Diffusibility Enhancement of Rejuvenator by Epoxidized Soybean Oil and Its Influence on the Performance of Recycled Hot Mix Asphalt Mixtures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Design and Preparation of RHMA

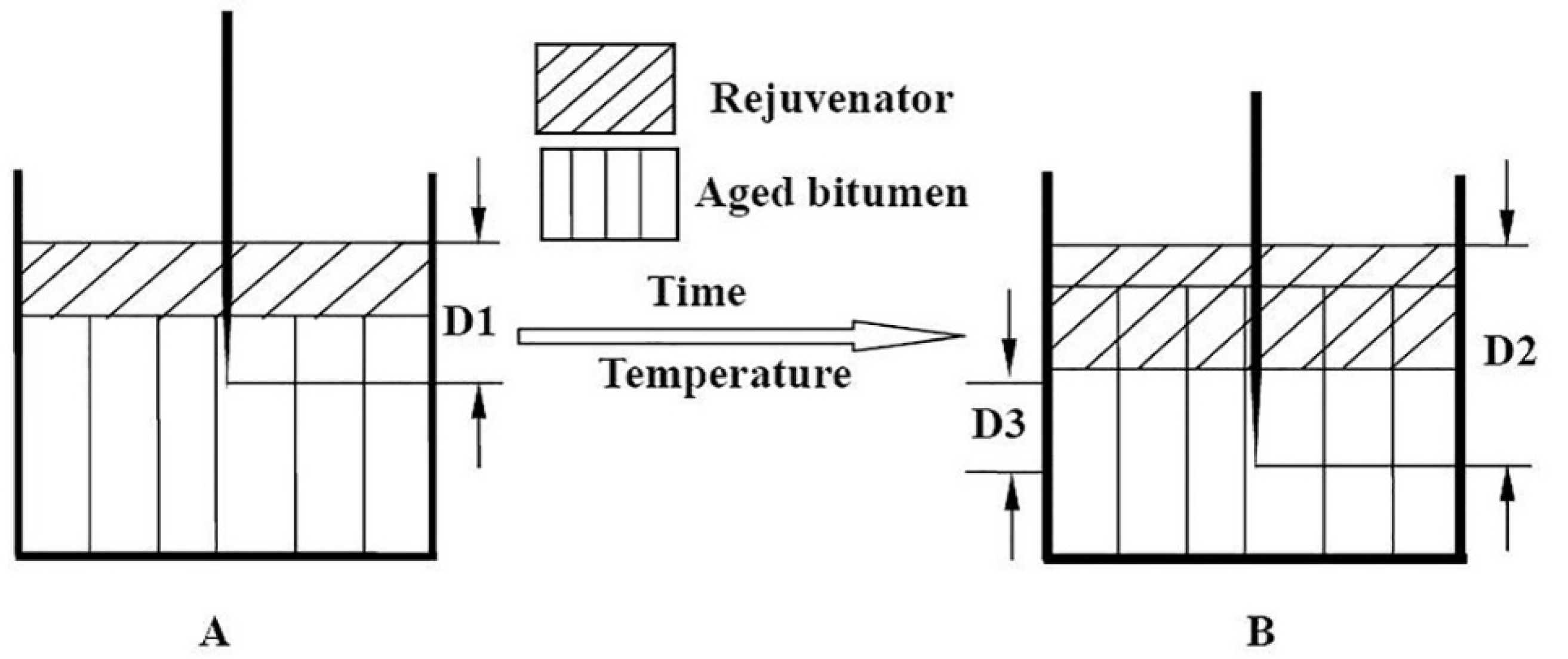

2.3. Diffusibility Testing Procedure of Rejuvenators

- Aged bitumen heated to 140 °C was poured into penetration molds A and B, of which the inner diameter and height were 55 mm and 35 mm, respectively, and was then placed in an oven at a temperature of 110 °C for 30 min. Then, the rejuvenator heated to 110 °C was coated on the surface of the aged bitumen and maintained in an oven at 110 °C for 10 min to ensure the rejuvenator was uniformly scattered on the surface of the aged bitumen. The dosages of the aged bitumen and rejuvenator were 50 g and 5 g, respectively.

- Mold B was placed in an oven at a different temperature for a certain time or constant temperature for different times, and then continuously placed in an oven without power supply for 2.5–3 h, allowing the temperature to decrease to room temperature gradually to reduce the influence of interface contraction induced by a rapid decline in temperature on the flatness of the rejuvenator coat.

2.4. Performance Testing of Asphalt Mixtures

3. Results and Discussion

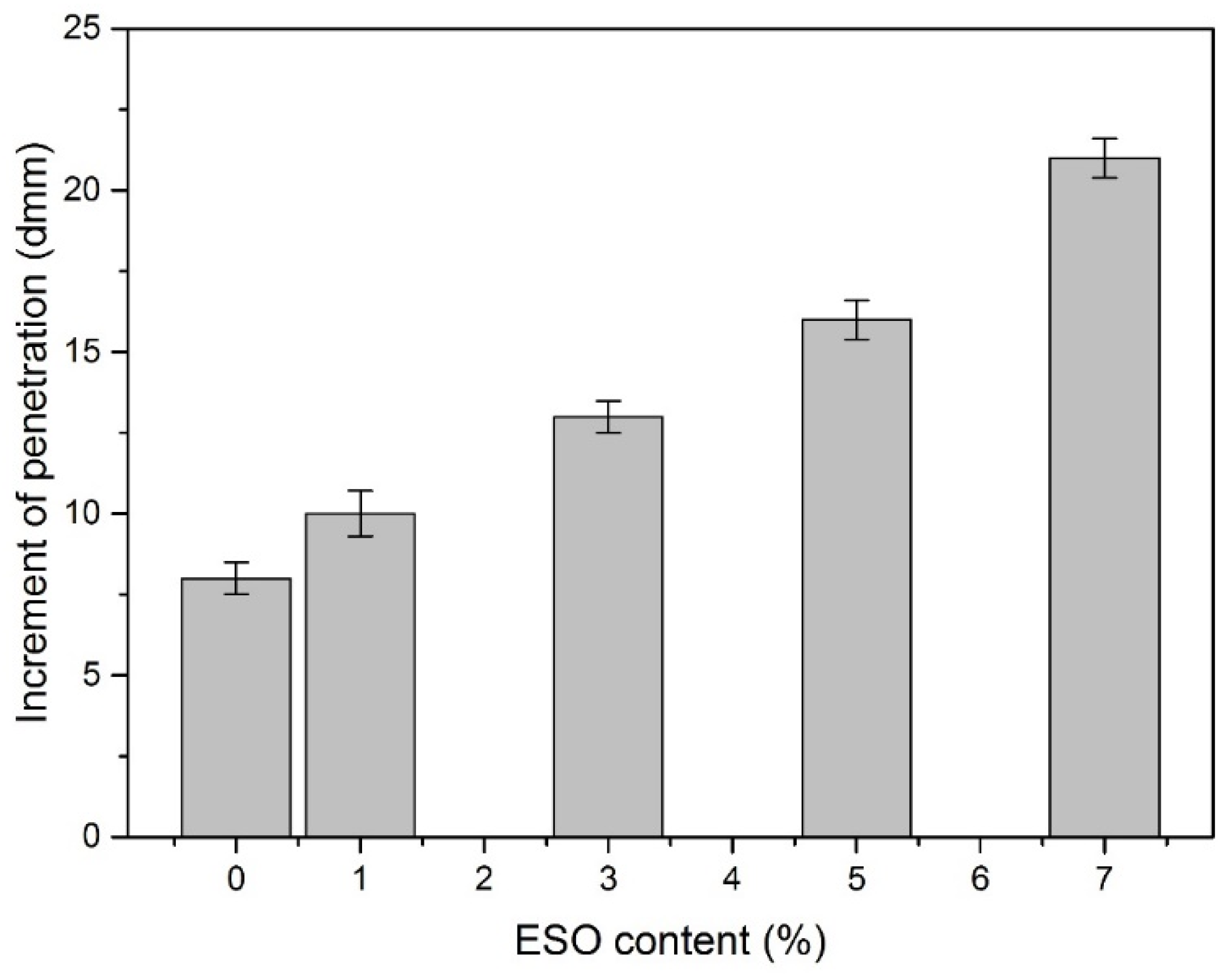

3.1. Effect of ESO on the Diffusibility of CR

3.2. Effect of CR on the Performance of RHMA

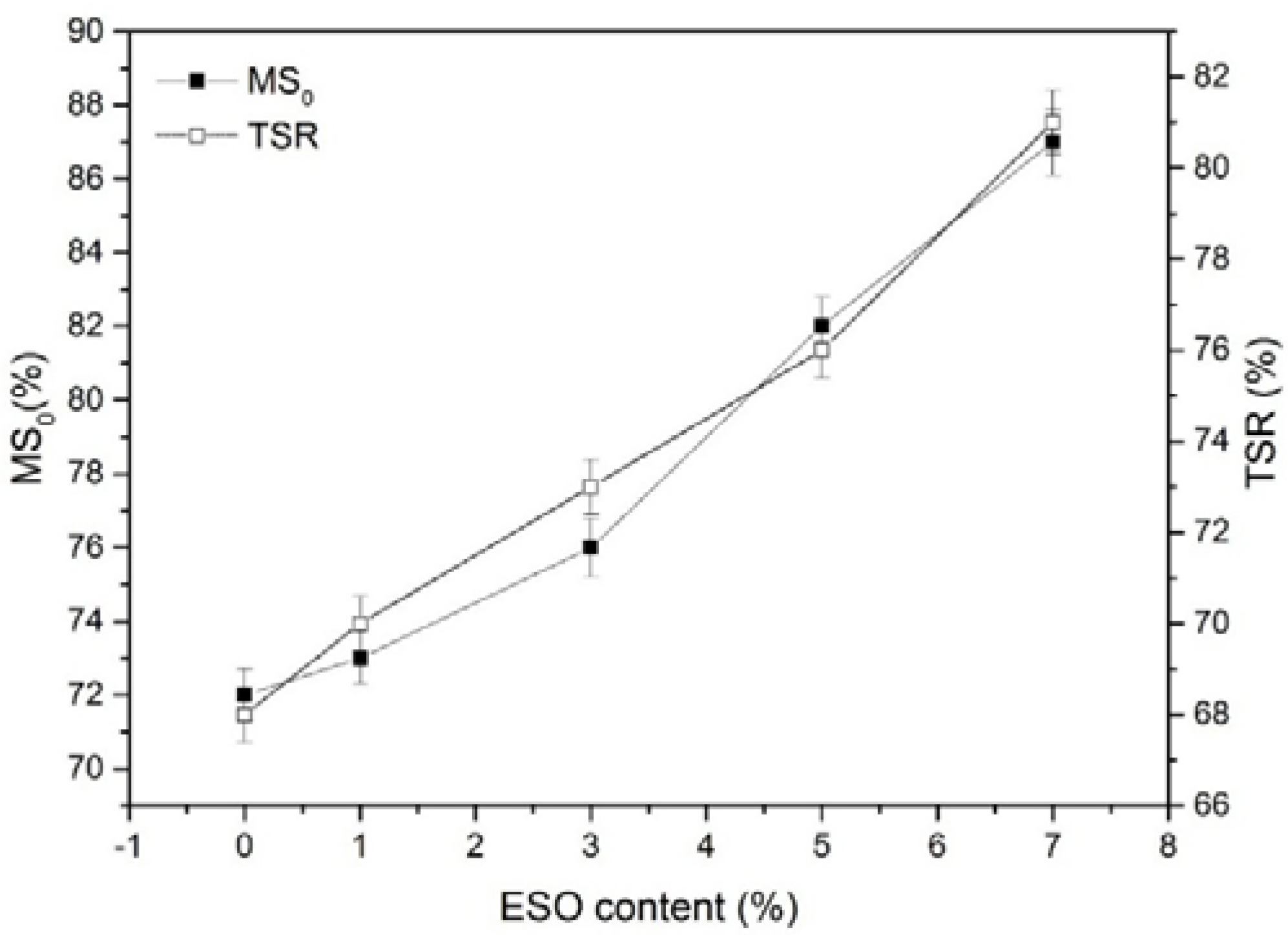

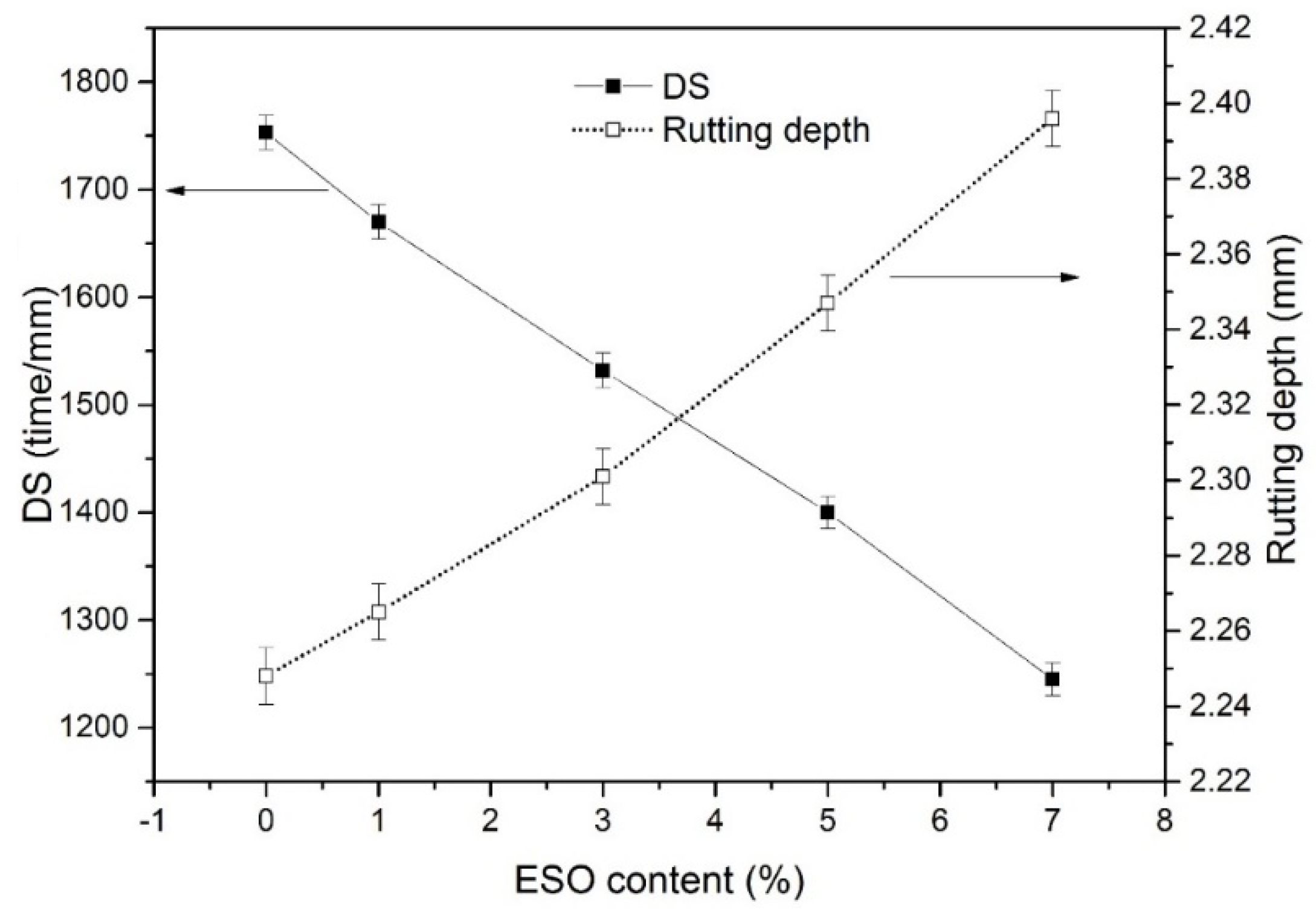

3.3. Effect of ESO on the Performance of RHMA with CR

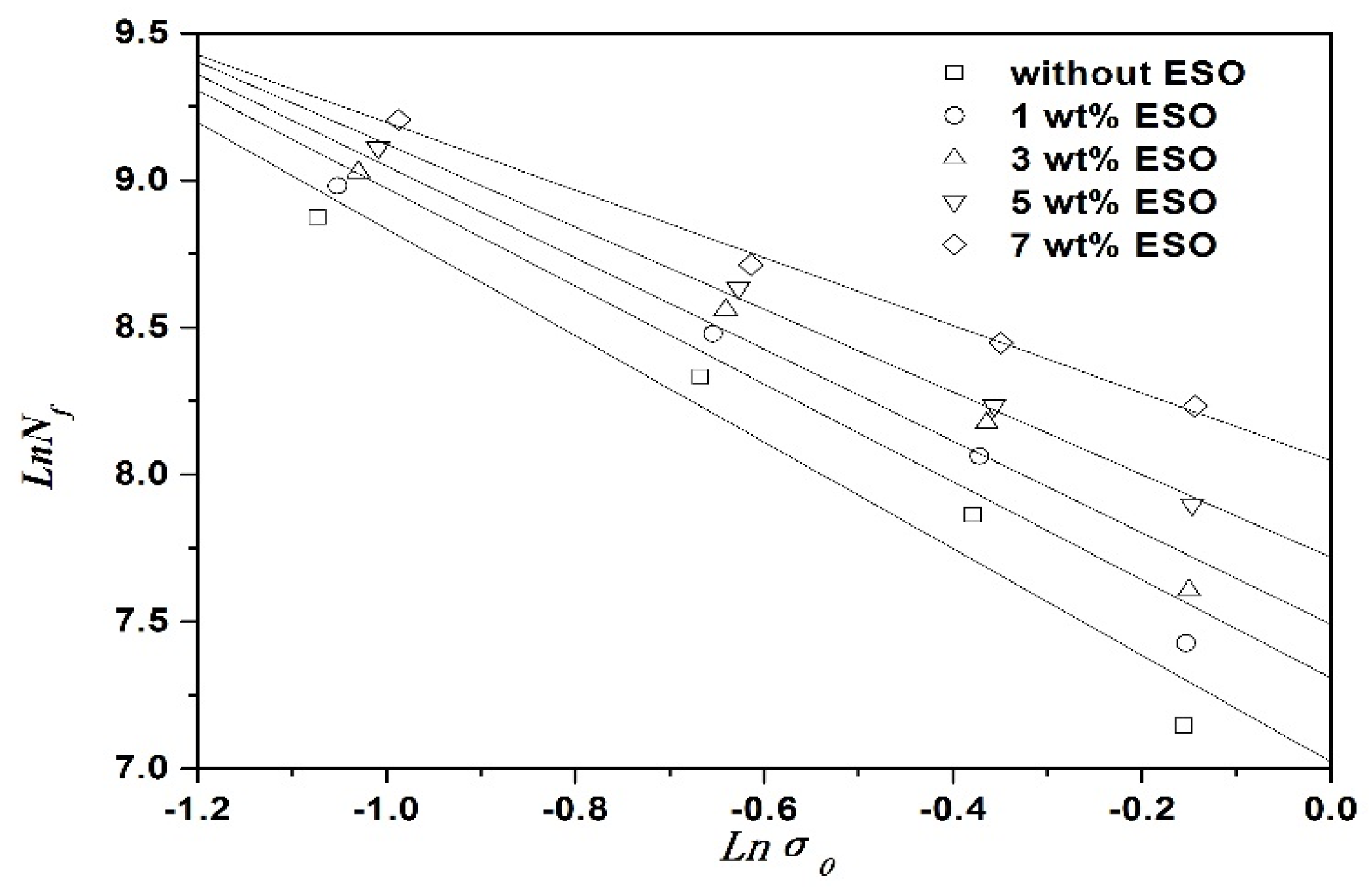

3.3.1. Fatigue Properties

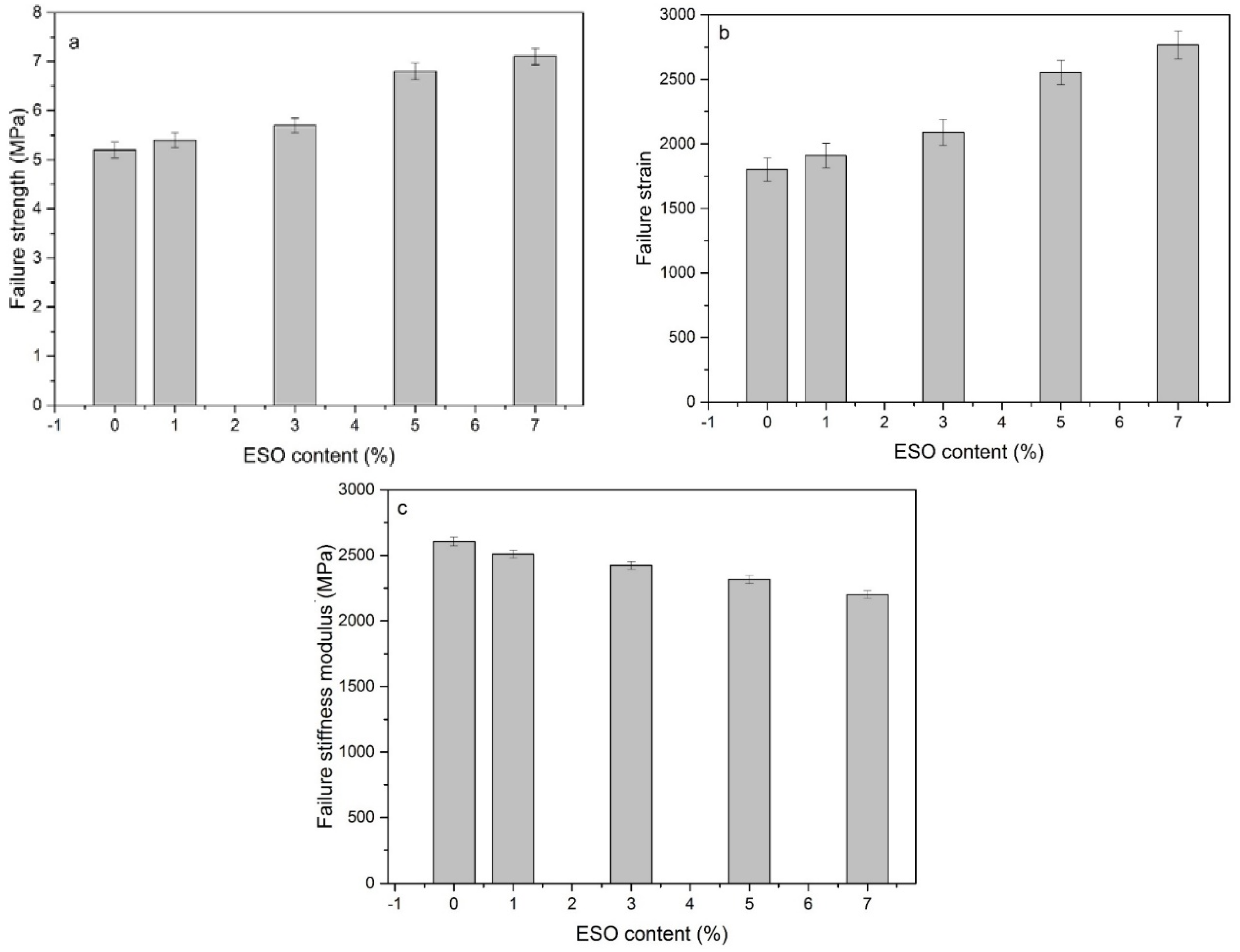

3.3.2. Cracking Resistance Properties

3.3.3. Water Stability

3.3.4. Rutting Resistance

4. Conclusions

- The diffusibility of the conventional rejuvenator was significantly enhanced by ESO because the epoxy group included in ESO contributes to the asphaltene dispersion in resin and aromatics due to its high polarity. In addition, the fluidity of aged bitumen is improved and the viscosity is reduced, which are helpful for rejuvenator diffusion into aged bitumen.

- The fatigue property, cracking resistance property as well as water stability of RHMA with the conventional rejuvenator were improved by ESO due to its facilitation of the diffusibility of the conventional rejuvenator. The fatigue property, cracking resistance property and water stability of the RHMA-containing conventional rejuvenator incorporated with 7 wt % approached those of the VHMA composed of the same virgin bitumen and virgin aggregates as RHMA.

- The conventional rejuvenator with ESO improved the fatigue property, cracking resistance property as well as water stability of the RHMA at a lower content; thus, the negative effect of the high rejuvenator content on the rutting resistance of the RHMA was eliminated. Although the rutting properties of the RHMA-containing conventional rejuvenator incorporated with 7% ESO declined compared to RHMA with only the conventional rejuvenator, they still approached those of the VHMA and meet the application requirements.

Author Contributions

Funding

Conflicts of Interest

References

- Shu, X.; Huang, B.S.; Vukosavljevic, D. Laboratory evaluation of fatigue characteristics of recycled asphalt mixture. Constr. Build. Mater. 2008, 7, 1323–1330. [Google Scholar] [CrossRef]

- Xu, J.Z.; Hao, P.W.; Zhang, D.P. Investigation of reclaimed asphalt pavement blending efficiency based on micro-mechanical properties of layered asphalt binders. Constr. Build. Mater. 2018, 163, 390–401. [Google Scholar] [CrossRef]

- Gao, L.; Li, H.; Xie, J.G.; Yu, Z.B. Evaluation of pavement performance for reclaimed asphalt materials in different layers. Constr. Build. Mater. 2018, 159, 561–566. [Google Scholar] [CrossRef]

- Sivilevicius, H.; Braziunas, J.; Prentkovskis, O. Technologies and Principles of Hot Recycling and Investigation of Preheated Reclaimed Asphalt Pavement Batching Process in an Asphalt Mixing Plant. Appl. Sci. 2017, 7, 1104. [Google Scholar] [CrossRef]

- Arshad, M.; Ahmed, M.F. Potential use of reclaimed asphalt pavement and recycled concrete aggregate in base/subbase layers of flexible pavements. Constr. Build. Mater. 2017, 151, 83–97. [Google Scholar] [CrossRef]

- Vega-Zamanillo, A.; Calzada-Perez, M.A.; Lastra-Gonzalez, P.; Indacoechea-Vega, I. Analysis of the use of cupola furnace slags, green sand and reclaimed asphalt pavement in asphalt concrete mixtures for low intensity traffic. Inf. Constr. 2017, 16, 229–237. [Google Scholar] [CrossRef]

- Singh, D.; Girimath, S.; Ashish, P.K. Performance Evaluation of Polymer-Modified Binder Containing Reclaimed Asphalt Pavement Using Multiple Stress Creep Recovery and Linear Amplitude Sweep Tests. J. Mater. Civ. Eng. 2018, 30, 40–50. [Google Scholar] [CrossRef]

- Elkashef, M.; Williams, R.C.; Cochran, E.W. Physical and chemical characterization of rejuvenated reclaimed asphalt pavement (RAP) binders using rheology testing and pyrolysis gas chromatography-mass spectrometry. Mater. Struct. 2018, 51, 11–19. [Google Scholar] [CrossRef]

- Zhang, K.; Muhunthan, B. Effects of production stages on blending and mechanical properties of asphalt mixtures with reclaimed asphalt pavement. Constr. Build. Mater. 2017, 149, 679–689. [Google Scholar] [CrossRef]

- Yang, S.H.; Lee, L.C. Characterizing the chemical and rheological properties of severely aged reclaimed asphalt pavement materials with high recycling rate. Constr. Build. Mater. 2016, 111, 139–146. [Google Scholar] [CrossRef]

- Su, J.F.; Wang, Y.Y.; Yang, P. Evaluating and Modeling the Internal Diffusion Behaviors of Microencapsulated Rejuvenator in Aged Bitumen by FTIR-ATR Tests. Materials 2016, 9, 932. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.Z.; Leng, B.B.; Wu, S.P. Physical, chemical and rheological properties of waste edible vegetable oil rejuvenated asphalt binders. Constr. Build. Mater. 2014, 66, 286–298. [Google Scholar] [CrossRef]

- Ma, T.; Huang, X.; Zhao, Y.; Zhang, Y. Influences of Preheating Temperature of RAP on Properties of Hot-Mix Recycled Asphalt Mixture. J. Test. Eval. 2016, 26, 43–46. [Google Scholar] [CrossRef]

- Vislavicius, K.; Sivilevicius, H. Effect of reclaimed asphalt pavement gradation variation on the homogeneity of recycled hot-mix asphalt. Arch. Civ. Mech. Eng. 2013, 13, 345–363. [Google Scholar] [CrossRef]

- Ding, Y.J.; Huang, B.S.; Shu, X. Use of molecular dynamics to investigate diffusion between virgin and aged asphalt binders. Fuel 2016, 174, 267–273. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, C.; Wan, M. Study of the Diffusion of Rejuvenators and Its Effect on Aged Bitumen Binder. Appl. Sci. 2017, 7, 397. [Google Scholar] [CrossRef]

- Mokhtari, A.; Lee, H.D.; Williams, R.C. A novel approach to evaluate fracture surfaces of aged and rejuvenator-restored asphalt using cryo-SEM and image analysis techniques. Constr. Build. Mater. 2017, 133, 301–313. [Google Scholar] [CrossRef]

- Anisimov, M.A.; Yudin, I.K.; Nikitin, V. Asphaltene Aggregation in Hydrocarbon Solutions Studied by Photon Correlation Spectroscopy. J. Phys. Chem. 1995, 99, 9576–9580. [Google Scholar] [CrossRef]

- Karlsson, R.; Isacsson, U. Application of FTIR-ATR to Characterization of Bitumen Rejuvenator Diffusion. J. Mater. Civ. Eng. 2003, 15, 157–165. [Google Scholar] [CrossRef]

- Lee, S.; Park, M.S.; Shin, J. Effect of the individual and combined use of cardanol-based plasticizers and epoxidized soybean oil on the properties of PVC. Polym. Degrad. Stab. 2018, 147, 1–11. [Google Scholar] [CrossRef]

- Calo, E.; Greco, A.; Maffezzoli, A. Effects of diffusion of a naturally-derived plasticizer from soft PVC. Polym. Degrad. Stab. 2011, 96, 784–789. [Google Scholar] [CrossRef]

- Hashmi, S.M.; Firoozabadi, A. Self-assembly of resins and asphaltenes facilitates asphaltene dissolution by an organic acid. J. Colloid Interface Sci. 2013, 394, 115–123. [Google Scholar] [CrossRef] [PubMed]

- Mangiafico, S.; Di Benedetto, H.; Sauzeat, C. Effect of colloidal structure of bituminous binder blends on linear viscoelastic behaviour of mixtures containing Reclaimed Asphalt Pavement. Mater. Des. 2016, 111, 126–139. [Google Scholar] [CrossRef]

- ASTM D2172. Standard Test Methods for Quantitative Extraction of Asphalt Binder from Asphalt Mixtures; American Society for Testing Materials: West Conshohocken, PA, USA, 2001. [Google Scholar]

- ASTM D6307. Standard Test Method for Asphalt Content of Asphalt Mixture by Ignition Method; American Society for Testing Materials: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Kuang, D.L.; Feng, Z.G.; Yu, J.Y. A New Approach for Evaluating Rejuvenator Diffusing into Aged Bitumen. J. Wuhan Univ. Technol. 2011, 26, 43–46. [Google Scholar] [CrossRef]

- ASTM D3685. Standard Method to Test Deformation Resistance by Asphalt Wheel Tracking Test; American Society for Testing Materials: West Conshohocken, PA, USA, 2001. [Google Scholar]

- ASTM D4867. Standard Test Method for Effect of Moisture on Asphalt Concrete Paving Mixtures; American Society for Testing Materials: West Conshohocken, PA, USA, 2009. [Google Scholar]

- ASTM D1559. Standard Test Method for Resistance to Plastic Flow of Bituminous Mixtures Using Marshall Apparatus; American Society for Testing Materials: West Conshohocken, PA, USA, 1982. [Google Scholar]

- ASTM D7460-2010. Standard Test Method for Determining Fatigue Failure of Compacted Asphalt Concrete Subjected to Repeated Flexural Bending; American Society for Testing Materials: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Wu, S.P.; Ye, Q.S.; Li, N. Investigation of rheological and fatigue properties of asphalt mixtures containing polyester fibers. Constr. Build. Mater. 2008, 22, 2111–2115. [Google Scholar] [CrossRef]

| Items | Value | |

|---|---|---|

| Physical properties | Softening point (°C) | 47.2 |

| Ductility (15 °C, cm) | >150 | |

| Penetration (25 °C, 0.1 mm) | 70 | |

| Viscosity (60 °C, Pa·s) | 232 | |

| Chemical components | Saturates (%) | 12.2 |

| Aromatics (%) | 50.2 | |

| Resins (%) | 26.1 | |

| Asphaltenes (%) | 11.5 | |

| Physical Properties | Items |

|---|---|

| Viscosity at 60 °C (cst) | 1700 |

| Flash point (°C) | >220 |

| Viscosity ratio before and after TFOT | 2.5 |

| Weight loss after TFOT (%) | −2.6 |

| Saturates content (%) | <30 |

| Properties | Value |

|---|---|

| Molecular | 1000 |

| Viscosity (cps, 25 °C) | 350 |

| Acid value | 0.45 |

| Iodine value (%) | 4.0 |

| Flash point (°C) | 280 |

| Epoxy value (%) | 6.1 |

| Weight loss after heating (%) | 0.08 |

| Specific gravity (25 °C) | 0.982 |

| Items | Value | |

|---|---|---|

| Physical properties | Softening point (°C) | 58.3 |

| Ductility (15 °C, cm) | 9.6 | |

| Penetration (25 °C, 0.1 mm) | 30 | |

| Viscosity (60 °C, Pa·s) | 410 | |

| Chemical components | Saturates (%) | 11.2 |

| Aromatics (%) | 31.3 | |

| Resins (%) | 29.1 | |

| Asphaltenes (%) | 28.4 | |

| Sieve (mm) | 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Passing (%) | 100 | 99.2 | 98.3 | 90.9 | 68.4 | 50.3 | 34.1 | 26 | 17.4 | 14.3 | 4.7 |

| Sieve (mm) | 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Passing (%) | 96.7 | 87.5 | 78.3 | 60.2 | 42.2 | 25.3 | 18.7 | 15.4 | 11.5 | 9.2 | 6.1 |

| Sieve (mm) | 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Passing (%) | 97.1 | 87.5 | 76.6 | 55.7 | 38.2 | 27.5 | 18.8 | 16.2 | 12.7 | 10.2 | 5.1 |

| Performance | VHMA | |

|---|---|---|

| Rutting resistance | d60 (mm) | 2.263 |

| DS (time/mm) | 1300 | |

| Water stability | MS0 (%) | 89 |

| TSR (%) | 83 | |

| Fatigue property | Nf at 0.2 P (times) | 10,350 |

| Nf at 0.3 P (times) | 7951 | |

| Nf at 0.4 P (times) | 4642 | |

| Nf at 0.5 P (times) | 3617 | |

| Crack resistance | Failure strength (MPa) | 7.3 |

| Failure strain (%) | 2990 | |

| Failure stiffness modulus (MPa) | 2120 | |

| Performance | CR Content (%) | |||||

|---|---|---|---|---|---|---|

| 0 | 5 | 10 | 15 | 20 | ||

| Rutting resistance | d60 (mm) | 2.011 | 2.137 | 2.248 | 2.352 | 2.473 |

| DS (time/mm) | 2650 | 2271 | 1753 | 1220 | 920 | |

| Water stability | MS0 (%) | 67 | 70 | 72 | 78 | 82 |

| TSR (%) | 61 | 64 | 68 | 73 | 79 | |

| Fatigue property | Nf at 0.2 P (times) | 5860 | 6760 | 7145 | 8542 | 9350 |

| Nf at 0.3 P (times) | 3155 | 3555 | 4153 | 6340 | 7620 | |

| Nf at 0.4 P (times) | 1375 | 2100 | 2600 | 3650 | 4100 | |

| Nf at 0.5 P (times) | 650 | 1000 | 1270 | 2005 | 2410 | |

| Crack resistance | Failure strength (MPa) | 4.2 | 4.5 | 5.2 | 5.8 | 6.7 |

| Failure strain (%) | 1400 | 1550 | 1800 | 2072 | 2300 | |

| Failure stiffness modulus (MPa) | 3020 | 2800 | 2605 | 2317 | 2150 | |

| ESO Content (%) | Nf | Fatigue Equation | Equation Parameters | ||||

|---|---|---|---|---|---|---|---|

| Stress Ratio | K | n | |||||

| 0.2 | 0.3 | 0.4 | 0.5 | ||||

| 0 | 7145 | 4153 | 2600 | 1270 | 1121 | 1.149 | |

| 1 | 7948 | 4810 | 3170 | 1680 | 1492 | 1.405 | |

| 3 | 8327 | 5210 | 3550 | 2010 | 1791 | 1.577 | |

| 5 | 9054 | 5620 | 3770 | 2690 | 2248 | 1.665 | |

| 7 | 9945 | 6074 | 4660 | 3757 | 3124 | 1.812 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuang, D.; Jiao, Y.; Ye, Z.; Lu, Z.; Chen, H.; Yu, J.; Liu, N. Diffusibility Enhancement of Rejuvenator by Epoxidized Soybean Oil and Its Influence on the Performance of Recycled Hot Mix Asphalt Mixtures. Materials 2018, 11, 833. https://doi.org/10.3390/ma11050833

Kuang D, Jiao Y, Ye Z, Lu Z, Chen H, Yu J, Liu N. Diffusibility Enhancement of Rejuvenator by Epoxidized Soybean Oil and Its Influence on the Performance of Recycled Hot Mix Asphalt Mixtures. Materials. 2018; 11(5):833. https://doi.org/10.3390/ma11050833

Chicago/Turabian StyleKuang, Dongliang, Yuan Jiao, Zhou Ye, Zaihong Lu, Huaxin Chen, Jianying Yu, and Ning Liu. 2018. "Diffusibility Enhancement of Rejuvenator by Epoxidized Soybean Oil and Its Influence on the Performance of Recycled Hot Mix Asphalt Mixtures" Materials 11, no. 5: 833. https://doi.org/10.3390/ma11050833

APA StyleKuang, D., Jiao, Y., Ye, Z., Lu, Z., Chen, H., Yu, J., & Liu, N. (2018). Diffusibility Enhancement of Rejuvenator by Epoxidized Soybean Oil and Its Influence on the Performance of Recycled Hot Mix Asphalt Mixtures. Materials, 11(5), 833. https://doi.org/10.3390/ma11050833