Carbon Fiber Reinforced Carbon–Al–Cu Composite for Friction Material

Abstract

1. Introduction

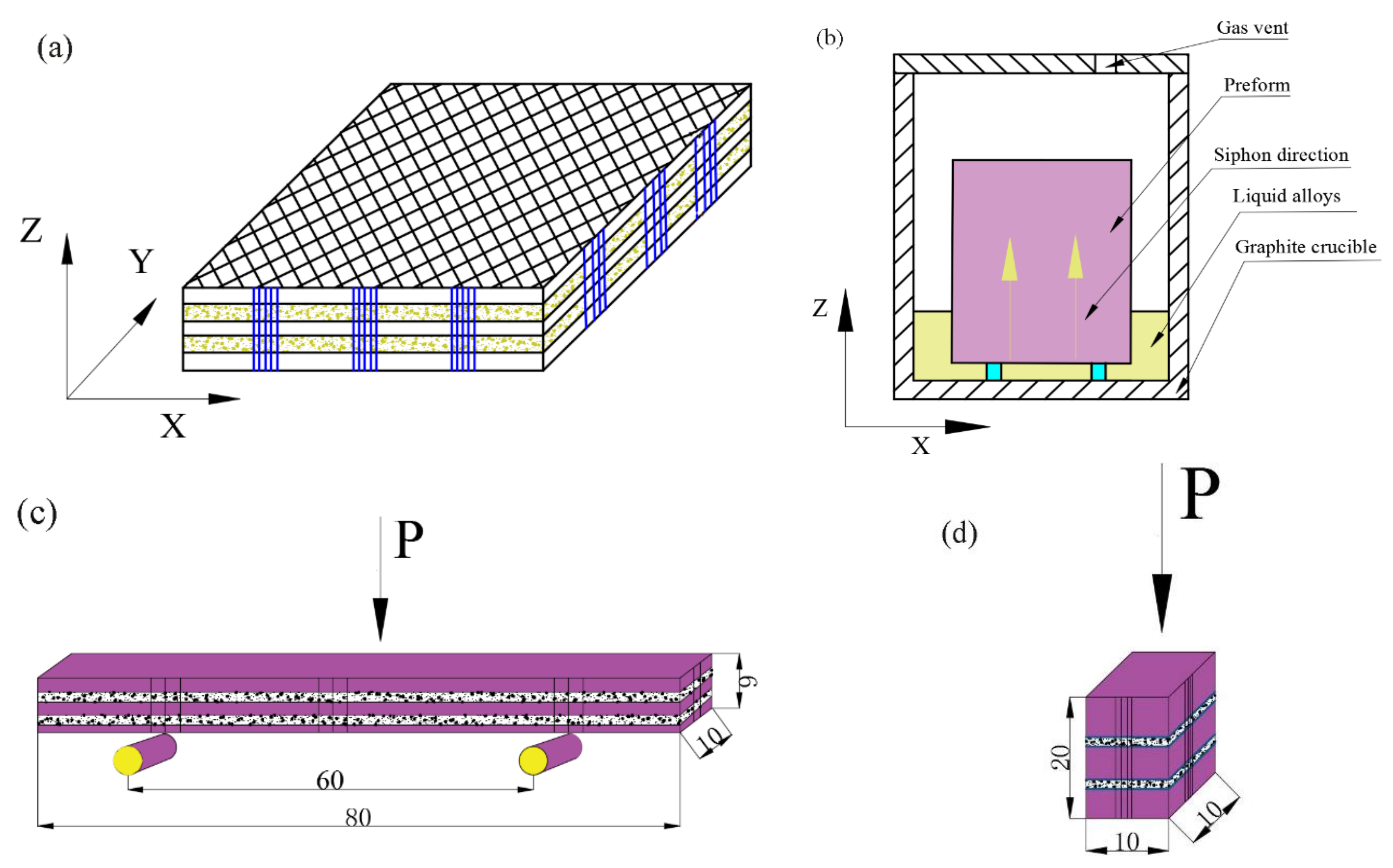

2. Experimental Procedure

2.1. Preparation of the Materials

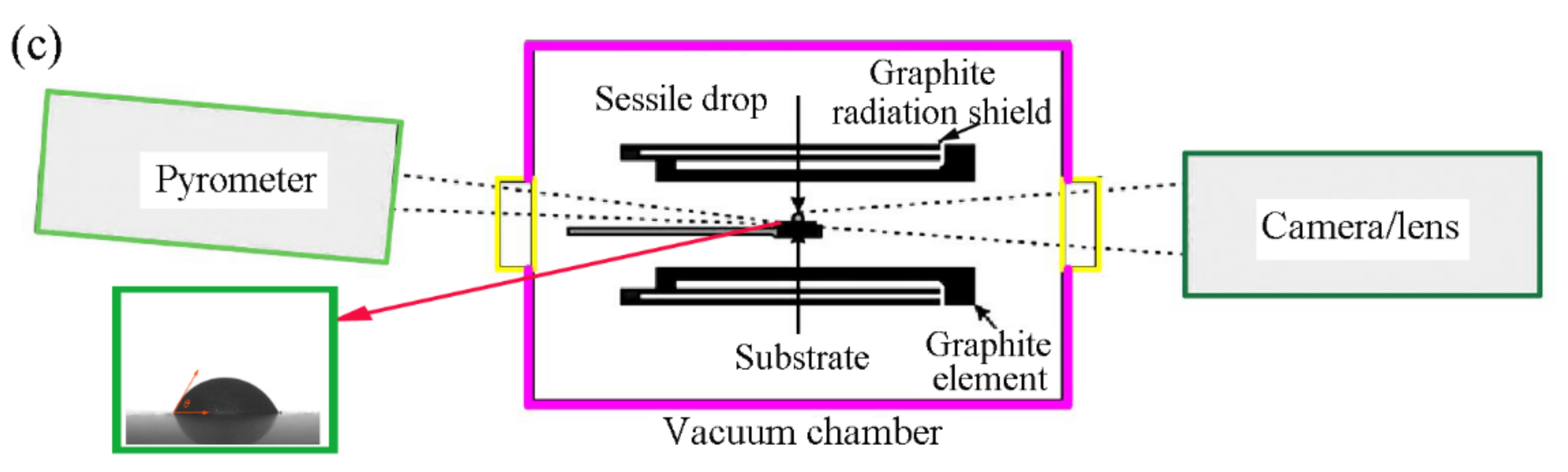

2.2. Testing Procedures

2.3. Electrical Resistivity Measurements

3. Results and Discussion

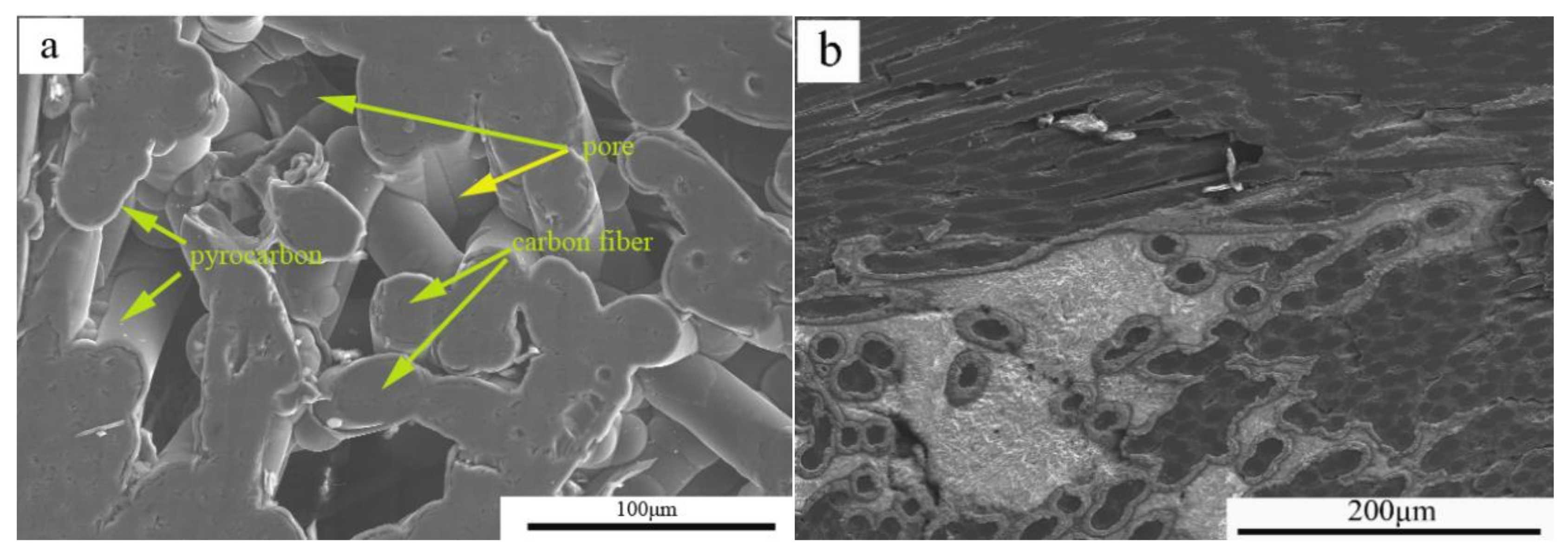

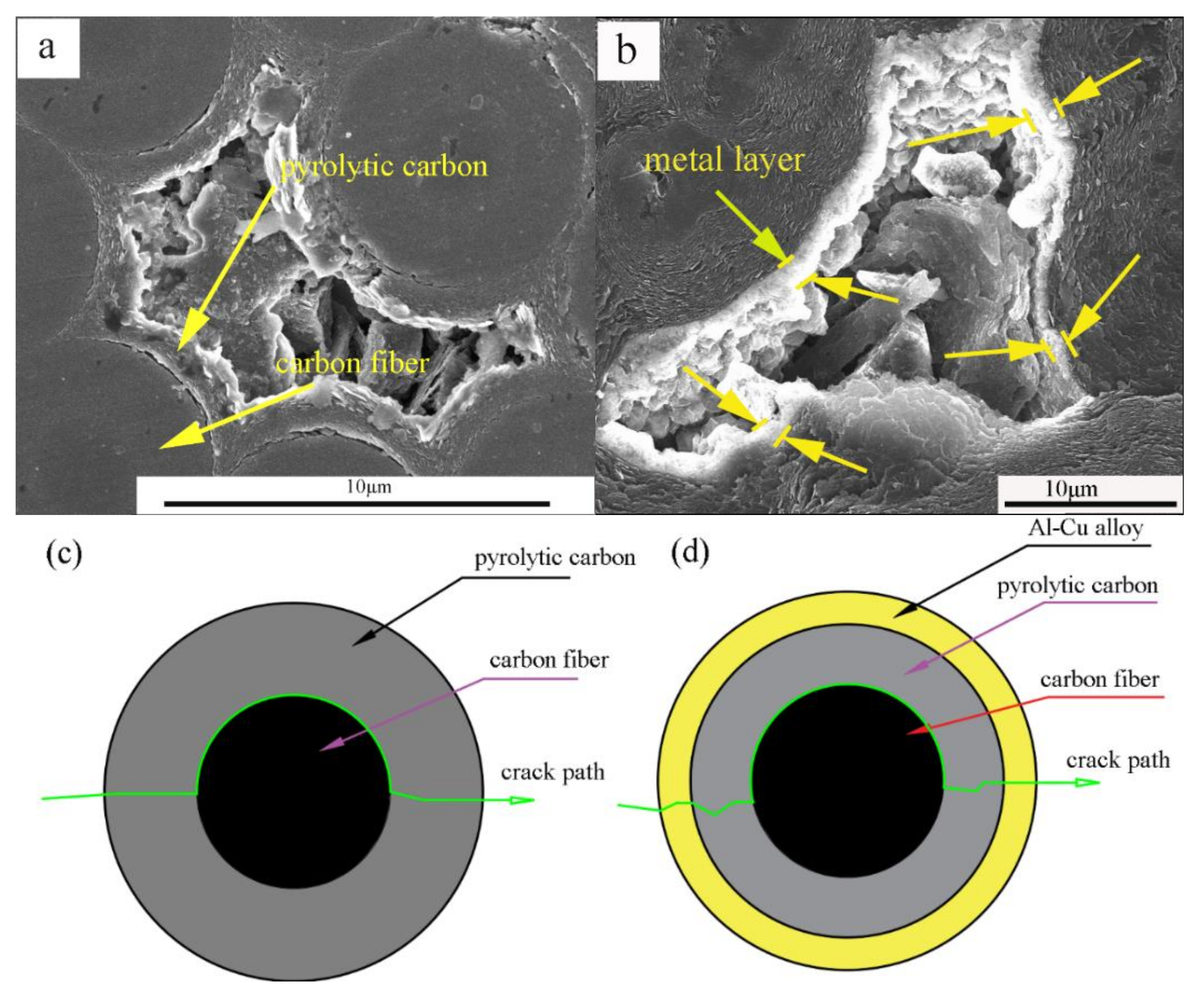

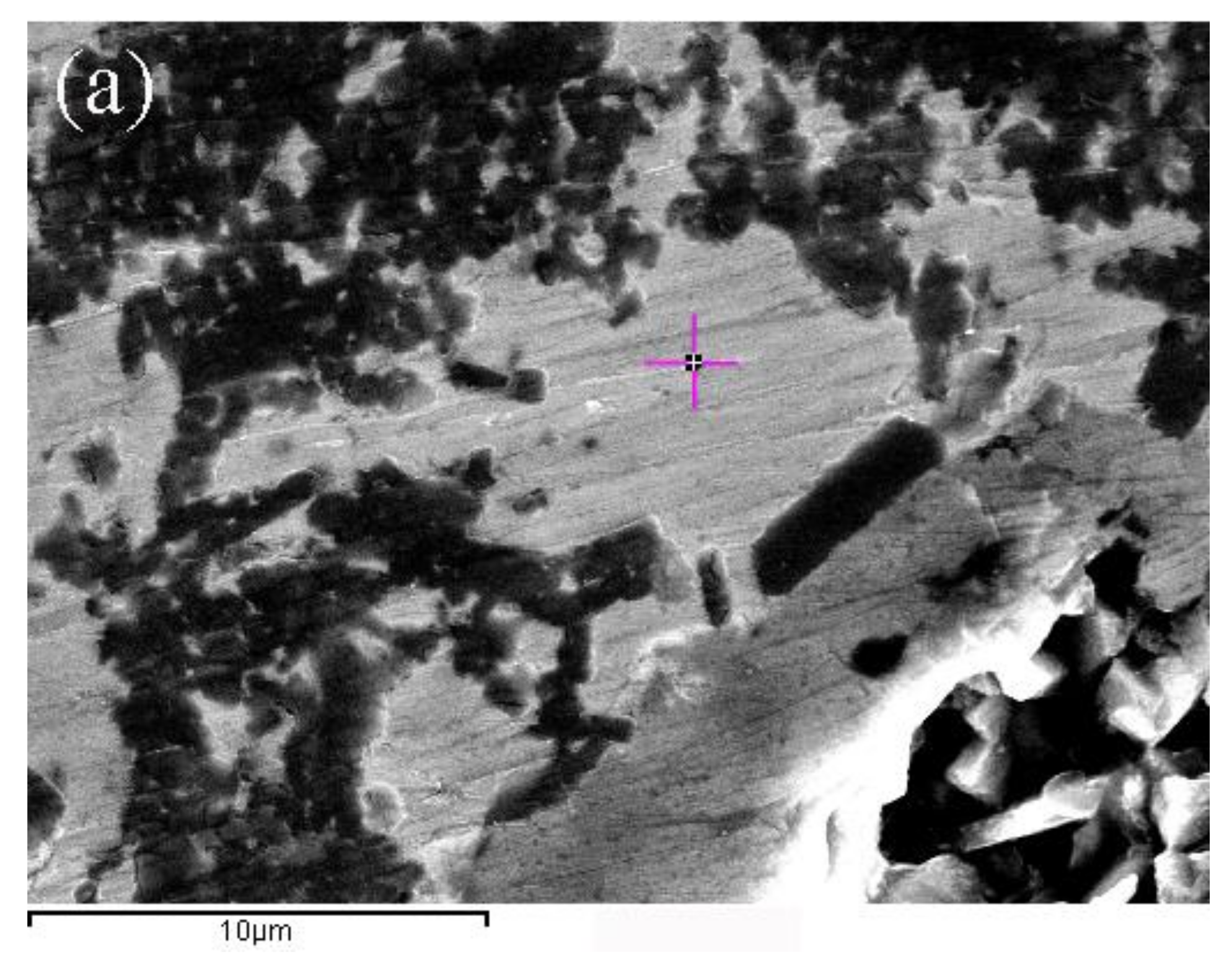

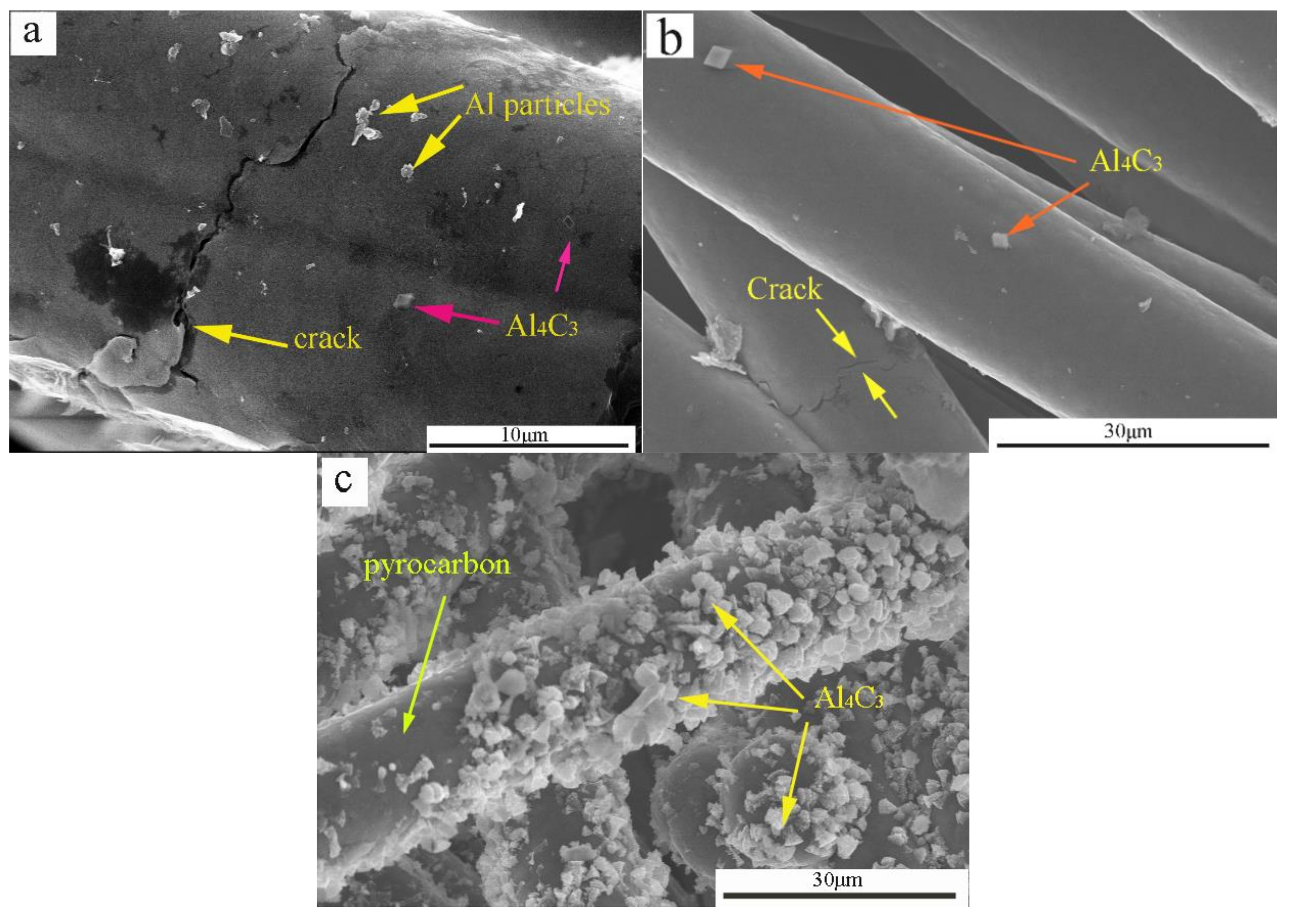

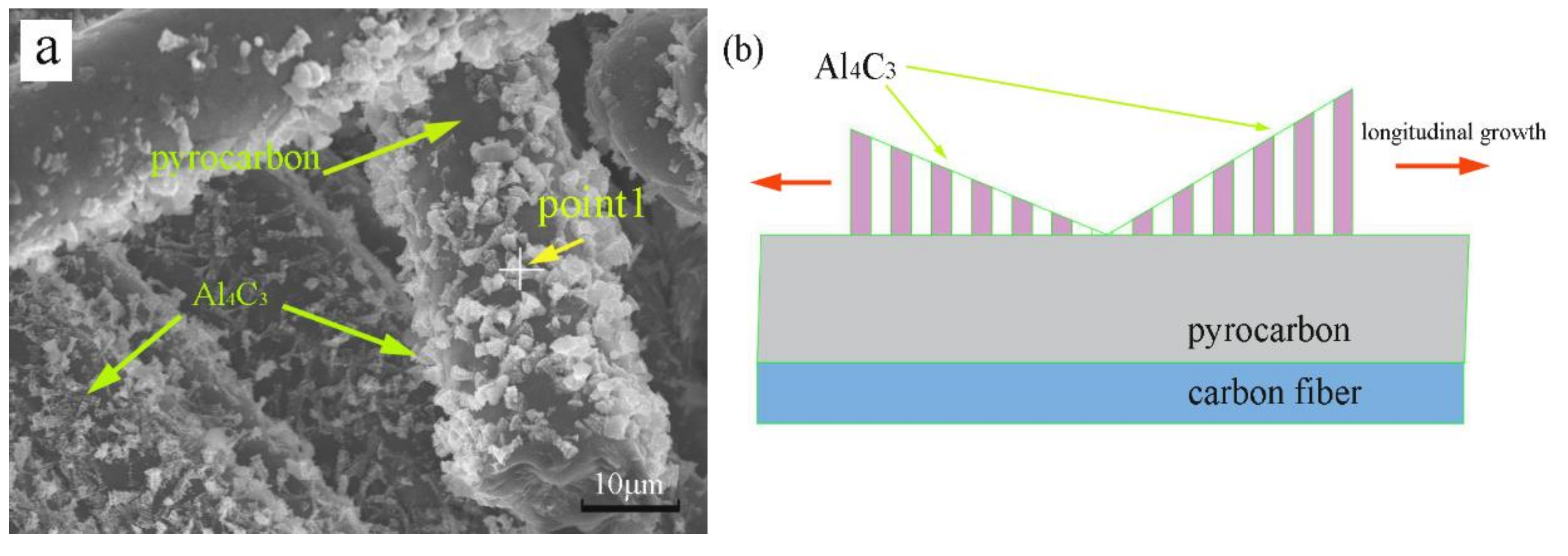

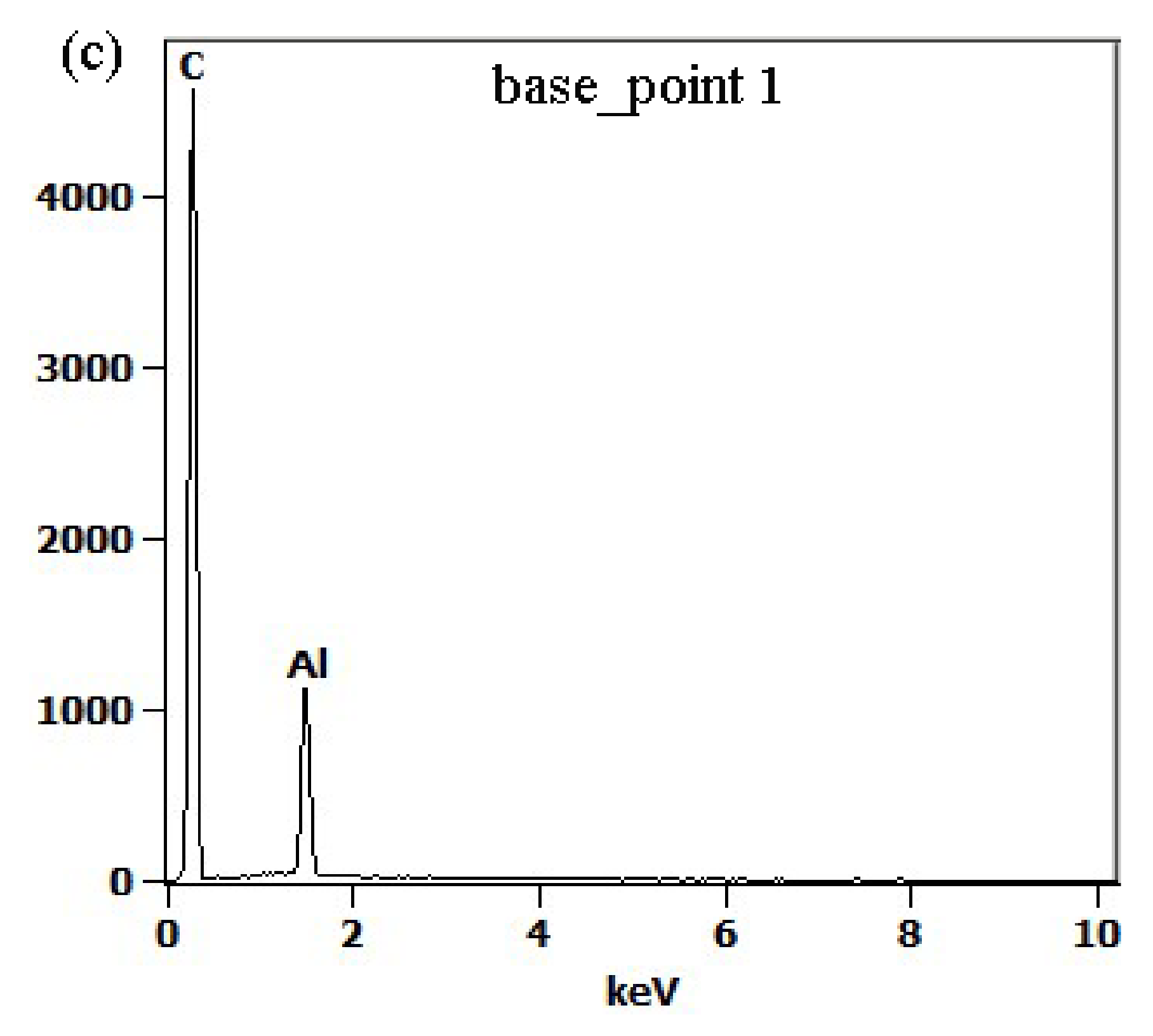

3.1. Microstructure and Morphology

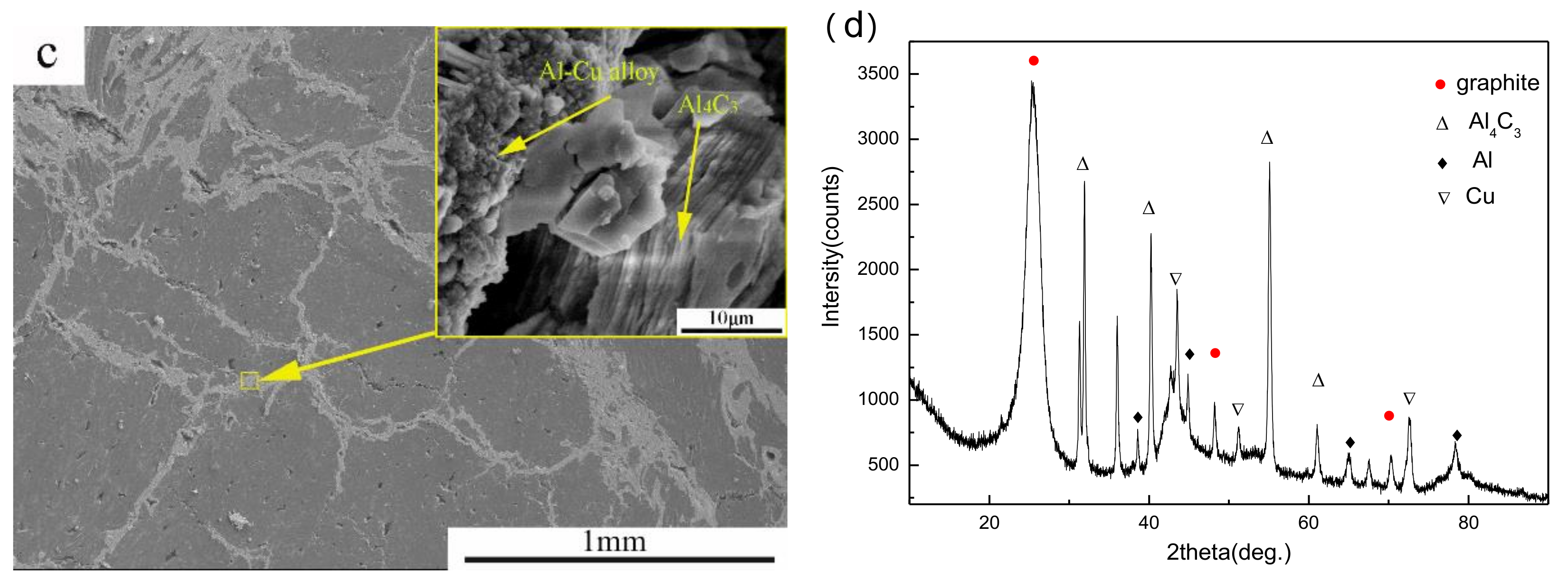

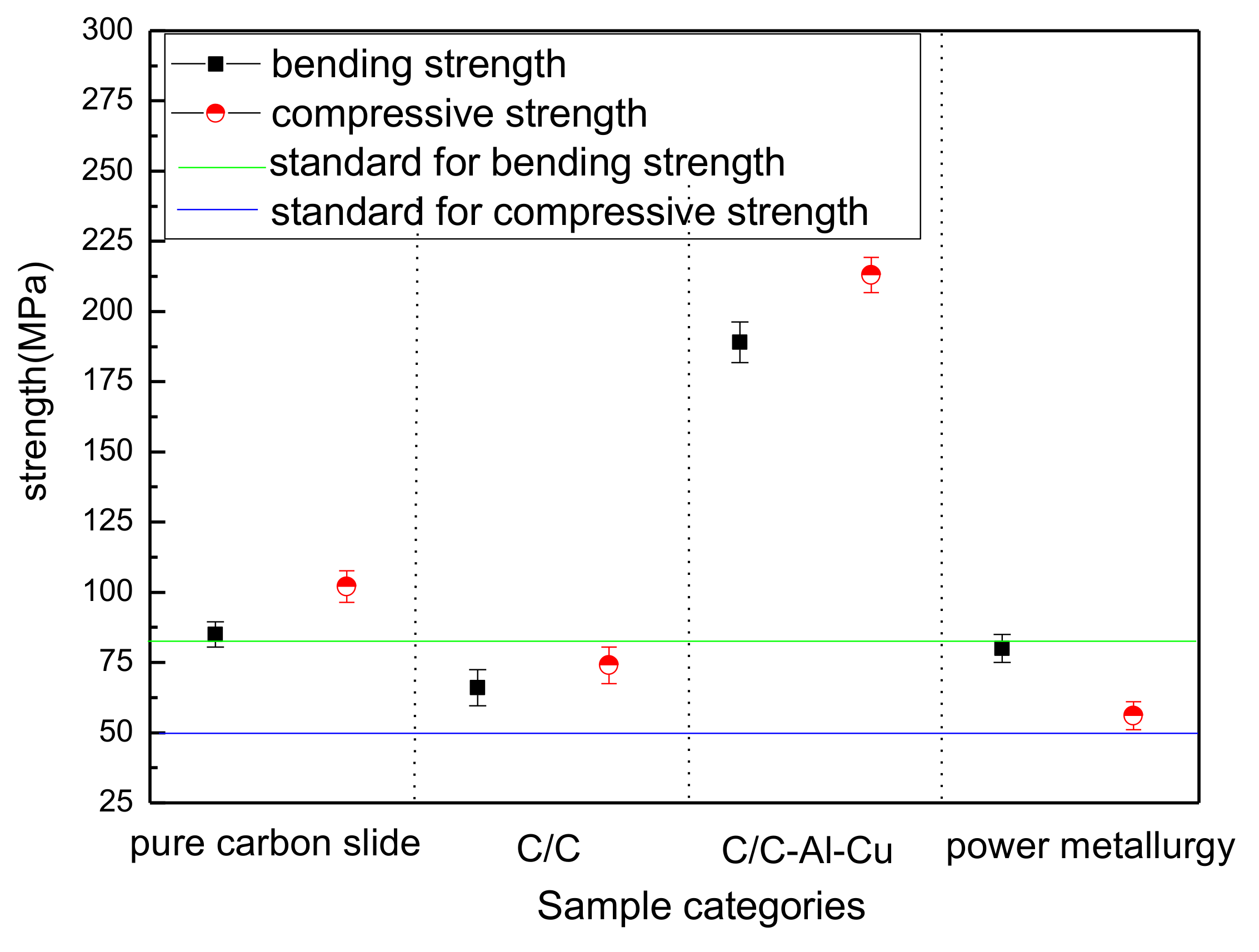

3.2. Mechanical Properties and Fracture Behavior of the Composites

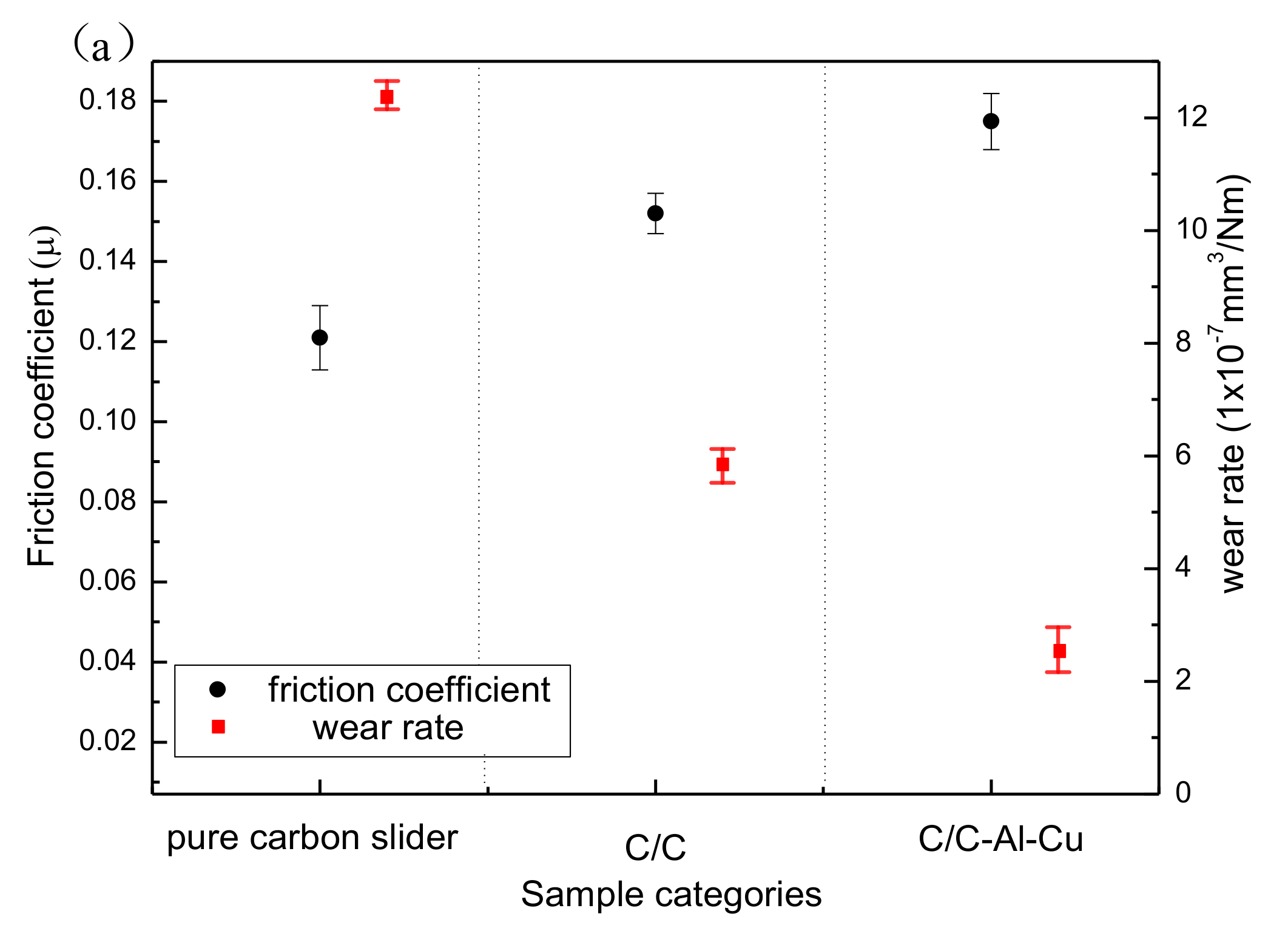

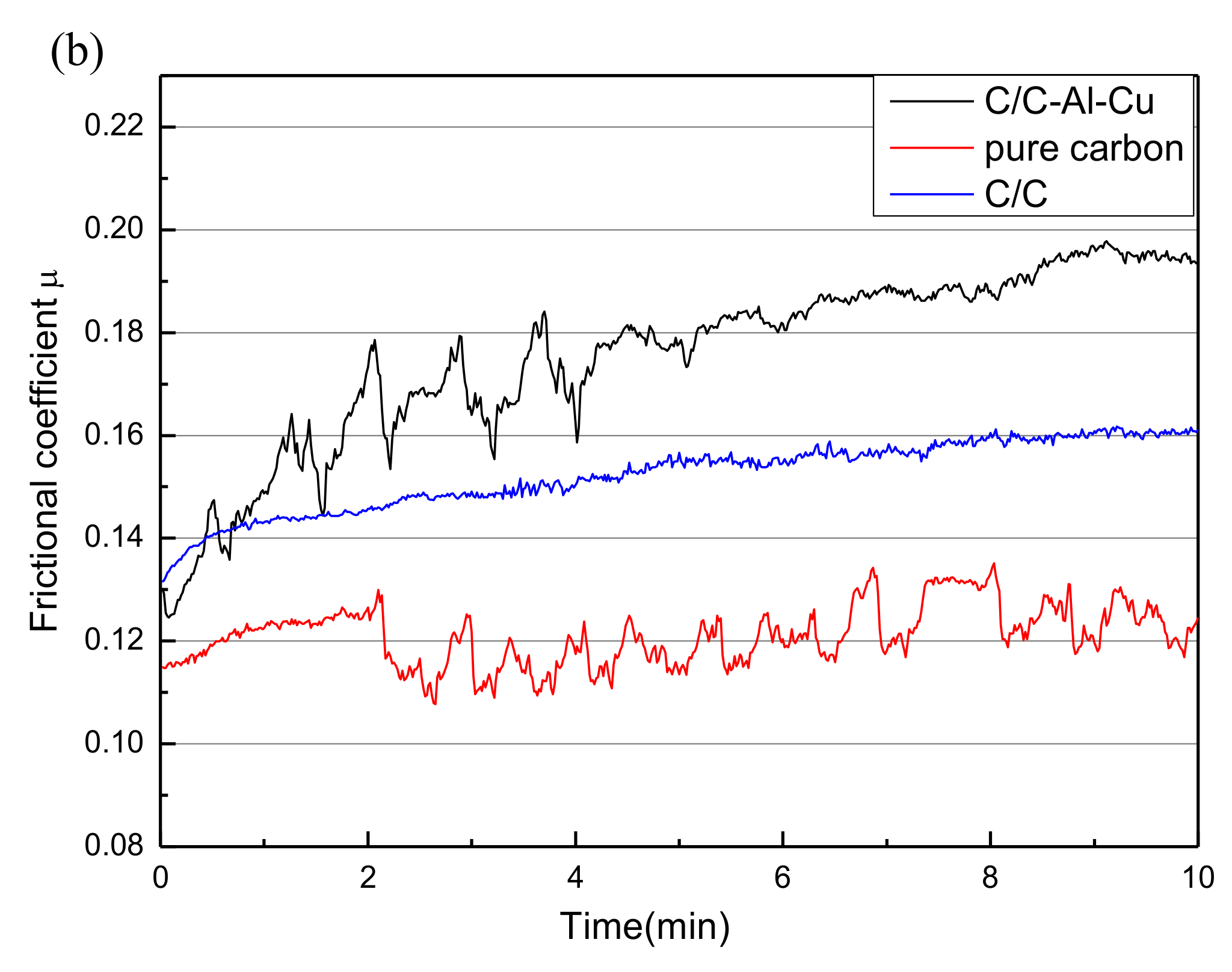

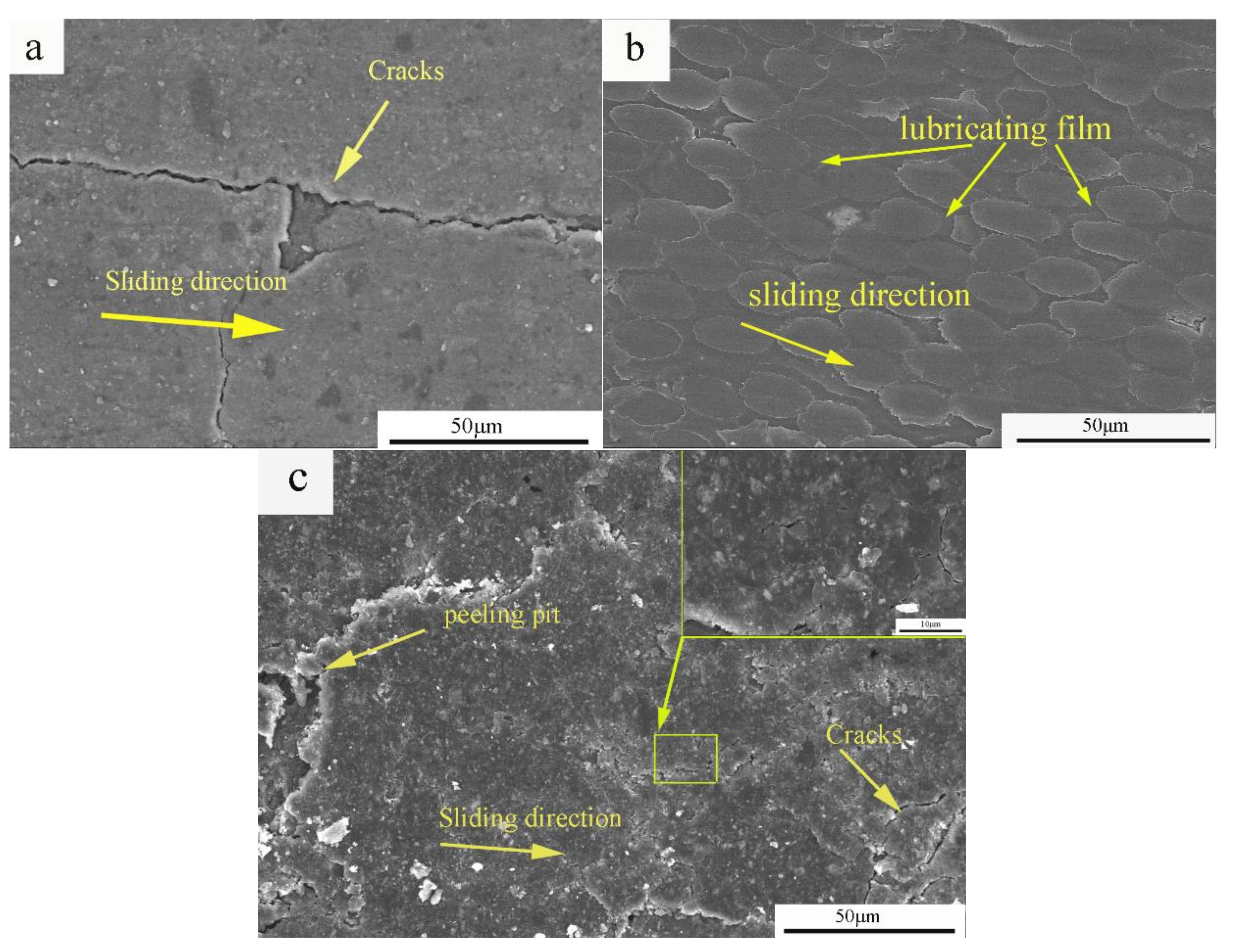

3.3. Friction Performance and Frictional Behavior of the Composites

3.4. Electrical Performance

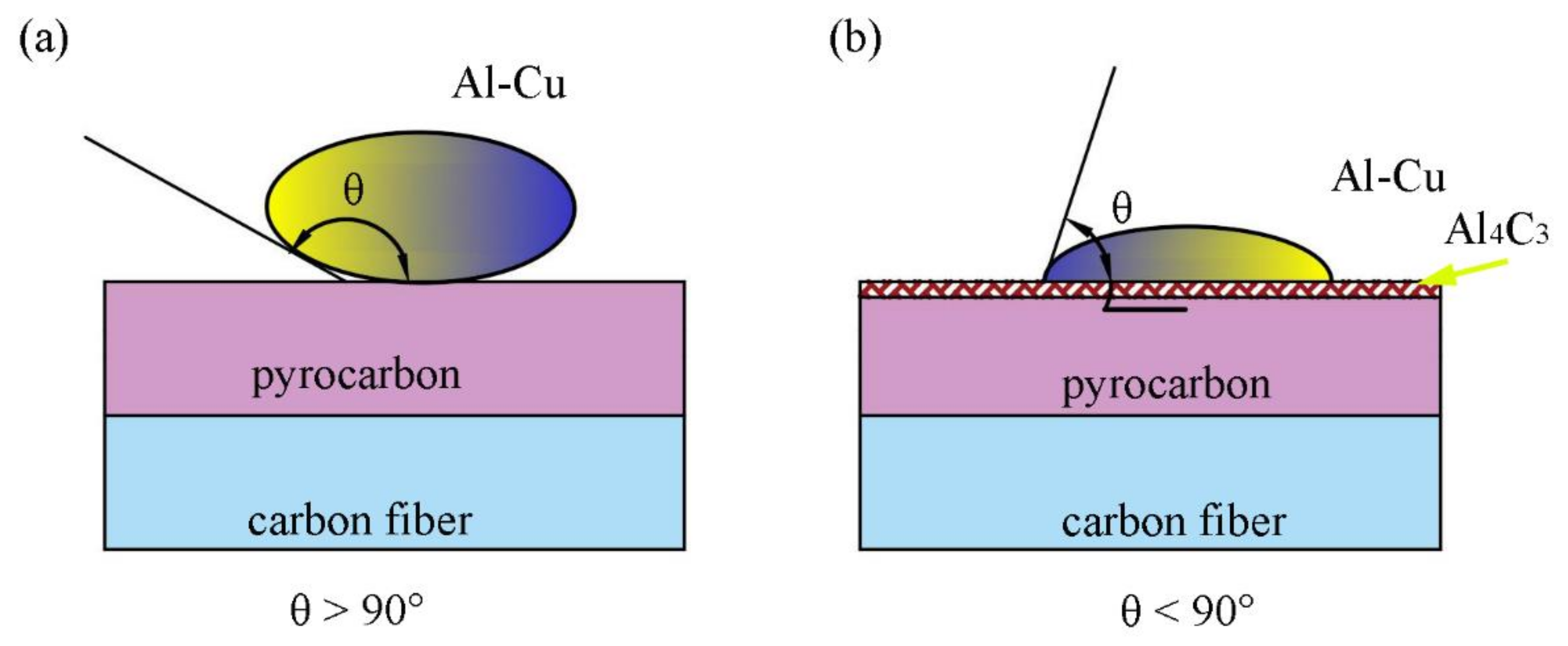

3.5. Wetting Performance

3.6. Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ding, T.; Chen, G.X.; Wang, X.; Zhu, M.H.; Zhang, W.H.; Zhou, W.X. Friction and wear behavior of pure carbon strip sliding against copper contact wire under AC passage at high speeds. Tribol. Int. 2011, 44, 437–444. [Google Scholar] [CrossRef]

- Bucca, G.; Collina, A. A procedure for the wear prediction of collector strip and contact wire in pantograph–catenary system. Wear 2009, 266, 46–59. [Google Scholar] [CrossRef]

- Luo, R.Y.; Liu, T.; Li, J.S.; Zhang, H.; Chen, Z.; Tian, G. Thermophysical properties of carbon/carbon composites and physical mechanism of thermal expansion and thermal conductivity. Carbon 2004, 42, 2887–2895. [Google Scholar] [CrossRef]

- Yang, W.; Luo, R.Y.; Hou, Z.H. Effect of interface modified by Graphene on the mechanical and frictional properties of carbon/grapheme/carbon composites. Materials 2016, 9, 492. [Google Scholar] [CrossRef] [PubMed]

- Li, K.Z.; Li, L.; Li, H.J. Electrophoretic deposition of carbon nanotubes onto carbon fiber felt for production of carbon/carbon composites with improved mechanical and thermal properties. Vacuum 2014, 104, 105–110. [Google Scholar] [CrossRef]

- Zhang, M.Y.; Li, K.Z.; Shi, X.H.; Guo, L.J.; Ma, C.H. Effect of vacuum thermal cyclic exposures on the carbon/carbon composites. Vacuum 2015, 111, 236–242. [Google Scholar] [CrossRef]

- He, D.H.; Manory, R. A novel electrical contact material with improved self lubrication for railway current collectors. Wear 2001, 249, 626–636. [Google Scholar] [CrossRef]

- Che, Z.F.; Zhang, Y.; Li, J.W.; Zhang, H.L.; Wang, X.T.; Sun, C.; Wang, J.G. Nucleation and growth mechanisms of interfacial Al4C3 in Al/diamond composites. J. Alloys Compd. 2016, 657, 81–89. [Google Scholar] [CrossRef]

- Park, J.K.; Lucas, J.P. Moisture effect on SiCp/6061 Al MMC: Dissolution of interfacial Al4C3. Scr. Mater. 1997, 37, 511–516. [Google Scholar] [CrossRef]

- Akhlaghi, F.; Bidaki, A.Z. Influence of graphite content on the dry sliding and oil impregnated sliding wear behavior of Al 2024-graphite composites produced by in sit powder metallurgy method. Wear 2009, 266, 37–45. [Google Scholar] [CrossRef]

- Guo, M.L.T.; Tsao, C.Y.A. Tribological behavior of aluminum/SiC/nichel-coated graphite hybrid composites. Mater. Sci. Eng. A 2002, 333, 134–145. [Google Scholar]

- Riahi, A.R.; Alpas, A.T. The role of tribo-layer on the sliding wear behavior of graphite aluminum matrix composites. Wear 2001, 251, 1396–1407. [Google Scholar] [CrossRef]

- Kestursatya, M.; Kim, J.K.; Rohatgi, P.K. Wear performance of copper-graphite composite and leaded copper alloy. Mater. Sci. Eng. A 2003, 39, 150–158. [Google Scholar] [CrossRef]

- Jaha, A.K.; Prasad, S.V.; Upadhyaya, G.S. Dry sliding wear of sintered 6061 aluminum alloy graphite particle composites. Tribol. Int. 1989, 22, 321–327. [Google Scholar] [CrossRef]

- Yen, B.K.; Ishihara, T. Effect of humidity on friction and wear of Al–Si eutectic alloy and Al–Si alloy-graphite composites. Wear 1996, 198, 169–175. [Google Scholar] [CrossRef]

- Yang, J.B.; Lin, C.B.; Wang, T.C.; Chu, H.Y. The tribological characteristics of A356.2 Al alloy/Gr(P) composites. Wear 2004, 257, 941–952. [Google Scholar] [CrossRef]

- Basavarajappa, S.; Chandramohan, G.; Mahadevan, A.; Thangavelu, A.; Subramanian, R.; Gopalakrishnan, P. Influence of sliding speed on the dry sliding wear behavior and the subsfurface deformation on hybrid metal matix composite. Wear 2007, 262, 1007–1012. [Google Scholar] [CrossRef]

- Wu, X.W.; Luo, R.Y. Mechanical properties investigation of carbon/carbon composites fabricated by a fast densification process. Mater. Des. 2011, 32, 2361–2364. [Google Scholar] [CrossRef]

- Yang, H.J.; Luo, R.Y. Effect of coal tar pitch modified by sulfur as a binder on the mechanical and tribological properties of bronze-impregnated carbon-matrix composites. Mater. Sci. Eng. A 2011, 528, 2929–2935. [Google Scholar] [CrossRef]

- Duarte, M.; Vragovic, I.; Molina, J.M.; Prieto, R.; Narciso, J.; Louis, E. 1/f noise in sliding friction under wear conditions: The role of debris. Phys. Rev. Lett. 2009, 102, 045501. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, P.; Modak, N.; Sahoo, P. Effect of normal load and velocity on continuous sliding friction and wear behavior of woven glass fiber reinforced epoxy composite. Materialstoday 2017, 4, 3082–3092. [Google Scholar] [CrossRef]

- Garcia-Cordovilla, C.; Narciso, J.; Louis, E. Abrasive wear resistance of aluminium alloy/ceramic particulate composites. Wear 1996, 192, 170–177. [Google Scholar] [CrossRef]

- Fu, Q.G.; Nan, X.Y.; Li, H.J.; Chen, X. Pre-oxidation of carbon/carbon composites to improve the bonding strength of Ti–Ni–Si joints. Mater. Sci. Eng. A 2015, 620, 428–434. [Google Scholar] [CrossRef]

- Yang, H.J.; Luo, R.Y.; Han, S.; Li, M.D. Effect of the ratio of graphite/pitch coke on the mechanical and tribological properties of copper-carbon composites. Wear 2010, 268, 1337–1341. [Google Scholar] [CrossRef]

- Mochizuki, A. Conventional line speed increase and development of shinkansen. Jpn. Railw. Transp. Rev. 2011, 57, 42–49. [Google Scholar]

- Campos, J.; Rus, G. Some stylized facts about high-speed rail: A review of HSR experiences around the world. Transp. Policy 2009, 16, 19–48. [Google Scholar] [CrossRef]

- Pei, Z.L.; Li, K.; Gong, J.; Shi, N.L.; Elangovan, E.; Sun, C. Micro-structural and tensile strength analyses on the magnesium matrix composites reinforced with coated carbon fiber. Mater. Sci. 2009, 44, 4124–4131. [Google Scholar] [CrossRef]

- Russell-Stevens, M.; Todd, R.; Papakyriacou, M. Microstructural analysis of a carbon fiber reinforced AZ91D magnesium alloy composite. Surf. Interface Anal. 2005, 37, 336–342. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, G.; Pei, R.; Hussain, M.; Wang, Y.; Li, D.; Wang, P.; Wu, G. Effect of Gd content on interfacial microstructures and mechanical properties of Cf/Mg composite. Mater. Des. 2015, 65, 567–574. [Google Scholar] [CrossRef]

- Feldhoff, A.; Pippel, E.; Woltersdorf, J. Interface engineering of carbon-fiber reinforced mg-al alloys. Adv. Eng. Mater. 2000, 2, 471–480. [Google Scholar] [CrossRef]

- Wessling, B. Electrical conductivity in heterogenous ployer systems (IV) a new dynamic interfacial percolation modle. Synth. Met. 1998, 7, 83–88. [Google Scholar]

- Bao, S.; Kvithyld, A.; Gaal, S.; Engh, T.; Tangstad, M. Wetting of pure aluminum on filter materials graphite, AlF3 and Al2O3. Light Met. 2009, 1, 767–773. [Google Scholar]

- Sarina, B.; Kai, T.; Kvithyld, A.; Engh, T.; Tangstad, M. Wetting of pure aluminium on graphite, SiC and Al2O3 in aluminium filtration. Trans. Nonferrous Met. Soc. China 2012, 22, 1930–1938. [Google Scholar]

- Tian, J.T.; Pinero, E.; Narciso, J.; Louis, E. Effects of temperature on pressure infiltration of liquid Al and Al–12 wt.% Si alloy into packed SiC particles. Scr. Mater. 2005, 53, 1483–1488. [Google Scholar] [CrossRef]

- Narciso, J.; Alonso, A.; Pamies, A.; Garcia-Cordovvila, C.; Louis, E. Wettability of binary and ternary alloys of the system Al–S–Mg with SiC. Scr. Metall. Mater. 1994, 31, 1495–1500. [Google Scholar] [CrossRef]

- Chen, G.X.; Li, F.X.; Dong, L.M.; Zhu, H. Friction and wear behavior of stainless steel rubbing against cooper-impregnated metalized carbon. Tribol. Int. 2009, 42, 934–939. [Google Scholar] [CrossRef]

- Calderon, R.N.R.; Voytovych, J.; Eustathopoulos, N.N. Wetting dynamics versus interfacial reactivity of AlSi alloys on carbn. J. Mater. Sci. 2010, 45, 2150–2156. [Google Scholar] [CrossRef]

- Calderon, R.N.R.; Voytovych, J.; Eustathopoulos, N.N. Pressureless infiltration versus wetting in AlSi/graphite system. J. Mater. Sci. 2010, 45, 4345–4350. [Google Scholar] [CrossRef]

- Danilo, S.; Antonio, C.; Jose, M.M.; Alberto, O.; Javier, N. Surface growth for molten silicon infiltration into carbon millimeter-sized channels; Lattic-Boltzmann simulations, experiments and models. Mod. Phys. C 2016, 27, 1650062. [Google Scholar]

- Mario, C.; Antonio, C.; Danilo, S.; Alberto, O.; Javier, N. Wetting and Navier-Stokes equation—The manufacture of composite materials. ResearchGate 2015. [Google Scholar] [CrossRef]

- Narciso, J.; Garcia-Cordovilla, C.; Louis, E. Reactivity of thermally oxidized and unoxidized SiC particulates with Aluminium–Silicon alloys. Mater. Sci. Eng. B 1992, 15, 148–155. [Google Scholar] [CrossRef]

- Alonso, A.; Narciso, J.; Pamies, C.; Garcia-Cordovvila, C.; Louis, E. Effect of K2ZrF6 coatings on pressure infiltration of packed SiC particulates by liquid aluminum. Scr. Metall. Mater. 1993, 29, 1559–1564. [Google Scholar] [CrossRef]

- Wang, X.; Wang, C.C.; Zhang, Z.C.; Liang, P.; Shi, Y.H. Interfacial microstructure and grown mechanism of Al4C3 in Grf/Al composites fabricated by liquid pressure method. Micron 2014, 65, 10–14. [Google Scholar]

| Type | Density (g/cm3) | Resistivity (μΩm) | Friction Coefficient | Wear Rate (mm3/Nm) | Mechanical Properties (MPa) | |

|---|---|---|---|---|---|---|

| Bending Strength | Compressive Strength | |||||

| Reference standard | ≤3.0 | ≤12 | ≤0.2 | ≤1.0 × 10−6 | ≥80 | ≥50 |

| Type | Industry Standard | (Copper/Graphite) Powder Metallurgy | Sintered Alloy | Pure Carbon Slide (CY280) | C/C Composites (ρ = 1.3 g/cm3) | C/C–Al–Cu Composites (ρ = 2.24 g/cm3) |

|---|---|---|---|---|---|---|

| Bending strength | ≥80 | ≥80 | ≥220 | 85 | 66 | 189 |

| Compressive strength | ≥50 | ≥56 | 300 | 102 | 74 | 213 |

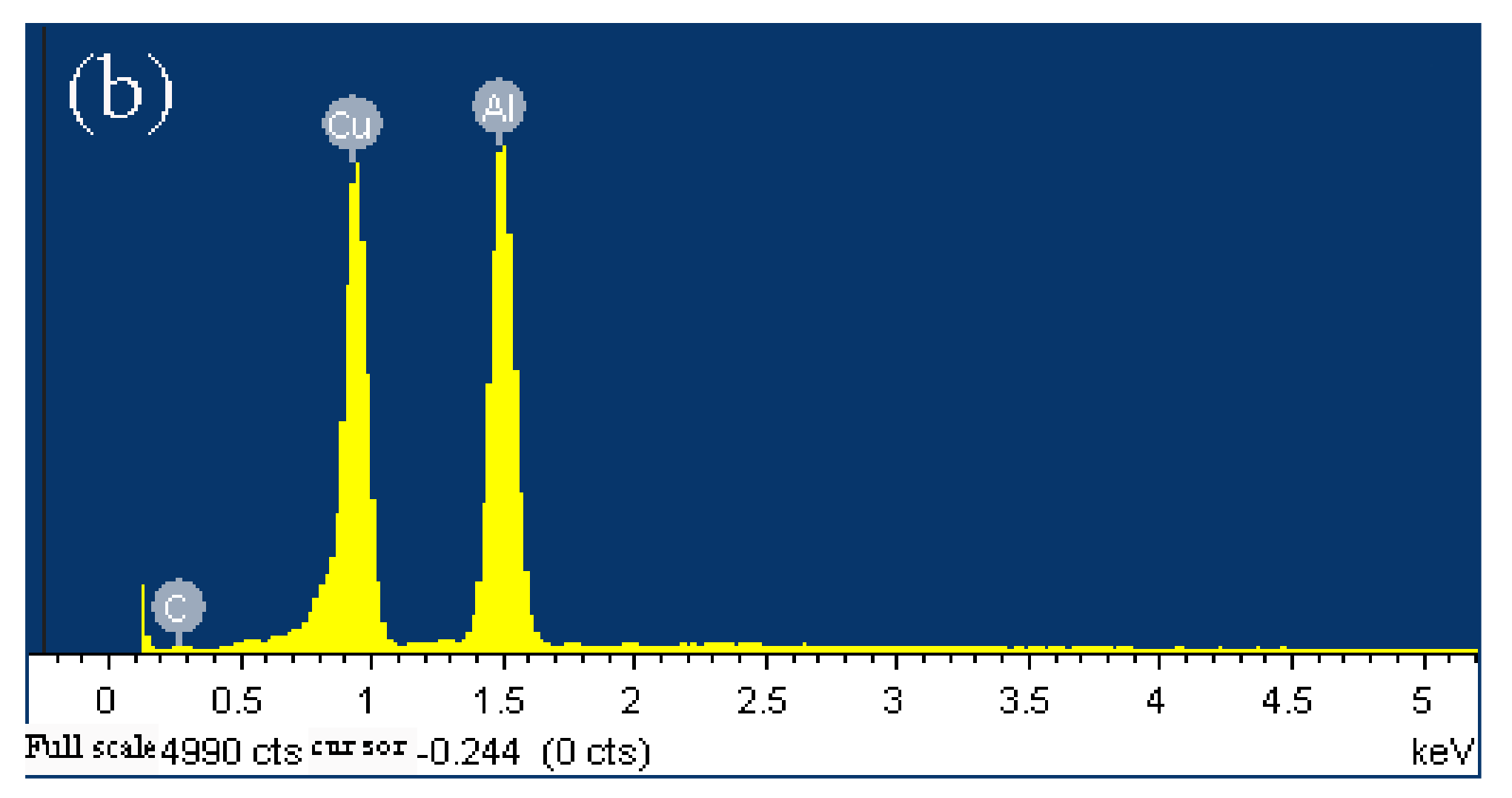

| Element | wt % | at % |

|---|---|---|

| C K | 4.49 | 13.73 |

| Al K | 39.62 | 53.95 |

| Cu L | 55.89 | 32.31 |

| Total weight | 100.00 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, L.; Luo, R.; Ma, D. Carbon Fiber Reinforced Carbon–Al–Cu Composite for Friction Material. Materials 2018, 11, 538. https://doi.org/10.3390/ma11040538

Cui L, Luo R, Ma D. Carbon Fiber Reinforced Carbon–Al–Cu Composite for Friction Material. Materials. 2018; 11(4):538. https://doi.org/10.3390/ma11040538

Chicago/Turabian StyleCui, Lihui, Ruiying Luo, and Denghao Ma. 2018. "Carbon Fiber Reinforced Carbon–Al–Cu Composite for Friction Material" Materials 11, no. 4: 538. https://doi.org/10.3390/ma11040538

APA StyleCui, L., Luo, R., & Ma, D. (2018). Carbon Fiber Reinforced Carbon–Al–Cu Composite for Friction Material. Materials, 11(4), 538. https://doi.org/10.3390/ma11040538