Porous Structure Properties of Andropogon gerardi Derived Carbon Materials

Abstract

:1. Introduction

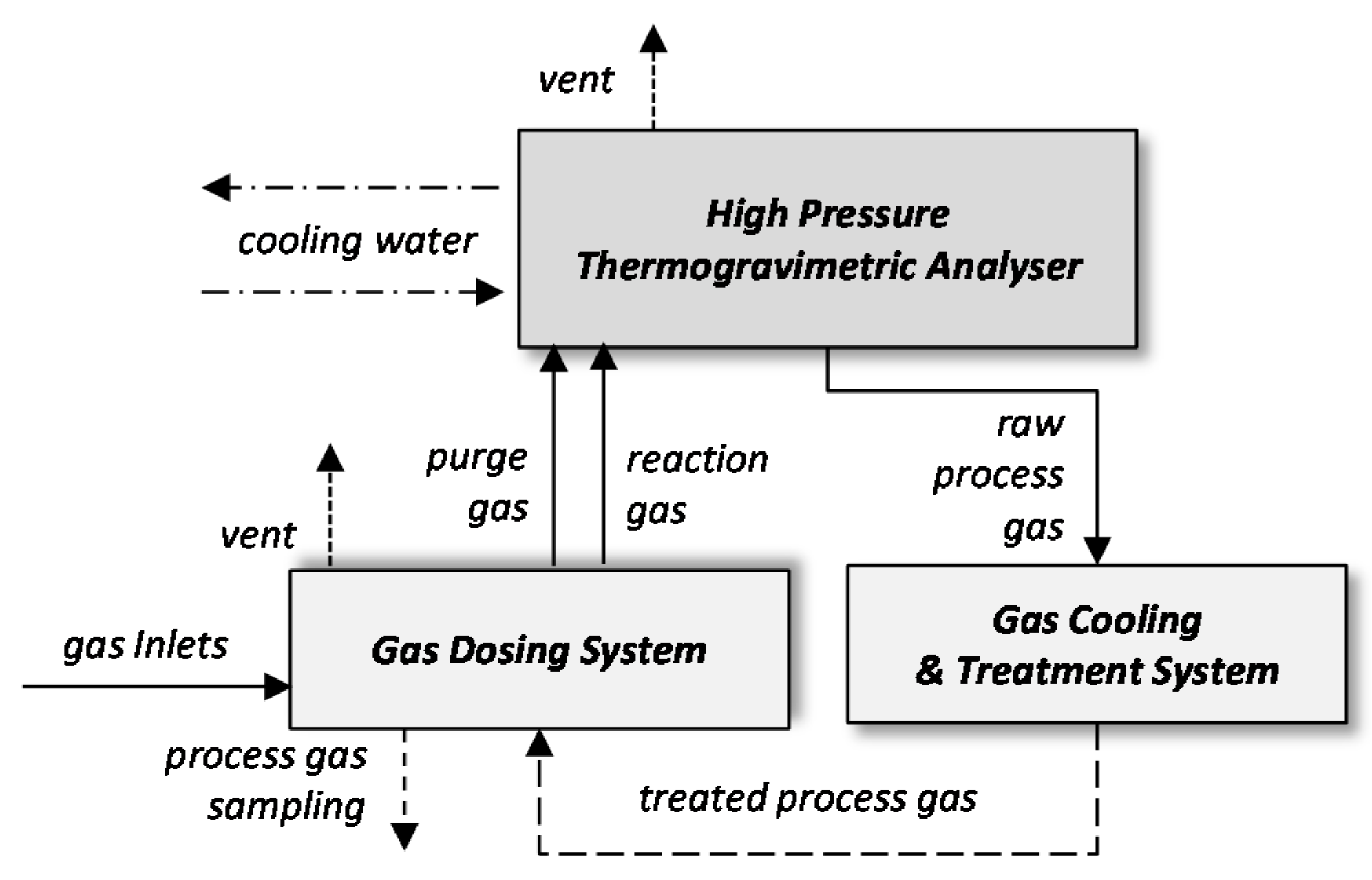

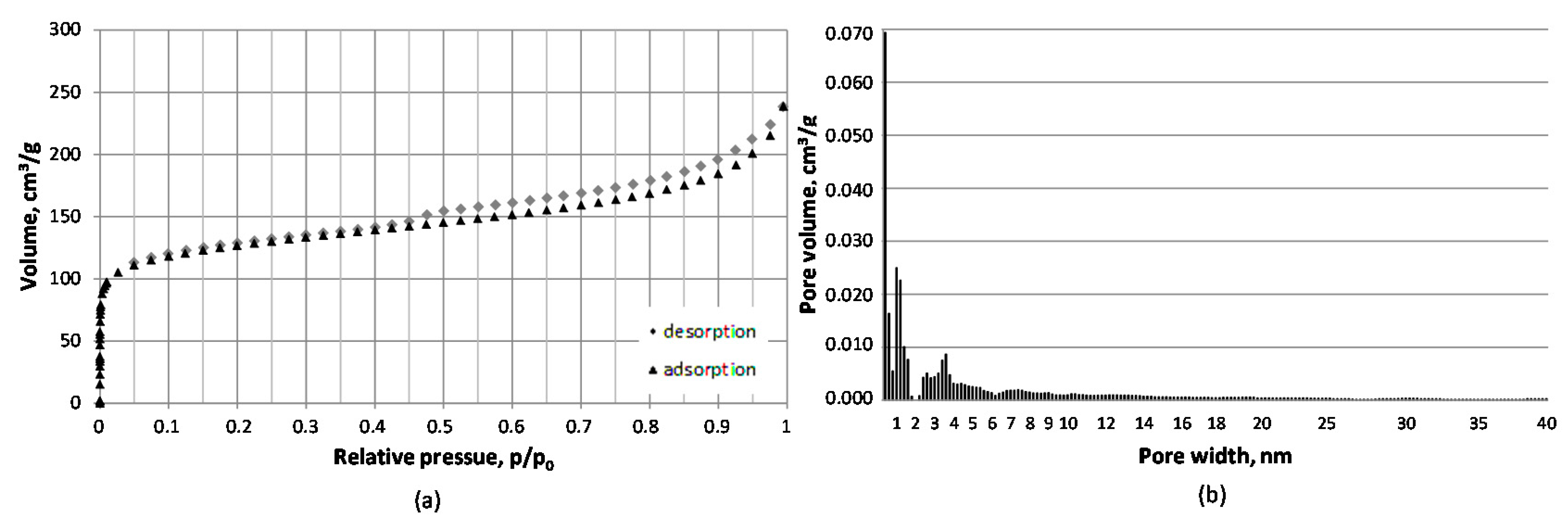

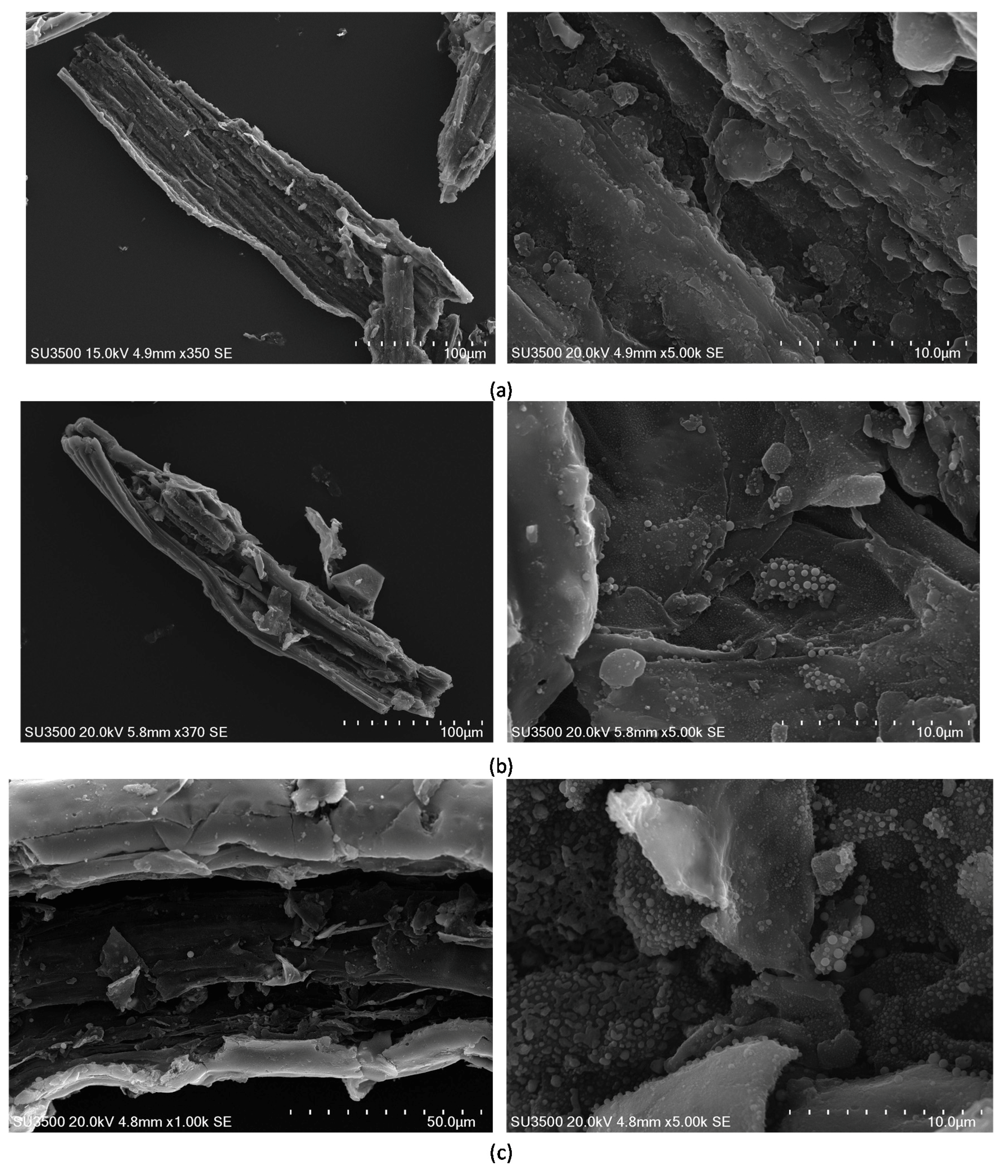

2. Materials and Methods

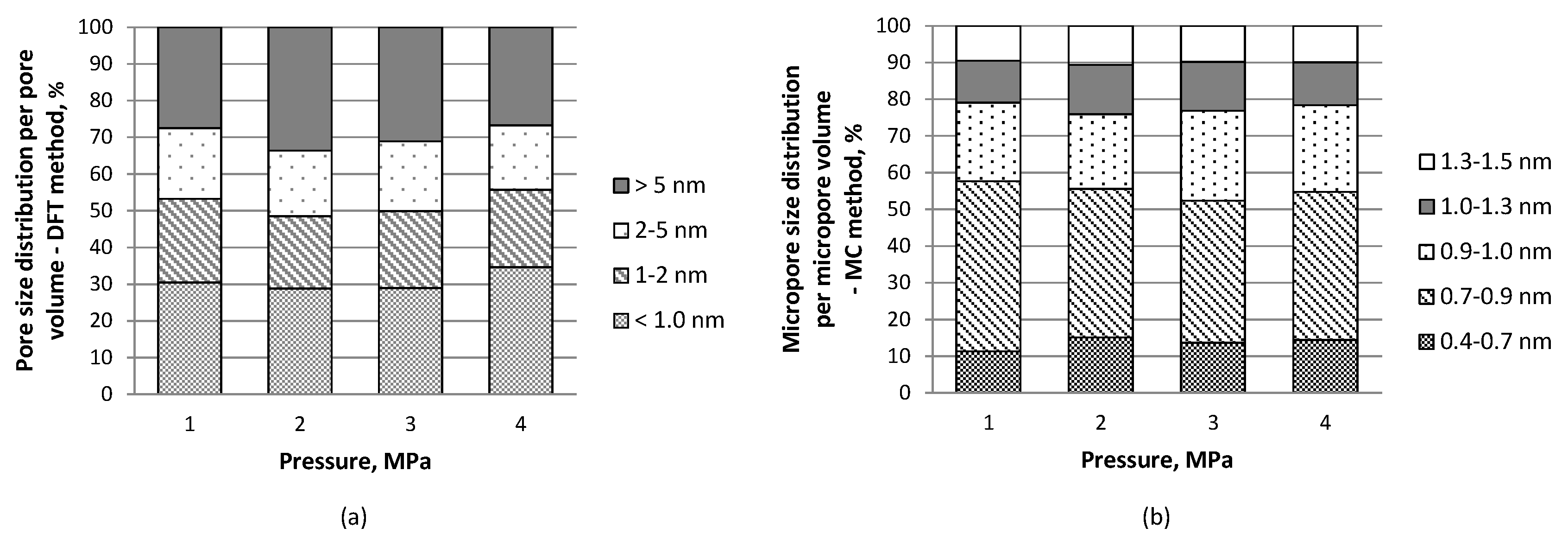

3. Results and Discussion

4. Conclusions

- Carbonization of the selected biomass under 3 MPa gives carbon materials with the most developed porous structure in terms of the specific surface area, the total pore volume, and microporosity, as determined by nitrogen sorption isotherm;

- The pressure of 2 MPa was proved to enhance the development of narrow microporosity, as quantified by carbon dioxide isotherm;

- Application of pressure during carbonization enables tailoring of the porous structure of carbon materials.

Author Contributions

Funding

Conflicts of Interest

References

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction, 2nd ed.; Academic Press: Oxford, UK, 2013. [Google Scholar]

- Howaniec, N.; Smoliński, A. Steam co-gasification of coal and biomass—Synergy in reactivity of fuel blends chars. Int. J. Hydrog. Energy 2013, 36, 16152–16160. [Google Scholar] [CrossRef]

- Howaniec, N.; Smoliński, A. Effect of fuel blend composition on the efficiency of hydrogen-rich gas. Fuel 2014, 128, 442–450. [Google Scholar] [CrossRef]

- Howaniec, N.; Smoliński, A. Influence of fuel blend ash components on steam co-gasification of coal and biomass—Chemometric study. Energy 2014, 78, 814–825. [Google Scholar] [CrossRef]

- Smoliński, A.; Howaniec, N.; Bąk, A. Utilization of energy crops and sewage sludge in the process of co-gasification for sustainable hydrogen production. Energies 2018, 11, 809. [Google Scholar] [CrossRef]

- Belhachemi, M.; Jeguirim, M.; Limousy, L.; Addoun, F. Comparison of NO2 removal using date pits activated carbon and modified commercialized activated carbon via different preparation methods: Effect of porosity and surface chemistry. Chem. Eng. J. 2014, 253, 121–129. [Google Scholar] [CrossRef]

- Unur, E. Functional nanoporous carbons from hydrothermally treated biomass for environmental purification. Microporous Mesoporous Mater. 2013, 168, 92–101. [Google Scholar] [CrossRef]

- Veksha, A.; Sasaoka, E.; Uddin, M.A. The influence of porosity and surface oxygen groups of peat-based activated carbons on benzene adsorption from dry and humid air. Carbon 2009, 47, 2371–2378. [Google Scholar] [CrossRef]

- Lee, K.T.; Mohtar, A.M.; Zainudin, N.F.; Bhatia, S.; Mohamed, A.R. Optimum conditions for preparation of flue gas desulfurization absorbent from rice husk ash. Fuel 2005, 84, 143–151. [Google Scholar] [CrossRef]

- Sharma, R.K.; Wooten, J.B.; Baliga, V.L.; Hajaligol, M.R. Characterization of chars from biomass-derived materials: Pectin chars. Fuel 2001, 80, 1825–1836. [Google Scholar] [CrossRef]

- Włodarczyk-Stasiak, M.; Jamroz, J. Specific surface area and porosity of starch extrudates determined from nitrogen adsorption data. J. Food Eng. 2009, 93, 379–385. [Google Scholar] [CrossRef]

- Vivo-Vilches, J.F.; Bailón-García, E.; Pérez-Cadenas, A.F.; Carrasco-Marín, F.; Maldonado-Hódar, F.J. Tailoring the surface chemistry and porosity of activated carbons: Evidence of reorganization and mobility of oxygenated surface groups. Carbon 2014, 68, 520–530. [Google Scholar] [CrossRef]

- Benaddi, H.; Bandosz, T.J.; Jagiello, J.; Schwarz, J.A.; Rouzaud, J.N.; Legras, D.; Béguin, F. Surface functionality and porosity of activated carbons obtained from chemical activation of wood. Carbon 2000, 38, 669–674. [Google Scholar] [CrossRef]

- Nahil, M.A.; Williams, P.T. Characterisation of Activated Carbons with High Surface Area and Variable Porosity Produced from Agricultural Cotton Waste by Chemical Activation and Co-activation. Waste Biomass Valoriz. 2012, 3, 117–130. [Google Scholar] [CrossRef]

- Tremel, A.; Haselsteiner, T.; Nakonz, M.; Spliethoff, H. Coal and char properties in high temperature entrained flow gasifier. Energy 2012, 45, 176–182. [Google Scholar] [CrossRef]

- Benfell, K.E.; Liu, G.; Roberts, D.G.; Harris, D.J.; Lucas, J.A.; Bailey, J.G. Modelling char combustion: The influence of parent coal petrography and pyrolysis pressure on the structure and intrinsic reactivity of its char. Proc. Combust. Inst. 2000, 28, 2233–2241. [Google Scholar] [CrossRef]

- Howaniec, N. The effects of pressure on coal chars porous structure development. Fuel 2016, 172, 118–123. [Google Scholar] [CrossRef]

- Howaniec, N. Development of porous structure of lignite chars at high pressure and temperature. Fuel Process. Technol. 2016, 154, 163–167. [Google Scholar] [CrossRef]

- Cetin, E.; Moghtaderi, B.; Gupta, R.; Wall, T.F. Influence of pyrolysis conditions on the structure and gasification reactivity of biomass chars. Fuel 2004, 83, 2139–2150. [Google Scholar] [CrossRef]

- Smoliński, A.; Howaniec, N. Analysis of Porous Structure Parameters of Biomass Chars Versus Bituminous Coal and Lignite Carbonized at High Pressure and Temperature—A Chemometric Study. Energies 2017, 10, 1457. [Google Scholar] [CrossRef]

- Van Dam, J.; Faaij, A.P.C.; Lewandowski, I.; Fischer, G. Biomass production potentials in Central and Eastern Europe under different scenarios. Biomass Bioenergy 2007, 31, 345–366. [Google Scholar] [CrossRef]

- Venendaal, R.; Jørgensen, U.; Foster, C.A. European energy crops: A synthesis. Biomass Bioenergy 1997, 13, 147–185. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Lowell, S.; Shields, J.E.; Thomas, M.A.; Thommes, M. Characterization of Porous Solids and Powders: Surface Area, Pore Size and Density; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2004. [Google Scholar]

- De Boer, J.H.; Linsen, B.G.; van der Plas, T.H.; Zondervan, G.J. Studies on pore systems in catalysts: VII. Description of the pore dimensions of carbon blacks by the t method. J. Catal. 1965, 4, 649–653. [Google Scholar] [CrossRef]

- Bottani, E.J.; Tascon, J.M.D. Adsorption by Carbons; Elsevier Ltd.: Oxford, UK, 2008. [Google Scholar]

| Parameter, Unit | Value |

|---|---|

| Proximate Analysis | |

| Total moisture, % w/w | 9.72 |

| Ash, % w/w | 3.87 |

| Volatiles, % w/w | 70.26 |

| Fixed carbon, % w/w | 16.15 |

| Ultimate Analysis | |

| Sulfur, % w/w | 0.06 |

| Carbon, % w/w | 53.3 |

| Hydrogen, % w/w | 7.57 |

| Nitrogen, % w/w | bdl |

| Oxygen, % w/w | 25.54 |

| Heating Value | |

| Lower heating value, kJ/kg | 14,242 |

| Ash Composition | |

| SiO2, % w/w | 14.67 |

| Al2O3, % w/w | 3.18 |

| Fe2O3, % w/w | 0.93 |

| CaO, % w/w | 37.10 |

| MgO, % w/w | 3.46 |

| Na2O, % w/w | 0.53 |

| K2O, % w/w | 22.13 |

| SO3, % w/w | 4.12 |

| TiO2, % w/w | 0.15 |

| P2O5, % w/w | 13.17 |

| ZnO, % w/w | bdl |

| Sample No. | Pressure, MPa | Multi-Point BET, m2/g | Average Pore Diameter, nm | Total Pore Volume, cm3/g | V-t-deBoer Volume, cm3/g | V-t-deBoer Area, m2/g | MC Volume, cm3/g | MC Area, m2/g |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 162.16 | 3.29 | 0.133 | 0.046 | 113.37 | 0.146 | 456.68 |

| 2 | 2 | 333.23 | 3.25 | 0.271 | 0.102 | 248.29 | 0.182 | 561.85 |

| 3 | 3 | 468.70 | 3.15 | 0.369 | 0.116 | 285.70 | 0.171 | 523.13 |

| 4 | 4 | 380.46 | 2.98 | 0.283 | 0.100 | 249.78 | 0.160 | 492.76 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Howaniec, N.; Smoliński, A. Porous Structure Properties of Andropogon gerardi Derived Carbon Materials. Materials 2018, 11, 876. https://doi.org/10.3390/ma11060876

Howaniec N, Smoliński A. Porous Structure Properties of Andropogon gerardi Derived Carbon Materials. Materials. 2018; 11(6):876. https://doi.org/10.3390/ma11060876

Chicago/Turabian StyleHowaniec, Natalia, and Adam Smoliński. 2018. "Porous Structure Properties of Andropogon gerardi Derived Carbon Materials" Materials 11, no. 6: 876. https://doi.org/10.3390/ma11060876

APA StyleHowaniec, N., & Smoliński, A. (2018). Porous Structure Properties of Andropogon gerardi Derived Carbon Materials. Materials, 11(6), 876. https://doi.org/10.3390/ma11060876