Evaluation of Fine Aggregate Morphology by Image Method and Its Effect on Skid-Resistance of Micro-Surfacing

Abstract

:1. Introduction

2. Materials and Research Methodologies

- Three types of fine aggregate are chosen which are steel slag, basalt, and limestone. Three grades 0.6–1.18, 1.18–2.36, and 2.36–4.75 are selected for each type of aggregate.

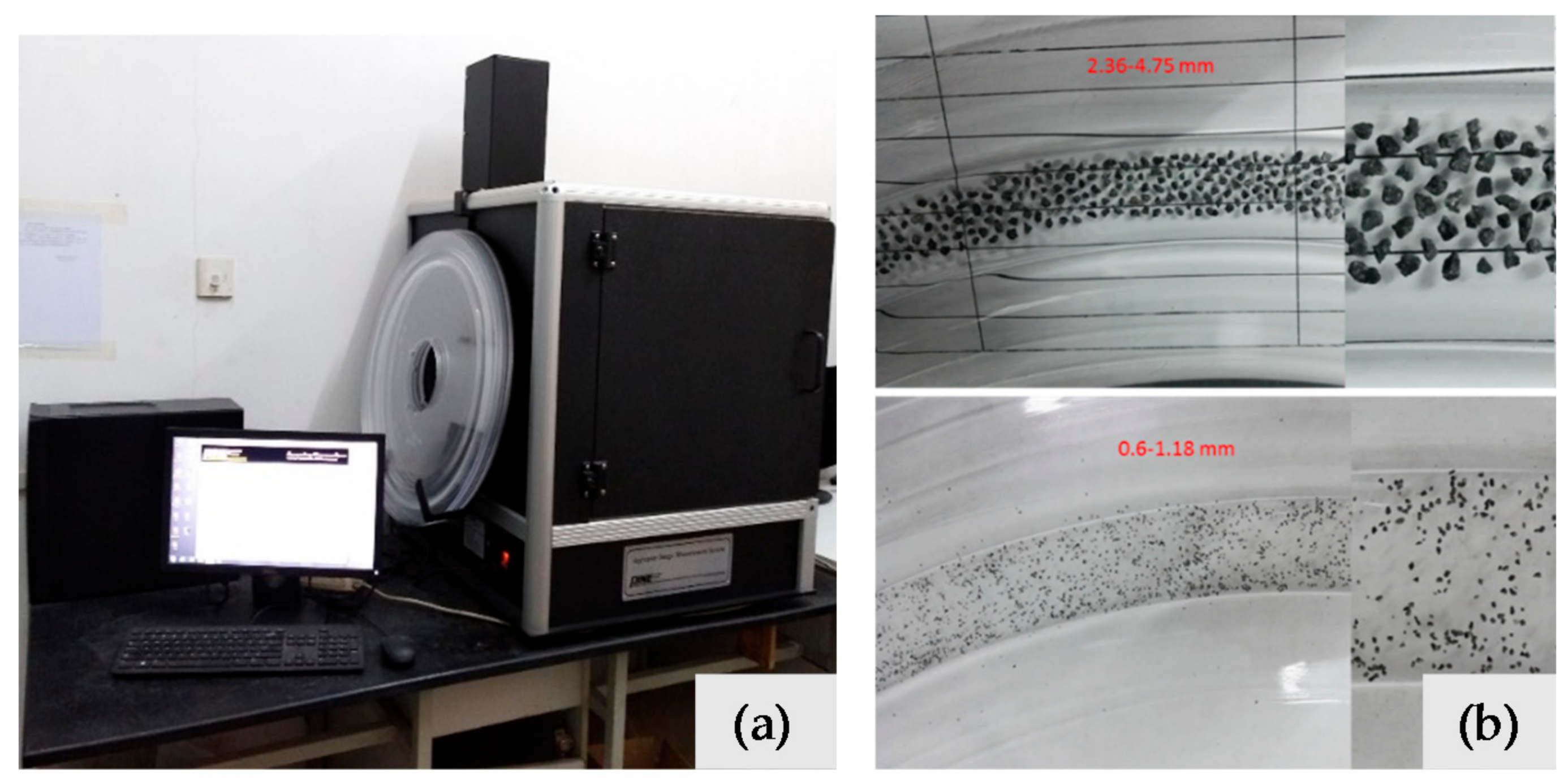

- AIMS was used to evaluate morphological characteristics of nine (3 × 3) kinds of fine aggregates.

- Modified emulsified asphalt used in micro-surfacing was prepared.

- Nine kinds of micro-surfacing slurry mixture with single-grade aggregate was prepared, corresponding to nine kinds of aggregate. Another normal-grade micro-surfacing mixture was also prepared for comparison with single-grade micro-surfacing. There are, in total, 10 kinds of micro-surfacing in this study.

- Sand patch test, British pendulum test, and image method were used to evaluate the skid-resistance of micro-surfacing. Wet abrasion test was used to test durability for verifying feasibility of single-grade micro-surfacing.

2.1. Materials

2.1.1. Aggregates

2.1.2. Modified Emulsified Asphalt

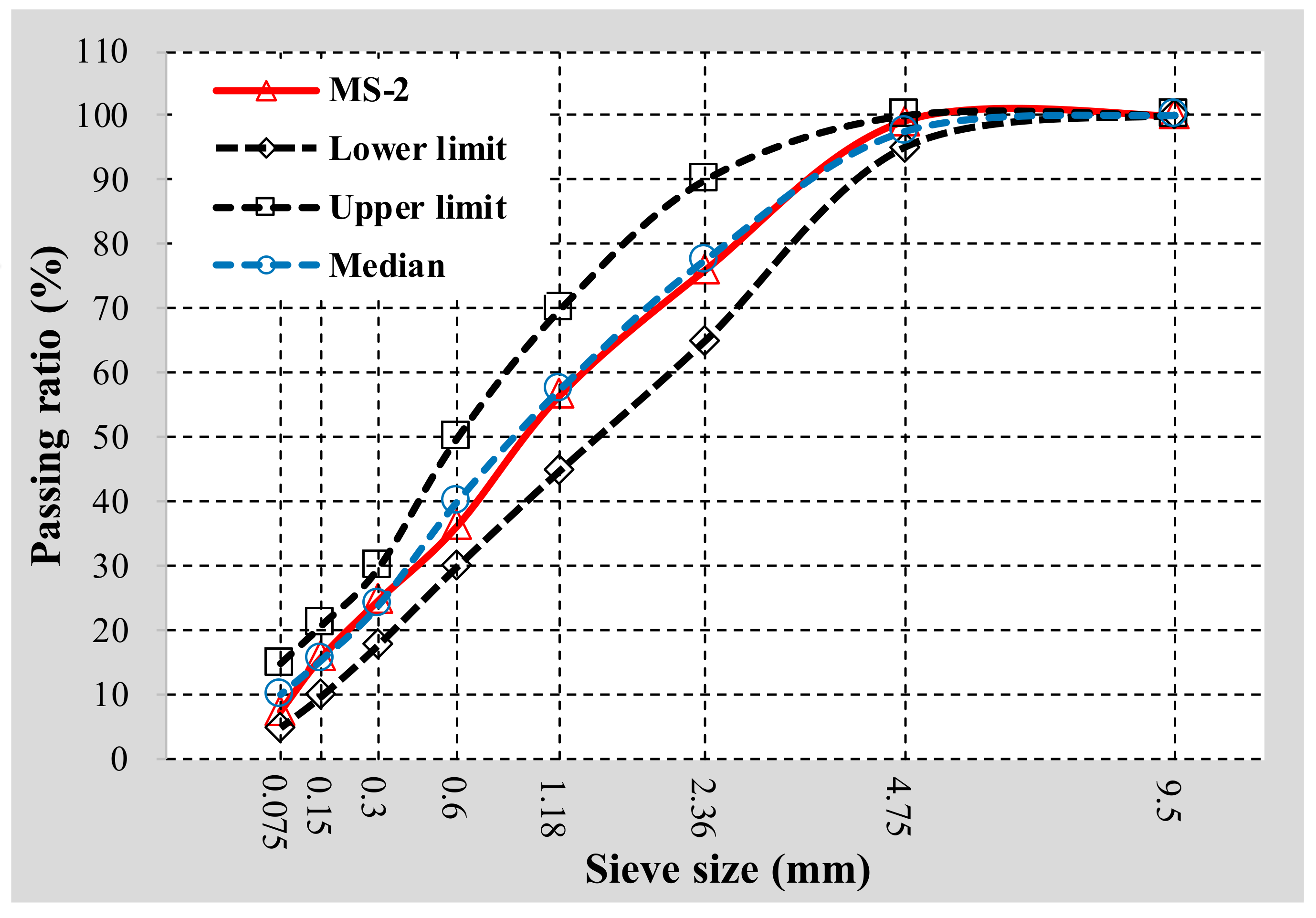

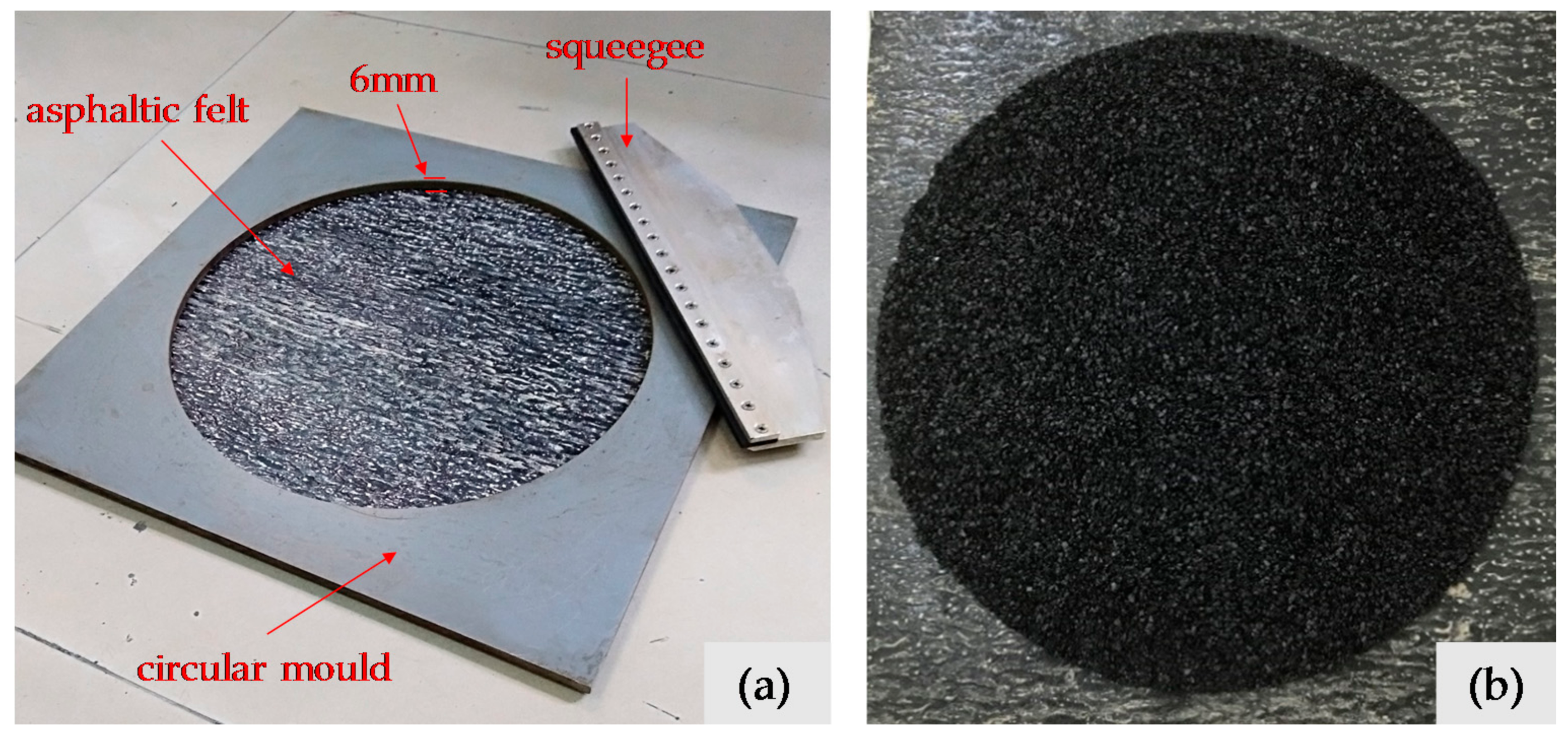

2.1.3. Micro-Surfacing Mixture

2.2. Research Methodologies

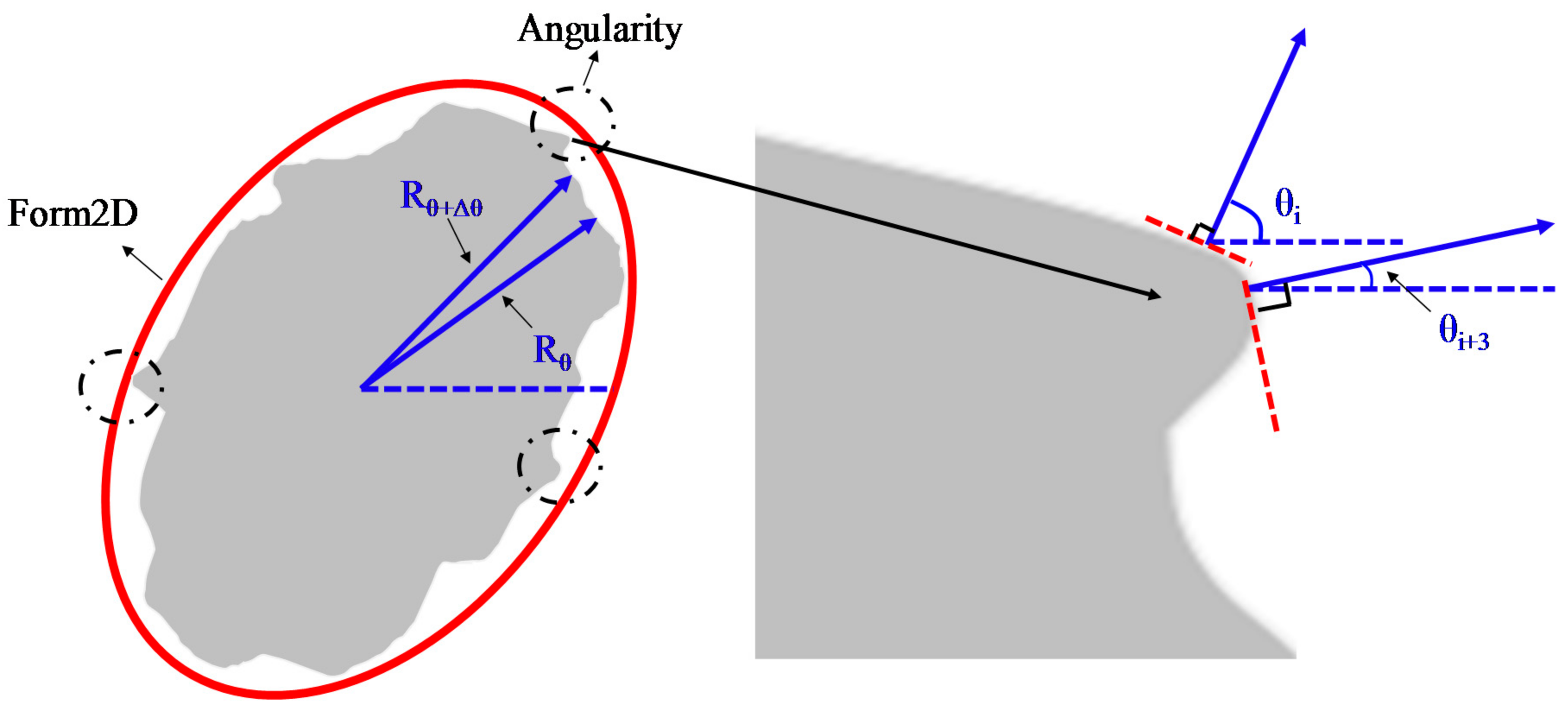

2.2.1. Aggregates Morphology Test

2.2.2. Micro-Surfacing Skid-Resistance Test

2.2.3. Wet Abrasion Test

3. Results and Discussions

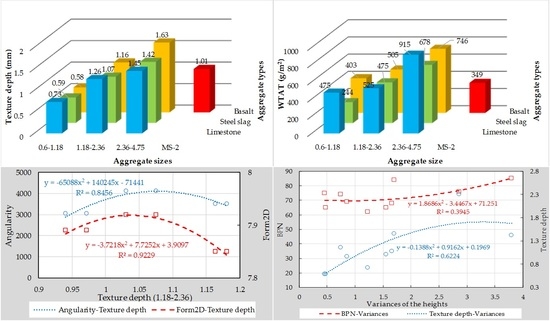

3.1. Fine Aggregates Morphology Characteristics

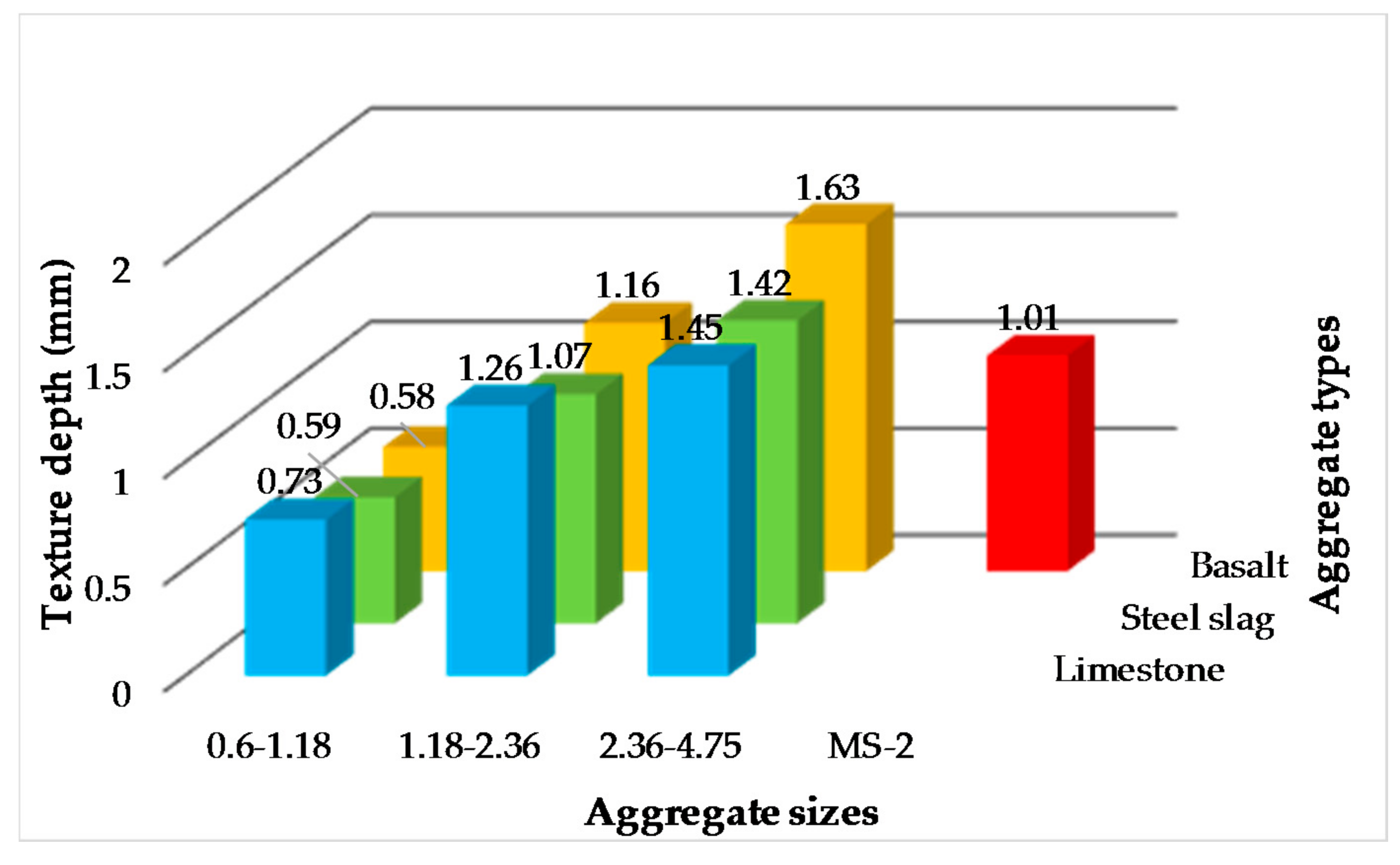

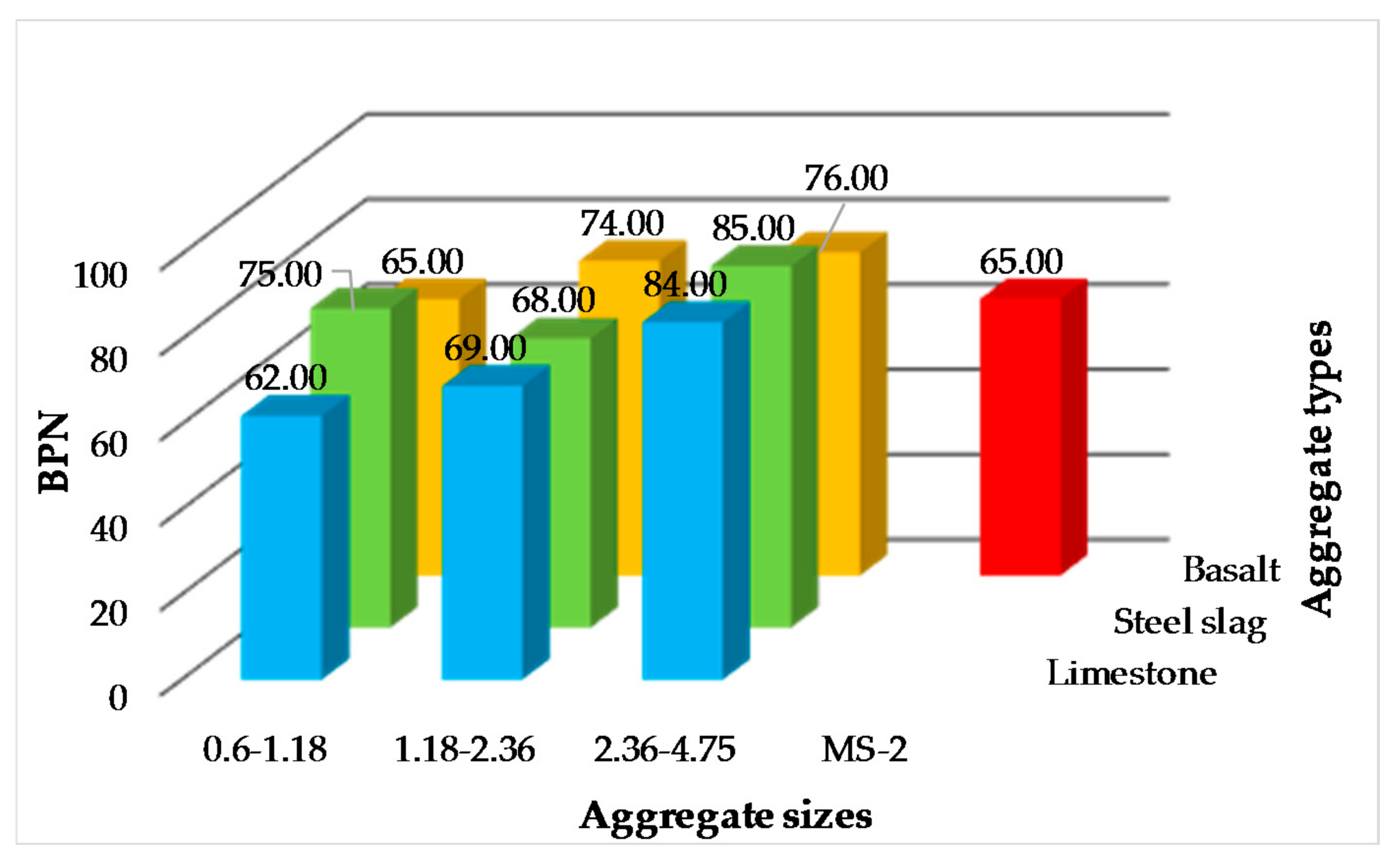

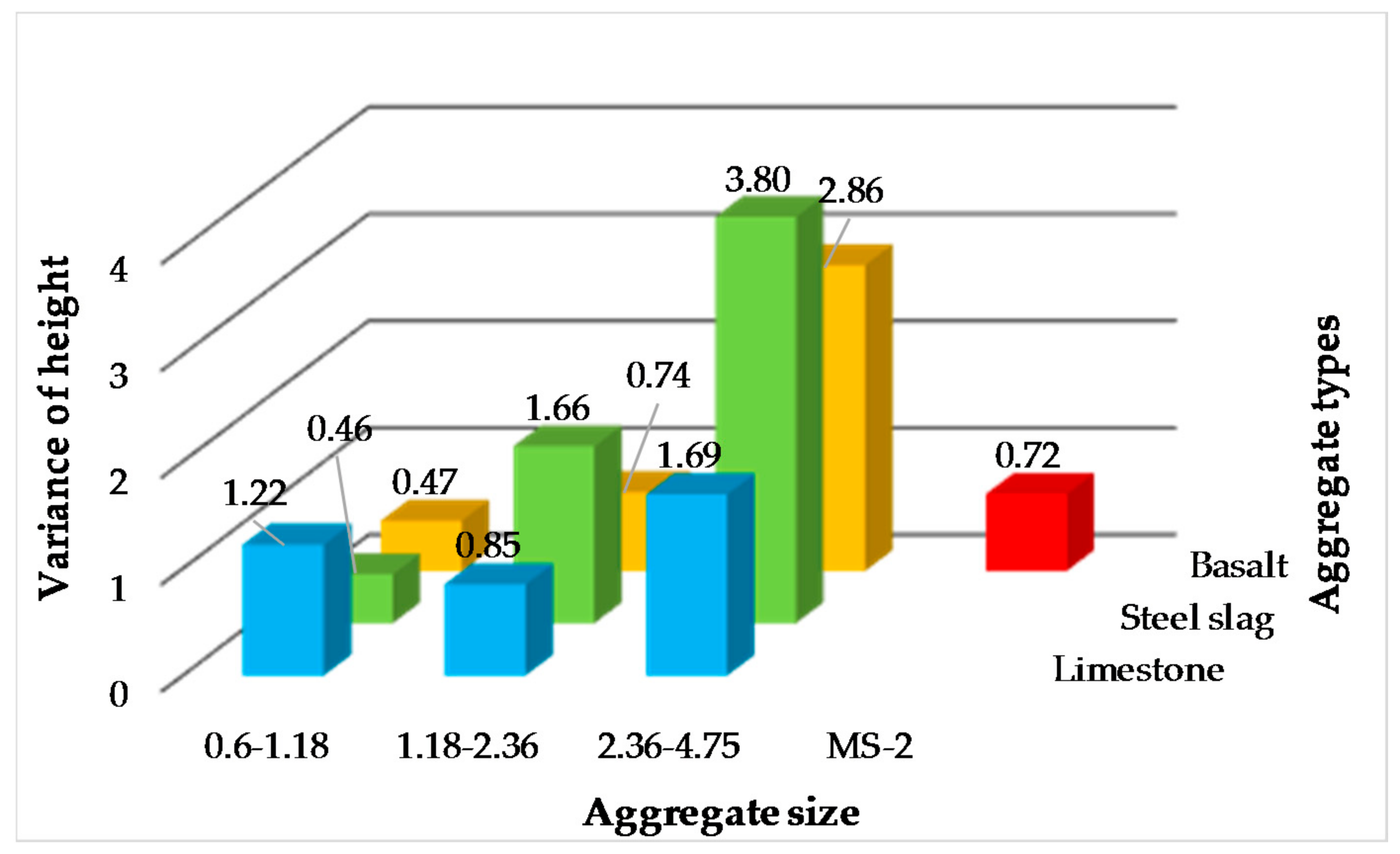

3.2. Skid-Resistance and Feasibility of Micro-Surfacing

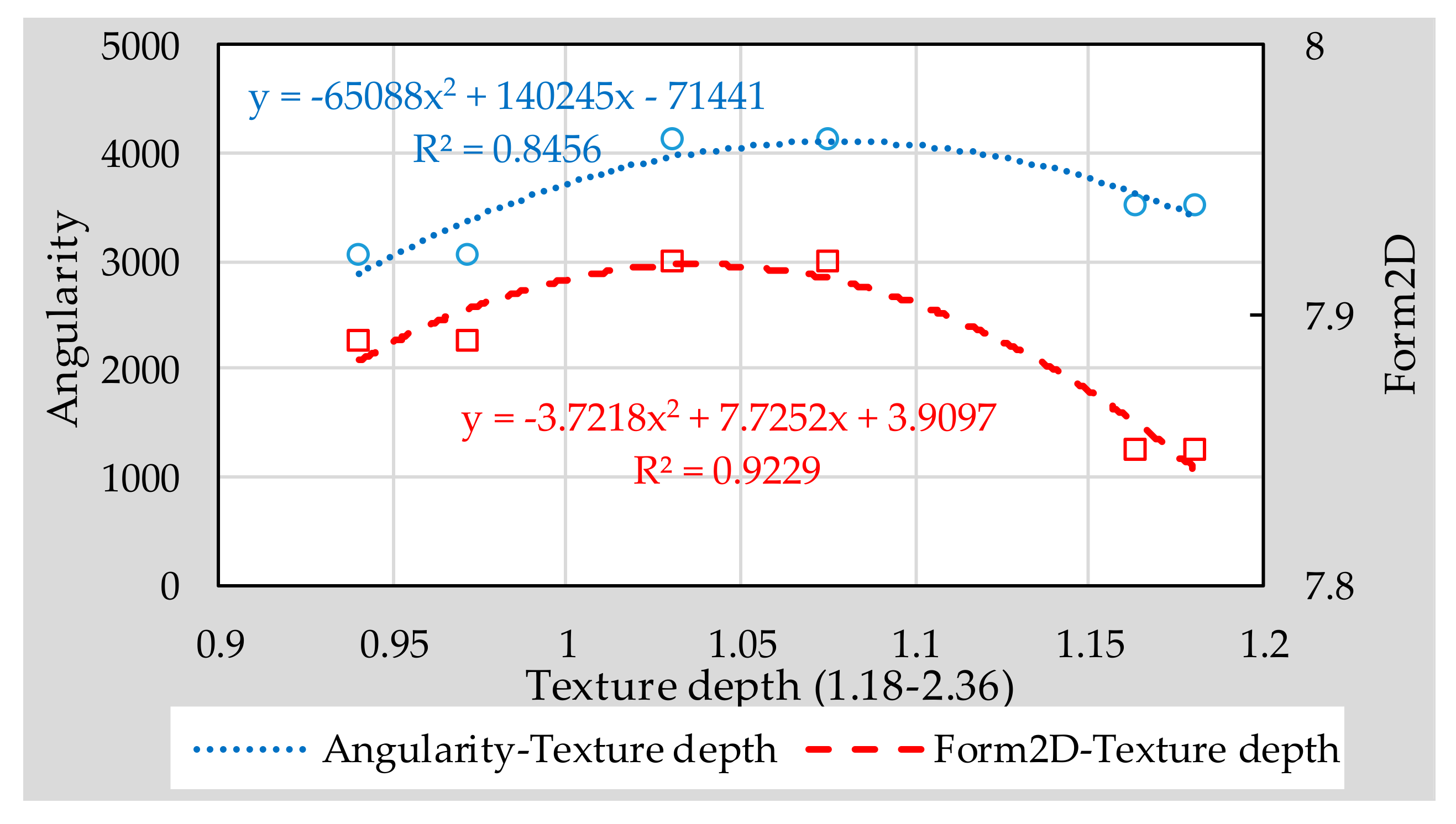

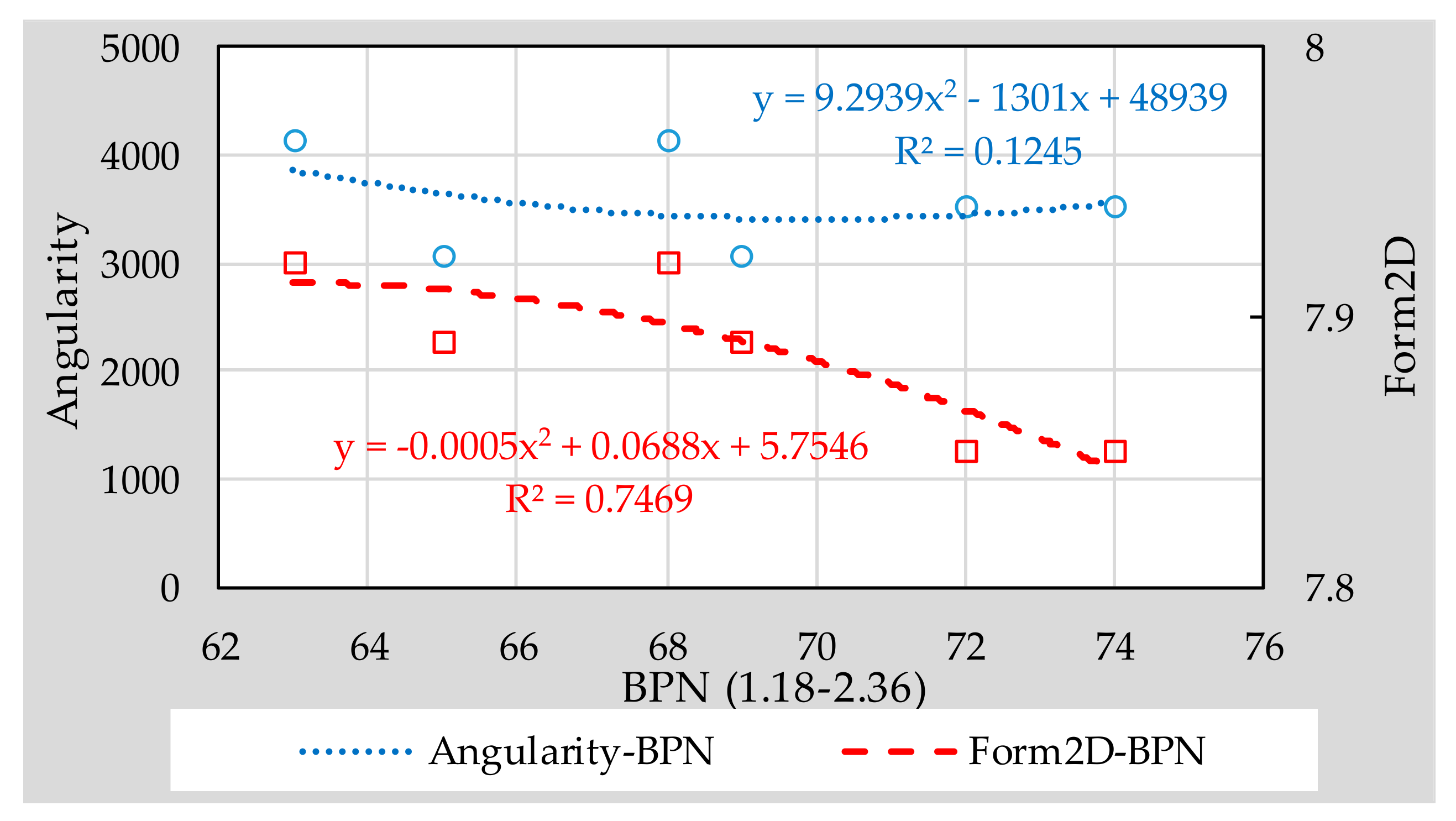

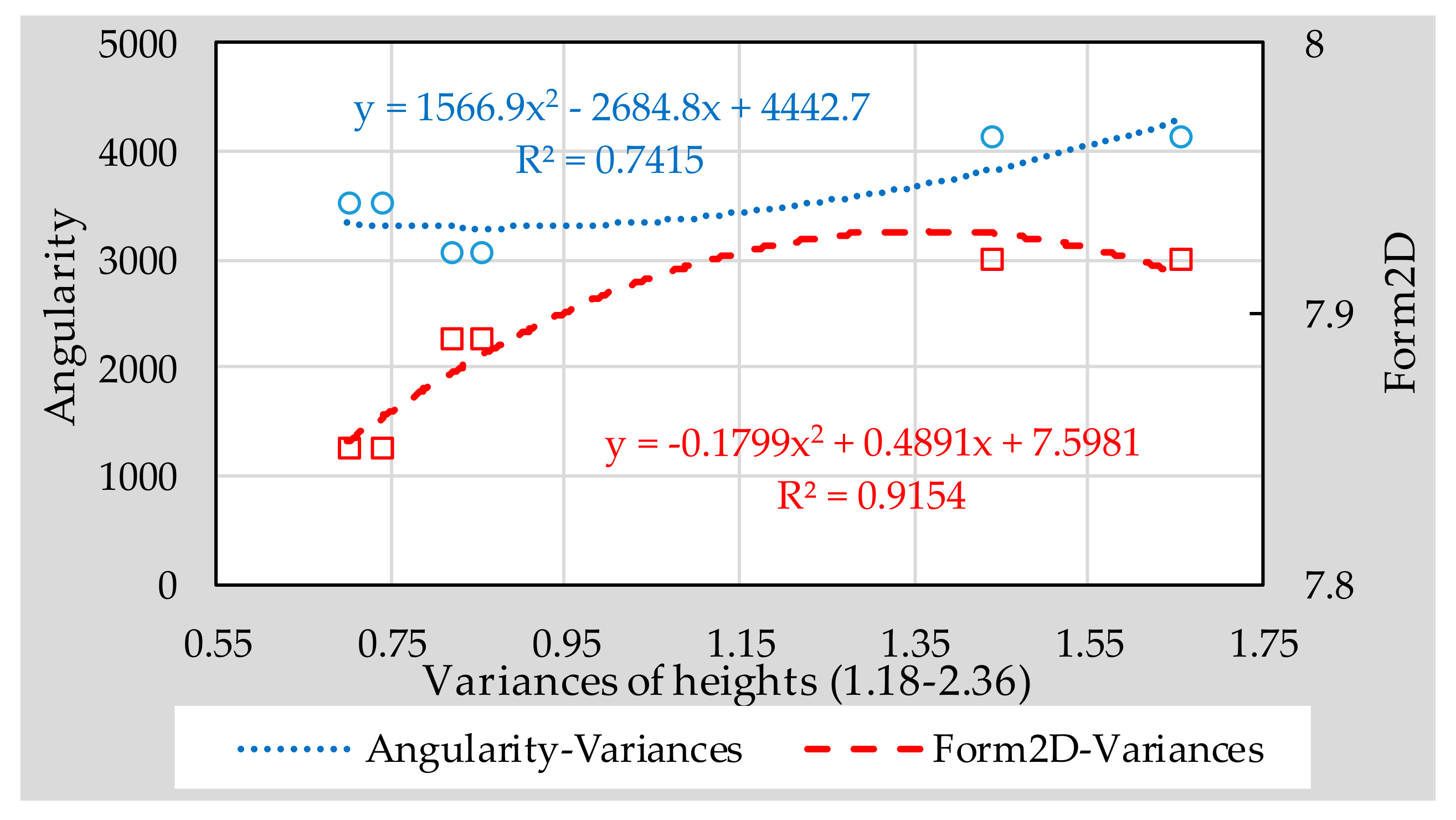

3.3. Correlation between Aggregate Morphology and Skid-Resistance

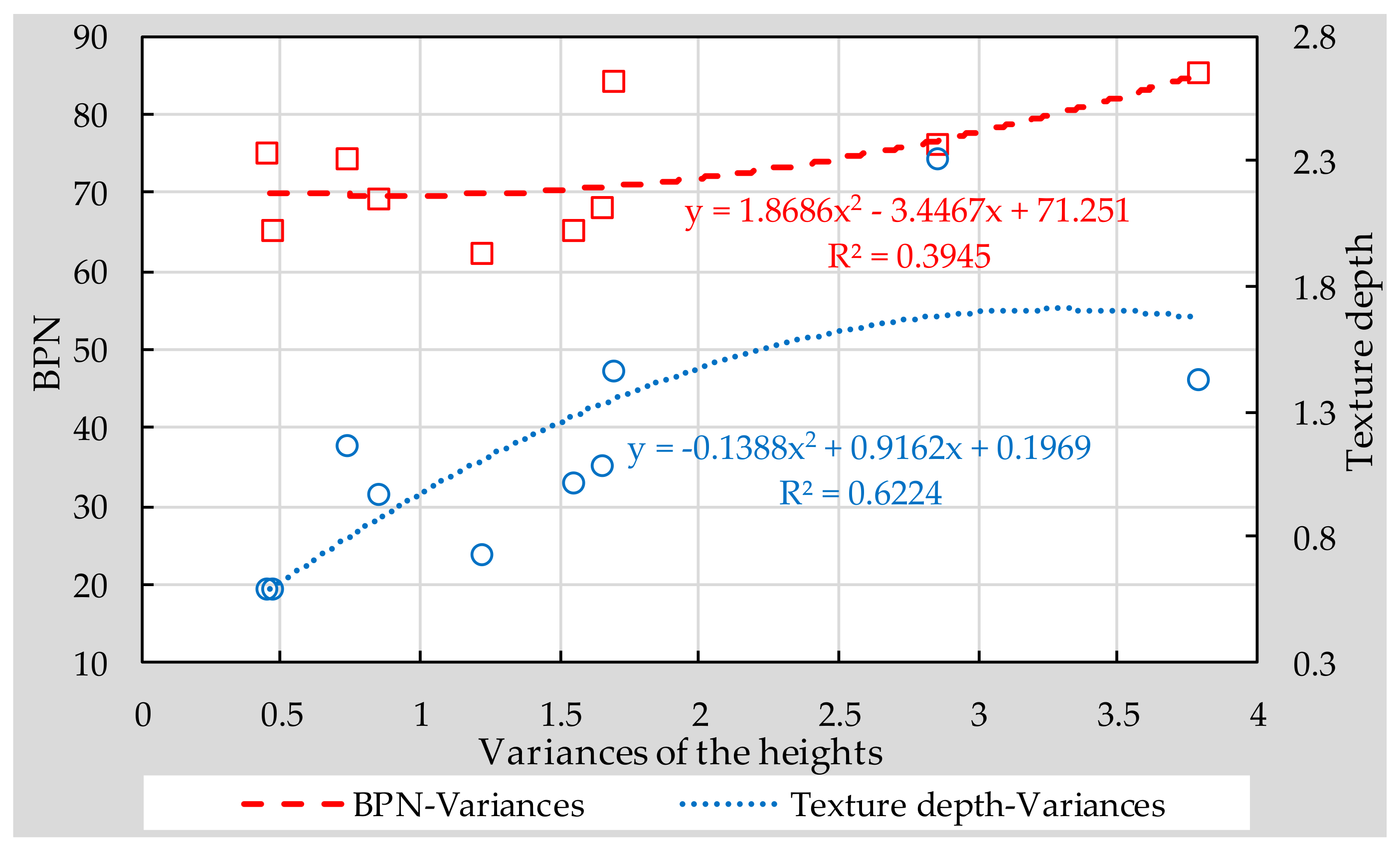

3.4. Correlation between Traditional Test and Digital Image Method

4. Conclusions

- Single-grade micro-surfacing can indeed increase the surface texture characteristics compared with standard micro-surfacing, thus increasing the skid-resistance.

- Combining the feasibility analysis of durability and skid-resistance, it can be summarized that the 1.18–2.36 type micro-surfacing meets the requirements of durability and skid-resistance at the same time.

- Form2D and angularity were characterized as morphologic indices of fine aggregates. Research results indicated that the effect of Form2D on skid-resistance of micro-surfacing is much stronger than that of angularity. Compared with BPN results, height of variance and texture depth correlated better with Form2D.

- The texture result obtained by sand patch test fits better with results of image method compared with British pendulum test. However, both of them are not strong.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Wang, Z.J.; Gao, J.; Ai, T.; Zhao, P. Laboratory investigation on microwave deicing function of micro surfacing asphalt mixtures reinforced by carbon fiber. J. Test. Eval. 2014, 42, 498–507. [Google Scholar] [CrossRef]

- Yu, J.M.; Zhang, X.N.; Xiong, C.L. A methodology for evaluating micro-surfacing treatment on asphalt pavement based on grey system models and grey rational degree theory. Constr. Build. Mater. 2017, 150, 214–226. [Google Scholar] [CrossRef]

- Xiu, S.C.; Liu, M.H.; Chao, C.X.; Li, S.J. Study on micro-surface texture and tribology characters of ground surface in point grinding process. Int. J. Surf. Sci. Eng. 2014, 8, 225–238. [Google Scholar]

- Kamaraj, C.; Lakshmi, S.; Rose, C.; Mani, U.; Paul, E.; Mandal, A.B.; Gangopadhyay, S. Experimental study on micro surfacing using chrome shaving impregnated with modified bitumen emulsion. J. Sci. Ind. Res. 2016, 75, 378–382. [Google Scholar]

- Huang, C.Y.; Huang, X. Effects of pavement texture on pavement friction: A review. Int. J. Veh. Des. 2014, 65, 256–269. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, Y.; Wu, S.; Yi, M. Assessment of bonding behaviours between ultrathin surface layer and asphalt mixture layer using modified pull test. J. Adhes. Sci. Technol. 2015, 29, 1508–1521. [Google Scholar] [CrossRef]

- Asi, I.M. Evaluating skid resistance of different asphalt concrete mixes. Build. Environ. 2007, 42, 325–329. [Google Scholar] [CrossRef]

- Kogbara, R.B.; Masad, E.A.; Kassem, E.; Scarpas, A.; Anupam, K. A state-of-the-art review of parameters influencing measurement and modeling of skid resistance of asphalt pavements. Constr. Build. Mater. 2016, 114, 602–617. [Google Scholar] [CrossRef]

- Fwa, T.F. Skid resistance determination for pavement management and wet-weather road safety. Int. J. Transp. Sci. Technol. 2017, 6, 217–227. [Google Scholar] [CrossRef]

- Kanafi, M.M.; Kuosmanen, A.; Pellinen, T.K.; Tuononen, A.J. Macro- and micro-texture evolution of road pavements and correlation with friction. Int. J. Pavement Eng. 2015, 16, 168–179. [Google Scholar] [CrossRef]

- Pratico, F.G.; Astolfi, A. A new and simplified approach to assess the pavement surface micro-and macrotexture. Constr. Build. Mater. 2017, 148, 476–483. [Google Scholar] [CrossRef]

- Kong, D.; Xiao, Y.; Wu, S.; Tang, N.; Ling, J.; Wang, F. Comparative evaluation of designing asphalt treated base mixture with composite aggregate types. Constr. Build. Mater. 2017, 156, 819–827. [Google Scholar] [CrossRef]

- Cui, P.; Wu, S.; Xiao, Y.; Wan, M.; Cui, P. Inhibiting effect of layered double hydroxides on the emissions of volatile organic compounds from bituminous materials. J. Clean. Prod. 2015, 108, 987–991. [Google Scholar] [CrossRef]

- Amarasiri, S.; Gunaratne, M.; Sarkar, S. Use of digital image modeling for evaluation of concrete pavement macrotexture and wear. J. Transp. Eng. 2012, 138, 589–602. [Google Scholar] [CrossRef]

- Araujo, V.M.C.; Bessa, I.S.; Castelo Branco, V.T.F. Measuring skid resistance of hot mix asphalt using the aggregate image measurement system (aims). Constr. Build. Mater. 2015, 98, 476–481. [Google Scholar] [CrossRef]

- Loprencipe, G.; Cantisani, G. Unified analysis of road pavement profiles for evaluation of surface characteristics. Mod. Appl. Sci. 2013, 7, 1–14. [Google Scholar] [CrossRef]

- Chen, J.; Wang, H.; Li, L. Virtual testing of asphalt mixture with two-dimensional and three-dimensional random aggregate structures. Int. J. Pavement Eng. 2015, 18, 824–836. [Google Scholar] [CrossRef]

- Mahmoud, E.; Gates, L.; Masad, E.; Erdogan, S.; Garboczi, E. Comprehensive evaluation of aims texture, angularity, and dimension measurements. J. Mater. Civ. Eng. 2010, 22, 369–379. [Google Scholar] [CrossRef]

- Wang, L.B.; Sun, W.J.; Tutumluer, E.; Druta, C. Evaluation of aggregate imaging techniques for quantification of morphological characteristics. Transp. Res. Rec. 2013, 2335, 39–49. [Google Scholar] [CrossRef]

- Bessa, I.S.; Franco Castelo Branco, V.T.; Soares, J.B. Evaluation of polishing and degradation resistance of natural aggregates and steel slag using the aggregate image measurement system. Road Mater. Pavement Des. 2014, 15, 385–405. [Google Scholar] [CrossRef]

- Ding, X.; Ma, T.; Gao, W. Morphological characterization and mechanical analysis for coarse aggregate skeleton of asphalt mixture based on discrete-element modeling. Constr. Build. Mater. 2017, 154, 1048–1061. [Google Scholar] [CrossRef]

- Puzzo, L.; Loprencipe, G.; Tozzo, C.; D’Andrea, A. Three-dimensional survey method of pavement texture using photographic equipment. Measurement 2017, 111, 146–157. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, X.; Yu, J.; Wang, Y. Impact of contact stress distribution on skid resistance of asphalt pavements. Constr. Build. Mater. 2017, 133, 330–339. [Google Scholar] [CrossRef]

- El-Desouky, A. Investigating the effect of temperature variations on the measured airfield pavement skid resistance. Constr. Build. Mater. 2018, 161, 649–653. [Google Scholar] [CrossRef]

- Wang, D.; Leng, Z.; Yu, H.; Hueben, M.; Kollmann, J.; Oeser, M. Durability of epoxy-bonded tio2-modified aggregate as a photocatalytic coating layer for asphalt pavement under vehicle tire polishing. Wear 2017, 382, 1–7. [Google Scholar] [CrossRef]

- Xiao, F.; Punith, V.S.; Amirkhanian, S.N.; Thodesen, C. Improved resistance of long-term aged warm-mix asphalt to moisture damage containing moist aggregates. J. Mater. Civ. Eng. 2013, 25, 913–922. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, S.; Xiao, Y.; Zeng, W.; Yi, M.; Wan, J. Effect of hydration and silicone resin on basic oxygen furnace slag and its asphalt mixture. J. Clean. Prod. 2016, 112, 392–400. [Google Scholar] [CrossRef]

- ASTM. Test Method for Sand Equivalent Value of Soils and Fine Aggregate; D2419-02; ASTM: West Conshohocken, PA, USA, 2005. [Google Scholar]

- ASTM. Test Method for Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate; C0088-99A; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM. Test Method for Density, Relative Density (Specific Gravity), and Absorption of Fine Aggregate; C0128-04A; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM. Test Methods for Uncompacted Void Content of Fine Aggregate (as Influenced by Particle Shape, Surface Texture, and Grading); C1252-03; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Guo, Y.; Ma, B.; Zhi, Z.; Tan, H.; Liu, M.; Jian, S.; Guo, Y. Effect of polyacrylic acid emulsion on fluidity of cement paste. Coll. Surf. A Physicochem. Eng. Asp. 2017, 535, 139–148. [Google Scholar] [CrossRef]

- ASTM. Test Methods and Practices for Emulsified Asphalts; D0244-04; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM. Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer; D4402-02; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM. Test Method for Penetration of Bituminous Materials; D0005-05; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM. Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus); D0036-95R00E01; ASTM: West Conshohocken, PA, USA, 2005. [Google Scholar]

- ASTM. Test Method for Ductility of Bituminous Materials; D0113-99; ASTM: West Conshohocken, PA, USA, 2005. [Google Scholar]

- ASTM. Test Method for Solubility of Asphalt Materials in Trichloroethylene; D2042-01; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Chen, J.S.; Hsieh, W.; Liao, M.C. Effect of coarse aggregate shape on engineering properties of stone mastic asphalt applied to airport pavements. Int. J. Pavement Res. Technol. 2013, 6, 595–601. [Google Scholar]

- Fletcher, T.; Chandan, C.; Masad, E.; Sivakumar, K. Measurement of aggregate texture and its influence on hot mix asphalt (hma) permanent deformation. J. Test. Eval. 2002, 30, 524–531. [Google Scholar]

- Souza, L.T.; Kim, Y.R.; Souza, F.V.; Castro, L.S. Experimental testing and finite-element modeling to evaluate the effects of aggregate angularity on bituminous mixture performance. J. Mater. Civ. Eng. 2012, 24, 249–258. [Google Scholar] [CrossRef]

- Maerz, N.H. Technical and computational aspects of the measurement of aggregate shape by digital image analysis. J. Comput. Civ. Eng. 2004, 18, 10–18. [Google Scholar] [CrossRef]

- Bessa, I.S.; Castelo Branco, V.T.F.; Soares, J.B.; Nogueira Neto, J.A. Aggregate shape properties and their influence on the behavior of hot-mix asphalt. J. Mater. Civ. Eng. 2015, 27, 04014212. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Measuring Pavement Macrotexture Depth Using a Volumetric Technique; E965–96; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM. Standard Test Method for Measuring Surface Frictional Proprieties Using the British Pendulum Tester; E303–93; ASTM: West Conshohocken, PA, USA, 2005. [Google Scholar]

| Properties | Unit | Technical Requirements | Tested Value | Specification Used | ||

|---|---|---|---|---|---|---|

| Basalt | Limestone | Steel Slag | ||||

| Sand equivalent | % | ≥60 | 68 | 71 | 75 | ASTM D 2419 [28] |

| Soundness | % | ≥12 | 15.7 | 15.1 | 13.6 | ASTM C 88 [29] |

| Apparent relative density | — | ≥2.5 | 2.978 | 2.708 | 2.872 | ASTM C 128 [30] |

| Angularity | s | ≥30 | 42 | 45 | 43 | ASTM C 1252 [31] |

| Materials | Modified Emulsified Asphalt | Asphalt | Water | SBR | Emulsifier | Calcium Chloride | PVA |

|---|---|---|---|---|---|---|---|

| Weight (g) | 500 | 300 | 177 | 12 | 10 | 0.5 | 0.5 |

| Ratio (%) | 100 | 60 | 35.4 | 2.4 | 2 | 0.1 | 0.1 |

| Properties | Unit | Technical Requirements | Tested Value | Specification Used | |

|---|---|---|---|---|---|

| Sieve residue (1.18) | % | ≤0.1 | 0.04 | ASTM D 244 [33] | |

| Charge | — | + | + | ASTM D 244 [33] | |

| Rotary viscosity | Pa · s | — | 98 | ASTM D 4402 [34] | |

| Evaporated residue content | % | ≥60 | 62.5 | ASTM D 244 [33] | |

| Evaporated residue properties | Penetration | 0.1 mm | 40–100 | 57.3 | ASTM D 5 [35] |

| Softening point | °C | ≥53 | 54.8 | ASTM D 36 [36] | |

| Ductility | cm | ≥20 | 56 | ASTM D 113 [37] | |

| Solubility | % | ≥97.5 | 99.3 | ASTM D 2042 [38] | |

| Storage stability | 1 day | % | ≤1 | 0.1 | ASTM D 244 [33] |

| 5 day | % | ≤5 | 1.2 | ||

| Mixture Types | Limestone | Basalt | Steel Slag | MS-2 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.6–1.18 | 1.18–2.36 | 2.36–4.75 | 0.6–1.18 | 1.18–2.36 | 2.36–4.75 | 0.6–1.18 | 1.18–2.36 | 2.36–4.75 | ||

| Thickness (mm) | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Cement (%) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Water (%) | 9.5 | 8.5 | 7.5 | 9.5 | 8.5 | 7.5 | 9.5 | 8.5 | 7.5 | 10 |

| Asphalt-aggregate ratio (%) | 7.5 | 7 | 6.5 | 7.5 | 7 | 6.5 | 7.5 | 7 | 6.5 | 10 |

| Properties | Limestone | Basalt | Steel Slag | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.6–1.18 | 1.18–2.36 | 2.36–4.75 | 0.6–1.18 | 1.18–2.36 | 2.36–4.75 | 0.6–1.18 | 1.18–2.36 | 2.36–4.75 | |

| Angularity | 3285 | 3050 | 2923 | 3706 | 3502 | 3327 | 3789 | 4124 | 4546 |

| Form2D | 7.35 | 7.89 | 7.20 | 7.71 | 7.85 | 7.64 | 7.69 | 7.92 | 8.33 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Wang, F.; Cui, P.; Lei, L.; Lin, J.; Yi, M. Evaluation of Fine Aggregate Morphology by Image Method and Its Effect on Skid-Resistance of Micro-Surfacing. Materials 2018, 11, 920. https://doi.org/10.3390/ma11060920

Xiao Y, Wang F, Cui P, Lei L, Lin J, Yi M. Evaluation of Fine Aggregate Morphology by Image Method and Its Effect on Skid-Resistance of Micro-Surfacing. Materials. 2018; 11(6):920. https://doi.org/10.3390/ma11060920

Chicago/Turabian StyleXiao, Yue, Feng Wang, Peide Cui, Lei Lei, Juntao Lin, and Mingwei Yi. 2018. "Evaluation of Fine Aggregate Morphology by Image Method and Its Effect on Skid-Resistance of Micro-Surfacing" Materials 11, no. 6: 920. https://doi.org/10.3390/ma11060920

APA StyleXiao, Y., Wang, F., Cui, P., Lei, L., Lin, J., & Yi, M. (2018). Evaluation of Fine Aggregate Morphology by Image Method and Its Effect on Skid-Resistance of Micro-Surfacing. Materials, 11(6), 920. https://doi.org/10.3390/ma11060920