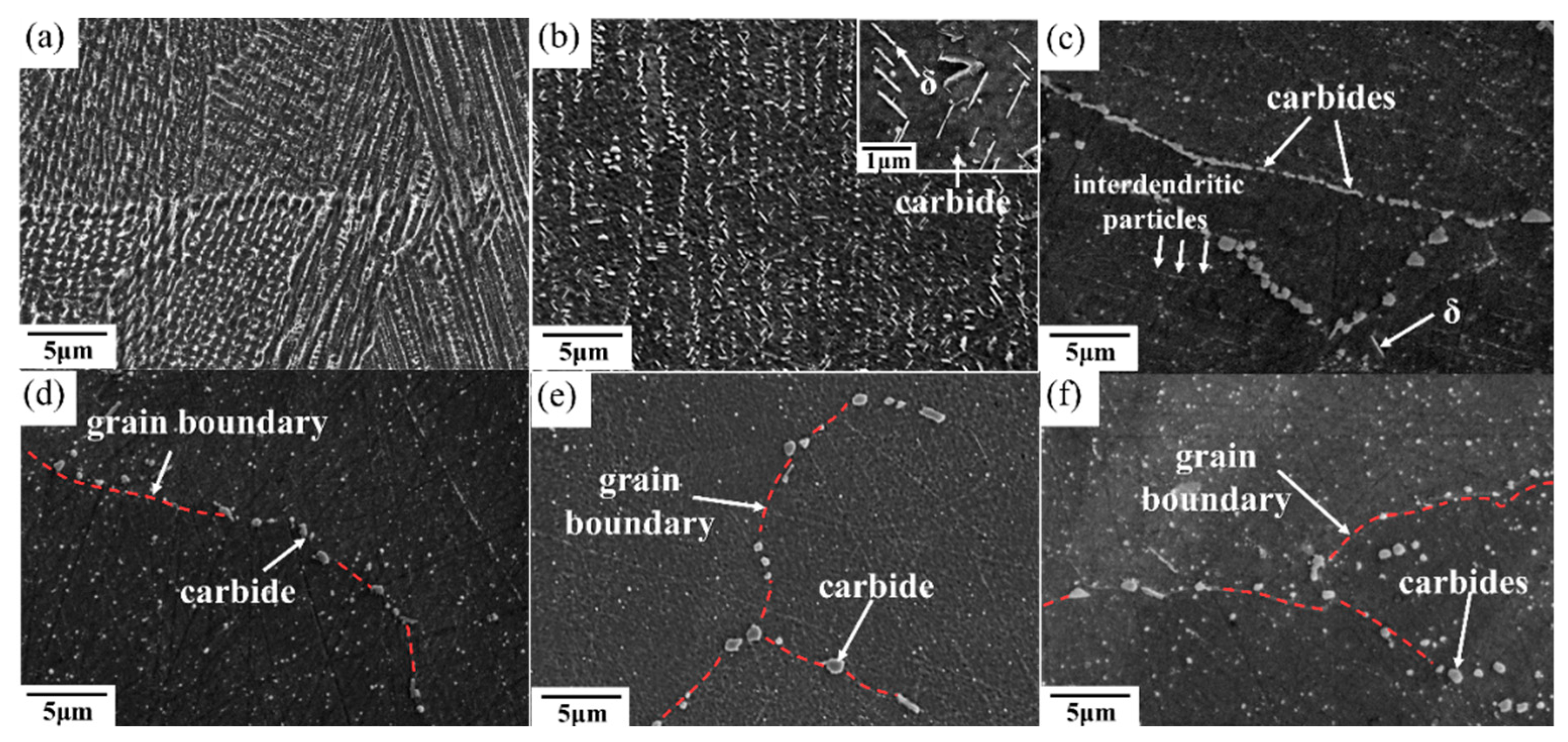

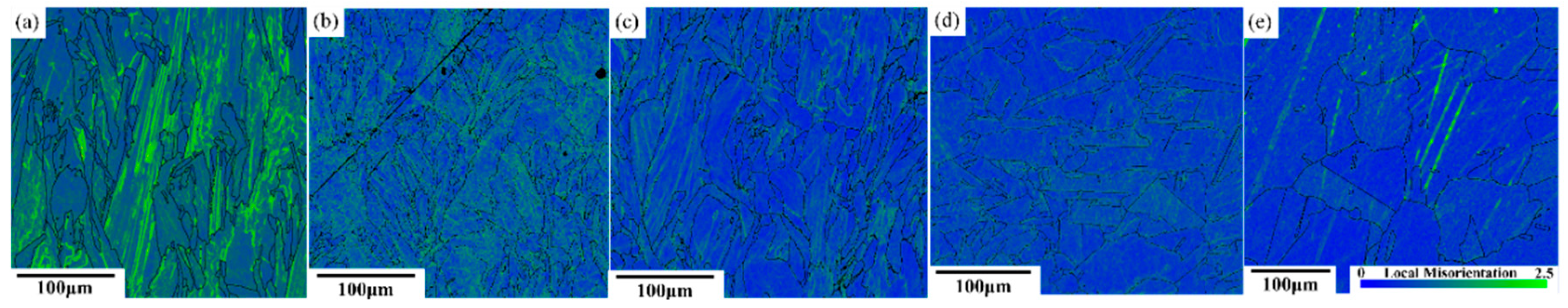

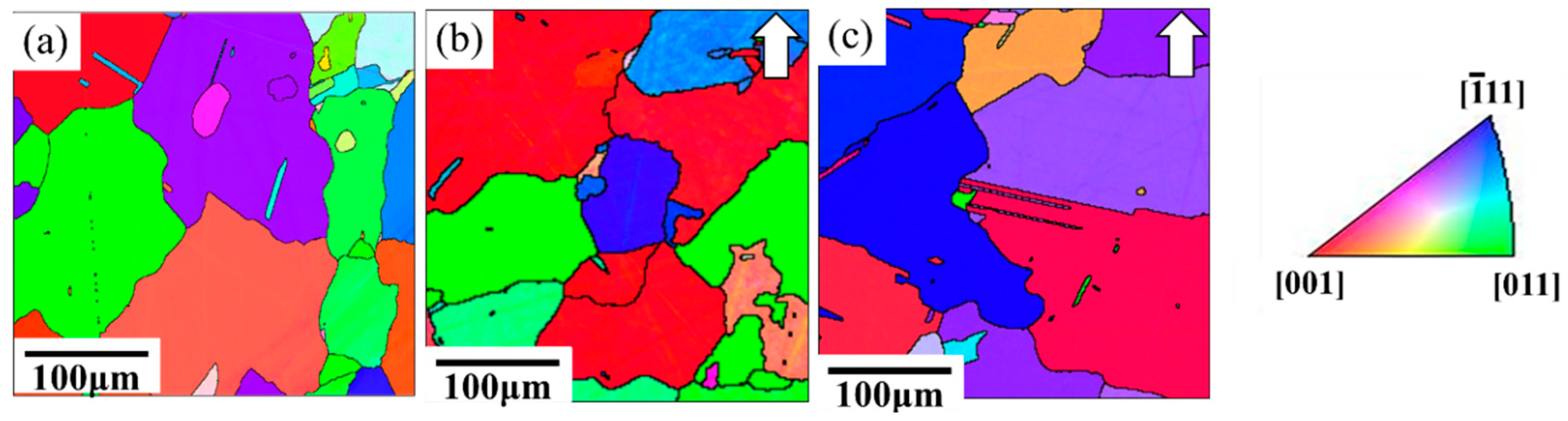

3.1.2. The Heat-Treated Microstructure

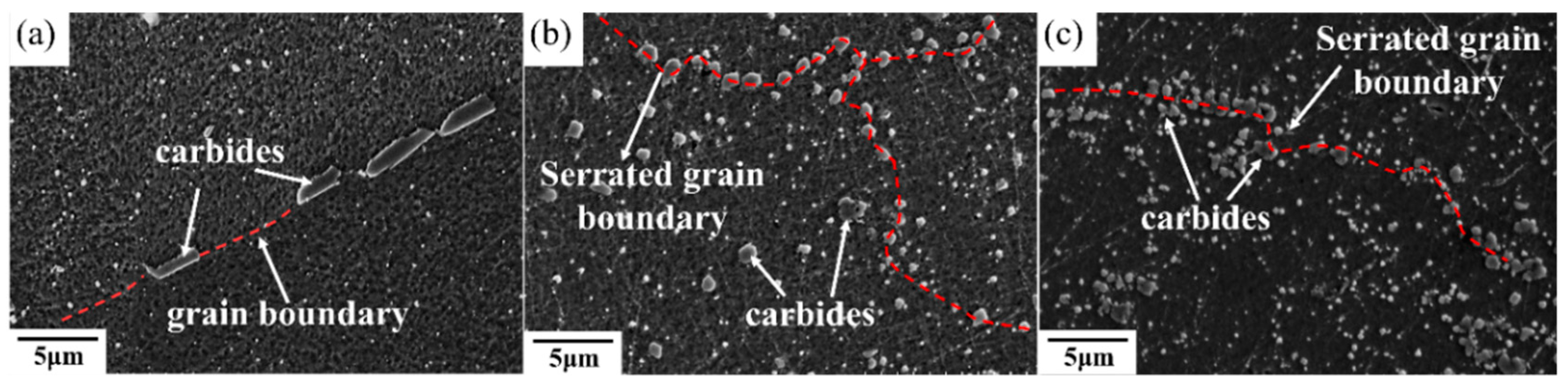

3.1.3. The HIPed Microstructure

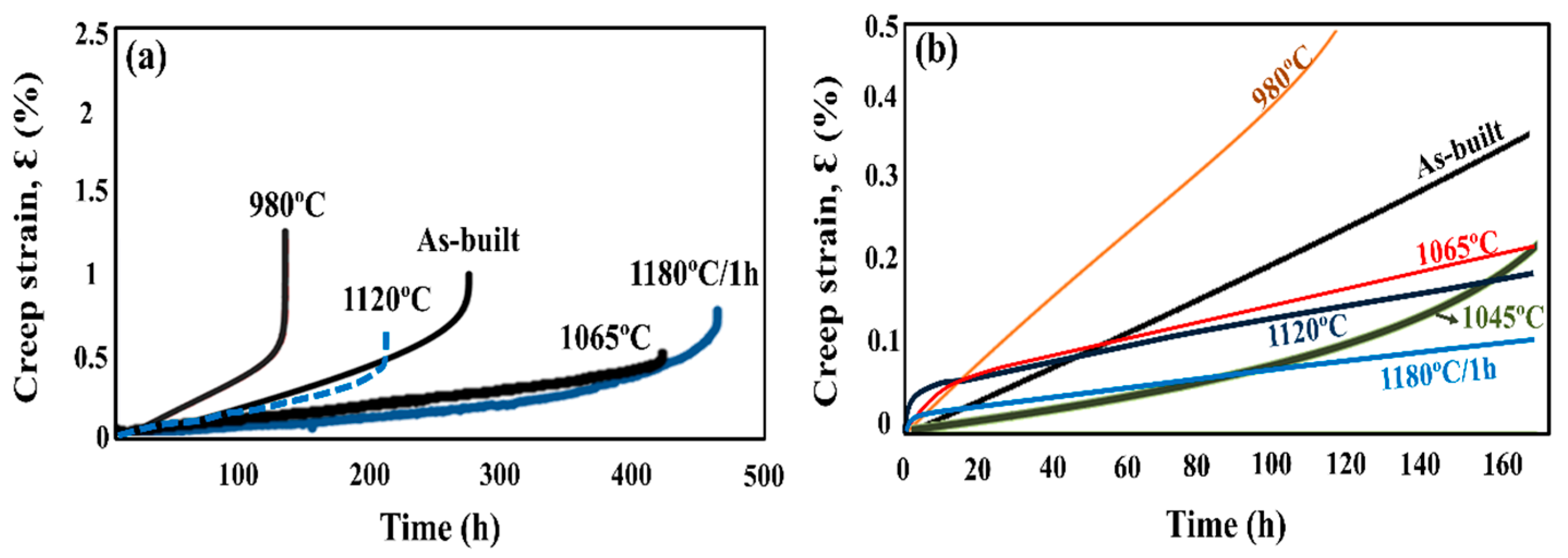

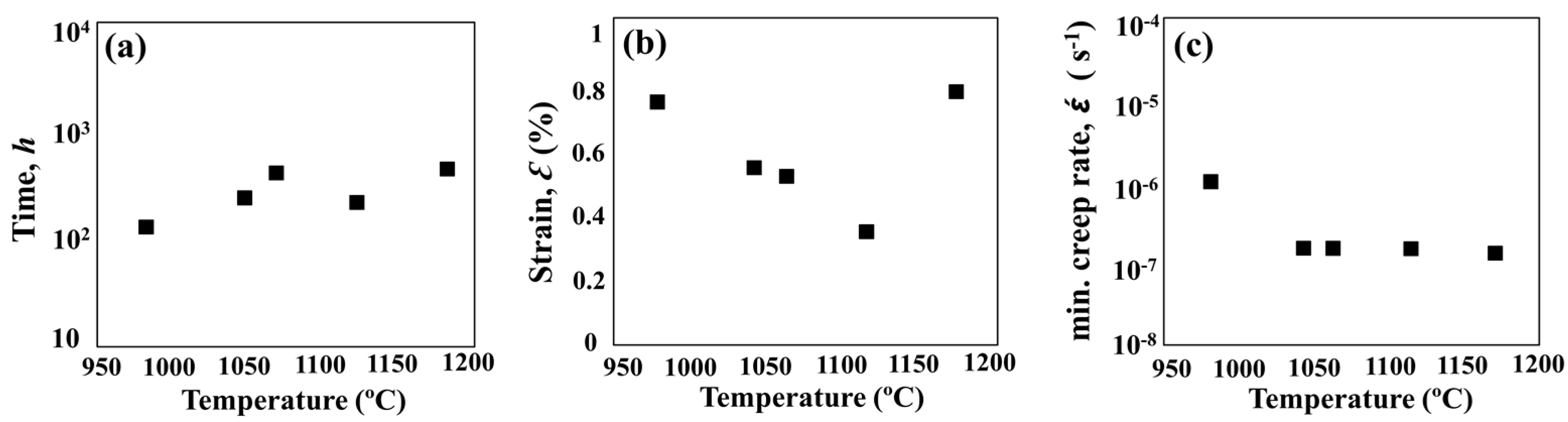

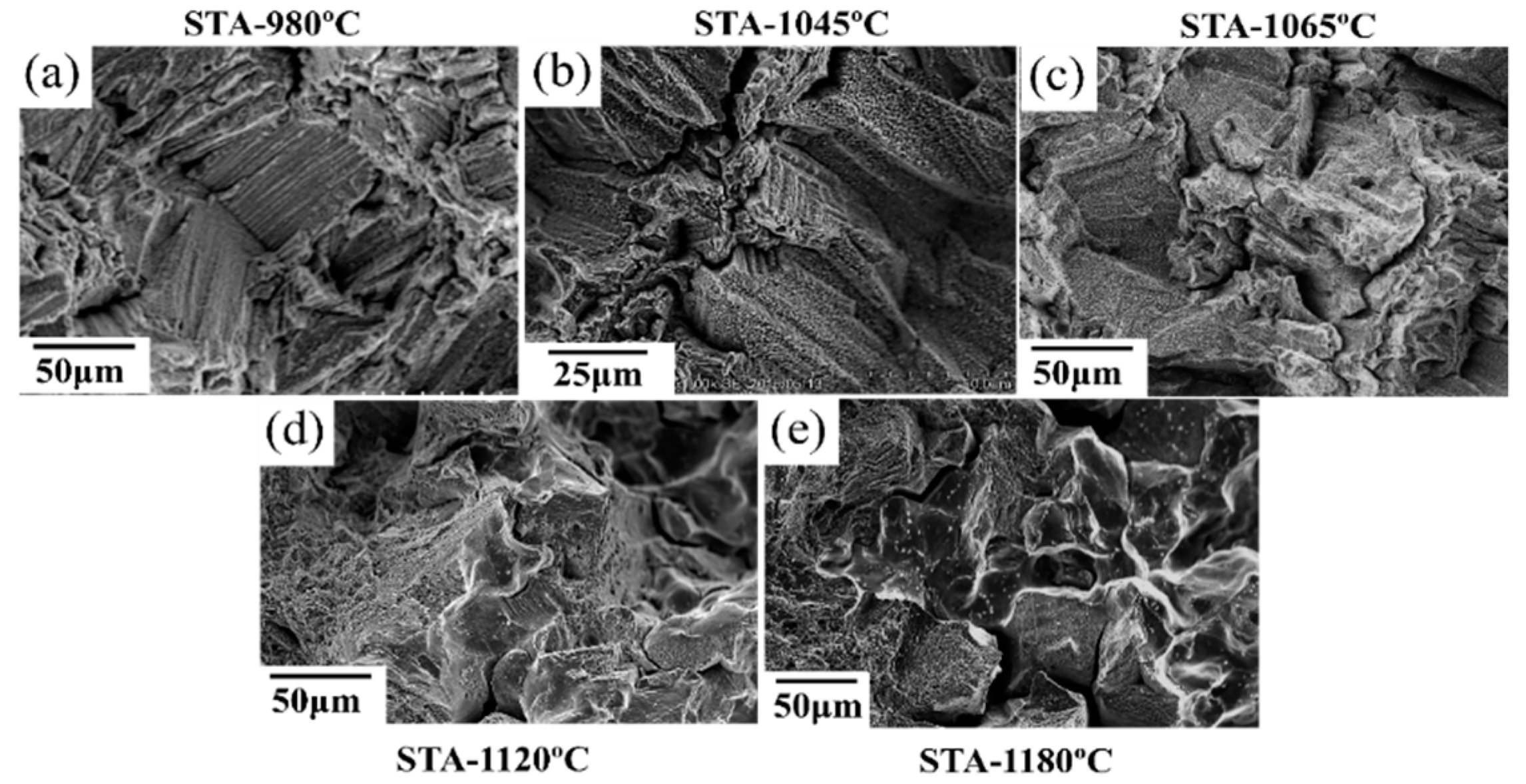

3.2. Mechanical Properties of Heat-Treated SLM Specimens

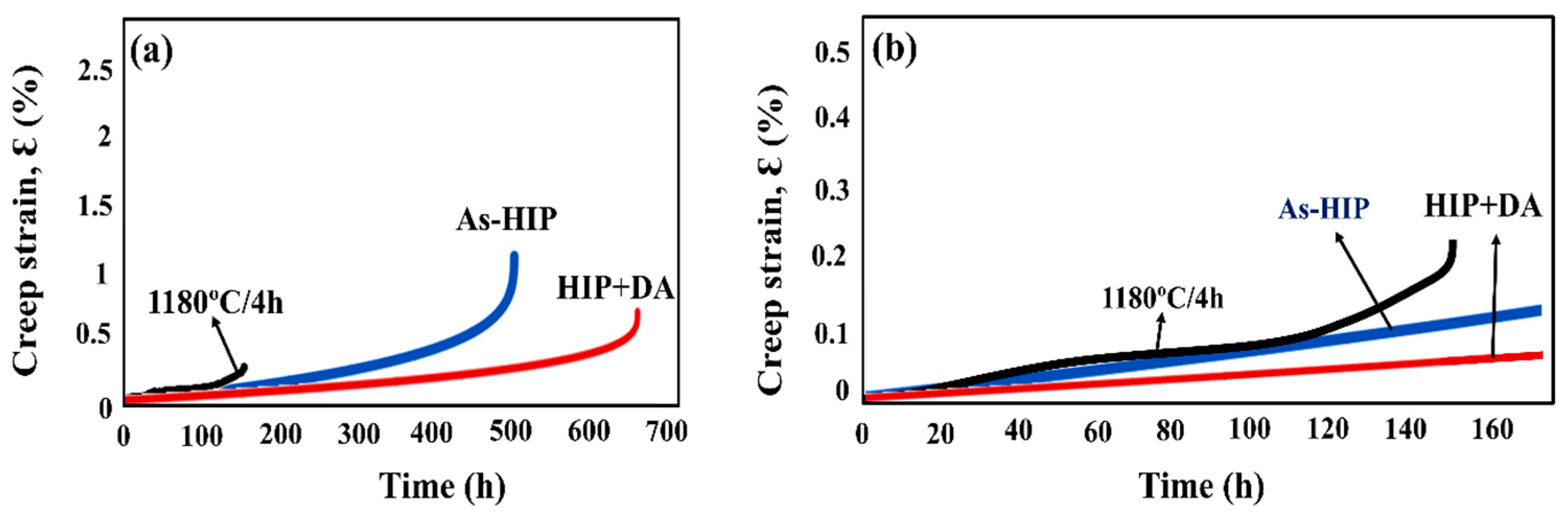

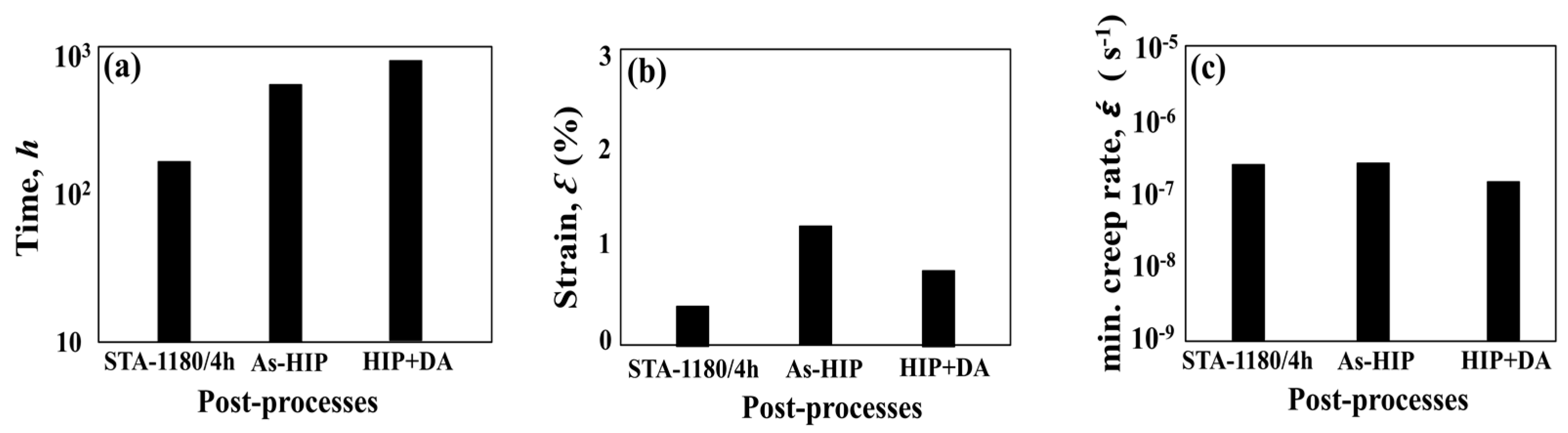

3.3. Mechanical Properties of HIPed SLM Specimens

4. Discussion

4.1. Effects of the Formation of Laves Phase/δ Phase in SLM Materials

4.2. Grain Morphologies of the As-Built Specimen

4.3. Inhomogeneous Grain Growth and Its Effects on Mechanical Properties

4.4. The Effects of HIP on the Mechanical Properties of SLM Specimens at 650 °C

5. Conclusions

- The dendrite structure and interdendritic regions were decorated with a continuous network of Laves phase and carbides in the as-built specimen. In addition, the rapid heating and cooling induces thermal variations that cause high-density dislocations.

- The originally recommended heat treatment process, STA-980 °C, for cast and wrought materials is not effective in SLM-processed specimens.

- Laves phases/δ phases were dissolved in the matrix by a solution treatment at higher temperatures; however, creep properties were not improved greatly because of the inhomogeneous grain growth.

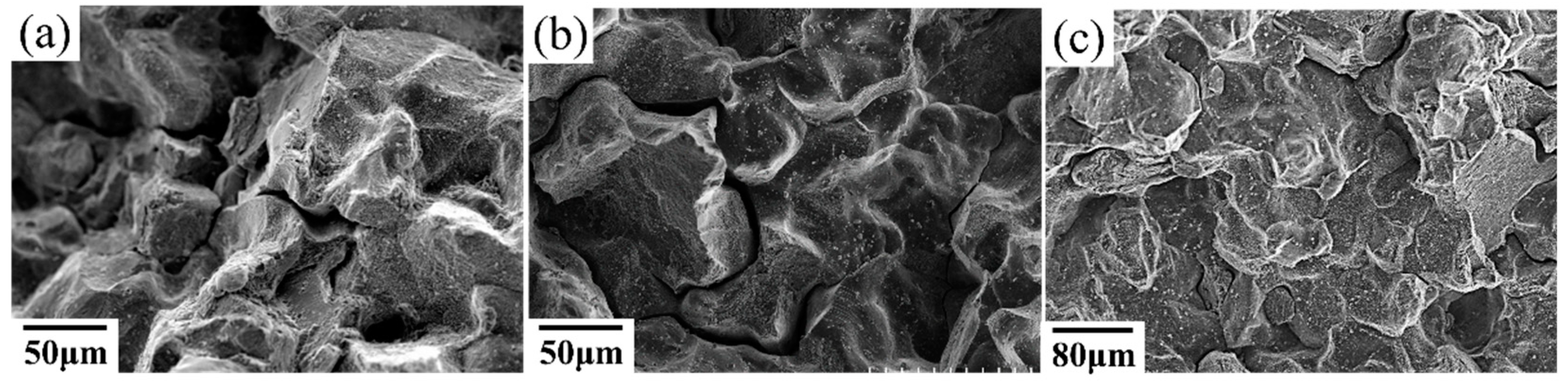

- The HIPed materials exhibited a serrated grain boundary with a high-volume fraction of carbide along the grain boundary. HIP improved the creep life, and the HIP+ direct aging process was the most effective among the post-processes for improving the creep behavior at 650 °C.

Author Contributions

Funding

Conflicts of Interest

References

- Yeh, A.C.; Lu, K.W.; Kuo, C.M.; Bor, H.Y.; Wei, C.N. Effect of serrated grain boundaries on the creep property of Inconel 718 superalloy. Mater. Sci. Eng. A 2011, 530, 525–529. [Google Scholar] [CrossRef]

- Kuo, Y.L.; Horikawa, S.; Kakehi, K. The effect of interdendritic δ phase on the mechanical properties of Alloy 718 built up by additive manufacturing. Mater. Des. 2017, 116, 411–418. [Google Scholar] [CrossRef]

- Ghosh, S.; Yadav, S.; Das, G. Study of standard heat treatment on mechanical properties of Inconel 718 using ball indentation technique. Mater Lett. 2008, 62, 2619–2622. [Google Scholar] [CrossRef]

- Kanagarajah, P.; Brenne, F.; Niendorf, T.; Maier, H.J. Inconel939 processed by selective laser melting: Effect of microstructure and temperature on the mechanical properties under static and cyclic loading. Mater. Sci. Eng. A 2013, 588, 188–195. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Thivillon, L.; Bertrand, P.; Smurov, I. Strategy of manufacturing components with designed internal structure by selective laser melting of metallic powder. Appl. Surf. Sci. 2007, 254, 980–983. [Google Scholar] [CrossRef]

- Brenne, F.; Niendorf, T.; Maier, H.J. Additively manufactured cellular structures: Impact of microstructure and local strains on the monotonic and cyclic behavior under uniaxial and bending load. J. Mater. Process Technol. 2013, 213, 1558–1564. [Google Scholar] [CrossRef]

- Li, R.; Liu, J.; Shi, Y.; Wang, L.; Jiang, W. Balling behavior of stainless steel and nickel powder during selective laser melting process. Int. J. Adv. Manuf. Technol. 2012, 59, 1025–1035. [Google Scholar] [CrossRef]

- Osakada, K.; Shiomi, M. Flexible manufacturing of metallic products by selective laser melting of powder. Int. J. Mach. Tools Manuf. 2006, 46, 1188–1193. [Google Scholar] [CrossRef]

- Amato, K.N.; Gaytan, S.M.; Murr, L.E.; Martinez, E.; Shindo, P.W.; Hernandez, J.; Collins, S.; Medina, F. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Mater. 2012, 60, 2229–2239. [Google Scholar] [CrossRef]

- Antonsson, T.; Fredriksson, H. The effect of cooling rate on the solidification of INCONEL 718. Metall. Mater. Trans. 2005, 36, 85–96. [Google Scholar] [CrossRef]

- Kuo, Y.L.; Horikawa, S.; Kakehi, K. Effects of build direction and heat treatment on creep properties of Ni-base superalloy built up by additive manufacturing. Scr. Mater. 2017, 129, 74–78. [Google Scholar] [CrossRef]

- Tillmann, W.; Schaak, C.; Nellesen, J.; Schaper, M.; Aydinöz, M.E.; Hoyer, K.-P. Hot isostatic pressing of IN718 components manufactured by selective laser melting. Addit. Manuf. 2017, 13, 93–102. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Turenne, S. Effect of heat treatment and hot isostatic pressing on the microstructure and mechanical properties of Inconel 625 alloy processed by laser powderbed fusion. Mater. Sci. Eng. A 2017, 689, 1–10. [Google Scholar] [CrossRef]

- Zhao, X.; Lin, X.; Chen, J.; Xue, L.; Huang, W. The effect of hot isostatic pressing on crack healing, microstructure, mechanical properties of Rene88DT superalloy prepared by laser solid forming. Mater. Sci. Eng. A 2009, 504, 129–134. [Google Scholar] [CrossRef]

- Chaturvedi, M.C.; Han, Y.-F. Strengthening mechanisms in Inconel 718 superalloy. Met. Sci. 1983, 17, 145–149. [Google Scholar] [CrossRef]

- Kuo, C.M.; Yang, Y.-T.; Bor, H.-Y.; Wei, C.-N.; Tai, C.-C. Aging effects on the microstructure and creep behavior of Inconel 718 superalloy. Mater. Sci. Eng. A 2009, 510, 289–294. [Google Scholar] [CrossRef]

- Chang, S.; Lee, S.; Tang, T.; Ho, H. Influences of soaking time in hot isostatic pressing on strength of inconel 718 superalloy. Mater. Trans. 2006, 47, 426–432. [Google Scholar] [CrossRef]

- Raghakrishna, C.H.; Rao, K.P. The formation and control of Laves phase in superalloy 718 welds. J. Mater. Sci. 1997, 32, 1977–1984. [Google Scholar] [CrossRef]

- Liu, F.; Lin, X.; Yang, G.; Song, M.; Chen, J.; Huang, W. Recrystallization and its influence on microstructures and mechanical properties of laser solid formed nickel base superalloy Inconel 718. Rare Met. 2011, 30, 433–438. [Google Scholar] [CrossRef]

- Wen, S.; Li, S.; Wei, Q.; Yan, C.; Sheng, Z.; Shi, Y. Effect of molten pool boundaries on the mechanical properties of selective laser melting parts. J. Mater. Process. Technol. 2014, 241, 2660–2667. [Google Scholar]

- DuPont, J.N.; Lippold, J.C.; Kiser, S.D. Welding Metallurgy and Weldability of Nickel Base Alloys; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009. [Google Scholar]

- Murr, L.E. Metallurgy of additive manufacturing: Examples from electron beam melting. Addit. Manuf. 2015, 5, 40–53. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Qi, H.; Azer, M.; Ritter, A. Studies of standard heat treatment effects on microstructure and mechanical properties of laser net shape manufactured Inconel 718. Metall. Mater. Trans. A 2009, 40, 2410–2422. [Google Scholar] [CrossRef]

- Matz, J.E.; Eagar, T.W. Carbide formation in Alloy718 during electron-beam solid freeform fabrication. Metall. Mater. Trans. A 2002, 33, 2559–2567. [Google Scholar] [CrossRef]

- Honeycombe, R.W.K. The Plastic Deformation of Metals; Edward Arnold: London, UK, 1984. [Google Scholar]

- Nabarro, F.R.N.; de-Villiers, H.L. The Physics of Creep Book; Taylor & Francis Ltd.: London, UK, 1995. [Google Scholar]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Pergamon Press: New York, NY, USA, 1995. [Google Scholar]

- Cao, J.; Liu, F.; Lin, X.; Huang, C.; Chen, J.; Huang, W. Effect of overlap rate on recrystallization behaviors of Laser Solid Formed Inconel 718 superalloy. Opt. Laser Technol. 2013, 45, 228–235. [Google Scholar] [CrossRef]

- Koul, A.K.; Thamburaj, R. Serrated grain boundary formation potential of Ni-based superalloys and its implications. Metall. Mater. Trans. A 1985, 16, 17–26. [Google Scholar] [CrossRef]

- Miyagawa, O.; Yamamoto, M.; Kobayashi, M. Zig-zag grain boundaries and strength of heat resisting alloys. In Proceedings of the Third International Symposium on Metallurgy and Manufacturing of Superalloys, Warrendale, PA, USA, 12–15 September 1976; pp. 245–254. [Google Scholar]

- Mujica Roncery, L.; Lopez Galilea, I.; Ruttert, B.; Bürger, D.; Wollgramm, P.; Eggeler, G.; Theisen, W. On the effect of hot isostatic pressing on the creep life of a single crystal superalloy. Adv. Eng. Mater. 2016, 18, 1381–1387. [Google Scholar] [CrossRef]

| Cr | Nb | Mo | Ti | Al | Co | Cu | C | Si, Mn | P, S | B | O | Fe | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19.6 | 5.05 | 2.85 | 1.10 | 0.46 | 0.03 | 0.05 | 0.04 | 0.04 | 0.0 | 0.002 | 0.019 | Balance | 52.59 |

| Variant | 1st Step: Solution Treatment | 2nd Step: Age Hardening |

| STA-980 °C | 980 °C/1 h/air cooling | 720 °C/8 h/furnace cooling to 620 °C + 620 °C/10 h/air cooling |

| STA-1045 °C | 1045 °C/1 h/air cooling | |

| STA-1065 °C | 1065 °C/1 h/air cooling | |

| STA-1120 °C | 1120 °C/1 h/air cooling | |

| STA-1180 °C/1 h | 1180 °C/1 h/air cooling | |

| STA-1180 °C/4 h | 1180 °C/4 h/furnace cooling | |

| Variant | 1st Step: HIP Process | 2nd Step: Post-Treatment |

| As-HIPed | HIP at 1180 °C/175 MPa/4 h | N/A |

| HIP + direct aging | HIP at 1180 °C/175 MPa/4 h | 720 °C/8 h/furnace cooling to 620 °C + 620 °C/10 h/air cooling |

| Variant | Density (g/cm3) | Density Compared with Cast and Wrought Alloy (%) |

|---|---|---|

| cast and wrought alloy | 8.23 | 100.00 |

| as-built | 8.20 | 99.62 |

| STA-980 °C | 8.19 | 99.46 |

| STA-1045 °C | 8.17 | 99.26 |

| STA-1065 °C | 8.20 | 99.59 |

| STA-1120 °C | 8.18 | 99.38 |

| STA-1180 °C/1 h | 8.20 | 99.61 |

| STA-1180 °C/4 h | 8.18 | 99.32 |

| as-HIPed | 8.19 | 99.45 |

| HIP+ direct aging | 8.24 | 100.11 |

| Elements | Al | Ti | Cr | Fe | Ni | Nb | Mo |

|---|---|---|---|---|---|---|---|

| Laves (as-built) | 2.20 | 1.09 | 12.74 | 11.28 | 45.42 | 22.06 | 5.21 |

| δ phase (STA-980 °C) | 0.84 | 2.43 | 4.17 | 3.41 | 51.16 | 35.86 | 2.12 |

| matrix (STA-980 °C) | 2.38 | 0.47 | 12.45 | 14.16 | 61.63 | 5.59 | 3.20 |

| Variant | STA-980 °C | STA-1045 °C | STA-1065 °C | STA-1120 °C | STA-1180 °C/1 h | STA-1180 °C/4 h | As-HIPed | HIP+ Direct Aging |

|---|---|---|---|---|---|---|---|---|

| steady-state rate, έ (10−7 s−1) | 10.7 | 1.59 | 1.90 | 1.59 | 1.37 | 1.74 | 1.73 | 0.89 |

| creep life (h) | 134 | 254 | 426 | 230 | 462 | 151 | 493 | 677 |

| strain (%) | 1.29 | 0.56 | 0.53 | 0.75 | 0.81 | 0.2 | 1.10 | 0.65 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuo, Y.-L.; Nagahari, T.; Kakehi, K. The Effect of Post-Processes on the Microstructure and Creep Properties of Alloy718 Built Up by Selective Laser Melting. Materials 2018, 11, 996. https://doi.org/10.3390/ma11060996

Kuo Y-L, Nagahari T, Kakehi K. The Effect of Post-Processes on the Microstructure and Creep Properties of Alloy718 Built Up by Selective Laser Melting. Materials. 2018; 11(6):996. https://doi.org/10.3390/ma11060996

Chicago/Turabian StyleKuo, Yen-Ling, Toshiki Nagahari, and Koji Kakehi. 2018. "The Effect of Post-Processes on the Microstructure and Creep Properties of Alloy718 Built Up by Selective Laser Melting" Materials 11, no. 6: 996. https://doi.org/10.3390/ma11060996

APA StyleKuo, Y.-L., Nagahari, T., & Kakehi, K. (2018). The Effect of Post-Processes on the Microstructure and Creep Properties of Alloy718 Built Up by Selective Laser Melting. Materials, 11(6), 996. https://doi.org/10.3390/ma11060996