Dislocation Based Flow Stress Model of 300M Steel in Isothermal Compression Process

Abstract

1. Introduction

2. Materials and Experimental Procedures

2.1. Materials

2.2. Experiments

3. Results and Discussion

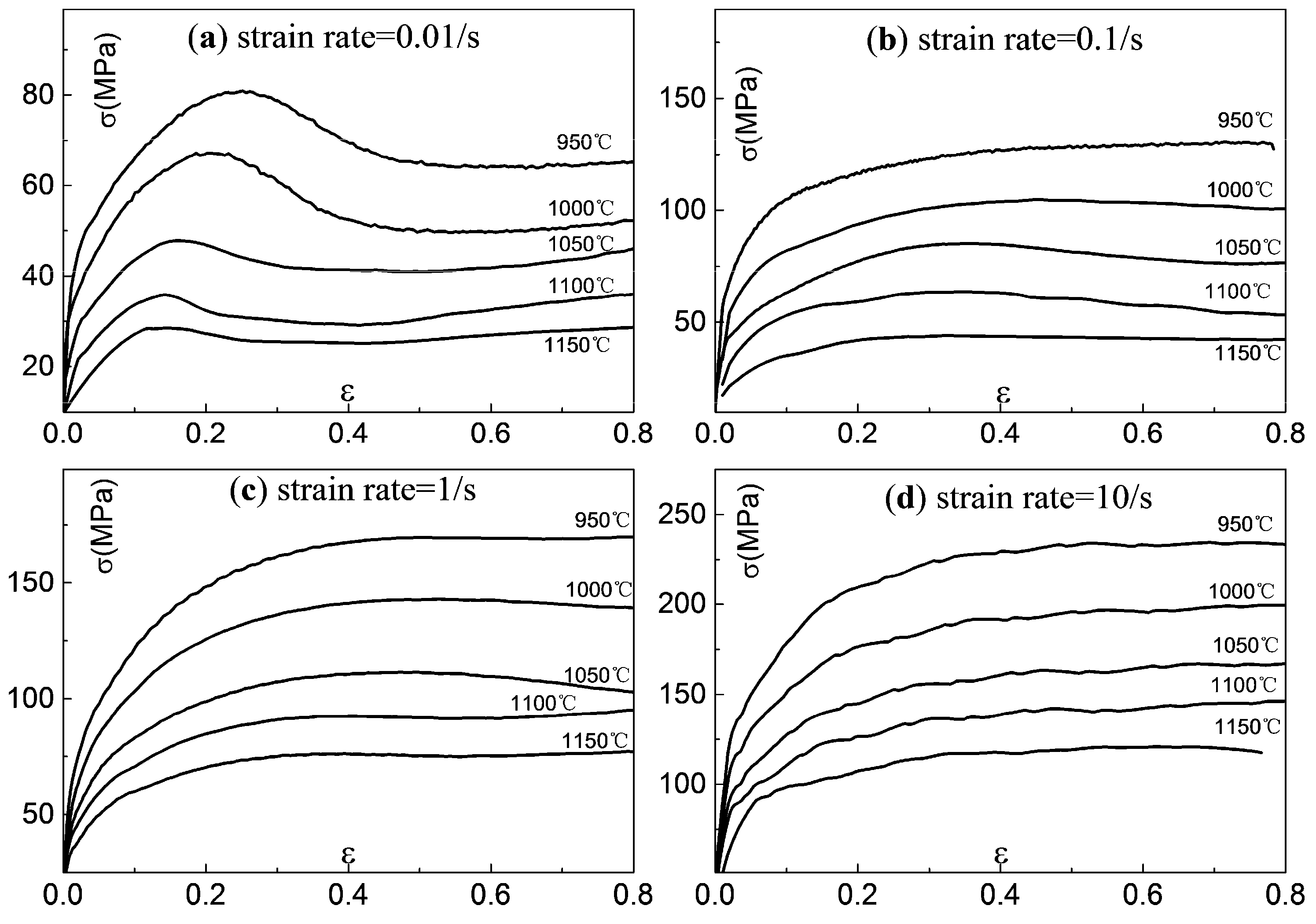

3.1. Deformation Behaviour

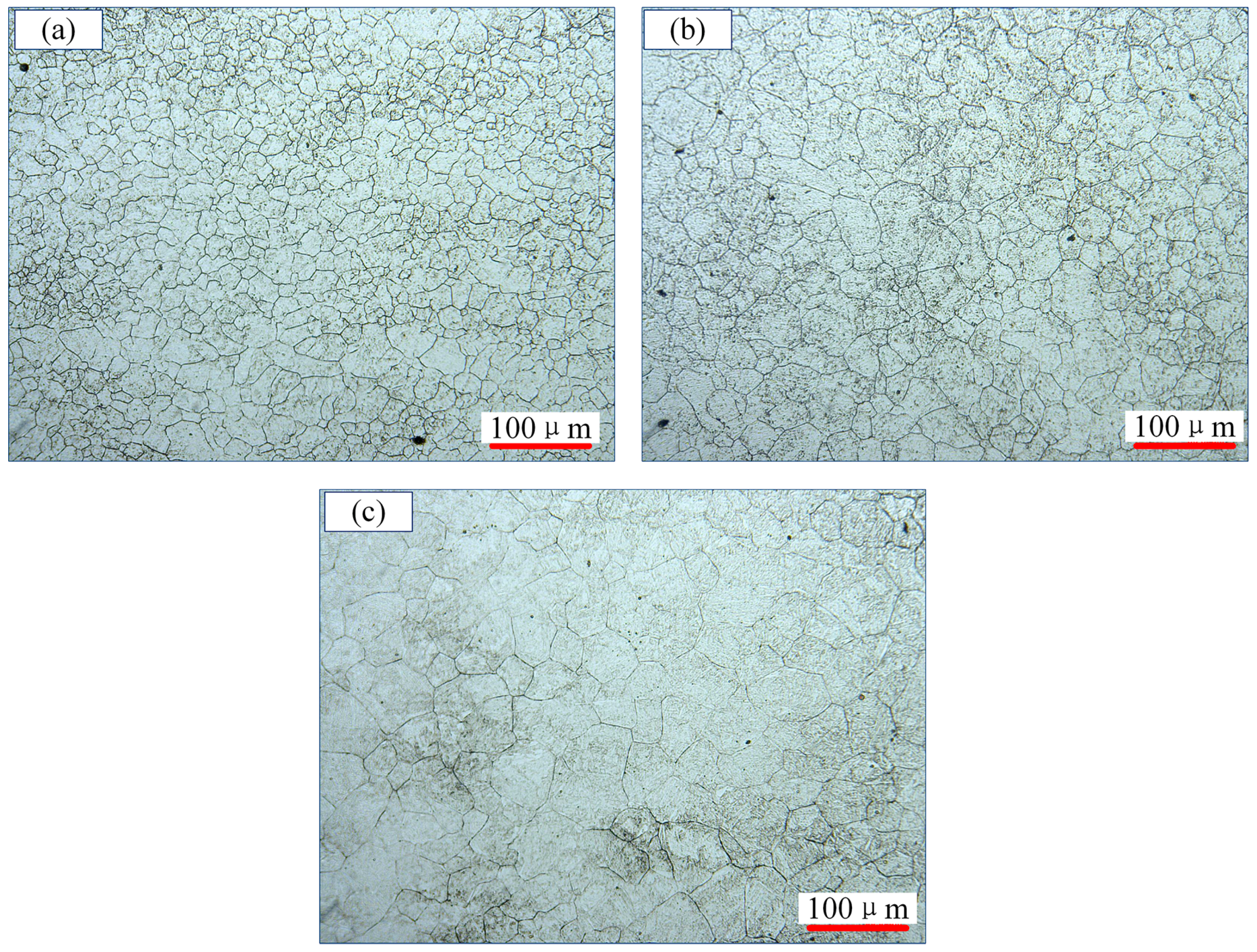

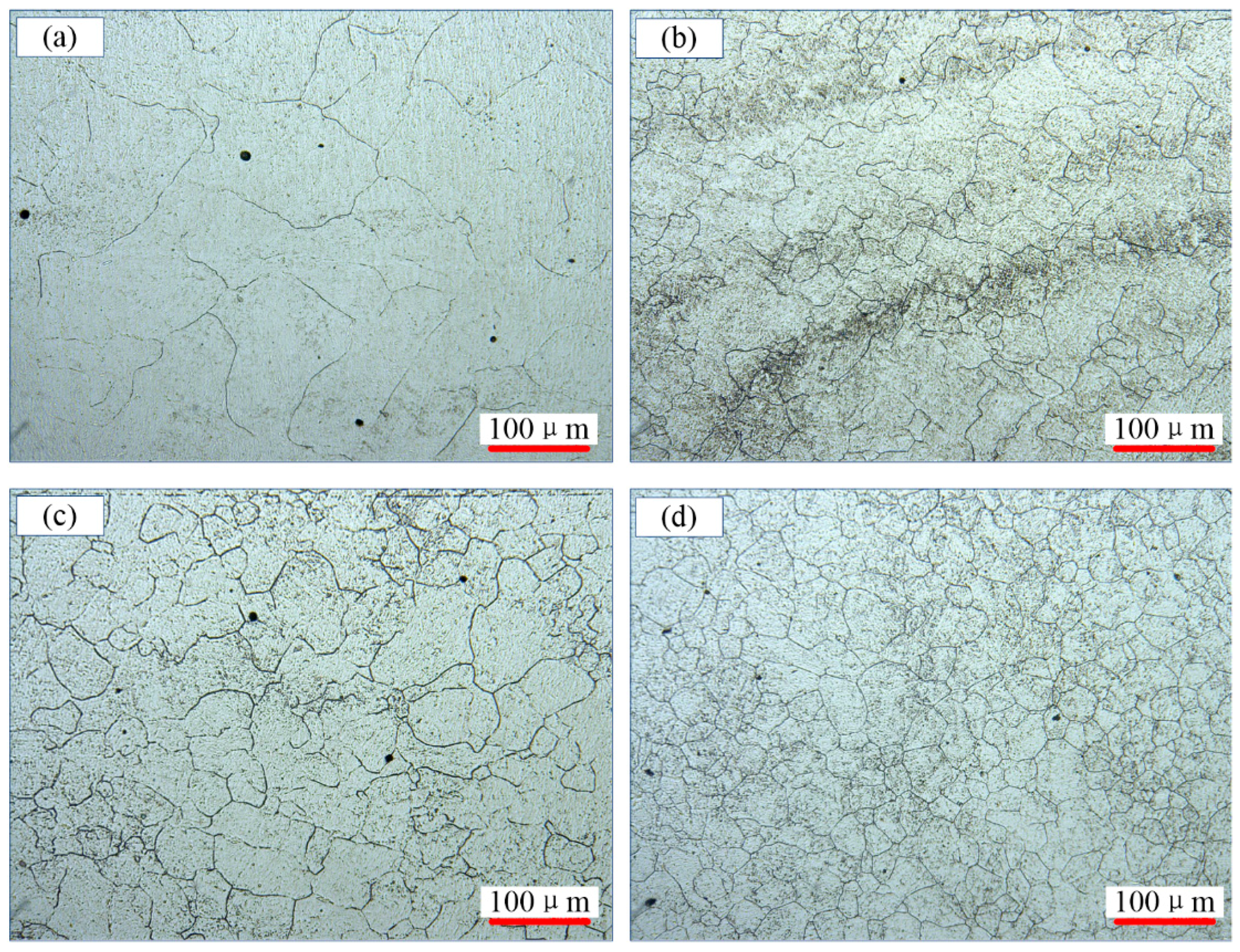

3.2. Microstructures Evolution

3.3. Dislocation Based Flow Stress Model

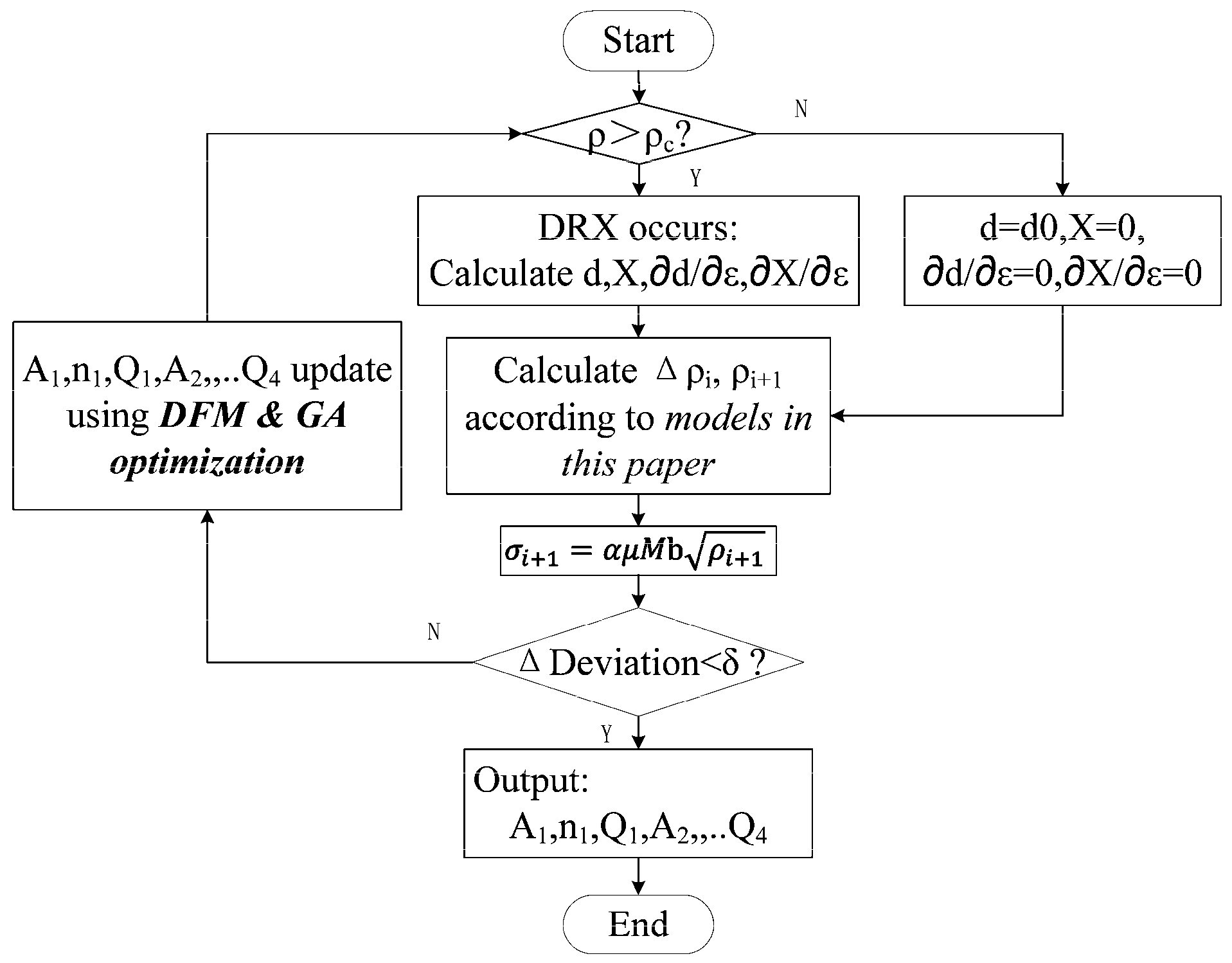

3.4. Model Parameter Determination

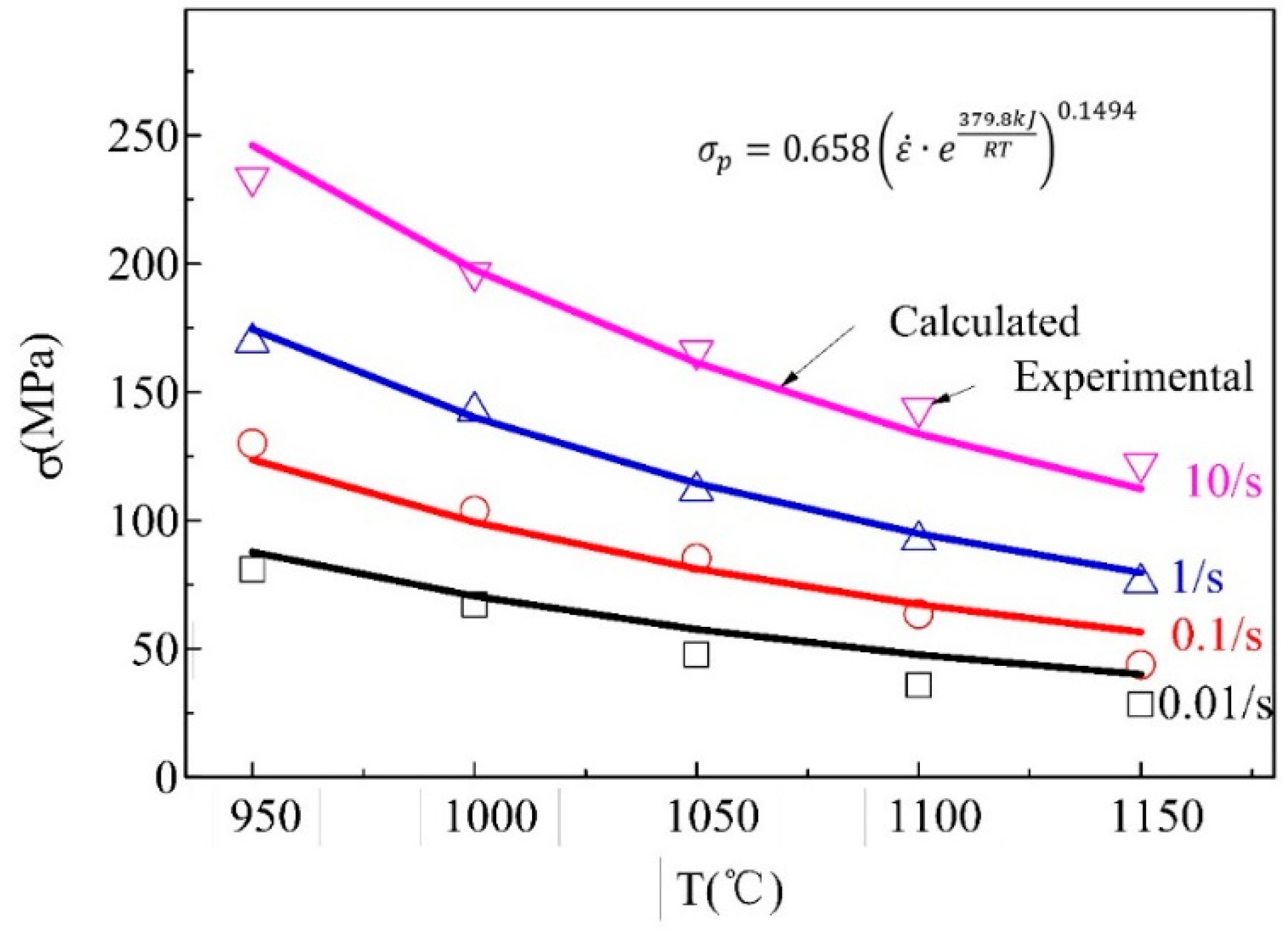

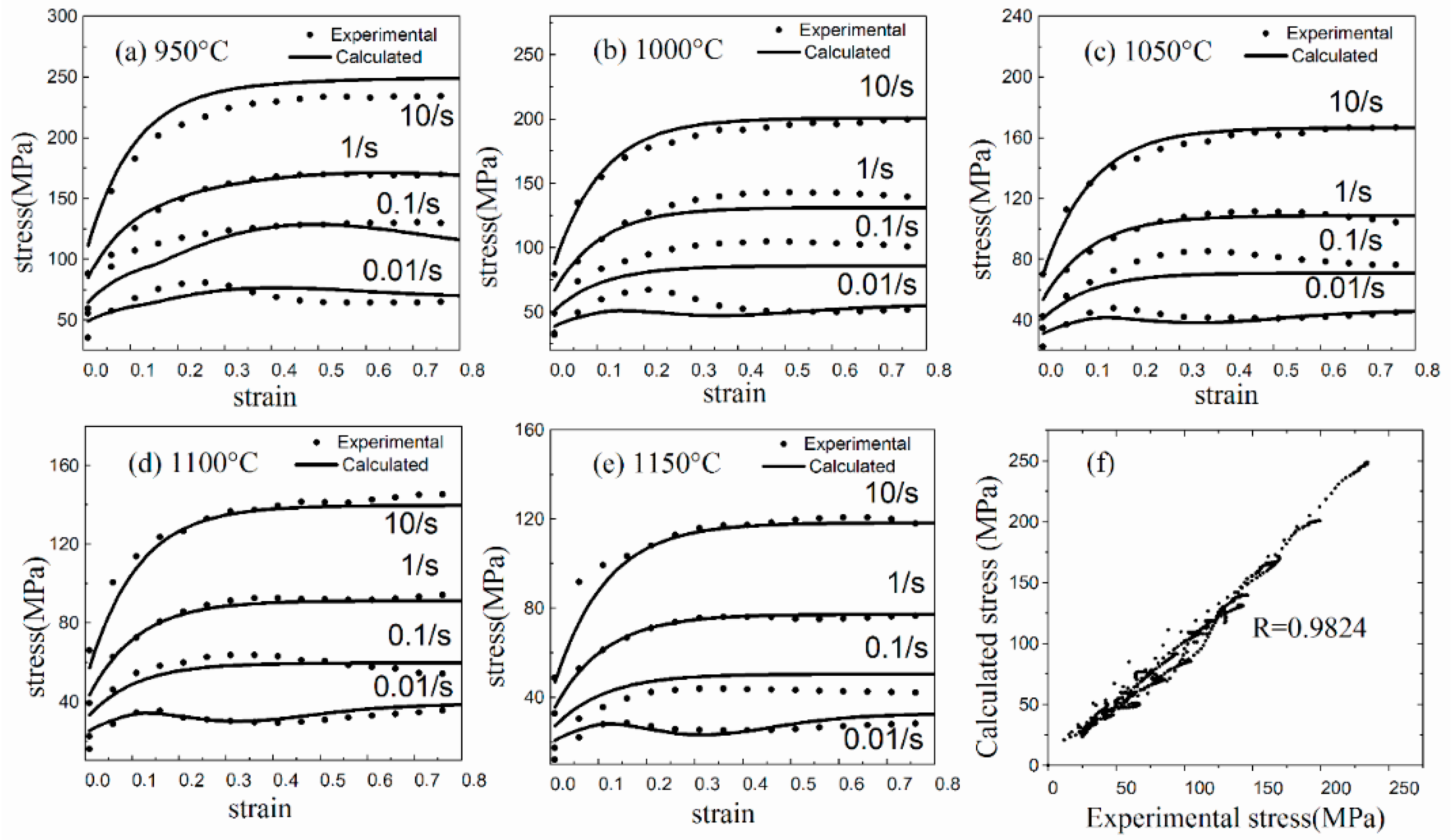

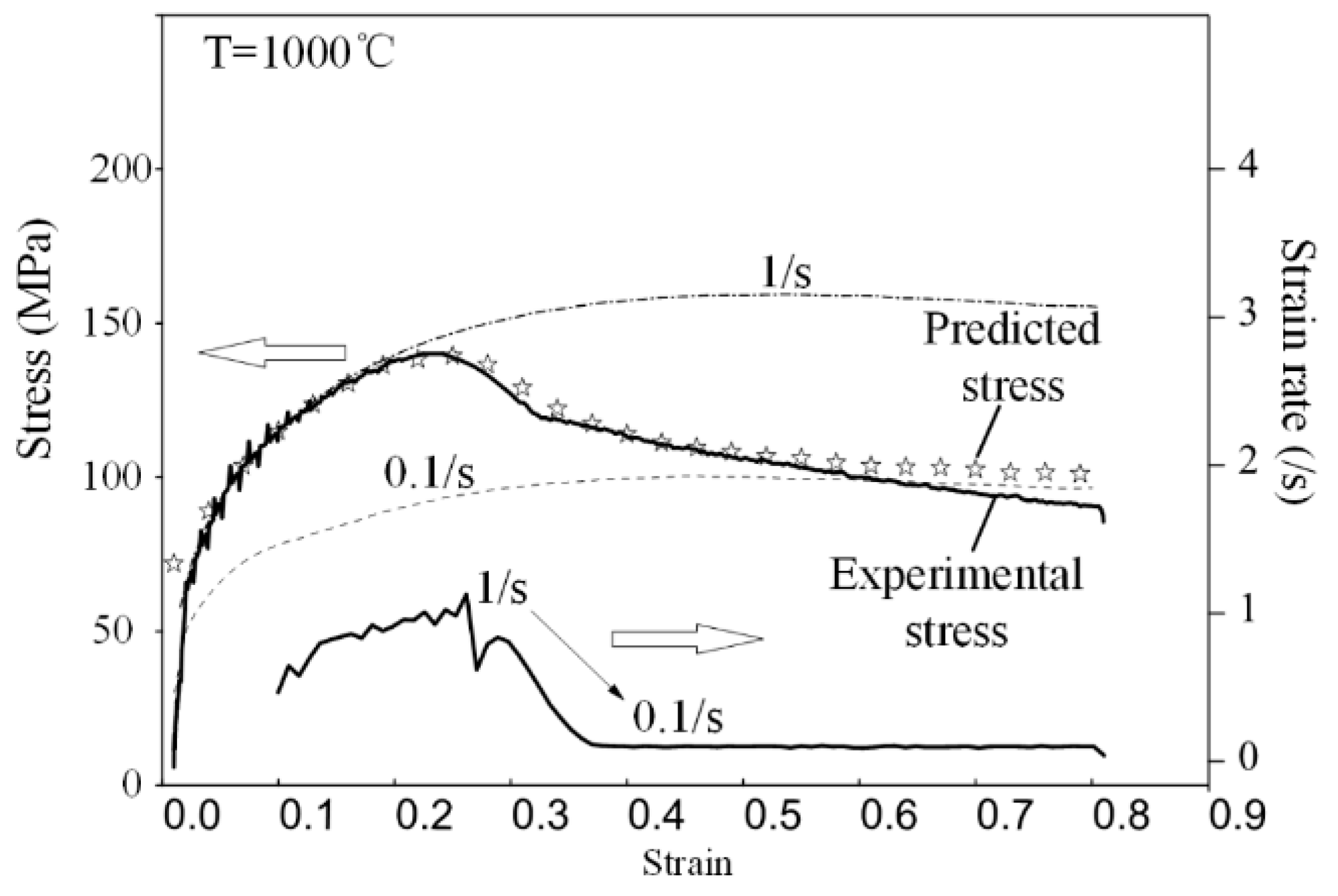

3.5. Verification and Comparison

4. Conclusions

- (1)

- A dislocation based flow stress model was proposed to take into consideration of dynamic recrystallization and Hall-Petch effect. The model was unified both at the recovery stage and at the recrystallization stage.

- (2)

- Microstructure evolution in dynamic recrystallization of 300M steel was established via metallography. The dynamic recrystallization of 300M steel was described in terms of the dynamic recrystallization volume fraction model and the average grain size model, which were determined by fitting.

- (3)

- Flow stress model parameters were obtained by an iterative procedure implemented in Matlab software. A comparison between predicted and experimental flow stresses both at constant strain rate compressions and at variable strain rate compressions was made, and results showed a high precision in flow stress prediction of 300M steel.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Samantaray, D.; Mandal, S.; Bhaduri, A.K. A comparative study on Johnson-Cook, modified Zerilli-Armstrong and Arrhenius-type constitutive models to predict elevated temperature flow behaviour in modified 9Cr-1Mo steel. Comput. Mater. Sci. 2009, 47, 568–576. [Google Scholar] [CrossRef]

- Li, H.; He, L.; Zhao, G.; Zhang, L. Constitutive relationships of hot stamping boron steel B1500HS based on the modified Arrhenius and Johnson–Cook model. Mater. Sci. Eng. A 2013, 580, 330–348. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, J.; Zhai, R.X.; Ma, R. Arrhenius-Type Constitutive Model and Dynamic Recrystallization Behavior of 20Cr2Ni4A Alloy Carburizing Steel. Steel Res. Int. 2016, 88, 1–9. [Google Scholar] [CrossRef]

- Mirzadeh, H. Constitutive modeling and prediction of hot deformation flow stress under dynamic recrystallization conditions. Mech. Mater. 2015, 85, 66–79. [Google Scholar] [CrossRef]

- Quan, G.; Mao, Y.; Li, G.; Lv, W.; Wang, Y.; Zhou, J. A characterization for the dynamic recrystallization kinetics of as-extruded 7075 aluminum alloy based on true stress-strain curves. Comput. Mater. Sci. 2012, 55, 65–72. [Google Scholar] [CrossRef]

- Yin, F.; Hua, L.; Mao, H.; Han, X. Constitutive modeling for flow behavior of GCr15 steel under hot compression experiments. Mater. Des. 2013, 43, 393–401. [Google Scholar] [CrossRef]

- Shu, X.; Lu, S.; Wang, K.; Li, G. A comparative study on constitutive equations and artificial neural network model to predict high-temperature deformation behavior in Nitinol 60 shape memory alloy. J. Mater. Res. 2015, 30, 1988–1998. [Google Scholar] [CrossRef]

- Yang, Y.Y.; Linkens, D.A.; Mahfouf, M. Genetic algorithms and hybrid neural network modelling for aluminium stress-strain prediction. Proc. Inst. Mech. Eng. 2003, 217, 7–21. [Google Scholar] [CrossRef]

- Srinivasu, G.S.; Rao, R.N. Artificial neural network approach for prediction of stress-strain curve of near β titanium alloy. Rare Met. 2013, 33, 249–257. [Google Scholar] [CrossRef]

- Zerilli, F.J.; Armstrong, R.W. Dislocation-mechanics-based constitutive relations for material dynamics calculations. J. Appl. Phys. 1987, 61, 1816–1825. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.-M. A combined Johnson–Cook and Zerilli–Armstrong model for hot compressed typical high-strength alloy steel. Comput. Mater. Sci. 2010, 49, 628–633. [Google Scholar] [CrossRef]

- He, A.; Xie, G.; Zhang, H.; Wang, X. A modified Zerilli–Armstrong constitutive model to predict hot deformation behavior of 20CrMo alloy steel. Mater. Des. 2014, 56, 122–127. [Google Scholar] [CrossRef]

- Cai, J.; Wang, K.; Han, Y. A Comparative Study on Johnson Cook, Modified Zerilli–Armstrong and Arrhenius-Type Constitutive Models to Predict High-Temperature Flow Behavior of Ti–6Al–4V Alloy in α + β Phase. High Temp. Mater. Process. 2016, 35, 297–307. [Google Scholar] [CrossRef]

- Puchi-Cabrera, E.S.; Guérin, J.-D.; Dubar, M.; Staia, M.H.; Lesage, J.; Chicot, D. Constitutive description for the design of hot-working operations of a 20MnCr5 steel grade. Mater. Des. 2014, 62, 255–264. [Google Scholar] [CrossRef]

- Chen, X.-M.; Lin, Y.C.; Wen, D.-X.; Zhang, J.-L.; He, M. Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation. Mater. Des. 2014, 57, 568–577. [Google Scholar] [CrossRef]

- Mecking, H.; Kocks, U.F. Kinetics of flow and strain-hardening. Acta Metall. 1981, 29, 1865–1875. [Google Scholar] [CrossRef]

- Pesin, A.; Korchunov, A.; Pustovoytov, D. Numerical Study of Grain Evolution and Dislocation Density during Asymmetric Rolling of Aluminum Alloy 7075. Key Eng. Mater. 2016, 685, 162–166. [Google Scholar] [CrossRef]

- Florando, J.N.; El-Dasher, B.S.; Chen, C.; Swift, D.C.; Barton, N.R.; McNaney, J.M.; Ramesh, K.T.; Hemker, K.J.; Kumar, M. Effect of strain rate and dislocation density on the twinning behavior in Tantalum. AIP Adv. 2016, 6, 1–157. [Google Scholar] [CrossRef]

- Goetz, R.; Seetharaman, V. Modeling Dynamic Recrystallization Using Cellular Automata. Scr. Mater. 1998, 38, 405–413. [Google Scholar] [CrossRef]

- Kim, S.-I.; Yoo, Y.-C. Dynamic recrystallization behavior of AISI 304 stainless steel. Mater. Sci. Eng. A 2001, 311, 108–113. [Google Scholar] [CrossRef]

- Laasraoui, A.; Jonas, J.J. Prediction of steel flow stresses at high temperatures and strain rates. Metall. Trans. A 1991, 22, 1545–1558. [Google Scholar] [CrossRef]

- Gurla, P.V.S.S. An Improved Dislocation Density Based Work Hardening Model for Al-Alloys; Aachen University: Aachen, Germany, 2007. [Google Scholar]

- Liu, J.; Edberg, J.; Tan, M.J.; Lindgren, L.E.; Castagne, S.; Jarfors, A.E.W. Finite element modelling of superplastic-like forming using a dislocation density-based model for AA5083. Model. Simul. Mater. Sci. Eng. 2013, 21, 25006–25028. [Google Scholar] [CrossRef]

- Svoboda, A.; Wedberg, D.; Lindgren, L.-E. Simulation of metal cutting using a physically based plasticity model. Model. Simul. Mater. Sci. Eng. 2010, 18, 1825–1830. [Google Scholar] [CrossRef]

- Evers, L.; Brekelmans, W.A.; Geers, M.G. Scale dependent crystal plasticity framework with dislocation density and grain boundary effects. Int. J. Solids Struct. 2004, 41, 5209–5230. [Google Scholar] [CrossRef]

- Lin, Y.C.; Wen, D.-X.; Chen, M.-S.; Liu, Y.-X.; Chen, X.-M.; Ma, X. Improved dislocation density-based models for describing hot deformation behaviors of a Ni-based superalloy. J. Mater. Res. 2016, 31, 2415–2429. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Chapter 2. The Deformed State. In Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2004; Volume 64, pp. 219–224. [Google Scholar]

- Chen, F.; Cui, Z.; Chen, S. Recrystallization of 30Cr2Ni4MoV ultra-super-critical rotor steel during hot deformation. Part Ш: Metadynamic recrystallization. Mater. Sci. Eng. A 2011, 528, 5073–5080. [Google Scholar] [CrossRef]

- Liu, Y.-X.; Lin, Y.C.; Li, H.-B.; Wen, D.-X.; Chen, X.-M.; Chen, M.-S. Study of dynamic recrystallization in a Ni-based superalloy by experiments and cellular automaton model. Mater. Sci. Eng. A 2015, 626, 432–440. [Google Scholar] [CrossRef]

- Puchi-Cabreraabc, E.S.; Guérind, J.D.; Dubard, M.; Staiaab, M.H.; Lesagec, J.; Chicotc, D. Constitutive description of Fe-Mn23-C0.6 steel deformed under hot-working conditions. Int. J. Mech. Sci. 2015, 99, 143–153. [Google Scholar] [CrossRef]

- Lao, L.; Ruimi, A.; Zbib, H.M. A dislocation-based model for deformation and size effect in multi-phase steels. Int. J. Plast. 2015, 72, 44–59. [Google Scholar] [CrossRef]

| Parameters | Value | Unit | Ref. |

|---|---|---|---|

| 0.3 | — | [22] | |

| 86.94 − 0.027T | GPa | [23] | |

| M | 3.06 | — | [22] |

| b | 2.54 × 10−10 | m | [24] |

| Parameters | |||

|---|---|---|---|

| 5.87 × 103 | −1.83 × 10−1 | 2.66 × 105 | |

| 1.35 × 101 | −1.60 × 10−3 | −2.42 × 106 | |

| 1.19 × 10−3 | −2.88 × 100 | 2.17 × 104 | |

| 6.33 × 10−43 | −4.95 × 10−1 | −2.28 × 106 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, R.; Guo, P.; Zheng, Z.; Li, J.; Feng, F. Dislocation Based Flow Stress Model of 300M Steel in Isothermal Compression Process. Materials 2018, 11, 972. https://doi.org/10.3390/ma11060972

Chen R, Guo P, Zheng Z, Li J, Feng F. Dislocation Based Flow Stress Model of 300M Steel in Isothermal Compression Process. Materials. 2018; 11(6):972. https://doi.org/10.3390/ma11060972

Chicago/Turabian StyleChen, Rongchuang, Peng Guo, Zhizhen Zheng, Jianjun Li, and Fei Feng. 2018. "Dislocation Based Flow Stress Model of 300M Steel in Isothermal Compression Process" Materials 11, no. 6: 972. https://doi.org/10.3390/ma11060972

APA StyleChen, R., Guo, P., Zheng, Z., Li, J., & Feng, F. (2018). Dislocation Based Flow Stress Model of 300M Steel in Isothermal Compression Process. Materials, 11(6), 972. https://doi.org/10.3390/ma11060972