Synthesis and Thermoelectric Properties of Pd-Doped ZrCoBi Half-Heusler Compounds

Abstract

1. Introduction

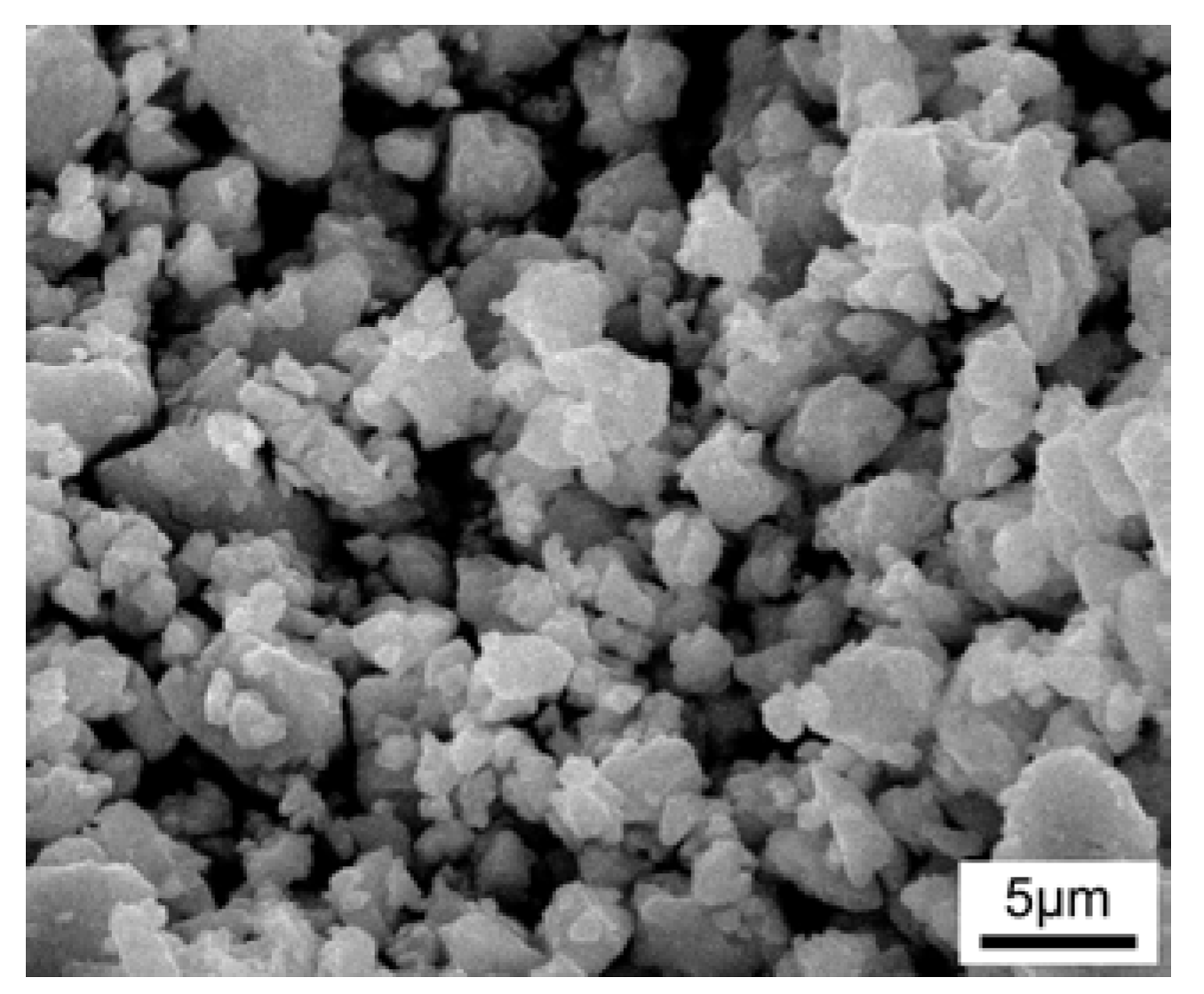

2. Experimental Procedures

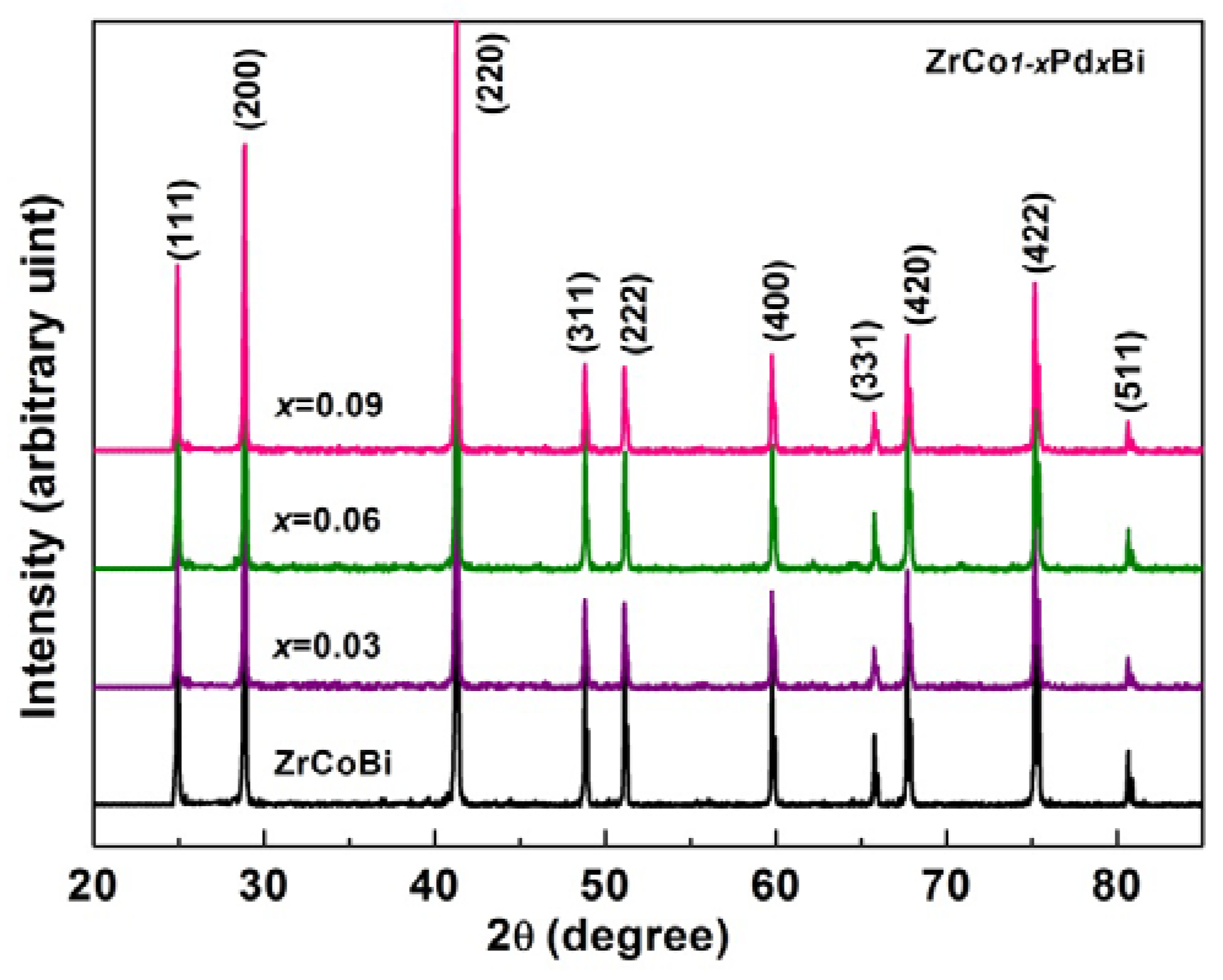

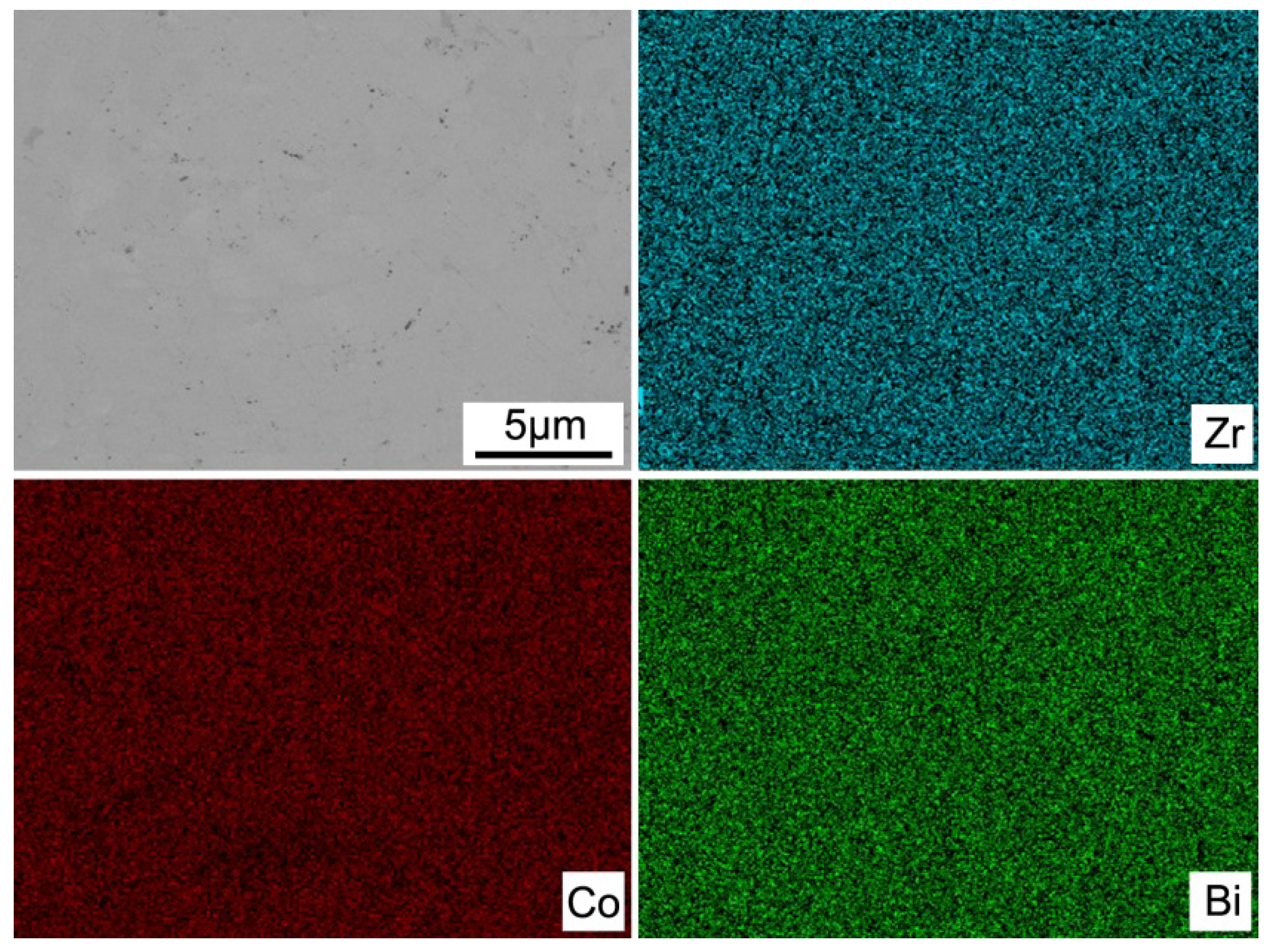

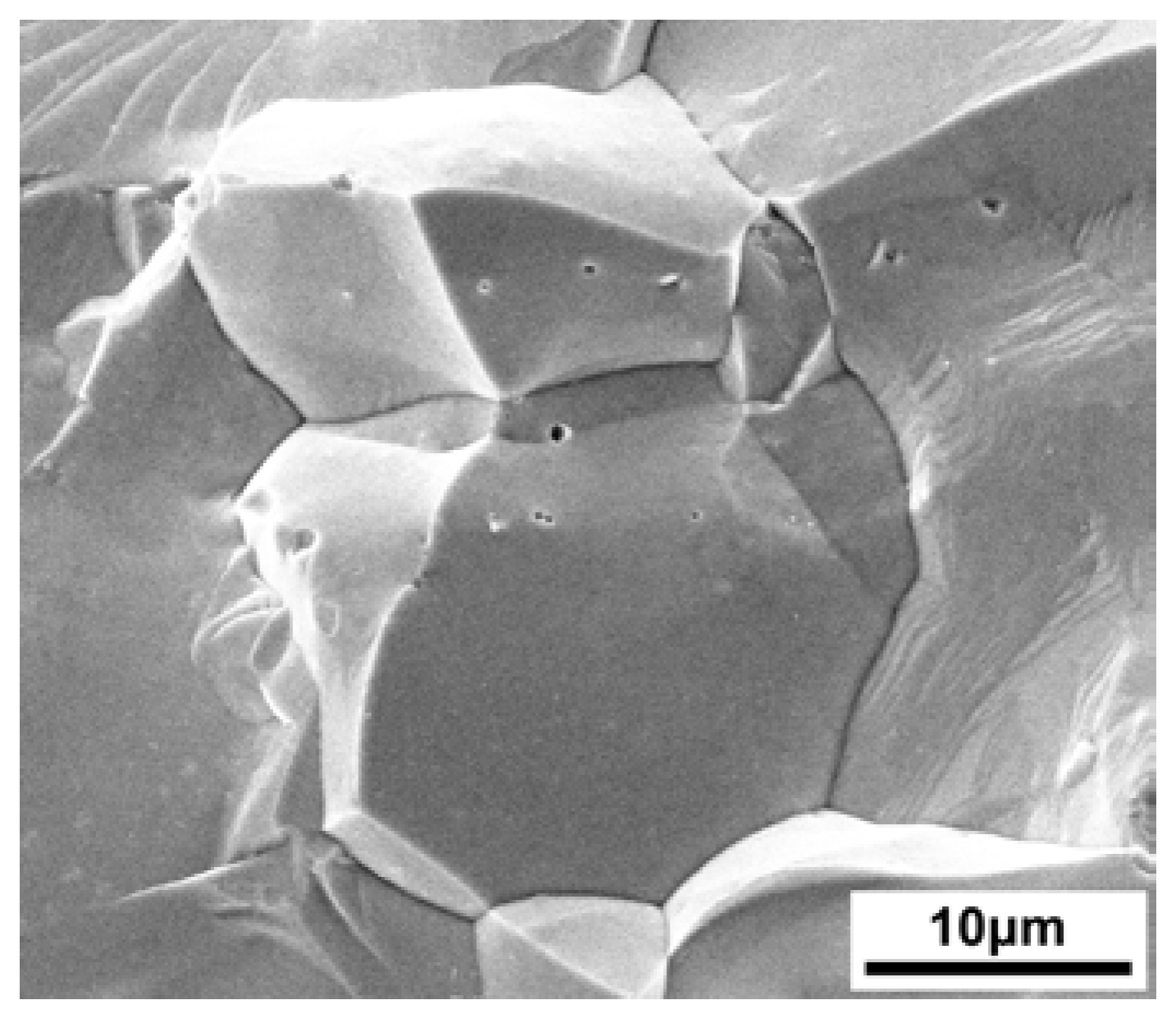

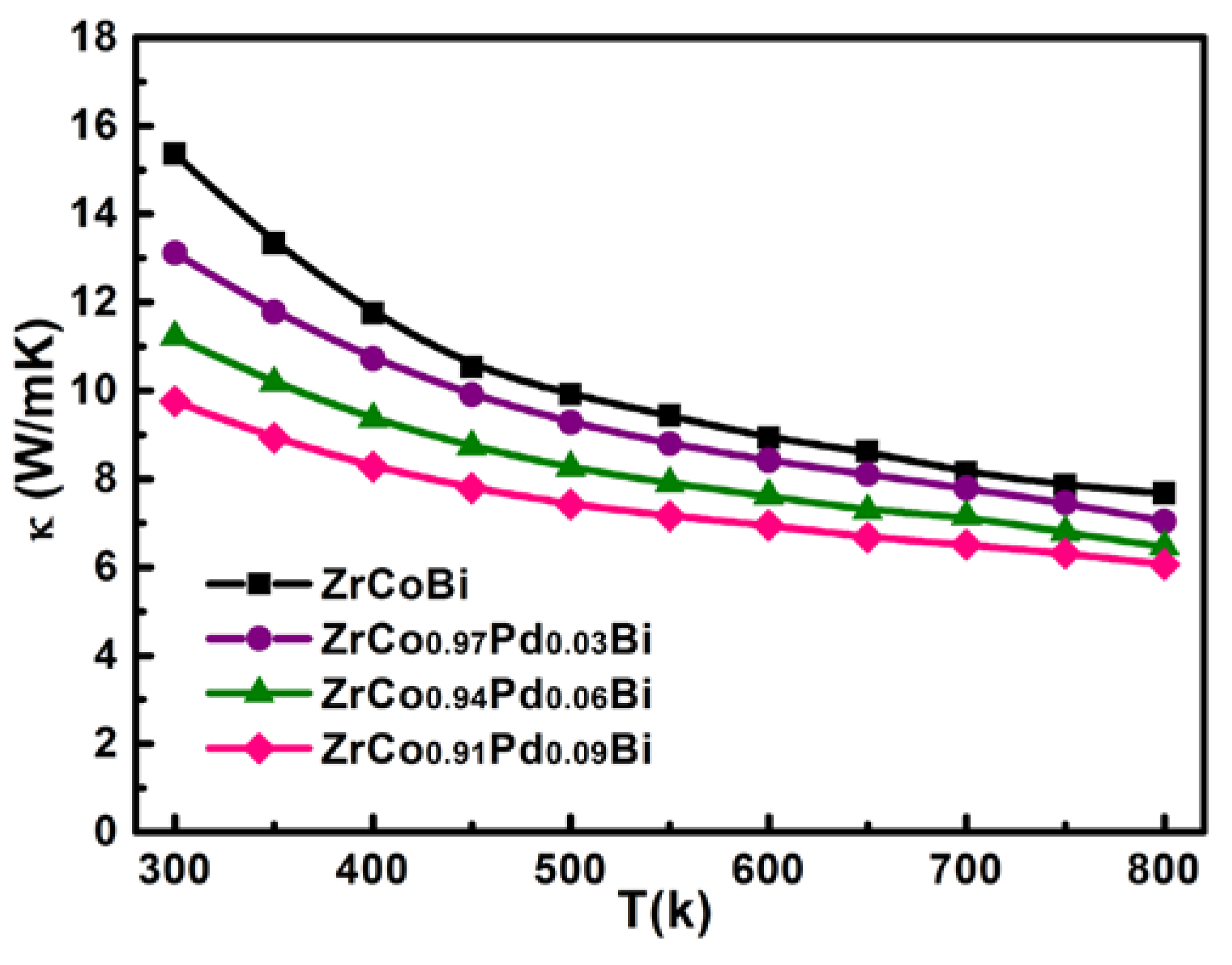

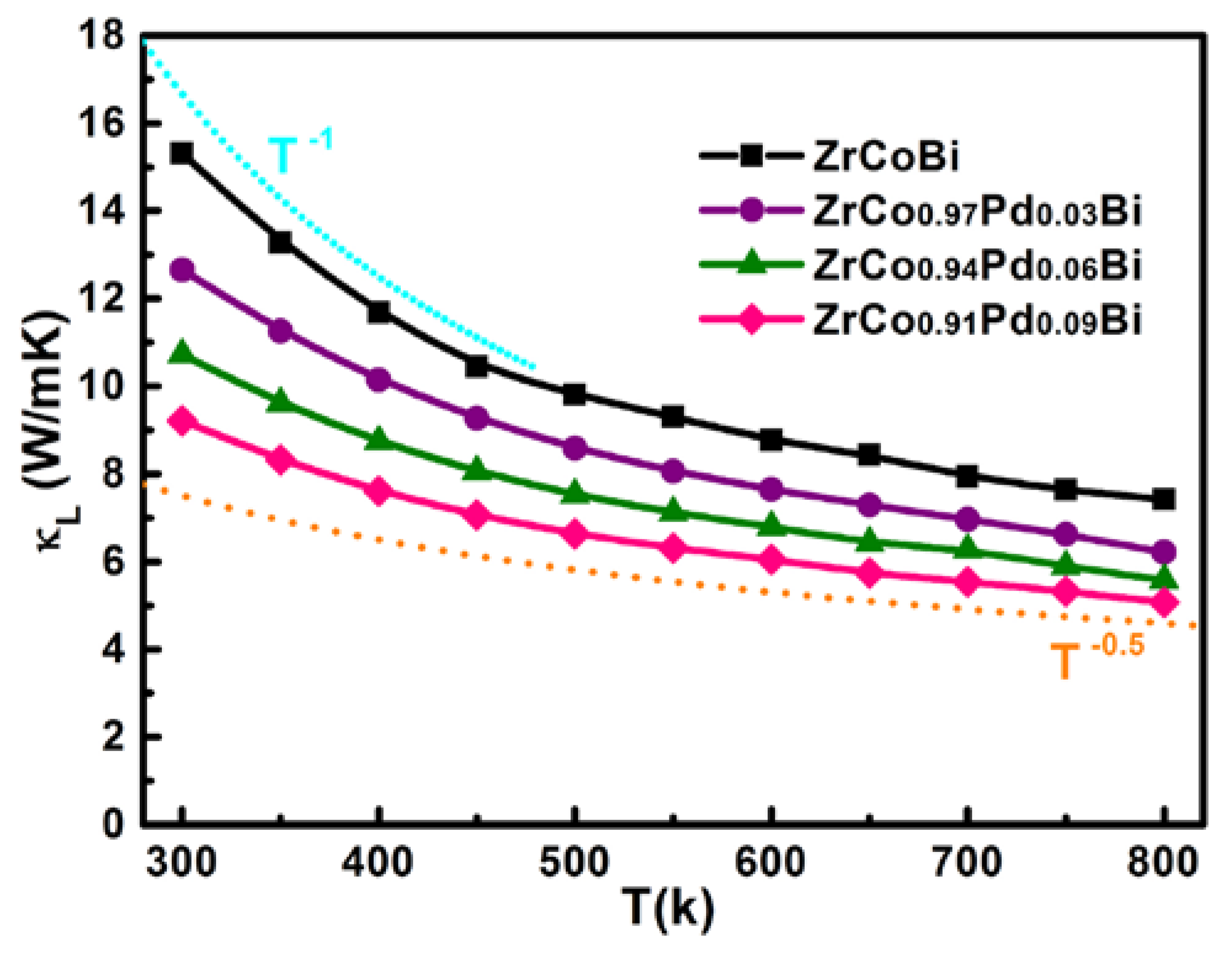

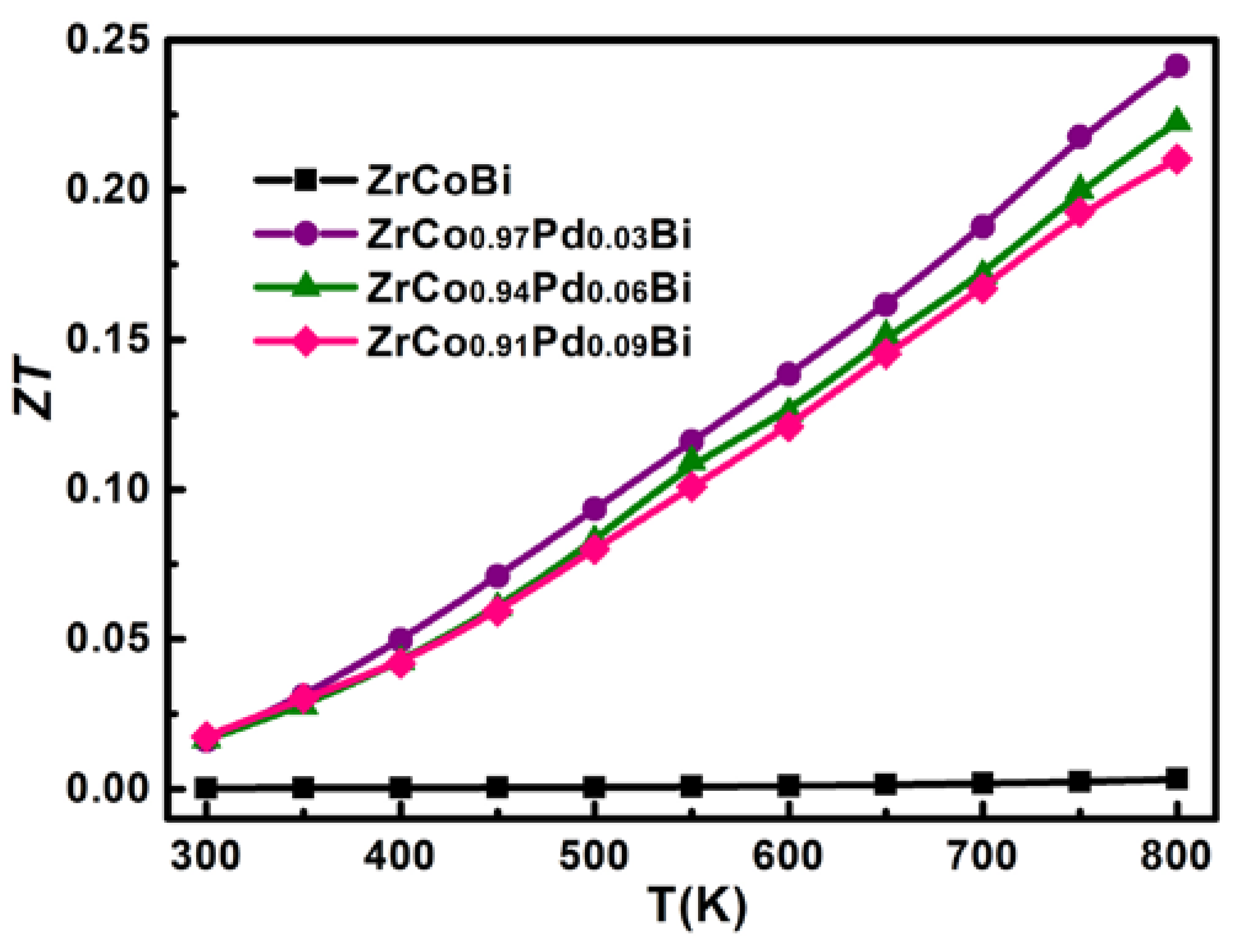

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gayner, C.; Kar, K.K. Recent advances in thermoelectric materials. Prog. Mat. Sci. 2016, 83, 330–382. [Google Scholar] [CrossRef]

- Liu, R.H.; Chen, H.Y.; Zhao, K.P.; Qin, Y.T.; Jiang, B.B.; Zhang, T.S.; Sha, G.; Shi, X.; Uher, C.; Zhang, W.Q; et al. Entropy as a gene-like performance indicator promoting thermoelectric materials. Adv. Mater. 2017, 29, 1702712. [Google Scholar] [CrossRef] [PubMed]

- Zhu, T.J.; Fu, C.G.; Xie, H.H.; Liu, Y.T.; Zhao, X.B. High efficiency half-Heusler thermoelectric materials for energy harvesting. Adv. Energy. Mater. 2015, 5, 1500588. [Google Scholar] [CrossRef]

- Huang, L.H.; Zhang, Q.Y.; Yuan, B.; Lai, X.; Yan, X.; Ren, Z.F. Recent progress in half-Heusler thermoelectric materials. Mater. Res. Bull. 2016, 76, 107–112. [Google Scholar] [CrossRef]

- Kangsabanik, J.; Alam, A. Bismuth based half-Heusler alloys with giant thermoelectric figures of merit. J. Mater. Chem. A 2017, 5, 6131–6139. [Google Scholar]

- Chen, L.; Zeng, X.Y.; Tritt, T.M.; Poon, S.J. Half-Heusler alloys for efficient thermoelectric power conversion. J. Electron. Mater. 2016, 45, 5554–5560. [Google Scholar] [CrossRef]

- Xia, K.Y.; Liu, Y.T.; Anand, S.; Snyder, G.J.; Xin, J.Z.; Yu, J.J.; Zhao, X.B.; Zhu, T.J. Enhanced Thermoelectric Performance in 18-Electron Nb0.8CoSb Half-Heusler Compound with Intrinsic Nb Vacancies. Adv. Funct. Mater. 2018, 28, 1705845. [Google Scholar] [CrossRef]

- Fu, C.G.; Bai, S.Q.; Liu, Y.T.; Tang, Y.S.; Chen, L.D.; Zhao, X.B.; Zhu, T.J. Realizing high figure of merit in heavy-band p-type half-Heusler thermoelectric materials. Nat. Commun. 2015, 6, 8144. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Ren, Z.F. Recent progress of half-Heusler for moderate temperature thermoelectric applications. Mater. Today 2013, 16, 387–395. [Google Scholar] [CrossRef]

- Tang, Y.L.; Li, X.S.; Martin, L.H.; Reyes, E.C.; Ivas, T.; Leinenbach, C.; Anand, S.; Peters, M.; Snyder, G.J.; Battaglia, C. Impact of Ni content on the thermoelectric properties of half-Heusler TiNiSn. Energy Environ. Sci. 2018, 11, 311–320. [Google Scholar] [CrossRef]

- Huang, L.H.; Zhang, Q.Y.; Wang, Y.M.; He, R.; Shuai, J.; Zhang, J.J.; Wang, C.; Ren, Z.F. The effect of Sn doping on thermoelectric performance of n-type half-Heusler NbCoSb. Phys. Chem. Chem. Phys. 2017, 19, 25683–25690. [Google Scholar] [CrossRef] [PubMed]

- Uher, C.; Yang, J.; Hu, S.; Morelli, D.T.; Meisner, G.P. Transport properties of pure and doped MNiSn (M = Zr, Hf). Phys. Rev. B 1999, 59, 8615–8621. [Google Scholar] [CrossRef]

- Rausch, E.; Castegnaro, M.V.; Bernardi, F.; Alves, M.C.; Morais, J.; Balke, B. Short and long range order of Half-Heusler phases in (Ti,Zr,Hf)CoSb thermoelectric compounds. Acta Mater. 2016, 115, 308–313. [Google Scholar] [CrossRef]

- Downie, R.A.; Barczak, S.A.; Bos, J.W. Compositions and thermoelectric properties of XNiSn (X = Ti, Zr, Hf) half-Heusler alloys. J. Mater. Chem. C 2015, 3, 10534–10542. [Google Scholar] [CrossRef]

- Schmitt, J.; Gibbs, Z.; Snyder, G.J.; Felser, C. Resolving the true band gap of ZrNiSn half-Heusler thermoelectric materials. Mater. Horiz. 2014, 2, 68–75. [Google Scholar] [CrossRef]

- Berry, T.; Ouardi, S.; Fecher, G.H.; Balke, B.; Kreiner, G.; Auffermann, G.; Schnelle, W.; Felser, C. Improving thermoelectric performance of TiNiSn by mixing MnNiSb in the half-Heusler structure. Phys. Chem. Chem. Phys. 2017, 19, 1543–1550. [Google Scholar] [CrossRef] [PubMed]

- Ponnambalam, V.; Zhang, B.; Tritt, T.M. Thermoelectric properties of half-Heusler bismuthides ZrCo1-xNixBi (x = 0.0 to 0.1). J. Electron. Mater. 2007, 36, 732–735. [Google Scholar] [CrossRef]

- Cullity, B.D.; Stock, S.R. Elements of X-ray Diffraction, 3rd ed.; Pearson: London, UK, 2001. [Google Scholar]

- Rizal, C.; Kolthammer, J.; Pokharel, R.K.; Choi, B.C. Magnetic properties of nanostructured Fe-Co alloys. J. Appl. Phys. 2013, 113, 113905. [Google Scholar] [CrossRef]

- Rizal, C.; Fullerton, E.E. Perpendicular magnetic anisotropy and microstructure properties of nanoscale Co/Au multilayers. J. Appl. Phys. 2017, 50, 355002. [Google Scholar] [CrossRef]

- Yuan, B.; Wang, B.; Huang, L.H.; Lei, X.B.; Zhao, L.D.; Wang, C.; Zhang, Q.Y. Effects of Sb Substitution by Sn on the Thermoelectric Properties of ZrCoSb. J. Electron. Mater. 2017, 46, 3076–3082. [Google Scholar] [CrossRef]

- Downie, R.A.; MacLaren, D.A.; Bos, J.W. Thermoelectric performance of multiphase XNiSn (X = Ti, Zr, Hf) half-Heusler alloys. J. Mater. Chem. A. 2014, 2, 6107–6114. [Google Scholar] [CrossRef]

- Romaka, V.V.; Romaka, L.; Rogl, P.; Stadnyk, Y.; Melnychenko, N.; Korzh, R. Peculiarities of thermoelectric half-Heusler phase formation in Zr-Co-Sb ternary system. J. Alloys Compd. 2014, 585, 448–454. [Google Scholar] [CrossRef]

- Qiu, P.F.; Shi, X.; Chen, X.H.; Huang, X.Y.; Liu, R.H.; Chen, L. Effects of Sn-doping on the electrical and thermal transport properties of p-type Cerium filled skutterudites. J. Alloys Compd. 2011, 509, 1101–1105. [Google Scholar] [CrossRef]

- Shi, X.; Yang, J.; Bai, S.Q.; Yang, J.H.; Wang, H.; Chi, M.F.; Salvador, J.R.; Zhang, W.Q.; Chen, L.D. On the design of high efficiency thermoelectric clathrates through a systematic cross substitution of framework elements. Adv. Funct. Mater. 2010, 20, 755–763. [Google Scholar] [CrossRef]

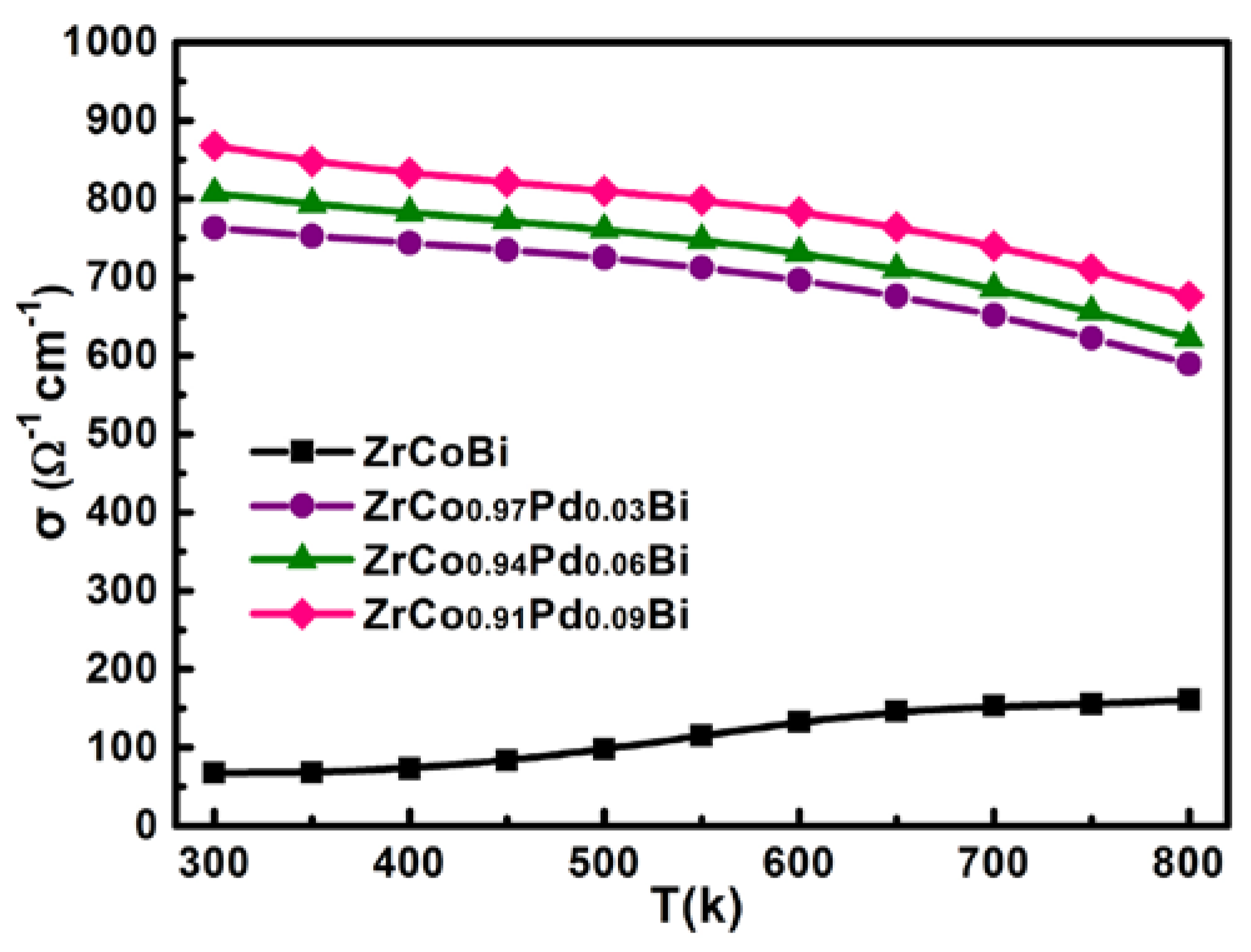

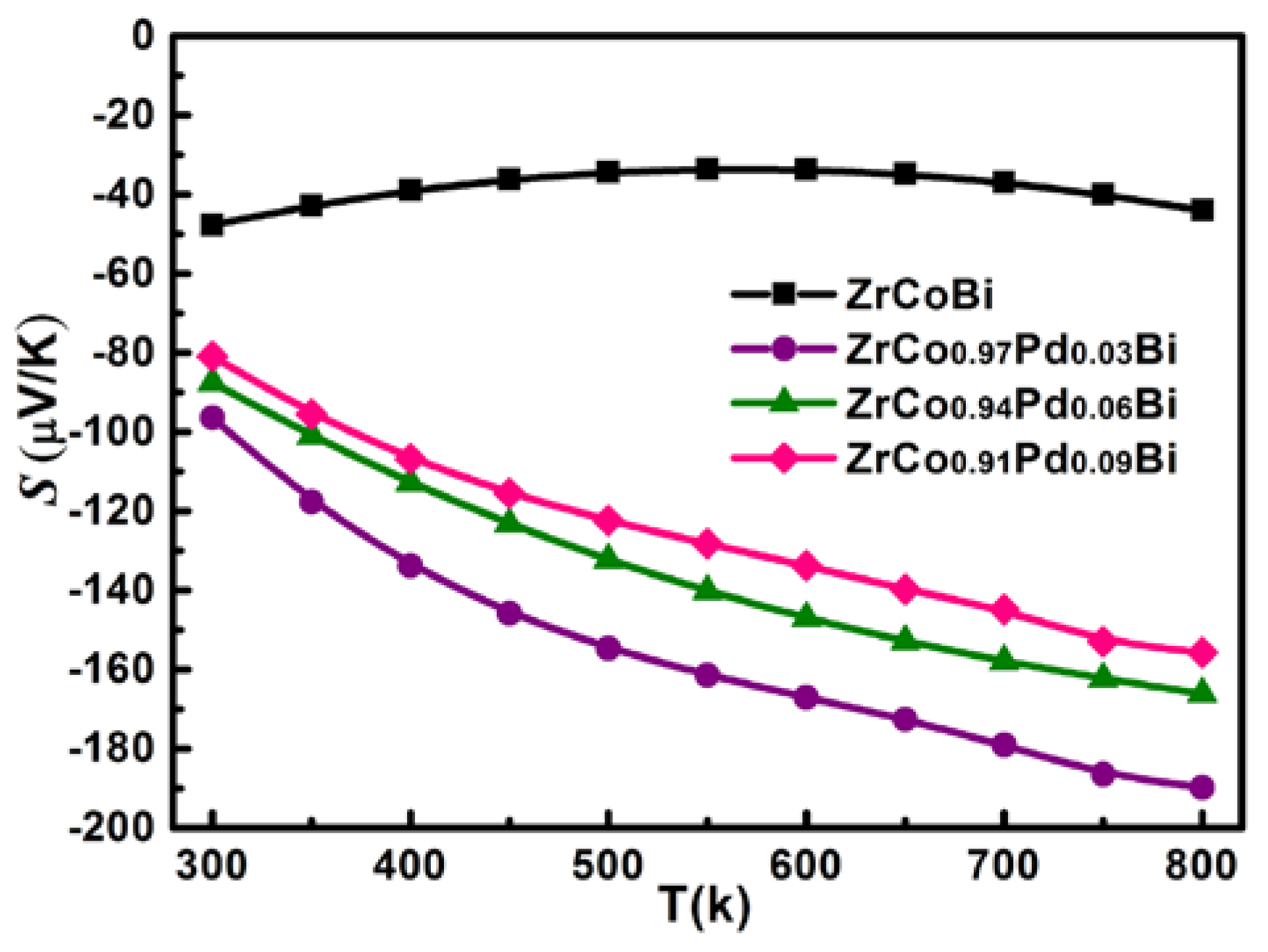

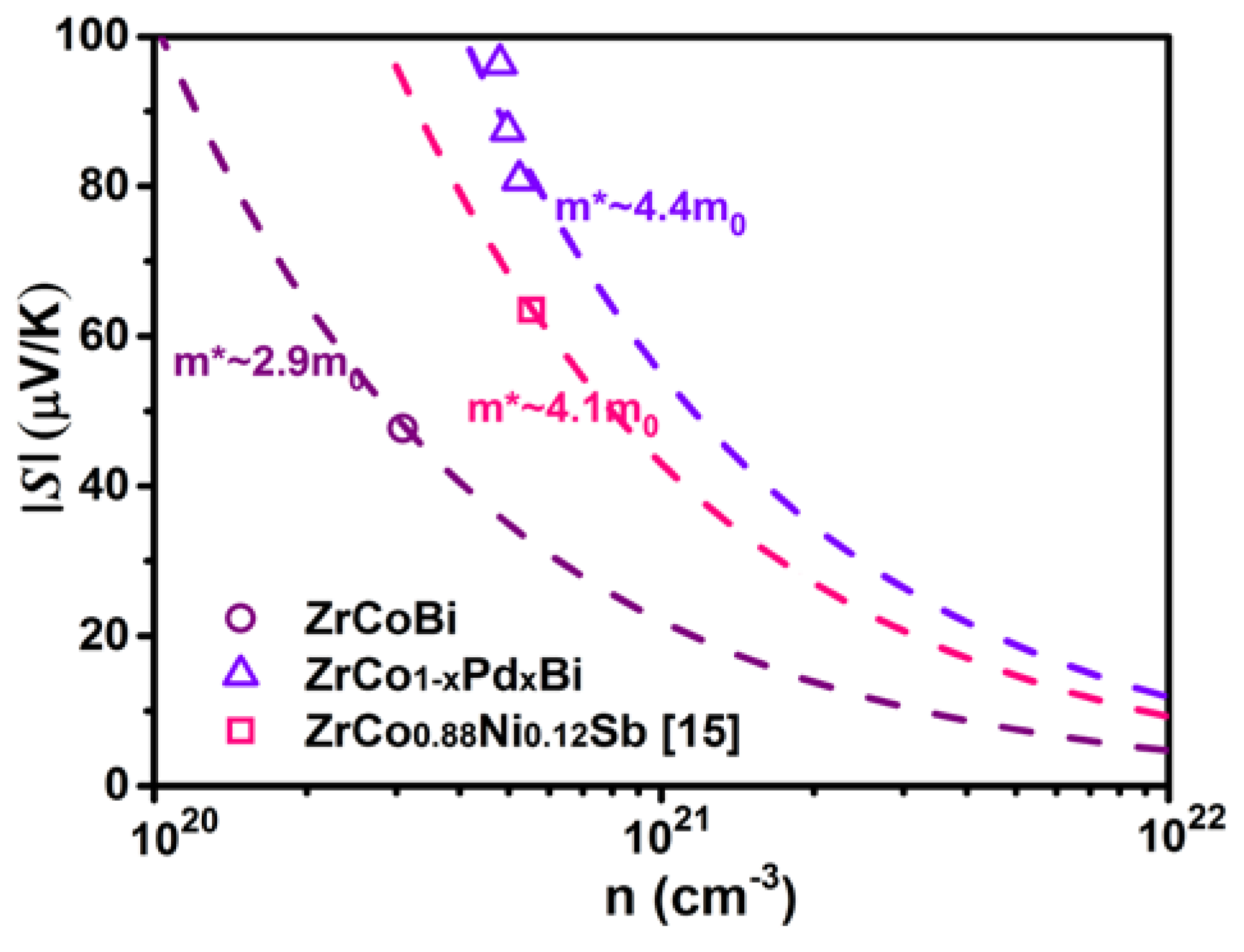

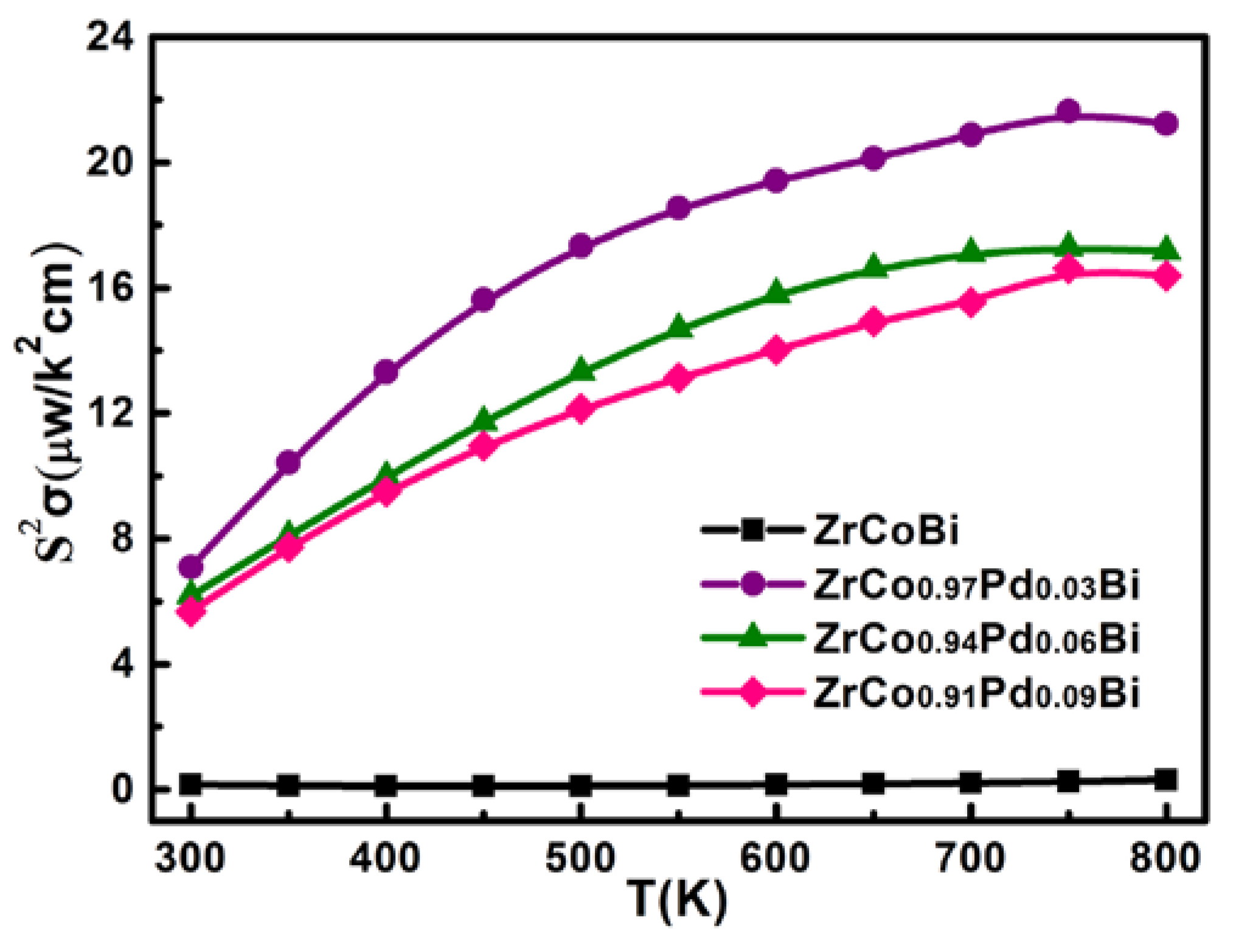

| x | Relative Density | S (μV/K) | μH (cm2·V−1·s−1) | σ (Ω−1·cm−1) | κL (W·m−1·K−1) | n (1020 cm−3) |

|---|---|---|---|---|---|---|

| 0 | 98.1% | −47.7 | 1.37 | 67.6 | 16.2 | 3.09 |

| 0.03 | 98.6% | −96.4 | 9.94 | 762.8 | 14.2 | 4.80 |

| 0.06 | 97.9% | −87.5 | 10.1 | 807.2 | 12.7 | 4.97 |

| 0.09 | 98.8% | −80.9 | 10.3 | 867.7 | 10.3 | 5.25 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, D.; Zuo, M.; Bo, L.; Wang, Y. Synthesis and Thermoelectric Properties of Pd-Doped ZrCoBi Half-Heusler Compounds. Materials 2018, 11, 728. https://doi.org/10.3390/ma11050728

Zhao D, Zuo M, Bo L, Wang Y. Synthesis and Thermoelectric Properties of Pd-Doped ZrCoBi Half-Heusler Compounds. Materials. 2018; 11(5):728. https://doi.org/10.3390/ma11050728

Chicago/Turabian StyleZhao, Degang, Min Zuo, Lin Bo, and Yongpeng Wang. 2018. "Synthesis and Thermoelectric Properties of Pd-Doped ZrCoBi Half-Heusler Compounds" Materials 11, no. 5: 728. https://doi.org/10.3390/ma11050728

APA StyleZhao, D., Zuo, M., Bo, L., & Wang, Y. (2018). Synthesis and Thermoelectric Properties of Pd-Doped ZrCoBi Half-Heusler Compounds. Materials, 11(5), 728. https://doi.org/10.3390/ma11050728