Fabrication of α-Fe/Fe3C/Woodceramic Nanocomposite with Its Improved Microwave Absorption and Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Preparation

2.2. Characterization

3. Results and Discussion

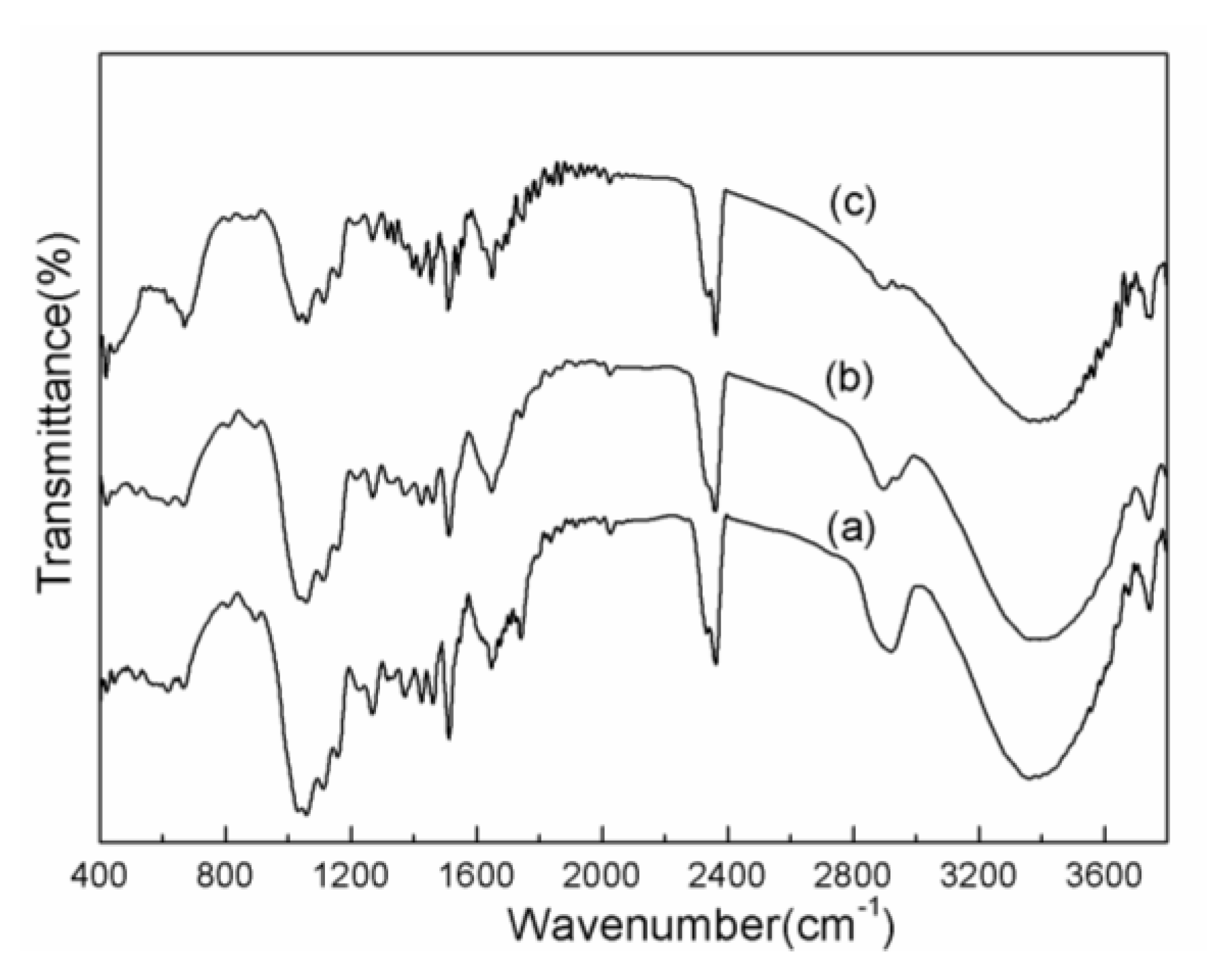

3.1. FTIR Analysis of Wood Powder

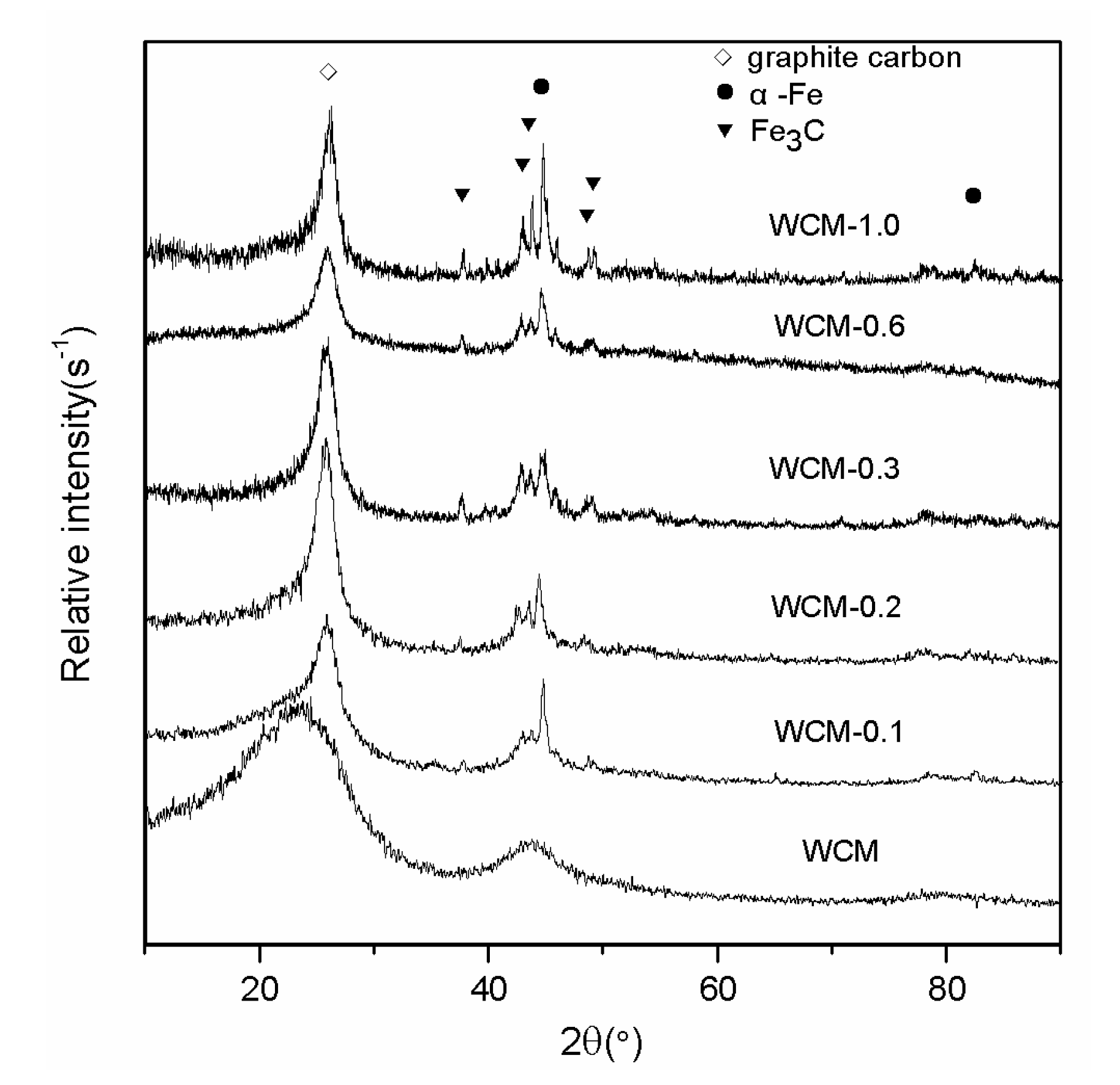

3.2. XRD Analysis of α-Fe/Fe3C/Woodceramic Nanocomposites

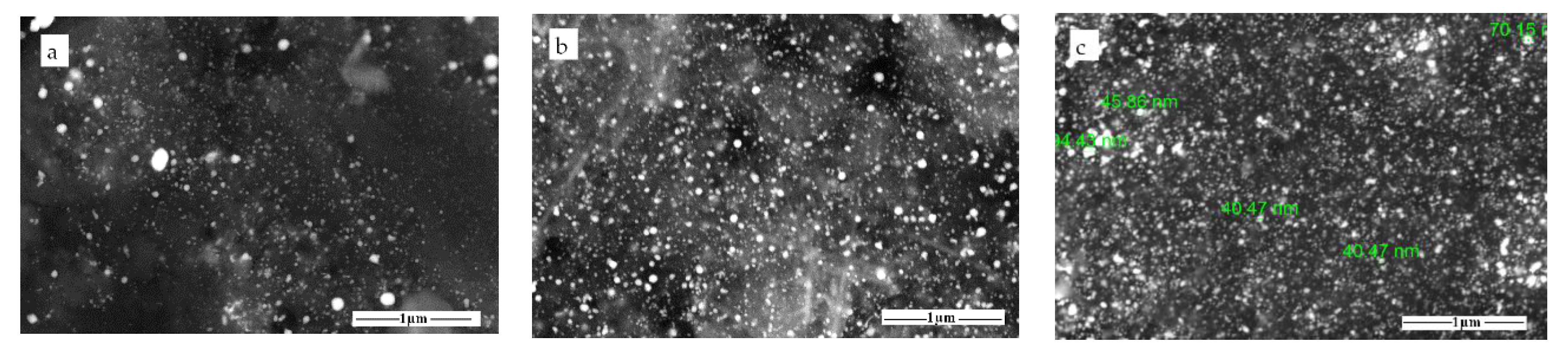

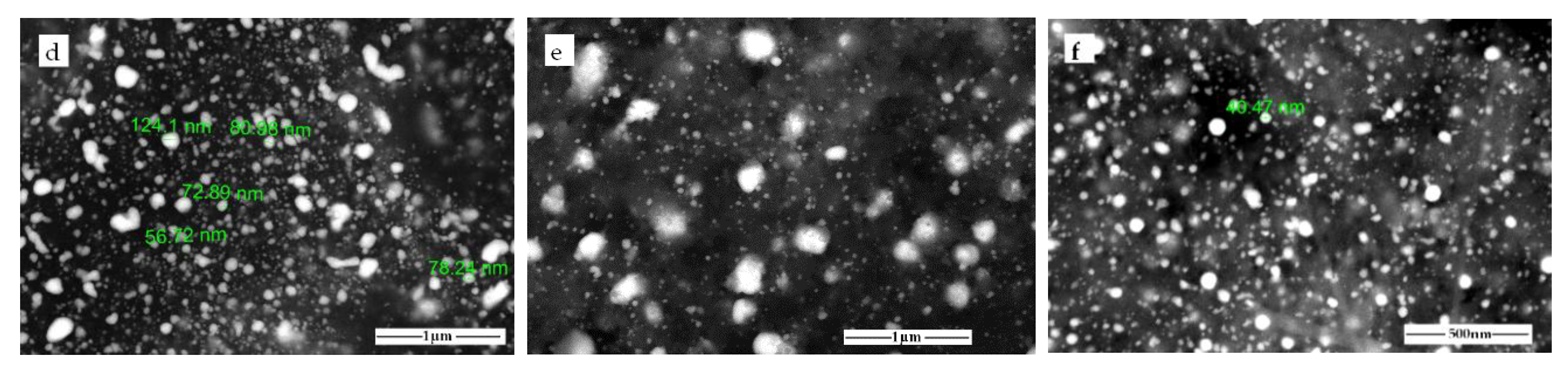

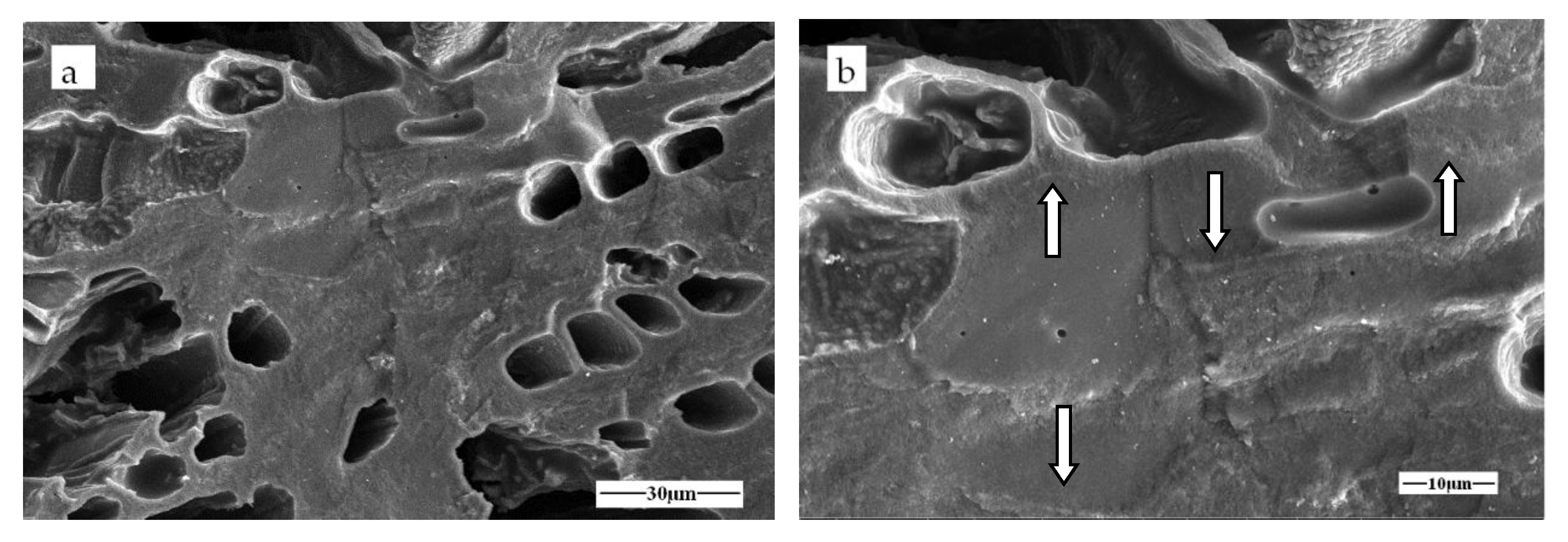

3.3. SEM Analysis

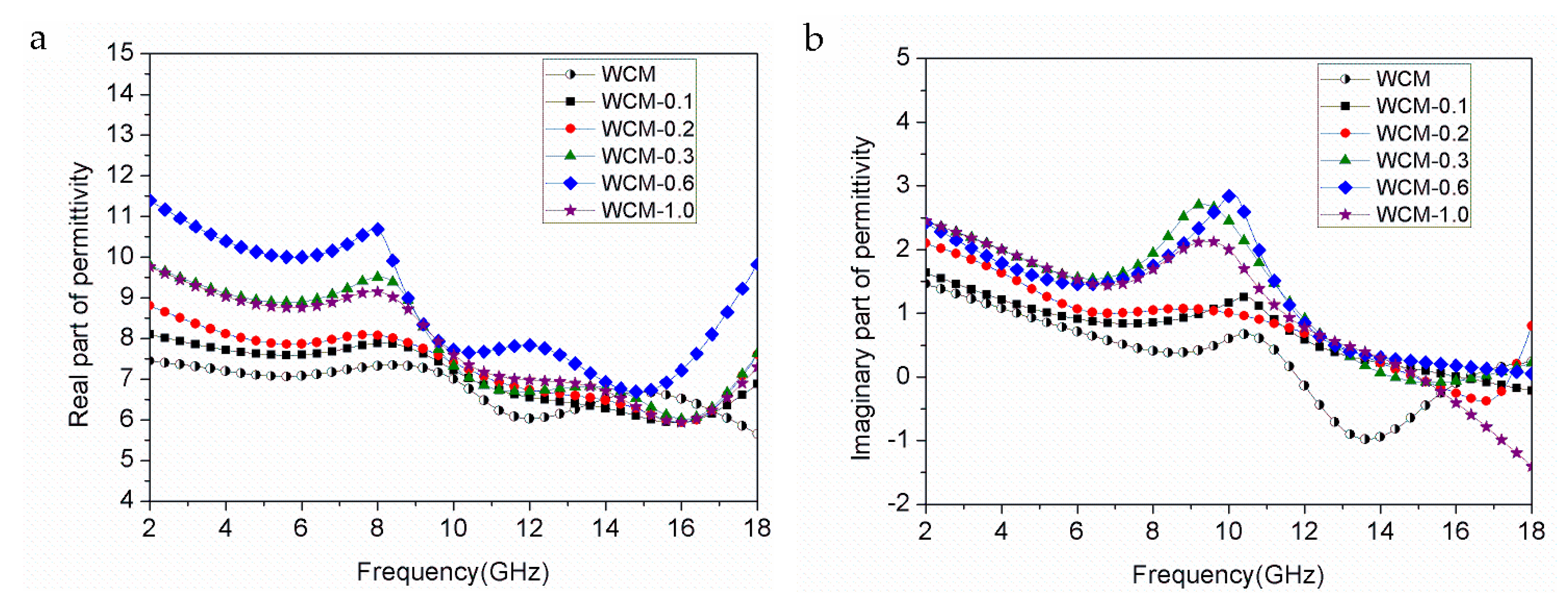

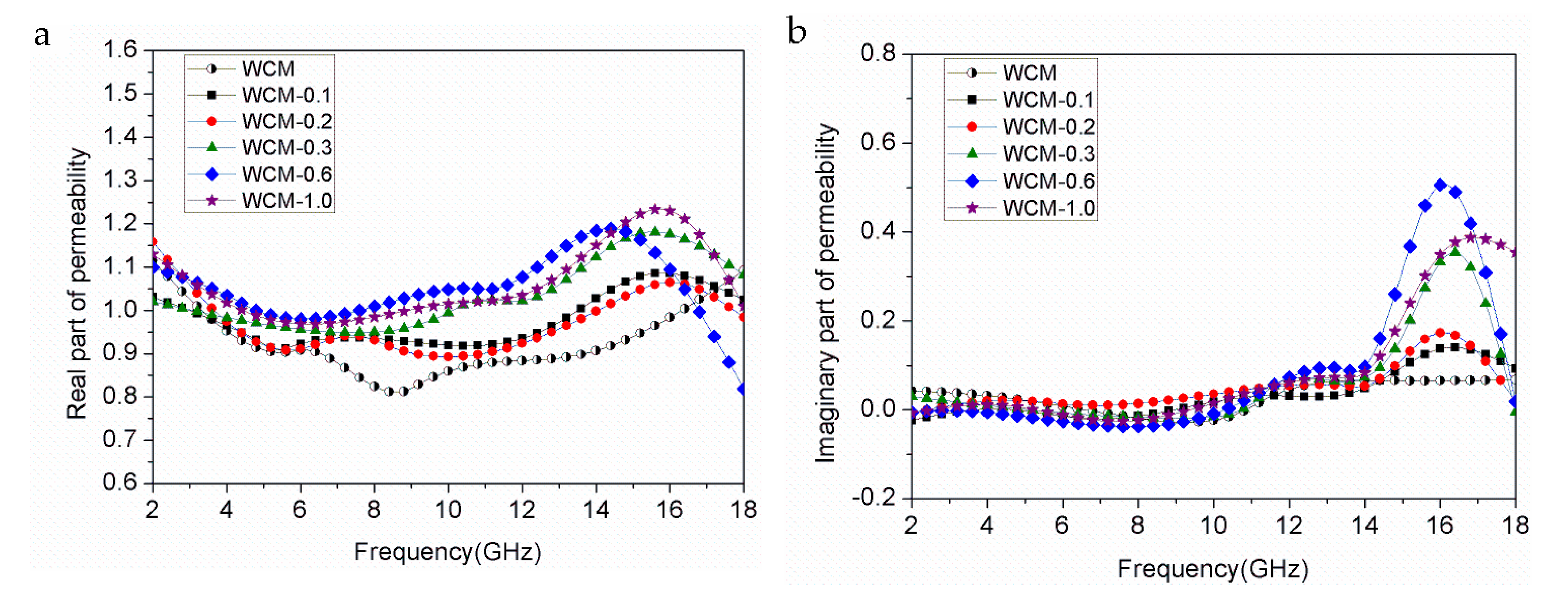

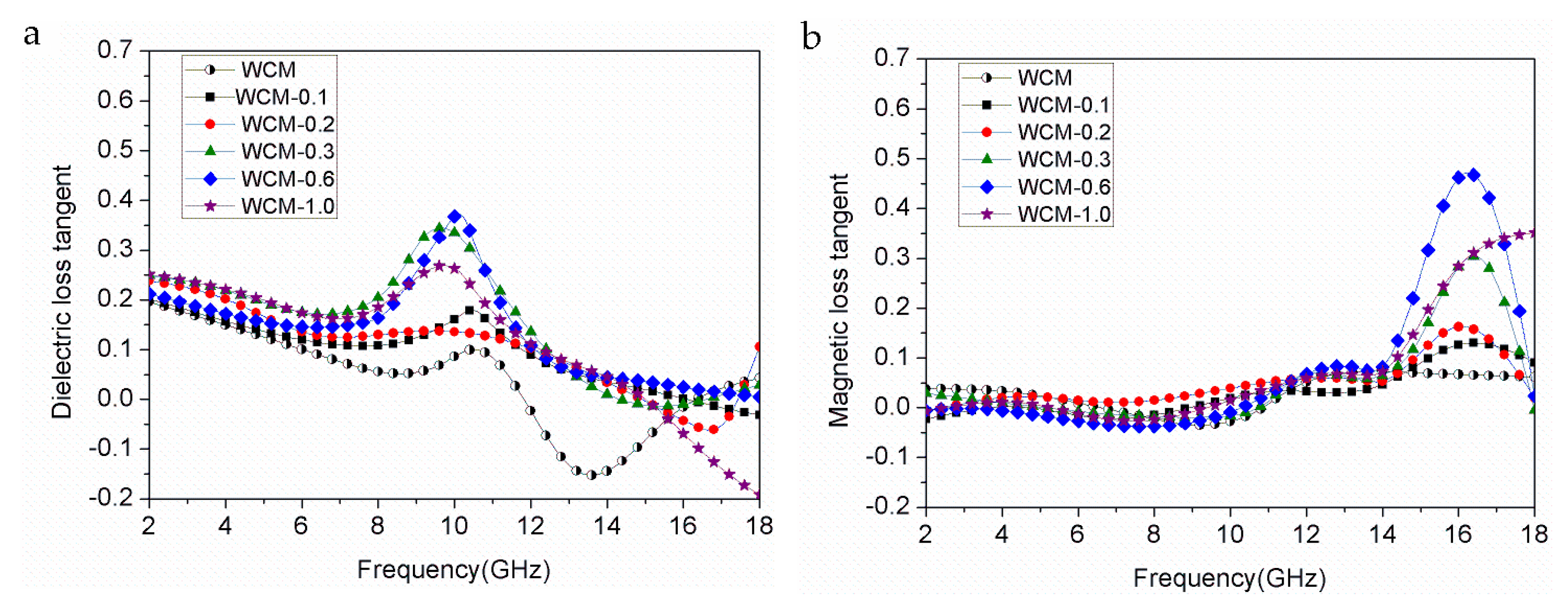

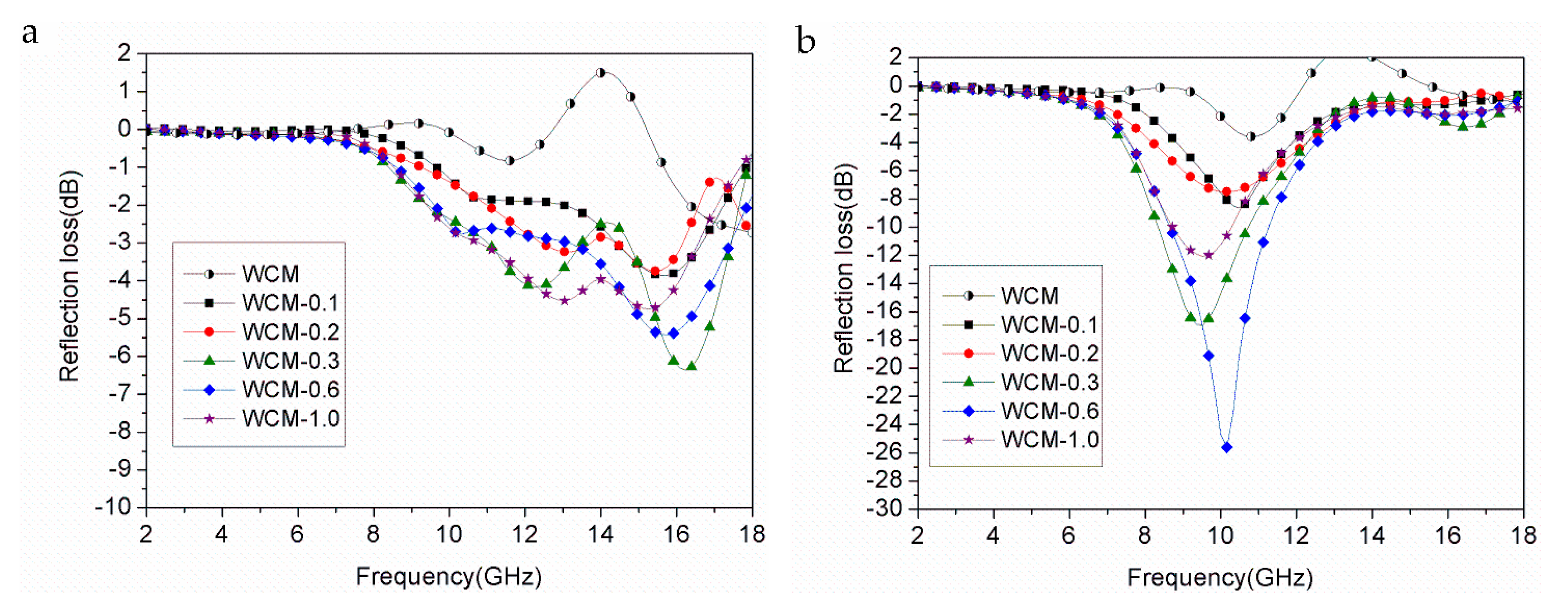

3.4. Microwave Absorption Properties

3.5. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, Z.; Bai, G.; Huang, Y.; Ma, Y.; Du, F.; Li, F. Reflection and absorption contributions to the electromagnetic interference shielding of single-walled carbon nanotube/polyurethane composites. Carbon 2007, 45, 821–827. [Google Scholar] [CrossRef]

- Oh, J.H.; Oh, K.S.; Hong, C.S. Design of radar absorbing structures using glass/epoxy composite containing carbon black in X-band frequency ranges. Compos. Part B 2004, 35, 49–56. [Google Scholar] [CrossRef]

- Xu, Y.G.; Zhang, D.Y.; Cai, J.; Yuan, L.M.; Zhang, W.Q. Microwave absorbing property of silicone rubber composites with added carbonyl iron particles and graphite platelet. J. Magn. Magn. Mater. 2013, 327, 82–86. [Google Scholar] [CrossRef]

- Akagaki, T.; Hokkirigawa, K.; Okabe, T.; Saito, K. Friction and wear of woodceramics under oil and water lubricated sliding contacts. J. Porous Mater. 1999, 6, 197–204. [Google Scholar] [CrossRef]

- Shibata, K.; Okabe, T.; Saito, K.; Okayama, T.; Shimada, M.; Yamamura, A.; Yamamoto, R. Electromagnetic shielding properties of woodceramics made from wastepaper. J. Porous Mater. 1997, 4, 269–275. [Google Scholar] [CrossRef]

- Yu, X.C.; Sun, D.L.; Sun, D.B.; Xu, Z.H.; Li, X.S. Basic properties of woodceramics made from bamboo powder and epoxy resin. Wood Sci. Technol. 2012, 46, 23–31. [Google Scholar] [CrossRef]

- Zhao, B.Y.; Hirose, T.; Okabe, T.; Zhang, D.; Fan, T.X.; Hu, K.A. Woodceramics prepared from wood powder/phenolated wood composite. J. Porous Mater. 2002, 9, 195–201. [Google Scholar] [CrossRef]

- Liu, Q.L.; Zhang, D.; Fan, T.X. Electromagnetic wave absorption properties of porous carbon/Co nanocomposites. Appl. Phys. Lett. 2008, 93, 013110. [Google Scholar] [CrossRef]

- Wu, K.H.; Shin, Y.M.; Yang, C.C.; Wang, G.P.; Horng, D.N. Preparation and characterization of bamboo charcoal/Ni0.5Zn0.5Fe2O4 composite with core-shell structure. Mater. Lett. 2006, 60, 2707–2710. [Google Scholar] [CrossRef]

- Bateer, B.; Wang, L.; Zhao, L.; Yu, P.; Tian, C.G.; Pan, K.; Fu, H.G. A novel Fe3C/graphitic carbon composite for electromagnetic wave absorption properties in C-band. RSC Adv. 2015, 5, 60135–60140. [Google Scholar] [CrossRef]

- Tang, Y.; Shao, Y.; Yao, K.F.; Zhong, Y.X. Fabrication and microwave absorption properties of carbon coated cementite nanocapsules. Nanotechnology 2014, 25, 035704. [Google Scholar] [CrossRef] [PubMed]

- Terada, M.; Itoh, M.; Liu, J.R.; Machida, K. Electromagnetic wave absorption properties of Fe3C/carbon nanocomposites prepared by a CVD method. J. Magn. Magn. Mater. 2009, 321, 1209–1213. [Google Scholar] [CrossRef]

- Hoste, S.; Verponek, L.; Van der Kelen, G.P. IR study on the solid state reaction between iron hydroxide and KCN. Bull. Soc. Chim. Belg. 1982, 91, 597–604. [Google Scholar] [CrossRef]

- Tang, H.X.; Stumm, W. The coagulating behavious of Fe (III) polymeric species—I. Preformed polymers by base addition. Water Res. 1987, 21, 115–121. [Google Scholar] [CrossRef]

- Sajitha, E.P.; Prasad, V.; Subramanyam, S.V.; Eto, S.; Takai, K.; Enoki, T. Synthesis and characteristics of iron nanoparticles in a carbon matrix along with the catalytic graphitization of amorphous carbon. Carbon 2004, 42, 2815–2820. [Google Scholar] [CrossRef]

- Tsubota, T.; Maguchi, Y.; Kamimura, S.; Ohno, T.; Yasuoka, T.; Nishida, H. Catalytic Graphitization for preparation of porous carbon material derived from bamboo precursor and performance as electrode of electrical double-layer capacitor. J. Electron. Mater. 2015, 44, 4933–4939. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, F.; Kang, Q.; Liu, S.; Cai, Q. The effect of magnetic field on the catalytic graphitization of phenolic resin in the presence of Fe–Ni. Carbon 2009, 47, 3233–3237. [Google Scholar] [CrossRef]

- Beale, A.M.; Soulimani, F.; Versluijs-Helder, M.; Kleut, D.V.D.; Koelewijn, J.M.; Geus, J.W.; Jenneskens, L.M. The effect of iron catalyzed graphitization on the textural properties of carbonized cellulose: Magnetically separable graphitic carbon bodies for catalysis and remediation. Carbon 2016, 107, 248–260. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, C.F.; Chen, Y.N.; Han, Z.; Wang, H.; Wang, Z.J.; Geng, D.Y.; Liu, W.; Zhang, Z.D. Effect of grain size on microwave resonance of Fe/TiO2 metal-semiconductor composite. Appl. Phys. Lett. 2010, 97, 133115. [Google Scholar] [CrossRef]

- Zhang, X.F.; Dong, X.L.; Huang, H.; Liu, Y.Y.; Wang, W.N.; Zhu, X.G.; Lv, B.; Lei, J.P. Microwave absorption properties of the carbon-coated nickel nanocapsules. Appl. Phys. Lett. 2006, 89, 053115. [Google Scholar] [CrossRef]

- Li, Q.H.; Liu, X.L.; Zhao, D.L. Preparation and microwave absorbing properties of carbon-encapsulated iron carbide magnetic nanoparticles. In Proceedings of the 7th National Conference on Functional Materials and Applications, Changsha, China, 15–18 October 2010. [Google Scholar]

- Liu, X.G.; Li, B.; Geng, D.Y.; Cui, W.B.; Yang, F.; Xie, Z.G.; Kang, D.J.; Zhang, Z.D. (Fe, Ni)/C nanocapsules for electromagnetic-wave-absorber in the whole Ku-band. Carbon 2009, 47, 470–474. [Google Scholar] [CrossRef]

- Matsumoto, M.; Miyata, Y. Thin electromagnetic wave absorber for quasi-microwave band containing aligned thin magnetic metal particles. IEEE Trans. Magn. 1997, 33, 4459–4464. [Google Scholar] [CrossRef]

- Pang, H.; Fan, M.; He, Z.F. A method for analyzing the microwave absorption properties of magnetic materials. J. Magn. Magn. Mater. 2012, 324, 2492–2495. [Google Scholar] [CrossRef]

- Hirose, I.I.; Fushitani, M.; Okabe, T.; Saito, K. Mechanical properties of woodceramics: A porous carbon material. J. Porous Mater. 1999, 6, 175–184. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, W.; Yu, Y.; Xiong, X.; Zhou, S. Fabrication of α-Fe/Fe3C/Woodceramic Nanocomposite with Its Improved Microwave Absorption and Mechanical Properties. Materials 2018, 11, 878. https://doi.org/10.3390/ma11060878

Zhou W, Yu Y, Xiong X, Zhou S. Fabrication of α-Fe/Fe3C/Woodceramic Nanocomposite with Its Improved Microwave Absorption and Mechanical Properties. Materials. 2018; 11(6):878. https://doi.org/10.3390/ma11060878

Chicago/Turabian StyleZhou, Weihong, Yunshui Yu, Xueliang Xiong, and Sicong Zhou. 2018. "Fabrication of α-Fe/Fe3C/Woodceramic Nanocomposite with Its Improved Microwave Absorption and Mechanical Properties" Materials 11, no. 6: 878. https://doi.org/10.3390/ma11060878

APA StyleZhou, W., Yu, Y., Xiong, X., & Zhou, S. (2018). Fabrication of α-Fe/Fe3C/Woodceramic Nanocomposite with Its Improved Microwave Absorption and Mechanical Properties. Materials, 11(6), 878. https://doi.org/10.3390/ma11060878