Effects of the Tempering and High-Pressure Torsion Temperatures on Microstructure of Ferritic/Martensitic Steel Grade 91

Abstract

:1. Introduction

2. Materials and Methods

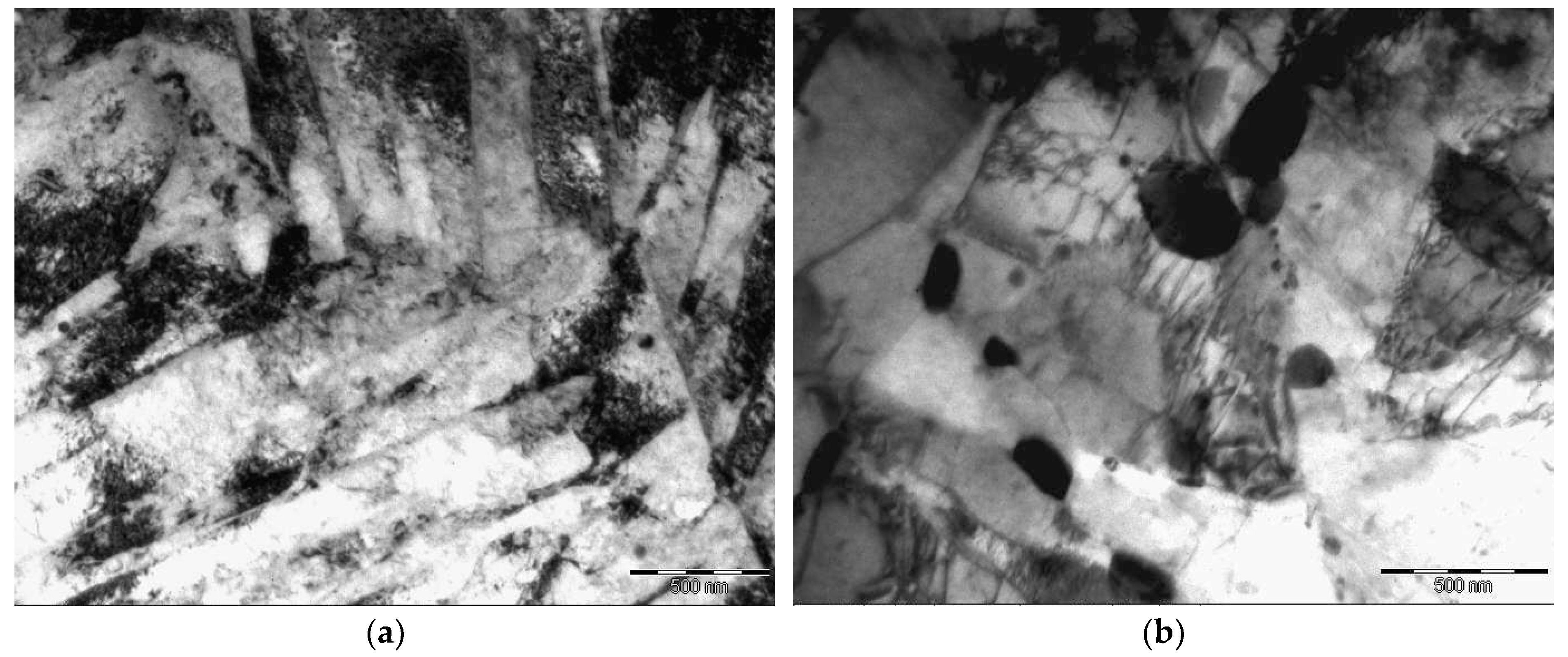

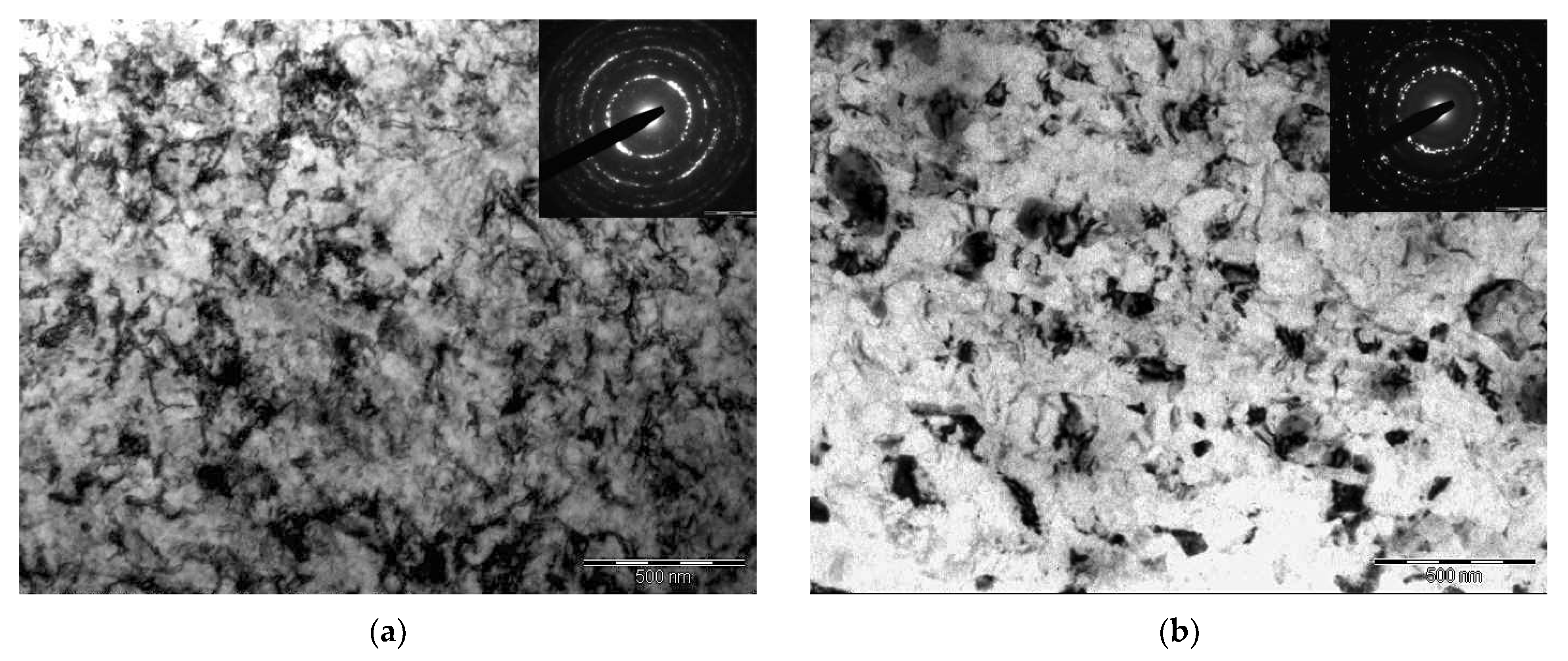

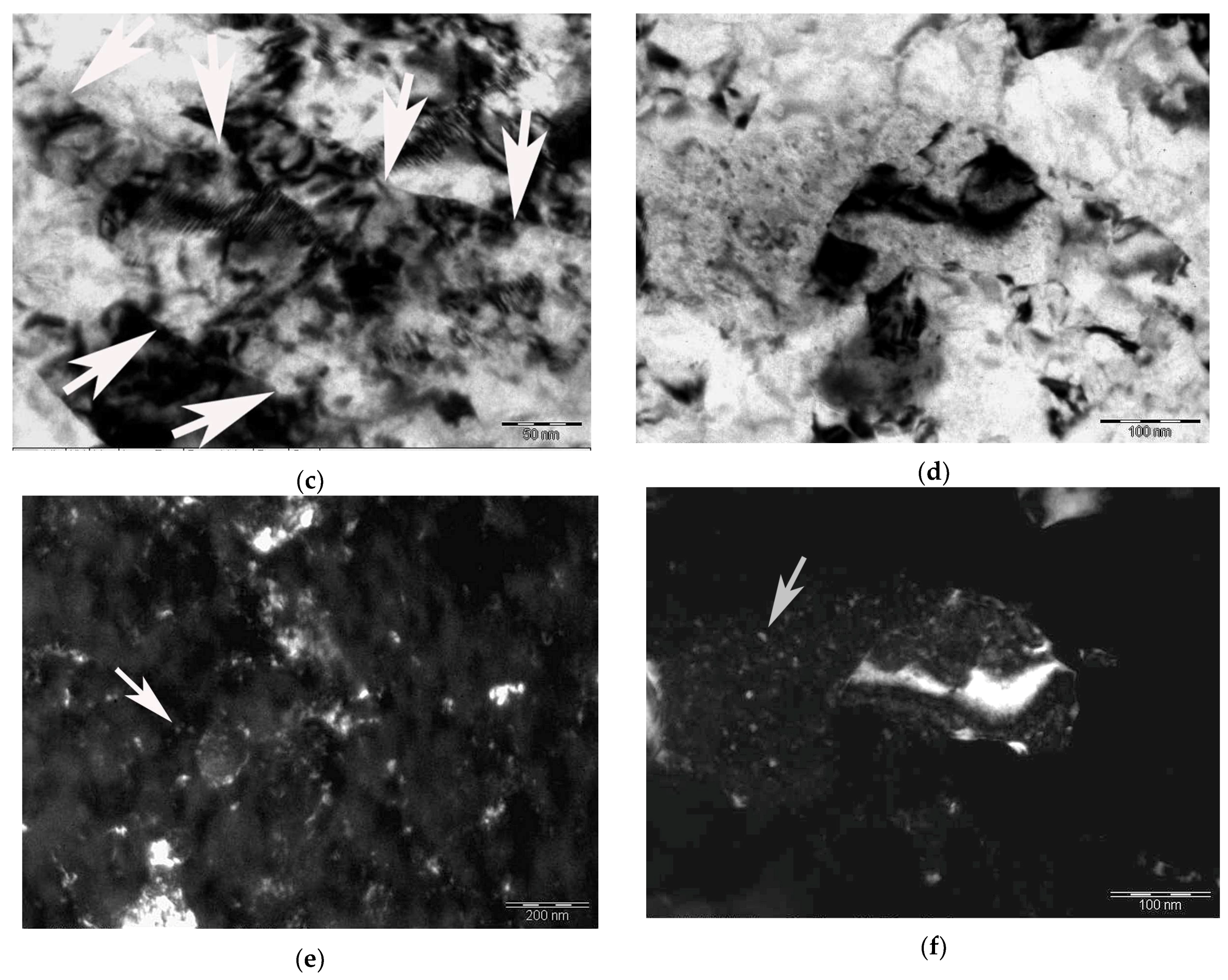

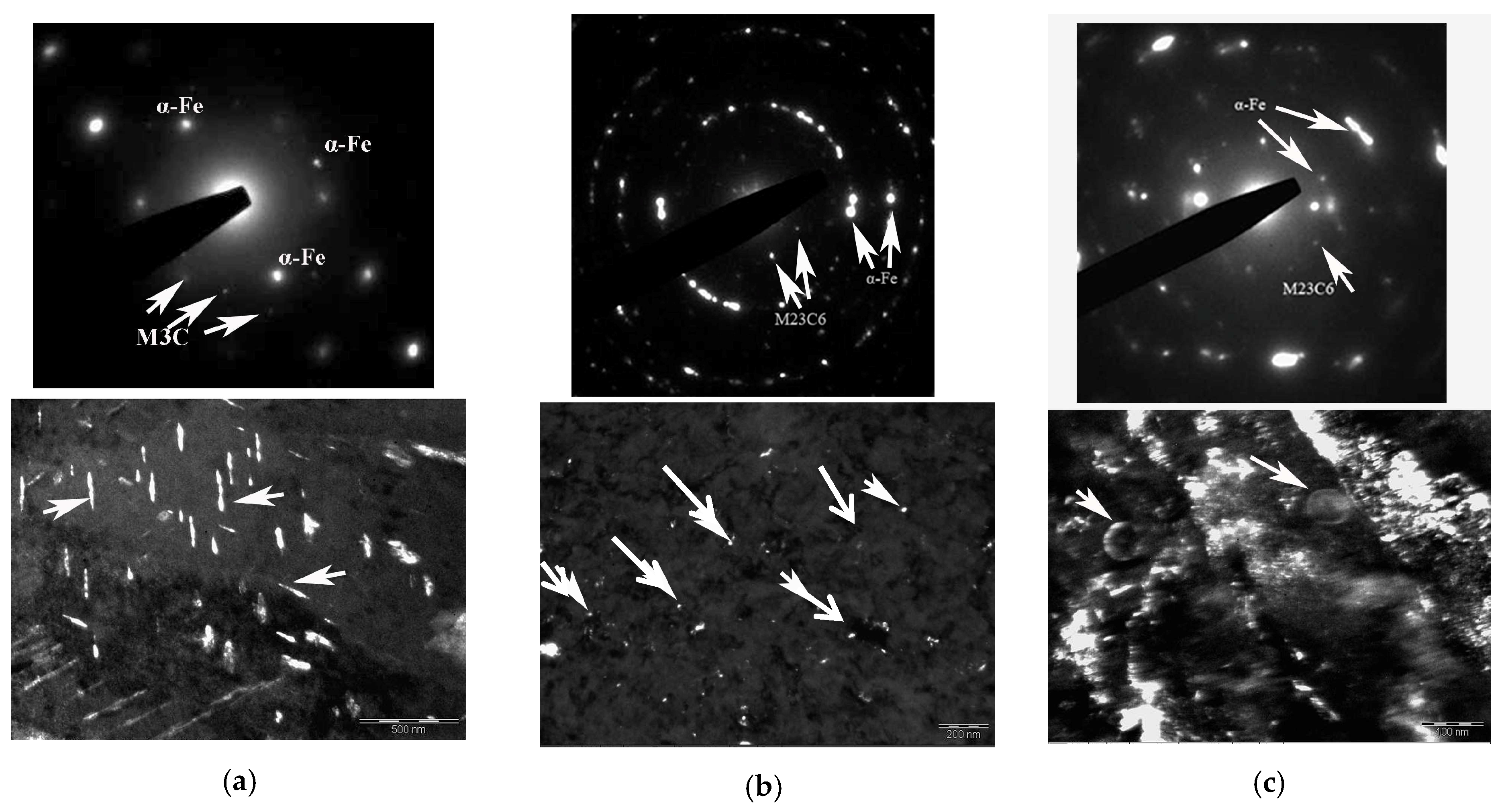

3. Results

4. Discussion

5. Conclusions

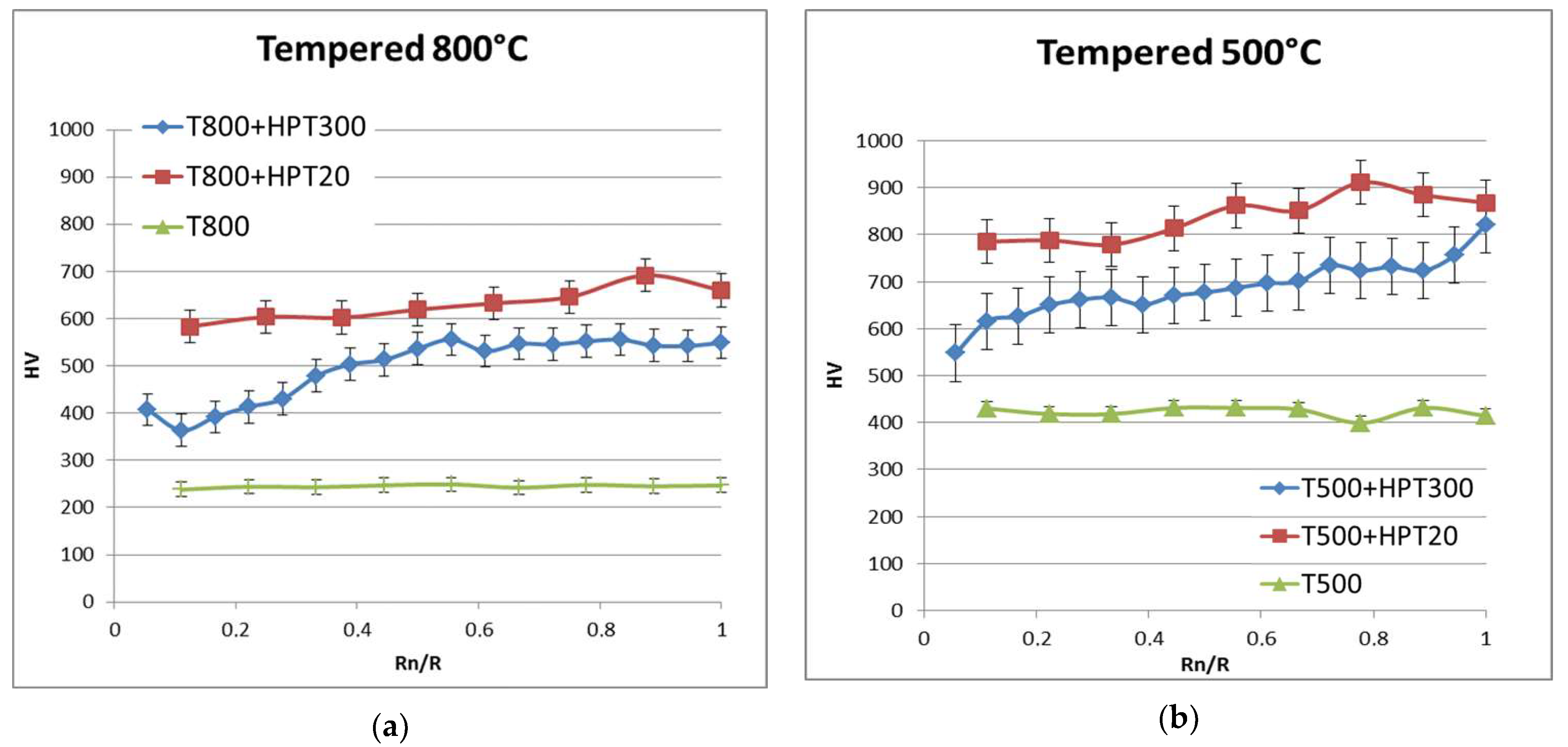

- After HPT of the samples containing martensite (tempered at 500 °С before HPT), the microhardness increases by two times to 8.4 GPa. Such microhardness is attributed to several factors: localization of plastic deformation inside martensitic plates inducing the formation of grains of 100–200 nm in size, the high degree of solid solution saturation, and high dislocation density. This may be due to the fact that the alloying elements necessary for the precipitations of carbonitrides remained in the solid solution.

- The increase in the microhardness after HPT processing of the ferritic samples (tempered at 800 °С before HPT) occurs mainly due to grain boundary strengthening. The microhardness increases by three times up to 6.4 GPa compared to the samples before HPT.

- The increase in HPT processing temperature from room temperature to 300 °С results in enhanced carbon diffusion, recovery, and significant reduction in the dislocation density.

- Severe plastic deformation has practically no significant effect on the refinement of coarse M23C6 carbides. Their fragmentation is possible if the carbide size does not exceed 100 nm. The increase in the temperature of the deformation leads only to a smaller scatter in size.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Abe, F. Precipitate design for creep strengthening of 9% Cr tempered martensitic steel for ultra-supercritical power plants. Sci. Technol. Adv. Mater. 2008, 9, 013002. [Google Scholar] [CrossRef] [PubMed]

- Shrestha, T.; Alsagabi, S.F.; Charit, I.; Potirniche, G.P.; Glazoff, M.V. Effect of heat treatment on microstructure and hardness of Grade 91 steel. Metals 2015, 5, 131–149. [Google Scholar] [CrossRef]

- Klueh, R.L.; Hashimoto, N.; Maziasz, P.J. New nano-particle-strengthened ferritic/martensitic steels by conventional thermo-mechanical treatment. J. Nucl. Mater. 2007, 367–370, 48–53. [Google Scholar] [CrossRef]

- Tan, L.; Hoelzer, D.T.; Busby, J.T.; Sokolov, M.A.; Klueh, R.L. Microstructure control for high strength 9Cr ferritic–martensitic steels. J. Nucl. Mater. 2012, 422, 45–50. [Google Scholar] [CrossRef]

- Hollner, S.; Fournier, B.; Le Pendu, J.; Cozzika, T.; Tournié, I.; Brachet, J.C.; Pineau, A. High-temperature mechanical properties improvement on modified 9Cr-1Mo martensitic steel through thermomechanical treatments. J. Nucl. Mater. 2010, 405, 101–105. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Song, M.; Wu, Y.D.; Wang, D.C.X.M.; Sun, C.; Yua, K.Y.; Chen, Y.; Shao, L.; Yang, Y.; Hartwig, K.T.; Zhang, X. Response of equal channel angular extrusion processed ultrafine-grained T91 steel subjected to high temperature heavy ion irradiation. Acta Mater. 2014, 74, 285–295. [Google Scholar] [CrossRef]

- Ueji, R.; Tsuji, N.; Minamino, Y.; Koizumi, Y. Ultragrain refinement of plain low carbon steel by cold-rolling and annealing of martensite. Acta Mater. 2002, 50, 4177. [Google Scholar] [CrossRef]

- Tsuji, N.; Ueji, R.; Minamino, Y.; Saito, Y. A new and simple process to obtain nano-structured bulk low-carbon steel with superior mechanical property. Scr. Mater. 2002, 46, 305–310. [Google Scholar] [CrossRef]

- Ueji, R.; Tsuji, N.; Minamino, Y.; Koizumi, Y. Effect of rolling reduction on ultrafine grained structure and mechanical properties of low-carbon steel thermomechanically processed from martensite starting structure. Sci. Technol. Adv. Mater. 2004, 5, 153–162. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Aydogan, E.; Chen, T.; Gigax, J.G.; Chen, D.; Wang, X.; Dzhumaev, P.S.; Emelyanova, O.V.; Ganchenkova, M.G.; Kalin, B.A.; Leontiva-Smirnova, M.; et al. Effect of self-ion irradiation on the microstructural changes of alloy EK-181 in annealed and severely deformed conditions. J. Nucl. Mater. 2017, 487, 96–104. [Google Scholar] [CrossRef]

- Kral, P.; Dvorak, J.; Sklenicka, V.; Masuda, T.; Horita, Z.; Kucharova, K.; Kvapilova, M.; Svobodova, M. Microstructure and creep behaviour of P92 steel after HPT. Mater. Sci. Eng. A 2018, 723, 287–295. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Sicupira, F.L.; Malheiros, L.R.C.; Kawasaki, M.; Santos, D.B.; Langdon, T.G. Formation of epsilon martensite by high-pressure torsion in a TRIP steel. Mater. Sci. Eng. A 2015, 625, 114–118. [Google Scholar] [CrossRef]

- Efros, B.; Pilyugin, V.; Patselov, A.; Gladkovskii, S.; Efros, N.; Loladze, L.; Varyukhin, V. Martensitic transitions in nanocrystalline metastable materials. Mater. Sci. Eng. A 2009, 503, 114–117. [Google Scholar] [CrossRef]

- Rybal’chenko, O.V.; Dobatkin, S.V.; Kaputkina, L.M.; Raab, G.I.; Krasilnikov, N.A. Strength of ultrafine-grained corrosion-resistant steels after severe plastic deformation. Mater. Sci. Eng. A 2004, 387–389, 244–248. [Google Scholar] [CrossRef]

- Litovchenko, I.Y.; Tyumentsev, A.N.; Zahozheva, M.I.; Korznikov, A.V. Direct and reverse martensitic transformation and formation of nanostructured states during severe plastic deformation of metastable austenitic stainless steel. Rev. Adv. Mater. Sci. 2012, 31, 47–53. [Google Scholar]

- Dobatkin, S.V.; Zrnik, J.; Mamuzic, I. Nanostructures by severe plastic deformation of steels: Advantages and problems. Metallurgija 2006, 45, 313–321. [Google Scholar]

- Scheriau, S.; Zhang, Z.; Kleber, S.; Pippan, R. Deformation mechanisms of a modified 316L austenitic steel subjected to high pressure torsion. Mater. Sci. Eng. A 2011, 528, 2776–2786. [Google Scholar] [CrossRef]

- Ganesh, B.J.; Raju, S.; Rai, A.K.; Mohandas, E.; Vijayalakshmi, M.; Rao, K.B.S.; Raj, B. Differential scanning calorimetry study of diffusional and martensitic phase transformations in some 9 wt % Cr low carbon ferritic steels. Mater. Sci. Technol. 2011, 27, 500–512. [Google Scholar] [CrossRef]

- Feng, B.; Levitas, V. Effects of gasket on coupled plastic flow and strain-induced phase transformations under high pressure and large torsion in a rotational diamond anvil cell. J. Appl. Phys. 2016, 119, 015902. [Google Scholar] [CrossRef]

- Kulagin, Y.B.R.; Toth, L.S.; Ivanisenko, Y. The self-similarity theory of high pressure torsion. Beilstein J. Nanotechnol. 2016, 7, 1267–1277. [Google Scholar] [CrossRef]

- Leoni, M.; Confente, T. Scardi, PM2K: A flexible program implementing Whole Powder Pattern Modelling. Z. Kristallogr. Suppl. 2006, 23, 249–254. [Google Scholar] [CrossRef]

- Cahn, R.W.; Haasen, P. (Eds.) Dislocations. In Physical Metallurgy, 4th ed.; Elsevier: Amsterdam, The Netherlands, 1996; Volume 3, pp. 1831–1875. [Google Scholar] [CrossRef]

- Swanson, H.E.; Fuyat, R.K.; Ugrinic, G.M. NBS Circular 539: Standard X-ray Diffraction Powder Patterns (Data for 30 Inorganic Substances); United States Government Publishing Office: Washington, DC, USA, 1954; Volume 3.

- Nishiyama, Z. Martensitic Transformations; Academic Press: New York, NY, USA, 2012; p. 480. ISBN 978-0-12-519850-9. [Google Scholar]

- Karavaeva, M.V.; Kiseleva, S.K.; Ganeev, A.V.; Protasova, E.O.; Ganiev, M.M.; Simonova, L.A.; Valiev, R.Z. Superior strength of carbon steel with an ultrafine-grained microstructure and its enhanced thermal stability. J. Mater. Sci. 2015, 50, 6730–6738. [Google Scholar] [CrossRef]

- Sauvage, X.; Quelennec, X.; Malandain, J.J.; Pareige, P.X. Nanostructure of a cold drawn tempered martensitic steel. Scr. Mater. 2006, 54, 1099–1103. [Google Scholar] [CrossRef]

- Ganeev, A.V.; Karavaeva, M.V.; Sauvage, X.; Valiev, R.Z. On the nature of high-strength state of carbon steel produced by severe plastic deformation. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2014. [Google Scholar]

- Zrnik, J.; Pippan, R.; Scheriau, S.; Kraus, L.; Fujda, M. Microstructure and mechanical properties of UFG medium carbon steel processed by HTP at increased temperature. J. Mater. Sci. 2010, 45, 4822–4826. [Google Scholar] [CrossRef]

- Hug, E.; Pralong, V.; Prasath, B.R.; Monnet, I.; Moisy, F.; Etienne, A.; Sauvage, X.; Radiguet, B.; Enikeev, N.; Abramova, M. Impact of the nanostructuration on the corrosion resistance and hardness of irradiated 316 austenitic stainless steels. Appl. Surface Sci. 2017, 392, 1026–1035. [Google Scholar] [CrossRef]

| С | Mn | P | S | Cu | Si | Ni | Cr | Mo | V | Ti | N |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.08 | 0.53 | 0.016 | 0.003 | 0.09 | 0.28 | 0.13 | 8.43 | 0.9 | 0.225 | 0.01 | 0.038 |

| State | Lattice Parameter (nm) | Size of CSD (nm) | Dislocation Density (10−15 m−2) |

|---|---|---|---|

| 500C +HPT 20C | 0.287957(2) | 34(3) | 22.4(2) |

| 500C + HPT 300C | 0.287869(11) | 57(4) | 11.9(3) |

| 800C + HPT 20C | 0.287802(10) | 36(3) | 10.5(4) |

| 800C + HPT 300C | 0.287436(7) | 61(4) | 3.5(2) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ganeev, A.; Nikitina, M.; Sitdikov, V.; Islamgaliev, R.; Hoffman, A.; Wen, H. Effects of the Tempering and High-Pressure Torsion Temperatures on Microstructure of Ferritic/Martensitic Steel Grade 91. Materials 2018, 11, 627. https://doi.org/10.3390/ma11040627

Ganeev A, Nikitina M, Sitdikov V, Islamgaliev R, Hoffman A, Wen H. Effects of the Tempering and High-Pressure Torsion Temperatures on Microstructure of Ferritic/Martensitic Steel Grade 91. Materials. 2018; 11(4):627. https://doi.org/10.3390/ma11040627

Chicago/Turabian StyleGaneev, Artur, Marina Nikitina, Vil Sitdikov, Rinat Islamgaliev, Andrew Hoffman, and Haiming Wen. 2018. "Effects of the Tempering and High-Pressure Torsion Temperatures on Microstructure of Ferritic/Martensitic Steel Grade 91" Materials 11, no. 4: 627. https://doi.org/10.3390/ma11040627

APA StyleGaneev, A., Nikitina, M., Sitdikov, V., Islamgaliev, R., Hoffman, A., & Wen, H. (2018). Effects of the Tempering and High-Pressure Torsion Temperatures on Microstructure of Ferritic/Martensitic Steel Grade 91. Materials, 11(4), 627. https://doi.org/10.3390/ma11040627